WO2012086243A1 - 管内で対象成分を操作するためのデバイス及び方法 - Google Patents

管内で対象成分を操作するためのデバイス及び方法 Download PDFInfo

- Publication number

- WO2012086243A1 WO2012086243A1 PCT/JP2011/065995 JP2011065995W WO2012086243A1 WO 2012086243 A1 WO2012086243 A1 WO 2012086243A1 JP 2011065995 W JP2011065995 W JP 2011065995W WO 2012086243 A1 WO2012086243 A1 WO 2012086243A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- tube

- aqueous liquid

- magnetic field

- magnetic particles

- nucleic acid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/0098—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor involving analyte bound to insoluble magnetic carrier, e.g. using magnetic separation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L3/00—Containers or dishes for laboratory use, e.g. laboratory glassware; Droppers

- B01L3/50—Containers for the purpose of retaining a material to be analysed, e.g. test tubes

- B01L3/502—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures

- B01L3/5025—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures for parallel transport of multiple samples

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L3/00—Containers or dishes for laboratory use, e.g. laboratory glassware; Droppers

- B01L3/50—Containers for the purpose of retaining a material to be analysed, e.g. test tubes

- B01L3/508—Containers for the purpose of retaining a material to be analysed, e.g. test tubes rigid containers not provided for above

- B01L3/5082—Test tubes per se

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C1/00—Magnetic separation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C1/00—Magnetic separation

- B03C1/005—Pretreatment specially adapted for magnetic separation

- B03C1/01—Pretreatment specially adapted for magnetic separation by addition of magnetic adjuvants

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C1/00—Magnetic separation

- B03C1/02—Magnetic separation acting directly on the substance being separated

- B03C1/025—High gradient magnetic separators

- B03C1/031—Component parts; Auxiliary operations

- B03C1/033—Component parts; Auxiliary operations characterised by the magnetic circuit

- B03C1/0332—Component parts; Auxiliary operations characterised by the magnetic circuit using permanent magnets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C1/00—Magnetic separation

- B03C1/02—Magnetic separation acting directly on the substance being separated

- B03C1/10—Magnetic separation acting directly on the substance being separated with cylindrical material carriers

- B03C1/12—Magnetic separation acting directly on the substance being separated with cylindrical material carriers with magnets moving during operation; with movable pole pieces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C1/00—Magnetic separation

- B03C1/02—Magnetic separation acting directly on the substance being separated

- B03C1/28—Magnetic plugs and dipsticks

- B03C1/288—Magnetic plugs and dipsticks disposed at the outer circumference of a recipient

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C1/00—Magnetic separation

- B03C1/02—Magnetic separation acting directly on the substance being separated

- B03C1/30—Combinations with other devices, not otherwise provided for

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00277—Apparatus

- B01J2219/00351—Means for dispensing and evacuation of reagents

- B01J2219/00364—Pipettes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00277—Apparatus

- B01J2219/00457—Dispensing or evacuation of the solid phase support

- B01J2219/00459—Beads

- B01J2219/00466—Beads in a slurry

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00277—Apparatus

- B01J2219/00457—Dispensing or evacuation of the solid phase support

- B01J2219/00459—Beads

- B01J2219/00468—Beads by manipulation of individual beads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2200/00—Solutions for specific problems relating to chemical or physical laboratory apparatus

- B01L2200/06—Fluid handling related problems

- B01L2200/0647—Handling flowable solids, e.g. microscopic beads, cells, particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2200/00—Solutions for specific problems relating to chemical or physical laboratory apparatus

- B01L2200/06—Fluid handling related problems

- B01L2200/0673—Handling of plugs of fluid surrounded by immiscible fluid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0832—Geometry, shape and general structure cylindrical, tube shaped

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0861—Configuration of multiple channels and/or chambers in a single devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0861—Configuration of multiple channels and/or chambers in a single devices

- B01L2300/087—Multiple sequential chambers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2400/00—Moving or stopping fluids

- B01L2400/04—Moving fluids with specific forces or mechanical means

- B01L2400/0403—Moving fluids with specific forces or mechanical means specific forces

- B01L2400/043—Moving fluids with specific forces or mechanical means specific forces magnetic forces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C2201/00—Details of magnetic or electrostatic separation

- B03C2201/18—Magnetic separation whereby the particles are suspended in a liquid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C2201/00—Details of magnetic or electrostatic separation

- B03C2201/26—Details of magnetic or electrostatic separation for use in medical or biological applications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

Definitions

- the present invention relates to a device and method for manipulating a target component using a gel. More specifically, the present invention relates to a device and method capable of subjecting a target component to various operations within the tube by manipulating magnetic particles with a magnetic field from outside the tube in a sealable tube. More specifically, the present invention performs extraction, purification, synthesis, elution, separation, recovery, analysis, and the like of the target component by manipulating magnetic particles in a thin tube containing a reagent solution using an oil gel. It relates to a method and apparatus that can be performed.

- the extraction / purification, separation, recovery, etc. of the target component can be performed by giving various chemical affinity to the surface of fine particles insoluble in water having a diameter of several tens to 0.5 ⁇ m.

- target cells can be collected by recognizing specific cell surface molecules. For this reason, fine particles in which a functional molecule is introduced on the particle surface according to the object are commercially available.

- fine particles in which a functional molecule is introduced on the particle surface according to the object are commercially available.

- those with a ferromagnetic material such as iron oxide can recover the target component with a magnet and eliminate the need for centrifugation, which is advantageous for automated chemical extraction and purification. .

- a system for continuously performing nucleic acid extraction from cells and analysis by gene amplification reaction with one device is commercially available.

- the process from nucleic acid extraction to analysis by gene amplification reaction can be performed with one cartridge type device, and the maximum number of simultaneously processed samples is 16.

- Disposal content of GeneXpert® System is described in Non-Patent Document 1.

- Simplexa (Non-Patent Document 2) of 3M Company performs a single disk-shaped device from nucleic acid extraction to PCR. Twelve specimens can be immobilized on the same.

- magnetic particles are commercially available as part of reagents as extraction / purification kits.

- the kit contains multiple reagents in separate containers, and the user dispenses and dispenses the reagent with a pipette when using it. Even in the case of an automated apparatus, in the apparatus currently on the market, the liquid is separated by a pipetting operation mechanically.

- Precision System Science Co., Ltd. markets a system (Non-patent Document 3) that performs nucleic acid extraction using magnetic particles.

- Pipetting which is essential when using an extraction / purification kit containing magnetic particles as a part of a reagent, involves generation of aerosol. This increases the risk of contamination that hinders analysis.

- the contamination source is accumulated in the apparatus due to the generation of the aerosol, it is necessary to periodically clean the apparatus.

- the apparatus automated by the pipette type dispensing mechanism has a complicated structure and it is difficult to completely remove the contamination source.

- the system for nucleic acid extraction using magnetic particles marketed by Precision System Science, it is possible to recover purified nucleic acid, but the analysis by gene amplification reaction etc. Must be done on another system.

- this system uses an open system for pipetting, there is always a risk of contamination.

- An object of the present invention is to provide a small and low running cost device capable of performing a desired series of operations in a completely sealed state while suppressing generation of a contamination source as much as possible.

- the object of the present invention is, for example, to extract and purify target components in a completely sealed container, or to perform analysis in the same container while maintaining a sealed state. To provide a device.

- the inventor has divided and accommodated one or more liquid reagents with a water-insoluble gel substance in a sealed capillary (capillary) without using a dispenser accompanied by generation of aerosol, and It is found that the object of the present invention is achieved by the presence of magnetic particles in the liquid reagent accommodated in the narrow tube and the magnetic field applying means operable from the outside of the narrow tube, thereby completing the present invention. It came to.

- the present invention includes the following inventions.

- a device for operating a target component in an operation tube A tube having an open end that may be closable for supplying a sample containing the target component on one side and a closed end on the other side, and a gel layer and an aqueous liquid layer that are contained in the tube and alternate in the longitudinal direction of the tube

- An operation tube including an operation medium layered thereon, Magnetic particles to capture and transport the target component;

- a magnetic field applying means capable of moving the magnetic particles in the longitudinal direction of the operation tube by applying a magnetic field to the operation tube.

- the open end is preferably closed so that all or a part thereof can be opened and closed. Examples of preferred open ends are shown in FIGS. 1 (2) and (3).

- the tube has a substantially inner diameter of 0.1 mm to 5 mm.

- the magnetic field applying unit is capable of moving the magnetic particles in the longitudinal direction of the operation tube outside the operation tube.

- the holding means is a holding substrate in which a plurality of holding holes capable of holding the closed end portion of the operation tube are formed.

- An example of the holding means which is the holding substrate of the above (5) is shown as 51 in FIGS. (6)

- An example of the holding means having the recess (7) is shown as 51 in FIG.

- the magnetic field applying unit has a mechanism for controlling the movement of the magnetic field in the longitudinal direction of the operation tube and the strength of the magnetic field.

- the magnetic field applying unit has a temperature control function.

- the magnetic field application unit includes any one of (5) to (10), including a movable substrate capable of moving in a longitudinal direction of the operation tube, and a plurality of magnetic force sources held in the movable substrate. Devices. An example of the magnetic field applying means (11) is shown as the movable magnet plate 53 in FIG.

- the magnetic particles have binding force or adsorption power to nucleic acid as a target component, and the operation medium liberates nucleic acid, and an aqueous liquid layer made of a liquid that binds or adsorbs to the magnetic particles, and

- the device according to any one of (1) to (12), comprising an aqueous liquid layer comprising a cleaning liquid for the magnetic particles.

- the operation medium further includes an aqueous liquid layer made of a nucleic acid amplification reaction solution, or an aqueous liquid layer made of a reverse transcription reaction solution and an aqueous liquid layer made of a nucleic acid amplification reaction solution. device.

- the device according to any one of (1) to (14), wherein the tube is integrally formed.

- the operation tube has an operation part A and a recovery part B,

- the tube constituting the operation tube has an operation tube portion a and a recovery tube portion b corresponding to the operation portion A and the recovery portion B, respectively.

- the operation part A includes the pipe part a and the operation medium accommodated in the pipe part a

- the recovery part B includes the pipe part b and a recovery medium that is accommodated in the pipe part b and includes at least one of an aqueous liquid layer and a gel layer.

- FIG. An example of the operation tube (16) is shown in FIG.

- the tube material is polyethylene, polypropylene, fluororesin, polyvinyl chloride, polystyrene, polycarbonate, acrylonitrile butadiene styrene copolymer (ABS resin), acrylonitrile styrene copolymer (AS resin), acrylic resin, polyvinyl acetate, polyethylene terephthalate, cyclic polyolefin

- a method for producing an operation tube included in the device according to (1) comprising a step of alternately laminating an aqueous liquid layer and a gel layer in a tube having an open end on one side and a closed end on the other side.

- a manufacturing method including the step of connecting the one end of the operation tube a of the operation unit A and the open end of the recovery tube b of the recovery unit B. The outline of the step (i) in the method (20) is shown in FIG.

- a method for manipulating a target component using the device according to (1) comprising the following steps: (I) obtaining an aqueous liquid mixture containing a sample containing the target component, magnetic particles and an aqueous liquid in the uppermost layer of the operation tube; (Ii) A magnetic field is generated by a magnetic field applying means, and the magnetic particles are transported together with the target component from the uppermost aqueous liquid mixture layer to the adjacent aqueous liquid layer through the gel layer.

- the target component is a nucleic acid

- the aqueous liquid contained in the uppermost aqueous liquid mixture is a liquid that liberates the nuclei and binds or adsorbs to the magnetic particles, and nucleic acid extraction is performed in the aqueous liquid.

- at least one of the aqueous liquid layers is composed of a cleaning solution for the magnetic particles, and nucleic acid purification is performed in the cleaning solution by removing contaminants associated with free nucleic acids. Or the method as described in (22).

- the lowermost layer comprises a nucleic acid amplification reaction solution, and the target nucleic acid in the purified nucleic acid is amplified in the nucleic acid amplification reaction solution.

- the layer immediately above the lowermost layer made of the nucleic acid amplification reaction solution is made of a reverse transcription reaction solution.

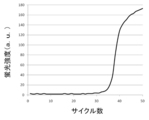

- the product of the nucleic acid amplification reaction is optically detected in real time.

- the small and low running cost device which can perform all of a desired series of operations, suppressing generation

- a small and low running cost device capable of performing extraction / purification of a target component in a completely sealed container, or further performing analysis in the same container while maintaining a sealed state. Can be provided.

- FIG. 1 It is a longitudinal cross-sectional view of the example of the operation pipe

- An example of the manufacturing method of the operating tube of this invention is shown.

- the process of extracting and purifying a nucleic acid from a nucleic acid containing sample using the operation tube of the present invention shown in FIG. 1 (3) is shown.

- purifies a nucleic acid from a nucleic acid containing sample using another example of the operating tube of this invention, and also performs the analysis by reverse transcription reaction and PCR reaction is shown.

- FIG. 6 is a longitudinal sectional view of a portion including a modified example of the magnetic field applying unit (movable magnet plate), a modified example of the holding unit (holding substrate), and an operation tube held by the holding unit shown in FIG. 5. It is the result obtained in Example 1 which performed the process shown in FIG. It is the result obtained in Example 2 which performed the process shown in FIG.

- target component to be operated in the present invention is not particularly limited as long as it is a component that can be normally operated in an aqueous liquid, an emulsion, or a hydrogel, and may be an in vivo component or a non-in vivo component.

- In vivo components include biomolecules such as nucleic acids (including DNA and RNA), proteins, lipids, and sugars.

- Non-in vivo components include non-biomolecules such as artificially modified (both chemical and biochemical) biomolecules, labeled and mutants, non-biomolecules derived from natural products, and other aqueous systems. Any component that can be manipulated in a liquid is included.

- the target component can usually be provided in the form of a sample containing the target component.

- a sample include biological-derived samples such as animal and plant tissues, body fluids, and excreta, and biomolecule-containing bodies such as cells, protozoa, fungi, bacteria, and viruses.

- Body fluids include blood, sputum, cerebrospinal fluid, saliva, and milk, and excreta includes feces, urine, and sweat, and combinations thereof may be used.

- the cells include leukocytes in blood, platelets, exfoliated cells of oral cells and other mucosal cells, and a combination thereof may be used. These samples may be obtained as clinical swabs.

- said sample may be prepared in aspects, such as a cell suspension, a homogenate, a liquid mixture with a cell lysis solution, for example.

- the sample containing the target component may be obtained by performing treatments such as modification, labeling, fragmentation, and mutation on the above sample.

- the sample containing the target component may be prepared by appropriately pretreating the above sample in advance.

- the pretreatment include a process of extracting, separating, and purifying the target component or the target component-containing body from a sample containing the target component.

- pre-processing can be performed in the device of the present invention, it is not always required to be performed in advance before being supplied into the device. By performing the pretreatment in the device of the present invention, it is possible to avoid the contamination problem that is usually a concern in the pretreatment of the sample.

- the sample containing the target component is supplied into the operation tube exemplified as 1 in FIG. 1, and the target component is operated in the operation tube.

- Manipulation of the target component in the present invention includes subjecting the target component to various processes and transporting the target component among a plurality of environments in which various processes are performed.

- the operation tube contains a gel layer and an aqueous liquid layer.

- the layers indicated by 2g and 3g are made of gel (gel plug), and the layer shown by 3l is made of an aqueous liquid.

- the layer indicated by 4 may be made of an aqueous liquid or a hydrogel as long as the aqueous liquid can maintain a gel state.

- An aqueous liquid or hydrogel constructs an environment for processing the target component. Therefore, more specifically, the operation of the target component in the present invention includes subjecting the target component to processing in an aqueous liquid or hydrogel, and transporting the target component between a plurality of processing environments through the gel plug. Including doing.

- the process in which the target component is provided includes a process involving a substance change of the target component and a process involving a physical change.

- the process accompanied by the substance change of the target component includes any process as long as it is a process that newly generates a different substance by generating or breaking a bond between substrates. More specifically, chemical reactions and biochemical reactions are included.

- a chemical reaction includes any reaction involving compounding, decomposition, oxidation and reduction. In the present invention, those usually performed in an aqueous liquid are included.

- a biochemical reaction includes any reaction accompanied by a change in a biological material, and usually refers to an in vitro reaction. For example, reactions based on the synthesis system, metabolic system and immune system of biological substances such as nucleic acids, proteins, lipids and sugars can be mentioned.

- Processes that involve physical changes in target components include any process that does not involve material changes. More specifically, denaturation of the target component (for example, when the target component is a biopolymer or other polymer containing nucleic acid or protein), dissolution, mixing, emulsification, dilution, and the like are included.

- the process of the present invention makes it possible to perform steps such as extraction, purification, synthesis, elution, separation, recovery and analysis of the target component. Through these steps, the target component can be finally isolated, detected, identified, and the like.

- the process in the present invention includes not only the target process (process in a process in which an effect such as isolation, detection and identification of the target component is directly obtained), but also a pre-process and / or a post-process associated therewith. Included as appropriate.

- steps such as nucleic acid amplification reaction, or nucleic acid amplification reaction and analysis of amplification product can be performed.

- pretreatment thereof extraction of nucleic acid from a nucleic acid-containing sample ( Cell lysis) and / or purification (washing) are essential, and amplification products may be recovered as a post-treatment.

- the target component is transported by magnetic particles and magnetic field application means.

- the magnetic particles are present in the operation tube at the time of operation, and the target component is transported by moving in the operation tube in a state of being captured by binding or adsorbing the target component to the surface thereof. It is something that can be done.

- the magnetic particles can be dispersed in the aqueous liquid layer in the operation tube, and are usually aggregated in the aqueous liquid layer by generating a magnetic field from the outside of the operation tube by a magnetic field applying means.

- the agglomerated magnetic particles can be moved from the outside of the operation tube as the magnetic field is generated by the magnetic field applying means. Aggregated magnetic particles can move into the gel layer.

- the aggregated magnetic particles can pass through without destroying the gel layer.

- the aggregated magnetic particles are accompanied by binding or adsorption of the target component.

- the aggregated magnetic particles are coated with a very small amount of aqueous liquid. That is, components other than the target component can be accompanied.

- the amount of the coated aqueous liquid is very small, it can be said that the aqueous liquid hardly accompanies. For this reason, the target component can be transported very efficiently.

- the device of the present invention has an operation tube.

- the structure of the operation tube will be described with reference to FIG. 1 (in the following description, the upper and lower sides are referred to based on FIG. 1). It is preferable that the upper end of the tube constituting the operation tube is opened for sample introduction, and the open end can be closed from the viewpoint of contamination. The lower end is closed.

- the tubes constituting the operation tube have a substantially circular cross section, but do not exclude tubes having other shapes of cross sections.

- An operation medium in which the aqueous liquid layer 1 and the gel layer g are alternately stacked in the longitudinal direction of the tube is accommodated in the tube.

- FIG. 1 exemplifies three modes (1) to (3) in which the upper and lower modes of the operation tube are different.

- the upper part and the lower part can be arbitrarily combined, and are not limited to the combinations shown in (1) to (3).

- the upper open end of the tube is a sample supply unit 5 for supplying a sample containing the target component, and the sample supply unit 5 that is the open end may be temporarily opened (FIG. 1 (1)), The whole (FIG. 1 (2)) or part may be closed so that opening is possible.

- a part is closed in a releasable manner, by using a septum having a check valve function, it is possible to supply a sample by puncture close to a sealed state by an injection needle. (FIG. 1 (3)).

- the sample supply unit 5 that is the open end is closed in that a completely sealed system can be constructed. The possibility of constructing a completely closed system is very effective because it can prevent external contamination during operation.

- the inner diameter of the sample supply part 5 may be the same as the inner diameter of the tube part a in which the gel layer and the aqueous liquid layer as the operation medium are accommodated (FIG. 1 (1)), and at the time of supplying the sample It may be appropriately formed so as to have a wider inner diameter from the viewpoint of operability (FIGS. 1 (2) and (3)).

- the tube is integrally formed.

- the pipe is composed of an operation pipe part a and a recovery pipe part b.

- the upper and lower ends of the operation tube portion a are open.

- the recovery pipe part b has an upper end opened and a lower end closed.

- the operation tube portion a and the collection tube portion b are connected to one end of the tube portion a and the open end of the tube portion b.

- the operation tube portion a and the recovery tube portion b may have a separable shape, or may have a shape that does not consider separation (a shape that cannot be separated).

- a gel layer 2g that closes one end and a multilayer layer, that is, an operation medium 3 that overlaps the gel layer 2 are accommodated.

- the operation medium 3 is configured by alternately layering an aqueous liquid layer 3l and a gel layer 3g.

- a portion composed of the operation tube portion a and the operation medium that is the container is referred to as an operation portion A.

- a recovery medium 4 containing at least one of the aqueous liquid and the gel is accommodated in the recovery tube portion b.

- a portion constituted by the collection pipe portion b and the collection medium 4 that is the contained material is referred to as a collection portion B.

- the operation unit A and the recovery unit B may be provided in a connected state or may be provided in an independent state.

- the substantially inner diameter of the tube constituting the operation tube is, for example, 0.1 mm to 5 mm, preferably 1 to 2 mm. Within this range, the operating tube can have good operability. Below this range, the tube wall must be thickened to maintain strength, the distance between the magnetic particles and the magnet increases, and the magnetic force on the magnetic particles becomes difficult to reach, which may cause operational problems. There is sex. On the other hand, when the inner diameter of the tube exceeds the above range, the multilayer of the gel layer and the aqueous liquid layer constituting the operation medium tends to be disturbed due to an impact from the outside or the influence of gravity.

- a tube having an inner diameter of 0.1 mm or less is not excluded as long as the capillary material can withstand high-precision processing.

- the length of the operation tube in the longitudinal direction is, for example, 1 to 30 cm, preferably 5 to 15 cm.

- the substantially internal diameter of the sample supply part 5 is larger than the above-mentioned range, and is 10 mm.

- it may be preferably 5 mm or less.

- the reagent supply unit has a wider inner diameter from the viewpoint of workability at the time of reagent supply. When the wider inner diameter exceeds the above range, for example, when processing a plurality of operation tubes at the same time, the operation tubes interfere with each other and the device integration tends to deteriorate.

- the material of the pipe constituting the operation pipe is not particularly limited.

- the inner wall which is the conveying surface is smooth and water-repellent.

- Examples of materials that give such properties include polyethylene, polypropylene, fluororesin (Teflon (registered trademark)), polyvinyl chloride, polystyrene, polycarbonate, acrylonitrile butadiene styrene copolymer (ABS resin), acrylonitrile styrene copolymer (AS resin),

- Examples of the resin material include acrylic resin, polyvinyl acetate, polyethylene terephthalate, and cyclic polyolefin.

- a resin material is preferable in that the layer in the operation tube is less likely to be disturbed even if the operation tube is dropped or bent, and is highly robust.

- the material of the tube may be glass if necessary in terms of transparency, heat resistance and / or workability.

- the materials of the reagent supply unit 5, the operation tube unit a, and the recovery tube unit b may be the same or different.

- the tube material is selected from the viewpoint of visibility during operation and from the viewpoint of optical detection when measuring absorbance, fluorescence, chemiluminescence, bioluminescence, refractive index change, etc. from the outside of the tube. It is preferable that it has permeability.

- FIG. 1 (1) a gel layer

- FIG. 1 (2) an aqueous liquid layer

- FIG. 1 (2) a gel layer

- the magnetic particles 6 may be included in the layer (FIG. 1 (3)) or may not be included (FIG. 1 (1)).

- the lowermost layer may be an aqueous liquid layer (FIGS. 1 (1) to (3)) or a gel layer.

- the tubes constituting the operation tube when the tubes constituting the operation tube are integrally formed, all the layers accommodated in the tube may be in contact with each other.

- the recovery tube portion b when the tube constituting the operation tube is composed of the operation tube portion a and the recovery tube portion b, the recovery tube portion b contains only an aqueous liquid as a recovery medium.

- the gel may be accommodated, or a multilayer in which the aqueous liquid layer and the gel layer are alternately stacked may be accommodated.

- the gel layer 2g accommodated at the lowermost end of the operation tube portion a and the aqueous liquid, gel contained in the collection tube portion b, or the multilayer uppermost layer contained in the collection tube portion b are: They may be in contact with each other or may not be in contact by sandwiching a gas layer between them (FIG. 1 (3)).

- the number and order of the layers accommodated in the tube are not particularly limited, and can be appropriately determined by those skilled in the art based on the number and order of the operation steps for providing the target component.

- Each of the aqueous liquid layers accommodated in one operation tube is preferably composed of two or more different types of aqueous liquids.

- a liquid that builds an environment necessary for each of the processing step and the reaction step for supplying the target component can be used in order from the upper end side of the operation tube.

- Each of the gel layers accommodated in one operation tube may be made of a different kind of gel or may be made of the same kind of gel.

- the gel when a treatment or reaction by heating is performed in a part of the plurality of aqueous liquid layers, the gel is only in the gel layer adjacent to the aqueous liquid layer even at the temperature required for the heating.

- a gel having a high sol-gel transition point capable of maintaining a state or a gel-sol intermediate state can be used, and a gel having a relatively low sol-gel transition point can be used for the other gel layers.

- those skilled in the art can appropriately select a gel having appropriate characteristics depending on the characteristics and volume of the aqueous liquid constituting the adjacent aqueous liquid layer.

- the gel layer serves as a plug (gel plug) that partitions the aqueous liquid layer on both sides in the longitudinal direction of the tube in the operation tube.

- a plug gel plug

- the thickness that functions as a plug in consideration of the inner diameter and length of the tube, the amount of magnetic particles conveyed by the magnetic field applying means, and the like.

- it can be 1 to 20 mm, preferably 3 to 10 mm.

- the strength as a plug tends to be lacking.

- the operation tube becomes long, and the operability, the durability of the device, and the accommodating property tend to deteriorate.

- the aqueous liquid layer provides an environment such as treatment or reaction in which a sample containing the target component is provided.

- the thickness is determined based on the inner diameter and length of the tube, the amount of the target component, the type of treatment and reaction to which the target component is provided, and the aqueous liquid that achieves the desired treatment or reaction for the target component. Those skilled in the art can appropriately determine the thickness to give the amount. For example, it can be 0.5 to 30 mm, preferably 3 to 10 mm. Below the above range, the treatment and reaction for the target component may not be sufficiently achieved, and there is a possibility that the plug becomes droplets and the magnetic particles cannot be combined with the reagent. When the above range is exceeded, the aqueous liquid layer is often too thick compared to the gel layer, which may cause the same problem as the gel plug, and when the specific gravity of the aqueous liquid is larger than the gel, Tend to collapse.

- the hydrogel layer when the gel layer is composed of a hydrogel, the hydrogel layer not only serves as a reagent partition, but can provide an environment such as a treatment or reaction in which a sample containing the target component is provided, similar to the aqueous liquid layer. it can.

- the hydrogel layer may be thicker than the aqueous liquid layer.

- the gel layer is made of a chemically inert substance that is insoluble or hardly soluble in the liquid constituting the aqueous liquid layer when it is overlaid with the aqueous liquid in the tube.

- Insoluble or hardly soluble in a liquid means that the solubility in the liquid at 25 ° C. is approximately 100 ppm or less.

- a chemically inert substance refers to a target component and an aqueous liquid or hydrogel in the operation of the target component (that is, treatment of the target component in an aqueous liquid or hydrogel and transport of the target component through a gel plug).

- the gel in the present invention includes both organogel and hydrogel.

- Organogel can be gelled by adding a gelling agent to a liquid substance that is usually insoluble or sparingly soluble in water.

- a gelling agent e.g., a gelling agent for a gelling agent for a gelling agent for a gelling agent for a gelling agent for a liquid substance that is usually insoluble or sparingly soluble in water.

- Liquid substances that are insoluble or sparingly soluble in water As the water-insoluble or hardly water-soluble liquid substance, oil having a solubility in water at 25 ° C. of approximately 100 ppm or less and liquid at room temperature (20 ° C. ⁇ 15 ° C.) can be used.

- 1 type, or 2 or more types from the group which consists of liquid fats and oils, ester oil, hydrocarbon oil, and silicone oil may be used.

- Liquid oils include linseed oil, camellia oil, macadamia nut oil, corn oil, mink oil, olive oil, avocado oil, sasanqua oil, castor oil, safflower oil, kyounin oil, cinnamon oil, jojoba oil, grape oil, sunflower oil, Almond oil, rapeseed oil, sesame oil, wheat germ oil, rice germ oil, rice bran oil, cottonseed oil, soybean oil, peanut oil, teaseed oil, evening primrose oil, egg yolk oil, liver oil, palm oil, palm oil, palm kernel oil, etc. Is mentioned.

- Ester oils include octanoic esters such as cetyl octanoate, lauric esters such as hexyl laurate, myristate esters such as isopropyl myristate and octyldodecyl myristate, palmitate esters such as octyl palmitate, isocetyl stearate, etc.

- octanoic esters such as cetyl octanoate

- lauric esters such as hexyl laurate

- myristate esters such as isopropyl myristate and octyldodecyl myristate

- palmitate esters such as octyl palmitate, isocetyl stearate, etc.

- Stearic acid ester isostearic acid ester such as isopropyl isostearate, isopalmitic acid ester such as octyl isopalmitate, oleic acid ester such as isodecyl oleate, adipic acid ester such as isopropyl adipate, sebacic acid such as ethyl sebacate

- esters malate esters such as isostearyl malate, glycerin trioctanoate, glycerin triisopalmitate, and the like.

- hydrocarbon oil examples include pentadecane, hexadecane, octadecane, mineral oil, liquid paraffin, and the like.

- silicone oil examples include dimethylpolysiloxane, methylphenylpolysiloxane and other phenyl group-containing silicone oils, and methylhydrogenpolysiloxane.

- gelling agent an oil gelling agent selected from the group consisting of hydroxy fatty acid, dextrin fatty acid ester, and glycerin fatty acid ester may be used alone or in combination.

- the hydroxy fatty acid is not particularly limited as long as it is a fatty acid having a hydroxyl group. Specific examples include hydroxymyristic acid, hydroxypalmitic acid, dihydroxypalmitic acid, hydroxystearic acid, dihydroxystearic acid, hydroxymargaric acid, ricinoleic acid, ricinaleic acid, and linolenic acid. Of these, hydroxystearic acid, dihydroxystearic acid, and ricinoleic acid are particularly preferable. These hydroxy fatty acids may be used alone or in combination of two or more. Moreover, animal and vegetable oil fatty acids (for example, castor oil fatty acid, hydrogenated castor oil fatty acid, etc.) that are a mixture of these can also be used as the hydroxy fatty acid.

- animal and vegetable oil fatty acids for example, castor oil fatty acid, hydrogenated castor oil fatty acid, etc.

- dextrin fatty acid esters examples include dextrin myristate [trade name “Leopard MKL”, manufactured by Chiba Flour Mills Co., Ltd.], dextrin palmitate [trade names “Leopard KL”, “Leopard TL”, both manufactured by Chiba Flour Mills Co., Ltd.] , (Palmitic acid / 2-ethylhexanoic acid) dextrin [trade name “Leopard TT”, manufactured by Chiba Flour Milling Co., Ltd.] and the like.

- glycerin fatty acid ester examples include glyceryl behenate, glyceryl octastearate, and glyceryl eicoate. These may be used in combination of one or more.

- the trade name “TAISET 26” (manufactured by Taiyo Chemical Co., Ltd.), 20% glyceryl behenate and 50% octastearic acid containing 20% glyceryl behenate, 20% glyceryl octastearate and 60% hydrogenated palm oil.

- a trade name “TAISET 50” (manufactured by Taiyo Kagaku Co., Ltd.) including glyceryl can be used.

- the content of the gelling agent added to the liquid substance that is not water-soluble or poorly water-soluble is, for example, 0.1 to 0.5% by weight, 0.5 to 2% by weight of the total weight of the liquid substance, Alternatively, an amount of gelling agent corresponding to 1 to 5% by weight can be used. However, without being limited thereto, those skilled in the art can appropriately determine the amount that can achieve the desired gel and sol state.

- the gelation method can be appropriately determined by those skilled in the art. Specifically, a liquid substance that is water-insoluble or poorly water-soluble is heated, a gelling agent is added to the heated liquid substance, the gelling agent is completely dissolved, and then cooled to Liquid substances can be gelled.

- the heating temperature may be appropriately determined in consideration of the liquid substance to be used and the physical properties of the gelling agent. For example, it may be preferable to set the temperature to about 60 to 70 ° C.

- the gelling agent is dissolved in the heated liquid substance, and at this time, it is preferable that the gelling agent is gently mixed. Cooling is preferably performed slowly. For example, it can be cooled for about 1 to 2 hours. For example, cooling can be completed when the temperature falls to room temperature (20 ° C.

- hydrogel for example, gelatin, collagen, starch, pectin, hyaluronic acid, chitin, chitosan or alginic acid and derivatives thereof are used as hydrogel materials, and those prepared by equilibrium swelling of the hydrogel material in water or an aqueous liquid are used. Can be.

- a hydrogel prepared from gelatin it is preferable to use a hydrogel prepared from gelatin.

- the hydrogel is obtained by chemically crosslinking the above hydrogel material, or by a gelling agent (for example, a salt of an alkali metal or alkaline earth metal such as lithium, potassium or magnesium, or a transition metal such as titanium, gold, silver or platinum). Or a silica, carbon, alumina compound, etc.).

- a gelling agent for example, a salt of an alkali metal or alkaline earth metal such as lithium, potassium or magnesium, or a transition metal such as titanium, gold, silver or platinum.

- a silica, carbon, alumina compound, etc.

- the hydrogel provides an environment such as a treatment or reaction in which a sample containing the target component is provided in the same manner as an aqueous liquid

- a person skilled in the art will have a composition suitable for such treatment and reaction.

- a DNA hydrogel (P-gel) based on polydimethylsiloxane capable of synthesizing proteins can be mentioned.

- This hydrogel is composed of DNA as part of the gel scaffold.

- Such a hydrogel can be subjected to a reaction for obtaining a protein from the target component when the target component is a substrate for protein synthesis (more specifically, Nature Materials 8, 432-437 (2009), And Nature Protocols 4: 1759-1770 (2009), which can be appropriately determined by those skilled in the art.

- the produced protein can be recovered, for example, by using magnetic particles having an antibody specific for the protein.

- the gel contained in the tube has a property of causing a sol-gel transition at a certain temperature.

- the sol-gel transition point may be in the range of 25-70 ° C. A sol-gel transition point in this range is desirable in a reaction system that requires fluidity by solification for recovery or the like.

- the sol-gel transition point may vary depending on conditions such as the type of organogel material (oil) or hydrogel material, the type of gelling agent, and the amount of gelling agent added. Accordingly, each condition is appropriately selected by those skilled in the art so as to have a desired sol-gel transition point.

- the gel plug allows the aqueous liquid in the tube to be fixed at a predetermined position in the tube by sandwiching it from both sides in the longitudinal direction of the tube.

- magnetic particles can be moved by an external magnetic field operation, and can pass through the gel. This is due to the thixotropic nature of the gel (thixotropic properties).

- the magnetic particles in the tube give a shearing force to the gel along the conveying surface by moving the magnet from the outside, and the gel in the forward direction of the magnetic particles is solated and fluidized, so that the magnetic particles proceed as they are. Can do.

- the sol released from the shearing force after the magnetic particles have passed through returns quickly to the gel state, so that the gel does not form through holes due to the passage of the magnetic particles.

- the object can easily move using the magnetic particles as a carrier, and therefore, various chemical environments provided with the object can be switched in a very short time.

- the processing time of the object can be greatly shortened. If the property of gelation at a temperature below room temperature is used, even a reagent that exhibits a liquid state at that temperature can be immobilized by being sandwiched by gel plugs in the tube.

- the state in which the capillary is preliminarily loaded with the liquid reagent can be maintained from the time of manufacturing the device to the hand of the user, and the liquid reagent can be stably supplied. Furthermore, reagent collection and dispensing operations for each process are unnecessary, and labor and time can be reduced, and deterioration of analysis accuracy due to contamination can be prevented.

- the storage viscoelasticity E ′ of the dynamic viscoelasticity can be preferably 10 to 100 kPa, more preferably 20 to 50 kPa at room temperature (20 ° C. ⁇ 15 ° C.).

- the strength as a gel plug tends to be lacking.

- even magnetic particles having a particle size of about several ⁇ m tend to be hindered in movement.

- it may have a kinematic viscosity of 5 mm 2 / s to 100 mm 2 / s, preferably 5 mm 2 / s to 50 mm 2 / s, for example about 20 mm 2 / s (50 ° C.).

- the aqueous liquid in the present invention may be an aqueous liquid that is insoluble or hardly soluble in the gel, and can be provided in the form of an emulsion called water, an aqueous solution or an emulsion, or a suspension in which fine particles are dispersed.

- the constituent component of the aqueous liquid includes any component that provides a reaction or treatment environment in which the target component in the present invention is provided.

- a liquid for releasing the component to be operated in the present invention in the aqueous liquid layer and binding or adsorbing it to the surface of the magnetic particles that is, separating the target component from the contaminants, the surface of the magnetic beads

- a liquid having an action of promoting binding to or adsorption to a target component a cleaning solution for removing foreign substances coexisting with the target component, an eluent for separating the target component adsorbed on the magnetic particle from the magnetic particle, and the target component

- a reaction solution for constructing a reaction system for a reaction system.

- the reagent solution (cell lysate) is used to destroy the cell, release the nucleic acid, and adsorb it onto the surface of the silica-coated magnetic particle, and the magnetic particle to remove components other than the nucleic acid Washing solution for washing the nucleic acid, elution solution for separating nucleic acid from magnetic particles (nucleic acid elution solution), nucleic acid amplification reaction solution for performing nucleic acid amplification reaction, and the like.

- the target component is a nucleic acid

- the treatment liquid and reaction liquid for the nucleic acid and the treatment and reaction in which they are provided will be further described.

- cell lysate An example of the cell lysate is a buffer containing a chaotropic substance.

- the buffer may further include EDTA or any other chelating agent, Triton X-100 or any other surfactant.

- the buffer is based on, for example, Tris-HCl or any other buffer.

- chaotropic substances include guanidine hydrochloride, guanidine isothiocyanate, potassium iodide, urea and the like.

- the chaotropic substance is a powerful protein denaturing agent, and has an action of pulling away proteins such as histones clinging to nucleic acids from the nucleic acids and promoting adsorption of the magnetic particles on the silica coating surface.

- the buffer can be used as an auxiliary agent for preparing a pH environment in which nucleic acids are easily adsorbed on the surface of magnetic particles.

- the chaotropic substance also has a cell lysis (ie, destroying cell membrane) action. However, a surfactant contributes more to the cell lysis (i.e., disrupts the cell membrane) than the chaotropic substance. Chelating agents can be used as adjuvants that promote cell lysis.

- a specific protocol for nucleic acid extraction from a sample containing nucleic acid can be appropriately determined by those skilled in the art.

- the magnetic particles are used for transporting the nucleic acid in the droplet encapsulating medium, it is preferable to adopt a method using the magnetic particles as the nucleic acid extraction method.

- a method for extracting and purifying nucleic acid using magnetic particles from a sample containing nucleic acid can be carried out.

- the nucleic acid is adsorbed on the surface of the magnetic particles, and the reagent used for other components other than the nucleic acid contained in the nucleic acid-containing sample (for example, protein, sugar, etc.)

- a solution capable of dissolving other components is preferred.

- Specific examples include high salt concentration aqueous solutions such as sodium chloride, potassium chloride, and ammonium sulfate, and aqueous alcohol solutions such as ethanol and isopropanol.

- the washing of the nucleic acid is a washing of the magnetic particles to which the nucleic acid has been adsorbed. A specific protocol for this washing can also be appropriately determined by those skilled in the art.

- the number of washings of the magnetic particles to which the nucleic acid has been adsorbed can be appropriately selected by those skilled in the art to such an extent that undesired inhibition does not occur during the nucleic acid amplification reaction. Further, when the influence of the inhibitory component can be ignored from the same viewpoint, the washing step can be omitted.

- the aqueous liquid layer made of the cleaning liquid is prepared at least as many times as the number of times of cleaning.

- nucleic acid eluate As the nucleic acid eluate, a buffer solution containing water or salt can be used. Specifically, a Tris buffer solution, a phosphate buffer solution, distilled water, or the like can be used. A person skilled in the art can also determine a specific method for separating the nucleic acid from the magnetic particles adsorbed with the nucleic acid and eluting it into the eluate.

- nucleic acid amplification reaction solution In the nucleic acid amplification reaction solution of the present invention, various elements usually used in the nucleic acid amplification reaction include at least a nucleic acid containing a base sequence to be amplified and magnetic particles adsorbed on the surface thereof.

- the nucleic acid amplification reaction is not particularly limited, and therefore various elements used in the nucleic acid amplification reaction can be appropriately determined by those skilled in the art based on known nucleic acid amplification methods exemplified below. it can.

- salts such as MgCl 2 and KCl, primers, deoxyribonucleotides, nucleic acid synthetase and pH buffer are included.

- the above salts can be used by appropriately changing to other salts.

- a substance for reducing non-specific priming such as dimethyl sulfoxide, betaine, or glycerol may be further added.

- the nucleic acid amplification reaction solution in the present invention can contain a blocking agent.

- the blocking agent can be used for the purpose of preventing the deactivation of the nucleic acid polymerizing enzyme due to adsorption to the inner wall of the reaction vessel or the surface of the magnetic particles.

- Specific examples of the blocking agent include bovine serum albumin (ie, BSA) and other albumins, gelatin (ie, denatured collagen), proteins such as casein and polylysine, peptides (both natural and synthetic), ficoll, and polyvinylpyrrolidone. And polyethylene glycol.

- the nucleic acid amplification reaction according to the present invention is not particularly limited.

- the PCR method (US Pat. Nos. 4,683,195, 4,683,202, 4,800,159, and 4,965,188), the LCR method (US Pat. No. 5,494,810). No. 4), Q ⁇ method (US Pat. No. 4,786,600), NASBA method (US Pat. No. 5,409,818), LAMP method (US Pat. No. 3,313,358), SDA method (US Pat. No. 5,455,166), RCA method ( U.S. Pat. No. 5,354,688), ICAN method (Japanese Patent No. 3433929), TAS method (Japanese Patent No. 2443586), and the like can be used.

- RT reaction can also be performed prior to the above reaction.

- the composition of the reaction solution necessary for these nucleic acid amplification reactions and the reaction temperature can be appropriately selected by those skilled in the art.

- a nucleic acid amplification reaction is further performed after the reverse transcriptase (RT) reaction

- the RT reaction is performed on the PCR reaction solution layer via a gel layer.

- the layers of the reaction solution can be overlaid (for example, illustrated in FIG. 4).

- the amplification product can be detected with a fluorescent dye capable of binding to double-stranded DNA or a probe labeled with the fluorescent dye.

- detection methods in the real-time nucleic acid amplification method include the following methods.

- an intercalator method using SYBR (registered trademark) GREEN I or the like is used.

- An intercalator that emits fluorescence by binding to double-stranded DNA binds to double-stranded DNA synthesized by a nucleic acid amplification reaction, and emits fluorescence of a specific wavelength when irradiated with excitation light. By detecting this fluorescence, the amount of amplification product generated can be monitored.

- This method does not require designing and synthesizing a target-specific fluorescently labeled probe, and can be easily used for measuring various targets.

- the fluorescent labeling probe method when it is necessary to distinguish and detect similar sequences, or when typing SNPs, the fluorescent labeling probe method is used.

- a TaqMan (registered trademark) probe method using an oligonucleotide whose 5 ′ end is modified with a fluorescent substance and whose 3 ′ end is modified with a quencher substance as a probe.

- the TaqMan probe specifically hybridizes to the template DNA in the annealing step.

- a quencher is present on the probe, fluorescence emission is suppressed even when irradiated with excitation light.

- the fluorescent dye is released from the probe, the suppression by the quencher is released, and the fluorescence is released. Emits light. By measuring the fluorescence intensity, the amount of amplification product generated can be monitored.

- PCR is performed using serially diluted standard samples with known concentrations as templates. Then, the number of cycles (threshold cycle; Ct value) reaching a certain amount of amplification product is obtained.

- Ct value the number of cycles reaching a certain amount of amplification product is obtained.

- a calibration curve is created by plotting the Ct value on the horizontal axis and the initial DNA amount on the vertical axis. For a sample of unknown concentration, a Ct value is obtained by performing a PCR reaction under the same conditions. From this value and the calibration curve described above, the target DNA amount in the sample can be measured.

- the temperature after the PCR reaction solution containing the fluorescent dye is gradually raised from 40 ° C. to about 95 ° C., and the fluorescence intensity is continuously monitored, a melting curve of the amplification product can be obtained.

- Double-stranded DNA generated by the nucleic acid amplification reaction has a unique Tm value depending on the length of the DNA and its base sequence. That is, when the temperature of the droplet containing DNA to which the fluorescent dye is bound is gradually increased, a temperature at which the fluorescence intensity rapidly decreases is observed. When the amount of change in the fluorescence intensity is examined, the temperature peak almost coincides with the Tm value defined by the base sequence and the length.

- composition of the respective aqueous liquid can be easily determined by those skilled in the art. Even if the target component is other than the above nucleic acid, the composition of each aqueous liquid can be easily determined by those skilled in the art.

- Operation tube manufacturing method As a method for producing the operation tube, there are the following two methods depending on an aspect in which a tube in which a multilayer as an operation medium is to be accommodated is prepared.

- the operation medium can be formed by filling the required aqueous liquid and gel alternately in the required order from the lower closed end, thereby forming the operation tube.

- the tube is composed of the operation tube portion a and the recovery tube portion b

- storage of the recovery medium necessary for configuring the recovery portion B that is, storage of the aqueous liquid, storage of the gel

- the recovery unit B is completed.

- the operation unit A is completed by accommodating the operation medium necessary for configuring the operation unit A, that is, forming a multilayer of an aqueous liquid layer and a gel layer.

- a more specific method for forming a multilayer by alternately layering an aqueous liquid and a gel can be appropriately performed by those skilled in the art according to the layering method in the case of 4-2 described later.

- the sample supply part which is an upper opening end may be closed suitably.

- the pipe may be composed of the operation pipe part a and the recovery pipe part b, and the pipe part a and the pipe part b may be prepared independently.

- the operation part A and the recovery part B are separately prepared by accommodating the necessary aqueous liquid and / or gel in the pipe part a and the pipe part b, and the prepared operation part A and recovery part are produced.

- An operation tube can be produced by connecting B to each other.

- FIG. 2 An outline of the method for manufacturing the operation unit A is schematically shown in FIG.

- the aqueous liquid L for example, cleaning liquid

- the gel G constituting the gel layer is accommodated in another container in a sol state.

- the sol state is maintained by heating with a constant temperature bath 21 at 70 ° C.

- the lower opening end of the pipe part a is prepared in a closed state by being pressed against the pressing mat 22.

- the liquid feeding system into the pipe part a includes tubes 23 and 23 ′ for feeding the aqueous liquid L or the sol-gel G, respectively, extending from the container in which the aqueous liquid L and the sol-gel G are accommodated.

- a liquid feeding means 24 (peristaltic pump in FIG. 2) to which a tube 23 ′ is connected, and a needle 25 for filling the tube portion a with a liquid substance in the tube sent by the liquid feeding means. It is preferable that the needle 25 has a length enough to reach the bottom of the tube part a by being inserted into the tube part a.

- a tube 23 extending from the container containing the aqueous liquid L and a tube 23 extending from the container containing the sol-gel G are connected to the switching valve 26.

- different liquid substances aqueous liquid L and sol-gel G

- This embodiment can be preferably used when the inner diameter of the tube portion a is relatively small because only one needle is inserted into the tube portion a.

- the liquid supply path from the container to the needle may be made independent without using the switching valve 26.

- the tube extended from the container in which the aqueous liquid was accommodated, the needle connected to the tube, the tube extended from the container in which the sol-gel was accommodated, and Two liquid feeding paths with the needle connected to the tube can be formed.

- two needles can be inserted into the tube portion a, it can be preferably used when the inner diameter of the tube portion a is relatively large.

- the sol gel G and the aqueous liquid L are alternately sent and filled into the tube portion a in order from the sol gel G.

- the tip of the needle 25 is raised as the liquid level in the pipe part a rises.

- the aqueous liquid L is layered as shown in FIG. 2 (2) after filling the sol-gel, the previously filled sol-gel may or may not be completely gelled. Good.

- a heat source (a constant temperature bath 21 in FIG. 2). In general, it can be in an intermediate state of gel-sol with increased viscoelasticity.

- the recovery unit B can be obtained by storing a necessary aqueous liquid or gel. Or the collection

- recovery part B can be obtained by forming the multilayer of an aqueous liquid layer and a gel layer in the order required suitably by the method similar to the above except not using the mat for suppression.

- the operation unit A and the recovery unit B obtained as described above are connected to each other.

- the operation unit A may be configured such that the pipe part a is tilted so that the contents do not slide down, the restraining mat is removed, and the collection unit B is connected in a tilted state or a sideways state.

- the pipe part a and the pipe part b may be wound with a tape or the like, or the pipe part a and the pipe part b each having a connection part that can be connected to each other are used. , You may connect both connection parts.

- the sample supply portion that is the upper open end of the operation tube portion a may be appropriately closed.

- the closing timing may be after the operation unit A is manufactured and before the operation unit A and the recovery unit B are connected, or the operation unit A and the recovery unit B are connected. It may be later.

- the magnetic particles are used to move the target component in the operation tube by being accompanied by a small amount of liquid mass accompanying the fluctuation of the magnetic field from the outside of the operation tube. Magnetic particles intended to enable separation, recovery and purification of specific components by such movement usually have a chemical functional group on the surface.

- the magnetic particles may not be accommodated in the operation tube in advance (FIGS. 1 (1) and 1 (2)) or may be accommodated (FIGS. 1 (3), 3 and 4). When it is accommodated in the operation tube in advance, it can be contained in the aqueous liquid constituting the uppermost layer.

- the magnetic particles are not previously stored in the operation tube, the magnetic particles are also supplied into the operation tube when the sample having the target component is supplied into the operation tube.

- the magnetic particle is not particularly limited as long as it is a particle that responds to magnetism, and examples thereof include particles having a magnetic material such as magnetite, ⁇ -iron oxide, and manganese zinc ferrite.

- the magnetic particle has a chemical structure that specifically binds to the target component subjected to the above treatment or reaction, such as amino group, carboxyl group, epoxy group, avidin, biotin, digoxigenin, protein A, protein G, complex

- the surface may be provided with a metal ion or an antibody, and may have a surface that specifically binds to the target component by electrostatic force or van der Waals force. Thereby, the target component to be subjected to the reaction or treatment can be selectively adsorbed to the magnetic particles.

- the hydrophilic group on the surface of the magnetic particles include a hydroxyl group, an amino group, a carboxyl group, a phosphoric acid group, and a sulfonic acid group.

- the magnetic particles can further include various elements appropriately selected by those skilled in the art.

- the surface is covered with particles made of a mixture of a magnetic material and silica and / or anion exchange resin, silica and / or anion exchange resin.

- Preferred examples include magnetic particles, magnetic particles whose surface is covered with gold having a hydrophilic group via a mercapto group, and gold particles containing a magnetic substance and having a hydrophilic group via a mercapto group on the surface. .

- the magnetic particles having hydrophilic groups on the surface may have an average particle size of about 0.1 ⁇ m to 500 ⁇ m. When the average particle size is small, the magnetic particles tend to exist in a dispersed state when released from the magnetic field in the aqueous liquid layer.

- Examples of commercially available magnetic particles include Magnetic Beads coated with silica for nucleic acid extraction, which is a constituent reagent of Plasmid DNA Purification Kit MagExtractor-Plasmid- sold by Toyobo. In this way, when sold as a component reagent of a kit, since the stock solution of the product containing magnetic particles contains a storage solution or the like, it can be washed by suspending it with pure water (for example, about 10 times the amount). preferable.

- This washing can be carried out by removing the supernatant by centrifuging or agglomerating with a magnet after suspending purely, and suspension and removal of the supernatant can be repeated.

- the magnetic field application means for applying a magnetic field fluctuation to move the magnetic particles will be described in detail in Item 8 below.

- FIGS. 3 (0) to (14) and FIGS. 4 (0) to (7) The operation of the target component in the operation tube is shown in FIGS. 3 (0) to (14) and FIGS. 4 (0) to (7). Hereinafter, a description will be given based on FIGS. 3 and 4.

- the sample 32 containing the target component is supplied from the reagent supply port 5 (FIG. 3 (1) and FIG. 4 (1)).

- the sample is supplied in a liquid form.

- the sample supply may be performed manually with a syringe or the like, or may be automatically controlled with a dispenser using a pipetter or the like.

- the sample supply can be performed in a state where the operation tube is set up by appropriate holding means (not shown; the holding means for holding the operation tube will be described in detail in item 7 described later).

- obtaining a sample 32, the magnetic particles 6 and an aqueous liquid 3l 1 aqueous liquid mixture 33 comprising including a target component can be obtained as follows.

- the sample may be supplied into the operation tube together with the magnetic particles, or the sample may be supplied into the operation tube together with the aqueous liquid and suspended magnetic particles. May be.

- an aqueous liquid mixture can be obtained from the aqueous liquid in the uppermost layer.

- the uppermost layer accommodated in the operation tube is made of an aqueous liquid containing magnetic particles (the case illustrated in FIGS.

- only the sample may be supplied into the operation tube.

- the sample may be supplied into the operation tube together with the aqueous liquid.

- an aqueous liquid mixture can be obtained from the aqueous liquid containing the magnetic particles in the uppermost layer.

- the sample may be supplied into the operation tube together with the aqueous liquid and the magnetic particles. Thereby, an aqueous liquid mixture can be newly formed as the uppermost layer on the gel layer.

- the operation tube that is supplied with the sample and the aqueous liquid mixture containing the sample and magnetic particles in the uppermost layer is prepared in the state where it is placed on the holding means or transferred to the holding means dedicated to the device. Can be set.

- a magnetic field is applied from the outside by bringing a magnetic field applying means (for example, a cylindrical neodymium magnet having a diameter of 1 mm to 5 mm and a length of 5 mm to 30 mm) 31 close to the operation tube 1 and dispersed in the aqueous liquid mixture layer 311.

- the formed magnetic particles 6 are aggregated together with the target component (FIGS. 3 (2) and 4 (2)).

- unnecessary components contained in the aqueous liquid mixture layer 3l 1 may also be aggregated together.

- the magnetic field applying means 31 By moving the magnetic field applying means 31 downward at a speed of 0.5 mm to 10 mm per second, the magnetic particles attracting the target component are passed from the aqueous liquid mixture layer 3l 1 through the gel layer 3g 1 directly below it (see FIG. 3 (3) and FIG. 4 (3)) and transport to the aqueous liquid layer 3 l 2 immediately below the gel layer 3 g 1 (FIGS. 3 (4) and 4 (4)).

- magnetic particles passing through the gel layer 3 g because they are thin-coated in an aqueous liquid mixture of the aqueous liquid mixture layer 3l 1 which has been subjected to prior pass, in addition to the target component, the concentration is low It is accompanied by the contaminated components.

- Such magnetic particles are further transported to the aqueous liquid layer 3l 2.

- the size and moving speed of the magnet are appropriately determined by those skilled in the art according to the amount of magnetic particles, the inner and outer diameters of the operation tube, the state of the gel plug, and the like.

- the magnetic field applying unit 31 repeated as necessary to transport the aqueous liquid layer 3l 2 through the gel layer to the other aqueous liquid layer.