JP4852278B2 - リソグラフィ装置及びデバイス製造方法 - Google Patents

リソグラフィ装置及びデバイス製造方法 Download PDFInfo

- Publication number

- JP4852278B2 JP4852278B2 JP2005233909A JP2005233909A JP4852278B2 JP 4852278 B2 JP4852278 B2 JP 4852278B2 JP 2005233909 A JP2005233909 A JP 2005233909A JP 2005233909 A JP2005233909 A JP 2005233909A JP 4852278 B2 JP4852278 B2 JP 4852278B2

- Authority

- JP

- Japan

- Prior art keywords

- gas

- substrate

- temperature

- lithographic apparatus

- liquid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 19

- 239000000758 substrate Substances 0.000 claims description 476

- 239000007788 liquid Substances 0.000 claims description 162

- 238000007789 sealing Methods 0.000 claims description 150

- 230000005855 radiation Effects 0.000 claims description 123

- 238000001704 evaporation Methods 0.000 claims description 56

- 230000008020 evaporation Effects 0.000 claims description 54

- 238000001816 cooling Methods 0.000 claims description 38

- 229920006395 saturated elastomer Polymers 0.000 claims description 15

- 238000007654 immersion Methods 0.000 description 63

- 238000010438 heat treatment Methods 0.000 description 45

- 239000012530 fluid Substances 0.000 description 37

- 238000000059 patterning Methods 0.000 description 36

- 238000000034 method Methods 0.000 description 32

- 238000005259 measurement Methods 0.000 description 23

- 230000008569 process Effects 0.000 description 21

- 230000006870 function Effects 0.000 description 16

- 238000005286 illumination Methods 0.000 description 16

- 239000000463 material Substances 0.000 description 14

- 230000006698 induction Effects 0.000 description 13

- 230000007246 mechanism Effects 0.000 description 13

- 238000009833 condensation Methods 0.000 description 11

- 230000005494 condensation Effects 0.000 description 11

- 230000000694 effects Effects 0.000 description 11

- 230000008901 benefit Effects 0.000 description 9

- 230000008859 change Effects 0.000 description 9

- 238000009529 body temperature measurement Methods 0.000 description 7

- 230000001419 dependent effect Effects 0.000 description 7

- 238000009826 distribution Methods 0.000 description 7

- 239000010410 layer Substances 0.000 description 7

- 230000003287 optical effect Effects 0.000 description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- 230000004044 response Effects 0.000 description 6

- 239000003381 stabilizer Substances 0.000 description 6

- 230000001133 acceleration Effects 0.000 description 5

- 238000004458 analytical method Methods 0.000 description 5

- 238000001459 lithography Methods 0.000 description 5

- 239000000203 mixture Substances 0.000 description 5

- 239000011295 pitch Substances 0.000 description 5

- 238000006073 displacement reaction Methods 0.000 description 4

- 238000009413 insulation Methods 0.000 description 4

- 239000000243 solution Substances 0.000 description 4

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 3

- 230000002411 adverse Effects 0.000 description 3

- 230000004075 alteration Effects 0.000 description 3

- 238000004422 calculation algorithm Methods 0.000 description 3

- 238000011109 contamination Methods 0.000 description 3

- 238000012937 correction Methods 0.000 description 3

- 238000013461 design Methods 0.000 description 3

- 238000002347 injection Methods 0.000 description 3

- 239000007924 injection Substances 0.000 description 3

- 230000003993 interaction Effects 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 230000010363 phase shift Effects 0.000 description 3

- 229910052710 silicon Inorganic materials 0.000 description 3

- 239000010703 silicon Substances 0.000 description 3

- 238000012360 testing method Methods 0.000 description 3

- 238000012546 transfer Methods 0.000 description 3

- 238000004026 adhesive bonding Methods 0.000 description 2

- 230000003321 amplification Effects 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000004590 computer program Methods 0.000 description 2

- 230000003111 delayed effect Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000005670 electromagnetic radiation Effects 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 238000003199 nucleic acid amplification method Methods 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 230000002829 reductive effect Effects 0.000 description 2

- 238000002310 reflectometry Methods 0.000 description 2

- 239000004065 semiconductor Substances 0.000 description 2

- 238000002791 soaking Methods 0.000 description 2

- 230000000087 stabilizing effect Effects 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 239000010409 thin film Substances 0.000 description 2

- 238000013459 approach Methods 0.000 description 1

- 238000003491 array Methods 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000013500 data storage Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000008713 feedback mechanism Effects 0.000 description 1

- 230000017525 heat dissipation Effects 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 238000003384 imaging method Methods 0.000 description 1

- 238000000671 immersion lithography Methods 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000010884 ion-beam technique Methods 0.000 description 1

- 239000002346 layers by function Substances 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 230000005381 magnetic domain Effects 0.000 description 1

- 238000007726 management method Methods 0.000 description 1

- 230000015654 memory Effects 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- -1 polytetrafluoroethylene Polymers 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000000750 progressive effect Effects 0.000 description 1

- 210000001747 pupil Anatomy 0.000 description 1

- 239000010453 quartz Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000003595 spectral effect Effects 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 238000010561 standard procedure Methods 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/027—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34

- H01L21/0271—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers

- H01L21/0273—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers characterised by the treatment of photoresist layers

- H01L21/0274—Photolithographic processes

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/708—Construction of apparatus, e.g. environment aspects, hygiene aspects or materials

- G03F7/70808—Construction details, e.g. housing, load-lock, seals or windows for passing light in or out of apparatus

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/70216—Mask projection systems

- G03F7/70341—Details of immersion lithography aspects, e.g. exposure media or control of immersion liquid supply

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/708—Construction of apparatus, e.g. environment aspects, hygiene aspects or materials

- G03F7/70808—Construction details, e.g. housing, load-lock, seals or windows for passing light in or out of apparatus

- G03F7/70841—Constructional issues related to vacuum environment, e.g. load-lock chamber

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/708—Construction of apparatus, e.g. environment aspects, hygiene aspects or materials

- G03F7/70858—Environment aspects, e.g. pressure of beam-path gas, temperature

- G03F7/70866—Environment aspects, e.g. pressure of beam-path gas, temperature of mask or workpiece

- G03F7/70875—Temperature, e.g. temperature control of masks or workpieces via control of stage temperature

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Public Health (AREA)

- Epidemiology (AREA)

- Environmental & Geological Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Atmospheric Sciences (AREA)

- Toxicology (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Computer Hardware Design (AREA)

- Manufacturing & Machinery (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Exposure And Positioning Against Photoresist Photosensitive Materials (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

Description

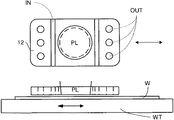

投影ビームB(例えば、紫外放射又は遠紫外放射)を調整するように構成された照明系(照明器)ILと、

パターン形成装置(例えば、マスク)MAを支持するように作製され、且つ幾つかのパラメータに従ってパターン形成装置を正確に位置決めするように構成された第1の位置決め装置PMに連結されている支持構造(例えば、マスク・テーブル)MTと、

基板(例えば、レジスト塗布ウェーハー)Wを保持するように作製され、且つ幾つかのパラメータに従って基板を正確に位置決めするように構成された第2の位置決め手段PWに連結されている基板テーブル(例えば、ウェーハー・テーブル)WTと、

パターン形成装置MAによって放射ビームBに付与されたパターンを基板Wの標的部分C(例えば、1個又は複数のダイを含む)の上に投影するように構成された投影系(例えば、屈折投影レンズ系)PSと、を備える。

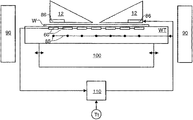

1. ステップ方式では、放射ビームに付与されたパターン全体を1回で標的部分Cの上に投影する間、マスク・テーブルMT及び基板テーブルWTを基本的に静止状態に保持する(即ち、単一静的露光)。次いで、異なる標的部分Cを露光できるように、基板テーブルWTをX方向及び/又はY方向に移動する。ステップ方式では、露光領域の最大の大きさが、単一静的露光で撮像される標的部分Cの大きさを限定する。

2. 走査方式では、放射ビームに付与されたパターンを標的部分C上に投影する間、マスク・テーブルMT及び基板テーブルWTを同期して走査する(即ち、単一動的露光)。マスク・テーブルMTに対する基板テーブルWTの速度及び方向は、投影系PSの(縮小/)拡大率と像反転特徴によって決定可能である。走査方式では、露光領域の最大の大きさが単一動的露光における標的部分の幅(非走査方向における)を限定する一方で、走査の移動長さが標的部分の高さ(走査方向における)を決定する。

3. 別の方式では、放射ビームに付与されたパターンを標的部分C上に投影する間、マスク・テーブルMTを基本的に静止状態に保ってプログラム可能なパターン形成装置を保持し、且つ基板テーブルWTを移動又は走査する。この方式では、一般にパルス放射源が使用され、基板テーブルWTの移動毎に又は走査時の連続的な放射パルス間に、プログラム可能なパターン形成手段を必要に応じて更新する。このような動作方式は、上に言及した種類のプログラマブル・ミラー・アレイなどのプログラム可能なパターン形成手段を利用するマスクレス・リソグラフィに容易に応用可能である。

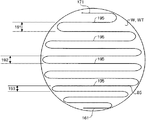

は基板テーブルWT中に埋め込まれたセンサ60によって計測された基板領域の現在温度であり、さらに

は当該領域に関する基板水準における温度差である。基板領域の温度、従って基板全体としての温度ファイル(必要であれば)は、この関係式に基づいて得ることができる。例えば、次のモデルが使用可能である。即ち、

Claims (13)

- リソグラフィ装置であって、

基板を保持する基板テーブルと、

パターン形成された放射ビームを投影する投影系と、

前記投影系と前記基板との間の空間の少なくとも一部に液体を充満する液体供給システムと、

前記投影系と前記基板との間の前記空間の内部に前記液体を実質的に閉じ込める封止部材と、

前記液体供給システムによって供給された液体の正味蒸発率を制御する液体蒸発制御装置と、

前記封止部材の境界によって一側を区切られ且つ前記基板によって第2の側を区切られた間隙を介して前記封止部材から逃げる液体の量を制御する、気体源に連結された気体シールと

を備え、

前記液体蒸発制御装置が、前記液体の前記正味蒸発率を制御する目的で10%よりも大きい制御された相対湿度を有する気体を前記気体シールに供給するために、前記気体源と相互作用して、前記気体源によって前記気体シールに供給された前記気体の相対湿度を調整する気体湿度制御装置を備えることを特徴とするリソグラフィ装置。 - 請求項1に記載のリソグラフィ装置において、前記気体湿度制御装置は、一定流量で湿度制御された気体の流れを生成し、さらに、前記気体源は気体シール流量制御装置を備え、当該気体シール制御装置が、前記一定の流れを前記気体湿度制御装置から受け取り、且つ前記気体湿度制御装置によって供給された前記一定の流れの一部を選択的に外部貯槽に排出することによって前記気体シールへの気体の流量を変更する、リソグラフィ装置。

- 請求項1に記載のリソグラフィ装置において、前記気体湿度制御装置は気体流を制御された範囲まで加湿する加湿部分を含み、前記加湿部分は、

相対的に乾燥した気体流を受け取り、少なくとも1つの液槽から蒸発した液体蒸気によって前記気体流の少なくとも一部を加湿する蒸発容器と、

前記蒸発容器の温度よりも実質的に低い温度に保持され、完全に飽和した気体流を得るために、前記少なくとも一部が加湿された気体流を冷却する冷却容器と、を備える、リソグラフィ装置。 - 請求項3に記載のリソグラフィ装置において、前記加湿部分は、凝縮容器の飽和気体出力に連結可能な乾燥気体源をさらに備え、前記気体湿度制御装置は、制御された相対湿度水準を有する気体流を得るために、乾燥気体が前記凝縮容器から出力された飽和気体の流れと混合される率を調整できる、リソグラフィ装置。

- 請求項1乃至4の何れかに記載のリソグラフィ装置において、前記気体源は、前記気体シールに供給された前記気体の温度を制御するために前記気体源を制御する気体温度制御装置を備え、前記シールに進入する前の前記気体の温度は、前記基板の平均温度よりも高くなるように設定されている、リソグラフィ装置。

- 請求項5に記載のリソグラフィ装置において、前記気体シールに進入する前の前記気体の温度は、前記基板の平均温度よりも1Kから5K高くなるように設定されている、リソグラフィ装置。

- 請求項1乃至6の何れかに記載のリソグラフィ装置において、前記気体源は、40%よりも大きな相対湿度を有する気体を供給する、リソグラフィ装置。

- 請求項1乃至7の何れかに記載のリソグラフィ装置において、前記リソグラフィ装置は、

前記基板、前記基板テーブル及び基板保持器の少なくとも1つの少なくとも一部の温度を計測する少なくとも1つの温度センサをさらに備え、

前記気体湿度制御装置は、前記少なくとも1つの温度センサによって計測された1つ以上の温度と少なくとも1つの標的温度との間の1つ以上の差を縮小するように、前記気体源によって前記気体シールに供給された前記気体の相対湿度を調整することができる、リソグラフィ装置。 - 請求項1乃至8の何れかに記載のリソグラフィ装置において、前記液体蒸発制御装置は、前記基板と前記投影系の最終要素との間の前記封止部材の外部領域に10%よりも大きい制御された相対湿度を有する気体を供給する気体シャワー放出口をさらに備えている、リソグラフィ装置。

- 請求項9に記載のリソグラフィ装置において、前記気体シャワー放出口は40%から50%の範囲内の相対湿度を有する気体を供給する、リソグラフィ装置。

- 請求項9又は10に記載のリソグラフィ装置において、前記リソグラフィ装置は、前記基板、前記基板テーブル及び基板保持器の少なくとも1つの少なくとも一部の温度を計測する少なくとも1つの温度センサと、

前記少なくとも1つの温度センサによって計測された1つ以上の温度と少なくとも1つの標的温度との間の1つ以上の差を縮小するように、前記気体シャワー放出口によって供給された前記気体の相対湿度を調整できる気体シャワー放出口制御装置と、をさらに備えている、リソグラフィ装置。 - 請求項1乃至11の何れかに記載のリソグラフィ装置において、前記リソグラフィ装置は、

前記気体源が10%よりも大きい制御された相対湿度を有する気体を供給し、

前記基板と前記投影系の最終要素との間の前記封止部材の外部領域に、前記気体源によって供給された前記気体の湿度と実質的に等しい制御された相対湿度を有する気体を供給する気体シャワー放出口をさらに備えている、リソグラフィ装置。 - デバイス製造方法であって、

基板を保持する基板テーブルを提供する工程と、

パターン形成された放射ビームを投影する投影系を提供する工程と、

前記投影系と前記基板との間の空間の少なくとも一部に液体を充満する液体供給システムを提供する工程と、

前記投影系と前記基板との間の前記空間の内部に前記液体を実質的に閉じ込める封止部材を提供する工程と、

前記液体供給システムによって供給された液体の正味蒸発率を制御する工程と、

前記封止部材の境界によって一側を区切られ且つ前記基板によって第2の側を区切られた間隙を介して前記封止部材から逃げる液体の量を制御し、気体源に連結された気体シールを提供する工程と、を有し

前記液体蒸発制御装置が、前記液体の前記正味蒸発率を制御する目的で10%よりも大きい制御された相対湿度を有する気体を前記気体シールに供給するために、前記気体源と相互作用して、前記気体源によって前記気体シールに供給された前記気体の相対湿度を調整する気体湿度制御装置を備えることを特徴とするデバイス製造方法。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/917,535 US7304715B2 (en) | 2004-08-13 | 2004-08-13 | Lithographic apparatus and device manufacturing method |

| US10/917,535 | 2004-08-13 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009024156A Division JP5275067B2 (ja) | 2004-08-13 | 2009-02-04 | リソグラフィ装置及びデバイス製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006054468A JP2006054468A (ja) | 2006-02-23 |

| JP4852278B2 true JP4852278B2 (ja) | 2012-01-11 |

Family

ID=34981965

Family Applications (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005233909A Active JP4852278B2 (ja) | 2004-08-13 | 2005-08-12 | リソグラフィ装置及びデバイス製造方法 |

| JP2009024156A Active JP5275067B2 (ja) | 2004-08-13 | 2009-02-04 | リソグラフィ装置及びデバイス製造方法 |

| JP2011285516A Active JP5699072B2 (ja) | 2004-08-13 | 2011-12-27 | リソグラフィ装置及びデバイス製造方法 |

| JP2013228111A Active JP5699197B2 (ja) | 2004-08-13 | 2013-11-01 | リソグラフィ装置 |

Family Applications After (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009024156A Active JP5275067B2 (ja) | 2004-08-13 | 2009-02-04 | リソグラフィ装置及びデバイス製造方法 |

| JP2011285516A Active JP5699072B2 (ja) | 2004-08-13 | 2011-12-27 | リソグラフィ装置及びデバイス製造方法 |

| JP2013228111A Active JP5699197B2 (ja) | 2004-08-13 | 2013-11-01 | リソグラフィ装置 |

Country Status (7)

| Country | Link |

|---|---|

| US (7) | US7304715B2 (ja) |

| EP (1) | EP1628161B1 (ja) |

| JP (4) | JP4852278B2 (ja) |

| KR (1) | KR100760317B1 (ja) |

| CN (2) | CN101923290B (ja) |

| SG (2) | SG120255A1 (ja) |

| TW (1) | TWI322929B (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170008863A (ko) * | 2014-06-19 | 2017-01-24 | 에이에스엠엘 네델란즈 비.브이. | 리소그래피 장치, 대상물 위치설정 시스템 및 디바이스 제조 방법 |

Families Citing this family (116)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7372541B2 (en) * | 2002-11-12 | 2008-05-13 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| SG2010050110A (en) | 2002-11-12 | 2014-06-27 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| SG150388A1 (en) | 2002-12-10 | 2009-03-30 | Nikon Corp | Exposure apparatus and method for producing device |

| KR101508810B1 (ko) | 2003-04-11 | 2015-04-14 | 가부시키가이샤 니콘 | 액침 리소그래피에 의한 광학기기의 세정방법 |

| TWI503865B (zh) | 2003-05-23 | 2015-10-11 | 尼康股份有限公司 | A method of manufacturing an exposure apparatus and an element |

| KR20060009956A (ko) | 2003-05-28 | 2006-02-01 | 가부시키가이샤 니콘 | 노광 방법, 노광 장치, 및 디바이스 제조 방법 |

| SG109000A1 (en) * | 2003-07-16 | 2005-02-28 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| DE602005019689D1 (de) * | 2004-01-20 | 2010-04-15 | Zeiss Carl Smt Ag | Belichtungsvorrichtung und messeinrichtung für eine projektionslinse |

| WO2005076324A1 (ja) | 2004-02-04 | 2005-08-18 | Nikon Corporation | 露光装置、露光方法及びデバイス製造方法 |

| CN105467775B (zh) | 2004-06-09 | 2018-04-10 | 株式会社尼康 | 曝光装置及元件制造方法 |

| US7304715B2 (en) | 2004-08-13 | 2007-12-04 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| JP2006134974A (ja) * | 2004-11-04 | 2006-05-25 | Canon Inc | 露光装置、判定方法及びデバイス製造方法 |

| SG124351A1 (en) | 2005-01-14 | 2006-08-30 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| JP4262252B2 (ja) * | 2005-03-02 | 2009-05-13 | キヤノン株式会社 | 露光装置 |

| JP5040646B2 (ja) * | 2005-03-23 | 2012-10-03 | 株式会社ニコン | 露光装置及び露光方法、並びにデバイス製造方法 |

| KR101555707B1 (ko) * | 2005-04-18 | 2015-09-25 | 가부시키가이샤 니콘 | 노광 장치 및 노광 방법, 그리고 디바이스 제조 방법 |

| US7652746B2 (en) * | 2005-06-21 | 2010-01-26 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| US7751027B2 (en) | 2005-06-21 | 2010-07-06 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| WO2007002833A2 (en) * | 2005-06-29 | 2007-01-04 | Blaise Corbett | Introduction of an intermediary refractive layer for immersion lithography |

| US7426011B2 (en) | 2005-09-12 | 2008-09-16 | Asml Netherlands B.V. | Method of calibrating a lithographic apparatus and device manufacturing method |

| TWI345685B (en) * | 2005-09-06 | 2011-07-21 | Asml Netherlands Bv | Lithographic method |

| JP4756984B2 (ja) * | 2005-10-07 | 2011-08-24 | キヤノン株式会社 | 露光装置、露光装置の制御方法およびデバイスの製造方法 |

| JP4125315B2 (ja) * | 2005-10-11 | 2008-07-30 | キヤノン株式会社 | 露光装置及びデバイス製造方法 |

| US7420188B2 (en) * | 2005-10-14 | 2008-09-02 | Taiwan Semiconductor Manufacturing Company, Ltd. | Exposure method and apparatus for immersion lithography |

| US7986395B2 (en) * | 2005-10-24 | 2011-07-26 | Taiwan Semiconductor Manufacturing Company, Ltd. | Immersion lithography apparatus and methods |

| TW200725195A (en) | 2005-12-06 | 2007-07-01 | Nikon Corp | Exposure method, exposure apparatus, and unit manufacturing method |

| US7420194B2 (en) | 2005-12-27 | 2008-09-02 | Asml Netherlands B.V. | Lithographic apparatus and substrate edge seal |

| US7649611B2 (en) * | 2005-12-30 | 2010-01-19 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| WO2007080779A1 (ja) * | 2006-01-12 | 2007-07-19 | Nikon Corporation | 物体搬送装置、露光装置、物体温調装置、物体搬送方法、及びマイクロデバイスの製造方法 |

| US8045134B2 (en) | 2006-03-13 | 2011-10-25 | Asml Netherlands B.V. | Lithographic apparatus, control system and device manufacturing method |

| US9477158B2 (en) * | 2006-04-14 | 2016-10-25 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| US7675604B2 (en) * | 2006-05-04 | 2010-03-09 | Taiwan Semiconductor Manufacturing Company, Ltd. | Hood for immersion lithography |

| DE102006021797A1 (de) | 2006-05-09 | 2007-11-15 | Carl Zeiss Smt Ag | Optische Abbildungseinrichtung mit thermischer Dämpfung |

| US7877895B2 (en) * | 2006-06-26 | 2011-02-01 | Tokyo Electron Limited | Substrate processing apparatus |

| US8564759B2 (en) * | 2006-06-29 | 2013-10-22 | Taiwan Semiconductor Manufacturing Company, Ltd. | Apparatus and method for immersion lithography |

| US7804582B2 (en) | 2006-07-28 | 2010-09-28 | Asml Netherlands B.V. | Lithographic apparatus, method of calibrating a lithographic apparatus and device manufacturing method |

| US8208116B2 (en) | 2006-11-03 | 2012-06-26 | Taiwan Semiconductor Manufacturing Company, Ltd. | Immersion lithography system using a sealed wafer bath |

| US8253922B2 (en) | 2006-11-03 | 2012-08-28 | Taiwan Semiconductor Manufacturing Company, Ltd. | Immersion lithography system using a sealed wafer bath |

| US7932019B2 (en) * | 2006-11-13 | 2011-04-26 | Samsung Electronics Co., Ltd. | Gettering members, methods of forming the same, and methods of performing immersion lithography using the same |

| US8068208B2 (en) * | 2006-12-01 | 2011-11-29 | Taiwan Semiconductor Manufacturing Company, Ltd. | System and method for improving immersion scanner overlay performance |

| US20080137055A1 (en) * | 2006-12-08 | 2008-06-12 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| US7791709B2 (en) * | 2006-12-08 | 2010-09-07 | Asml Netherlands B.V. | Substrate support and lithographic process |

| US8416383B2 (en) * | 2006-12-13 | 2013-04-09 | Asml Netherlands B.V. | Lithographic apparatus and method |

| US7866637B2 (en) * | 2007-01-26 | 2011-01-11 | Asml Netherlands B.V. | Humidifying apparatus, lithographic apparatus and humidifying method |

| US8947629B2 (en) * | 2007-05-04 | 2015-02-03 | Asml Netherlands B.V. | Cleaning device, a lithographic apparatus and a lithographic apparatus cleaning method |

| US7866330B2 (en) * | 2007-05-04 | 2011-01-11 | Asml Netherlands B.V. | Cleaning device, a lithographic apparatus and a lithographic apparatus cleaning method |

| US7900641B2 (en) | 2007-05-04 | 2011-03-08 | Asml Netherlands B.V. | Cleaning device and a lithographic apparatus cleaning method |

| US8011377B2 (en) * | 2007-05-04 | 2011-09-06 | Asml Netherlands B.V. | Cleaning device and a lithographic apparatus cleaning method |

| US8264662B2 (en) | 2007-06-18 | 2012-09-11 | Taiwan Semiconductor Manufacturing Company, Ltd. | In-line particle detection for immersion lithography |

| TWI541615B (zh) | 2007-07-13 | 2016-07-11 | 瑪波微影Ip公司 | 在微影裝置中交換晶圓的方法 |

| US8705010B2 (en) | 2007-07-13 | 2014-04-22 | Mapper Lithography Ip B.V. | Lithography system, method of clamping and wafer table |

| US9025126B2 (en) * | 2007-07-31 | 2015-05-05 | Nikon Corporation | Exposure apparatus adjusting method, exposure apparatus, and device fabricating method |

| US8582079B2 (en) * | 2007-08-14 | 2013-11-12 | Applied Materials, Inc. | Using phase difference of interference lithography for resolution enhancement |

| NL1036009A1 (nl) * | 2007-10-05 | 2009-04-07 | Asml Netherlands Bv | An Immersion Lithography Apparatus. |

| JP5369443B2 (ja) * | 2008-02-05 | 2013-12-18 | 株式会社ニコン | ステージ装置、露光装置、露光方法、及びデバイス製造方法 |

| NL1036835A1 (nl) * | 2008-05-08 | 2009-11-11 | Asml Netherlands Bv | Lithographic Apparatus and Method. |

| NL2002964A1 (nl) * | 2008-06-16 | 2009-12-17 | Asml Netherlands Bv | Lithographic Apparatus, a Metrology Apparatus and a Method of Using the Apparatus. |

| EP2136250A1 (en) * | 2008-06-18 | 2009-12-23 | ASML Netherlands B.V. | Lithographic apparatus and method |

| EP2172766A1 (en) * | 2008-10-03 | 2010-04-07 | ASML Netherlands B.V. | Lithographic apparatus and humidity measurement system |

| NL2003758A (en) * | 2008-12-04 | 2010-06-07 | Asml Netherlands Bv | A member with a cleaning surface and a method of removing contamination. |

| US8739383B2 (en) * | 2009-04-20 | 2014-06-03 | Nikon Corporation | Method and apparatus for aligning mirror blocks of a multi-element mirror assembly |

| NL2004547A (en) * | 2009-05-14 | 2010-11-18 | Asml Netherlands Bv | An immersion lithographic apparatus and a device manufacturing method. |

| NL2004808A (en) * | 2009-06-30 | 2011-01-12 | Asml Netherlands Bv | Fluid handling structure, lithographic apparatus and device manufacturing method. |

| NL2004980A (en) * | 2009-07-13 | 2011-01-17 | Asml Netherlands Bv | Heat transfers assembly, lithographic apparatus and manufacturing method. |

| NL2005009A (en) * | 2009-07-27 | 2011-01-31 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method. |

| NL2005207A (en) * | 2009-09-28 | 2011-03-29 | Asml Netherlands Bv | Heat pipe, lithographic apparatus and device manufacturing method. |

| JP2011192991A (ja) | 2010-03-12 | 2011-09-29 | Asml Netherlands Bv | リソグラフィ装置および方法 |

| EP2381310B1 (en) | 2010-04-22 | 2015-05-06 | ASML Netherlands BV | Fluid handling structure and lithographic apparatus |

| NL2006536A (en) * | 2010-05-13 | 2011-11-15 | Asml Netherlands Bv | A substrate table, a lithographic apparatus, a method of flattening an edge of a substrate and a device manufacturing method. |

| NL2006913A (en) | 2010-07-16 | 2012-01-17 | Asml Netherlands Bv | Lithographic apparatus and method. |

| TWI501046B (zh) | 2010-07-30 | 2015-09-21 | 卡爾蔡司Smt有限公司 | 超紫外線曝光裝置 |

| NL2007768A (en) | 2010-12-14 | 2012-06-18 | Asml Netherlands Bv | Substrate holder, lithographic apparatus, device manufacturing method, and method of manufacturing a substrate holder. |

| NL2007834A (en) * | 2010-12-23 | 2012-06-27 | Asml Netherlands Bv | Lithographic apparatus and removable member. |

| EP2490073B1 (en) | 2011-02-18 | 2015-09-23 | ASML Netherlands BV | Substrate holder, lithographic apparatus, and method of manufacturing a substrate holder |

| NL2008630A (en) * | 2011-04-27 | 2012-10-30 | Asml Netherlands Bv | Substrate holder, lithographic apparatus, device manufacturing method, and method of manufacturing a substrate holder. |

| NL2009189A (en) | 2011-08-17 | 2013-02-19 | Asml Netherlands Bv | Support table for a lithographic apparatus, lithographic apparatus and device manufacturing method. |

| SG188036A1 (en) | 2011-08-18 | 2013-03-28 | Asml Netherlands Bv | Lithographic apparatus, support table for a lithographic apparatus and device manufacturing method |

| NL2009272A (en) * | 2011-08-31 | 2013-03-04 | Asml Netherlands Bv | A fluid handling structure, a lithographic apparatus and a device manufacturing method. |

| JP5686779B2 (ja) | 2011-10-14 | 2015-03-18 | キヤノン株式会社 | インプリント装置、それを用いた物品の製造方法 |

| US9778579B2 (en) | 2011-11-10 | 2017-10-03 | Nikon Corporation | System and method for controlling a temperature of a reaction assembly |

| CN103959171B (zh) * | 2011-11-17 | 2017-11-28 | Asml荷兰有限公司 | 光刻设备及器件制造方法 |

| WO2013113569A1 (en) | 2012-02-03 | 2013-08-08 | Asml Netherlands B.V. | Substrate holder and method of manufacturing a substrate holder |

| CN104520770B (zh) * | 2012-04-23 | 2017-01-18 | Asml荷兰有限公司 | 静电夹持装置、光刻设备和方法 |

| JP6122252B2 (ja) | 2012-05-01 | 2017-04-26 | キヤノン株式会社 | 露光装置及びデバイスの製造方法 |

| KR101911400B1 (ko) | 2012-05-29 | 2018-10-24 | 에이에스엠엘 네델란즈 비.브이. | 대상물 홀더 및 리소그래피 장치 |

| JP6041541B2 (ja) * | 2012-06-04 | 2016-12-07 | キヤノン株式会社 | 露光装置及びデバイス製造方法 |

| JP2014086701A (ja) * | 2012-10-26 | 2014-05-12 | Canon Inc | 保持装置、リソグラフィ装置及び物品の製造方法 |

| WO2014095266A2 (en) * | 2012-12-17 | 2014-06-26 | Asml Netherlands B.V. | Substrate support for a lithographic apparatus and lithographic apparatus |

| NL2012204A (en) * | 2013-02-07 | 2014-12-18 | Asml Holding Nv | Lithographic apparatus and method. |

| US10216095B2 (en) | 2013-08-30 | 2019-02-26 | Asml Netherlands B.V. | Immersion lithographic apparatus |

| US9541846B2 (en) | 2013-09-06 | 2017-01-10 | Taiwan Semiconductor Manufacturing Co., Ltd. | Homogeneous thermal equalization with active device |

| WO2015043890A1 (en) | 2013-09-27 | 2015-04-02 | Asml Netherlands B.V. | Support table for a lithographic apparatus, lithographic apparatus and device manufacturing method |

| JP6336275B2 (ja) * | 2013-12-26 | 2018-06-06 | キヤノン株式会社 | インプリント装置、および物品の製造方法 |

| CN103757591B (zh) * | 2013-12-31 | 2016-03-30 | 深圳市华星光电技术有限公司 | 一种坩埚设备及其在液晶面板生产中的应用 |

| US9575415B2 (en) * | 2014-05-22 | 2017-02-21 | Taiwan Semiconductor Manufacturing Company, Ltd. | Wafer stage temperature control |

| JP6371865B2 (ja) * | 2014-06-10 | 2018-08-08 | エーエスエムエル ネザーランズ ビー.ブイ. | リソグラフィ装置及びリソグラフィ装置を製造する方法 |

| NL2014792A (en) | 2014-06-16 | 2016-03-31 | Asml Netherlands Bv | Lithographic apparatus, method of transferring a substrate and device manufacturing method. |

| JP6525567B2 (ja) * | 2014-12-02 | 2019-06-05 | キヤノン株式会社 | インプリント装置及び物品の製造方法 |

| NL2016541A (en) * | 2015-04-21 | 2016-10-24 | Asml Netherlands Bv | Lithographic Apparatus. |

| CN107168015B (zh) * | 2016-02-29 | 2019-01-04 | 上海微电子装备(集团)股份有限公司 | 一种浸液限制机构及温度补偿方法 |

| JP2017183397A (ja) * | 2016-03-29 | 2017-10-05 | 株式会社東芝 | パターン転写装置及びパターン転写方法 |

| US9933314B2 (en) | 2016-06-30 | 2018-04-03 | Varian Semiconductor Equipment Associates, Inc. | Semiconductor workpiece temperature measurement system |

| WO2018006258A1 (en) * | 2016-07-05 | 2018-01-11 | Shenzhen Xpectvision Technology Co., Ltd. | Bonding materials of dissimilar coefficients of thermal expansion |

| NL2019362A (en) * | 2016-09-02 | 2018-03-06 | Asml Netherlands Bv | Lithographic Apparatus |

| KR102499301B1 (ko) * | 2016-11-15 | 2023-02-10 | 에이에스엠엘 네델란즈 비.브이. | 방사선 분석 시스템 |

| US10503085B2 (en) * | 2017-11-16 | 2019-12-10 | Taiwan Semiconductor Manufacturing Co., Ltd. | Lithography apparatus and method |

| KR102511272B1 (ko) * | 2018-02-23 | 2023-03-16 | 삼성전자주식회사 | 노광 장치 및 이를 이용하는 반도체 장치의 제조 방법 |

| KR101924174B1 (ko) * | 2018-04-04 | 2019-02-22 | (주)유티아이 | 근적외선 필터 및 그 필터의 제조방법 |

| JP7034825B2 (ja) * | 2018-05-16 | 2022-03-14 | 株式会社ニューフレアテクノロジー | 荷電粒子ビーム描画装置及び荷電粒子ビーム描画方法 |

| EP3899666A1 (en) * | 2018-12-21 | 2021-10-27 | ASML Holding N.V. | Reticle sub-field thermal control |

| US10788762B2 (en) * | 2019-02-25 | 2020-09-29 | Applied Materials, Inc. | Dynamic cooling control for thermal stabilization for lithography system |

| CN115023655A (zh) * | 2020-02-06 | 2022-09-06 | Asml荷兰有限公司 | 使用双平台光刻设备的方法以及光刻设备 |

| JP6842225B1 (ja) * | 2020-11-12 | 2021-03-17 | ハイソル株式会社 | チャックユニット及びチャックユニットの温度制御方法 |

| CN114264889B (zh) * | 2021-12-16 | 2023-07-21 | 中国工程物理研究院应用电子学研究所 | 一种高功率毫米波功率测量校准装置 |

| DE102021214981A1 (de) * | 2021-12-23 | 2023-06-29 | Carl Zeiss Smt Gmbh | Verfahren und trockenvorrichtung |

| WO2024170178A1 (en) * | 2023-02-13 | 2024-08-22 | Asml Netherlands B.V. | Gas supply module, fluid handling system, lithographic apparatus and device manufacturing method |

Family Cites Families (175)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE206607C (ja) | ||||

| DE242880C (ja) | ||||

| DE224448C (ja) | ||||

| DE221563C (ja) | ||||

| GB1242527A (en) * | 1967-10-20 | 1971-08-11 | Kodak Ltd | Optical instruments |

| US3573975A (en) * | 1968-07-10 | 1971-04-06 | Ibm | Photochemical fabrication process |

| US4213698A (en) * | 1978-12-01 | 1980-07-22 | Bell Telephone Laboratories, Incorporated | Apparatus and method for holding and planarizing thin workpieces |

| EP0023231B1 (de) | 1979-07-27 | 1982-08-11 | Tabarelli, Werner, Dr. | Optisches Lithographieverfahren und Einrichtung zum Kopieren eines Musters auf eine Halbleiterscheibe |

| FR2474708B1 (fr) | 1980-01-24 | 1987-02-20 | Dme | Procede de microphotolithographie a haute resolution de traits |

| JPS5754317A (en) * | 1980-09-19 | 1982-03-31 | Hitachi Ltd | Method and device for forming pattern |

| US4509852A (en) * | 1980-10-06 | 1985-04-09 | Werner Tabarelli | Apparatus for the photolithographic manufacture of integrated circuit elements |

| US4346164A (en) * | 1980-10-06 | 1982-08-24 | Werner Tabarelli | Photolithographic method for the manufacture of integrated circuits |

| US4390273A (en) * | 1981-02-17 | 1983-06-28 | Censor Patent-Und Versuchsanstalt | Projection mask as well as a method and apparatus for the embedding thereof and projection printing system |

| JPS57153433A (en) * | 1981-03-18 | 1982-09-22 | Hitachi Ltd | Manufacturing device for semiconductor |

| JPS57169244A (en) * | 1981-04-13 | 1982-10-18 | Canon Inc | Temperature controller for mask and wafer |

| DD160756A3 (de) * | 1981-04-24 | 1984-02-29 | Gudrun Dietz | Anordnung zur verbesserung fotochemischer umsetzungsprozesse in fotoresistschichten |

| JPS58202448A (ja) | 1982-05-21 | 1983-11-25 | Hitachi Ltd | 露光装置 |

| DD206607A1 (de) | 1982-06-16 | 1984-02-01 | Mikroelektronik Zt Forsch Tech | Verfahren und vorrichtung zur beseitigung von interferenzeffekten |

| DD242880A1 (de) | 1983-01-31 | 1987-02-11 | Kuch Karl Heinz | Einrichtung zur fotolithografischen strukturuebertragung |

| JPS59144127A (ja) | 1983-02-07 | 1984-08-18 | Canon Inc | 像調整された光学装置 |

| JPS6018680U (ja) | 1983-07-13 | 1985-02-08 | 愛知電機株式会社 | 無整流子電動機 |

| US4564284A (en) * | 1983-09-12 | 1986-01-14 | Canon Kabushiki Kaisha | Semiconductor exposure apparatus |

| DD221563A1 (de) | 1983-09-14 | 1985-04-24 | Mikroelektronik Zt Forsch Tech | Immersionsobjektiv fuer die schrittweise projektionsabbildung einer maskenstruktur |

| JPS60163046A (ja) | 1984-02-03 | 1985-08-24 | Nippon Kogaku Kk <Nikon> | 投影露光光学装置及び投影露光方法 |

| DD224448A1 (de) | 1984-03-01 | 1985-07-03 | Zeiss Jena Veb Carl | Einrichtung zur fotolithografischen strukturuebertragung |

| JPS6265326A (ja) | 1985-09-18 | 1987-03-24 | Hitachi Ltd | 露光装置 |

| JPS6265326U (ja) | 1985-10-16 | 1987-04-23 | ||

| JPS62121417A (ja) | 1985-11-22 | 1987-06-02 | Hitachi Ltd | 液浸対物レンズ装置 |

| JPS62121417U (ja) | 1986-01-24 | 1987-08-01 | ||

| JPS63157419A (ja) | 1986-12-22 | 1988-06-30 | Toshiba Corp | 微細パタ−ン転写装置 |

| JPH033222Y2 (ja) | 1986-12-23 | 1991-01-28 | ||

| JPH07106317B2 (ja) | 1987-02-13 | 1995-11-15 | 触媒化成工業株式会社 | 炭化水素油の接触分解用触媒組成物の製造方法 |

| US4825247A (en) | 1987-02-16 | 1989-04-25 | Canon Kabushiki Kaisha | Projection exposure apparatus |

| JPS63157419U (ja) | 1987-03-31 | 1988-10-14 | ||

| JPH01152639A (ja) | 1987-12-10 | 1989-06-15 | Canon Inc | 吸着保持装置 |

| US5040020A (en) * | 1988-03-31 | 1991-08-13 | Cornell Research Foundation, Inc. | Self-aligned, high resolution resonant dielectric lithography |

| FR2631165B1 (fr) * | 1988-05-05 | 1992-02-21 | Moulene Daniel | Support conditionneur de temperature pour petits objets tels que des composants semi-conducteurs et procede de regulation thermique utilisant ce support |

| EP0357423B1 (en) | 1988-09-02 | 1995-03-15 | Canon Kabushiki Kaisha | An exposure apparatus |

| JP2774574B2 (ja) * | 1989-05-30 | 1998-07-09 | キヤノン株式会社 | 露光装置 |

| EP0363098B1 (en) | 1988-10-03 | 1995-04-05 | Canon Kabushiki Kaisha | Temperature controlling device |

| US5231291A (en) | 1989-08-01 | 1993-07-27 | Canon Kabushiki Kaisha | Wafer table and exposure apparatus with the same |

| JPH03209479A (ja) | 1989-09-06 | 1991-09-12 | Sanee Giken Kk | 露光方法 |

| JPH03198320A (ja) | 1989-12-27 | 1991-08-29 | Nikon Corp | 投影光学装置 |

| JPH0428216A (ja) | 1990-05-23 | 1992-01-30 | Matsushita Electric Ind Co Ltd | 露光装置 |

| NL9002077A (nl) | 1990-09-22 | 1992-04-16 | Imec Inter Uni Micro Electr | Sensor. |

| US5142132A (en) | 1990-11-05 | 1992-08-25 | Litel Instruments | Adaptive optic wafer stepper illumination system |

| US5121256A (en) * | 1991-03-14 | 1992-06-09 | The Board Of Trustees Of The Leland Stanford Junior University | Lithography system employing a solid immersion lens |

| JPH04305915A (ja) | 1991-04-02 | 1992-10-28 | Nikon Corp | 密着型露光装置 |

| JPH04305917A (ja) | 1991-04-02 | 1992-10-28 | Nikon Corp | 密着型露光装置 |

| JP3210029B2 (ja) | 1991-06-11 | 2001-09-17 | キヤノン株式会社 | 画像処理装置及びその方法 |

| JP3218478B2 (ja) | 1992-09-04 | 2001-10-15 | 株式会社ニコン | 投影露光装置及び方法 |

| US5294778A (en) | 1991-09-11 | 1994-03-15 | Lam Research Corporation | CVD platen heater system utilizing concentric electric heating elements |

| US5402224A (en) | 1992-09-25 | 1995-03-28 | Nikon Corporation | Distortion inspecting method for projection optical system |

| JPH06124873A (ja) | 1992-10-09 | 1994-05-06 | Canon Inc | 液浸式投影露光装置 |

| JP2753930B2 (ja) | 1992-11-27 | 1998-05-20 | キヤノン株式会社 | 液浸式投影露光装置 |

| JP2520833B2 (ja) | 1992-12-21 | 1996-07-31 | 東京エレクトロン株式会社 | 浸漬式の液処理装置 |

| US6753948B2 (en) | 1993-04-27 | 2004-06-22 | Nikon Corporation | Scanning exposure method and apparatus |

| JPH0684757U (ja) | 1993-05-06 | 1994-12-02 | 太陽誘電株式会社 | 電源切替回路 |

| JPH07106317A (ja) | 1993-10-08 | 1995-04-21 | Sony Corp | 試料台 |

| JPH07220990A (ja) | 1994-01-28 | 1995-08-18 | Hitachi Ltd | パターン形成方法及びその露光装置 |

| US5612683A (en) * | 1994-08-26 | 1997-03-18 | Trempala; Dohn J. | Security key holder |

| JPH08124873A (ja) | 1994-10-24 | 1996-05-17 | Sony Corp | コンタクトホールの形成方法 |

| US5638687A (en) | 1994-11-21 | 1997-06-17 | Dainippon Screen Mfg. Co., Ltd. | Substrate cooling method and apparatus |

| JPH08316124A (ja) * | 1995-05-19 | 1996-11-29 | Hitachi Ltd | 投影露光方法及び露光装置 |

| JPH09270384A (ja) | 1996-03-29 | 1997-10-14 | Nikon Corp | 温度制御装置及び露光装置 |

| WO1998009278A1 (en) * | 1996-08-26 | 1998-03-05 | Digital Papyrus Technologies | Method and apparatus for coupling an optical lens to a disk through a coupling medium having a relatively high index of refraction |

| US5825043A (en) * | 1996-10-07 | 1998-10-20 | Nikon Precision Inc. | Focusing and tilting adjustment system for lithography aligner, manufacturing apparatus or inspection apparatus |

| JPH10189242A (ja) | 1996-12-20 | 1998-07-21 | Sanyo Electric Co Ltd | 波長変換型発光装置 |

| JP3612920B2 (ja) | 1997-02-14 | 2005-01-26 | ソニー株式会社 | 光学記録媒体の原盤作製用露光装置 |

| TW404063B (en) * | 1997-02-27 | 2000-09-01 | Toshiba Corp | Semiconductor integrated circuit apparatus and semiconductor memory apparatus |

| JPH10255319A (ja) | 1997-03-12 | 1998-09-25 | Hitachi Maxell Ltd | 原盤露光装置及び方法 |

| JP3849822B2 (ja) | 1997-04-07 | 2006-11-22 | 株式会社ニコン | リソク゛ラフィシステム |

| US6882403B1 (en) * | 1997-04-07 | 2005-04-19 | Nikon Corporation | Lithography system and method |

| JP3747566B2 (ja) | 1997-04-23 | 2006-02-22 | 株式会社ニコン | 液浸型露光装置 |

| JP3817836B2 (ja) | 1997-06-10 | 2006-09-06 | 株式会社ニコン | 露光装置及びその製造方法並びに露光方法及びデバイス製造方法 |

| US5900354A (en) * | 1997-07-03 | 1999-05-04 | Batchelder; John Samuel | Method for optical inspection and lithography |

| JPH11195602A (ja) | 1997-10-07 | 1999-07-21 | Nikon Corp | 投影露光方法及び装置 |

| KR19990034784A (ko) | 1997-10-30 | 1999-05-15 | 윤종용 | 노광장비의 척부 |

| JPH11176727A (ja) | 1997-12-11 | 1999-07-02 | Nikon Corp | 投影露光装置 |

| WO1999031717A1 (fr) | 1997-12-12 | 1999-06-24 | Nikon Corporation | Procede d'exposition par projection et graveur a projection |

| AU2747999A (en) | 1998-03-26 | 1999-10-18 | Nikon Corporation | Projection exposure method and system |

| JP3745167B2 (ja) * | 1998-07-29 | 2006-02-15 | キヤノン株式会社 | ステージ装置、露光装置およびデバイス製造方法ならびにステージ駆動方法 |

| JP2000058436A (ja) | 1998-08-11 | 2000-02-25 | Nikon Corp | 投影露光装置及び露光方法 |

| US6623639B2 (en) * | 1999-03-19 | 2003-09-23 | Bend Research, Inc. | Solvent-resistant microporous polybenzimidazole membranes |

| KR200224439Y1 (ko) | 1999-04-16 | 2001-05-15 | 나재흠 | 파일직기에 있어서 침포롤러 |

| TWI242111B (en) * | 1999-04-19 | 2005-10-21 | Asml Netherlands Bv | Gas bearings for use in vacuum chambers and their application in lithographic projection apparatus |

| US6225224B1 (en) | 1999-05-19 | 2001-05-01 | Infineon Technologies Norht America Corp. | System for dispensing polishing liquid during chemical mechanical polishing of a semiconductor wafer |

| US6446355B1 (en) | 1999-05-27 | 2002-09-10 | Lam Research Corporation | Disk drying apparatus and method |

| US6322626B1 (en) * | 1999-06-08 | 2001-11-27 | Micron Technology, Inc. | Apparatus for controlling a temperature of a microelectronics substrate |

| JP4504479B2 (ja) | 1999-09-21 | 2010-07-14 | オリンパス株式会社 | 顕微鏡用液浸対物レンズ |

| JP2001118783A (ja) | 1999-10-21 | 2001-04-27 | Nikon Corp | 露光方法及び装置、並びにデバイス製造方法 |

| JP2001272604A (ja) * | 2000-03-27 | 2001-10-05 | Olympus Optical Co Ltd | 液浸対物レンズおよびそれを用いた光学装置 |

| JP3870002B2 (ja) * | 2000-04-07 | 2007-01-17 | キヤノン株式会社 | 露光装置 |

| JP3531914B2 (ja) | 2000-04-14 | 2004-05-31 | キヤノン株式会社 | 光学装置、露光装置及びデバイス製造方法 |

| JP3859937B2 (ja) * | 2000-06-02 | 2006-12-20 | 住友大阪セメント株式会社 | 静電チャック |

| US6699630B2 (en) | 2000-07-07 | 2004-03-02 | Nikon Corporation | Method and apparatus for exposure, and device manufacturing method |

| TW591653B (en) * | 2000-08-08 | 2004-06-11 | Koninkl Philips Electronics Nv | Method of manufacturing an optically scannable information carrier |

| KR100866818B1 (ko) * | 2000-12-11 | 2008-11-04 | 가부시키가이샤 니콘 | 투영광학계 및 이 투영광학계를 구비한 노광장치 |

| JP4606600B2 (ja) * | 2001-01-09 | 2011-01-05 | 東京エレクトロン株式会社 | 処理空気供給装置及び方法 |

| WO2002091078A1 (en) * | 2001-05-07 | 2002-11-14 | Massachusetts Institute Of Technology | Methods and apparatus employing an index matching medium |

| US6954255B2 (en) | 2001-06-15 | 2005-10-11 | Canon Kabushiki Kaisha | Exposure apparatus |

| JP4302376B2 (ja) | 2001-09-03 | 2009-07-22 | 東京エレクトロン株式会社 | 液処理方法及び液処理装置 |

| US6600547B2 (en) * | 2001-09-24 | 2003-07-29 | Nikon Corporation | Sliding seal |

| US6696887B2 (en) | 2001-09-27 | 2004-02-24 | Matthew S. Taubman | Transistor-based interface circuitry |

| CN1791839A (zh) * | 2001-11-07 | 2006-06-21 | 应用材料有限公司 | 光点格栅阵列光刻机 |

| JP4028216B2 (ja) | 2001-11-19 | 2007-12-26 | 大日本印刷株式会社 | 減容化可能なボトル |

| JP2003195476A (ja) | 2001-12-27 | 2003-07-09 | Toshiba Corp | パターン形成装置およびパターン形成方法 |

| DE10210899A1 (de) * | 2002-03-08 | 2003-09-18 | Zeiss Carl Smt Ag | Refraktives Projektionsobjektiv für Immersions-Lithographie |

| DE10229818A1 (de) * | 2002-06-28 | 2004-01-15 | Carl Zeiss Smt Ag | Verfahren zur Fokusdetektion und Abbildungssystem mit Fokusdetektionssystem |

| US7362508B2 (en) | 2002-08-23 | 2008-04-22 | Nikon Corporation | Projection optical system and method for photolithography and exposure apparatus and method using same |

| JP3767815B2 (ja) * | 2002-08-26 | 2006-04-19 | 京楽産業株式会社 | メダル研磨装置 |

| US6788477B2 (en) * | 2002-10-22 | 2004-09-07 | Taiwan Semiconductor Manufacturing Co., Ltd. | Apparatus for method for immersion lithography |

| SG121822A1 (en) | 2002-11-12 | 2006-05-26 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| DE60335595D1 (de) | 2002-11-12 | 2011-02-17 | Asml Netherlands Bv | Lithographischer Apparat mit Immersion und Verfahren zur Herstellung einer Vorrichtung |

| JP3953460B2 (ja) | 2002-11-12 | 2007-08-08 | エーエスエムエル ネザーランズ ビー.ブイ. | リソグラフィ投影装置 |

| EP1420300B1 (en) | 2002-11-12 | 2015-07-29 | ASML Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| CN101470360B (zh) | 2002-11-12 | 2013-07-24 | Asml荷兰有限公司 | 光刻装置和器件制造方法 |

| EP1420298B1 (en) | 2002-11-12 | 2013-02-20 | ASML Netherlands B.V. | Lithographic apparatus |

| SG2010050110A (en) * | 2002-11-12 | 2014-06-27 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| SG131766A1 (en) | 2002-11-18 | 2007-05-28 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| TWI255971B (en) | 2002-11-29 | 2006-06-01 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| DE10258718A1 (de) * | 2002-12-09 | 2004-06-24 | Carl Zeiss Smt Ag | Projektionsobjektiv, insbesondere für die Mikrolithographie, sowie Verfahren zur Abstimmung eines Projektionsobjektives |

| KR101157002B1 (ko) | 2002-12-10 | 2012-06-21 | 가부시키가이샤 니콘 | 노광 장치 및 디바이스 제조 방법 |

| WO2004053951A1 (ja) | 2002-12-10 | 2004-06-24 | Nikon Corporation | 露光方法及び露光装置並びにデバイス製造方法 |

| KR101036114B1 (ko) | 2002-12-10 | 2011-05-23 | 가부시키가이샤 니콘 | 노광장치 및 노광방법, 디바이스 제조방법 |

| KR20110086130A (ko) * | 2002-12-10 | 2011-07-27 | 가부시키가이샤 니콘 | 노광 장치 및 디바이스 제조 방법 |

| DE10257766A1 (de) | 2002-12-10 | 2004-07-15 | Carl Zeiss Smt Ag | Verfahren zur Einstellung einer gewünschten optischen Eigenschaft eines Projektionsobjektivs sowie mikrolithografische Projektionsbelichtungsanlage |

| TW200421444A (en) | 2002-12-10 | 2004-10-16 | Nippon Kogaku Kk | Optical device and projecting exposure apparatus using such optical device |

| SG150388A1 (en) | 2002-12-10 | 2009-03-30 | Nikon Corp | Exposure apparatus and method for producing device |

| WO2004053952A1 (ja) | 2002-12-10 | 2004-06-24 | Nikon Corporation | 露光装置及びデバイス製造方法 |

| JP4352874B2 (ja) | 2002-12-10 | 2009-10-28 | 株式会社ニコン | 露光装置及びデバイス製造方法 |

| SG152063A1 (en) | 2002-12-10 | 2009-05-29 | Nikon Corp | Exposure apparatus and method for producing device |

| AU2003289272A1 (en) | 2002-12-10 | 2004-06-30 | Nikon Corporation | Surface position detection apparatus, exposure method, and device porducing method |

| EP1429190B1 (en) * | 2002-12-10 | 2012-05-09 | Canon Kabushiki Kaisha | Exposure apparatus and method |

| JP4232449B2 (ja) | 2002-12-10 | 2009-03-04 | 株式会社ニコン | 露光方法、露光装置、及びデバイス製造方法 |

| EP1573730B1 (en) * | 2002-12-13 | 2009-02-25 | Koninklijke Philips Electronics N.V. | Liquid removal in a method and device for irradiating spots on a layer |

| EP1732075A3 (en) | 2002-12-19 | 2007-02-21 | Koninklijke Philips Electronics N.V. | Method and device for irradiating spots on a layer |

| EP1579435B1 (en) | 2002-12-19 | 2007-06-27 | Koninklijke Philips Electronics N.V. | Method and device for irradiating spots on a layer |

| EP1431825A1 (en) * | 2002-12-20 | 2004-06-23 | ASML Netherlands B.V. | Lithographic apparatus, device manufacturing method, and substrate holder |

| US6781670B2 (en) * | 2002-12-30 | 2004-08-24 | Intel Corporation | Immersion lithography |

| KR101181688B1 (ko) * | 2003-03-25 | 2012-09-19 | 가부시키가이샤 니콘 | 노광 장치 및 디바이스 제조 방법 |

| DE602004020200D1 (de) * | 2003-04-07 | 2009-05-07 | Nippon Kogaku Kk | Belichtungsgerät und verfahren zur herstellung einer vorrichtung |

| CN104597717B (zh) | 2003-04-10 | 2017-09-05 | 株式会社尼康 | 包括用于沉浸光刻装置的真空清除的环境系统 |

| TWI295414B (en) | 2003-05-13 | 2008-04-01 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| KR20060009956A (ko) | 2003-05-28 | 2006-02-01 | 가부시키가이샤 니콘 | 노광 방법, 노광 장치, 및 디바이스 제조 방법 |

| JP5143331B2 (ja) | 2003-05-28 | 2013-02-13 | 株式会社ニコン | 露光方法及び露光装置、並びにデバイス製造方法 |

| US6867844B2 (en) | 2003-06-19 | 2005-03-15 | Asml Holding N.V. | Immersion photolithography system and method using microchannel nozzles |

| US6809794B1 (en) | 2003-06-27 | 2004-10-26 | Asml Holding N.V. | Immersion photolithography system and method using inverted wafer-projection optics interface |

| SG109000A1 (en) | 2003-07-16 | 2005-02-28 | Asml Netherlands Bv | Lithographic apparatus and device manufacturing method |

| US7326522B2 (en) | 2004-02-11 | 2008-02-05 | Asml Netherlands B.V. | Device manufacturing method and a substrate |

| US6954256B2 (en) | 2003-08-29 | 2005-10-11 | Asml Netherlands B.V. | Gradient immersion lithography |

| US7545481B2 (en) | 2003-11-24 | 2009-06-09 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| US7589818B2 (en) | 2003-12-23 | 2009-09-15 | Asml Netherlands B.V. | Lithographic apparatus, alignment apparatus, device manufacturing method, and a method of converting an apparatus |

| US7394521B2 (en) | 2003-12-23 | 2008-07-01 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| JP4429023B2 (ja) * | 2004-01-07 | 2010-03-10 | キヤノン株式会社 | 露光装置及びデバイス製造方法 |

| DE602005019689D1 (de) * | 2004-01-20 | 2010-04-15 | Zeiss Carl Smt Ag | Belichtungsvorrichtung und messeinrichtung für eine projektionslinse |

| JP5167572B2 (ja) | 2004-02-04 | 2013-03-21 | 株式会社ニコン | 露光装置、露光方法及びデバイス製造方法 |

| WO2005076324A1 (ja) | 2004-02-04 | 2005-08-18 | Nikon Corporation | 露光装置、露光方法及びデバイス製造方法 |

| US7050146B2 (en) | 2004-02-09 | 2006-05-23 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| JP4479269B2 (ja) * | 2004-02-20 | 2010-06-09 | 株式会社ニコン | 露光装置及びデバイス製造方法 |

| JP4510494B2 (ja) * | 2004-03-29 | 2010-07-21 | キヤノン株式会社 | 露光装置 |

| US7561251B2 (en) * | 2004-03-29 | 2009-07-14 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| US20050229854A1 (en) * | 2004-04-15 | 2005-10-20 | Tokyo Electron Limited | Method and apparatus for temperature change and control |

| JP2005310933A (ja) * | 2004-04-20 | 2005-11-04 | Nikon Corp | 基板保持部材、露光装置及びデバイス製造方法 |

| US7501226B2 (en) * | 2004-06-23 | 2009-03-10 | Taiwan Semiconductor Manufacturing Co., Ltd. | Immersion lithography system with wafer sealing mechanisms |

| US8769126B2 (en) * | 2004-06-24 | 2014-07-01 | International Business Machines Corporation | Expanded membership access control in a collaborative environment |

| JP2006013130A (ja) * | 2004-06-25 | 2006-01-12 | Nikon Corp | 露光装置、露光方法、及びデバイスの製造方法 |

| US20060001851A1 (en) * | 2004-07-01 | 2006-01-05 | Grant Robert B | Immersion photolithography system |

| US7304715B2 (en) * | 2004-08-13 | 2007-12-04 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| US7532310B2 (en) | 2004-10-22 | 2009-05-12 | Asml Netherlands B.V. | Apparatus, method for supporting and/or thermally conditioning a substrate, a support table, and a chuck |

| US20060228632A1 (en) * | 2005-04-11 | 2006-10-12 | Boyer James L | Treated filler and process for producing |

| US7652746B2 (en) * | 2005-06-21 | 2010-01-26 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| US20070007316A1 (en) | 2005-07-08 | 2007-01-11 | John Witczak | Bicycle carrier |

| JP2010034605A (ja) | 2009-11-17 | 2010-02-12 | Canon Inc | 露光装置及びデバイス製造方法 |

| NL2007768A (en) * | 2010-12-14 | 2012-06-18 | Asml Netherlands Bv | Substrate holder, lithographic apparatus, device manufacturing method, and method of manufacturing a substrate holder. |

-

2004

- 2004-08-13 US US10/917,535 patent/US7304715B2/en not_active Expired - Lifetime

-

2005

- 2005-07-29 EP EP05254783A patent/EP1628161B1/en not_active Ceased

- 2005-08-08 SG SG200505017A patent/SG120255A1/en unknown

- 2005-08-08 SG SG200701400-4A patent/SG131107A1/en unknown

- 2005-08-12 CN CN2010101865871A patent/CN101923290B/zh active Active

- 2005-08-12 KR KR1020050074411A patent/KR100760317B1/ko active IP Right Grant

- 2005-08-12 CN CN2005101132352A patent/CN1746775B/zh active Active

- 2005-08-12 TW TW094127593A patent/TWI322929B/zh active

- 2005-08-12 JP JP2005233909A patent/JP4852278B2/ja active Active

- 2005-08-17 US US11/205,325 patent/US7804575B2/en not_active Expired - Lifetime

-

2009

- 2009-02-04 JP JP2009024156A patent/JP5275067B2/ja active Active

-

2010

- 2010-08-26 US US12/869,560 patent/US9268242B2/en not_active Expired - Fee Related

-

2011

- 2011-11-03 US US13/288,831 patent/US9188880B2/en active Active

- 2011-12-27 JP JP2011285516A patent/JP5699072B2/ja active Active

-

2013

- 2013-11-01 JP JP2013228111A patent/JP5699197B2/ja active Active

-

2015

- 2015-10-13 US US14/882,241 patent/US10254663B2/en active Active

-

2019

- 2019-04-05 US US16/376,535 patent/US10838310B2/en not_active Expired - Lifetime

-

2020

- 2020-11-13 US US17/098,073 patent/US11378893B2/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170008863A (ko) * | 2014-06-19 | 2017-01-24 | 에이에스엠엘 네델란즈 비.브이. | 리소그래피 장치, 대상물 위치설정 시스템 및 디바이스 제조 방법 |

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5699197B2 (ja) | リソグラフィ装置 | |

| JP5033854B2 (ja) | リソグラフィ装置 | |

| JP4495046B2 (ja) | リソグラフィ装置、照明システムを有する装置、投影システムを有する装置、リソグラフィ装置の光学要素およびデバイス製造方法 | |

| US7751027B2 (en) | Lithographic apparatus and device manufacturing method | |

| JP5529865B2 (ja) | 温度安定化システム、リソグラフィ投影装置、および温度制御方法 | |

| JP2008288300A (ja) | 静電吸着保持装置及びそれを有する露光装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20060904 |

|

| RD05 | Notification of revocation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7425 Effective date: 20070622 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20081104 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090204 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090901 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091201 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100701 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20100930 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20101005 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101224 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110926 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111024 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 4852278 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141028 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |