WO2010055926A1 - 成膜装置 - Google Patents

成膜装置 Download PDFInfo

- Publication number

- WO2010055926A1 WO2010055926A1 PCT/JP2009/069398 JP2009069398W WO2010055926A1 WO 2010055926 A1 WO2010055926 A1 WO 2010055926A1 JP 2009069398 W JP2009069398 W JP 2009069398W WO 2010055926 A1 WO2010055926 A1 WO 2010055926A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- gas

- separation

- region

- turntable

- nozzle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45523—Pulsed gas flow or change of composition over time

- C23C16/45525—Atomic layer deposition [ALD]

- C23C16/45544—Atomic layer deposition [ALD] characterized by the apparatus

- C23C16/45548—Atomic layer deposition [ALD] characterized by the apparatus having arrangements for gas injection at different locations of the reactor for each ALD half-reaction

- C23C16/45551—Atomic layer deposition [ALD] characterized by the apparatus having arrangements for gas injection at different locations of the reactor for each ALD half-reaction for relative movement of the substrate and the gas injectors or half-reaction reactor compartments

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45519—Inert gas curtains

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45563—Gas nozzles

- C23C16/45578—Elongated nozzles, tubes with holes

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45587—Mechanical means for changing the gas flow

- C23C16/45591—Fixed means, e.g. wings, baffles

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02225—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer

- H01L21/0226—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process

- H01L21/02263—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase

- H01L21/02271—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase deposition by decomposition or reaction of gaseous or vapour phase compounds, i.e. chemical vapour deposition

- H01L21/0228—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase deposition by decomposition or reaction of gaseous or vapour phase compounds, i.e. chemical vapour deposition deposition by cyclic CVD, e.g. ALD, ALE, pulsed CVD

Definitions

- the present invention relates to a membrane device.

- a first reactive gas is adsorbed on a surface of a semiconductor wafer (hereinafter simply referred to as “wafer”) as a substrate in a vacuum atmosphere, and then a gas supplied is a second reactive gas.

- wafer a semiconductor wafer

- a gas supplied is a second reactive gas.

- ALD Atomic Layer Deposition

- MLD Molecular Layer Deposition

- a high dielectric film used for a gate oxide film can be given.

- a silicon oxide film (SiO 2 film) for example, a Vista butylaminosilane (hereinafter referred to as “BTBAS”) gas or the like is used as the first reaction gas (or source gas).

- BBAS Vista butylaminosilane

- ozone gas or the like is used as the second reactive gas (or oxidizing gas).

- the film forming method described above has a problem that the gas replacement with the purge gas takes a long time and the number of cycles is, for example, several hundred times, so that there is a problem that the processing time is long. It is requested.

- the separation gas is supplied from the separation gas supply means, and the separation gas spreads on the rotary table on both sides in the rotation direction, and a separation space is formed in the separation region to prevent the reaction gases from mixing with each other. Is done. Then, the reaction gas supplied to the processing region is exhausted from an exhaust port provided in the vacuum vessel together with, for example, a separation gas spreading on both sides in the rotation direction. In this way, while supplying the processing gas in the processing region and the separation gas in the separation region, the wafer placed on the table by rotating the rotary table is transferred from one processing region to another processing region. Then, the ALD or MLD process is performed by repeatedly moving from one process area to another process area alternately.

- Such a film forming apparatus eliminates the need for gas replacement in the processing atmosphere as described above, and can form films on a plurality of substrates at the same time, so that high throughput is expected to be obtained.

- Patent Document 1 a flat cylindrical vacuum vessel is separated into left and right, and a separation gas discharge port is formed between the left semicircular contour and the right semicircular contour, that is, in the diameter region of the vacuum vessel.

- a film forming apparatus has been proposed.

- four wafers are arranged at an equal distance along a rotation direction on a wafer support member (or a rotary table), while the first reaction gas is opposed to the wafer support member.

- the apparatus has a configuration in which the discharge nozzle and the second reactive gas discharge nozzle are arranged at equal distances along the rotation direction, the separation gas nozzle is arranged between these nozzles, and the wafer support member is horizontally rotated to perform the film forming process. Proposed.

- the problem that the film formation rate on the substrate decreases as a result of the decrease in the concentration of the reaction gas and the contact time with the substrate in the processing region described later has not been recognized. This problem cannot be solved.

- Patent Documents 3, 4 and 5 in performing an atomic layer CVD method in which a plurality of gases are alternately adsorbed on a target (corresponding to a wafer), the susceptor on which the wafer is placed is rotated, An apparatus for supplying a source gas and a purge gas from above has been proposed.

- a partition wall extends radially from the center of the chamber, a gas outflow hole for supplying a reaction gas or a purge gas to the susceptor is provided under the partition wall, and an inert gas flows out from the gas outflow hole from the partition wall. It has been proposed to form a gas curtain.

- the problem that the film forming rate on the substrate by the separation gas decreases is not recognized, and this problem cannot be solved.

- Patent Document 6 proposes an ALD apparatus including a rotary table on which a plurality of wafers are arranged along the rotation direction, and a chamber upper portion facing the rotary table.

- a plurality of intake zones (or supply ports) that extend in the radial direction of the rotary table and supply different reaction gases are provided on the back surface of the upper portion of the chamber at intervals in the circumferential direction.

- Two exhaust zones (or exhaust ports) extending in the radial direction are provided between the mouths in the circumferential direction.

- the distance from the rotary table is equal between each intake zone and each discharge port, and is formed as a flat ceiling surface.

- each reaction gas supplied from each intake zone during the rotation of the rotary table flows through a gap between the ceiling surface and the rotary table, and is exhausted from an exhaust zone adjacent to the intake zone to which the reaction gas is supplied.

- the region where each reaction gas is supplied is partitioned to perform the ALD process or the MLD process.

- the exhaust zones adjacent to each other are close to each other, the reaction gases from each intake zone toward these exhaust zones are mixed with each other, and reaction by-products that cause particles are generated inside the chamber. It can happen.

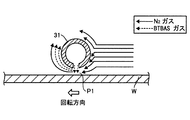

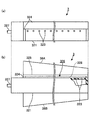

- FIG. 1 is a development view in which the apparatus is developed in a longitudinal direction in the rotation direction of the rotary table 2.

- reference numeral 31 denotes a first reactive gas nozzle which is a means for supplying BTBAS gas, and a region below the first gas nozzle 31 is configured as a first processing region P1.

- Reference numerals 41 and 42 denote separation gas nozzles as separation gas supply means.

- reaction gas nozzles and separation gas nozzles are formed on the turntable 2 so as to extend in the radial direction of the turntable 2, and BTBAS gas, which is a film forming gas, and separation gas along the radial direction downward.

- BTBAS gas which is a film forming gas, and separation gas along the radial direction downward.

- Each N 2 gas is discharged.

- the discharged N 2 gas is not directly exhausted from the separation region D, but is exhausted after going to the processing region. More specifically, the N 2 gas that flows from the separation region D toward the downstream side in the rotation direction of the turntable 2 as shown by the solid arrow in FIG. Passing over the upper portion of 31 and passing through a gap R provided between the reaction gas nozzle 31 and the ceiling surface 45 above the reaction gas nozzle 31, further to the outer position of the turntable 2 on the downstream side in the rotation direction from the reaction gas nozzle 31. The BTBAS gas discharged from the reaction gas nozzle 31 flows into the exhaust port provided and is exhausted.

- the present inventors have obtained the following knowledge as a result of studies on this apparatus.

- the rotational speed of the turntable 2 is low, it is considered that the BTBAS gas molecules are saturated below the gas nozzle 31 and are saturated and adsorbed to the wafer W.

- the turntable 2 is, for example, 120 rpm or more. Need to rotate at high speed.

- the rotational speed is increased in this way, as indicated by the solid line arrow in FIG. 2, the N 2 gas sinks below the reactive gas nozzle 31 due to an increase in the flow velocity, and the first processing region P1.

- the saturated adsorption of the BTBAS gas is not performed, and the amount of adsorption of the BTBAS molecules on the wafer W is proportional to the gas concentration and the contact time in the processing region P1.

- the gas concentration is reduced as described above, the adsorption amount of BTBAS gas molecules is reduced.

- the gas flow flowing toward a certain object has a property of flowing around to the back side where the pressure is low, assuming that the side of the object that receives the gas flow is the front side in terms of fluid dynamics. That is, the N 2 gas that flows toward the reaction gas nozzle 31 and sinks below the reaction gas nozzle 31 soars upward as viewed from the rotary table 2, and circulates downstream of the gas nozzle 31 in the rotation direction.

- the BTBAS gas discharged from the reaction gas nozzle 31 to the processing region P1 also rises upward from the turntable 2 in accordance with the flow of the N 2 gas.

- the BTBAS gas concentration in the region P1 is further lowered and the contact time of the BTBAS gas to the wafer W is shortened. As a result, the adsorption amount of BTBAS gas molecules is further reduced.

- the rotation speed of the turntable 2 is limited in order to increase the contact time of the reaction gas with the wafer W, to prevent the concentration of the reaction gas from decreasing, and to normally adsorb molecules contained in the reaction gas to the wafer W. Therefore, there is a possibility that the throughput cannot be sufficiently increased.

- the present invention has been made based on such circumstances, and one of its purposes is to sequentially supply a plurality of reaction gases that react with each other to the surface of a substrate in a vacuum vessel, and to produce a reaction product.

- a plurality of layers are stacked to form a thin film, and a first processing region to which a first reactive gas is provided along a circumferential direction of a turntable on which a substrate is placed is supplied, and a second reactive gas is supplied.

- Another object of the present invention is to provide a film forming apparatus capable of suppressing a decrease in film forming speed in a film forming apparatus provided with a second processing region and a separation region for separating the atmosphere of these processing regions.

- a film forming apparatus supplies at least two kinds of reaction gases that react with each other in a vacuum vessel in order to the surface of a substrate and executes this supply cycle, thereby generating a reaction product.

- a rotary table provided in the vacuum vessel, a substrate mounting area provided for mounting a substrate on the rotary table, and the rotary table

- the first reaction gas supply means and the second reaction for supplying the first reaction gas and the second reaction gas to the substrate, respectively, are fixedly provided above the turntable in the rotation direction of In order to separate the atmosphere of the gas supply means, the first processing region to which the first reaction gas is supplied, and the second processing region to which the second reaction gas is supplied, these processing regions in the rotation direction Between A separation region provided with a separation gas supply means for supplying a separation gas, and an exhaust port for evacuating the inside of the vacuum vessel, the first reaction gas supply means and the second reaction At least one of the gas supply

- the rectifying member may extend from the gas nozzle to both the upstream side and the downstream side, and each rectifying member has a larger width in the rotational direction, for example, at a portion away from the central portion side of the rotary table.

- the planar shape of the rectifying member may be formed in a fan shape.

- the separation area is located on both sides in the rotation direction of the separation gas supply means, for example, and a ceiling surface for forming a narrow space between the separation area and the turntable for the separation gas to flow from the separation area to the processing area side.

- a central region in which holes are formed may be provided.

- the central region is defined by the rotation central portion of the rotary table and the upper surface side of the vacuum vessel, and the separation gas is purged. is there.

- the exhaust port is provided so as to exhaust the reaction gas together with the separation gas diffusing on both sides of the separation region and the separation gas discharged from the central region.

- the exhaust ports may be provided on both sides of the separation region in the rotational direction when viewed in a plane in order to exhaust each reaction gas exclusively.

- the gas discharge holes of the separation gas supply means are arranged, for example, from one side to the other side of the rotation center portion and the peripheral portion of the rotary table, and the vacuum on the ceiling surface of the separation region A portion on the outer edge side of the container is bent so as to face the outer end surface of the turntable to form a part of the inner peripheral wall of the vacuum vessel, and a gap between the bent portion of the ceiling surface and the outer end surface of the turntable These may be set to dimensions that can prevent the invasion of reaction gas. Further, on the ceiling surface of the separation region, the upstream portion in the rotation direction of the rotary table relative to the separation gas supply means may be configured such that, for example, the portion located at the outer edge has a larger width in the rotation direction. Good.

- a film forming apparatus rotates a rotary table on which a plurality of substrates are placed in a vacuum vessel, and the substrates sequentially contact with reaction gases supplied to a plurality of different processing regions.

- a separation gas that is provided between the plurality of processing regions and prevents a different reaction gas from reacting in a space away from the substrate surface is provided.

- the height of the ceiling of the processing area from the surface of the substrate placed on the turntable may be formed higher than the ceiling of the separation area, and the height of the ceiling of the processing area in a plurality of different reaction areas. May be selectively determined according to the type of reaction gas supplied to the processing region and the amount of gas supplied.

- a gas nozzle that extends to intersect the moving direction of the substrate mounting area of the turntable and forms a reactive gas supply means that includes discharge holes formed along the length direction thereof;

- a rectifying member projecting from the gas nozzle toward at least one of the upstream side and the downstream side in the rotation direction of the turntable, and the rectifying member from one of the upstream side and the downstream side to the other side.

- the separation gas is guided to the flow space for allowing the separation gas to flow through the gas.

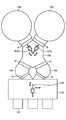

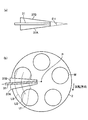

- FIG. 4 is a transverse plan view of the film forming apparatus of FIG. 3.

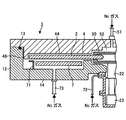

- FIG. 3 is a longitudinal cross-sectional view which shows an example of the process area

- a film forming apparatus includes a flat vacuum container 1 having a substantially circular planar shape as shown in FIG. 3 (a cross-sectional view taken along a line II ′ in FIG. 5 described later), A rotary table 2 provided in the vacuum vessel 1 and having a rotation center at the center of the vacuum vessel 1 is provided.

- the vacuum vessel 1 is configured such that the top plate 11 can be separated from the vessel body 12.

- the top plate 11 is pressed against the container main body 12 through a sealing member, for example, an O-ring 13 due to an internal decompression state, and maintains an airtight state.

- the top plate 11 is illustrated when the top plate 11 is separated from the container main body 12. It is lifted upward by a drive mechanism that does not.

- the rotary table 2 is fixed to a cylindrical core portion 21 at the center, and the core portion 21 is fixed to the upper end of a rotary shaft 22 extending in the vertical direction.

- the rotating shaft 22 penetrates the bottom surface portion 14 of the vacuum vessel 1 and its lower end is attached to a driving portion 23 that rotates the rotating shaft 22 around the vertical axis in this example in the clockwise direction.

- the rotating shaft 22 and the drive unit 23 are accommodated in a cylindrical case body 20 whose upper surface is open.

- a substrate placement area for placing a plurality of, for example, five wafers W along the rotation direction (or circumferential direction).

- a circular recess 24 is provided.

- the recess 24 is formed to have a diameter slightly larger than the diameter of the wafer W, and the wafer W is positioned and does not pop out due to the centrifugal force associated with the rotation of the turntable 2.

- the wafer W is drawn only in one recess 24 for convenience.

- the plurality of wafers W are placed on a common flat turntable 2, and when the wafer W is placed on the recess 24, the turntable 2 has a surface height of the wafer W and a surface of the turntable 2.

- the height is substantially the same.

- the substantially coincident height means that, for example, the difference between these heights is within 5 mm.

- FIG. 6 is a development view in which the rotary table 2 is cut along a concentric circle and expanded sideways.

- the recess 24 is formed so that the surface of the wafer and the surface of the turntable 2 (that is, the area on which the wafer is not placed) become substantially zero.

- the pressure fluctuation caused by the difference in height between the surface of W and the surface of the turntable 2 can be suppressed, and the in-plane uniformity of the film thickness can be made uniform.

- three elevating pins (described later) (see FIG. 12 described later) for supporting the back surface of the wafer W and moving the wafer W up and down and delivering the wafer W to and from the transfer mechanism 10.

- a penetrating through hole (not shown) is formed.

- the vacuum vessel 1 includes a first reactive gas nozzle 31, a second reactive gas nozzle 32, and two separated gas nozzles 41 at positions facing the passage area of the recess 24 in the rotary table 2.

- , 42 extend radially from the central portion at intervals from each other in the circumferential direction of the vacuum vessel 1 (the rotation direction of the rotary table 2).

- the reaction gas nozzles 31 and 32 and the separation gas nozzles 41 and 42 are attached to, for example, the side peripheral wall of the vacuum vessel 1, and the gas introduction ports 31 a, 32 a, 41 a, and 42 a, which are base ends thereof, pass through the side walls. Yes.

- the reaction gas nozzles 31 and 32 are respectively a gas supply source of BTBAS (Bistal Butylaminosilane) gas, which is a first reaction gas, and a gas supply source of O 3 (ozone) gas, which is a second reaction gas.

- the separation gas nozzles 41 and 42 are both connected to a gas supply source (not shown) of N 2 gas (nitrogen gas) which is a separation gas.

- N 2 gas nitrogen gas

- reaction gas nozzles 31, 32 discharge holes 33 for discharging the reaction gas are arranged on the lower side at intervals in the nozzle length direction.

- the diameter of the discharge port of each gas nozzle is 0.5 mm, and they are arranged at intervals of, for example, 10 mm along the length direction of each nozzle.

- the reaction gas nozzles 31 and 32 correspond to the first reaction gas supply unit and the second reaction gas supply unit, respectively, and the lower regions thereof are the first processing regions P1 and O 3 for adsorbing the BTBAS gas to the wafer W, respectively. It becomes the second processing region P2 for adsorbing the gas to the wafer W.

- the separation gas nozzles 41 and 42 are included in two separation regions D formed by the first ceiling surface 44, and each separation region D has a fan shape in plan view, and the rotation of the turntable 2. They are formed away from each other in the direction. Planar fan-shaped regions 48 and 49 are provided so as to be adjacent to these separation regions D. These regions 48 and 49 are hereinafter referred to as diffusion regions 48 and 49 in order to distinguish them from the names of other regions.

- the diffusion regions 48 and 49 are formed by the second ceiling surface 45 whose height from the turntable 2 is higher than the first ceiling surface 44 that forms the separation region D, and the processing regions P1 and P2. Are included in diffusion regions 48 and 49, respectively.

- the characteristics of reaction time, the rotational speed (or processing speed) of the rotary table 2, the size of the diffusion regions 48 and 49, that is, The length of the diffusion regions 48 and 49 in the rotation direction and the height position of the second ceiling surface 45 are appropriately designed.

- the reaction gas nozzles 31 and 32 are respectively provided in the central part in the rotational direction or on the upstream side in the rotational direction from the central part.

- the second reaction gas nozzle 42 rotates the diffusion region 49 as shown in FIG.

- the length of the diffusion region 49 provided upstream of the center of the direction and further including the second reaction gas nozzle 42 in the rotational direction is the length of the diffusion region 48 including the first reaction gas nozzle 41 in the rotation direction. Longer than that.

- the flow rate of the BTBAS gas from the first reaction gas nozzle 41 is set to, for example, 100 sccm, whereas the flow rate of O 3 gas from the second reaction gas nozzle 42 is set to, for example, 10000 sccm to ensure oxidation. Is set.

- the ceiling surface 45 of the diffusion region 49 is formed higher than the ceiling surface 45 of the diffusion region 48 in order to supply a relatively large flow rate of O 3 gas.

- FIG. 7A and 7B show an example in which the second ceiling surface 45 of each of the diffusion regions 48 and 49 is configured to have the same height, and the apparatus can be configured in this way. Good.

- FIG. 7B the flow of the separation gas is indicated by a solid arrow. 7, parts that are substantially the same as those in FIG. 6 are given the same reference numerals, and descriptions thereof are omitted.

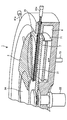

- the reactive gas nozzles 31 and 32 are provided with a nozzle cover 34 shown in FIG.

- the nozzle cover 34 includes a base portion 35 that extends along the length direction of the gas nozzles 31 and 32 and has a U-shaped longitudinal section.

- the base portion 35 covers the upper and side portions of the gas nozzles 31 and 32. Is done.

- the rectifying plate 36A and the rectifying plate 36B protrude in the horizontal direction from the left and right of the lower end of the base portion 35, that is, on the upstream side and the downstream side in the rotational direction of the turntable 2. As shown in FIGS.

- the plates 36 ⁇ / b> A and 36 ⁇ / b> B are formed so as to protrude from the base portion 35 toward the peripheral edge side from the center side of the turntable 2, and have a fan shape in plan view.

- the fan plates 36A and 36B forming the rectifying members are formed symmetrically with respect to the base portion 35, and the extended lines of the contour lines of the fan plates 36A and 36B shown by dotted lines in FIG.

- the angle (fan opening angle) ⁇ is, for example, 10 °.

- ⁇ is appropriately designed in consideration of the size in the circumferential direction of the separation region D to which N 2 gas is supplied and the size in the circumferential direction of the diffusion regions 48 and 49.

- ⁇ is 5 ° or more and 90 °. Is less than.

- the nozzle cover 34 has a fan table 36 ⁇ / b> A, 36 ⁇ / b> B whose front end side (or narrow side) is close to the protruding portion 5 and whose rear end side (or wide side) is a rotary table. It is provided so as to face the outer edge of 2. Further, the nozzle cover 34 is provided so as to be separated from the separation region D and between the second ceiling surface 45 via a gap R which is a gas flow space.

- the flow of each gas on the turntable 2 is indicated by dotted arrows, and as shown in FIG. 6, the gap R is a flow path for N 2 gas from the separation region D toward the processing regions P 1 and P 2. I am doing.

- the height of the gap R in the diffusion region 48 (the region where the reaction gas nozzle 31 is disposed) indicated by h3 in FIG. 6 is, for example, 10 mm to 70 mm, and the diffusion region 49 (the reaction gas nozzle 32 is disposed) indicated by h5.

- the height of the gap R in the region is, for example, 10 mm to 100 mm.

- the height from the surface of the wafer W to the second ceiling surface 45 in the diffusion region 48 indicated by h3 ′ is 15 to 100 mm, for example, 32 mm, and the wafer in the diffusion region 49 indicated by h5 ′.

- the height from the surface of W to the second ceiling surface 45 is, for example, 15 mm to 150 mm.

- the heights h3 and h5 of the gap R can be appropriately changed depending on the gas type and process conditions, and the separation gas (or N 2 gas) from the nozzle cover 34 is guided to the gap R for processing.

- the size is set such that the rectification effect for suppressing the flow into the regions P1 and P2 is as effective as possible.

- the heights h3 and h5 are preferably equal to or higher than the heights of the rotary table 2 and the lower ends of the gas nozzles 31 and 32.

- the lower surfaces of the fan plates 36A and 36B of the nozzle cover 34 are formed at the same height as the lower ends of the discharge ports 33 of the reaction gas nozzles 31 and 32.

- the height of fan plates 36A and 36B from the surface of turntable 2 (or the surface of wafer W) is 0.5 mm to 4 mm.

- the height h4 is not limited to 0.5 mm to 4 mm, but the N 2 gas is guided to the gap R as described above, and the reaction gas concentration in the processing regions P1 and P2 is processed on the wafer W. It may be set to a height that can secure a sufficient concentration so that, for example, 0.2 mm to 10 mm may be used.

- the fan plates 36A and 36B of the nozzle cover 34 reduce the flow rate of the N 2 gas entering from the separation region D below the gas nozzles 31 and 32, as will be described later, and are supplied from the reaction gas nozzles 31 and 32, respectively. It has a role of restricting and preventing the BTBAS gas and O 3 gas from rising from the turntable 2, and if it can fulfill this role, it is not limited to being provided at the position shown here.

- the rotation speed increases from the rotation center toward the peripheral edge of the rotary table 2.

- the same flow rate of gas is supplied to the central side of the rotating rotary table and the peripheral edge side.

- the gas concentration on the peripheral edge side tends to be lower than that on the central side.

- the reaction gas nozzles 31 and 32 and the separation gas nozzles 41 and 42 are provided so as to extend from the outer peripheral side of the vacuum vessel 1 toward the rotation center of the rotary table 2 and are separated into the nozzles from the outer peripheral side. Gas and reaction gas are supplied.

- the flow rate can be increased toward the peripheral edge side of the rotary table 2 if, for example, the diameters of the gas holes are the same in the length direction.

- the diameter of the gas hole of each nozzle it is preferable at the point which can form such a discharge flow rate distribution easily.

- Such a discharge flow rate distribution in the length direction of the nozzle is preferable in that it can suppress a decrease in gas concentration on the peripheral edge side, and the gas concentration in the length direction of the turntable 2 can be made uniform.

- the fan plates 36A and 36B extend in the rotation direction of the rotary table, and the fan plates 36A and 36B are below the fan plates 36A and 36B. It is possible to reduce the flow rate of the N 2 gas that sinks into the gas and to improve the concentration of the reaction gas below the fan plates 36A and 36B. Further, by adjusting the length of the fan plates 36A and 36B in the rotation direction, the area of the area for controlling the concentration of the reaction gas and the amount of N 2 gas guided to the gap R can be adjusted.

- discharge holes 40 for discharging the separation gas are formed on the lower side at intervals in the length direction.

- the diameter of the discharge port of each gas nozzle is 0.5 mm.

- the nozzles are arranged at intervals of 10 mm along the length direction of each nozzle.

- These separation gas nozzles 41 and 42 are for forming a separation region D for separating the first processing region P1 and the second processing region P2, and the top of the vacuum vessel 1 in the separation region D.

- the plate 11 is formed by dividing a circle drawn around the rotation center of the turntable 2 and along the vicinity of the inner peripheral wall of the vacuum vessel 1 in the circumferential direction.

- a convex portion 4 having a sector shape and protruding downward is provided.

- the separation gas nozzles 41 and 42 are accommodated in a groove 43 formed so as to extend in the radial direction of the circle at the circumferential center of the circle in the convex portion 4.

- the distance from the central axis of the separation gas nozzle 41 (or 42) to the fan-shaped edges (the upstream edge and the downstream edge in the rotation direction) of the convex portion 4 is set to the same length.

- the groove portion 43 is formed so as to bisect the convex portion 4.

- the upstream side in the rotational direction of the rotary table 2 in the convex portion 4 is the rotational direction. It may be formed so as to be wider than the downstream side.

- a flat low ceiling surface 44 (or a first ceiling surface) that is a lower surface of the convex portion 4 exists on both sides in the circumferential direction of the separation gas nozzles 41 and 42, and both sides of the ceiling surface 44 in the circumferential direction are present.

- the ceiling surface 45 (or the second ceiling surface) higher than the ceiling surface 44 exists, and these constitute the lower surface of the top plate 11.

- the role of the convex portion 4 is a separation space that is a narrow space for preventing the first reactive gas and the second reactive gas from entering the rotary table 2 to prevent the mixing of the reactive gases. Is to form.

- the O 3 gas is prevented from entering from the upstream side in the rotation direction of the turntable 2, and the BTBAS gas is prevented from entering from the downstream side in the rotation direction.

- Preventing gas intrusion means that the N 2 gas, which is the separation gas discharged from the separation gas nozzle 41, diffuses between the first ceiling surface 44 and the surface of the turntable 2. It blows out to the space below the 2nd ceiling surface 45 adjacent to the 1 ceiling surface 44, and this means that the gas from the said adjacent space cannot penetrate

- the "gas can not be penetration” does not mean only if it can not completely penetrate the lower side space of the convex portion 4 from the adjacent space, although somewhat invading, O 3 were respectively entering from both sides This also means a case where a state in which the gas and the BTBAS gas are not mixed in the convex portion 4 is ensured. As long as such an action is obtained, the atmosphere of the first processing region P1 which is the role of the separation region D and the first The separation effect from the atmosphere of the second processing region P2 can be exhibited.

- the degree of narrowing in the narrow space is the pressure between the narrow space (that is, the space below the convex portion 4) and the area adjacent to the space (that is, the space below the second ceiling surface 45 in this example). It can be said that the difference is set to a size that can ensure the effect of “the gas cannot enter”, and the specific dimensions thereof vary depending on the area of the convex portion 4 and the like. Further, the gas adsorbed on the wafer can naturally pass through the separation region D, and the prevention of gas intrusion means the gas in the gas phase.

- the separation gas is not limited to N 2 gas, and the type of gas is not particularly limited as long as it does not affect the film forming process.

- a protruding portion 5 is provided so as to face a portion on the outer peripheral side of the core portion 21 in the rotary table 2 and along the outer periphery of the core portion 21.

- the projecting portion 5 is formed continuously with the portion on the rotation center side of the convex portion 4, and the lower surface thereof is formed at the same height as the lower surface (ceiling surface 44) of the convex portion 4.

- 4 and 5 show the top plate 11 cut horizontally at a position lower than the second ceiling surface 45 and higher than the separation gas nozzles 41 and 42.

- the protrusion part 5 and the convex-shaped part 4 are not necessarily restricted to integral, The separate body may be sufficient.

- the convex portion 4 has a circumferential length (that is, the rotary table 2) at the boundary portion with the protruding portion 5 that is 140 mm away from the rotation center.

- the length of the circular arc of concentric circles) is, for example, 146 mm

- the circumferential length is, for example, 502 mm at the outermost portion of the wafer mounting area (that is, the recess 24).

- the circumferential length L of the convex portion 4 located on the left and right sides from both sides of the separation gas nozzle 41 (or 42) is 246 mm. As shown in FIG.

- the height h1 of the lower surface of the convex portion 4 from the surface of the turntable 2 on the ceiling surface 44 is, for example, 0.5 mm to 4 mm, and the turntable from the lower end of the separation gas nozzle 41 (or 42).

- the height h2 to the surface of 2 is 0.5 mm to 4 mm.

- FIGS. 4 and 9 show respective longitudinal sections of the region where the high second ceiling surface 45 and the low first ceiling surface 44 are provided.

- the peripheral edge portion of the fan-shaped convex portion 4 (that is, the portion on the outer edge side of the vacuum vessel 1) is L-shaped so as to face the outer end surface of the rotary table 2.

- a bent portion 46 is formed by bending.

- the bent portion 46 is also provided for the purpose of preventing the reaction gas from entering from both sides in the same manner as the convex portion 4 and preventing the mixture of both reaction gases.

- the inner peripheral surface of the bent portion 46 and the rotary table are provided. 2 and the gap between the outer peripheral surface of the bent portion 46 and the container body 12 are set to the same dimensions as the height h1 of the ceiling surface 44 with respect to the surface of the turntable 2.

- the inner peripheral wall of the container main body 12 is formed in a vertical plane close to the outer peripheral surface of the bent portion 46 as shown in FIG. 8, but in a portion other than the separation region D, FIG.

- the vertical cross-sectional shape is cut out in a rectangular shape from the portion facing the outer end surface of the turntable 2 to the bottom surface portion 14 and is recessed outward. If this recessed portion is called an exhaust region 6, for example, two exhaust ports 61 and 62 are provided at the bottom of the exhaust region 6 as shown in FIGS. These exhaust ports 61 and 62 are respectively connected to a common vacuum pump 64 which is a vacuum exhaust means via an exhaust pipe 63.

- a common vacuum pump 64 which is a vacuum exhaust means via an exhaust pipe 63.

- reference numeral 65 denotes a pressure adjusting means, which may be provided for each of the exhaust ports 61 and 62 or may be shared. With such a structure, an exhaust flow toward the outside of the turntable 2 can be formed, and the gas supplied to the vacuum vessel 1 can be exhausted.

- the exhaust ports 61 and 62 are not limited to opening downward, but open upward or sideward. It may be a simple configuration. Further, when the exhaust port is provided in the inner region from the peripheral end of the turntable 2, the exhaust port may be provided so as to open upward or laterally. However, in consideration of suppressing the generation of particles, the downward opening is provided. It is preferable. Further, the normal vacuum vessel 1 is provided at an upper position away from the floor, for example, in order to easily perform maintenance or the like. Therefore, when the exhaust ports 61 and 62 are opened downward, the exhaust pipe 63 can also be drawn downward, and the pipe 63 can be routed to the space between the floor and the vacuum vessel 1. The installation space can be reduced.

- the exhaust port 61 (or 62) or a portion for exhausting more gas in the vacuum vessel 1 corresponding to the exhaust port is located downstream of the reaction gas nozzle 31 (or 32) in the rotation direction of the turntable 2. Further, the position is preferably in the diffusion region 48 (or 49) including the reactive gas nozzle 31 (or 32) or on the outer peripheral side of the diffusion region 48 (or 49). With such an arrangement, it is possible to prevent the reaction gas from flowing backward with respect to the rotation direction or toward the inner peripheral side without going to the outer peripheral side of the turntable 2. Further, the separation gas smoothly flows into the exhaust ports 61 and 62 through the gap R by the rectifying action of the fan plates 36A and 36B.

- the exhaust ports 61 and 62 are provided in the exhaust region 6, respectively.

- the exhaust region 6 is disposed on the radially outer side of the turntable 2 in the first and second diffusion regions 48 and 49, but is not provided on the radially outer side of the turntable 2 in the separation region D. . Therefore, due to the rectifying action of the fan plates 36A and 36B and the arrangement of the exhaust ports 61 and 62, the gases supplied from the gas nozzles smoothly flow into the exhaust ports 61 and 62 and diffuse on the rotary table 2. In the regions 48 and 49, a flow is formed in which the first and second reaction gases are separated.

- the exhaust ports 61 and 62 are provided on both sides in the rotational direction of the separation region D when viewed in a plane so that the separation action of the separation region D works reliably, and each reaction gas (BTBAS gas and O 3 gas). Is exhausted exclusively.

- the exhaust port 61 is provided between the first reaction gas nozzle 31 and the separation region D adjacent to the reaction gas nozzle 31 on the downstream side in the rotation direction, and the exhaust port 62 is connected to the second reaction gas nozzle 32 and the reaction gas. It is provided between the separation region D adjacent to the gas nozzle 32 on the downstream side in the rotation direction.

- the exhaust port 61 may be provided between the first reactive gas nozzle 31 and the separation region D adjacent to the reactive gas nozzle 31 on the upstream side in the rotation direction, and the exhaust port 62 may The reaction gas nozzle 32 and the separation region D adjacent to the reaction gas nozzle 32 on the upstream side in the rotation direction may be provided.

- a heater unit 7 is provided in the space between the turntable 2 and the bottom surface portion 14 of the vacuum vessel 1, and the temperature on the wafer on the turntable 2 is determined by a process recipe.

- reference numeral 71 denotes a cover member whose upper edge is bent outward and formed into a flange shape, and prevents gas from entering the inside from the outside.

- the bottom surface portion 14 in the portion closer to the rotation center than the space where the heater unit 7 is disposed is near the center portion of the lower surface of the turntable 2 and is close to the core portion 21, and the space therebetween is narrow.

- reference numeral 73 denotes a purge gas supply pipe for purging the arrangement space of the heater unit 7.

- the flow of purge gas is indicated by arrows, and the space from the inside of the case body 20 to the arrangement space of the heater unit 7 is purged with N 2 gas, and this purge gas is interposed between the rotary table 2 and the cover member 71.

- the air is exhausted from the gap to the exhaust ports 61 and 62 through the exhaust region 6. This prevents the BTBAS gas or the O 3 gas from flowing from one of the first processing region P1 and the second processing region P2 described above to the other through the lower part of the turntable 2, so that this purge gas is It also plays the role of separation gas.

- a separation gas supply pipe 51 is connected to the center of the top plate 11 of the vacuum vessel 1 so that N 2 gas as separation gas is supplied to a space 52 between the top plate 11 and the core portion 21. It is configured.

- the separation gas supplied to the space 52 is discharged toward the periphery along the surface of the turntable 2 on the wafer mounting region side through a narrow gap 50 between the protruding portion 5 and the turntable 2. Since the space surrounded by the protrusion 5 is filled with the separation gas, the reaction gas (BTBAS gas) is interposed between the first processing region P1 and the second processing region P2 via the center of the turntable 2. Alternatively, mixing of O 3 gas) is prevented.

- this film forming apparatus is partitioned by the rotation center portion of the turntable 2 and the vacuum vessel 11 in order to separate the atmosphere of the first processing region P1 and the second processing region P2, and the separation gas is purged.

- the discharge port for discharging the separation gas on the surface of the turntable 2 includes the central region C formed along the rotation direction.

- the discharge port here corresponds to a narrow gap 50 between the protruding portion 5 and the rotary table 2.

- a transfer port 15 for transferring a wafer between the external transfer arm 10 and the rotary table 2 is formed on the side wall of the vacuum container 1.

- the port 15 is opened and closed by a gate valve (not shown).

- the film forming apparatus of this embodiment is provided with a control unit 100 including a computer for controlling the operation of the entire apparatus, and a program for operating the apparatus is stored in the memory of the control unit 100. ing.

- This program has a set of steps so as to execute the operation of the apparatus described later, and is installed in the control unit 100 from a storage medium such as a hard disk, a compact disk, a magneto-optical disk, a memory card, or a flexible disk.

- a gate valve (not shown) is opened, and the wafer is transferred from the outside into the recess 24 of the turntable 2 through the transfer port 15 by the transfer arm 10.

- This delivery is performed by raising and lowering the lift pins 16 from the bottom side of the vacuum vessel through the through holes in the bottom surface of the recesses 24 as shown in FIG. 12 when the recesses 24 stop at the position facing the transport port 15. .

- the delivery of the wafer W is performed by intermittently rotating the turntable 2, and the wafer W is placed in each of the five recesses 24 of the turntable 2.

- the inside of the vacuum vessel 1 is evacuated to a preset pressure by the vacuum pump 64 and the wafer W is heated by the heater unit 7 while rotating the rotary table 2 clockwise.

- the turntable 2 is heated in advance to, for example, 300 ° C. by the heater unit 7, and the wafer W is heated by being placed on the turntable 2.

- the BTBAS gas and the O 3 gas are discharged from the first reaction gas nozzle 31 and the second reaction gas nozzle 32, respectively, and the separation gas nozzle 41 is discharged.

- 42 is discharged with N 2 gas which is a separation gas.

- N 2 gas as separation gas is also supplied from the separation gas supply pipe 51, and thereby, from the central region C, that is, between the protrusion 5 and the center of the turntable 2, to the surface of the turntable 2. Along with this, N 2 gas is discharged.

- the N 2 gas supplied from the separation gas nozzles 41 and 42 passes through the regions where the reaction gas nozzles 31 and 32 are arranged, respectively. It flows into the exhaust ports 61 and 62.

- the N 2 gas stream flows below the reaction gas nozzles 31 and 32 as described in the section of the problem to be solved by the invention.

- the inventors have intensively studied on this problem, and in the present embodiment, the fan plates 36A and 36B are attached to the gas nozzles 31 and 32 in order to suppress the downward flow.

- the N 2 gas discharged downward from the separation gas nozzles 41 and 42 hits the surface of the turntable 2 (both the surface of the wafer W and the surface of the non-mounting area of the wafer W), and the upstream side in the rotation direction along the surface. Go downstream. Further, the BTBAS gas and the O 3 gas discharged downward from the respective reaction gas nozzles 31 and 32 strike the surface of the turntable 2 and ride on the flow of the separation gas toward the downstream side in the rotation direction.

- the inner peripheral wall of the container body 12 along the space below the second ceiling surface 45 where the reaction gas nozzles 31 and 32 are arranged is notched and widened as described above. Since the exhaust ports 61 and 62 are located below the wide space, the second ceiling surface is smaller than the narrow space below the first ceiling surface 44 and the pressure in the central region C. The pressure in the space below 45 is lower.

- FIG. 13 schematically shows the state of the gas flow on the turntable 2 discharged from each part

- FIG. 14 shows the apparatus vertically cut along the circumferential direction of the turntable 2 and developed on the paper surface.

- FIG. 14 shows the apparatus vertically cut along the circumferential direction of the turntable 2 and developed on the paper surface.

- FIG. 14 shows the flow of each gas for convenience.

- the processing areas P1 and P2 and the separation area D and the exhaust ports 61 and 62 are shown on the same plane.

- FIG. 14 shows an apparatus in which the height of the second ceiling surface 45 of the diffusion regions 48 and 49 is set to the same height as in FIG. 7A for convenience. Also when the height positions of the respective second ceiling surfaces 45 are different as shown in FIG. 6, the respective gases flow in the same manner as in FIG.

- each gas on the turntable 2 will be described with reference to FIGS. 13 and 14.

- the N 2 gas discharged from the separation gas nozzle 41 and flowing downstream in the rotation direction is separated from the separation region D into the second ceiling surface. 45, and the exhaust gas is exhausted by the exhaust port 61 provided on the downstream side of the first reactive gas nozzle 31, so that the downstream side of the first reactive gas nozzle is below the ceiling surface 45. It flows toward 31.

- the flow of the N 2 gas around the first reactive gas nozzle 31 is indicated by a solid line arrow.

- BTBAS gas is discharged to the first processing region P1 below the reactive gas nozzle 31, and the flow is indicated by dotted arrows. Since the discharged BTBAS gas is restricted by the fan plates 36A and 36B from rising from below the fan plates 36A and 36B, the lower region of the fan plates 36A and 36B is the upper region of the fan plates 36A and 36B.

- the pressure is higher than

- the flow of N 2 gas heading from the upstream side in the rotation direction toward the reaction gas nozzle 31 is restricted by the pressure difference and the fan plate 36A protruding upstream in the rotation direction. Dive is prevented and heads downstream.

- the N 2 gas travels in the rotational direction toward the downstream side of the first reactive gas nozzle 31 through a gap R provided between the nozzle cover 34 and the ceiling surface 45. That is, the fan plate 36 ⁇ / b> A is arranged at a position where most of the N 2 gas traveling from the upstream side to the downstream side of the reactive gas nozzle 31 can be guided to the gap R by bypassing the lower side of the reactive gas nozzle 31. Therefore, the amount of N 2 gas flowing into the first processing region P1 is suppressed.

- the N 2 gas flowing into the first processing region P1 has a pressure on the downstream side (back side) as compared to the upstream side (front side) of the reaction gas nozzle 31 that receives the gas. Therefore, the BTBAS gas discharged from the reaction gas nozzle 31 and moving toward the downstream side in the rotation direction also rises from the turntable 2 due to the rise toward the downstream position of the reaction gas nozzle 31.

- the fan plate 36B provided on the downstream side in the rotation direction prevents the BTBAS gas and the N 2 gas from rising by limiting the fan plate 36B and the rotary table. 2 flows downstream, and merges with the N 2 gas that has flowed downstream through the gap R on the upper side of the reaction gas nozzle 31 on the downstream side of the processing region P1.

- the N 2 gas supplied from the BTBAS gas and the separation gas nozzle 41 is pushed by the N 2 gas directed upstream from the separation gas nozzle 42 located on the downstream side of the processing region P1, and the separation gas nozzle 42 is provided. was it been prevented from entering the lower side of the convex portion 4, the exhaust through the N 2 gas from the separation gas nozzle 42, an exhaust region 6 with N 2 gas is discharged from the center area C The air is exhausted from the port 61.

- the N 2 gas discharged from the separation gas nozzle 42 and flowing downstream in the rotation direction flows from the separation region D to the lower side of the second ceiling surface 45, and is provided downstream of the second reaction gas nozzle 32. Since the exhaust is performed by the exhaust port 62, the exhaust flows toward the second reactive gas nozzle 32 below the ceiling surface 45.

- O 3 gas is discharged to the second processing region P2 below the reactive gas nozzle 32, and the flow is indicated by a dotted arrow in FIG. Since the discharged O 3 gas is restricted by the fan plates 36A and 36B from rising from below the fan plates 36A and 36B, the lower region of the fan plates 36A and 36B is located above the fan plates 36A and 36B. The pressure is higher than the area.

- the flow of the N 2 gas from the upstream side in the rotation direction toward the reaction gas nozzle 32 is restricted by such a pressure difference and the fan plate 36A protruding upstream in the rotation direction. Therefore, the N 2 gas is prevented from entering the processing region P 2 below the reactive gas nozzle 32, and is provided on the nozzle cover 34 between the nozzle cover 34 and the ceiling surface 45 toward the downstream side. It flows through the gap R to the downstream side of the processing region P2. That is, the fan plate 36A is arranged at a position where most of the N 2 gas traveling from the upstream side to the downstream side of the reactive gas nozzle 32 can be guided to the gap R by bypassing the lower side of the reactive gas nozzle 32. Therefore, the amount of N 2 gas flowing into the second processing region P2 is suppressed.

- the N 2 gas flowing into the second processing region P2 has a lower pressure on the downstream side (back side) than the upstream side (front side) of the reaction gas nozzle 32 that receives the N 2 gas flow. From this point, the reaction gas nozzle 32 tends to rise toward the downstream position, and the O 3 gas discharged from the reaction gas nozzle 32 toward the downstream side in the rotation direction also rises to that position. However, as shown in FIG. 15 (b), the fan plate 36B provided on the downstream side in the rotation direction prevents the O 3 gas and N 2 gas from rising and is prevented from rotating with the fan plate 36B. It goes downstream with the table 2 and merges with the N 2 gas that has flowed downstream through the gap R on the upper side of the reactive gas nozzle 32 on the downstream side of the processing region P2.

- the wafer W alternately passes through the first processing region P1 in which the first reaction gas nozzle 31 is provided and the second processing region P2 in which the second reaction gas nozzle 32 is provided by the rotation of the turntable 2, so that the BTBAS.

- Gas is adsorbed and then O 3 gas is adsorbed to oxidize BTBAS molecules to form one or more silicon oxide molecular layers.

- silicon oxide molecular layers are sequentially stacked to form silicon having a predetermined thickness. An oxide film is formed.

- the height of the ceiling surface 44 of the convex portion 4 and the length in the circumferential direction are determined by the gas intrusion to the lower side of the ceiling surface 44 in the process parameters during operation including the flow rate of each gas. Therefore, the BTBAS gas and the O 3 gas can hardly reach the lower part of the fan-shaped convex portion 4 or can reach the vicinity of the separation gas nozzle 41 even if it flows slightly. Instead, it is pushed back upstream and downstream in the rotational direction by the N 2 gas discharged from the separation gas nozzle 41 and exhausted as described above.

- each separation region D invasion of BTBAS gas or O 3 gas which is a reactive gas flowing in the atmosphere is prevented, but the gas molecules adsorbed on the wafer remain as they are in the separation region, that is, the fan-shaped convex portion 4. It passes under the low ceiling surface 44 due to the above and contributes to film formation.

- the wafers are sequentially carried out by the transfer arm 10 by an operation reverse to the carry-in operation.

- the rotation speed of the turntable 2 is, for example, 1 rpm to 500 rpm

- the process pressure is, for example, 1067 Pa (8 Torr)

- the heating temperature is 350 ° C.

- the flow rates of BTBAS gas and O 3 gas are 100 sccm and 10000 sccm, respectively

- the flow rate of N 2 gas from the separation gas nozzles 41 and 42 is 20000 sccm

- the flow rate of N 2 gas from is, for example, 5000 sccm.

- the number of reaction gas supply cycles for one wafer that is, the number of times the wafer passes through each of the processing regions P1 and P2, varies depending on the target film thickness, but is many times, for example, 6000 times.

- What can be said from the ratio of the gas flow rate as described above is that the gas flow in the first processing region P1 and the second processing region P2 is greatly influenced by the N 2 gas supplied from the separation region D. Therefore, it is important to suppress the inflow of N 2 gas into the first processing region P1 and the second processing region P2, and for this purpose, it is effective to provide the fan plates 36A and 36B as described above.

- the separation region D is located above the first reaction gas nozzle 31 provided on the turntable 2 on which the wafer W is placed, and the rotation direction of the turntable 2 is changed from the upstream side to the downstream side.

- nozzle cover 34 to the first reaction gas nozzle 31 with a clearance R is provided with a fan plate 36A protruding to the upstream side of the rotational direction forming an through passage of N 2 gas is provided toward.

- the concentration of BTBAS gas in the first processing region P1 can be suppressed, and even when the rotation speed of the turntable 2 is increased, the BTBAS gas molecules are reliably adsorbed on the wafer W and can be normally formed.

- a membrane can be performed. Accordingly, the deposition rate on the wafer W is improved, and the throughput can be improved. Further, the film can be formed on the wafer W with high uniformity. Furthermore, the film quality is improved, that is, a film having a desired property can be obtained.

- the nozzle cover 34 is provided with a fan plate 36B so as to protrude downstream in the rotation direction.

- the N 2 gas that has flowed from the separation region D on the upstream side to the first processing region P1 by the fan plate 36B is first from the rotary table 2 together with the BTBAS gas discharged from the processing region P1 from the reaction gas nozzle 31.

- Ascending to the back surface of the first reactive gas nozzle 31 on the downstream side in the rotational direction of the reactive gas nozzle 31 is suppressed. Therefore, the decrease in the concentration of the BTBAS gas in the processing region P1 and the contact time of the BTBAS gas with the wafer W can be suppressed, so that even when the rotation speed of the turntable 2 is increased, the molecules of the BTBAS gas are increased. Can be reliably adsorbed to the wafer W and film formation can be performed normally. As a result, throughput can be improved. In addition, the film can be formed on the wafer W with high uniformity, and the film quality can be improved.

- the N 2 gas flow path from the upstream side to the downstream side in the rotation direction of the turntable 2 is also provided above the second reaction gas nozzle 32 in the same manner as the first reaction gas nozzle.

- the second reaction gas nozzle 32 is provided with a nozzle cover 34 provided with a fan plate 36A protruding upstream in the rotation direction.

- the N 2 gas can be prevented from flowing into the second processing region P2, and the O 3 gas concentration in the second processing region P2 can be suppressed from decreasing. Therefore, even when the rotation speed of the turntable 2 is high, BTBAS can be sufficiently oxidized and a film with less impurities can be formed, so that the film formation rate can be increased. As a result, throughput can be improved. In addition, the film can be formed on the wafer W with high uniformity, and the film quality can be improved.

- the second reaction gas nozzle 32 is also provided with a fan plate 36B protruding toward the downstream side in the rotation direction.

- the fan 36B is separated from the separation region D into the second processing region P2. Since the flow of N 2 gas is suppressed from rising from the rotary table 2 to the downstream side in the rotation direction of the second reaction gas nozzle 32 along with the O 3 gas discharged from the reaction gas nozzle 32 from the processing region P2, in the process area P2 with the concentration of O 3 gas is suppressed to be reduced time of contact with the O 3 gas and the wafer W is suppressed to be reduced.

- the BTBAS can be sufficiently oxidized and a film with less impurities can be formed, so that the film formation rate can be increased. As a result, throughput can be improved.

- the film can be formed on the wafer W with high uniformity, and the film quality can be improved.

- the gas nozzles 31 and 32 In order to suppress the inflow of N 2 gas, which is a separation gas, between the gas nozzles 31 and 32 and the rotary table by forming a pressure difference above and below the gas nozzles 31 and 32, the gas nozzles 31 and 32

- the fan plate 36A may be protruded only on the upstream side in the rotation direction. However, since the pressure difference can be more reliably formed by projecting the fan plate 36B to the downstream side in the rotation direction, the above-described effect can be obtained with certainty. Further, in order to restrict and prevent the reaction gas from rising, the fan plate 36B may be protruded from the gas nozzles 31 and 32 only to the downstream side in the rotation direction.

- the separation gas flows from the upstream side in the rotation direction of the turntable 2 to the reaction gas nozzles 31 and 32, but each of the separation gas nozzles 41 and 42, the reaction gas nozzles 31 and 32, and the exhaust ports 61 and 62.

- the separation gas may be directed to the reaction gas nozzles 31 and 32 from both upstream and downstream directions in the rotation direction.

- the fan plate 36B protruding to the downstream side forms a pressure difference above and below the reaction gas nozzle 31 from the downstream side. , 32 is guided to the gap R.

- the fan plate 36B plays a role similar to that of the fan plate 36A for the separation gas flowing from the upstream side in the rotation direction with respect to the separation gas flowing from the downstream side in the rotation direction to the reaction gas nozzles 31 and 32.

- the separation gas is also directed to the reaction gas nozzles 31 and 32 from the downstream side in the rotation direction, the reaction gas rises to the upstream side in the rotation direction of the reaction gas nozzles 31 and 32 by the separation gas to the upstream side. It can be limited and prevented by the protruding fan plate 36A. That is, the fan plate 36A plays a role similar to that of the fan plate 36B for the separation gas flowing from the upstream side in the rotation direction with respect to the separation gas flowing from the downstream side in the rotation direction.

- the fan plate may be provided only on the downstream side in the rotation direction.

- the separation gas directed from the downstream side toward the reaction gas nozzles 31 and 32 can be guided to the gap R to prevent a decrease in the concentration of the reaction gas in the processing regions P1 and P2.

- the processing gas that can be used in the present embodiment includes DCS [dichlorosilane], HCD [hexachlorodisilane], TMA [trimethylaluminum], 3DMAS [trisdimethylaminosilane], TEMAZ [tetrakisethylmethyl] in addition to the above-described examples.

- Aminozirconium] TEMHF [tetrakisethylmethylaminohafnium], Sr (THD) 2 [strontium bistetramethylheptanedionato], Ti (MPD) (THD) 2 [titanium methylpentanedionatobistetramethylheptandionato], And monoaminosilane.

- the upstream side portion of the turntable 2 in the rotation direction with respect to the separation gas nozzles 41 and 42 has a larger width in the rotation direction as a portion located on the outer edge. The reason is that the flow of the gas from the upstream side toward the separation region D by the rotation of the turntable 2 is so fast that it approaches the outer edge. From this point of view, it is a good idea to configure the convex portion 4 in a fan shape as described above.

- the first ceiling surface 44 which forms a narrow space located on both sides of the separation gas supply nozzle 41 (42), has the separation gas supply nozzle 41 shown in FIGS. 16 (a) and 16 (b).

- the width dimension L along the rotation direction of the turntable 2 is 50 mm or more at the portion through which the center WO of the wafer W passes. .

- the distance between the first ceiling surface 44 and the turntable 2 is set to a certain size, the speed of the turntable 2 increases as the distance from the rotation center of the turntable 2 increases.

- the width dimension L required to obtain the intrusion prevention effect becomes longer as the distance from the rotation center increases.

- the width dimension L in the portion through which the center WO of the wafer W passes is smaller than 50 mm, the distance between the first ceiling surface 44 and the turntable 2 needs to be considerably reduced.

- a device for suppressing the swing of the rotary table 2 as much as possible is required.

- the width dimension L is smaller than 50 mm, the width dimension L is preferably 1/10 to 1/1 of the diameter of the wafer W, and more preferably about 1/6 or more.

- the reaction gas nozzles 31 and 32 may be provided with only a fan plate without providing the base 34.

- FIG. 17A shows a reactive gas nozzle 31 (or 32) provided with fan plates 37A and 37B configured in the same manner as the fan plates 36A and 36B so as to protrude from the lower end to the upstream side and the downstream side in the rotation direction, respectively.

- FIG. 17B is a longitudinal sectional view of the reactive gas nozzle 31 (or 32). Further, the distance from the rotation center of the turntable 2 toward the outer edge of the turntable 2 increases the moving distance of the turntable 2 and the gas flow on the turntable 2 becomes faster.

- the rectifying plates provided in the reaction gas nozzles 31 and 32 in order to reliably regulate the flow of each gas, the further away from the rotation center of the rotary table 2, the larger the upstream in the rotational direction and the downstream. Since it is preferable to project, it is preferable to form the rectifying plate so that its planar shape is a fan like 36A, 36B, 37A, 37B.

- the direction in which the current plate protrudes is not limited to the horizontal direction as in the above examples.

- the fan plates 37A and 37B may be provided so as to protrude obliquely downward from the reaction gas nozzle 31 as shown in FIG.

- the current plate is fan-shaped for the above reasons.

- the rectifying plate only needs to cover a portion where the gas concentration is reduced in the processing region, and therefore the shape can be freely changed according to the gas concentration.

- 18A shows the upper surface side of the gas nozzle 31 to which the above-described fan plates 37A and 37B shown in FIG. 17A are attached

- FIGS. 18B to 18D show the fan plates 37A and 37B.

- the upper surface side of the gas nozzle 31 to which the rectifying plates 301A to 304A and 301B to 304B having shapes different from the fan plates 37A and 37B are attached is shown.

- the current plate is not limited to the fan shape.

- the rectifying plate may be integrated with the reactive gas nozzle and have a rectifying function. Further, the current plate may be formed separately from the reactive gas nozzle.

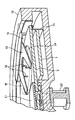

- the reactive gas nozzle 3 includes an elongated rectangular tube-shaped nozzle body 321 and a guide plate 325 provided on a side surface of the nozzle body 321.

- the aforementioned fan plates 37A and 37B are provided at the lower ends of the nozzle body 321 and the guide plate 325 so as to sandwich the nozzle body 321 and the guide plate 325.

- the interior of the nozzle body 321 is hollow, and constitutes a flow space 322 for allowing the reaction gas supplied from the gas introduction pipe 327 provided at the base end of the nozzle body 321 to flow.

- a diameter of 0.5 mm is provided on one side of the side wall portion that is a tube wall of the nozzle body 321, for example, on the upstream side wall portion as viewed from the rotation direction of the rotary table 2.

- a plurality of reaction gas outflow holes 323 are arranged along the length direction of the nozzle body 321 with an interval of, for example, 5 mm.

- a guide plate 325 is fixed to the side wall portion through a gap adjusting member 324 so as to be parallel to the side wall portion.

- FIG. 20A is a side view of the reactive gas nozzle 3 with the guide plate 325 removed. As shown in FIG.

- the gap adjusting member 324 is composed of a plurality of plates having the same thickness, and surrounds the region where the reaction gas outflow holes 323 in the side wall of the nozzle body 321 are arranged, for example, It arrange

- the space surrounded by the outer surface of the side wall portion, the gap adjusting member 324, and the guide plate 325 has a flat belt-like gas flow space 326 through which the gas discharged from the reaction gas outflow hole 323 flows.

- the gap adjusting member 324 is not disposed on the lower side of the region where the reaction gas outflow holes 323 are arranged, the gas flow space 326 is shown in the bottom view of FIG.

- the reaction gas nozzle 3 is arranged on the radius of the turntable 2 in the same manner as the reaction gas nozzles 31 and 32 with the gas discharge port 328 facing the turntable 2.

- the thickness of the gap adjusting member 324 is, for example, 0.3 mm, and therefore the width of the gas flow space 326 from the discharge port 328 that is the outlet of the reaction gas outflow hole 323 to the guide plate 325 is also 0.3 mm. Yes.

- the reaction gas discharged from the reaction gas outflow hole 323 is collided with a guide plate 325 provided at a position facing the reaction gas outflow hole 323, and then the vacuum is applied.

- the flow of the reaction gas can be dispersed in the direction in which the gas flow space 326 formed between the guide plate 325 and the nozzle body 321 extends.

- the point that the nozzle main body 321 is configured by a cylindrical member and the point that the guide plate 325 is configured by a partially cylindrical member are: Different from the reactive gas nozzle 3.

- a plurality of reaction gas outflow holes 323 having a diameter of 0.5 mm, for example, are arranged on the side wall surface of the tubular nozzle body 321 along the length direction of the nozzle body 321 at intervals of, for example, 10 mm. Has been.

- the guide plate 325 is fixed to the upper end of the nozzle body 321 with one end extending in the length direction of the partial cylinder whose longitudinal side surface is arcuate, for example, obtained by cutting a cylinder having a diameter larger than that of the nozzle body 321 in the radial direction. It has become the composition.

- fan plates 37A and 37B are provided so as to sandwich the nozzle body 321 and the guide plate 325.