EP0802300B1 - Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer - Google Patents

Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer Download PDFInfo

- Publication number

- EP0802300B1 EP0802300B1 EP97111156A EP97111156A EP0802300B1 EP 0802300 B1 EP0802300 B1 EP 0802300B1 EP 97111156 A EP97111156 A EP 97111156A EP 97111156 A EP97111156 A EP 97111156A EP 0802300 B1 EP0802300 B1 EP 0802300B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- framework according

- metal

- heat

- central portion

- metal profile

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 229910052751 metal Inorganic materials 0.000 title claims abstract description 80

- 239000002184 metal Substances 0.000 title claims abstract description 80

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims abstract description 43

- 229910052782 aluminium Inorganic materials 0.000 claims abstract description 42

- 239000000463 material Substances 0.000 claims abstract description 19

- 239000003463 adsorbent Substances 0.000 claims abstract description 11

- 239000004411 aluminium Substances 0.000 claims abstract 9

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 29

- 229940037003 alum Drugs 0.000 claims description 13

- 239000002131 composite material Substances 0.000 claims description 13

- GRLPQNLYRHEGIJ-UHFFFAOYSA-J potassium aluminium sulfate Chemical compound [Al+3].[K+].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O GRLPQNLYRHEGIJ-UHFFFAOYSA-J 0.000 claims description 13

- 235000011126 aluminium potassium sulphate Nutrition 0.000 claims description 12

- 229940050271 potassium alum Drugs 0.000 claims description 12

- 229910052602 gypsum Inorganic materials 0.000 claims description 11

- 239000010440 gypsum Substances 0.000 claims description 11

- 230000004044 response Effects 0.000 claims description 8

- 238000004873 anchoring Methods 0.000 claims description 5

- 239000011521 glass Substances 0.000 claims description 5

- 239000004033 plastic Substances 0.000 claims description 4

- 229920003023 plastic Polymers 0.000 claims description 4

- 239000011159 matrix material Substances 0.000 claims description 2

- 230000004907 flux Effects 0.000 claims 2

- 239000003365 glass fiber Substances 0.000 claims 1

- 239000013078 crystal Substances 0.000 description 12

- 239000011505 plaster Substances 0.000 description 12

- 238000000465 moulding Methods 0.000 description 8

- 238000010276 construction Methods 0.000 description 6

- 238000002425 crystallisation Methods 0.000 description 6

- 230000008025 crystallization Effects 0.000 description 6

- 238000009413 insulation Methods 0.000 description 4

- 238000001816 cooling Methods 0.000 description 3

- 238000011049 filling Methods 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 238000005265 energy consumption Methods 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 238000004080 punching Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 239000000567 combustion gas Substances 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000003779 heat-resistant material Substances 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 239000012071 phase Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 230000008092 positive effect Effects 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 239000011814 protection agent Substances 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 239000012808 vapor phase Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/267—Frames with special provision for insulation with insulating elements formed in situ

- E06B3/2675—Frames with special provision for insulation with insulating elements formed in situ combined with prefabricated insulating elements

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/26301—Frames with special provision for insulation with prefabricated insulating strips between two metal section members

- E06B3/26303—Frames with special provision for insulation with prefabricated insulating strips between two metal section members with thin strips, e.g. defining a hollow space between the metal section members

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/2634—Frames with special provision for insulation without separate insulating elements, e.g. the heat transmission being reduced by a smaller cross-section

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B5/00—Doors, windows, or like closures for special purposes; Border constructions therefor

- E06B5/10—Doors, windows, or like closures for special purposes; Border constructions therefor for protection against air-raid or other war-like action; for other protective purposes

- E06B5/16—Fireproof doors or similar closures; Adaptations of fixed constructions therefor

- E06B5/162—Fireproof doors having windows or other openings, e.g. for permitting ventilation or escape

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/2632—Frames with special provision for insulation with arrangements reducing the heat transmission, other than an interruption in a metal section

- E06B2003/26321—Frames with special provision for insulation with arrangements reducing the heat transmission, other than an interruption in a metal section with additional prefab insulating materials in the hollow space

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B2003/26349—Details of insulating strips

- E06B2003/2635—Specific form characteristics

- E06B2003/26359—Specific form characteristics making flush mounting with neighbouring metal section members possible

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B2003/26349—Details of insulating strips

- E06B2003/2635—Specific form characteristics

- E06B2003/26361—Openings, incisions or indents

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B2003/26349—Details of insulating strips

- E06B2003/26369—Specific material characteristics

- E06B2003/26374—Specific material characteristics with parts of differing nature

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B2003/26349—Details of insulating strips

- E06B2003/26369—Specific material characteristics

- E06B2003/26376—Non-plastic materials, e.g. wood, metal

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B2003/26349—Details of insulating strips

- E06B2003/26387—Performing extra functions

- E06B2003/2639—Provisions for fittings, e.g. locks or hinges

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B2003/26394—Strengthening arrangements in case of fire

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S49/00—Movable or removable closures

- Y10S49/01—Thermal breaks for frames

Definitions

- the invention relates to a framework made of metal profiles in fire protection design for windows, doors, facades and glass roofs, the metal profiles with a Chamber-provided outer parts made of light metal, preferably aluminum and have a central part in which the heat flow is reduced.

- EP-A-0 590 2366 A framework of this type is known (EP-A-0 590 236), which consists of a composite profile is made.

- This composite profile is provided with outer parts made of extruded Aluminum profiles are formed, each having an outer chamber. No fire protection material is arranged in these outer chambers. From Aluminum-made outer parts are in the central area of the composite profile connected by insulating strips made of a mechanically strong material, which is poorly heat-conductive and melts when exposed to heat. As a manufacturing material are called polyamide or a cast resin.

- the chamber in the middle part of the composite profile is supported by a supporting and insulating profile filled out, which is made of heat-resistant material and in the event of fire a load-bearing Function takes over while the aluminum profile is affected by the fire melts.

- the invention has for its object a framework of the aforementioned Art to design so that under fire exposure for the entire construction a long Tool life is given.

- This object is achieved in that between the outer parts a breakthrough central part made of metal or a bridge bridge made of metal having central part is provided and fire protection plates in the chambers of the outer parts are arranged.

- the middle part By forming the middle part, the heat flow between the outer parts reduced, however, sufficient stability is maintained and melting of parts in the middle during the safety period in the event of fire Avoid the area of the multi-chamber profile.

- the metal profiles provided with three chambers formed as a one-piece, extruded aluminum profiles, in which holes are punched in the middle area.

- the fire protection strip has the task of removing the perforated metal strip from the cover visible folds and on the other hand to ensure that the Folding space is largely closed by an inflation of the material Prevent the passage of fire gases.

- the metal profiles can be designed as composite profiles and are made of extruded Aluminum hollow chamber profiles and a central part made of metal, in which the heat flow compared to that made of aluminum External parts is reduced.

- Metal profiles can cover these covering plates or other moldings from one heat-binding, hydrophilic adsorbent with a high water content or a heat-binding, plates or hydrophilic adsorbent with a high water content other moldings to be attached.

- the plates or other shaped bodies made of a heat-binding, hydrophilic Adsorbents with a high water content advantageously consist of alum and gypsum.

- the alum is so-called metal double salts, which are able in very high degree of weight-related storage of crystal water.

- potassium alum which can be referred to chemically as potassium aluminum sulfate 12 hydrate.

- the chemical formula is: KA1 (SO 4 ) 2 x 12 H 2 O.

- This potassium alum is able to produce approximately 45 percent water of crystallization per unit weight bind physically.

- the release of the crystal water from the potassium alum in pure form takes place at 72 ° C.

- the volume of the stored crystal water is approx. 50 percent.

- the potassium alum can be embedded in a plaster matrix and behaves completely neutral with regard to the hardening of the gypsum, so that those produced from it Plates, molded parts and profiles have sufficient stability for their use in fire protection have.

- the potassium alum does not change the setting properties of the plaster.

- the Gypsum does not become the physical water absorption of the alum impaired.

- the plates or other molded parts that are provided with a hydrophilic adsorbent are preferably 50 percent modified plaster and 50 percent Percent from potassium alum.

- the energy consumption of such a component is approximately 1,100 j / cm 3 .

- the mixing ratio between alum and plaster can be varied. With a mixing ratio of 50:50 between plaster and alum there is a 32 percent share of the stored crystal water.

- potassium alum has an effective temperature of 73 ° C by itself, the Effective temperature in connection with the plaster to a higher value, namely approx. 85 ° C installed. This results from the fact that the water released in the alum simple suction is held up to 85 ° C by the plaster, before it is transferred to the vapor phase.

- a favorable working temperature occurs here, which is at a sufficient distance from the Operating temperatures, which may 70 ° C when exposed to direct sunlight Can reach plates or moldings.

- the combination of plaster and alum has the further advantage that it is in the plaster bound crystal water is only released at an effective temperature of 125 ° C and this multi-stage crystal water release has a positive effect on the cooling process of the frame profiles affects which the described plates or other shaped bodies be assigned. In addition, another takes place at about 215 ° C slight release of water bound in the gypsum instead of subordinate Meaning is.

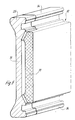

- the metal profile shown in FIG. 1 has extruded aluminum profiles as outer parts 1,2, between which a central part 3 is provided, which in this Embodiment of two metal strips 4 running parallel to one another exists, which reduced compared to the aluminum profiles 1 and 2 in their heat transmission are.

- the metal strips 4 can be made of aluminum or another Metal, e.g. be made of steel.

- Aluminum profiles 1 and 2 have inner chambers 5,6, into the molded part completely or partially filling the inner chamber can be introduced from a heat-binding, hydrophilic adsorbent.

- the Aluminum profiles 1 and 2 have anchoring grooves 7,8 for the footbridges 11 of the Metal strips 4, which after inserting the footbridges into the anchoring grooves be determined by molding the outer groove webs 9.

- the metal strips 4 together with the aluminum profiles 1 and 2 limit another inner chamber 10, so that the composite profile according to fig. 1 with three inner chambers for receiving of moldings with a high proportion of water of crystallization.

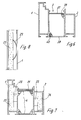

- the in Fig. 2nd Metal strip 4 shown has foot ridges 11 at the edges and is in the area provided with cutouts 12 between the footsteps 11, so that between the Punchings 12, which are triangular in the embodiment according to FIG. 2 are formed, narrow bridge webs 13 remain.

- a metal strip 4 is shown, the rectangular punched-out 14 is provided, between which only bridge webs 15 remain for heat conduction.

- the cut-outs can have any geometric shape.

- the width b of the bridge web and its thickness d can be varied by the Reduce or increase heat flow.

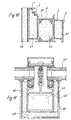

- the frame 16 was made from a profile, as shown in FIG. 1 is.

- the frame profile is composed of aluminum profiles 1 and 2, which are connected by metal strips 4, the metal strips being punched out Have 12 or 14, so that the heat flow through this the middle part of the Composite profile forming metal strips 4 is reduced.

- the sash 17 consists of the outer parts forming profile shells 18, 19 which are made of aluminum and by metal strips 4, which form thermal insulation, are connected.

- the sash frame is completed by a glass retaining strip 20, which has an inner chamber 21 for receiving an alum and plaster Has molded body 22.

- a glass retaining strip 20 which has an inner chamber 21 for receiving an alum and plaster Has molded body 22.

- In the inner chambers 5 and 6 of the frame 16 and in the inner chambers 23 and 24 of the casement 17 are also shaped bodies 25,26,27 and 28 made of alum and gypsum with a high crystal water content arranged.

- the moldings can also be composed of other components, from which at least one has a high proportion of water of crystallization, at a temperature is released below the melting temperature of the fire Light metal profile lies. The crystal water released is used for cooling of the metal profiles.

- the plate-shaped body 25,26,27,28, which the respective inner chamber only partially fill in, are inserted into the inner chambers with metal springs 29, wherein the metal springs 29 on the plate-shaped bodies with their free Claw ends and thus secure their position.

- the energy-consuming shaped bodies can also be shaped parts of any length, which are adapted to the inner contour of the inner chamber of the metal profiles.

- the energy-consuming material can also enter the inner chamber in liquid form a metal profile can be filled and then binds to one in the inner chamber solid molded body.

- the inner chambers must be filled with an energy-consuming molded body with a high proportion of water of crystallization after the surface treatment of the profiles because the drying temperatures the powder coating are in a temperature range that the response temperature of the energy-consuming material.

- Fig. 4 is in the fitting between the frame and sash in front of each Metal strip 4 a groove 30 is provided in which a fire protection strip 31 from below Inflating material is provided.

- the fire protection strip 31 has on the one hand the task of covering the perforated metal strip 4 from the visible fold and on the other hand to ensure in the event of fire that the rebate area as large as possible is closed by inflating material to prevent the passage of combustion gases to prevent.

- the metal strip 4 from an extruded profile into which openings are punched or made of rolled steel has the great advantage that it is processed separately and assembled with known composite methods with the other hollow chamber profiles can be.

- the energy-consuming moldings are set so that they have a response temperature in the range of 80 ° C to 150 ° C.

- the filling of the respective inner chambers of the metal profiles can vary respectively.

- a multi-part insulating strip 32 can also be used instead of the metal bar 4 in the middle part 3 of the profile.

- This multi-part insulating strip 32 consists of an extruded, poorly heat-conducting plastic strip 33, which extends over the entire length of the insulating strip and on its longitudinal edges Has foot profiles 34. These foot profiles 34 are preferred cut out at equal intervals and there are recesses in these the foot profiles 34 contour foot profiles 35 of a bridge web 36 made of metal, preferably made of aluminum.

- the foot profiles are anchored in the grooves of aluminum profiles 1 and 2.

- the metallic Bridge bridges have the task of creating a heat flow between the aluminum profiles 1 and 2 ensure.

- the width of the bridges and the distances to each other can be varied so that the energy flow between can influence the aluminum profiles 1 and 2.

- FIG. 6 A further embodiment of the middle part 3, which is designed as a thermal insulation zone between the aluminum profiles 1 and 2 is shown in Fig. 6, in which the perforated metal strips 37.38 in one piece with the aluminum profile 1 or with the Aluminum 2 are.

- the metal bar 37 arranged on the aluminum profile 1 engages a footbridge 39 in the associated anchoring groove of the aluminum profile 2, while the one-piece metal strip 38 with the aluminum profile 2 with its foot bridge 40 engages in the anchoring groove of the aluminum profile 1.

- the metal strips 37, 38 are corresponding the illustrations 2 and 3 are punched out and form one shown there Lattice work, through which the heat flow between the aluminum profiles 1 and 2 is reduced becomes.

- FIG. 9 is a diagram with regard to an energy-consuming shaped body shown, which is composed of potassium alum and plaster.

- Curve 1 shows the response temperatures of the molded body plotted against the lower temperature axis. The response temperatures are too high from this curve recognize where crystal water is released. The area under curve 1 represents the total energy consumption.

- the curve only shows the mass loss that occurs during the course of the temperature increase sets.

- FIG. 10 shows a metal profile which, like the profile according to FIG. 1 from the aluminum profiles 1 and 2 and in the middle part from the perforated metal strips 4 composed.

- the inner chambers 5,6 and 10 are with energy-consuming and Molded bodies releasing water of crystallization 41, 42, 43, which e.g. from alum and Plaster can exist.

- a facade or a roof structure is shown, in which the Facade fields or the frame fields of the roof filled with glass panes 45 are.

- a main profile 46 made of aluminum is provided on the inside of the room. This The main profile is formed by plate-shaped, energy-consuming moldings 47, 48 and 49 covered, which release crystal water when a response temperature is reached and thereby cool the main profile.

- the plate-shaped body 47,48,49 can be glued to the main profile or connected by mechanical means.

- a sheet metal cover 50 is made of light metal or be made of stainless steel and also to fix the plate-shaped body can be used.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Special Wing (AREA)

- Building Environments (AREA)

- Wing Frames And Configurations (AREA)

- Roof Covering Using Slabs Or Stiff Sheets (AREA)

Description

- Figur 1

- ein aus zwei Außenteilen und einem Mittelteil sich zusammensetzendes Verbundprofil im Schnitt,

- Figur 2

- eine im Mittelteil verwendete Profilleiste mit herabgesetztem Wärmedurchfluß, und zwar im Querchnitt und im Aufriß,

- Figur 3

- eine Abwandlungsform der Ausführung nach der Fig. 2,

- Figur 4

- die Rahmenprofile einer Tür im Schnitt,

- Figur 5

- eine im Mittelteil eines Verbundprofils nach Fig. 1 einsetzbare Profilleiste, die aus Kunststoff besteht und mit in Abstand voneinander angeordneten Brückenstegen aus Metall versehen ist,

- Figur 6

- eine weitere Ausführungsform eines aus zwei Außenteilen und einem Mittelteil bestehenden Rahmenprofil,

- Figur 7

- ein weiteres Ausführungsbeispiel eines mit Brandschutzmitteln versehenen Rahmenprofils,

- Figur 8

- eine konstruktive Einzelheit zu der Konstruktion nach der Fig. 7,

- Figur 9

- ein Schaubild mit Kurven I und II, von denen die Kurve 1 die Ansprechzeiten eines Kalium-Alaun-Gipsformkörpers und die Fig. 2 den sich im Verlauf der Temperaturerhöhung einstellenden Masseverlust aufzeigt,

- Figur 10

- ein weiteres Profil in Brandschutzausführung im Schnitt und

- Figur 11

- ein Hauptprofil sowie das zugeordnete Abdeckprofil einer Fassadenoder einer Glasdachkonstruktion.

Claims (23)

- Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer, wobei die Metallprofile mit einer Kammer (5,6) versehene, aus Leichtmetall, vorzugsweise aus Aluminium, gefertigte Außenteile (1,2) und ein Mittelteil aufweisen, in dem der Wärmefluß herabgesetzt ist, dadurch gekennzeichnet, daß zwischen den Außenteilen (1,2) ein mit Durchbrüchen (12,14) versehenes Mittelteil (3) aus Metall oder ein Brückenstege (36) aus Metall aufweisendes Mittelteil vorgesehen ist und in den Kammern (5,6) Brandschutzplatten angeordnet sind.

- Rahmenwerk nach Anspruch 1, dadurch gekennzeichnet, daß die mit drei Innenkammern (5,6,10) versehenen Metallprofile als einstückige, stranggepreßte Aluminiumprofile ausgebildet sind, die im mittleren Bereich Löcher eingestanzt sind.

- Rahmenwerk nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß im Beschlagfalz zwischen Blend- und Flügelrahmen einer Tür jeweils vor der gelochten Metallleiste (4) ein Brandschutzstreifen (31) aus unter Temperaturbelastung aufblähendem Material angeordnet ist.

- Rahmenwerk nach Anspruch 1, dadurch gekennzeichnet, daß die Metallprofile als Verbundprofile ausgebildet sind und Außenteile aufweisen, die aus stranggepreßten Aluminium-Hohlkammerprofilen (1,2) gebildet sind und zwischen denen ein Mittelteil (3) aus Metall angeordnet ist.

- Rahmenwerk nach Anspruch 4, dadurch gekennzeichnet, daß das Mittelteil der Metallprofile Brückenstege (13,15) aus Metall zwischen den Außenteilen aus Aluminium aufweist oder ausschließlich aus Brückenstegen aus Metall besteht.

- Rahmenwerk nach Anspruch 5, dadurch gekennzeichnet, daß die metallischen Brückenstege (13,15) des Mittelteils der Metallprofile an einem Ende oder an beiden Enden in einer Verankerungsnut des zugeordneten Außenteils festgelegt sind.

- Rahmenwerk nach Anspruch 1, dadurch gekennzeichnet, daß das Mittelteil des Leichtmetallprofils sich aus mindestens einer über die gesamte Länge des Mittelteils erstreckenden Kunststoffleiste (33) und aus metallischen Brückenstegen (36) zusammensetzt, die zueinander parallel und quer zur Längsachse des Leichtmetallprofils verlaufen, wobei die Fußprofilierungen der metallischen Brückenstege in Ausnehmungen (36) der Kunststoffleiste (33) angeordnet sind.

- Rahmenwerk nach Anspruch 1, dadurch gekennzeichnet, daß an den Außenseiten oder/und an den Innenseiten der aus Aluminium gefertigten Metallprofile diese abdeckende Platten oder sonstige Formkörper aus einem wärmebindenden, hydrophilen Adsorbens mit hohem Wasseranteil oder ein wärmebindendes, hydrophiles Adsorbens mit hohem Wasseranteil enthaltende Platten oder sonstige Formkörper befestigt sind.

- Rahmenwerk nach Anspruch 8, dadurch gekennzeichnet, daß das wärmebindende hydrophile Adsorbens aus Alaun und Gips besteht.

- Rahmenwerk nach Anspruch 9, dadurch gekennzeichnet, daß das wärmebindende, hydrophile Adsorbens aus Kalium-Alaun und Gips besteht, wobei das Kalium-Alaun in eine Gipsmatrix eingebunden ist.

- Rahmenwerk Anspruch 10, dadurch gekennzeichnet, daß die wärmebindenden Platten oder sonstigen Formkörper zu 50 Prozent aus Kalium-Alaun und zu 50 Prozent aus einem modifizierten Gips bestehen.

- Rahmenwerk nach Anspruch 4, dadurch gekennzeichnet, daß das Mittelteil der Leichtmetallprofile aus einem oder mehreren parallelaufenden Blechstreifen, vorzugsweise aus Aluminium besteht und diese Blechstreifen durch Ausstanzungen beliebiger Konfiguration nur einen herabgesetzten Wärmefluß ermöglichen.

- Rahmenwerk nach Anspruch 12, dadurch gekennzeichnet, daß die Ausstanzungsreihe durch wechselweise gegeneinander versetzte Dreiecke gebildet ist (Fig. 2).

- Rahmenwerk nach Anspruch 12 oder 13, dadurch gekennzeichnet, daß die das Mittelteil bildenden Blechsstreifen Fußstege (11) aufweisen, die in Nuten der Außenteile der Leichtmetallprofils verankert sind.

- Rahmenwerk nach Anspruch 8, dadurch gekennzeichnet, daß die Platten oder sonstigen Formkörper aus einem oder mit einem wärmebindenden, hydrophilen Adsorbens an beiden Außenteilen der Leichtmetallprofile befestigt sind.

- Rahmenwerk nach Anspruch 4, dadurch gekennzeichnet, daß an beiden oder an einem Außenteil der Leichtmetallprofile und an dem Mittelteil oder in einer Kammer des Mittelteils Platten oder sonstige Formkörper aus wärmebindendem Material mit hohem Wasseranteil vorgesehen sind.

- Rahmenwerk nach Anspruch 15, dadurch gekennzeichnet, daß die Außenteile der Leichtmetallprofile als geschlossene oder offene Hohlprofile aus Aluminium ausgebildet sind und in den Hohlkammern die Hohlkammern teilweise oder vollständig ausfüllende Formkörper aus wärmebindendem Material mit hohem Wasseranteil angeordnet sind.

- Rahmenwerk nach Anspruch 17, dadurch gekennzeichnet, daß zusätzlich zu der Anordnung der Formkörper aus wärmebindendem Material in einer geschlossenen oder offenen Hohlkammer eines oder beider Außenteile oder/und in einer geschlossenen oder offenen Hohlkammer des Mittelteils an der Außenfläche eines Außenteils des Leichtmetallprofils eine Abdeckplatte aus wärmebindendem Material befestigt ist.

- Rahmenwerk nach Anspruch 18, dadurch gekennzeichnet, daß die an der Außenseite der einen Rahmen bildenden Leichtmetallprofile befestigten Platten aus wärmebindendem Material Teile eines geschlossenen Rahmens sind.

- Rahmenwerk nach Anspruch 16 oder 17, dadurch gekennzeichnet, daß in den Außenschichten der Formkörper Gewebe, vorzugsweise Glasfasergewebe eingebettet sind.

- Rahmenwerk nach Anspruch 17, 18 oder 19, dadurch gekennzeichnet, daß den plattenförmigen Formkörpern (47,48,49) eine Blechabdeckung (50) zugeordnet ist.

- Rahmenwerk nach einem der Ansprüche 8 bis 21, dadurch gekennzeichnet, daß die energieverzehrenden Formkörper (25,26,27,28) durch Metallfedern (29) in ihrer Lage in der zugeordneten Innenkammer des Metallprofils gesichert sind.

- Rahmenwerk nach einem der Ansprüche 8 bis 22, dadurch gekennzeichnet, daß die Ansprechtemperaturen der einem Metallprofil zugeordneten Formkörper unterschiedlich sind.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4443762 | 1994-12-08 | ||

| DE4443762A DE4443762A1 (de) | 1994-12-08 | 1994-12-08 | Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer |

| EP95118182A EP0717165B2 (de) | 1994-12-08 | 1995-11-18 | Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95118182.5 Division | 1995-11-18 | ||

| EP95118182A Division EP0717165B2 (de) | 1994-12-08 | 1995-11-18 | Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP0802300A2 EP0802300A2 (de) | 1997-10-22 |

| EP0802300A3 EP0802300A3 (de) | 1998-05-06 |

| EP0802300B1 true EP0802300B1 (de) | 1999-09-22 |

| EP0802300B2 EP0802300B2 (de) | 2014-09-24 |

Family

ID=6535312

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97111156.2A Expired - Lifetime EP0802300B2 (de) | 1994-12-08 | 1995-11-18 | Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer |

| EP95118182A Expired - Lifetime EP0717165B2 (de) | 1994-12-08 | 1995-11-18 | Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95118182A Expired - Lifetime EP0717165B2 (de) | 1994-12-08 | 1995-11-18 | Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US5694731A (de) |

| EP (2) | EP0802300B2 (de) |

| JP (1) | JPH08218745A (de) |

| KR (1) | KR100380989B1 (de) |

| AT (2) | ATE180040T1 (de) |

| CZ (1) | CZ290046B6 (de) |

| DE (5) | DE9422222U1 (de) |

| DK (2) | DK0717165T4 (de) |

| ES (2) | ES2131254T5 (de) |

| FI (1) | FI104991B (de) |

| HU (1) | HU217682B (de) |

| IL (1) | IL116227A0 (de) |

| PL (1) | PL178256B1 (de) |

| SK (1) | SK281995B6 (de) |

Families Citing this family (71)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DK45896A (da) * | 1996-04-18 | 1997-10-19 | H S Hansens Fabrikker A S | Profil til anbringelse mellem en indre del og en ydre del i en rammekonstruktion |

| DE19651376C2 (de) * | 1996-12-11 | 1999-11-11 | Hueck Eduard Gmbh Co Kg | Brandgeschütztes Mehrkammer-Hohlprofil aus Aluminium oder dergleichen |

| DE19700696B4 (de) * | 1997-01-13 | 2008-07-31 | SCHÜCO International KG | Fassade oder Glasdach in Brandschutzausführung |

| DE19708443A1 (de) * | 1997-03-01 | 1998-09-24 | Wicona Bausysteme Gmbh | Brandschutzelement |

| SE512278C2 (sv) * | 1997-12-19 | 2000-02-21 | Sapa Ab | Brandhärdigt byggelement |

| DE19818769C2 (de) * | 1998-04-27 | 2001-07-12 | Ingbuero Dr Ing Harald Schulz | Wärmedämmleiste |

| DE19900793C2 (de) | 1999-01-12 | 2001-11-22 | Ingbuero Dr Ing Harald Schulz | Brandschutzleiste |

| DK1020608T4 (da) * | 1999-01-15 | 2013-11-25 | Forster Rohr & Profiltechnik Ag | Kompositprofil til rammer for vægelementer, døre og vinduer |

| DE10003953A1 (de) * | 2000-01-29 | 2001-08-09 | Wicona Bausysteme Gmbh | Fassade oder Glasdach in Brandschutzausführung mit einer aus vertikalen und horizontalen Profilen bestehenden Tragkonstruktion |

| DE10016012B4 (de) | 2000-03-31 | 2004-02-05 | SCHÜCO International KG | Verbundprofil für Fenster, Fassaden, Türen oder Lichtdächer |

| DE10041603A1 (de) | 2000-08-24 | 2002-03-07 | Evg Bauprofil System Entwicklungs & Vermarktungsgesellschaft Mbh | Wärmedämmprofil für Brandschutzkonstruktionen |

| ATE470042T1 (de) * | 2001-04-10 | 2010-06-15 | Vkr Holding As | Feuerhemmendes fenster |

| ATE280884T1 (de) | 2001-07-07 | 2004-11-15 | Bemo Brandschutzsysteme Gmbh | Feuerwiderstandsfähiges profilbauteil und verfahren zu seiner herstellung |

| DE10144820A1 (de) * | 2001-09-10 | 2003-03-27 | Bemofensterbau Gmbh | Brandschutzelement, Verfahren zu dessen Herstellung und brandschutzgesichertes Rahmenwerk für ein Gebäudeteil, wie für eine Gebäudefassade oder dgl. |

| DE10144551A1 (de) * | 2001-09-10 | 2003-03-27 | Bemofensterbau Gmbh | Brandschutzelement, Verfahren zu dessen Herstellung und brandschutzgesichertes Rahmenwerk für ein Gebäudeteil, wie für eine Gebäudefassade oder dgl. |

| DE10201419A1 (de) * | 2002-01-15 | 2003-07-24 | Hoermann Kg | Modulsystem und Verfahren zum Herstellen eines Feuerschutzbauelements sowie damit hergestelltes Feuerschutzbauelement |

| PL208873B1 (pl) * | 2002-06-20 | 2011-06-30 | Metalplast Bielsko Społka Akcyjna | Zestaw kształtowników oraz elementów ościeżnicy i skrzydła w konstrukcji ognioodpornej |

| TWI331640B (en) * | 2003-05-26 | 2010-10-11 | Sekisui Chemical Co Ltd | Fire retardant resin sash |

| PL1510643T3 (pl) * | 2003-09-01 | 2018-06-29 | Forster Profilsysteme Ag | Profil i sposób wytwarzania profilu |

| EP1531228B1 (de) * | 2003-11-11 | 2012-10-10 | Technoform Bautec Holding GmbH | Verbundprofil |

| US20050193652A1 (en) * | 2004-02-24 | 2005-09-08 | Expi-Door Systems Inc. | Door jamb assemblies and door assemblies |

| EP1712718A1 (de) * | 2005-04-13 | 2006-10-18 | Forster Rohr- & Profiltechnik AG | Verbundprofil und Verfahren zur Herstellung eines Verbundprofils für Rahmen von Wandelementen, Türen oder Fenstern |

| JP2007132070A (ja) * | 2005-11-10 | 2007-05-31 | Matsushita Electric Ind Co Ltd | 移動建材 |

| US7776178B2 (en) * | 2006-10-25 | 2010-08-17 | Applied Materials, Inc. | Suspension for showerhead in process chamber |

| DE102006061035C5 (de) * | 2006-12-22 | 2014-09-04 | Technoform Bautec Holding Gmbh | Kunststoffprofil für Fenster-, Türen- und Fassadenelemente |

| DE102007008346A1 (de) * | 2007-02-20 | 2008-08-21 | Eduard Hueck Gmbh & Co. Kg | Hohlprofil und Hohlprofilanordnung für Brandschutzkonstruktionen |

| DE102007008345A1 (de) | 2007-02-20 | 2008-08-21 | Eduard Hueck Gmbh & Co. Kg | Rahmenvorrichtung mit Brandschutzfunktion |

| DE202007016649U1 (de) * | 2007-04-02 | 2008-04-30 | Technoform Caprano Und Brunnhofer Gmbh & Co. Kg | Leiterförmiger Isoliersteg für ein Verbundprofil für Fenster-, Türen- und Fassadenelemente und Verbundprofil für Fenster-, Türen- und Fassadenelemente |

| USD590519S1 (en) * | 2008-02-07 | 2009-04-14 | Royal Group, Inc. | Window frame profile |

| USD597220S1 (en) * | 2008-02-07 | 2009-07-28 | Royal Group, Inc. | Window frame profile |

| USD590520S1 (en) * | 2008-02-07 | 2009-04-14 | Royal Group, Inc. | Window frame profile |

| USD590962S1 (en) * | 2008-03-05 | 2009-04-21 | Royal Group, Inc. | Window frame profile |

| USD591432S1 (en) * | 2008-03-05 | 2009-04-28 | Royal Group, Inc. | Window frame profile |

| USD590965S1 (en) * | 2008-03-05 | 2009-04-21 | Royal Group, Inc. | Window frame profile |

| USD590964S1 (en) * | 2008-03-05 | 2009-04-21 | Royal Group, Inc. | Window frame profile |

| EP2136024B1 (de) | 2008-06-18 | 2011-11-09 | Technoform Bautec Holding GmbH | Verbundprofil für Fenster-, Türen-, oder Fassadenelement mit vorbestimmten Brandschutzeigenschaften und Isoliersteg für ein Verbundprofil mit Brandschutzeigenschaften |

| EP2157270B1 (de) | 2008-08-18 | 2016-03-30 | RP Technik GmbH Profilsysteme | Wärmedämmprofil für Brandschutzkonstruktionen sowie Verbundprofil für Fassaden, Fenster und Türen |

| DE102008063650A1 (de) * | 2008-12-18 | 2010-07-01 | Hydro Aluminium As | Brandschutzelement |

| EP2317059B1 (de) | 2009-10-28 | 2012-04-18 | Technoform Bautec Holding GmbH | Verbundprofil für Fenster-, Türen- oder Fassadenelemente mit vorbestimmten Brandschutzeigenschaften und Verbinder und Anschlusselement dafür |

| DE202010008621U1 (de) * | 2010-09-24 | 2011-10-14 | Heroal - Johann Henkenjohann Gmbh & Co. Kg | Leichtmetallprofil für Fassaden, Fenster, Türen o.dgl. |

| EP2500504A1 (de) * | 2011-03-16 | 2012-09-19 | esco Metallbausysteme GmbH | Einschub für ein Feuerschutzabschlussprofil, Feuerschutzabschluss und Verfahren zum Versehen eines Feuerschutzabschlusses mit einer verbesserten Feuerbeständigkeit |

| USD706458S1 (en) * | 2012-09-07 | 2014-06-03 | Mikron Industries, Inc. | Window component extrusion |

| JP6157177B2 (ja) * | 2013-03-29 | 2017-07-05 | 株式会社Lixil | 開口部装置 |

| JP6275430B2 (ja) * | 2013-09-17 | 2018-02-07 | 株式会社Lixil | 窓の防火構造 |

| DE102013112435A1 (de) | 2013-11-12 | 2015-05-13 | SCHÜCO International KG | Verbundprofil und Verfahren zum Herstellen eines Verbundprofils |

| DE202013105101U1 (de) | 2013-11-12 | 2013-11-21 | SCHÜCO International KG | Verbundprofil |

| DE102014106226A1 (de) * | 2014-05-05 | 2015-11-05 | SCHÜCO International KG | Verbundprofil für Türen, Fenster oder Fassadenelemente |

| DE102014112091A1 (de) | 2014-08-25 | 2016-02-25 | SCHÜCO International KG | Verbundprofil für Türen, Fenster oder Fassadenelemente |

| DE102014108264A1 (de) * | 2014-06-12 | 2015-12-17 | Ensinger Gmbh | Wärmeisolierendes Abstandhalterprofil |

| DE102014112107A1 (de) | 2014-08-25 | 2016-02-25 | SCHÜCO International KG | Tür oder Fenster mit Brandschutzeigenschaften |

| ES2571677B1 (es) * | 2014-11-26 | 2017-03-03 | Puertas Padilla, S.L. | Marco tubular de instalación invisible para puertas metálicas de exterior e interior que tiene la posibilidad de ser cortafuegos |

| US9234345B1 (en) * | 2015-04-21 | 2016-01-12 | William F. O'Keeffe | Snap-together fire resistant fenestration frame apparatus |

| CA2916964C (fr) | 2016-01-08 | 2018-02-27 | 9519785 Canada Inc. | Sceau d'etancheite a fixation magnetique |

| PL3423662T3 (pl) | 2016-02-29 | 2023-08-14 | SCHÜCO International KG | Ramiak ościeżnicy i/lub ramiak ramy skrzydłowej, oraz drzwi, okno i element fasady |

| DE102016121068A1 (de) | 2016-02-29 | 2017-08-31 | SCHÜCO International KG | Verbundprofil für eine Tür, ein Fenster oder ein Fassadenelement sowie Verfahren zur Herstellung des Verbundprofils |

| DE102017100336A1 (de) | 2016-02-29 | 2017-08-31 | SCHÜCO International KG | Tür, Fenster oder Fassadenelement |

| EP3228794B1 (de) * | 2016-04-05 | 2019-05-08 | Forster Profilsysteme AG | Profil für rahmen von türen, wandelementen oder fenstern |

| US20180135346A1 (en) | 2016-11-15 | 2018-05-17 | Prestige Storefront Systems LLC | Modular storefront system |

| US11486150B2 (en) | 2016-12-20 | 2022-11-01 | Clarkwestern Dietrich Building Systems Llc | Finishing accessory with backing strip |

| JP6545749B2 (ja) * | 2017-06-05 | 2019-07-17 | 株式会社Lixil | サッシ |

| LT3467250T (lt) | 2017-10-09 | 2020-09-10 | Hydro Building Systems Poland Sp. z o.o. | Ugniai atsparus įdėklas statybiniam elementui, statybinis elementas ir būdas tokiam statybiniam elementui gaminti |

| DE102018125362A1 (de) | 2018-10-12 | 2020-04-16 | Heroal - Johann Henkenjohann Gmbh & Co. Kg | Mehrkammerhohlprofil für Brandschutztüren oder -fenster und Verfahren sowie Vorrichtung zum Herstellen eines solchen Mehrkammerhohlprofils |

| DE102020103737A1 (de) | 2020-02-13 | 2021-08-19 | SCHÜCO International KG | Blend- und/oder Flügelrahmen für ein Brandschutzfenster, eine Brandschutztür und/oder eine Brandschutzfassade |

| CN111593999A (zh) * | 2020-05-21 | 2020-08-28 | 晋中鑫铭格新材料科技有限公司 | 一种新型三层复合粘接式节能门窗型材及制作工艺 |

| US20220120130A1 (en) * | 2020-10-15 | 2022-04-21 | Allmark Door Company, LLC | Powder coated metal door with core |

| USD1026252S1 (en) | 2020-11-12 | 2024-05-07 | Clarkwestern Dietrich Building Systems Llc | Control joint |

| US11885138B2 (en) | 2020-11-12 | 2024-01-30 | Clarkwestern Dietrich Building Systems Llc | Control joint |

| DE102022130070A1 (de) * | 2022-11-14 | 2024-05-16 | HUECK System GmbH & Co. KG | Verbinder zum verbinden von hohlprofilen |

| DE102023105033A1 (de) * | 2023-03-01 | 2024-09-05 | SCHÜCO International KG | Verbundprofil, Rahmen und Verfahren zur Herstellung des Verbundprofils |

| DE102023105783A1 (de) | 2023-03-08 | 2024-09-12 | HUECK System GmbH & Co. KG | Profilrahmen-konstruktion in brandschutzausführung |

| EP4617464A1 (de) | 2024-03-12 | 2025-09-17 | Hydro Building Systems Lüdenscheid GmbH | Profilrahmen-konstruktion in brandschutzausführung |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1092931A (en) * | 1910-05-18 | 1914-04-14 | Benjamin S Mcclellan | Metallic sash. |

| DE2905191A1 (de) † | 1979-02-12 | 1980-08-21 | Straub Theodor | Profilkonstruktion |

| DE2948039A1 (de) | 1979-11-29 | 1981-06-04 | SCHÜCO Heinz Schürmann GmbH & Co, 4800 Bielefeld | Schutztuer gegen feuer und rauch mit einer verglasung |

| DE3224001A1 (de) * | 1982-06-26 | 1983-12-29 | Schock & Co Gmbh, 7060 Schorndorf | Brandschutz-gebaeudebauteil |

| DE3236460C2 (de) † | 1982-10-01 | 1985-03-07 | Josef Gartner & Co, 8883 Gundelfingen | Fassadenkonstruktion |

| US4601143A (en) † | 1984-01-26 | 1986-07-22 | O'keefe's, Inc. | Fire rated wall/door system |

| DE8419182U1 (de) † | 1984-06-26 | 1985-10-24 | Hörmann KG Freisen, 6699 Freisen | Feuerschutztür |

| DE3438861C2 (de) † | 1984-10-24 | 1986-10-09 | Fa. Eduard Hueck, 5880 Lüdenscheid | Verbundprofil zur Herstellung von Fenster-, Türrahmen, Fassadenkonstruktionen u.dgl. |

| DE3621765A1 (de) † | 1986-06-28 | 1988-01-07 | Hueck Fa E | Verwendung von zu polyurethanen ausreagierenden giessmassen zur herstellung von isolierstegen fuer metall-verbundprofile |

| HU200789B (en) * | 1986-11-14 | 1990-08-28 | Mta Koezponti Kemiai Kutato In | Process for localization of fire in burning buildings and for protection against effect of fire |

| DE3709394A1 (de) † | 1987-03-21 | 1988-10-06 | Wieland Werke Ag | Waermegedaemmtes verbundprofil mit brandsicherung |

| DE3713723C1 (en) † | 1987-04-24 | 1988-07-28 | Wieland Werke Ag | Heat-insulated composite profile |

| DE3719803C2 (de) * | 1987-06-13 | 1996-09-12 | Brandschutz Indverband | Feuerhemmende verglaste Trennwand |

| DE8715082U1 (de) † | 1987-11-13 | 1988-02-25 | Bubeck, Paul, Dipl.-Ing., 7000 Stuttgart | Metall-Rahmen-Traggerippe für Fassadenelemente, insbesondere Fensterwand-Elemente |

| DE3919090C1 (en) * | 1989-06-10 | 1990-05-31 | Theo 5140 Erkelenz De Schroeders | Fire resistant strip - has foamable core of sodium or potassium silicate in sleeve of thermoplastic PVC extruded as hollow profile |

| US5347780A (en) * | 1989-10-12 | 1994-09-20 | Georgia-Pacific Corporation | Gypsum fiberboard door frame |

| DE69015802T2 (de) † | 1990-03-01 | 1995-05-11 | Yoshitomi Onoda | Struktur zum Einbau einer Brennstoffzelle. |

| DE4018056C1 (en) * | 1990-06-06 | 1991-07-11 | Deutsche Metalltueren-Werke Dmw Schwarze Gmbh & Co Industrietore Kg, 4800 Bielefeld, De | Refractory insulating material - comprises kaolin, sodium- or potassium-metasilicate and calcined gypsum |

| US5058351A (en) † | 1990-10-22 | 1991-10-22 | Azon Systems, Inc. | Thermal frame section with offset dual skip debridgings |

| DE4104967A1 (de) * | 1991-02-18 | 1992-08-20 | Fachverband Glasdach Und Metal | Waermedaemmittel fuer brandschutzkonstruktionen |

| DE4135416C1 (de) * | 1991-10-26 | 1993-04-15 | Dmw Schwarze Gmbh & Co Industrietore Kg, 4800 Bielefeld, De | |

| US5274171A (en) † | 1992-01-22 | 1993-12-28 | Givaudan-Roure Corporation | Process for the palladium catalyzed coupling of a diazonium salt with an olefinic bond |

| DE4224923C2 (de) * | 1992-07-28 | 1996-08-29 | Sommer Metallbau Stahlbau Gmbh | Bauelement |

| DE4244727C2 (de) * | 1992-08-13 | 1997-09-11 | Sommer Metallbau Stahlbau Gmbh | Bauelement, insbesondere Wand- oder Türelement |

| DE4226878C2 (de) * | 1992-08-13 | 1996-05-23 | Sommer Metallbau Stahlbau Gmbh | Bauelement, insbesondere Wand- oder Türelement |

| DE9211214U1 (de) * | 1992-08-21 | 1992-10-29 | Metallbau-Bedarf GmbH, 4156 Willich | Tür- oder Fensterrahmen mit Brandschutzeinlagen |

| DE9211944U1 (de) * | 1992-09-04 | 1994-01-13 | Hörmann KG Eckelhausen, 66625 Nohfelden | Feuerschutzabschluß im Gebäudebereich |

| DE4232312A1 (de) * | 1992-09-26 | 1994-03-31 | Trube & Kings Kg | Feuerhemmendes Bauteil |

| DE4240234A1 (de) * | 1992-11-30 | 1994-06-01 | Hartmann & Co W | Brandschutzverbundprofil |

| US5469683A (en) * | 1994-02-09 | 1995-11-28 | Kawneer Company, Inc. | Thermally insulating composite frame member with snap-in thermal isolator |

-

1994

- 1994-12-08 DE DE9422222U patent/DE9422222U1/de not_active Expired - Lifetime

- 1994-12-08 DE DE4443762A patent/DE4443762A1/de not_active Withdrawn

- 1994-12-08 DE DE9422023U patent/DE9422023U1/de not_active Expired - Lifetime

-

1995

- 1995-11-18 DK DK95118182T patent/DK0717165T4/da active

- 1995-11-18 AT AT95118182T patent/ATE180040T1/de active

- 1995-11-18 EP EP97111156.2A patent/EP0802300B2/de not_active Expired - Lifetime

- 1995-11-18 EP EP95118182A patent/EP0717165B2/de not_active Expired - Lifetime

- 1995-11-18 ES ES95118182T patent/ES2131254T5/es not_active Expired - Lifetime

- 1995-11-18 DE DE59506920T patent/DE59506920D1/de not_active Expired - Lifetime

- 1995-11-18 DE DE59505903T patent/DE59505903D1/de not_active Expired - Lifetime

- 1995-11-18 AT AT97111156T patent/ATE184956T1/de active

- 1995-11-18 DK DK97111156T patent/DK0802300T3/da active

- 1995-11-18 ES ES97111156T patent/ES2137034T3/es not_active Expired - Lifetime

- 1995-11-29 HU HU9503412A patent/HU217682B/hu not_active IP Right Cessation

- 1995-12-01 IL IL11622795A patent/IL116227A0/xx not_active IP Right Cessation

- 1995-12-04 PL PL95311623A patent/PL178256B1/pl not_active IP Right Cessation

- 1995-12-05 SK SK1534-95A patent/SK281995B6/sk not_active IP Right Cessation

- 1995-12-06 JP JP7317995A patent/JPH08218745A/ja active Pending

- 1995-12-07 FI FI955880A patent/FI104991B/fi not_active IP Right Cessation

- 1995-12-07 US US08/568,931 patent/US5694731A/en not_active Expired - Fee Related

- 1995-12-08 KR KR1019950047669A patent/KR100380989B1/ko not_active Expired - Fee Related

- 1995-12-08 CZ CZ19953254A patent/CZ290046B6/cs not_active IP Right Cessation

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0802300B1 (de) | Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer | |

| DE2746243C2 (de) | Fenster mit verlängerter Feuerwiderstandsfähigkeit | |

| DE3050570C2 (de) | Feuerwiderstandsfähige Verglasung | |

| CH651342A5 (de) | Rahmenbauteil. | |

| DE102011009359A1 (de) | Abstandshalterprofil und Isolierscheibeneinheit mit einem solchen Abstandshalterprofil | |

| EP1961905A2 (de) | Hohlprofil und Hohlprofilanordnung für Brandschutzkonstruktionen | |

| EP2864567B2 (de) | Isoliersteg für ein verbundprofil für fenster-, türen- oder fassadenelemente und verfahren zum herstellen eines solchen isolierstegs und verbundprofil mit einem solchen isoliersteg | |

| DE3438861C2 (de) | Verbundprofil zur Herstellung von Fenster-, Türrahmen, Fassadenkonstruktionen u.dgl. | |

| DE3402226C1 (de) | Verbundprofil fuer einen Fluegel- oder Blendrahmen fuer Fenster oder verglaste Tueren | |

| DE2507244C2 (de) | Lichtdurchlässige Brandschutz-Verbundscheibe, bestehend aus mindestens zwei Glasplatten und einer Zwischenschicht aus einem bei Hitzeeinwirkung expandierenden Ma terial | |

| EP2893097B1 (de) | Bauelement zur fassadendämmung und verfahren zu seiner herstellung | |

| DE102008063650A1 (de) | Brandschutzelement | |

| DE19736768A1 (de) | Lichtdurchlässiges Bauelement | |

| DE19804222C2 (de) | Isoliersteg für Verbundprofile von Fenster- oder Türrahmen | |

| DE202007005298U1 (de) | Tür, Metallkonstruktionsprofil für eine Zarge oder einen Rahmen für eine Tür oder ein Fenster | |

| EP1435424B1 (de) | Glaswand | |

| DE10063894A1 (de) | Dämmleiste aus einem Kunststoff hoher Festigkeit zur gegenseitigen Verbindung zweier Metallprofile zu einem Verbundprofil | |

| EP1484437B1 (de) | Schaftstab, Herstellungsverfahren für diesen und Webschaft | |

| EP0030246B1 (de) | Lichtdurchlässiges wärmedämmendes Verbundelement | |

| EP2157270A1 (de) | Wärmedämmprofil für Brandschutzkonstruktionen sowie Verbundprofil für Fassaden, Fenster und Türen | |

| DE102007002922A1 (de) | Rahmen mit Brandschutzeinrichtung für Isolierverglasungen | |

| AT383862B (de) | Rahmen fuer fenster, tueren od.dgl. | |

| CH661092A5 (de) | Verbundprofil fuer feuerhemmende tueren oder fenster. | |

| DE3326218A1 (de) | Rahmenelement fuer brandschutztueren | |

| DE3325630C2 (de) | Feuerschutztür oder dergleichen feuerhemmender Abschluß von Gebäudeöffnungen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 717165 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL PT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19980814 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19990408 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| ITF | It: translation for a ep patent filed | ||

| AC | Divisional application: reference to earlier application |

Ref document number: 717165 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL PT SE |

|

| REF | Corresponds to: |

Ref document number: 184956 Country of ref document: AT Date of ref document: 19991015 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990922 |

|

| REF | Corresponds to: |

Ref document number: 59506920 Country of ref document: DE Date of ref document: 19991028 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2137034 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19990930 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: EDUARD HUECK GMBH & CO. KG Effective date: 20000525 |

|

| 26 | Opposition filed |

Opponent name: WICONA BAUSYSTEME GMBH & CO. KG Effective date: 20000623 Opponent name: REYNAERS ALUMINIUM N.V. Effective date: 20000621 Opponent name: EDUARD HUECK GMBH & CO. KG Effective date: 20000525 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: WICONA BAUSYSTEME GMBH & CO. KG Opponent name: REYNAERS ALUMINIUM N.V. Opponent name: EDUARD HUECK GMBH & CO. KG |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20091112 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20101124 Year of fee payment: 16 Ref country code: AT Payment date: 20101119 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20101126 Year of fee payment: 16 Ref country code: GB Payment date: 20101123 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20110518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110518 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20111221 Year of fee payment: 17 Ref country code: FR Payment date: 20120103 Year of fee payment: 17 Ref country code: ES Payment date: 20111219 Year of fee payment: 17 Ref country code: SE Payment date: 20111220 Year of fee payment: 17 Ref country code: CH Payment date: 20111222 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20111220 Year of fee payment: 17 |

|

| BERE | Be: lapsed |

Owner name: *SCHUCO INTERNATIONAL K.G. Effective date: 20121130 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20130601 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 184956 Country of ref document: AT Kind code of ref document: T Effective date: 20121118 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20121118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121119 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121118 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121118 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121118 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20140304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121119 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20140924 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL PT SE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 59506920 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 59506920 Country of ref document: DE Effective date: 20140924 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20141201 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59506920 Country of ref document: DE |