WO2014168188A1 - 積層体 - Google Patents

積層体 Download PDFInfo

- Publication number

- WO2014168188A1 WO2014168188A1 PCT/JP2014/060340 JP2014060340W WO2014168188A1 WO 2014168188 A1 WO2014168188 A1 WO 2014168188A1 JP 2014060340 W JP2014060340 W JP 2014060340W WO 2014168188 A1 WO2014168188 A1 WO 2014168188A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- polymer

- surface layer

- piezoelectric material

- group

- compound

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/36—Layered products comprising a layer of synthetic resin comprising polyesters

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/80—Constructional details

- H10N30/85—Piezoelectric or electrostrictive active materials

- H10N30/857—Macromolecular compositions

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/80—Constructional details

- H10N30/88—Mounts; Supports; Enclosures; Casings

- H10N30/883—Additional insulation means preventing electrical, physical or chemical damage, e.g. protective coatings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/20—Properties of the layers or laminate having particular electrical or magnetic properties, e.g. piezoelectric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/51—Elastic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/54—Yield strength; Tensile strength

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/704—Crystalline

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/20—Displays, e.g. liquid crystal displays, plasma displays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/20—Displays, e.g. liquid crystal displays, plasma displays

- B32B2457/202—LCD, i.e. liquid crystal displays

Definitions

- the present invention relates to a laminate.

- polymer piezoelectric materials using helical chiral polymers having optical activity have been reported.

- a polymer piezoelectric material that exhibits a piezoelectric constant of about 10 pC / N at room temperature by stretching a molded product of polylactic acid has been disclosed (for example, see JP-A-5-152638).

- high piezoelectricity of about 18 pC / N is produced by a special orientation method called forging (see, for example, JP-A-2005-213376). .

- a touch panel using a molecular oriented polylactic acid film and a touch input device using this touch panel are also known (see, for example, International Publication No. 2010/143528 pamphlet).

- a linear polarizer may be used in a display device such as a liquid crystal display device or an organic electroluminescence display device (for example, Japanese Patent Application Laid-Open Nos. 2006-268018, 2009-192611, and 2009-). No. 21408).

- the crystalline polymer piezoelectric material may be provided with a surface layer for adhesion for the purpose of adhering to other members such as electrodes, or a protective surface layer for the purpose of protection.

- a surface layer for adhesion for the purpose of adhering to other members such as electrodes, or a protective surface layer for the purpose of protection.

- the formation of such a surface layer tends to lower the piezoelectric constant in the laminate of the crystalline polymer piezoelectric material and the surface layer.

- peeling may occur in the surface layer formed so as to be in contact with at least a part of the crystalline polymer piezoelectric material, and further improvement in the adhesion between the crystalline polymer piezoelectric material and the surface layer is desired.

- the subject of the 1st aspect of this invention is providing the laminated body by which the fall of the sensitivity was suppressed.

- the subject of the 2nd aspect of this invention is providing the laminated body excellent in the adhesive force of a crystalline polymer piezoelectric material and

- 1st aspect of this invention is a laminated body as described in following [1].

- a second aspect of the present invention is the laminate described in the following [6].

- An overlapping portion may exist between the range of the first aspect and the range of the second aspect.

- the surface layer is an acrylic compound, methacrylic compound, vinyl compound, allyl compound, urethane compound, epoxy compound, epoxide compound, glycidyl compound, oxetane compound, melamine compound, cellulose type. Including at least one material selected from the group consisting of compounds, ester compounds, silane compounds, silicone compounds, siloxane compounds, silica-acrylic hybrid compounds, silica-epoxy hybrid compounds, metals, and metal oxides, [1] The laminate according to any one of [4].

- Crystalline polymer piezoelectric material having a normalized molecular orientation MORc of 2.0 to 10.0 when the reference thickness measured by a microwave transmission type molecular orientation meter is 50 ⁇ m, and the crystalline polymer And a surface layer including at least a part of the piezoelectric body and including a carbonyl group and a polymer.

- the laminate described in [6] is preferably the laminate described in any one of [1] to [5]. That is, in the laminated body according to any one of [1] to [5], the crystalline polymer piezoelectric material has a reference thickness measured by a microwave transmission molecular orientation meter of 50 ⁇ m.

- the normalized molecular orientation MORc is 2.0 to 10.0, the surface layer is disposed so as to be at least partially in contact with the crystalline polymer piezoelectric material, includes a carbonyl group and includes a polymer. preferable.

- the crystalline polymer piezoelectric material includes a polymer having a repeating unit structure having a functional group of at least one of a carbonyl group and an oxy group (preferably a helical chiral polymer having optical activity). ] To [10].

- the crystalline polymer piezoelectric material includes an optically active helical chiral polymer having a weight average molecular weight of 50,000 to 1,000,000, and has a crystallinity of 20% to 80% obtained by a DSC method.

- the laminate according to any one of [1] to [11].

- the crystalline polymer piezoelectric material includes a stabilizer having a weight average molecular weight of 200 to 60,000 having at least one functional group selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group,

- the stabilizer has one functional group selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group in one molecule.

- the laminated body by which the fall of the sensitivity was suppressed can be provided.

- the laminated body excellent in the adhesive force of a crystalline polymer piezoelectric material and a surface layer can be provided.

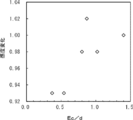

- FIG. 6 is a graph showing the relationship between Ec / d and sensitivity change in Examples 1A to 7A and Comparative Examples 1A to 2A.

- FIG. 1 is a graph showing a range where Ec / d is 0 to 1.5.

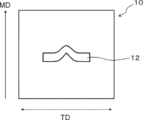

- FIG. 5 is a conceptual diagram showing the cut-out direction of a test piece in the measurement of tear strength in Examples 15B to 21B.

- the laminate according to the first aspect of the present invention includes a crystalline polymer piezoelectric material having molecular orientation and a surface layer.

- the relationship between the tensile modulus Ec (GPa) and the thickness d ( ⁇ m) satisfies the following formula (A). 0.6 ⁇ Ec / d Formula (A)

- a crystalline polymer piezoelectric body (hereinafter also simply referred to as “piezoelectric body”) is provided with an adhesive surface layer for the purpose of adhering to other members such as electrodes, or a protective surface layer for the purpose of protection.

- an adhesive surface layer for the purpose of adhering to other members such as electrodes, or a protective surface layer for the purpose of protection.

- the formation of such a surface layer tends to lower the piezoelectric constant in the laminate of the piezoelectric body and the surface layer.

- the decrease in the sensitivity of the piezoelectric body can be suppressed by adjusting the relationship between the thickness d of the surface layer and the tensile elastic modulus Ec to a range satisfying the above formula (A). it can.

- the surface layer in the first aspect refers to a layer existing on the surface side of the piezoelectric body. Therefore, another member may be provided on the surface layer, and the surface layer does not necessarily indicate a layer that is the outermost surface of the final molded product.

- an electrode is mentioned, for example.

- the electrode may be an electrode layer that covers the entire surface layer, or an electrode pattern that is formed so as to cover a part of the surface layer.

- the surface layer in the first aspect may be composed of only one layer or a multilayer film in which a plurality of functional layers are laminated.

- the surface layer in the first embodiment may be on both sides as well as on one side of the piezoelectric body, and the functions and materials may be different.

- the surface layer in the first aspect satisfies the formula (A).

- the ratio (Ec / d) between the tensile elastic modulus Ec and the thickness d satisfies the above formula, a decrease in sensitivity of the piezoelectric body in the laminate can be suppressed.

- the ratio (Ec / d) is more preferably 1.0 or more, further preferably 1.4 or more, and further preferably 3 or more. Although there is no restriction

- the ratio (Ec / d) is more preferably 30 or less, further preferably 25 or less, and further preferably 17.72 or less.

- the ratio (Ec / d) is particularly preferably 1.4 or more and 17.72 or less.

- the tensile modulus Ec of the surface layer is not particularly limited, but is preferably in the range of 0.1 GPa to 1000 GPa.

- the tensile elastic modulus Ec is equal to or higher than the lower limit, a decrease in the tensile elastic modulus of the laminate can be suppressed.

- the tensile elastic modulus Ec is less than or equal to the above upper limit value, the laminate can be deformed by a general human force and can be used as a sensor.

- the upper limit value of the tensile elastic modulus Ec is more preferably 300 GPa or less, and still more preferably 100 GPa or less. Further, the lower limit value is more preferably 1 GPa or more, and further preferably 2 GPa or more.

- the surface layer in the first aspect may be a very thin layer, it may be difficult to directly measure the tensile elastic modulus of only the surface layer. Therefore, in this specification, calculation of the tensile elastic modulus Ec of the surface layer is performed by the following formula.

- Tensile modulus of surface layer Ec [tensile modulus of laminate- ⁇ tensile modulus of piezoelectric body only ⁇ (thickness of piezoelectric body / thickness of laminate) ⁇ ] / (thickness of surface layer / laminate) Thickness)

- the tensile elastic modulus Ec represents an average tensile elastic modulus in the entire multilayer film.

- the tensile elastic modulus Ec represents the average tensile elastic modulus in the entire surface layer on both sides.

- the “tensile modulus of the laminate” in the above formula is measured by the following method.

- the laminated body is cut into 120 mm in a direction of 45 ° with respect to the stretching direction (for example, MD direction) of the crystalline polymer piezoelectric material, and 10 mm in a direction orthogonal to the direction of 45 ° to produce a rectangular sample.

- the obtained sample is set in a tensile testing machine (manufactured by AND, TENSILON RTG-1250) with a distance between chucks of 70 mm so as not to be loosened.

- “Tensile elastic modulus of piezoelectric body only” is the same as the tensile elastic modulus of the laminated body after removing the surface layer from the laminated body or forming the same piezoelectric body as the piezoelectric body in the laminated body. To measure.

- control of the tensile elasticity modulus Ec in a surface layer is performed by selecting the material which comprises a surface layer, for example.

- the material constituting the surface layer includes a cured product of a curable compound

- the crosslink density can be increased and the tensile modulus Ec can be increased.

- the thickness (average thickness) d of the surface layer is not particularly limited, but is preferably in the range of 0.01 ⁇ m to 10 ⁇ m.

- the thickness d is equal to or greater than the lower limit value, for example, the surface layer exhibits functions such as a hard coat layer described later.

- the thickness d is equal to or less than the above upper limit value, a large charge is generated in the electrode when an electrode is further provided on the surface layer in the laminate.

- the upper limit value of the thickness d is more preferably 6 ⁇ m or less, and even more preferably 3 ⁇ m or less. Further, the lower limit value is more preferably 0.2 ⁇ m or more, and further preferably 0.3 ⁇ m or more.

- the thickness d represents the thickness of the entire multilayer film.

- the surface layer may be provided on both sides of the piezoelectric body. In this case, the thickness d is the sum of the thicknesses on both sides.

- the thickness d of the surface layer is determined by the following formula using a digital length measuring device DIGIMICRO STAND MS-11C manufactured by Nikon Corporation.

- Formula d dt ⁇ dp dt: Average thickness of 10 laminated bodies

- dt Average thickness of 10 piezoelectric bodies before forming the surface layer or after removing the surface layer

- Examples of the surface layer formed on the surface of the piezoelectric body include various functional layers.

- a functional layer for example, an easy adhesion layer, a hard coat layer, a refractive index adjustment layer, an antireflection layer, an antiglare layer, an easy slip layer, an antiblock layer, a protective layer, an adhesive layer, an adhesive layer, an antistatic layer, a heat dissipation layer, Examples include an ultraviolet absorbing layer, an anti-Newton ring layer, a light scattering layer, a polarizing layer, a gas barrier layer, and a hue adjusting layer.

- Another member may be formed on the surface layer of the laminate in which the piezoelectric body and the surface layer are laminated.

- Examples of the other member include an electrode.

- functional layers such as an easy-adhesion layer, a hard coat layer, and a refractive index adjustment layer are generally provided as the surface layer in the aspect in which the electrode is provided. Further, by forming the surface layer, defects such as die lines and dents on the surface of the piezoelectric body are filled, and the appearance is improved. In this case, the smaller the refractive index difference between the piezoelectric body and the surface layer, the more the reflection at the interface between the piezoelectric body and the surface layer is reduced, and the appearance is further improved.

- the material of the surface layer is not particularly limited, but for example, acrylic compounds, methacrylic compounds, vinyl compounds, allyl compounds, urethane compounds, epoxy compounds, epoxide compounds, glycidyl compounds Compound, oxetane compound, melamine compound, cellulose compound, ester compound, silane compound, silicone compound, siloxane compound, silica-acrylic hybrid compound, silica-epoxy hybrid compound, metal, and metal oxide It is preferable to include at least one material selected from the group. Among these, acrylic compounds, epoxy compounds, silane compounds, and metal oxides are more preferable.

- ⁇ Formation method As a method for forming the surface layer, a known method that has been generally used can be appropriately used. For example, a wet coating method is first given. For example, acrylic compounds, methacrylic compounds, vinyl compounds, allyl compounds, urethane compounds, epoxy compounds, epoxide compounds, glycidyl compounds, oxetane compounds, melamine compounds, cellulose compounds, ester compounds, A surface layer is formed by applying a coating liquid in which a material such as a silane compound, a silicone compound, a siloxane compound, a silica-acrylic hybrid compound, or a silica-epoxy hybrid compound is dispersed or dissolved.

- a material such as a silane compound, a silicone compound, a siloxane compound, a silica-acrylic hybrid compound, or a silica-epoxy hybrid compound is dispersed or dissolved.

- the surface layer is cured by applying heat or active energy rays (ultraviolet rays, electron beams, radiation, etc.) to the material (curable compound) applied as described above.

- active energy rays ultraviolet rays, electron beams, radiation, etc.

- the surface layer contains a cured product of the curable compound as described above, by reducing the equivalent of the polymerizable functional group of the curable compound (that is, the polymerizability contained per unit molecular weight of the curable compound).

- the crosslink density can be increased and the tensile modulus Ec can be increased.

- the material contained in the surface layer is preferably an active energy ray curable resin cured by irradiation with active energy rays (ultraviolet rays, electron beams, radiation, etc.) among the above cured products.

- active energy rays ultraviolet rays, electron beams, radiation, etc.

- the production efficiency can be improved, and the performance deterioration of the piezoelectric body caused by the surface layer formation can be further suppressed.

- a cured product having a three-dimensional cross-linked structure is preferable among the cured products.

- a crosslinking density can be raised and the tensile elasticity modulus Ec can be enlarged.

- a method using a monomer having three or more polymerizable functional groups as a curable compound, or a crosslinking having three or more polymerizable functional groups.

- examples include a method using a crosslinking agent (a trifunctional or higher functional crosslinking agent), and a method using a crosslinking agent such as an organic peroxide as the crosslinking agent.

- a crosslinking agent a trifunctional or higher functional crosslinking agent

- a crosslinking agent such as an organic peroxide

- Examples of the tri- or higher functional monomer include (meth) acrylic compounds having three or more (meth) acrylic groups in one molecule, and epoxy compounds having three or more epoxy groups in one molecule. .

- (meth) acrylic group represents at least one of an acrylic group and a methacrylic group.

- “having three or more (meth) acrylic groups in one molecule” means having at least one of an acrylic group and a methacrylic group in one molecule, and an acrylic group and a methacrylic group in one molecule. The total number is 3 or more.

- the gel fraction can be derived from the insoluble matter after the surface layer is immersed in a solvent for 24 hours.

- a solvent having a gel fraction of a certain level or more has a three-dimensional crosslinked structure, whether the solvent is a hydrophilic solvent such as water or a new oily solvent such as toluene.

- the use of the surface layer by the wet coating method can be applied to any of the above-listed layers.

- the piezoelectric liquid may be stretched after the coating liquid has been applied to the original film before stretching of the piezoelectric body, or the coating liquid may be applied after the piezoelectric body film has been stretched.

- the thickness (one layer) of the surface layer by wet coating is preferably in the range of several tens of nm to 10 ⁇ m.

- various organic substances such as a refractive index adjusting agent, an ultraviolet absorber, a leveling agent, an antistatic agent, and an antiblocking agent and inorganic substances can be added to the surface layer according to the purpose.

- a dry coating method may also be used as a method for forming the surface layer.

- a vacuum deposition method, a sputtering method, an ion plating method, a CVD method, and the like can be given, and it is suitably used when forming a metal film, a metal oxide film, or the like.

- Examples of the use of the surface layer by the dry coating method include an easy adhesion layer, a refractive index adjustment layer, an anti-reflection layer, and the like.

- the thickness (one layer) of the surface layer by the dry coating method is preferably in the range of several tens of nm to several hundreds of nm.

- the surface of the piezoelectric body is treated by corona treatment, itro treatment, ozone treatment, plasma treatment, etc. You can also.

- the relative dielectric constant of the surface layer is preferably 1.5 or more, more preferably 2.0 or more and 20000 or less, and further preferably 2.5 or more and 10,000 or less. When the relative dielectric constant is in the above range, a large charge is generated by the electrode when an electrode is further provided on the surface layer in the laminate.

- the relative dielectric constant of the surface layer is measured by the following method. After a surface layer is formed on one side of the piezoelectric body, Al of about 50 nm is deposited on both sides of the laminate using Showa Vacuum SIP-600. A 50 mm ⁇ 50 mm film is cut out from this laminate. This test piece is connected to LCR METER 4284A manufactured by HEWLETT PACKARD, the capacitance C is measured, and the relative dielectric constant ⁇ c of the surface layer is calculated by the following equation.

- ⁇ c (C ⁇ d ⁇ 2.7) / ( ⁇ 0 ⁇ 2.7 ⁇ S ⁇ C ⁇ dp)

- d surface layer thickness

- ⁇ 0 vacuum dielectric constant

- S specimen area

- dp piezoelectric thickness

- the internal haze of the surface layer is preferably 10% or less, more preferably 0.0% or more and 5% or less, and further preferably 0.01% or more and 2% or less.

- excellent transparency is exhibited, and it can be effectively used as a touch panel, for example.

- the internal haze Hc of the surface layer is calculated by the following formula.

- Hc H ⁇ Hp H: Internal haze of laminate

- Hp Internal haze of piezoelectric body before surface layer formation or after removal of surface layer

- the internal haze of the piezoelectric body is a crystalline polymer having a thickness of 0.03 mm to 0.05 mm This is the value when the piezoelectric body is measured at 25 ° C. using a haze measuring machine (manufactured by Tokyo Denshoku Co., Ltd., TC-HIII DPK) according to JIS-K7105. This will be described in detail in Examples.

- the internal haze of the laminate is also measured according to the method for measuring the internal haze of the piezoelectric body.

- the surface layer in the first aspect described above may correspond to the surface layer in the second aspect described later.

- the surface layer in the first aspect includes a carbonyl group (—C ( ⁇ O) —) and may include a polymer.

- the polymer may have a three-dimensional crosslinked structure.

- the polymer may be a polymer of a compound having a (meth) acryl group.

- the polymer may be an active energy ray curable resin cured by active energy ray irradiation (for example, an ultraviolet curable resin cured by ultraviolet ray irradiation). Details of the surface layer in the second aspect will be described later.

- crystalline polymer piezoelectric material piezoelectric material

- piezoelectric material piezoelectric material

- a conventionally known crystalline polymer piezoelectric material can be used without any particular limitation.

- a crystalline polymer piezoelectric material including a helical chiral polymer having optical activity which is preferably used in the first embodiment, will be described as an example.

- the helical chiral polymer having optical activity refers to a polymer having molecular optical activity whose molecular structure is a helical structure.

- the above-mentioned “helical chiral polymer having optical activity” is also referred to as “optically active polymer”.

- the optically active polymer include polypeptides, cellulose, cellulose derivatives, polylactic acid polymers, polypropylene oxide, poly ( ⁇ -hydroxybutyric acid), and the like.

- the polypeptide include poly (glutarate ⁇ -benzyl), poly (glutarate ⁇ -methyl) and the like.

- the cellulose derivative include cellulose acetate and cyanoethyl cellulose.

- the optically active polymer preferably has an optical purity of 95.00% ee or more, more preferably 99.00% ee or more, from the viewpoint of improving the piezoelectricity of the crystalline polymer piezoelectric material. More preferably, it is 99% ee or more. Desirably, it is 100.00% ee.

- the optical purity of the optically active polymer is a value calculated by the following formula.

- Optical purity (% ee) 100 ⁇

- Optical purity (% ee) 100 ⁇

- the value obtained by the method using a high performance liquid chromatography is used for the quantity [mass%] of the L form of an optically active polymer and the quantity [mass%] of the D form of an optically active polymer. Details of the specific measurement will be described later.

- a polymer having a main chain containing a repeating unit represented by the following formula (1) is preferable from the viewpoint of increasing optical purity and improving piezoelectricity.

- polylactic acid-based polymers examples include polylactic acid-based polymers.

- polylactic acid is preferable, and L-lactic acid homopolymer (PLLA) or D-lactic acid homopolymer (PDLA) is most preferable.

- PLLA L-lactic acid homopolymer

- PDLA D-lactic acid homopolymer

- the polylactic acid polymer refers to “polylactic acid”, “a copolymer of L-lactic acid or D-lactic acid and a copolymerizable polyfunctional compound”, or a mixture of both.

- the above-mentioned “polylactic acid” is a polymer in which lactic acid is polymerized by an ester bond and is connected for a long time, a lactide method via lactide, a direct polymerization method in which lactic acid is heated in a solvent under reduced pressure and polymerized while removing water. It is known that can be manufactured by.

- polylactic acid examples include a homopolymer of L-lactic acid, a homopolymer of D-lactic acid, a block copolymer containing at least one polymer of L-lactic acid and D-lactic acid, and L-lactic acid and D-lactic acid.

- Examples of the “copolymerizable polyfunctional compound” include glycolic acid, dimethyl glycolic acid, 3-hydroxybutyric acid, 4-hydroxybutyric acid, 2-hydroxypropanoic acid, 3-hydroxypropanoic acid, 2-hydroxyvaleric acid, 3 -Hydroxyvaleric acid, 4-hydroxyvaleric acid, 5-hydroxyvaleric acid, 2-hydroxycaproic acid, 3-hydroxycaproic acid, 4-hydroxycaproic acid, 5-hydroxycaproic acid, 6-hydroxycaproic acid, 6-hydroxy Hydroxycarboxylic acids such as methylcaproic acid and mandelic acid, glycolides, cyclic esters such as ⁇ -methyl- ⁇ -valerolactone, ⁇ -valerolactone and ⁇ -caprolactone, oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid , Pimelic acid, azelaic acid, sebacic acid, undecanedioic acid, Polyvalent carboxylic acids such as decaned

- the “copolymer of L-lactic acid or D-lactic acid and a copolymerizable polyfunctional compound” includes a block copolymer or a graft copolymer having a polylactic acid sequence capable of forming a helical crystal.

- the concentration of the structure derived from the copolymer component in the optically active polymer is preferably 20 mol% or less.

- the optically active polymer is a polylactic acid polymer

- the copolymer component is preferably 20 mol% or less based on the total.

- the optically active polymer (for example, polylactic acid polymer) is obtained by, for example, a method of directly dehydrating and condensing lactic acid described in JP-A-59-096123 and JP-A-7-033861. US Pat. Nos. 2,668,182 and 4,057,357 can be used for the production by ring-opening polymerization using lactide, which is a cyclic dimer of lactic acid. Furthermore, the optically active polymer (for example, polylactic acid-based polymer) obtained by each of the above production methods has, for example, a case where polylactic acid is produced by the lactide method so that the optical purity is 95.00% ee or more. It is preferable to polymerize lactide having an optical purity of 95.00% ee or higher by crystallization operation.

- the optically active polymer in the first aspect preferably has a weight average molecular weight (Mw) of 50,000 to 1,000,000.

- Mw weight average molecular weight

- the lower limit of the weight average molecular weight of the optically active polymer is 50,000 or more, sufficient mechanical strength can be obtained when the optically active polymer is a molded body.

- the lower limit of the weight average molecular weight of the optically active polymer is preferably 100,000 or more, and more preferably 150,000 or more.

- the upper limit of the weight average molecular weight of the optically active polymer is 1,000,000 or less, the optically active polymer can be easily molded (for example, formed into a film shape by extrusion molding or the like).

- the upper limit of the weight average molecular weight is preferably 800,000 or less, and more preferably 300,000 or less.

- the molecular weight distribution (Mw / Mn) of the optically active polymer is preferably 1.1 to 5 and more preferably 1.2 to 4 from the viewpoint of the strength of the crystalline polymer piezoelectric material. preferable. Further, it is preferably 1.4 to 3.

- the weight average molecular weight Mw and molecular weight distribution (Mw / Mn) of a polylactic acid-type polymer are measured by the following GPC measuring method using a gel permeation chromatograph (GPC).

- -GPC measuring device Waters GPC-100 -column- Made by Showa Denko KK, Shodex LF-804 -Sample preparation-

- a polylactic acid polymer is dissolved in a solvent (for example, chloroform) at 40 ° C. to prepare a sample solution having a concentration of 1 mg / mL.

- a solvent for example, chloroform

- -Measurement condition 0.1 mL of the sample solution is introduced into the column at a solvent [chloroform], a temperature of 40 ° C., and a flow rate of 1 mL / min.

- a universal calibration curve is created with a polystyrene standard sample, and the weight average molecular weight (Mw) and molecular weight distribution (Mw / Mn) of the polylactic acid polymer are calculated based on the created universal calibration curve.

- polylactic acid polymer commercially available polylactic acid may be used.

- examples of commercially available polylactic acid include PURASORB (PD, PL) manufactured by PURAC, LACEA (H-100, H-400) manufactured by Mitsui Chemicals, Ingeo 4032D, 4043D manufactured by NatureWorks, and the like.

- the optically active polymer is produced by the lactide method or the direct polymerization method in order to increase the weight average molecular weight (Mw) of the polylactic acid polymer to 50,000 or more. It is preferable to do.

- the crystalline polymer piezoelectric material in the first embodiment may contain only one kind of the optically active polymer described above, or may contain two or more kinds.

- the content of the optically active polymer (the total content in the case of two or more types; the same shall apply hereinafter) is not particularly limited, but the crystalline polymer piezoelectric material is not particularly limited. It is preferable that it is 80 mass% or more with respect to the whole body mass. When the content is 80% by mass or more, the piezoelectric constant tends to be larger.

- the crystalline polymer piezoelectric material according to the first aspect includes other components other than the above-described optically active polymer (for example, known resins typified by polyvinylidene fluoride, polyethylene resin and polystyrene resin, silica, hydroxyapatite) , Inorganic fillers such as montmorillonite, and known crystal nucleating agents such as phthalocyanine).

- the crystalline polymer piezoelectric material in the first embodiment includes a stabilizer such as a carbodiimide compound typified by Carbodilite (registered trademark) from the viewpoint of further suppressing structural changes due to hydrolysis or the like.

- the crystalline polymer piezoelectric material in the first aspect may contain at least one inorganic filler.

- an inorganic filler such as hydroxyapatite may be nano-dispersed in the crystalline polymer piezoelectric material in order to make the crystalline polymer piezoelectric material a transparent film in which voids such as bubbles are suppressed.

- voids such as bubbles are suppressed.

- the inorganic filler In order to nano-disperse the inorganic filler, a large amount of energy is required for crushing the aggregate, and when the inorganic filler is not nano-dispersed, the transparency of the film may be lowered.

- the content of the inorganic filler with respect to the total mass of the crystalline polymer piezoelectric material is preferably less than 1% by mass.

- the content of the component other than the optically active polymer is 20% by mass or less based on the total mass of the crystalline polymer piezoelectric material. It is preferably 10% by mass or less.

- the crystalline polymer piezoelectric material in the first aspect may contain at least one crystal accelerator (crystal nucleating agent).

- the crystal accelerator (crystal nucleator) is not particularly limited as long as the effect of promoting crystallization is recognized, but is a substance having a crystal structure having a face spacing close to the face spacing of the crystal lattice of the optically active polymer. It is desirable to select. This is because a substance with a close spacing is more effective as a nucleating agent.

- the organic material is zinc phenylsulfonate, melamine polyphosphate, melamine cyanurate, zinc phenylphosphonate, calcium phenylphosphonate, magnesium phenylphosphonate,

- examples include inorganic substances such as talc and clay.

- zinc phenylphosphonate is most preferable because the plane spacing is most similar to the plane spacing of polylactic acid and provides a good crystal formation promoting effect.

- the commercially available crystal accelerator can be used. Specific examples include zinc phenylphosphonate; Eco Promote (manufactured by Nissan Chemical Industries, Ltd.) and the like.

- the content of the crystal nucleating agent is usually 0.01 to 1.0 part by weight, preferably 0.01 to 0.5 part by weight, based on 100 parts by weight of the optically active polymer. From the viewpoint of maintenance, it is particularly preferably 0.02 to 0.2 parts by weight. When the content of the crystal nucleating agent is 0.01 parts by weight or more, the effect of promoting crystallization can be obtained more effectively. When the content of the crystal nucleating agent is less than 1.0 part by weight, the crystallization rate can be more easily controlled.

- a crystalline polymer piezoelectric material does not contain components other than the helical chiral polymer (optically active polymer) having optical activity from the viewpoint of transparency.

- the crystalline polymer piezoelectric material in the first embodiment may contain a stabilizer.

- the stabilizer used in the first embodiment is a compound having one or more functional groups selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group and having a weight average molecular weight of 200 to 60,000. This stabilizer is used to suppress the hydrolyzability of the optically active polymer and to improve the moisture and heat resistance of the obtained piezoelectric body.

- a method of reducing low molecular weight compounds such as unreacted monomers and impurities in a polymer such as polyester and chain / cyclic oligomers for example, And JP-A-9-12688, a method for adding an aromatic carbodiimide (for example, JP-T-2001-525473), a method for adding an oxazoline compound (for example, JP-A-2007-77193), and the like.

- the method is known.

- the present inventors have added a specific amount of a stabilizer having a specific functional group to the optically active polymer, so that the hydrolysis of the optically active polymer can be achieved without greatly reducing the piezoelectricity and transparency. It has been found that the heat resistance and reliability of the piezoelectric body can be improved.

- the specific functional group capable of interacting with both a hydroxyl group and a carboxy group includes at least one functional group selected from the group consisting of a carbodiimide group, an isocyanate group, and an epoxy group having the following structure.

- a carbodiimide group is preferable from the viewpoint of effects.

- the weight average molecular weight of the stabilizer used in the present embodiment is preferably 200 to 60000, more preferably 200 to 30000, and further preferably 300 to 18000. If the molecular weight is within the above range, it is presumed that the stabilizer can be easily transferred as described above, and the effect of improving the heat and moisture resistance can be sufficiently obtained.

- the weight average molecular weight of the stabilizer is particularly preferably 200 to 900. Note that the weight average molecular weight of 200 to 900 is almost the same as the number average molecular weight of 200 to 900. In particular, when the weight average molecular weight is 200 to 900, the molecular weight distribution may be 1.0. In this case, “weight average molecular weight 200 to 900” is simply rephrased as “molecular weight 200 to 900”. You can also.

- the carbodiimide compound having a carbodiimide group used as a stabilizer in the first embodiment has one or more carbodiimide groups in the molecule.

- the carbodiimide compound including the polycarbodiimide compound

- those synthesized by a generally well-known method can be used.

- an organophosphorus compound or organometallic compound is used as a catalyst, and various isocyanates can be synthesized by subjecting them to a decarboxylation condensation reaction in a solvent-free or inert solvent at a temperature of about 70 ° C. or higher. Can be mentioned.

- Examples of the monocarbodiimide compound contained in the carbodiimide compound include dicyclohexylcarbodiimide, dimethylcarbodiimide, diisobutylcarbodiimide, dioctylcarbodiimide, t-butylisopropylcarbodiimide, diphenylcarbodiimide, di-t-butylcarbodiimide, di- ⁇ -naphthylcarbodiimide and the like.

- dicyclohexylcarbodiimide or bis-2,6-diisopropylphenylcarbodiimide is preferable from the viewpoint of easy industrial availability.

- polycarbodiimide compound contained in the carbodiimide compound those produced by various methods can be used.

- Conventional methods for producing polycarbodiimides see, for example, US Pat. No. 2,941,956, Japanese Patent Publication No. 47-33279, J.0rg.Chem.28, 2069-2075 (1963), Chemical Review 1981, Vol. 4, p619-621) can be used.

- a carbodiimide compound described in Japanese Patent No. 4084953 can also be used.

- polycarbodiimide compound examples include poly (4,4′-dicyclohexylmethanecarbodiimide), poly (tetramethylxylylenecarbodiimide), poly (N, N-dimethylphenylcarbodiimide), and poly (N, N′-di-2,6).

- -Diisopropylphenylcarbodiimide and the like, and any carbodiimide compound having one or more carbodiimide groups in the molecule having such a function is not particularly limited.

- the carbodiimide compound a commercially available product may be used.

- Examples of the compound having an isocyanate group (isocyanate compound) used as a stabilizer in the first embodiment include hexyl isocyanate, cyclohexyl isocyanate, benzyl isocyanate, phenethyl isocyanate, butyl isocyanatoacetate, dodecyl isocyanate, octadecyl isocyanate, and isocyanate 3- (Triethoxysilyl) propyl, 2,4-tolylene diisocyanate, 2,6-tolylene diisocyanate, m-phenylene diisocyanate, p-phenylene diisocyanate, 4,4'-diphenylmethane diisocyanate, 2,4'-diphenylmethane diisocyanate, 2 , 2'-diphenylmethane diisocyanate, 3,3'-dimethyl-4,4'-biphenylene diisocyan

- Examples of the compound having an epoxy group (epoxy compound) used as a stabilizer in the first embodiment include N-glycidylphthalimide, orthophenylphenyl glycidyl ether, phenyl glycidyl ether, pt-butylphenyl glycidyl ether, hydroquinone diester.

- Glycidyl ether Glycidyl ether, resorcin diglycidyl ether, 1,6-hexanediol diglycidyl ether, diethylene glycol diglycidyl ether, polyethylene glycol diglycidyl ether, trimethylolpropane triglycidyl ether, bisphenol A-diglycidyl ether, hydrogenated bisphenol A-diglycidyl Ether, phenol novolac epoxy resin, cresol novolac epoxy resin, epoxidized polybutadiene, etc. It is.

- a preferred embodiment of the stabilizer is a stabilizer (B1) having at least one functional group selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group, and having a number average molecular weight of 200 to 900. And a stabilizer (B2) having two or more functional groups selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group in one molecule and having a weight average molecular weight of 1,000 to 60,000. The aspect of using together is mentioned.

- the weight average molecular weight of the stabilizer (B1) having a number average molecular weight of 200 to 900 is about 200 to 900, and the number average molecular weight and the weight average molecular weight of the stabilizer (B1) are almost the same value. .

- the stabilizer (B1) specifically, dicyclohexylcarbodiimide, bis-2,6-diisopropylphenylcarbodiimide, hexyl isocyanate, octadecyl isocyanate, 3- (triethoxysilyl) propyl isocyanate, N-glycidyl

- examples thereof include phthalimide, orthophenylphenyl glycidyl ether, phenyl glycidyl ether, pt-butylphenyl glycidyl ether, and the like.

- the stabilizer (B2) include poly (4,4′-dicyclohexylmethanecarbodiimide), poly (tetramethylxylylene carbodiimide), poly (N, N-dimethylphenylcarbodiimide), poly ( N, N'-di-2,6-diisopropylphenylcarbodiimide), diphenylmethane diisocyanate polyisocyanate, 1,6-hexamethylene diisocyanate polyisocyanate, xylylene diisocyanate polyisocyanate, isophorone diisocyanate polyisocyanate, phenol novolac epoxy Examples thereof include resins, cresol novolac type epoxy resins, and epoxidized polybutadiene.

- the moisture and heat resistance is particularly improved by including a stabilizer (B1) having a relatively low molecular weight and a stabilizer (B2) having a multifunctional and relatively high molecular weight.

- a stabilizer (B1) having a relatively low molecular weight and a stabilizer (B2) having a multifunctional and relatively high molecular weight.

- the stabilizer (B2) is preferably in the range of 10 parts by weight to 150 parts by weight from the viewpoint of achieving both transparency and wet heat resistance, and more preferably in the range of 50 parts by weight to 100 parts by weight. .

- the stabilizer includes a stabilizer (B3) having one functional group in one molecule selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group, and the dimensional stability is improved.

- the stabilizer (B3) has only one functional group selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group in one molecule, it has an optical activity having a hydroxyl group or a carboxyl group generated by hydrolysis. The polymer portion is less likely to be cross-linked with the stabilizer (B3) interposed therebetween.

- the weight average molecular weight of the compound having one functional group selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group in one molecule is preferably 200 to 2000, more preferably 200 to 1500, and more preferably 300 to 900. Further preferred.

- the compound having one functional group selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group in one molecule include dicyclohexylcarbodiimide, bis-2,6-diisopropylphenylcarbodiimide, hexyl isocyanate, and octadecyl isocyanate.

- 3- (triethoxysilyl) propyl isocyanate N-glycidylphthalimide, orthophenylphenyl glycidyl ether, phenyl glycidyl ether, and pt-butylphenyl glycidyl ether.

- dicyclohexylcarbodiimide and bis-2,6-diisopropylphenylcarbodiimide are preferable, and bis-2,6-diisopropylphenylcarbodiimide is more preferable.

- the stabilizer (B3) and the stabilizer (B4) having two or more functional groups selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group in one molecule for example, the aforementioned stabilizer (B2 ) May be used in combination.

- the stabilizer (B4) having two or more functional groups selected from the group consisting of a carbodiimide group, an epoxy group, and an isocyanate group in one molecule with respect to 100 parts by weight of the stabilizer (B3)

- the range of 200 parts by weight is preferable from the viewpoint of the balance of transparency, heat-and-moisture resistance, and dimensional stability, and the range of 10 to 100 parts by weight is more preferable.

- Weight average molecular weight and number average molecular weight of stabilizer Both the number average molecular weight (Mn) and the weight average molecular weight (Mw) of the stabilizer are similarly measured by a measurement method using a gel permeation chromatograph (GPC) described in the section of the optically active polymer.

- GPC gel permeation chromatograph

- the addition amount of the stabilizer is preferably 0.01 to 10 parts by weight with respect to 100 parts by weight of the optically active polymer. Further, in order to obtain higher reliability (specifically, reliability in a reliability test of 500 hours), the amount added is more preferably 0.7 parts by weight or more. In particular, when aliphatic carbodiimide is used as a stabilizer, it is more preferably contained in an amount of 0.01 to 2.8 parts by weight from the viewpoint of transparency. When the addition amount is in the above range, the reliability of the piezoelectric body can be enhanced without significantly impairing the internal haze of the piezoelectric body of the first aspect. In addition, the said addition amount shows those total amounts, when using together 2 or more types of stabilizers.

- the addition amount of the stabilizer is 0.01 to 1.2 parts by weight with respect to 100 parts by weight of the optically active polymer.

- Part by weight preferably 0.01 part by weight to 0.7 part by weight, more preferably 0.01 part by weight to 0.6 part by weight.

- the polymer preferably optically active polymer

- the polymer is oriented.

- an index representing this orientation there is a “molecular orientation degree MOR”.

- the molecular orientation MOR Molecular Orientation Ratio

- the microwave measurement method That is, the sample surface (film surface) is placed in the microwave resonance waveguide of a known microwave molecular orientation degree measuring apparatus (also referred to as a microwave transmission type molecular orientation meter) in the microwave traveling direction. ) To be vertical.

- the sample is rotated by 0 to 360 ° in a plane perpendicular to the traveling direction of the microwave, and the microwave transmitted through the sample is transmitted.

- the degree of molecular orientation MOR is determined by measuring the strength.

- the normalized molecular orientation MORc can be measured with a known molecular orientation meter, for example, a microwave molecular orientation meter MOA-2012A or MOA-6000 manufactured by Oji Scientific Instruments Co., Ltd. at a resonance frequency near 4 GHz or 12 GHz.

- the normalized molecular orientation MORc can be controlled by the crystallization conditions (for example, heating temperature and heating time) and the stretching conditions (for example, stretching temperature and stretching speed) in manufacturing the crystalline polymer piezoelectric material. .

- the normalized molecular orientation MORc can also be converted into a birefringence ⁇ n obtained by dividing the retardation amount (retardation) by the thickness of the piezoelectric body. Specifically, retardation can be measured using RETS100 manufactured by Otsuka Electronics Co., Ltd. MORc and ⁇ n are approximately in a linear proportional relationship, and when ⁇ n is 0, MORc is 1.

- Crystalline polymeric piezoelectric member in the first embodiment it piezoelectric constant is large (preferably, at 25 ° C. stress - it is the piezoelectric constant d 14 is 1 pC / N or more as measured by a charge method) is preferred. Furthermore, it is preferable that the crystalline polymer piezoelectric material in the first aspect is excellent in transparency and longitudinal tear strength (that is, tear strength in a specific direction; the same applies hereinafter).

- the piezoelectric constant of the crystalline polymer piezoelectric material is a value measured as follows. First, the crystalline polymer piezoelectric material is cut to 150 mm in a direction formed by 45 ° with respect to the stretching direction (for example, MD direction) of the crystalline polymer piezoelectric material, and is cut to 50 mm in a direction orthogonal to the direction formed by 45 ° to form a rectangular shape. A test piece is prepared. Next, the test piece obtained on the test stand of Showa vacuum SIP-600 is set, and Al is vapor-deposited on one surface of the test piece so that the deposition thickness of Al is about 50 nm. Next, Al is vapor-deposited in the same manner on the other surface of the test piece. As described above, an Al conductive layer is formed on both sides of the test piece.

- a test piece (crystalline polymer piezoelectric body) of 150 mm ⁇ 50 mm in which an Al conductive layer is formed on both surfaces is 120 mm in a direction that makes 45 ° with respect to the stretching direction (for example, MD direction) of the crystalline polymer piezoelectric body, Cut to 10 mm in a direction orthogonal to the 45 ° direction, and cut out a 120 mm ⁇ 10 mm rectangular film. This is a piezoelectric constant measurement sample.

- the obtained sample is set in a tensile testing machine (manufactured by AND, TENSILON RTG-1250) with a distance between chucks of 70 mm so as not to be loosened. A force is periodically applied so that the applied force reciprocates between 4N and 9N at a crosshead speed of 5 mm / min.

- a capacitor having a capacitance Qm (F) is connected in parallel to the sample, and the voltage Vm between terminals of the capacitor Cm (95 nF) is converted into a buffer amplifier. Measure through.

- the generated charge amount Q (C) is calculated as the product of the capacitor capacitance Cm and the terminal voltage Vm.

- the stress at 25 ° C. - piezoelectric constant d 14 measured by the charge method is preferably more than 1 pC / N, more preferably at least pC / N, more preferably more than 4Pc / N.

- the upper limit of the piezoelectric constant is not particularly limited, but from the viewpoint of balance such as transparency described later, a crystalline polymer piezoelectric material using a helical chiral polymer (optically active polymer) having optical activity is 50 pC. / N or less is preferable, and 30 pC / N or less is more preferable.

- a piezoelectric constant d 14 measured by a resonance method is not more than 15pC / N.

- the “MD direction” is a direction in which the film flows (Machine Direction)

- the “TD direction” is a direction perpendicular to the MD direction and parallel to the main surface of the film (Transverse Direction). ).

- the crystallinity of the crystalline polymer piezoelectric material in the first embodiment is preferably 20% to 80%, more preferably 30% to 70%.

- the crystallinity of the crystalline polymer piezoelectric material refers to the crystallinity obtained by the DSC method. If the degree of crystallinity is within the above range, the crystalline polymer piezoelectric material has good balance of piezoelectricity, transparency, and longitudinal crack strength, and when the crystalline polymer piezoelectric material is stretched, whitening or breakage occurs. Easy to manufacture. Specifically, when the crystallinity is 20% or more, a decrease in piezoelectricity is suppressed.

- crystallinity is 80% or less.

- the crystallinity is more preferably 70% or less, further preferably 40.8% or less, and particularly preferably 40.0% or less, from the viewpoint of further improving the longitudinal crack strength and transparency.

- the crystallinity of the crystalline polymer piezoelectric material is in the range of 20% to 80%. Can be adjusted.

- the crystalline polymer piezoelectric material in the first embodiment includes a helical chiral polymer having optical activity with a weight average molecular weight of 50,000 to 1,000,000, and has a crystallinity of 20% to 80% obtained by the DSC method. It is particularly preferred that

- the transparency of the crystalline polymer piezoelectric material can be evaluated by, for example, visual observation or haze measurement.

- the crystalline polymer piezoelectric material preferably has an internal haze with respect to visible light of 50% or less.

- the internal haze is measured with respect to a crystalline polymer piezoelectric material having a thickness of 0.03 mm to 0.05 mm in accordance with JIS-K7105, according to JIS-K7105 [Tokyo Denshoku, TC-HIII DPK. ] Is a value measured at 25 ° C., and details of the measuring method will be described in detail in Examples.

- the internal haze of the crystalline polymer piezoelectric material is preferably 40% or less, more preferably 20% or less, further preferably 13% or less, and further preferably 5% or less. preferable. Further, the internal haze of the crystalline polymer piezoelectric material is preferably 2.0% or less, particularly preferably 1.0% or less, from the viewpoint of further improving the longitudinal crack strength. Further, the internal haze of the crystalline polymer piezoelectric material is preferably as low as possible, but from the viewpoint of balance with the piezoelectric constant and the like, it is preferably 0.0% to 40%, preferably 0.01% to It is more preferably 20%, more preferably 0.01% to 13%, further preferably 0.01% to 5%, and more preferably 0.01% to 2.0%.

- the “internal haze” of the crystalline polymer piezoelectric material referred to in the present application is a haze excluding the haze due to the shape of the outer surface of the crystalline polymer piezoelectric material as described later in Examples.

- Crystalline polymeric piezoelectric member in the first embodiment is 50% or less internal haze to visible light, and the stress at 25 ° C. - particularly that the piezoelectric constant d 14 measured by the charge method is 1 pC / N or more preferable.

- the crystalline polymer piezoelectric material in the first embodiment preferably has a normalized molecular orientation MORc of 1.0 to 15.0, more preferably 2.0 to 10.0, and 4.0 to More preferably, it is 10.0. If the normalized molecular orientation MORc is 1.0 or more, there are many optically active polymer molecular chains (for example, polylactic acid molecular chains) arranged in the stretching direction, and as a result, the rate of formation of oriented crystals increases. High piezoelectricity can be expressed. If the normalized molecular orientation MORc is 15.0 or less, the longitudinal crack strength is further improved. Further, from the viewpoint of further improving the adhesion between the crystalline polymer piezoelectric material and the surface layer, the normalized molecular orientation MORc is preferably 7.0 or less.

- the product of the crystallinity of the crystalline polymer piezoelectric material and the normalized molecular orientation MORc is preferably 25 to 700, more preferably 40 to 700, and more preferably 40 to 250. More preferably.

- the product of the crystallinity of the crystalline polymer piezoelectric material and the normalized molecular orientation MORc is 25 or more, a decrease in piezoelectricity is suppressed.

- the product of the crystallinity of the crystalline polymer piezoelectric material and the normalized molecular orientation MORc is 700 or less, the longitudinal crack strength and the transparency are prevented from being lowered.

- the product of the crystallinity and MORc is more preferably 50 to 200, more preferably 100 to 190.

- the product of the crystallinity of the crystalline polymer piezoelectric material and the normalized molecular orientation MORc is obtained. Can be adjusted within the above range.

- the crystalline polymer piezoelectric material has a low dimensional change rate at a temperature under heating, particularly in an environment where it is incorporated and used in a device or equipment such as a speaker or a touch panel described later. This is because if the dimensions of the crystalline polymer piezoelectric material change in the usage environment of the device, etc., the position of the wiring connected to the crystalline polymer piezoelectric material may move, causing malfunction of the device, etc. .

- the dimensional stability of the crystalline polymer piezoelectric material is evaluated by the dimensional change rate before and after being treated for 10 minutes at 150 ° C., which is a temperature slightly higher than the usage environment of the device.

- the dimensional change rate is preferably 10% or less, and more preferably 5% or less.

- crystalline polymer piezoelectric material for example, crystallization and stretching (whichever is first) may be performed on an amorphous sheet containing the optically active polymer described above. ).

- the non-crystalline sheet refers to a sheet obtained by heating an optically active polymer alone or a mixture containing an optically active polymer to a temperature equal to or higher than the melting point Tm of the optically active polymer and then rapidly cooling it.

- An example of the rapid cooling temperature is 50 ° C.

- the optically active polymer such as a polylactic acid polymer

- the optically active polymer is used as a raw material for the crystalline polymer piezoelectric material (or an amorphous sheet).

- One kind may be used alone, or a mixture of two or more of the optically active polymers described above (such as polylactic acid polymers), or at least one of the optically active polymers described above and other components.

- a mixture with at least one kind may be used.

- the above mixture is preferably a mixture obtained by melt kneading.

- optically active polymers to be mixed are mixed with a melt kneader (manufactured by Toyo Seiki Co., Ltd., Laboplast Mixer) under conditions of mixer rotation speed 30 rpm to 70 rpm, 180 ° C. to 250 ° C.

- a melt kneader manufactured by Toyo Seiki Co., Ltd., Laboplast Mixer

- mixer rotation speed 30 rpm to 70 rpm 180 ° C. to 250 ° C.

- the crystalline polymer piezoelectric material according to the first aspect includes a step of stretching a sheet containing an optically active polymer (preferably an amorphous sheet) mainly in a uniaxial direction and an annealing treatment step in this order. It can also be manufactured by a manufacturing method including

- the crystalline polymer piezoelectric material in the first aspect described above may correspond to a crystalline polymer piezoelectric body in the second aspect described later.

- the crystalline polymer piezoelectric material in the first aspect may be a crystalline polymer piezoelectric material having the normalized molecular orientation MORc of 2.0 to 10.0.

- the crystalline polymer piezoelectric material in the first aspect further improves the adhesion between the crystalline polymer piezoelectric material and the surface layer, and further improves the moisture and heat resistance and tear strength of the crystalline polymer piezoelectric material. From the viewpoint of improvement, the ratio of the acrylic terminal of the polymer contained in the crystalline polymer piezoelectric material may be adjusted.

- the crystalline polymer piezoelectric material according to the first aspect was obtained by measuring a 1 H-NMR spectrum of a solution in which 20 mg of the crystalline polymer piezoelectric material was dissolved in 0.6 mL of deuterated chloroform.

- the ratio of the acrylic terminal of the polymer was determined when the ratio of the acrylic terminal of the polymer contained in the crystalline polymer piezoelectric material was determined by the following formula (X). May be 2.0 ⁇ 10 ⁇ 5 to 10.0 ⁇ 10 ⁇ 5 .

- Ratio of acrylic end of the polymer integral value of peak derived from acrylic end of polymer / integral value of peak derived from methine in the main chain of the polymer Formula (X)

- the crystalline polymer piezoelectric material in the first embodiment may contain at least one colorant in order to adjust the hue.

- the colorant include a bluing agent for correcting yellowishness.

- the laminate according to the first aspect includes a speaker, a headphone, a touch panel, a remote controller, a microphone, an underwater microphone, an ultrasonic transducer, an ultrasonic applied measuring instrument, a piezoelectric vibrator, a mechanical filter, a piezoelectric transformer, a delay device, a sensor, Acceleration sensor, shock sensor, vibration sensor, pressure sensor, tactile sensor, electric field sensor, sound pressure sensor, display, fan, pump, variable focus mirror, sound insulation material, sound insulation material, keyboard, sound equipment, information processing machine, measurement equipment It can be used in various fields such as medical equipment.

- the laminate according to the first aspect further has an electrode part, and is suitably used as a piezoelectric device having a crystalline polymer piezoelectric material, a surface layer, and an electrode part in this order.

- the crystalline polymer piezoelectric material in the first aspect has at least two surfaces, and is used as a piezoelectric element in which electrodes are provided on one surface (surface having at least a surface layer) and the other surface. It is preferred that The electrode may be provided on at least two surfaces of the crystalline polymer piezoelectric material. Although it does not restrict

- a hard coat layer is formed as a surface layer on the piezoelectric material, and an ITO electrode is formed on the hard coat layer.

- the thermal deformation of the piezoelectric body at the time of ITO crystallization can be relaxed by the hard coat layer, and ITO with few defects can be formed.

- ITO in addition, by providing a refractive index adjustment layer between the hard coat layer and ITO, it is possible to reduce reflectance, prevent bone appearance, and reduce coloring.

- the crystalline polymer piezoelectric material in the first aspect and the electrode can be repeatedly stacked, and the surface layer can be interposed between at least a part of the piezoelectric material and the electrode, so that it can be used as a laminated piezoelectric element.

- a unit of a crystalline polymer piezoelectric material having a surface layer on both sides and an electrode unit are repeatedly stacked, and finally the main surface of the crystalline polymer piezoelectric material not covered with an electrode is covered with an electrode.

- the electrode, surface layer, crystalline polymer piezoelectric material, surface layer, electrode, surface layer, crystalline polymer piezoelectric material, surface layer, electrode are stacked in this order.

- the crystalline polymer piezoelectric material used in the laminated piezoelectric element may be a laminated body in which the crystalline polymer piezoelectric material of one layer and the surface layer of one layer are the first embodiment, and the other layers are the first layer.

- the surface layer and the crystalline polymer piezoelectric material in the laminate of the aspect may not be used.

- the optical activity of the optically active polymer contained in the crystalline polymer piezoelectric material of a certain layer If L is an L-form, the optically active polymer contained in the crystalline polymer piezoelectric material of the other layer may be an L-form or a D-form.

- the arrangement of the crystalline polymer piezoelectric material can be appropriately adjusted according to the use of the piezoelectric element.

- the transparency of the electrode specifically means that the internal haze is 40% or less (total light transmittance is 60% or more).

- the laminated body which concerns on the 1st aspect demonstrated above may correspond to the laminated body which concerns on the below-mentioned 2nd aspect.

- the crystalline polymer piezoelectric material has a normalized molecular orientation MORc of 2.0 when the reference thickness measured by a microwave transmission type molecular orientation meter is 50 ⁇ m.

- the surface layer may be disposed so as to be at least partially in contact with the crystalline polymer piezoelectric material, and may include a carbonyl group and a polymer.

- the laminate according to the second aspect of the present invention includes a crystalline polymer piezoelectric material and a surface layer disposed so as to be at least partially in contact with the crystalline polymer piezoelectric material.

- the crystalline polymer piezoelectric material (hereinafter also simply referred to as “piezoelectric material”) has a normalized molecular orientation MORc of 2.0 to 2.0 when the reference thickness measured by a microwave transmission type molecular orientation meter is 50 ⁇ m. 10.0.

- the surface layer includes a carbonyl group and a polymer.

- the crystalline polymer piezoelectric material may be provided with an adhesive surface layer for the purpose of adhering to other members such as electrodes, or a protective surface layer for the purpose of protection.

- peeling may occur in the surface layer formed so as to be in contact with at least a part of the piezoelectric body, and further improvement in the adhesion between the piezoelectric body and the surface layer is desired.

- the piezoelectric body has a normalized molecular orientation MORc of 2.0 to 10.0, a surface layer containing a carbonyl group and a polymer. Excellent adhesion to the surface layer.

- the surface layer in the second aspect refers to a layer that is present on the surface side of the piezoelectric body and at least a part of which is in contact with the piezoelectric body. Therefore, another member may be provided on the surface layer, and the surface layer does not necessarily indicate a layer that is the outermost surface of the final molded product.

- an electrode is mentioned, for example.

- the electrode may be an electrode layer that covers the entire surface layer, or an electrode pattern that is formed so as to cover a part of the surface layer.

- a multilayer film formed by laminating a plurality of functional layers may be formed on the piezoelectric body in the second aspect, and in this case, the surface layer is at least partially in contact with the piezoelectric body. It refers to the layer that is placed. Further, the surface layer in the second aspect may be on both sides as well as on one side of the piezoelectric body, and the functions and materials may be different.

- Examples of the surface layer formed on the surface of the piezoelectric body include various functional layers. For example, easy adhesion layer, hard coat layer, refractive index adjustment layer, hue adjustment layer, anti-reflection layer, anti-glare layer, slippery layer, anti-block layer, protective layer, adhesive layer, adhesive layer, antistatic layer, heat dissipation layer, Examples include an ultraviolet absorption layer, an anti-Newton ring layer, a light scattering layer, a polarizing layer, and a gas barrier layer.

- Another member may be formed on the surface layer of the laminate in which the piezoelectric body and the surface layer are laminated. Examples of the other member include an electrode.

- functional layers such as an easy-adhesion layer, a hard coat layer, and a refractive index adjustment layer are generally provided as the surface layer in the aspect in which the electrode is provided. Further, by forming the surface layer, defects such as die lines and dents on the surface of the piezoelectric body are filled, and the appearance is improved. In this case, the smaller the refractive index difference between the piezoelectric body and the surface layer, the more the reflection at the interface between the piezoelectric body and the surface layer is reduced, and the appearance is further improved.

- an adhesive layer as a surface layer on the piezoelectric body by the wet coating method described later, not only defects on the surface are filled, but also when OCA (Optical Clear Adhesive) is used when bonding with other materials in a later process. Film rolls that do not need to be used can be produced. If the OCA or adhesive layer is thick, the mechanical energy applied from the outside or the mechanical energy generated by the piezoelectric body is relaxed by the OCA or adhesive layer, and the sensor performance and actuator performance deteriorate. The thickness of the pressure-sensitive adhesive layer formed by the coating method is also advantageous in that it can be easily made thinner than OCA.

- the adhesive layer as the surface layer may or may not include a three-dimensional crosslinked structure, and may be formed only on one side of the piezoelectric body or on both sides.

- the surface layer contains a carbonyl group (—C ( ⁇ O) —) and contains a polymer.

- the surface layer contains a carbonyl group

- the adhesion with the piezoelectric body having the normalized molecular orientation MORc in the above range is excellent.

- the polymer in the surface layer has a three-dimensional crosslinked structure. By having a three-dimensional cross-linking structure, the adhesion to the piezoelectric body can be further improved.

- Examples of the method for forming a surface layer containing a carbonyl group and a polymer include a method of polymerizing a composition containing a compound having a carbonyl group and a functional compound having a reactive group.

- the compound having the carbonyl group and the functional compound may or may not be the same.

- the reactive group of the functional compound itself may contain a carbonyl group, and other than the reactive group of the functional compound.

- the structure may contain a carbonyl group.

- the compound having the carbonyl group and the functional compound are not the same, the compound having the carbonyl group has one or more reactive groups capable of reacting with the functional compound.

- the polymerization reaction in the above polymerization may be a reaction between one type of reactive group or a reaction between two or more different types of reactive groups.

- the polymerization reaction is a reaction of two or more types of reactive groups

- compounds having two or more types of reactive groups in the same compound may be used for the polymerization reaction, or the same reactive group

- a functional compound having two or more different reactive groups capable of reacting with the reactive group may be used in combination.

- Examples of the reactive group that reacts with one kind of reactive group include an acryl group, a methacryl group, a vinyl group, an allyl group, an isocyanate group, and an epoxy group. It is done.

- An acrylic group, a methacryl group, and an isocyanate group have a carbonyl group in the reactive group.

- a vinyl group, an allyl group, or an epoxy group a compound having a carbonyl group in the structure other than the reactive group can be used. From the viewpoint of imparting a three-dimensional crosslinked structure to the polymer, a three-dimensional crosslinked structure can be formed if any of these bifunctional or higher functional compounds having the same reactive group is present in the composition.

- the reactive group that reacts with two or more types of reactive groups includes an epoxy group and a carboxyl group, an epoxy group and an amino group, an epoxy group and a hydroxyl group, and an epoxy group.

- the carboxyl group, acid anhydride group, hydrazide group, and isocyanate group have a carbonyl group among the reactive groups.

- compounds having a carbonyl group in the structure other than the reactive group can be used.

- Examples of the functional compound having an epoxy group and a carbonyl group in the same molecule include epoxy acrylate.

- Examples of the functional compound having a hydroxyl group and a carbonyl group in the same molecule include polyester polyol, polyurethane polyol, acrylic polyol, polycarbonate polyol, and partial carboxymethyl cellulose.

- Examples of the functional compound having an amino group and a carbonyl group in the same molecule include terminal amine polyamide, terminal amine polyimide, terminal amine polyurethane and the like.

- the polymer of the compound which has a (meth) acryl group among the above is more preferable.

- the “(meth) acryl group” represents at least one of an acryl group and a methacryl group as described above.

- the surface layer As a method for forming the surface layer, known methods that have been generally used can be used as appropriate, and examples thereof include a wet coating method.

- the surface layer is formed by applying a coating liquid in which a material for forming the surface layer (polymerizable compound or polymerized polymer compound) is dispersed or dissolved, and performing an operation such as drying as necessary. It is formed. Polymerization of the polymerizable compound may be performed before coating or after coating.

- the surface layer may be cured by irradiating the material (polymerizable compound) with heat or active energy rays (ultraviolet rays, electron beams, radiation, etc.) during the polymerization.

- active energy rays ultraviolet rays, electron beams, radiation, etc.