EP0959002B1 - Dispositif pour emballer des groupes d'emballages (individuels) - Google Patents

Dispositif pour emballer des groupes d'emballages (individuels) Download PDFInfo

- Publication number

- EP0959002B1 EP0959002B1 EP99109676A EP99109676A EP0959002B1 EP 0959002 B1 EP0959002 B1 EP 0959002B1 EP 99109676 A EP99109676 A EP 99109676A EP 99109676 A EP99109676 A EP 99109676A EP 0959002 B1 EP0959002 B1 EP 0959002B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- packs

- row

- pusher

- pack

- grouping

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B57/00—Automatic control, checking, warning, or safety devices

- B65B57/10—Automatic control, checking, warning, or safety devices responsive to absence, presence, abnormal feed, or misplacement of articles or materials to be packaged

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B35/00—Supplying, feeding, arranging or orientating articles to be packaged

- B65B35/30—Arranging and feeding articles in groups

- B65B35/40—Arranging and feeding articles in groups by reciprocating or oscillatory pushers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B5/00—Packaging individual articles in containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, jars

- B65B5/10—Filling containers or receptacles progressively or in stages by introducing successive articles, or layers of articles

- B65B5/105—Filling containers or receptacles progressively or in stages by introducing successive articles, or layers of articles by grippers

Definitions

- the invention relates to a device for packaging objects, in particular cuboid packs of approximately the same size in a blank or in a large container, in particular in a carton, wherein from the continuously supplied items or packs first one Row and from several rows a position by shifting the rows is formed and the entire location can be detected by a lifting conveyor and the Cardboard or the like can be fed, the objects or packs to form the row individually, one after the other in a grouping station against one Stop wall are conveyable and the row on a cross slide full length is detectable and can be pushed in the transverse direction onto a collecting plate.

- GB-A-914 957 shows a device according to the preamble as claim 1, with which fed in a row Objects are pushed across to form a layer. Subsequently the position thus formed by a lifting conveyor in a container discontinued.

- GB-A-1 055 611 shows a device which can also be used Rows of objects are pushed across to form a layer. On the first row pushed off creates a counter pressure by one of one Weight loaded counter slide.

- the invention has for its object to propose a device that efficient treatment of objects or packs if necessary different sizes for the formation of orderly containers or for filling of cardboard boxes and works largely automatically without errors.

- the invention is based on the knowledge that the group of (Individual) packs, namely rows and layers formed from them, must be correctly positioned so that an error-free transfer to the blank for wrapping the groups or to the filling carton runs correctly.

- the cross slide cooperating counter slide as well as lateral Guide walls ensures that even at high working speeds correct positions from orderly lying Packs are formed.

- Guide and support walls for the (single) packs are adjustable, so that the device to process different Packs is customizable. Furthermore are selected Areas of optoelectronic monitoring organs, in particular Photoelectric sensors, positioned that the error-free process ensure group formation and packaging.

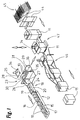

- the device shown in the drawings is concerned with the handling of cuboid packs 10. This deals especially large-volume soft packs, for example Foil packs for cellulose products, such as diapers, Handkerchiefs, napkins etc.

- the packs 10 are said to be in one large-volume carton 11 can be filled.

- the device can also be used in the manufacture of Large containers from, for example, one or more layers of Packs 10 surrounded by a blank as an envelope are.

- the packs 10 are, for example, from a manufacturing machine coming, fed on a feed conveyor 12.

- the packs 10 are fed as a single row with irregular intervals.

- the packs 10 are first pack rows 13 formed and from these layers 14.

- a layer 14 is used as a handling or packaging unit recorded and in the open Carton 11 introduced.

- the feed conveyor 12 consists of a belt conveyor 15 on which the packs 10 rest. Are above the belt conveyor 15 Side guides 16, 17 arranged between which the packs 10 can be transported. A side guide 16 is transverse to Conveying direction adjustable, so that the feed conveyor 12 on packs 10 different sizes, especially different ones Width, can be adjusted.

- the packs 10 arriving on the feed conveyor 12 are passed through this does not directly form a grouping station 23 the pack series 13 supplied. Rather, it is a funding body interposed, namely a separating belt 18, which connects to the feed conveyor 12 in the conveying direction.

- the separation band 18 takes into account the workflow in the area of Grouping station 23, namely the transverse pushing of the one after the other Pack series formed 13.

- the singling belt 18 preferably driven at the same speed as the feed conveyor 12, so that the packs 10 may have different Distances from each other in the grouping station 23 enter.

- the supply of further packs 10 to the grouping station 23 be temporarily interrupted.

- the separation band 18 stopped so that no further packs 10 can exit on the side facing the grouping station 23. Because by the feed conveyor 12 even during this phase Packs 10 can be supplied on the entry side of the Separation belt 18 a pack jam or a sealing row of packs 10 arise.

- the separating belt 18 consists of two opposite one another Side straps 19, 20, which with their conveyor strands Packs 10 capture on opposite sides and during stop the standstill phase.

- the packs are on a fixed document 21 slidably promoted.

- the packs 10 facing conveyor belts of the side belts 19, 20 are by resilient pressing members 22 in the sense of pressing on the packs 10 loaded.

- a side strap 19 is adjustable in the transverse direction to change the distance between the side straps 19, 20th

- the separating belt 18 gives individual packs 10 in succession free. These are fed to a grouping station 23. In the area of which the individual pack rows 13 are first formed. For this purpose, those from the singling band 18 released packs 10 of one at higher speed driven grouping belt 24 conveyed against a stop, namely against one extending transversely to the conveying direction Stop wall 25. The grouping belt 24 extends from the singling band 18 to an area beyond Stop wall 25. The packs 10 lie on an upper conveyor strand of the grouping tape 24. In a first funding area following the singling band 18, the (individual) Packs 10 conveyed between side walls 26, 27, the proper management of the packs 10 in the area of Secure grouping tape 24.

- the row of packs formed by accumulation on the stop wall 25 13 from, for example, three packs 10 becomes in the transverse direction conveyed, namely by a cross slide 28 of the Grouping belt 24 pushed onto a collecting plate 29.

- the cross slide 28 has a slide plate 30 which is in the starting position positioned in the extension of one side wall 26 is.

- the slide plate 32 of the counter slide 31 forms in the starting position, namely when the first pack row 13 is created, a continuation of the side wall 27.

- the counter slide 31 of the pushing movement of the cross slide 28 follows and thereby supports the packs 10 or the row of packs 13, if these from the grouping belt 24 is pushed off and pushed onto the collecting plate 29. After this Put down one or each row of packs 13 on the collecting plate 29 the counter slide 31 remains in this position as a stop or system for the first set of packs 13 (item 7 or 8).

- the cross slide 28 returns back to the starting position (Fig. 8).

- next pack series 13 are described in US Pat Formed on the grouping belt 24 and successively in Transverse direction from the cross slide 28 on the collecting plate 29 stored.

- the existing packing group or Partial layer moved one row of packs each.

- the Counter slide 31 follows this cyclical movement while maintaining the function as a support body for the first deported Pack row 13 (Fig. 9, Fig. 10).

- a pack group formed from several pack rows 13, namely a layer 14 is by a lifting conveyor 33 on the Detected top, lifted from the collecting plate 29 and one Packing station fed, in the present case in a Cardboard 11 inserted from above.

- the lifting conveyor 33 has an up and down movable lifting head 34, each one Complete group of packs 10, i.e. a complete layer 14 seized by suction organs, lifts and from above into a box 11 introduces.

- the lifting conveyor 33 can be used in a suitable manner be trained.

- a lifting conveyor is advantageous in its design and operation according to DE-A-196 54 041.0.

- the (partial) layers 14 become sliding on the collecting plate 29 cyclically moved by the cross slide 28.

- the side bridge 36 is one in the present embodiment Unit with the stop wall 25.

- the slide namely cross slide 28 and counter slide 31, are movable by linear drives 37, 38. These are below the plane of movement of the packs 10 together with the drive motor.

- the linear drive mounted below the collecting plate 29 38 for the counter slide 31 is over an upright web 39 connected to the counter slide 31.

- the web 39 passes through a slot 40 in the collector plate 29 therethrough.

- the area of the grouping station 23 is also different Dimensions of the packs 10 and / or the pack rows 13 and Layers 14 customizable.

- the side web 35 is in Transverse direction on the appropriately dimensioned collector plate 29 adjustable.

- other organs are exchanged for suitable ones, for example the side walls 26, 27, which have the appropriate dimensions the pack series 13 to be formed are also omitted without replacement can.

- cross slide 28 and counter slide 31 by changing to the respective dimensions of the Pack rows 13 or layers 14 adapted, expediently only the slide plates 30, 32 are interchangeable.

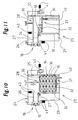

- Another special feature is the monitoring of the self-employed Flow of movement of the packs 10. So they are out of range of the separation band 18 emerging (individual) Packs 10 counted by a counting organ 41, which the packs 10 passing by are detected.

- the counting organ 41 exists in the present case from a light barrier with a counting unit works together in the area of a central control. The counting organ 41 monitors the completion of the Pack rows.

- Another optoelectronic monitoring device namely a Light switch 42 is adjustable in the area of the grouping station 23 arranged such that the correct end region a pack row 13 is recognized. In the event of any misalignment of packs 10 of a pack row 13 is by the Light sensor 42 generates a signal.

- a monitoring body has a special task, namely Light barrier 43, in the area of the transition from the grouping belt 24 to the collecting plate 29.

- the transverse to the direction of thrust of the pack rows 13 directed light barrier 43 is primarily intended to determine whether all packs 10 of a layer 14 are picked up by the lifting conveyor 33 and have been transported away. After taking off the Position 14 namely the counter slide 31 returns to the starting position 2 back. It will inevitably be on the Collecting plate 29 packs 10 remaining in a layer 14 taken and pushed towards the grouping belt 24. there such individual packs 10 pass through the light barrier 43 through (Fig. 11). Upon detection of such a lagging Pack 10 the device is turned off.

- the cartons 11 or partially prefabricated carton blanks 44 are taken from a blank magazine 45.

- the cardboard blanks 44 are then erected such that folding flaps for a bottom and end wall are directed downwards or upwards.

- the erected carton 11 is along a carton web 46 promoted and in the area of a loading station 47, which itself is in the extension or continuation of the collecting plate 29, filled with packs of 10. After that, the cartons 11 become known Way closed during onward transport.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Container Filling Or Packaging Operations (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

Claims (7)

- Dispositif d'emballage d'objets, en particulier de paquets parallélépipédiques rectangles (20) de dimension à peu près concordante dans une découpe ou dans un grand récipient, en particulier dans un carton (11), avec lequel, d'abord, est formée une file d'objets ou de paquets (10) amenés de façon continue, ensuite, une couche (14) de plusieurs files (13) est formée par déplacement transversal des files (13), puis un transporteur élévateur (33) saisit la couche complète (14) et la conduit au carton (11) ou au récipient semblable, les objets ou les paquets (10) étant, pour la formation de la file (13), amenés individuellement l'un après l'autre, à un poste de groupement (23), contre une paroi de butée (25), et la file (13) étant saisie sur toute sa longueur par un poussoir transversal (28) et glissée dans la direction transversale sur une plaque collectrice (29), caractérisé par les caractéristiques suivantes :a) sur le côté opposé au poussoir transversal (28), les files (13) sont calées par un contre-poussoir (31),b) le contre-poussoir (31) est mû avec les files (13) déplacées pas à pas pour la formation d'une couche (14), la file (13) formée en premier s'appuyant contre le contre-poussoir (31),c) le poussoir transversal (28) et le contre-poussoir (31) sont soumis à va-et-vient par des moteurs linéaires (37, 38), le contre-poussoir (31) suivant le mouvement de repoussement du poussoir transversal (28) et produisant alors un calage de la file (13) déposée en premier.

- Dispositif selon la revendication 1, caractérisé par le fait que les paquets (10) sont amenés en file irrégulière au poste de groupement (23) par un transporteur d'amenée (12), et dans la zone d'une bande de séparation (18) faisant suite au transporteur d'amenée (12), les paquets (10) sont groupés avec formation d'une couche serrée et chaque fois un paquet avant individuel (10) est amené de façon commandée à une bande de groupement (24) faisant suite à la bande de séparation (18) pour la formation d'une file de paquets (13).

- Dispositif selon l'une des revendications 1 et 2, caractérisé par le fait que le poussoir transversal (28) glisse la file de paquets (13) formée sur la bande de groupement (24), perpendiculairement à la direction de transport de celle-ci, de celle-ci sur la plaque collectrice (29) contiguë latéralement à celle-ci.

- Dispositif selon la revendication 1 ou une des autres revendications, caractérisé par le fait que les moteurs linéaires (37, 38) et le moteur d'entraínement sont placés au-dessous du plan de transport des paquets (10) ou des files de paquets (13), les poussoirs (28, 31), plus précisément leurs plaques pousseuses (30, 32) sont joints par des entretoises (39) au moteur linéaire (37, 38), et une fente (40) est prévue dans la zone de la plaque collectrice (29) pour le passage de l'entretoise (39) pour le contre-poussoir (31).

- Dispositif selon la revendication 1 ou une des autres revendications, caractérisé par le fait qu'après la bande de séparation (18) est placé un organe de comptage (41) pour les comptage des paquets (10) amenés au poste de groupement (23), de préférence une barrière lumineuse dirigée transversalement qui coopère avec une unité de comptage dans la zone d'une commande centrale.

- Dispositif selon la revendication 1 ou une des autres revendications, caractérisé par le fait que dans la zone de la bande de groupement (24) est placé à l'extrémité de la file de paquets (13) formée un organe de contrôle pour la constatation du positionnement correct des paquets (10) d'une file de paquets (10), en particulier un palpeur lumineux (42) dans la zone d'une surface d'extrémité arrière du paquet (10) amené en dernier d'une file de paquets (13).

- Dispositif selon la revendication 1 ou une des autres revendications, caractérisé par un organe de contrôle dans la zone de la plaque collectrice (29) pour la constatation de la prise correcte d'une couche complète (14) par le transporteur élévateur (33), de préférence par une barrière lumineuse (43) dans la zone de passage de la bande de groupement (24) à la plaque collectrice (29), la barrière lumineuse (43), après prise d'une couche (14) et retour du contre-poussoir (31) en position initiale, agissant pour saisir les éventuels paquets (10) non pris.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19821969 | 1998-05-18 | ||

| DE19821969A DE19821969A1 (de) | 1998-05-18 | 1998-05-18 | Vorrichtung zum Verpacken von Gruppen von (Einzel-)Packungen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0959002A1 EP0959002A1 (fr) | 1999-11-24 |

| EP0959002B1 true EP0959002B1 (fr) | 2004-03-17 |

Family

ID=7867970

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99109676A Expired - Lifetime EP0959002B1 (fr) | 1998-05-18 | 1999-05-17 | Dispositif pour emballer des groupes d'emballages (individuels) |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6164045A (fr) |

| EP (1) | EP0959002B1 (fr) |

| JP (1) | JP4136190B2 (fr) |

| CN (1) | CN1126693C (fr) |

| BR (1) | BR9902088A (fr) |

| CA (1) | CA2271587C (fr) |

| DE (2) | DE19821969A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108394624A (zh) * | 2018-04-17 | 2018-08-14 | 顾宸华 | 订书钉装盒装置 |

Families Citing this family (135)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE59805845D1 (de) * | 1998-12-28 | 2002-11-07 | Mohr Adolf Maschf | Verfahren und Vorrichtung zum Puffern von reihenweise angeordneten Schneidgutstapeln aus blättrigem Gut |

| DE10300642C5 (de) * | 2003-01-09 | 2018-02-22 | Krones Aktiengesellschaft | Fördervorrichtung |

| US6792741B1 (en) | 2003-09-08 | 2004-09-21 | Dominic Theriault | Container packing system |

| ITBO20030539A1 (it) * | 2003-09-17 | 2005-03-18 | Gd Spa | Dispositivo per il trattamento di prodotti di forma |

| US7571590B2 (en) | 2004-04-16 | 2009-08-11 | Maja-Maschinenfabrik Hermann Schill Gmbh & Co. | Apparatus and method for transporting and depositing items into a package |

| ITBO20040347A1 (it) * | 2004-05-31 | 2004-08-31 | Packservice S R L | Macchina incartonatrice semiautomatica |

| ITMI20051444A1 (it) * | 2005-07-26 | 2007-01-27 | Ocme Srl | Dispositovo formatore di lotti di quantita'variabili di oggetti per uno strato da pallettizzare |

| DE202005019907U1 (de) * | 2005-12-19 | 2007-04-26 | Autefa Automation Gmbh | Umsetzeinrichtung für Stückgüter, insbesondere Flaschen |

| FR2896230B1 (fr) * | 2006-01-16 | 2010-04-30 | Sidel Participations | Procede et poste de groupage pour paletisseur. |

| CN100462285C (zh) * | 2006-02-22 | 2009-02-18 | 广州达意隆包装机械股份有限公司 | 一种瓶子分堆机 |

| NL1032449C2 (nl) * | 2006-09-06 | 2008-03-07 | Robert Bosch Verpakkingsmachin | Inrichting voor het in een doos verpakken van voorwerpen alsmede een dergelijke werkwijze. |

| ES2345675T3 (es) * | 2007-05-11 | 2010-09-29 | Sca Hygiene Products Ab | Dispositivo de envasado y suministro para agrupar articulos de productos. |

| FR2918359B1 (fr) * | 2007-07-04 | 2009-09-25 | Sidel Participations | Procede de groupage de flacons, bouteilles ou autres |

| US7506490B1 (en) * | 2007-09-04 | 2009-03-24 | Dyco, Inc. | System and method for packaging article layers |

| DE102007045883A1 (de) * | 2007-09-25 | 2009-04-09 | Focke & Co.(Gmbh & Co. Kg) | Verfahren und Vorrichtung zum Handhaben von stückigen oder körnigen Tabakartikeln, insbesondere Kautabak oder Kautabakersatz (Snus) |

| US7856797B2 (en) * | 2008-04-03 | 2010-12-28 | Arm Automation, Inc. | Automated collector device and methods |

| GB0812201D0 (en) * | 2008-07-04 | 2008-08-13 | Meadwestvaco Packaging Systems | Packaging machine and method therefor |

| US9162817B2 (en) * | 2008-09-09 | 2015-10-20 | Walter Winkler | Conveyor system, storage and retrieval device and logistics system |

| FR2940788B1 (fr) * | 2009-01-06 | 2011-02-11 | Sidel Participations | Procede de groupage de produits du genre flacons ou autres |

| US8157080B2 (en) * | 2009-03-12 | 2012-04-17 | Pearson Packaging Systems | Product aggregating apparatus |

| FR2948650B1 (fr) * | 2009-07-30 | 2015-02-27 | Sidel Participations | Procede de groupage lateral de produits, en vue de leur encaissage |

| CN101628630B (zh) * | 2009-08-19 | 2012-10-03 | 深圳捷佳德现金自动化处理设备有限公司 | 自动钞捆装载系统 |

| ITBO20090686A1 (it) * | 2009-10-22 | 2011-04-23 | Zucchini Packaging Lines S R L | Gruppo di confezionamento secondario. |

| EP2501633B1 (fr) * | 2009-11-18 | 2014-08-20 | Cardinal Machine Corp. USA | Chargeur rotatif de lopins |

| US8256192B2 (en) * | 2009-12-03 | 2012-09-04 | Alain Cerf | Film wrapping gable containers |

| FR2954755B1 (fr) * | 2009-12-30 | 2012-04-20 | Sidel Participations | Procede d'orientation et de groupage de produits en vue de leur encaissage |

| DE102010046561A1 (de) * | 2010-09-27 | 2012-03-29 | WINKLER+DüNNEBIER AG | Verfahren zum Verpacken von Produkten und Verpackungsanlage zur Durchführung des Verfahrens |

| JP5549934B2 (ja) * | 2010-10-04 | 2014-07-16 | 株式会社安川電機 | 双腕ロボット、梱包システム、及び梱包方法 |

| US9475649B2 (en) * | 2010-12-15 | 2016-10-25 | Symbolic, LLC | Pickface builder for storage and retrieval systems |

| DE102011002575A1 (de) * | 2011-01-12 | 2012-07-12 | Robert Bosch Gmbh | Verpackungsvorrichtung |

| CN102180286B (zh) * | 2011-03-28 | 2013-04-17 | 维达纸业(广东)有限公司 | 一种面巾车间自动生产线系统 |

| CN102398698A (zh) * | 2011-05-20 | 2012-04-04 | 苏州工业园区德森包装机械有限公司 | 用于包装设备的全自动多工位传送装置 |

| CN102398697A (zh) * | 2011-05-20 | 2012-04-04 | 苏州工业园区德森包装机械有限公司 | 用于包装设备的全自动移位传送装置 |

| DE102011103563A1 (de) * | 2011-05-30 | 2012-12-06 | Winkler + Dünnebier Gmbh | Verfahren zum Überführen von Gegenständen und Umlenkeinheit |

| CN102219064B (zh) * | 2011-05-31 | 2013-01-23 | 杭州永创智能设备股份有限公司 | 装箱装置 |

| CN102205885A (zh) * | 2011-05-31 | 2011-10-05 | 上海华中药业有限公司 | 软袋包装分装机控制装置 |

| CN102241280B (zh) * | 2011-06-30 | 2013-01-09 | 佛山市海天调味食品股份有限公司 | 一种自动装箱机 |

| CN102923343B (zh) * | 2011-07-15 | 2015-12-02 | 杭州永创智能设备股份有限公司 | 循环刮装式装箱装置 |

| PL3138672T3 (pl) | 2011-11-10 | 2020-05-18 | Packsize Llc | Maszyna przekształcająca |

| CN102490931A (zh) * | 2011-11-30 | 2012-06-13 | 颐中(青岛)烟草机械有限公司 | 防滑挡烟方法及其专用装置 |

| ITMI20112429A1 (it) * | 2011-12-29 | 2013-06-30 | Emmeti Spa | Macchina di formazione di uno strato di oggetti e relativo metodo |

| CN102514757A (zh) * | 2012-01-05 | 2012-06-27 | 杨益服 | 一种铝塑包装机的高速辊板下料装置 |

| CN102514758B (zh) * | 2012-01-05 | 2014-07-23 | 浙江希望机械有限公司 | 一种单版奶片版块的装盒机构 |

| CN102658884A (zh) * | 2012-05-29 | 2012-09-12 | 金坛市金旺包装科技有限公司 | 一种全自动物料整列机构 |

| CN102673816B (zh) * | 2012-06-11 | 2015-05-20 | 姜广峻 | 货物分拣分装设备 |

| CN102887236B (zh) * | 2012-10-18 | 2014-05-07 | 冠达星股份有限公司 | 布衣柜连接管包装机 |

| DE102012022855A1 (de) * | 2012-11-23 | 2014-05-28 | Focke & Co. (Gmbh & Co. Kg) | Verfahren und Vorrichtung zum Befüllen von Verpackungen mit Produkten |

| NL2009988C2 (nl) * | 2012-12-14 | 2014-06-17 | Hoppmann B V | Inrichting en werkwijze voor het positioneren van een aantal flessen op een houder. |

| CN102963569A (zh) * | 2012-12-14 | 2013-03-13 | 湖南中烟工业有限责任公司 | 装箱机的缺条检测系统 |

| CN104340736A (zh) * | 2012-12-24 | 2015-02-11 | 颐中(青岛)烟草机械有限公司 | 条烟装封箱机集中式供箱坯的方法 |

| CN103072710B (zh) * | 2013-01-09 | 2015-04-29 | 安徽金寨将军磁业有限公司 | 磁瓦自动包装机 |

| CN103057732B (zh) * | 2013-01-24 | 2015-07-15 | 维达纸业(四川)有限公司 | 一种面巾软抽装箱装置 |

| CN104029840B (zh) * | 2013-03-06 | 2016-05-04 | 深圳市金奥博科技有限公司 | 直落式装箱机及包装线 |

| TWI594933B (zh) | 2013-03-15 | 2017-08-11 | 辛波提克有限責任公司 | 自動化貯藏及取放系統 |

| DE102013009229B4 (de) | 2013-05-31 | 2017-02-23 | Meurer Verpackungssysteme Gmbh | Verpackungsmaschine |

| EP2818435B1 (fr) * | 2013-06-28 | 2016-04-06 | Tetra Laval Holdings & Finance S.A. | Système de distribution destiné à une unité servant à transférer des emballages scellés |

| CN103662166B (zh) * | 2013-08-27 | 2016-01-06 | 新疆蓝山屯河型材有限公司 | 型材自动包装生产线 |

| US10894663B2 (en) | 2013-09-13 | 2021-01-19 | Symbotic Llc | Automated storage and retrieval system |

| CN103523260B (zh) * | 2013-10-21 | 2015-07-15 | 安徽工业大学 | 一种洗衣液的收集与装箱装置 |

| WO2015107452A1 (fr) * | 2014-01-15 | 2015-07-23 | Lusia Soluzioni Meccaniche S.R.L. | Dispositif d'identification et d'accumulation d'articles |

| CN103754411B (zh) * | 2014-02-20 | 2016-04-13 | 上海宗义自动化设备制造有限公司 | 全自动纸盒开装封贴带一体机 |

| CN103921985B (zh) * | 2014-04-18 | 2016-03-23 | 山东中科凤祥生物工程有限公司 | 用于包装块料产品的封装机 |

| CN103950589A (zh) * | 2014-05-07 | 2014-07-30 | 江苏达伦电子股份有限公司 | 一种盒子供给机构 |

| DE202014102298U1 (de) * | 2014-05-15 | 2014-09-25 | MSK-Verpackungs-Systeme Gesellschaft mit beschränkter Haftung | System zum Abtransport von Gutstapeln, die aus Paletten mit darauf gestapelten Gütern bestehen |

| CN103979175B (zh) * | 2014-05-27 | 2015-11-11 | 马鞍山市安工大工业技术研究院有限公司 | 一种洗衣液的输送与装箱装置 |

| CN104044761B (zh) * | 2014-06-26 | 2016-04-20 | 无锡诺飞高新技术有限公司 | 一种母轨装箱机 |

| CN104118602B (zh) * | 2014-06-30 | 2016-08-17 | 北京专益科技有限公司 | 一种铅布电池极板装箱和出箱的方法 |

| US10894621B2 (en) * | 2014-07-17 | 2021-01-19 | Pacwell Ip Pty Ltd | Carton packing apparatus |

| CN104150013B (zh) * | 2014-07-23 | 2016-03-02 | 常州常利来电子有限公司 | 包装机 |

| CN104210697B (zh) * | 2014-09-05 | 2016-07-13 | 山东大学 | 一种用于微注塑磁件的自动包装系统 |

| CN104229204B (zh) * | 2014-09-09 | 2016-02-10 | 杭州中亚机械股份有限公司 | 一种推送装置 |

| DE102014113347B3 (de) * | 2014-09-16 | 2016-01-07 | Mohrbach Verpackungsmaschinen Gmbh | Vorrichtung und Verfahren zum Verpacken von spezifikationsgerechten Portionsverpackungen in Schachteln |

| DE102014221232A1 (de) * | 2014-10-20 | 2016-04-21 | Krones Aktiengesellschaft | Vorrichtung und Verfahren zum Umgang mit Artikeln |

| US10093438B2 (en) | 2014-12-29 | 2018-10-09 | Packsize Llc | Converting machine |

| WO2016163963A2 (fr) * | 2015-04-06 | 2016-10-13 | Duas Makina San. Tic. Ltd. Şti̇. | Innovations apportées à une machine d'emballage de lingettes humides |

| CN104828287B (zh) * | 2015-04-24 | 2017-06-16 | 成都松川雷博机械设备有限公司 | 食品装盒机 |

| FR3035864B1 (fr) * | 2015-05-07 | 2019-10-04 | C.E.R.M.E.X. Constructions Etudes Et Recherches De Materiels Pour L'emballage D'expedition | Architecture de conditionnement par lots avec alimentation controlee |

| US10144596B2 (en) * | 2015-05-26 | 2018-12-04 | Dyco, Inc. | System and method for forming and moving an article array |

| CN105035401B (zh) * | 2015-06-02 | 2017-03-08 | 北京高立开元创新科技股份有限公司 | 一种全自动盒子处理装置 |

| US9580254B2 (en) | 2015-06-09 | 2017-02-28 | The Procter & Gamble Company | Apparatus for grouping articles into arrays of various configurations |

| US9663305B2 (en) * | 2015-06-09 | 2017-05-30 | The Procter & Gamble Company | Method of grouping articles into arrays of various configurations |

| US9573771B2 (en) * | 2015-06-09 | 2017-02-21 | The Procter & Gamble Company | Systems, apparatus, and methods for grouping articles into arrays of various configurations |

| SI3106412T1 (sl) * | 2015-06-15 | 2021-04-30 | Wipotec Gmbh | Razvrščanje blaga v skupine |

| DE102015113021A1 (de) * | 2015-06-15 | 2016-12-15 | Wipotec Wiege- Und Positioniersysteme Gmbh | Gruppieren von Gütern |

| CN105173686A (zh) * | 2015-07-17 | 2015-12-23 | 江苏晨阳机械有限公司 | 筒子纱预处理用全自动智能定重机 |

| CN105151428B (zh) * | 2015-07-17 | 2017-04-12 | 江苏晨阳机械有限公司 | 一体自动化智能控制的筒子纱包装系统 |

| CN105129141A (zh) * | 2015-08-24 | 2015-12-09 | 德清奥元生物科技有限公司 | 一种面膜箱子整理机构 |

| US10759550B2 (en) * | 2015-09-25 | 2020-09-01 | Douglas Machine Inc. | Intermittent case packer assembly and methods |

| CN105217102B (zh) * | 2015-10-19 | 2017-11-14 | 广东鑫星机器人科技有限公司 | 机器人小盘纸装箱机及小盘纸自动装箱的方法 |

| CN105857726B (zh) * | 2016-03-29 | 2018-07-06 | 射阳华为纺织机械制造有限公司 | 一种计数式零件自动装箱装置 |

| US10850469B2 (en) | 2016-06-16 | 2020-12-01 | Packsize Llc | Box forming machine |

| WO2017218296A1 (fr) | 2016-06-16 | 2017-12-21 | Packsize Llc | Système et procédé de production de modèle de boîte |

| CN106394992B (zh) * | 2016-09-14 | 2019-07-19 | 四川长虹电器股份有限公司 | 基于流水线的自动装箱控制系统 |

| CN106428758B (zh) * | 2016-11-30 | 2018-09-25 | 重庆奇甫机械有限责任公司 | 一种钢筋套筒打包装置及钢筋套筒生产线 |

| DE102016014333A1 (de) * | 2016-12-02 | 2018-06-07 | Focke & Co. (Gmbh & Co. Kg) | Verfahren und Vorrichtung zum Befüllen eines Behälters mit Produkten |

| CN106516245B (zh) * | 2016-12-23 | 2018-10-16 | 大连佳林设备制造有限公司 | 在线整列立盒机构 |

| US11242214B2 (en) | 2017-01-18 | 2022-02-08 | Packsize Llc | Converting machine with fold sensing mechanism |

| US20180208338A1 (en) * | 2017-01-20 | 2018-07-26 | Alain Cerf | Sleeve Film Wrapping a Pack of Containers |

| DE112018000498T5 (de) * | 2017-01-24 | 2019-10-31 | Coextrusionsolutions, Llc | Verfahren und System zum Laden koextrudierter Fleischprodukte in eine Verpackungsmaschine durch gesteuerte Förderung und Handhabung |

| CN110325449B (zh) * | 2017-02-01 | 2022-07-26 | 希科夫股份公司 | 用于序列化多个产品的方法和编码线 |

| SE541921C2 (en) | 2017-03-06 | 2020-01-07 | Packsize Llc | A box erecting method and system |

| SE540672C2 (en) | 2017-06-08 | 2018-10-09 | Packsize Llc | Tool head positioning mechanism for a converting machine, and method for positioning a plurality of tool heads in a converting machine |

| CN107399451A (zh) * | 2017-08-24 | 2017-11-28 | 泉州市科盛包装机械有限公司 | 一种矩形物品包装机 |

| US11173685B2 (en) | 2017-12-18 | 2021-11-16 | Packsize Llc | Method for erecting boxes |

| CN108058860A (zh) * | 2018-01-18 | 2018-05-22 | 安徽海思达机器人有限公司 | 一种肥皂自动化装箱与码垛的生产设备 |

| US11305903B2 (en) | 2018-04-05 | 2022-04-19 | Avercon BVBA | Box template folding process and mechanisms |

| US11247427B2 (en) | 2018-04-05 | 2022-02-15 | Avercon BVBA | Packaging machine infeed, separation, and creasing mechanisms |

| US11634244B2 (en) | 2018-06-21 | 2023-04-25 | Packsize Llc | Packaging machine and systems |

| CN109018513B (zh) * | 2018-08-09 | 2021-03-19 | 广西中烟工业有限责任公司 | 一种烟包分拣排列方法 |

| SE543046C2 (en) | 2018-09-05 | 2020-09-29 | Packsize Llc | A box erecting method and system |

| CN109279109B (zh) * | 2018-09-13 | 2020-11-03 | 湖北工业大学 | 一种弹夹式电容自动装盘装箱装置 |

| US11524474B2 (en) | 2018-11-30 | 2022-12-13 | Packsize Llc | Adjustable cutting and creasing heads for creating angled cuts and creases |

| CN109533464B (zh) * | 2018-12-13 | 2020-09-01 | 温州兄弟机械有限公司 | 推入式自动装箱机 |

| CN109573164B (zh) * | 2018-12-28 | 2020-08-07 | 常德烟草机械有限责任公司 | 一种物料输送装置及方法 |

| DE112020000348T5 (de) | 2019-01-07 | 2021-09-16 | Packsize Llc | Kartonaufrichtungsmaschine |

| CN109703809A (zh) * | 2019-03-12 | 2019-05-03 | 天津华帅科技股份有限公司 | 一种装箱机的送瓶装置 |

| US11701854B2 (en) | 2019-03-14 | 2023-07-18 | Packsize Llc | Packaging machine and systems |

| CN109835511A (zh) * | 2019-03-27 | 2019-06-04 | 上海理工大学 | 用于盒状产品的自动化包装设备 |

| US10689207B1 (en) | 2019-03-27 | 2020-06-23 | Delkor Systems, Inc. | Compact collator, system and method of use |

| DE102019113144A1 (de) * | 2019-05-17 | 2020-11-19 | Illinois Tool Works Inc. | Verpackungsmaschine zum verpacken von produkten in kartons und verfahren hierfür |

| CN110182394A (zh) * | 2019-05-31 | 2019-08-30 | 广东斯玛特自动化科技有限公司 | 罐体装箱装置 |

| JP7513242B2 (ja) * | 2019-09-30 | 2024-07-09 | 株式会社イシダ | 物品移載装置 |

| CN110745283B (zh) * | 2019-10-30 | 2021-11-19 | 林建国 | 一种用于耐老化超净无屑橡皮擦的包装设备 |

| CN110893921B (zh) * | 2019-12-09 | 2021-09-10 | 红塔辽宁烟草有限责任公司营口卷烟厂 | 一种条烟装箱设备及其应用 |

| CN112938025B (zh) * | 2019-12-11 | 2022-09-30 | 泰科电子(上海)有限公司 | 电子产品包装系统 |

| CN110979854B (zh) * | 2019-12-31 | 2022-02-18 | 长沙而道新能源科技有限公司 | 一种真空自动包装成型机 |

| KR102147806B1 (ko) * | 2020-02-24 | 2020-08-26 | 이래용 | 올인원 박스 포장시스템 |

| CN111453076B (zh) * | 2020-05-20 | 2024-07-16 | 成都青山利康药业股份有限公司 | 血液净化制品包装袋上袋系统及方法 |

| KR102179337B1 (ko) * | 2020-07-02 | 2020-11-16 | 이래용 | 두부용 낱개 포장용기의 자동 포장시스템 |

| CN111846431B (zh) * | 2020-08-03 | 2021-12-28 | 湖北慧智德自动化设备有限公司 | 一种全自动装箱机 |

| CN112109976B (zh) * | 2020-09-29 | 2024-07-09 | 泉州市鲤城区中科达机械设备有限公司 | 一种物料包装设备 |

| CN113306786B (zh) * | 2021-06-18 | 2023-01-06 | 哈工大机器人南昌智能制造研究院 | 一种糕点自动封盒包装方法 |

| CN113306776B (zh) * | 2021-06-18 | 2023-01-06 | 哈工大机器人南昌智能制造研究院 | 一种糕点的自动包装方法 |

| CN113652820A (zh) * | 2021-08-18 | 2021-11-16 | 盐城永辉化纤有限公司 | 一种涤纶原料的阻燃处理设备及方法 |

| CN115417175A (zh) * | 2022-09-26 | 2022-12-02 | 安泰爱科科技有限公司 | 一种用于钕铁硼稀土永磁体生产用精准摆料设备 |

Family Cites Families (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE241575C (fr) * | ||||

| US2470795A (en) * | 1945-03-30 | 1949-05-24 | American Can Co | Can stacking machine |

| US2681171A (en) * | 1951-11-30 | 1954-06-15 | Robert E Johnson | Box loading and conveying machine |

| US2834167A (en) * | 1953-11-18 | 1958-05-13 | Loveridge William Barnum | Milk bottle case loading machine |

| US2904944A (en) * | 1955-02-18 | 1959-09-22 | Int Machinery Corp Sa | Machines for filling cases, cartons or other packages with containers such as cans |

| GB914957A (en) * | 1959-11-12 | 1963-01-09 | S C Lomax Ltd | Improvements in or relating to packaging machinery |

| US3046712A (en) * | 1960-11-02 | 1962-07-31 | Terry L Carter | Case packer |

| US3069823A (en) * | 1961-01-30 | 1962-12-25 | Foremost Dairies Inc | Case filling and stacking machine |

| US3273304A (en) * | 1963-04-17 | 1966-09-20 | Windor Inc | Casing machine |

| US3250371A (en) * | 1964-06-29 | 1966-05-10 | Ceson Containers Mfg Corp | Apparatus for transferring articles |

| US3327450A (en) * | 1964-08-12 | 1967-06-27 | Terry L Carter | Case packer |

| GB1055611A (en) * | 1964-09-08 | 1967-01-18 | Metal Box Co Ltd | Improvements in or relating to apparatus for loading articles in rows on a supporting base |

| US3593488A (en) * | 1968-08-02 | 1971-07-20 | Heinz Co H J | Container-loading apparatus |

| US3682290A (en) * | 1969-10-31 | 1972-08-08 | George E Von Gal Jr | Can palletizer |

| US3659726A (en) * | 1970-04-29 | 1972-05-02 | Crown Cork & Seal Co | Palletizing apparatus |

| US3708947A (en) * | 1971-04-09 | 1973-01-09 | Cozzoli Machine | Automatic tray loader |

| SE385566B (sv) * | 1973-05-16 | 1976-07-12 | J Nordqvist | Sett att vid forpackning av ett antal, i tversnitt vesentligen runda foremal placera dessa i en i huvudsak parallellepipedisk formation med foremalen anordnade i skra jemte anordning for utforande av settet |

| US3914921A (en) * | 1974-04-10 | 1975-10-28 | Windor Inc | High speed carton casing apparatus |

| US4003185A (en) * | 1975-06-06 | 1977-01-18 | Otis Ward Goff | Caser apparatus |

| US3984964A (en) * | 1975-09-15 | 1976-10-12 | Bristol-Myers Canada Limited | Bottle packing system |

| JPS6164627A (ja) * | 1984-09-03 | 1986-04-03 | エービー テトラパック | 物品集積装置における集積物品の分割装置 |

| DD241575A1 (de) * | 1985-10-11 | 1986-12-17 | Schwarzheide Synthesewerk Veb | Verfahren zum verpacken forminstabiler gefuellter folienschlauchbeutel |

| US4713926A (en) * | 1986-06-26 | 1987-12-22 | Wheeling Stamping Company | Packaging machine and method |

| FR2609277B1 (fr) * | 1987-01-05 | 1989-09-15 | Letard Guy | Procede de mise en conteneur de produits de detail des conteneurs et un systeme pour la mise en oeuvre de ce procede |

| US4843797A (en) * | 1987-10-05 | 1989-07-04 | Doran Brothers Inc. | Dairy casing method and apparatus |

| US4942720A (en) * | 1988-07-29 | 1990-07-24 | Berney Joseph C | Bottom case loader and method |

| DE3839939A1 (de) * | 1988-11-26 | 1990-05-31 | Leifeld & Lemke Maschf | Verfahren zum stufenfoermigen gruppieren von produkten und vorrichtung zur durchfuehrung des verfahrens |

| DE4002724A1 (de) * | 1990-01-31 | 1991-08-01 | Manfred Haiss | Verfahren zum zufuehren von produkten zu einer verpackungsmaschine sowie vorrichtung zur durchfuehrung eines solchen verfahrens |

| DE9006384U1 (de) * | 1990-06-06 | 1990-08-09 | Bernhard Beumer Maschinenfabrik Kg, 4720 Beckum | Vorrichtung zum Umhüllen von Stückgut mit Stretchfolie |

| IT1246827B (it) * | 1990-07-04 | 1994-11-28 | Gd Spa | Dispositivo per la formazione ed il trasferimento di gruppi di a prodotti. |

| DE4434866C2 (de) * | 1994-09-29 | 2002-10-31 | Focke & Co | Verfahren und Vorrichtung zum Einführen von zusammendrückbaren Packungen in Behälter |

| DE29500685U1 (de) * | 1995-01-18 | 1995-03-23 | Affeldt Verpackungsmaschinen GmbH, 25335 Neuendorf | Vorrichtung zum abgezählten Befüllen von Versandbehältern |

| DE19654041A1 (de) | 1996-12-23 | 1998-06-25 | Focke & Co | Vorrichtung zum Handhaben von Gegenständen |

| DE19700150A1 (de) * | 1997-01-06 | 1998-07-09 | Focke & Co | Vorrichtung zum Befüllen von Kartons |

-

1998

- 1998-05-18 DE DE19821969A patent/DE19821969A1/de not_active Withdrawn

-

1999

- 1999-05-13 CA CA002271587A patent/CA2271587C/fr not_active Expired - Fee Related

- 1999-05-17 DE DE59908844T patent/DE59908844D1/de not_active Expired - Lifetime

- 1999-05-17 US US09/312,850 patent/US6164045A/en not_active Expired - Lifetime

- 1999-05-17 BR BR9902088-2A patent/BR9902088A/pt not_active IP Right Cessation

- 1999-05-17 EP EP99109676A patent/EP0959002B1/fr not_active Expired - Lifetime

- 1999-05-18 JP JP13682699A patent/JP4136190B2/ja not_active Expired - Fee Related

- 1999-05-18 CN CN99106652A patent/CN1126693C/zh not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108394624A (zh) * | 2018-04-17 | 2018-08-14 | 顾宸华 | 订书钉装盒装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| BR9902088A (pt) | 2000-01-04 |

| DE19821969A1 (de) | 1999-11-25 |

| CA2271587A1 (fr) | 1999-11-18 |

| US6164045A (en) | 2000-12-26 |

| DE59908844D1 (de) | 2004-04-22 |

| CN1235921A (zh) | 1999-11-24 |

| CN1126693C (zh) | 2003-11-05 |

| JP4136190B2 (ja) | 2008-08-20 |

| JPH11348930A (ja) | 1999-12-21 |

| EP0959002A1 (fr) | 1999-11-24 |

| CA2271587C (fr) | 2005-11-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0959002B1 (fr) | Dispositif pour emballer des groupes d'emballages (individuels) | |

| EP2139776B1 (fr) | Dispositif et procédé pour la manipulation d'objets plats, en particulier de couches | |

| EP2313332B1 (fr) | Dispositif et procede pour le regroupement de lots pour une machine d'emballage | |

| EP1452452B1 (fr) | Procédé et machine pour fabriquer des emballages (de cigarettes) | |

| EP1718549A1 (fr) | Dispositif de fabrication et de palettisation d'emballages carton | |

| DE2500569A1 (de) | Verpackungsmaschine | |

| EP0187981A2 (fr) | Procédé et dispositif d'alimentation d'emballages vers une station d'accumulation et d'emballage | |

| DE69701563T2 (de) | Verfahren und vorrichtung zum übernehmen und stapeln von gegenständen in mehreren reihen und zum fördern der so erhältlichen stapel von gegenständen zu einer verpackungslinie | |

| DE102019113129B4 (de) | Verpackungsmaschine zum anordnen von elementen, vorzugsweise kartons, auf paletten, und verfahren hierfür | |

| DE19753019A1 (de) | Verfahren und Vorrichtung zum Handhaben von insbesondere Folien-Weichpackungen | |

| EP1829783B1 (fr) | Dispositif et procédé de fabrication d'emballages doubles | |

| EP0405121B1 (fr) | Installation de production pour fabriquer de grands emballages en forme de paquets mis en carton, de groupes de petits emballages de mouchoirs en papier | |

| EP0957055A2 (fr) | Dispositif d'empilage | |

| DE102019113144A1 (de) | Verpackungsmaschine zum verpacken von produkten in kartons und verfahren hierfür | |

| DE69214122T2 (de) | Verfahren und system zum aufreihen von artikeln | |

| EP1107865B1 (fr) | Dispositif permettant de produire et de decharger des piles de sachets plastique, notamment des sachets pour machines automatiques | |

| EP3549879B1 (fr) | Dispositif d'emballage pour articles et procédé de fourniture des découpages d'emballage plans pour articles | |

| DE4237937C2 (de) | Vorrichtung zum Transport von Zuschnittstapeln | |

| EP1220786B1 (fr) | Systeme de voie de transport dans un poste de remplissage | |

| DE3825715C1 (fr) | ||

| EP0700832B1 (fr) | Appareil pour grouper des sachets | |

| EP2133271B1 (fr) | Dispositif et procédé de transmission de marchandises sur un système de transport de marchandises ou sur un dispositif de stockage | |

| DE4119514C2 (de) | Vorrichtung zum Transportieren von quaderförmigen Packungen von einer Verpackungsmaschine zu einer nachfolgenden Bearbeitungsmaschine | |

| EP2133293B1 (fr) | Dispositif de transmission de marchandises sur un système de transport de marchandises ou sur un dispositif de stockage | |

| DE102008018125B3 (de) | Verfahren und Vorrichtung zum stapelweisen Zusammenführen mehrlinig zugeführter flacher Produkte |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE FR GB IT LI NL |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20000419 |

|

| AKX | Designation fees paid |

Free format text: CH DE FR GB IT LI NL |

|

| 17Q | First examination report despatched |

Effective date: 20021217 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB IT LI NL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59908844 Country of ref document: DE Date of ref document: 20040422 Kind code of ref document: P |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040421 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: R. A. EGLI & CO. PATENTANWAELTE |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: FOCKE & CO. (GMBH & CO. KG) |

|

| ET | Fr: translation filed | ||

| NLT2 | Nl: modifications (of names), taken from the european patent patent bulletin |

Owner name: FOCKE & CO. (GMBH & CO. KG) |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20041220 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20100525 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20100501 Year of fee payment: 12 Ref country code: IT Payment date: 20100522 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20100514 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20100512 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20111201 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20110517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111201 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110531 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110517 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140530 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59908844 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151201 |