WO2017126607A1 - 化学強化ガラスおよび化学強化用ガラス - Google Patents

化学強化ガラスおよび化学強化用ガラス Download PDFInfo

- Publication number

- WO2017126607A1 WO2017126607A1 PCT/JP2017/001755 JP2017001755W WO2017126607A1 WO 2017126607 A1 WO2017126607 A1 WO 2017126607A1 JP 2017001755 W JP2017001755 W JP 2017001755W WO 2017126607 A1 WO2017126607 A1 WO 2017126607A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- glass

- mpa

- chemically strengthened

- value

- less

- Prior art date

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C3/00—Glass compositions

- C03C3/04—Glass compositions containing silica

- C03C3/076—Glass compositions containing silica with 40% to 90% silica, by weight

- C03C3/083—Glass compositions containing silica with 40% to 90% silica, by weight containing aluminium oxide or an iron compound

- C03C3/085—Glass compositions containing silica with 40% to 90% silica, by weight containing aluminium oxide or an iron compound containing an oxide of a divalent metal

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C21/00—Treatment of glass, not in the form of fibres or filaments, by diffusing ions or metals in the surface

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C21/00—Treatment of glass, not in the form of fibres or filaments, by diffusing ions or metals in the surface

- C03C21/001—Treatment of glass, not in the form of fibres or filaments, by diffusing ions or metals in the surface in liquid phase, e.g. molten salts, solutions

- C03C21/002—Treatment of glass, not in the form of fibres or filaments, by diffusing ions or metals in the surface in liquid phase, e.g. molten salts, solutions to perform ion-exchange between alkali ions

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C3/00—Glass compositions

- C03C3/04—Glass compositions containing silica

- C03C3/076—Glass compositions containing silica with 40% to 90% silica, by weight

- C03C3/083—Glass compositions containing silica with 40% to 90% silica, by weight containing aluminium oxide or an iron compound

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C3/00—Glass compositions

- C03C3/04—Glass compositions containing silica

- C03C3/076—Glass compositions containing silica with 40% to 90% silica, by weight

- C03C3/083—Glass compositions containing silica with 40% to 90% silica, by weight containing aluminium oxide or an iron compound

- C03C3/085—Glass compositions containing silica with 40% to 90% silica, by weight containing aluminium oxide or an iron compound containing an oxide of a divalent metal

- C03C3/087—Glass compositions containing silica with 40% to 90% silica, by weight containing aluminium oxide or an iron compound containing an oxide of a divalent metal containing calcium oxide, e.g. common sheet or container glass

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C3/00—Glass compositions

- C03C3/04—Glass compositions containing silica

- C03C3/076—Glass compositions containing silica with 40% to 90% silica, by weight

- C03C3/089—Glass compositions containing silica with 40% to 90% silica, by weight containing boron

- C03C3/091—Glass compositions containing silica with 40% to 90% silica, by weight containing boron containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C3/00—Glass compositions

- C03C3/04—Glass compositions containing silica

- C03C3/076—Glass compositions containing silica with 40% to 90% silica, by weight

- C03C3/089—Glass compositions containing silica with 40% to 90% silica, by weight containing boron

- C03C3/091—Glass compositions containing silica with 40% to 90% silica, by weight containing boron containing aluminium

- C03C3/093—Glass compositions containing silica with 40% to 90% silica, by weight containing boron containing aluminium containing zinc or zirconium

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C3/00—Glass compositions

- C03C3/04—Glass compositions containing silica

- C03C3/076—Glass compositions containing silica with 40% to 90% silica, by weight

- C03C3/097—Glass compositions containing silica with 40% to 90% silica, by weight containing phosphorus, niobium or tantalum

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C4/00—Compositions for glass with special properties

- C03C4/18—Compositions for glass with special properties for ion-sensitive glass

Definitions

- the present invention relates to chemically tempered glass.

- cover glasses made of chemically strengthened glass have been used in order to enhance the protection and aesthetics of display devices of mobile devices such as mobile phones, smartphones, personal digital assistants (PDAs), and tablet terminals.

- mobile devices such as mobile phones, smartphones, personal digital assistants (PDAs), and tablet terminals.

- PDAs personal digital assistants

- Patent Document 1 discloses a formula (10) indicating an allowable limit of internal tensile stress of tempered glass, and chemicals with less scattering of fragments even if the strength of chemically tempered glass is increased by adjusting CT ′ below. It was said that tempered glass was obtained.

- the internal tensile stress CT ′ described in Patent Document 1 is derived from the following formula (11) using measured values of CS and DOL ′.

- CT ′ ⁇ ⁇ 38.7 ⁇ ln (t) +48.2 (10)

- CS ⁇ DOL ′ (t ⁇ 2 ⁇ DOL ′) ⁇ CT ′ (11)

- DOL ′ corresponds to the depth of the ion exchange layer.

- Patent Document 1 sometimes lacks the strength of chemically strengthened glass. This is because the influence of the glass composition is not fully taken into account, the above formula for obtaining CT ′ assumes that the stress profile is linearly approximated, and the point at which the stress is zero is equal to the ion diffusion layer depth It is thought that the cause is.

- the present invention improves these problems and provides a chemically strengthened glass with higher strength.

- the first aspect of the present invention is a chemically strengthened glass having a surface compressive stress (CS) of 300 MPa or more, and a compressive stress value (CS 90 ) at a depth of 90 ⁇ m from the glass surface is 25 MPa or more, or glass.

- the compressive stress value (CS 100 ) at a depth of 100 ⁇ m from the surface is 15 MPa or more, Each of SiO 2 , Al 2 O 3 , B 2 O 3 , P 2 O 5 , Li 2 O, Na 2 O, K 2 O, MgO, CaO, SrO, BaO and ZrO 2 in the mother composition of the chemically strengthened glass.

- X SiO 2 ⁇ 329 + Al 2 O 3 ⁇ 786 + B 2 O 3 ⁇ 627 + P 2 O 5 ⁇ ( ⁇ 941) + Li 2 O ⁇ 927 + Na 2 O ⁇ 47.5 + K 2 O ⁇ ( ⁇ 371) + MgO ⁇ 1230 + CaO ⁇ 1154 + SrO ⁇ 733 + ZrO 2 ⁇ 51.8

- the first aspect of the present invention is a chemically strengthened glass having a surface compressive stress (CS) of 300 MPa or more, and a compressive stress value (CS 90 ) at a depth of 90 ⁇ m from the glass surface is 25 MPa or more, or glass.

- the compressive stress value (CS 100 ) at a depth of 100 ⁇ m from the surface is 15 MPa or more, Each of SiO 2 , Al 2 O 3 , B 2 O 3 , P 2 O 5 , Li 2 O, Na 2 O, K 2 O, MgO, CaO, SrO, BaO and ZrO 2 in the mother composition of the chemically strengthened glass.

- Chemically tempered glass having a Z value of 20000 or more calculated based on the following formula using the content of the component in terms of mole percentage based on the oxide may be used.

- Z SiO 2 ⁇ 237 + Al 2 O 3 ⁇ 524 + B 2 O 3 ⁇ 228 + P 2 O 5 ⁇ ( ⁇ 756) + Li 2 O ⁇ 538 + Na 2 O ⁇ 44.2 + K 2 O ⁇ ( ⁇ 387) + MgO ⁇ 660 + CaO ⁇ 569 + SrO ⁇ 291 + ZrO 2 ⁇ 510

- the chemically tempered glass of the first aspect is preferably a plate having a thickness t of 2 mm or less.

- the second aspect of the present invention is a chemically strengthened glass having a surface compressive stress (CS) of 300 MPa or more and satisfying the following formulas (1) and (2).

- StL (t) ⁇ a ⁇ t + 7000 (unit: MPa ⁇ ⁇ m) (1) a ⁇ 30000 (unit: MPa ⁇ ⁇ m / mm) (2) (Here, t is the plate thickness (mm), and StL (t) is the value of St Limit when the plate thickness is t.)

- the chemically tempered glass of the second aspect preferably satisfies a ⁇ 35000.

- the second aspect may be a chemically strengthened glass having a surface compressive stress (CS) of 300 MPa or more and satisfying the following formulas (3), (4), and (5).

- CS surface compressive stress

- the chemically tempered glass of the second aspect is preferably a plate having a thickness t of 2 mm or less.

- the compressive stress value (CS 90 ) at a depth of 90 ⁇ m from the glass surface is 25 MPa or more, or the compressive stress value (CS 100 ) at a depth of 100 ⁇ m from the glass surface. Is preferably 15 MPa or more.

- an average crack height by a sand drop test described later is 250 mm or more, a number of crushing by an indenter press-in test described later is 30 or less, and a sheet thickness t is 0.4-2 mm.

- a chemically strengthened glass having a surface compressive stress (CS) of 300 MPa or more and a depth (DOL) of the compressive stress layer of 100 ⁇ m or more.

- the product (CS 100 ⁇ t 2 ) of the compressive stress value at a depth of 100 ⁇ m from the glass surface and the square of the plate thickness t (mm) (CS 100 ⁇ t 2 ) is 5 MPa ⁇ mm 2 or more. preferable.

- the area Sc (MPa ⁇ ⁇ m) of the compressive stress layer is preferably 30000 MPa ⁇ ⁇ m or more.

- Chemically tempered glass of the present invention is preferably a depth d h in areas of one-half the size of the surface compressive stress of the internal compressive stress (CS) is 8 ⁇ m or more.

- Chemically tempered glass of the present invention it is preferable to position d M compressive stress is maximum in the range of 5 ⁇ m from the glass surface.

- the depth (DOL) of the compressive stress layer is preferably 110 ⁇ m or more.

- ⁇ CS DOL-20 (unit: MPa / ⁇ m) calculated by the following formula using the compressive stress value CS DOL-20 at a depth of 20 ⁇ m on the glass surface side from DOL is 0. .4 or more is preferable.

- ⁇ CS DOL-20 CS DOL-20 / 20

- ⁇ CS 100-90 (CS 90 -CS 100 ) / (100-90)

- the fracture toughness value (K1c) of the glass having the matrix composition of the chemically strengthened glass is 0.7 MPa ⁇ m 1/2 or more.

- the area St (MPa ⁇ ⁇ m) of the internal tensile layer is preferably StL (t) (MPa ⁇ ⁇ m) or less.

- t is the plate thickness (mm)

- StL (t) is the value of St Limit when the plate thickness is t.

- the internal tensile layer stress CT (MPa) is preferably CTL (t) (MPa) or less.

- t is the plate thickness (mm)

- CTL (t) is the value of CT Limit at the plate thickness t.

- the matrix composition of the chemically tempered glass is expressed in terms of mole percentage on the basis of oxide, and SiO 2 is 50 to 80%, Al 2 O 3 is 1 to 30%, and B 2 O 3 is 0. ⁇ 6%, P 2 O 5 0 ⁇ 6%, Li 2 O 0 ⁇ 20%, Na 2 O 0 ⁇ 8%, K 2 O 0 ⁇ 10%, MgO 0 ⁇ 20%, CaO It is preferable to contain 0-20%, SrO 0-20%, BaO 0-15%, ZnO 0-10%, TiO 2 0-5%, and ZrO 2 0-8%.

- the present invention is expressed in terms of mole percentage based on oxides, and SiO 2 is 63 to 80%, Al 2 O 3 is 7 to 30%, B 2 O 3 is 0 to 5%, and P 2 O 5 is 0 to 4%, Li 2 O 5-15%, Na 2 O 4-8%, K 2 O 0-2%, MgO 3-10%, CaO 0-5%, SrO 0-20% the BaO 0 ⁇ 15% of ZnO 0 ⁇ 10% of TiO 2 0 ⁇ 1% of ZrO 2 containing 0-8% Does not contain Ta 2 O 5 , Gd 2 O 3 , As 2 O 3 , Sb 2 O 3 , Mole percentages based on oxides of each component of SiO 2 , Al 2 O 3 , B 2 O 3 , P 2 O 5 , Li 2 O, Na 2 O, K 2 O, MgO, CaO, SrO, BaO and ZrO 2.

- X SiO 2 ⁇ 329 + Al 2 O 3 ⁇ 786 + B 2 O 3 ⁇ 627 + P 2 O 5 ⁇ ( ⁇ 941) + Li 2 O ⁇ 927 + Na 2 O ⁇ 47.5 + K 2 O ⁇ ( ⁇ 371) + MgO ⁇ 1230 + CaO ⁇ 1154 + SrO ⁇ 733 + ZrO 2 ⁇ 51.8

- the content of ZrO 2 in terms of oxide-based mole percentage is 1.2% or less. Further, it is preferable that the K 2 O content by mole percentage based on oxides is 0.5% or more. Further, it is preferable content of B 2 O 3 by mole percentage based on oxides is 1% or less. Further, it is preferable that the content of Al 2 O 3 by mole percentage based on oxides is not more than 11%. Further, the devitrification temperature T is preferably equal to or lower than the temperature T4 at which the viscosity becomes 10 4 dPa ⁇ s.

- the present invention provides a high-strength chemically strengthened glass in which scattering of fragments due to breakage is suppressed.

- FIG. 1 is a conceptual diagram showing a stress profile of chemically strengthened glass

- (a) is a view showing an example of a stress profile of chemically strengthened glass

- (b) is an enlarged left half of the stress profile of (a).

- It is a figure and (c) is a figure which shows the depth of the position where the compressive stress in each of profile A and B becomes the maximum.

- FIG. 2 is a schematic diagram showing how a sample for measuring the surface compressive stress (CS) of chemically strengthened glass is produced, (a) shows a sample before polishing, and (b) shows a thin piece after polishing. The sample is shown.

- FIG. 3 is a schematic diagram showing a test method for a drop-on-sand test.

- FIG. 4 is a graph plotting the relationship between DOL and average crack height of chemically strengthened glass or glass.

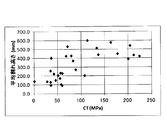

- FIG. 5 is a graph plotting the relationship between CT and average crack height of chemically strengthened glass or glass.

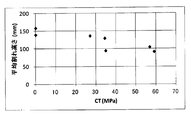

- FIG. 6 is a graph plotting the relationship between CT and average crack height of chemically strengthened glass.

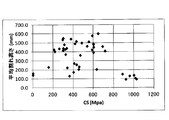

- FIG. 7 is a graph plotting the relationship between the surface compressive stress value CS and the average crack height of chemically strengthened glass or glass.

- FIG. 8 is a graph plotting the relationship between the compressive stress value CS 90 and the average crack height of chemically strengthened glass or glass.

- FIG. 9 is a graph plotting the relationship between the compressive stress value CS 100 and the average crack height of chemically strengthened glass or glass.

- FIG. 10 is a graph plotting the relationship between the product of the compressive stress value CS 100 and the square of the sheet thickness t (CS 100 ⁇ t 2 ) and the average crack height of chemically strengthened glass or glass.

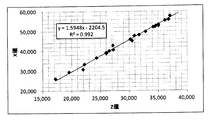

- FIG. 11 is a graph showing test results of a four-point bending test for chemically strengthened glass.

- FIG. 12 is a graph plotting the relationship between CS and bending strength for chemically strengthened glass.

- FIG. 13 is a graph plotting the relationship between DOL and bending strength for chemically strengthened glass.

- FIG. 14 is a graph showing a stress profile of virtual chemically strengthened glass.

- FIG. 15 shows measurement examples of St Limit and CT Limit

- (a) is a graph showing the relationship between the area St of the internal tensile stress layer and the number of fractures, and (b) is surrounded by a dotted line in (a).

- (C) is a graph showing the relationship between the internal tensile stress CT and the number of fractures, and (d) is an enlarged view of a portion surrounded by a dotted line in (c).

- FIG. 16 is an explanatory diagram of a sample used for fracture toughness measurement by the DCDC method.

- FIG. 17 is a diagram showing a K1-v curve showing the relationship between the stress intensity factor K1 and the crack growth rate v used for the measurement of fracture toughness value by the DCDC method.

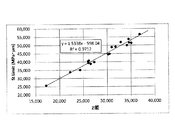

- FIG. 18 is a graph plotting the relationship between St Limit and X value for chemically strengthened glass.

- FIG. 19 is a graph plotting the relationship between St Limit and Z value for chemically strengthened glass.

- FIG. 20 is a graph plotting the relationship between St Limit and Young's modulus for chemically strengthened glass.

- FIG. 21 is a graph plotting the relationship between the X value and the Z value for chemically strengthened glass.

- FIG. 22 is a graph obtained by plotting ST Limit of chemically strengthened glass against the plate thickness t.

- FIG. 23 is a graph in which the CT limit of chemically strengthened glass is plotted against the thickness t.

- the surface compressive stress (CS) is 300 MPa or more, and the compressive stress value (CS 90 ) of a portion having a depth of 90 ⁇ m from the glass surface is 25 MPa or more, or a depth of 100 ⁇ m from the glass surface.

- This is a chemically strengthened glass having a partial compressive stress value (CS 100 ) of 15 MPa or more.

- the chemically strengthened glass of the first aspect has a compressive stress layer formed on the surface by chemical strengthening treatment (ion exchange treatment).

- the surface of the glass is ion-exchanged to form a surface layer in which compressive stress remains.

- an alkali metal ion typically Li ion or Na ion

- an alkali ion having a larger ionic radius Typically, Na ions or K ions are substituted for Li ions, and K ions are substituted for Na ions.

- the surface compressive stress (CS) of the chemically strengthened glass is 300 MPa or more.

- CS surface compressive stress

- the CS of the chemically strengthened glass is preferably 350 MPa or more, more preferably 400 MPa or more, and further preferably 450 MPa or more.

- the upper limit of CS of chemically tempered glass is not particularly limited, but if CS is too large, there will be a greater risk of splattering if it breaks. From this viewpoint, it is, for example, 2000 MPa or less, preferably 1500 MPa or less, more preferably 1000 MPa or less, and further preferably 800 MPa or less.

- CS of chemically strengthened glass can be appropriately adjusted by adjusting chemical strengthening conditions, glass composition, and the like.

- CS of chemically tempered glass of the first aspect the value CS F and CS A by the following two kinds of measurement methods are defined as follows. The same applies to the compressive stress value (CS x ) at the depth of x ⁇ m from the glass surface.

- CS F is a value determined by the accessory program FsmV of measured surface stress meter with a surface stress meter FSM-6000 of Orihara Seisakusho.

- CS A is a value measured by the following procedure using a birefringence imaging system Abrio-IM manufactured by Tokyo Instruments Inc.

- a cross section of chemically tempered glass having a size of 10 mm ⁇ 10 mm or more and a thickness of about 0.2 to 2 mm is polished in a range of 150 to 250 ⁇ m and thinned.

- grinding to a target thickness of about 50 ⁇ m with a # 1000 diamond electrodeposition grindstone then grinding to a target thickness of about 10 ⁇ m using a # 2000 diamond electrodeposition grindstone, and finally mirroring with cerium oxide The target thickness.

- F ⁇ / (C ⁇ t ′)

- Formula (A) Wherein (A), F represents a stress (MPa), [delta] is a phase difference (retardation) (nm), C is a photoelastic constant (nm cm -1 MPa), t ' is the sample thickness (cm).

- the inventors of the present invention are excellent in chemically strengthened glass (hereinafter also referred to as high-DOL glass) having a DOL of a predetermined value or more and a compressive stress value at a predetermined depth inside the compressive stress layer of a predetermined value or more. It has been found that it has resistance to falling on sand. Moreover, it has been found that such high DOL glass has high resistance to falling on sand even when CT is relatively large. From the above viewpoint, in the first aspect, the compressive stress value (CS 90 ) of the portion of the chemically strengthened glass having a depth of 90 ⁇ m from the glass surface is preferably 25 MPa or more, and more preferably 30 MPa or more. preferable.

- the compression stress value of the depth of the portion of 100 ⁇ m from the glass surface (CS 100) is not less than 15 MPa, and more preferably not less than 20 MPa.

- the product CS 100 ⁇ t 2 of the compressive stress value at a depth of 100 ⁇ m from the glass surface and the square of the plate thickness t (mm) is 5 MPa ⁇ mm 2 or more. Preferably there is.

- CS 90 When CS 90 is 25 MPa or more, it can have sufficient resistance against breakage caused by scratches caused by collision with sharp corners such as sand that can collide with chemically strengthened glass in a practical situation, that is, Excellent resistance to falling on sand. Further, the present inventors have found that a chemically strengthened glass having a CS 90 of 25 MPa or more can provide a chemically strengthened glass having a high resistance to dropping on sand even if CT is relatively large.

- CS 90 is more preferably 30 MPa or more, further preferably 35 MPa or more, still more preferably 40 MPa or more, particularly preferably 45 MPa or more, and most preferably 50 MPa or more.

- the upper limit of CS 90 is not particularly limited, but from the viewpoint of safety at the time of destruction, it is, for example, 250 MPa or less, preferably 200 MPa or less, more preferably 150 MPa or less, particularly preferably. 100 MPa or less, and most preferably 75 MPa or less.

- CS 100 is more preferably 20 MPa or more, further preferably 23 MPa or more, still more preferably 26 MPa or more, particularly preferably 30 MPa or more, and most preferably 33 MPa or more.

- the upper limit of CS 100 is not particularly limited, it is, for example, 200 MPa or less, preferably 150 MPa or less, more preferably 100 MPa or less, and particularly preferably 75 MPa or less, from the viewpoint of safety at breakage. Most preferably, it is 50 MPa or less.

- CS 100 ⁇ t 2 is preferably 5 MPa ⁇ mm 2 or more, more preferably 7 MPa ⁇ mm 2 or more, further preferably 10 MPa ⁇ mm 2 or more, and particularly preferably 15 MPa ⁇ mm 2 or more. Most preferably, it is 20 MPa ⁇ mm 2 or more.

- CS 100 ⁇ t 2 is particularly limited, from the viewpoint of safety at break, for example at 120 MPa ⁇ mm 2 or less, preferably not more 100 MPa ⁇ mm 2 or less, more preferably 80MPa ⁇ Mm 2 or less, particularly preferably 60 MPa ⁇ mm 2 or less, and most preferably 40 MPa ⁇ mm 2 or less.

- the depth d h (see FIG. 1B) where the internal compressive stress is half the surface compressive stress (CS) is 8 ⁇ m or more. Preferably there is.

- d h is at 8 ⁇ m or more, resistance is improved with respect to strength reduction of the flexural strength at the scratching.

- d h is preferably 8 ⁇ m or more, more preferably 10 ⁇ m or more, further preferably 12 ⁇ m or more, and particularly preferably 15 ⁇ m or more.

- d h it is not particularly restricted upper limit of d h, from the viewpoint of safety at break is, for example, 70 ⁇ m or less, preferably 60 ⁇ m or less, more preferably 50 ⁇ m or less, more preferably 40 ⁇ m or less And particularly preferably 30 ⁇ m or less.

- the depth d M (see FIG. 1 (c)) where the compressive stress is maximized is in the range of 10 ⁇ m or less from the glass surface. If d M is located deeper than 10 ⁇ m from the glass surface, the effect of the bending strength improvement by the chemical strengthening treatment is not sufficiently obtained, which may lead to a bending strength decreases.

- d M is preferably 10 ⁇ m or less, more preferably 8 ⁇ m or less, more preferably 5 ⁇ m or less.

- the DOL is preferably 100 ⁇ m or more.

- the DOL is 100 ⁇ m or more, it can have sufficient resistance against breakage caused by scratches caused by collision with a sharp object such as sand that can collide with chemically strengthened glass in a practical scene.

- the DOL is more preferably 110 ⁇ m or more, further preferably 120 ⁇ m or more, and particularly preferably 130 ⁇ m or more.

- the upper limit of DOL is not particularly limited, but from the viewpoint of safety at the time of destruction, it is, for example, 200 ⁇ m or less, preferably 180 ⁇ m or less, more preferably 160 ⁇ m or less, and particularly preferably 150 ⁇ m. It is as follows.

- the DOL can be adjusted as appropriate by adjusting chemical strengthening conditions, glass composition, and the like.

- ⁇ CS DOL-20 (unit: MPa / ⁇ m) calculated by the following formula using the compressive stress value CS DOL-20 at a depth of 20 ⁇ m from the DOL on the glass surface side is 0.4.

- the above is preferable.

- ⁇ CS DOL-20 CS DOL-20 / 20

- ⁇ CS DOL-20 is more preferably 0.5 or more, 0.6 or more, 0.7 or more, 0.8 or more, 0.9 or more, 1.0 or more, 1.2 or more step by step. 1.4 or more, 1.5 or more.

- the upper limit of ⁇ CS DOL-20 is not particularly limited, but from the viewpoint of crushing safety, it is, for example, 4.0 or less, preferably 3.0 or less, more preferably 2.0 or less, More preferably, it is 1.7 or less, typically 1.6 or less.

- ⁇ CS 100-90 (unit: MPa / ⁇ m) calculated by the following formula using CS 90 and CS 100 is preferably 0.4 or more.

- ⁇ CS 100-90 (CS 90 -CS 100 ) / (100-90)

- DerutaCS 100-90 is more preferably less stepwise, of 0.5 or more, 0.6 or more, 0.7 or more, 0.8 or more, 0.9 or more, 1.0 or more, 1.2 or more 1.4 or more, 1.5 or more.

- the upper limit of ⁇ CS 100-90 is not particularly limited, but from the viewpoint of crushing safety, it is, for example, 4.0 or less, preferably 3.0 or less, more preferably 2.0 or less, More preferably, it is 1.7 or less, typically 1.6 or less.

- the DOL of the chemically strengthened glass in the first embodiment is the depth from the glass surface where the stress becomes zero in the stress profile, and is measured by a surface stress meter FSM-6000 manufactured by Orihara Seisakusho Co., Ltd. Is the value analyzed by.

- the measurement can be performed using a thinned sample as shown in FIG. 2B using a birefringence imaging system Abrio-IM manufactured by Tokyo Instruments Inc.

- the area Sc (MPa ⁇ ⁇ m) of the compressive stress layer is preferably 30000 MPa ⁇ ⁇ m or more.

- the area Sc (MPa ⁇ ⁇ m) of the compressive stress layer is 30000 MPa ⁇ ⁇ m or more, by introducing larger CS and DOL, sharp objects such as sand that can collide with chemically strengthened glass in practical situations It is possible to obtain chemically strengthened glass having sufficient resistance against breakage caused by scratches caused by collision with the glass.

- Sc is more preferably 32000 MPa ⁇ ⁇ m or more, and in the following, stepwise is 34000 MPa ⁇ ⁇ m or more, 36000 MPa ⁇ ⁇ m or more, 38000 MPa ⁇ ⁇ m or more, 40000 MPa ⁇ ⁇ m or more, 42000 MPa ⁇ ⁇ m or more, 44000 MPa ⁇ ⁇ m or more, 44000 MPa ⁇ ⁇ m or more. Further preferred.

- Sc of chemically tempered glass of the first aspect is the value Sc F and Sc A by the following two kinds of measurement methods are defined as follows.

- Sc F is a value calculated using a value measured by a surface stress meter FSM-6000 manufactured by Orihara Seisakusho Co., Ltd. and analyzed by the attached program FsmV

- Sc A is a method similar to the CS A measurement described above. It is a value obtained by measurement using a certain birefringence imaging system Abrio-IM and a thinned sample.

- the area St (MPa ⁇ ⁇ m) of the internal tensile layer of the chemically strengthened glass in the first aspect is defined as follows by values St F and St A obtained by the following two types of measurement methods.

- St F is a value calculated using a value measured by a surface stress meter FSM-6000 manufactured by Orihara Seisakusho Co., Ltd. and analyzed by an attached program FsmV

- St A is a method similar to the above-mentioned CS A measurement. It is a value obtained by measurement using a certain birefringence imaging system Abrio-IM and a thinned sample.

- a stress profile is created by two methods, St F or St A is calculated, and St can be obtained.

- Fig. 1 (a) shows a conceptual diagram of Sc and St. Sc and St are theoretically equal values, and it is preferable to calculate such that 0.95 ⁇ Sc / St ⁇ 1.05.

- the mother composition of chemically strengthened glass is the composition of glass before chemical strengthening (hereinafter also referred to as chemically strengthened glass).

- the part (henceforth a tensile-stress part) which has the tensile stress of chemically strengthened glass is a part which is not ion-exchanged.

- the tensile-stress part of chemically strengthened glass has the same composition as the glass before chemical strengthening.

- the composition of the tensile stress portion can be regarded as the matrix composition.

- the preferable aspect of the mother composition of chemically strengthened glass is mentioned later.

- the inventors of the present invention have a good correlation between the X value and the Z value calculated based on the above formulas and the number of fragments (the number of fractures) generated at the time of breaking (crushing) the chemically strengthened glass, and the larger the X value and the Z value are. It was experimentally found that the number of pieces to be crushed at the time of breaking the glass tends to be reduced.

- the X value is preferably 30000 MPa ⁇ ⁇ m or more, and stepwise below. 32,000 MPa ⁇ ⁇ m or more, 34000 MPa ⁇ ⁇ m or more, 36000 MPa ⁇ ⁇ m or more, 38000 MPa ⁇ ⁇ m or more, 40000 MPa ⁇ ⁇ m or more, 42000 MPa ⁇ ⁇ m or more, 44000 MPa ⁇ ⁇ m or more, 45000 MPa ⁇ ⁇ m or more, 46000 MPa ⁇ ⁇ m or more preferable.

- the Z value is preferably 20000 MPa ⁇ ⁇ m or more.

- stepwise 22000 MPa ⁇ ⁇ m or more, 24000 MPa ⁇ ⁇ m or more, 26000 MPa ⁇ ⁇ m or more, 28000 MPa ⁇ ⁇ m or more, 29000 MPa ⁇ ⁇ m or more.

- 30000 MPa ⁇ ⁇ m or more is more preferable.

- X value and Z value can be adjusted by the amount of each component in the mother composition of chemically strengthened glass.

- the matrix composition of the chemically strengthened glass is not particularly limited, but the chemical strengthening treatment that gives the above-described chemical strengthening characteristics to the glass after chemical strengthening is applicable, and the value of X May be selected as appropriate so that the glass composition is 30000 or more and / or the value of Z is 20000 or more.

- the Y value calculated based on the following formula correlates with the number of fragments (the number of fractures) generated when the chemically strengthened glass is broken (crushed), and the larger the Y value, the smaller the number of fractures when the glass is broken.

- the Y value is 0.7 or more in the chemically tempered glass of the first aspect from the viewpoint of reducing the number of crushed and higher safety even when the glass breaks. Is preferably 0.75 or more, more preferably 0.77 or more, particularly preferably 0.80 or more, and most preferably 0.82 or more.

- the devitrification temperature T is preferably a temperature T4 or less at which the viscosity becomes 10 4 dPa ⁇ s. This is because when the devitrification temperature T is higher than T4, quality deterioration due to devitrification is likely to occur during glass plate forming by the float method or the like.

- the chemically strengthened glass of the first aspect is plate-shaped (glass plate)

- its thickness (t) is not particularly limited, but in order to increase the effect of chemical strengthening, for example, 2 mm Or less, preferably 1.5 mm or less, more preferably 1 mm or less, further preferably 0.9 mm or less, particularly preferably 0.8 mm or less, and most preferably 0.7 mm or less.

- the plate thickness is, for example, 0.1 mm or more, preferably 0.2 mm or more, more preferably 0.4 mm or more, from the viewpoint of obtaining a sufficient strength improvement effect by the chemical strengthening treatment. More preferably, it is 0.5 mm or more.

- the chemically strengthened glass of the first aspect may have a shape other than a plate shape depending on a product to be used, an application, and the like.

- the glass plate may have an edge shape etc. from which the outer periphery thickness differs.

- the said glass plate has two main surfaces and the end surface which forms plate thickness adjacent to these, and the two main surfaces may form the flat surface mutually parallel.

- the form of the glass plate is not limited to this.

- the two main surfaces may not be parallel to each other, and all or a part of one or both of the two main surfaces may be a curved surface.

- the glass plate may be, for example, a flat glass plate without warpage or a curved glass plate having a curved surface.

- security is obtained.

- a mobile device such as a smartphone

- a collision object having a collision part with a small angle hereinafter also referred to as an acute angle object

- sand a collision object having a collision part with a small angle

- sand a collision object having a collision part with a small angle

- sand a collision object having a collision part with a small angle

- sand such as sand

- the chemically strengthened glass according to the first embodiment is also excellent in resistance to breakage (drop resistance on sand) caused by scratches caused by collision with sharp objects such as sand that can collide in a practical scene.

- ⁇ Second aspect> It continues and demonstrates the chemically strengthened glass which concerns on a 2nd aspect.

- One of the chemically strengthened glasses of the second aspect is a chemically strengthened glass having a surface compressive stress (CS) of 300 MPa or more and satisfying the following formulas (1) and (2).

- StL (t) is a value obtained by the following measurement.

- a glass of 25 mm ⁇ 25 mm ⁇ plate thickness t (mm) is subjected to a chemical strengthening treatment under various chemical strengthening treatment conditions so that the internal tensile stress area (St; unit MPa ⁇ ⁇ m) is changed.

- a chemically strengthened glass having a tensile stress area (St; unit MPa ⁇ ⁇ m) is produced.

- each of these chemically strengthened glasses was broken by an indenter press-in test in which a load of 3 to 10 kgf was held for 15 seconds, and the pieces of chemically strengthened glass after breakage were broken.

- the number (number of crushing) of each is measured.

- Stn value which is the St value of the maximum number of fractures n of less than 10 and the Stm value of the minimum number of fractures m of more than 10

- StL (t) value is defined by the equation.

- StL (t) value Stn + (10 ⁇ n) ⁇ (Stm ⁇ Stn) / (mn)

- a region of 25 mm ⁇ 25 mm is displayed in the chemically strengthened glass, and the above StL (t) measurement is performed in the region.

- StL (t) depends on the plate thickness t (mm) and a, and a is a parameter depending on the glass composition. StL (t) changes linearly with respect to t, and its slope can be described by a parameter a that changes with composition. In addition, by setting the value of a to 30000 MPa ⁇ ⁇ m / mm or more, even when larger CS and DOL are introduced, it is possible to obtain a highly safe crushing mode with less crushing number.

- the value of a is more preferably 32000 MPa ⁇ ⁇ m / mm or more, and in the following steps, 34000 MPa ⁇ ⁇ m / mm or more, 36000 MPa ⁇ ⁇ m / mm or more, 38000 MPa ⁇ ⁇ m / mm or more, 40000 MPa ⁇ ⁇ m / mm or more. It is more preferably 42,000 MPa ⁇ ⁇ m / mm or more, 44000 MPa ⁇ ⁇ m / mm or more, 46000 MPa ⁇ ⁇ m / mm or more, 48000 MPa ⁇ ⁇ m / mm or more, 50000 MPa ⁇ ⁇ m / mm or more.

- the value of a is preferably 53000 MPa ⁇ ⁇ m / mm or less.

- One of the chemically strengthened glasses of the second aspect is a chemically strengthened glass having a surface compressive stress (CS) of 300 MPa or more and satisfying the following formulas (3), (4) and (5).

- CS surface compressive stress

- CTL (t) is a value obtained by the following measurement. Specifically, a glass of 25 mm ⁇ 25 mm ⁇ sheet thickness t (mm) is subjected to chemical strengthening treatment under various chemical strengthening treatment conditions so that the internal tensile stress CT (unit: MPa) changes, A chemically tempered glass having an internal tensile stress CT (unit: MPa) of 1 is prepared. Then, using a diamond indenter having a facing indenter angle of 60 degrees, each of these chemically strengthened glasses was broken by an indenter press-in test in which a load of 3 to 10 kgf was held for 15 seconds, and the pieces of chemically strengthened glass after breakage were broken. The number (number of crushing) of each is measured.

- CT Limit value CTL (t) when the plate thickness is t (mm).

- CTn value that is the CT value of the maximum number of fractures n that is less than 10

- CTm value that is the CT value of the minimum number of fractures m that is greater than 10

- CTL (t) value CTn + (10 ⁇ n) ⁇ (CTm ⁇ CTn) / (mn)

- CTL (t) value CTn + (10 ⁇ n) ⁇ (CTm ⁇ CTn) / (mn)

- CTL (t) depends on the plate thickness t (mm), b, and c, and b and c are parameters that depend on the glass composition. CTL (t) decreases with increasing t and can be described using natural logarithm as shown in Equation (3). According to this embodiment, by setting the values of b and c to 14 MPa or more and 48.4 MPa or more, respectively, even when a larger CS and DOL are introduced than before, the number of crushing is less and the crushing mode is high in safety. It can be.

- the value of b is more preferably 14 MPa or more.

- stepwise 15 MPa or more, 16 MPa or more, 17 MPa or more, 18 MPa or more, 19 MPa or more, 20 MPa or more, 21 MPa or more, 22 MPa or more, 23 MPa or more, 24 MPa or more, 25 MPa.

- it is preferably 26 MPa or more, 27 MPa or more, 28 MPa or more, 29 MPa or more, or 30 MPa or more.

- the value of c is more preferably 48.4 MPa or more.

- stepwise 49 MPa or more, 50 MPa or more, 51 MPa or more, 52 MPa or more, 53 MPa or more, 54 MPa or more, 55 MPa or more, 56 MPa or more, 57 MPa or more, 58 MPa or more.

- CTL (t) is preferably smaller than ⁇ 35 ⁇ ln (t) +75.

- the St value and the CT value are the values St F and CT F measured by the surface stress meter FSM-6000 manufactured by Orihara Seisakusho and analyzed by the attached program FsmV, or the birefringence imaging system Abrio-IM and the thinned sample.

- CT F is equal to the analyzed values CT_CV at FsmV, is different from the CT 'obtained by the following equation (11).

- DOL ′ (t ⁇ 2 ⁇ DOL ′) ⁇ CT ′ (11)

- DOL ′ corresponds to the depth of the ion exchange layer.

- CT ′ approximates the stress profile linearly and assumes that the point at which the stress becomes zero is equal to the ion diffusion layer depth, so it is estimated to be larger than the actual internal tensile stress. This is not suitable as an index of internal tensile stress in this embodiment.

- the chemically strengthened glass of the second aspect has a compressive stress layer formed on the surface by chemical strengthening treatment (ion exchange treatment).

- the chemically strengthened glass of the second aspect has a surface compressive stress (CS) of 300 MPa or more.

- CS surface compressive stress

- the reason for limitation of CS and the preferable numerical range in the chemically strengthened glass of the second aspect are the same as those of the first aspect.

- CS 90, CS 100 and CS 100 ⁇ accompanying the preferable range and it t 2 in the chemical strengthened glass according to the second embodiment is the same as the first embodiment.

- the compressive stress value (CS 90 ) at a depth of 90 ⁇ m from the glass surface is 25 MPa or more, or the compressive stress value (CS 100 ) at a depth of 100 ⁇ m from the glass surface is 15 MPa or more, it is practical. It can have sufficient resistance against damage caused by scratches caused by collision with sand and other sharp objects that can collide with chemically strengthened glass in a typical situation, that is, chemical strengthening with excellent resistance to falling on sand Can with glass.

- preferable numerical ranges and technical effects associated therewith of d h and d M in the chemical strengthened glass according to the second embodiment is the same as the first embodiment.

- preferable numerical range of DOL in the chemically strengthened glass of the second aspect and the technical effect associated therewith are the same as those of the first aspect.

- preferred numerical ranges of Sc and St and the technical effects associated therewith in the chemically strengthened glass of the second aspect are the same as those of the first aspect.

- the chemically strengthened glass of the second aspect is a plate having a plate thickness t of 2 mm or less.

- the preferred numerical range of the plate thickness t and the technical effect associated therewith in the chemically strengthened glass of the second aspect are the same as in the first aspect.

- the chemically strengthened glass of the second aspect can take various shapes other than the plate shape, similarly to the chemically strengthened glass of the first aspect.

- the average crack height by the sand drop test under the following conditions is 250 mm or more, The number of crushing by indentation test under the following conditions is 30 or less, The plate thickness t is 0.4-2 mm, The surface compressive stress (CS) is 300 MPa or more, and The depth (DOL) of a compressive-stress layer is related with the chemically strengthened glass which is 100 micrometers or more.

- the average crack height of the chemically tempered glass in the third aspect by a drop-on-sand test is 250 mm or more, preferably 300 mm or more, more preferably 350 mm or more from the viewpoint of having excellent drop-to-sand resistance.

- the average crack height of the chemically strengthened glass in the third aspect is measured by a drop-on-sand test under the following conditions.

- Sand drop test conditions Chemically tempered glass (50 mm x 50 mm x plate thickness t (mm)) is bonded to a hard nylon mock board (50 mm x 50 mm, weight: 54 g) via a double-sided sponge tape (50 mm x 50 mm x thickness 3 mm) and measured. Prepare a sample. Next, on a SUS plate having a size of 15 cm ⁇ 15 cm, 1 g of silica sand (No. 5 silica sand made by Takefori Co., Ltd.) is evenly spread, and the prepared measurement sample is placed with chemically tempered glass facing down. It is dropped from a predetermined height (falling height) onto the surface of the SUS plate coated with silica sand.

- silica sand No. 5 silica sand made by Takefori Co., Ltd.

- the drop test is carried out by starting from a drop height of 10 mm and increasing the height by 10 mm.

- the height at which the chemically strengthened glass is broken is defined as the crack height (unit: mm).

- the drop test is carried out five times or more for each example, and the average value of the crack height in the drop test is defined as the average crack height (unit: mm).

- the number of crushing by the indentation test of the chemically strengthened glass in the third aspect is 30 or less, preferably 20 from the viewpoint that even if it breaks (crushing), it becomes safer (crushing). Or less, more preferably 10 or less, still more preferably 5 or less, and particularly preferably 2 or less.

- the number of fractures of the chemically strengthened glass in the third aspect is measured by an indenter press-in test under the following conditions.

- Indenter press-fit test conditions Using a diamond indenter with an indenter angle of 60 degrees facing the chemically tempered glass of 25 mm x 25 mm x plate thickness t (mm), a chemical strengthening is performed by an indentation press-in test that holds a load of 3 to 10 kgf for 15 seconds. The glass is broken, and the number of fractures of the chemically strengthened glass after the breakage is measured. When chemically tempered glass having a size larger than 25 mm ⁇ 25 mm is used, a 25 mm ⁇ 25 mm region is displayed in the chemically tempered glass, and an indenter press-in test and the number of fractures are measured in the region. When the chemically tempered glass has a curved surface shape, a projected area of 25 mm ⁇ 25 mm is displayed on the curved surface of the chemically tempered glass, and the indenter press-in test and the number of crushing are measured within the region.

- the chemically strengthened glass of the third aspect is plate-shaped (glass plate), and the thickness (t) thereof is, for example, 2 mm or less from the viewpoint of enabling remarkable strength improvement by chemical strengthening, Preferably it is 1.5 mm or less, More preferably, it is 1 mm or less, More preferably, it is 0.9 mm or less, Especially preferably, it is 0.8 mm or less, Most preferably, it is 0.7 mm or less.

- board thickness is 0.3 mm or more from a viewpoint of obtaining the effect of sufficient intensity

- the chemically strengthened glass of the third aspect has a surface compressive stress (CS) of 300 MPa or more.

- CS surface compressive stress

- the reason for limitation of CS and the preferable numerical range in the chemically strengthened glass of the third aspect are the same as those of the first aspect.

- the DOL in the chemically strengthened glass of the third aspect has sufficient resistance against breakage caused by scratches caused by collision with sharp objects such as sand that can collide with the chemically strengthened glass in a practical situation. From this point of view, it is 100 ⁇ m or more.

- the DOL is more preferably 110 ⁇ m or more, further preferably 120 ⁇ m or more, and particularly preferably 130 ⁇ m or more.

- the preferable numerical ranges of CS 90 , CS 100 and CS 100 ⁇ t 2 in the chemically strengthened glass of the third aspect and the technical effects associated therewith are the same as those of the first aspect.

- preferable numerical ranges and technical effects associated therewith of d h and d M in the chemical strengthened glass of the third aspect is similar to the first embodiment.

- preferable numerical ranges of Sc and St in the chemically strengthened glass of the third aspect and the technical effects associated therewith are the same as those of the first aspect.

- the chemically tempered glass according to the third aspect is a chemically tempered glass having a low safety and high safety even if CT or St is large.

- the glass composition of the chemically strengthened glass may be referred to as a mother composition of the chemically strengthened glass.

- the portion having the tensile stress of the chemically strengthened glass (hereinafter also referred to as the tensile stress portion) is a portion that is not ion-exchanged. It has the same composition as the glass before chemical strengthening. In that case, the composition of the tensile stress portion of the chemically strengthened glass can be regarded as the mother composition of the chemically strengthened glass.

- composition of the glass can be simply determined by semi-quantitative analysis by a fluorescent X-ray method, but more accurately, it can be measured by a wet analysis method such as ICP emission analysis.

- content of each component shall be represented by the molar percentage display of an oxide basis.

- the composition for the chemically strengthened glass of the present invention (the mother composition of the chemically strengthened glass of the present invention)

- SiO 2 is 50 to 80%

- Al 2 O 3 is 1 to 30%

- B 2 O 3 is 0. ⁇ 5%

- P 2 O 5 0-4% Li 2 O 3-20%, Na 2 O 0-8%

- K 2 O 0-10% MgO 3-20%

- CaO It preferably contains 0-20%, SrO 0-20%, BaO 0-15%, ZnO 0-10%, TiO 2 0-1% and ZrO 2 0-8%.

- Z SiO 2 ⁇ 237 + Al 2 O 3 ⁇ 524 + B 2 O 3 ⁇ 228 + P 2 O 5 ⁇ (-756) + Li 2 O ⁇ 538 + Na 2 O ⁇ 44.2 + K 2 O ⁇ (-387) + MgO ⁇ 660 + CaO ⁇ 569 + SrO ⁇

- the value of Z calculated based on 291 + ZrO 2 ⁇ 510 is preferably 20000 or more.

- SiO 2 is a component constituting the skeleton of glass. Further, a component to increase chemical durability, and a component to reduce the occurrence of cracks when scratched (indentation) on the glass surface, it is preferable that the content of SiO 2 is 50% or more. More preferably, the content of SiO 2 is 54% or more, 58% or more, 60% or more, 63% or more, 66% or more, 68% or more in a stepwise manner. On the other hand, if the content of SiO 2 exceeds 80%, the meltability is remarkably lowered. The content of SiO 2 is 80% or less, more preferably 78% or less, still more preferably 76% or less, particularly preferably 74% or less, and most preferably 72% or less.

- Al 2 O 3 is a component that improves the friability of chemically strengthened glass.

- the high crushability of the glass means that the number of fragments when the glass is broken is small. Highly friable glass is safe because it is difficult for fragments to scatter when broken.

- the content of Al 2 O 3 is 1% or more. It is preferable.

- Al 2 O 3 is a component that increases the Tg of the glass and is also a component that increases the Young's modulus.

- the content of Al 2 O 3 is more preferably 3% or more, 5% or more, 7% or more, 8% or more, 9% or more, 10% or more, 11% or more, or 12% or more step by step. 13% or more.

- the content of Al 2 O 3 is more than 30%, the acid resistance of the glass is lowered or the devitrification temperature is increased. Further, the viscosity of the glass increases and the meltability decreases.

- the content of Al 2 O 3 is preferably 30% or less, more preferably 25% or less, still more preferably 20% or less, particularly preferably 18% or less, and most preferably 15% or less.

- Al 2 O 3 content is preferably not more than 11%, or less, in stages, 10%, 9% or less, 8% or less, 7% or less Is preferred.

- B 2 O 3 is a component that improves the chipping resistance of the chemically strengthened glass or chemically strengthened glass and improves the meltability.

- B 2 O 3 is not essential, but the content in the case of containing B 2 O 3 is preferably 0.5% or more, more preferably 1% or more, further preferably, in order to improve the meltability. 2% or more.

- the content of B 2 O 3 exceeds 5%, striae are generated at the time of melting and the quality of the glass for chemical strengthening tends to deteriorate, so 5% or less is preferable.

- the content of B 2 O 3 is more preferably 4% or less, still more preferably 3% or less, and particularly preferably 1% or less. It is preferably not contained in order to increase acid resistance.

- P 2 O 5 is a component that improves ion exchange performance and chipping resistance.

- P 2 O 5 may not be contained, but the content in the case of containing P 2 O 5 is preferably 0.5% or more, more preferably 1% or more, and further preferably 2% or more. is there.

- the content of P 2 O 5 exceeds 4%, the crushed property of the chemically strengthened glass is lowered, and the acid resistance is remarkably lowered.

- the content of P 2 O 5 is preferably 4% or less, more preferably 3% or less, still more preferably 2% or less, and particularly preferably 1% or less. It is preferably not contained in order to increase acid resistance.

- Li 2 O is a component that forms surface compressive stress by ion exchange and is a component that improves the friability of chemically strengthened glass.

- the content of Li 2 O is preferably 3% or more, more preferably 4%. More preferably, it is 5% or more, particularly preferably 6% or more, and typically 7% or more.

- the content of Li 2 O exceeds 20%, the acid resistance of the glass is significantly reduced.

- the Li 2 O content is preferably 20% or less, more preferably 18% or less, still more preferably 16% or less, particularly preferably 15% or less, and most preferably 13% or less.

- the magnitude of compressive stress is such that the Li 2 O content exceeds 3%. Decreases, and it becomes difficult for CS 90 to achieve 30 MPa or more.

- the content of Li 2 O is preferably 3% or less, more preferably 2% or less, further preferably 1% or less, particularly preferably 0.5% or less, and most preferably Li 2.

- O is not substantially contained. In the present specification, “substantially does not contain” means that it is not contained except for inevitable impurities contained in raw materials and the like, that is, it is not intentionally contained. Specifically, it indicates that the content in the glass composition is less than 0.1 mol%.

- Na 2 O is a component that forms a surface compressive stress layer by ion exchange and improves the meltability of the glass.

- Li ion on the glass surface is exchanged with Na ion and chemical strengthening treatment is performed such that the CS 90 is 30 MPa or more

- Na 2 O may not be contained, but when the melting property of glass is important. You may contain.

- the content when Na 2 O is contained is preferably 1% or more.

- the content of Na 2 O is more preferably 2% or more, and further preferably 3% or more.

- the content of Na 2 O exceeds 8%, the surface compressive stress formed by ion exchange is remarkably reduced.

- the content of Na 2 O is preferably 8% or less, more preferably 7% or less, still more preferably 6% or less, particularly preferably 5% or less, and most preferably 4% or less.

- Na is essential, and its content is 5% or more.

- the Na 2 O content is preferably 5% or more, more preferably 7% or more, still more preferably 9% or more, particularly preferably 11% or more, and most preferably 12% or more.

- the content of Na 2 O exceeds 20%, the acid resistance of the glass is significantly reduced.

- the content of Na 2 O is preferably 20% or less, more preferably 18% or less, further preferably 16% or less, particularly preferably 15% or less, and most preferably 14% or less.

- the content of Na 2 O is preferably 10 % Or less, more preferably 9% or less, further preferably 7% or less, particularly preferably 6% or less, and most preferably 5% or less.

- the content of Na 2 O is preferably 2% or more, more preferably 3% or more, and further preferably 4% or more.

- K 2 O may be included to improve ion exchange performance.

- the content is preferably 0.5% or more, more preferably 1% or more, still more preferably 2% or more, and particularly preferably 3% or more.

- the content of K 2 O is more than 10%, the friability of the chemically strengthened glass is lowered, so the content of K 2 O is preferably 10% or less.

- the content of K 2 O is more preferably 8% or less, further preferably 6% or less, particularly preferably 4% or less, and most preferably 2% or less.

- MgO is a component that increases the surface compressive stress of chemically strengthened glass, and is a component that improves crushability, and is preferably contained.

- the content is preferably 3% or more, and more preferably 4% or more, 5% or more, 6% or more, 7% or more, or 8% or more stepwise.

- the content of MgO exceeds 20%, the glass for chemical strengthening tends to devitrify when melted.

- the content of MgO is preferably 20% or less, more preferably 18% or less, 15% or less, 14% or less, 13% or less, 12% or less, 11% or less, 10% or less stepwise. .

- CaO is a component that improves the meltability of the chemically strengthened glass, and is a component that improves the crushability of the chemically strengthened glass, and may be contained.

- the content is preferably 0.5% or more, more preferably 1% or more, further preferably 2% or more, particularly preferably 3% or more, and most preferably 5% or more. is there.

- the content of CaO exceeds 20%, the ion exchange performance is remarkably deteriorated, so 20% or less is preferable.

- the content of CaO is more preferably 14% or less, and still more preferably 10% or less, 8% or less, 6% or less, 3% or less, 1% or less stepwise.

- SrO is a component that improves the meltability of the chemically strengthened glass, and is a component that improves the crushability of the chemically strengthened glass, and may be contained.

- the content is preferably 0.5% or more, more preferably 1% or more, further preferably 2% or more, particularly preferably 3% or more, and most preferably 5% or more. is there.

- the SrO content exceeds 20%, the ion exchange performance is remarkably lowered, so 20% or less is preferable.

- the content of the SrO content is more preferably 14% or less, and further preferably 10% or less, 8% or less, 6% or less, 3% or less, or 1% or less stepwise.

- BaO is a component that improves the meltability of the chemically strengthened glass, and is a component that improves the crushability of the chemically strengthened glass, and may be contained.

- the content is preferably 0.5% or more, more preferably 1% or more, still more preferably 2% or more, particularly preferably 3% or more, and most preferably 5% or more. is there.

- the content of BaO exceeds 15%, the ion exchange performance is significantly lowered.

- the content of BaO is preferably 15% or less, more preferably 10% or less, 8% or less, 6% or less, 3% or less, 1% or less.

- ZnO is a component that improves the meltability of the glass and may be contained. Content in the case of containing ZnO becomes like this. Preferably it is 0.25% or more, More preferably, it is 0.5% or more. On the other hand, when the ZnO content exceeds 10%, the weather resistance of the glass is significantly lowered.

- the content of ZnO is preferably 10% or less, more preferably 7% or less, further preferably 5% or less, particularly preferably 2% or less, and most preferably 1% or less.

- TiO 2 is a component that improves the crushability of chemically strengthened glass, and may be contained.

- the content of the case of containing the TiO 2 is preferably 0.1% or more, more preferably 0.15% or more, further preferably 0.2% or more.

- the content of TiO 2 is preferably 1% or less, more preferably 0.5% or less, and still more preferably 0.25% or less.

- ZrO 2 is a component that increases the surface compressive stress due to ion exchange, has the effect of improving the crushability of the glass for chemical strengthening, and may be contained.

- the content is preferably 0.5% or more, more preferably 1% or more.

- the content of ZrO 2 is easily devitrified when melted is 8 percent, the quality of the chemically tempered glass may be lowered.

- the content of ZrO 2 is preferably 8% or less, more preferably 6% or less, further preferably 4% or less, particularly preferably 2% or less, and most preferably 1.2% or less. .

- Y 2 O 3 , La 2 O 3 , and Nb 2 O 5 are components that improve the crushability of the chemically strengthened glass, and may be contained.

- the content is preferably 0.5% or more, more preferably 1% or more, still more preferably 1.5% or more, particularly preferably 2% or more, most preferably Preferably it is 2.5% or more.

- the contents of Y 2 O 3 , La 2 O 3 , and Nb 2 O 5 are each over 8%, the glass tends to be devitrified at the time of melting, and the quality of the chemically strengthened glass may be deteriorated.

- Y 2 O 3 , La 2 O 3 and Nb 2 O 5 are each preferably 8% or less, more preferably 6% or less, still more preferably 5% or less, and particularly preferably 4%. Or less, most preferably 3% or less.

- Ta 2 O 5 and Gd 2 O 3 may be contained in a small amount in order to improve the crushability of chemically strengthened glass. However, the refractive index and the reflectance are increased, so 1% or less is preferable, and 0.5% or less. Is more preferable, and it is still more preferable not to contain.

- coloring and using glass you may add a coloring component in the range which does not inhibit achievement of a desired chemical strengthening characteristic.

- the coloring component include Co 3 O 4 , MnO 2 , Fe 2 O 3 , NiO, CuO, Cr 2 O 3 , V 2 O 5 , Bi 2 O 3 , SeO 2 , TiO 2 , CeO 2 , and Er 2.

- O 3 , Nd 2 O 3 and the like are preferable.

- the content of the coloring component is preferably in a range of 7% or less in total in terms of oxide-based mole percentage. If it exceeds 7%, the glass tends to be devitrified, which is not desirable. This content is preferably 5% or less, more preferably 3% or less, and even more preferably 1% or less. When giving priority to the visible light transmittance of glass, it is preferable that these components are not substantially contained.

- SO 3 As a fining agent for melting the glass, SO 3 , chloride, fluoride and the like may be appropriately contained. It is preferable not to contain As 2 O 3 . When containing Sb 2 O 3 content of preferably 0.3% or less, more preferably 0.1% or less, and most preferably not contained.

- the chemically strengthened glass of the present invention can impart antibacterial properties by having silver ions on the surface.

- the glass for chemical strengthening of the present invention preferably has a fracture toughness value (K1c) of 0.7 MPa ⁇ m 1/2 or more, more preferably 0.75 MPa ⁇ m 1/2 or more, and 0 further preferably .77MPa ⁇ m 1/2 or more, particularly preferably at 0.80 MPa ⁇ m 1/2 or more, and most preferably 0.82 MPa ⁇ m 1/2 or more.

- K1c fracture toughness value

- the fracture toughness value (K1c) in the present specification is a fracture toughness value obtained by measuring a K1-v curve by a DCDC method described in detail in Examples described later.

- the area St (MPa ⁇ ⁇ m) of the internal tensile layer is preferably not more than StL (t) (MPa ⁇ ⁇ m). If St is equal to or less than StL (t), the number of pieces to be crushed is reduced even if it is actually broken.

- the internal tensile stress CT is preferably CTL (t) (MPa) or less. If CT is equal to or less than CTL (t), the number of fractures is reduced even if the CT is actually destroyed.

- the Young's modulus of the chemically strengthened glass is 70 GPa or more, the compressive stress value (CS 0 ) at the outermost surface of the chemically strengthened glass, and the compressive stress value at a depth of 1 ⁇ m from the glass surface ( The difference from CS 1 ) is preferably 50 MPa or less. This is preferable because warpage hardly occurs when the glass surface is polished after the chemical strengthening treatment.

- the Young's modulus of the glass for chemical strengthening is more preferably 74 GPa or more, particularly preferably 78 GPa or more, and further preferably 82 GPa or more.

- the upper limit of the Young's modulus is not particularly limited, but is, for example, 90 GPa or less, preferably 88 GPa or less.

- the Young's modulus can be measured by, for example, an ultrasonic pulse method.

- CS 0 and CS 1 are preferably 50 MPa or less, more preferably 40 MPa or less, and further preferably 30 MPa or less.

- CS 0 is preferably 300 MPa or more, more preferably 350 MPa or more, and further preferably 400 MPa or more.

- the upper limit of CS 0 is not particularly limited, but is, for example, 1200 MPa or less, preferably 1000 MPa or less, and more preferably 800 MPa or less.

- CS 1 is preferably not less than 250 MPa, more preferably at least 300 MPa, more preferably at least 350 MPa.

- the upper limit of CS 1 is not particularly limited, but is, for example, 1150 MPa or less, preferably 1100 MPa or less, and more preferably 1050 MPa or less.

- the chemically strengthened glass of the present invention can be produced, for example, as follows.

- the glass for chemical strengthening treatment is preferably the glass for chemical strengthening of the present invention.

- Glass subjected to the chemical strengthening treatment can be produced by a usual method. For example, the raw material of each component of glass is prepared and heated and melted in a glass melting furnace. Thereafter, the glass is homogenized by a known method, formed into a desired shape such as a glass plate, and slowly cooled.

- Examples of the glass plate forming method include a float method, a press method, a fusion method, and a downdraw method.

- a float method suitable for mass production is preferable.

- continuous molding methods other than the float method, that is, the fusion method and the downdraw method are also preferable.

- the molded glass is ground and polished as necessary to form a glass substrate.

- the glass substrate is cut into a predetermined shape and size, or when the glass substrate is chamfered, if the glass substrate is cut or chamfered before the chemical strengthening process described later, the subsequent chemical strengthening process is performed. Is preferable because a compressive stress layer is also formed on the end face.

- the chemically strengthened glass of the present invention can be produced by subjecting the obtained glass plate to chemical strengthening treatment, followed by washing and drying.

- the chemical strengthening treatment can be performed by a conventionally known method.

- the glass plate is brought into contact with a melt of a metal salt (for example, potassium nitrate) containing a metal ion (typically, K ions) having a large ionic radius by dipping or the like.

- a metal salt for example, potassium nitrate

- K ions typically, K ions

- Small ion radius metal ions typically Na or Li ions

- the chemical strengthening treatment is not particularly limited. For example, by immersing the glass plate in a molten salt such as potassium nitrate heated to 360 to 600 ° C. for 0.1 to 500 hours. It can be carried out.

- the heating temperature of the molten salt is preferably 375 to 500 ° C.

- the immersion time of the glass plate in the molten salt is preferably 0.3 to 200 hours.

- Examples of molten salts for performing chemical strengthening treatment include nitrates, sulfates, carbonates, and chlorides.

- examples of the nitrate include lithium nitrate, sodium nitrate, potassium nitrate, cesium nitrate, and silver nitrate.

- examples of the sulfate include lithium sulfate, sodium sulfate, potassium sulfate, cesium sulfate, and silver sulfate.

- Examples of the carbonate include lithium carbonate, sodium carbonate, and potassium carbonate.

- Examples of the chloride include lithium chloride, sodium chloride, potassium chloride, cesium chloride, silver chloride and the like. These molten salts may be used alone or in combination of two or more.

- the treatment conditions for the chemical strengthening treatment are not particularly limited, and the characteristics and composition of the glass, the type of the molten salt, and the surface compressive stress (CS) and compression desired for the chemically strengthened glass finally obtained.

- Appropriate conditions may be selected in consideration of chemical strengthening characteristics such as stress layer depth (DOL).

- the chemical strengthening treatment may be performed only once, or multiple times of chemical strengthening treatment (multi-stage strengthening) may be performed under two or more different conditions.

- multi-stage strengthening may be performed under two or more different conditions.

- the first-stage chemical strengthening process after performing the chemical strengthening process under the condition that the CS is relatively low, the second-stage chemical strengthening process is performed under the condition that the CS is relatively high.

- the tempering process is performed, the internal tensile stress area (St) can be suppressed while increasing the CS on the outermost surface of the chemically strengthened glass, and as a result, the internal tensile stress (CT) can be suppressed to a low level.

- the chemically tempered glass of the present invention is particularly useful as a cover glass used for mobile devices such as mobile phones, smartphones, personal digital assistants (PDAs), and tablet terminals.

- mobile devices such as mobile phones, smartphones, personal digital assistants (PDAs), and tablet terminals.

- non-portable products such as televisions (TVs), personal computers (PCs), cover glass for display devices such as touch panels, wall surfaces of elevators, wall surfaces of buildings such as houses and buildings (full display), and construction of window glass, etc.

- TVs televisions

- PCs personal computers

- cover glass for display devices such as touch panels, wall surfaces of elevators, wall surfaces of buildings such as houses and buildings (full display), and construction of window glass, etc.

- materials such as construction materials, table tops, interiors of automobiles, airplanes, etc., and cover glasses thereof, and for applications such as a casing having a curved surface shape that is not a plate shape by bending or molding.

- the glass plates were formed so as to have respective glass compositions represented by mole percentages based on oxides shown in the table.

- Example S-1 to S-6, S-13 to S-23, and S-30 to S-33 the glass plates were formed so as to have respective glass compositions represented by mole percentages based on oxides shown in the table.

- Example S-1 to S-6, S-13 to S-23, and S-30 to S-33 the glass plates were formed so as to have respective glass compositions represented by mole percentages based on oxides shown in the table.

- the table was produced in a float kiln.

- Commonly used glass raw materials such as oxides, hydroxides, carbonates or nitrates are appropriately selected and melted in a melting kiln, and formed to a plate thickness of 1.1 to 1.3 mm by a float process.

- the obtained plate glass was cut and ground, and finally both surfaces were processed into mirror surfaces to obtain plate glass having a length of 50 mm ⁇ width 50 mm ⁇ plate thickness

- the glass compositions are expressed in terms of mole percentages based on the oxides shown in the table.

- a glass plate was prepared by melting a platinum crucible. Commonly used glass materials such as oxides, hydroxides, carbonates or nitrates were appropriately selected and weighed so as to give 1000 g of glass. Next, the mixed raw materials were put into a platinum crucible, put into a resistance heating electric furnace at 1500 to 1700 ° C., melted for about 3 hours, defoamed and homogenized. The obtained molten glass was poured into a mold material, held at a temperature of glass transition point + 50 ° C.

- the obtained glass block was cut and ground, and finally both surfaces were processed into mirror surfaces to obtain a plate glass having a length of 50 mm, a width of 50 mm, and a plate thickness t (mm).

- the plate thickness t (mm) is shown in the table.

- a chemically strengthened glass was obtained by subjecting each glass of Examples S-1 to S-13, S-15 to S-29, and S-31 to S-53 to a chemical strengthening treatment.

- the chemical strengthening treatment conditions for each glass are shown in the table.

- the glasses of Examples S-14 and S-30 were not subjected to chemical strengthening treatment.

- surface compressive stress CS (unit: MPa), compressive stress layer thickness DOL (unit: ⁇ m), internal tensile stress CT ( (Unit: MPa), compressive stress value CS x (unit: MPa) at a depth of x ⁇ m from the glass surface, compressive stress value at a depth of x ⁇ m from the glass surface and the square of the thickness t (mm)

- the product CS x ⁇ t 2 (unit: MPa ⁇ mm 2 ), the depth d h (unit: ⁇ m) from the glass surface at which the compressive stress value is one half of the surface compressive stress, is the surface made by Orihara Seisakusho.

- CS was measured with a surface stress meter FSM-6000 manufactured by Orihara Seisakusho Co., and the above-mentioned Abrio-IM and a method using a thin sample was measured DOL, CT, the CS x, CS x ⁇ t 2 , d h. These results are shown in the table.

- the Sc value (unit: MPa ⁇ ⁇ m), ⁇ CS 100-90 (unit: MPa / ⁇ m), CS DOL-20 (unit: MPa), ⁇ CS DOL-20 (unit: MPa / MPa) ( ⁇ m) is also shown.

- Examples S-1 to S-53 For each of Examples S-1 to S-53, X and Z values were calculated based on the glass composition.

- the chemically tempered glasses of Examples S-1 to S-13, S-15 to S-29, and S-31 to S-53 have the same glass composition before chemical tempering (the mother composition of chemically tempered glass). Based on this, X and Z values were calculated. These results are shown in the table.

- ⁇ Devitrification temperature T> The glass before chemical strengthening was pulverized, classified using a sieve of 4 mm mesh and 2 mm mesh, washed with pure water, and dried to obtain cullet. 2-5g cullet placed on a platinum plate and kept in an electric furnace maintained at a constant temperature for 17 hours, taken out into the air at room temperature, cooled, and then repeatedly observed for the presence of devitrification with a polarizing microscope.

- the devitrification temperature T was estimated. The results are shown in Table 1.

- the description that the devitrification temperature T is T1 to T2 means that there is devitrification at T1, and no devitrification at T2.

- FIG. 3 is a schematic diagram showing a test method for a drop-on-sand test.

- chemically tempered glass is also described as “glass”.

- a hard nylon mock plate 11 50 mm ⁇ 50 mm ⁇ thickness 18 mm, weight: 54 g

- glass 13 50 mm ⁇ 50 mm ⁇ plate thickness t (mm)

- sponge double-sided tape 12 # 2310 manufactured by Sekisui Chemical Co., Ltd.

- 50 mm ⁇ 50 mm ⁇ thickness 3 mm to obtain a measurement sample 1 (total weight: 61 g).

- 1 g of silica sand 22 No.

- FIG. 4 shows a graph plotting the relationship between the DOL (unit: ⁇ m) and the average crack height (unit: mm) of the chemically strengthened glass or glass of Examples S-1 to S-35.

- FIG. 5 shows a graph plotting the relationship between the CT (unit: MPa) and the average crack height (unit: mm) of the chemically strengthened glass or glass of Examples S-1 to S-35.

- FIG. 6 shows the relationship between the CT (unit: MPa) and the average crack height (unit: mm) of the glass having a DOL of less than 50 ⁇ m among the chemically strengthened glasses of Examples S-1 to S-35. The plotted graph is shown.

- FIG. 7 is a graph plotting the relationship between the surface compressive stress value CS (unit: MPa) and the average crack height (unit: mm) of the chemically strengthened glass or glass of Examples S-1 to S-35.

- FIG. 8 shows the compressive stress value CS 90 (unit: MPa) and average crack height (unit: unit) of the chemically tempered glass or glass of Examples S-1 to S-35 at a depth of 90 ⁇ m from the glass surface. mm) is plotted.

- FIG. 9 shows the compressive stress value CS 100 (unit: MPa) and the average crack height (unit) of the chemically tempered glass or glass of Examples S-1 to S-35 at a depth of 100 ⁇ m from the glass surface. : Mm) is plotted.

- FIG. 10 shows that the average crack height is highly correlated with CS 100 ⁇ t 2 .

- the average crack height as the CS 100 ⁇ t 2 is more than 5 MPa ⁇ mm 2 becomes more about 300 mm, it can be seen that achieved a significant improvement in strength.

- Example S-1 ⁇ Four-point bending test after wounding or unscratched>

- a glass plate having the same glass composition as in Example S-1 and a thickness of 1.1 to 1.3 mm was produced by the float process under the same conditions as in Example S-1.

- the obtained plate glass was cut and ground, and finally processed into a double-sided mirror surface to obtain a plate glass having a length of 5 mm ⁇ width of 40 mm ⁇ thickness of 1.0 mm.

- chemical strengthening treatment was performed under the chemical strengthening conditions shown in the columns of Examples 4PB-1 to 4PB-6 in Table 10 to produce the chemically strengthened glasses of Examples 4PB-1 to 4PB-6.