JP4225207B2 - 高分子光導波路の製造方法 - Google Patents

高分子光導波路の製造方法 Download PDFInfo

- Publication number

- JP4225207B2 JP4225207B2 JP2004015388A JP2004015388A JP4225207B2 JP 4225207 B2 JP4225207 B2 JP 4225207B2 JP 2004015388 A JP2004015388 A JP 2004015388A JP 2004015388 A JP2004015388 A JP 2004015388A JP 4225207 B2 JP4225207 B2 JP 4225207B2

- Authority

- JP

- Japan

- Prior art keywords

- core

- optical waveguide

- mold

- curable resin

- clad

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000003287 optical effect Effects 0.000 title claims description 135

- 229920000642 polymer Polymers 0.000 title claims description 59

- 238000004519 manufacturing process Methods 0.000 title claims description 32

- 229920005989 resin Polymers 0.000 claims description 145

- 239000011347 resin Substances 0.000 claims description 145

- 239000000758 substrate Substances 0.000 claims description 62

- 238000005253 cladding Methods 0.000 claims description 24

- 238000011049 filling Methods 0.000 claims description 10

- 229920002050 silicone resin Polymers 0.000 claims description 7

- 230000009471 action Effects 0.000 claims description 6

- 238000000034 method Methods 0.000 description 29

- 239000010408 film Substances 0.000 description 21

- 239000010410 layer Substances 0.000 description 16

- 239000000178 monomer Substances 0.000 description 12

- 239000004205 dimethyl polysiloxane Substances 0.000 description 11

- 229920000435 poly(dimethylsiloxane) Polymers 0.000 description 11

- 229920002379 silicone rubber Polymers 0.000 description 11

- 230000008859 change Effects 0.000 description 10

- 238000002347 injection Methods 0.000 description 10

- 239000007924 injection Substances 0.000 description 10

- 229920001187 thermosetting polymer Polymers 0.000 description 9

- -1 polydimethylsiloxane Polymers 0.000 description 8

- 239000007788 liquid Substances 0.000 description 7

- 239000004593 Epoxy Substances 0.000 description 6

- 239000000047 product Substances 0.000 description 6

- 239000004945 silicone rubber Substances 0.000 description 6

- 238000010438 heat treatment Methods 0.000 description 5

- 229920001296 polysiloxane Polymers 0.000 description 5

- 239000000243 solution Substances 0.000 description 5

- 239000004944 Liquid Silicone Rubber Substances 0.000 description 4

- 230000002411 adverse Effects 0.000 description 4

- 238000000206 photolithography Methods 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 3

- 229920001971 elastomer Polymers 0.000 description 3

- 239000011521 glass Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 239000002086 nanomaterial Substances 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 239000012792 core layer Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 229920005570 flexible polymer Polymers 0.000 description 2

- 238000001053 micromoulding Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000006082 mold release agent Substances 0.000 description 2

- 230000000149 penetrating effect Effects 0.000 description 2

- 238000001020 plasma etching Methods 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 238000004528 spin coating Methods 0.000 description 2

- 239000010409 thin film Substances 0.000 description 2

- 238000009281 ultraviolet germicidal irradiation Methods 0.000 description 2

- 239000004925 Acrylic resin Substances 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000004061 bleaching Methods 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000004070 electrodeposition Methods 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000005357 flat glass Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 229920002313 fluoropolymer Polymers 0.000 description 1

- 230000009477 glass transition Effects 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 238000002256 photodeposition Methods 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000002174 soft lithography Methods 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

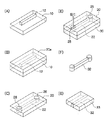

- B29D11/00—Producing optical elements, e.g. lenses or prisms

- B29D11/00663—Production of light guides

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/10—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings of the optical waveguide type

- G02B6/12—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings of the optical waveguide type of the integrated circuit kind

- G02B6/13—Integrated optical circuits characterised by the manufacturing method

- G02B6/138—Integrated optical circuits characterised by the manufacturing method by using polymerisation

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Ophthalmology & Optometry (AREA)

- Mechanical Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Optical Integrated Circuits (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004015388A JP4225207B2 (ja) | 2004-01-23 | 2004-01-23 | 高分子光導波路の製造方法 |

| US10/936,639 US7569168B2 (en) | 2004-01-23 | 2004-09-09 | Method of producing polymer optical waveguide |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004015388A JP4225207B2 (ja) | 2004-01-23 | 2004-01-23 | 高分子光導波路の製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005208376A JP2005208376A (ja) | 2005-08-04 |

| JP2005208376A5 JP2005208376A5 (enExample) | 2007-03-15 |

| JP4225207B2 true JP4225207B2 (ja) | 2009-02-18 |

Family

ID=34792435

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004015388A Expired - Fee Related JP4225207B2 (ja) | 2004-01-23 | 2004-01-23 | 高分子光導波路の製造方法 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US7569168B2 (enExample) |

| JP (1) | JP4225207B2 (enExample) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4175183B2 (ja) * | 2003-06-04 | 2008-11-05 | 富士ゼロックス株式会社 | 高分子光導波路の製造方法 |

| JP2007047320A (ja) * | 2005-08-08 | 2007-02-22 | Fuji Xerox Co Ltd | 双方向通信用光導波路及びその製造方法 |

| KR100810916B1 (ko) | 2006-03-30 | 2008-03-10 | 부산대학교 산학협력단 | 피시비의 광도파로 형성방법 |

| JP2008058531A (ja) * | 2006-08-30 | 2008-03-13 | Nippon Telegr & Teleph Corp <Ntt> | 光導波路を作製するための金型の作製方法 |

| JP2008058530A (ja) * | 2006-08-30 | 2008-03-13 | Nippon Telegr & Teleph Corp <Ntt> | 押し出しラミネートによる導波路作製方法および金型の作製方法 |

| JP2008083205A (ja) * | 2006-09-26 | 2008-04-10 | Nippon Telegr & Teleph Corp <Ntt> | 積層導波路およびその作製方法 |

| JP5111474B2 (ja) * | 2009-10-06 | 2013-01-09 | 日東電工株式会社 | 光導波路基材の製造方法およびそれによって得られた光導波路基材を用いた光導波路の製造方法 |

Family Cites Families (46)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60250915A (ja) | 1984-05-28 | 1985-12-11 | Polyplastics Co | 成形用金型付着物の除去法 |

| JPH0432565Y2 (enExample) | 1986-08-29 | 1992-08-05 | ||

| JP2760381B2 (ja) | 1988-12-09 | 1998-05-28 | 大日本印刷株式会社 | スタンパ |

| JP3057621B2 (ja) | 1991-09-06 | 2000-07-04 | 日本電信電話株式会社 | 非線形光学素子の作製方法 |

| JPH06114845A (ja) | 1992-10-02 | 1994-04-26 | Toshiba Silicone Co Ltd | シリコーンゴム型 |

| JPH06216175A (ja) | 1993-01-15 | 1994-08-05 | Toshiba Corp | 半導体製造装置及び半導体装置の製造方法 |

| DE4304291A1 (de) | 1993-02-12 | 1994-08-18 | Hoechst Ag | Cycloolefincopolymere mit niedriger Schmelzeviskosität und niedriger optischer Dämpfung |

| JPH06304933A (ja) | 1993-04-21 | 1994-11-01 | Toppan Printing Co Ltd | フレネルレンズの製造方法 |

| JP3151364B2 (ja) | 1994-12-05 | 2001-04-03 | シャープ株式会社 | 高分子光導波路の製造方法 |

| JP3203178B2 (ja) | 1996-02-27 | 2001-08-27 | 日立電線株式会社 | 光導波路、光モジュール及び光システム |

| US6355198B1 (en) | 1996-03-15 | 2002-03-12 | President And Fellows Of Harvard College | Method of forming articles including waveguides via capillary micromolding and microtransfer molding |

| JPH09269429A (ja) | 1996-04-02 | 1997-10-14 | Sharp Corp | 光導波路装置、その製造方法及び光学式走査装置 |

| KR100236432B1 (ko) | 1996-07-31 | 1999-12-15 | 미야즈 쥰이치로 | 광학 편광기, 이의 제조 방법 및 광학 편광기 제조용 블레이드 |

| JP3753508B2 (ja) | 1996-07-31 | 2006-03-08 | 日本電信電話株式会社 | 光路変換素子の作製方法、および光路変換素子作製用のブレード |

| JPH1090532A (ja) | 1996-09-17 | 1998-04-10 | Sharp Corp | 光導波路及びその作製方法 |

| DE19642866A1 (de) | 1996-10-17 | 1998-04-23 | Bayer Ag | Palladium-Katalysatoren für die Polymerisation |

| JPH113545A (ja) | 1997-06-12 | 1999-01-06 | Furukawa Electric Co Ltd:The | 光romカード |

| US6314228B1 (en) | 1998-02-02 | 2001-11-06 | Matsushita Electric Industrial Co., Ltd. | Optical waveguide component and a method of producing the same |

| JP2000039531A (ja) | 1998-07-22 | 2000-02-08 | Sony Corp | 光信号伝送システムおよびその製造方法 |

| JP3858460B2 (ja) | 1998-07-22 | 2006-12-13 | ソニー株式会社 | 光信号伝送システムおよびその製造方法 |

| JP2000081520A (ja) | 1998-09-03 | 2000-03-21 | Nippon Kayaku Co Ltd | 高分子光導波路用樹脂組成物及びそれを用いた高分子光導波路 |

| JP3100584B2 (ja) | 1999-02-15 | 2000-10-16 | 日本電信電話株式会社 | 光電子集積回路およびその作製方法 |

| JP2001027714A (ja) | 1999-05-12 | 2001-01-30 | Mitsubishi Chemicals Corp | 光メモリ素子及びその製造方法 |

| US6243517B1 (en) | 1999-11-04 | 2001-06-05 | Sparkolor Corporation | Channel-switched cross-connect |

| US6500603B1 (en) | 1999-11-11 | 2002-12-31 | Mitsui Chemicals, Inc. | Method for manufacturing polymer optical waveguide |

| JP4665322B2 (ja) | 2000-03-16 | 2011-04-06 | 東レ株式会社 | ポリ(脂環式オレフィン) |

| JP2001269958A (ja) | 2000-03-27 | 2001-10-02 | Fjc:Kk | 樹脂成形体の製造方法並びに成形型 |

| JP3454474B2 (ja) | 2000-09-14 | 2003-10-06 | 東北ムネカタ株式会社 | 熱可塑性樹脂の射出成形方法及び金型 |

| JP2002090565A (ja) | 2000-09-19 | 2002-03-27 | Toshiba Corp | 光導波路 |

| JP3922338B2 (ja) | 2000-09-20 | 2007-05-30 | セイコーエプソン株式会社 | 基板の製造方法及び製造装置 |

| JP3762208B2 (ja) | 2000-09-29 | 2006-04-05 | 株式会社東芝 | 光配線基板の製造方法 |

| JP3864211B2 (ja) | 2000-11-07 | 2006-12-27 | 独立行政法人産業技術総合研究所 | 真空紫外レーザーを用いたフッ素系高分子成型品の表面改質方法 |

| JP3862995B2 (ja) | 2001-02-16 | 2006-12-27 | 富士通株式会社 | 光スイッチモジュール |

| JP2002333538A (ja) | 2001-03-05 | 2002-11-22 | Fuji Xerox Co Ltd | 光導波路形成方法、これに用いる電着液および光導波路製造装置 |

| JP2002284812A (ja) | 2001-03-27 | 2002-10-03 | Toray Ind Inc | ポリマーの製造方法 |

| JP4604385B2 (ja) | 2001-04-18 | 2011-01-05 | 凸版印刷株式会社 | 光導波路の製造方法 |

| JP2002350640A (ja) | 2001-05-28 | 2002-12-04 | Nitto Denko Corp | 偏光板用保護フイルムの製造方法および偏光板、偏光板を用いた光学フイルムならびに液晶表示装置 |

| JP4703065B2 (ja) | 2001-09-14 | 2011-06-15 | 大日本印刷株式会社 | 光導波路回路の製造方法 |

| CN1656401A (zh) | 2002-05-28 | 2005-08-17 | 松下电工株式会社 | 光路-电路混载基板用材料以及光路-电路混载基板 |

| JP3945322B2 (ja) | 2002-06-27 | 2007-07-18 | 富士ゼロックス株式会社 | 光学素子およびその製造方法 |

| JP2004086144A (ja) | 2002-06-27 | 2004-03-18 | Fuji Xerox Co Ltd | 高分子光導波路の製造方法 |

| JP2004109927A (ja) | 2002-09-20 | 2004-04-08 | Fuji Xerox Co Ltd | 高分子光導波路の製造方法 |

| JP2004144987A (ja) | 2002-10-24 | 2004-05-20 | Fuji Xerox Co Ltd | 高分子光導波路の製造方法 |

| JP2005181662A (ja) | 2003-12-19 | 2005-07-07 | Fuji Xerox Co Ltd | 高分子光導波路の製造方法 |

| JP4196839B2 (ja) | 2004-01-16 | 2008-12-17 | 富士ゼロックス株式会社 | 高分子光導波路の製造方法 |

| JP2006017885A (ja) | 2004-06-30 | 2006-01-19 | Fuji Xerox Co Ltd | 導波路フィルム型光モジュール、光導波路フィルム及びその製造方法 |

-

2004

- 2004-01-23 JP JP2004015388A patent/JP4225207B2/ja not_active Expired - Fee Related

- 2004-09-09 US US10/936,639 patent/US7569168B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US20050163446A1 (en) | 2005-07-28 |

| US7569168B2 (en) | 2009-08-04 |

| JP2005208376A (ja) | 2005-08-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4144468B2 (ja) | 積層型高分子光導波路およびその製造方法 | |

| JP2004086144A (ja) | 高分子光導波路の製造方法 | |

| JP4196839B2 (ja) | 高分子光導波路の製造方法 | |

| US7294292B2 (en) | Process for producing polymer optical waveguide and resin injecting device | |

| JP2004109927A (ja) | 高分子光導波路の製造方法 | |

| JP3969263B2 (ja) | 高分子光導波路の製造方法 | |

| JP2006126568A (ja) | 高分子光導波路デバイスの製造方法 | |

| JP2005181662A (ja) | 高分子光導波路の製造方法 | |

| JP2008020722A (ja) | 光導波路及びその製造方法 | |

| JP4265293B2 (ja) | 鋳型及びコネクタ一体型高分子光導波路の製造方法 | |

| JP4225207B2 (ja) | 高分子光導波路の製造方法 | |

| JP4175183B2 (ja) | 高分子光導波路の製造方法 | |

| JP4581328B2 (ja) | 高分子光導波路及び光学素子の製造方法 | |

| JP2009075288A (ja) | 高分子光回路の製造方法 | |

| JP2004069955A (ja) | 高分子光導波路の製造方法 | |

| JP4140475B2 (ja) | 高分子光導波路作製用原盤及び高分子光導波路の製造方法 | |

| JP4534415B2 (ja) | 高分子光導波路の製造方法 | |

| JP4292892B2 (ja) | 積層型高分子光導波路の製造方法及びこの方法により作製される積層型高分子光導波路 | |

| JP4214862B2 (ja) | ピッチ変換導波路アレイ | |

| JP4337559B2 (ja) | 高分子光導波路製造用鋳型及び高分子光導波路の製造方法 | |

| JP4273975B2 (ja) | フレキシブル高分子光導波路の製造方法 | |

| JP2005043652A (ja) | 高分子光導波路の製造方法及びその製造装置 | |

| JP4517704B2 (ja) | 高分子光導波路の製造方法 | |

| JP2007233303A (ja) | 高分子光導波路モジュールの製造方法 | |

| JP4259222B2 (ja) | クロスコネクト光配線シート及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070122 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070122 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20081022 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20081104 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20081117 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111205 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111205 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121205 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121205 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131205 Year of fee payment: 5 |

|

| LAPS | Cancellation because of no payment of annual fees |