JP2015100761A - 支持具、粉体塗布システム、粉体塗布方法、及びキャリパ - Google Patents

支持具、粉体塗布システム、粉体塗布方法、及びキャリパ Download PDFInfo

- Publication number

- JP2015100761A JP2015100761A JP2013244106A JP2013244106A JP2015100761A JP 2015100761 A JP2015100761 A JP 2015100761A JP 2013244106 A JP2013244106 A JP 2013244106A JP 2013244106 A JP2013244106 A JP 2013244106A JP 2015100761 A JP2015100761 A JP 2015100761A

- Authority

- JP

- Japan

- Prior art keywords

- powder

- workpiece

- support

- caliper

- powder coating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/08—Plant for applying liquids or other fluent materials to objects

- B05B5/081—Plant for applying liquids or other fluent materials to objects specially adapted for treating particulate materials

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D65/00—Parts or details

- F16D65/005—Components of axially engaging brakes not otherwise provided for

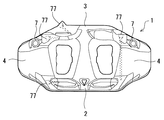

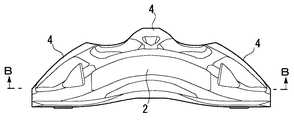

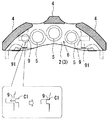

- F16D65/0068—Brake calipers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B1/00—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means

- B05B1/14—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means with multiple outlet openings; with strainers in or outside the outlet opening

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B12/00—Arrangements for controlling delivery; Arrangements for controlling the spray area

- B05B12/16—Arrangements for controlling delivery; Arrangements for controlling the spray area for controlling the spray area

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B12/00—Arrangements for controlling delivery; Arrangements for controlling the spray area

- B05B12/16—Arrangements for controlling delivery; Arrangements for controlling the spray area for controlling the spray area

- B05B12/18—Arrangements for controlling delivery; Arrangements for controlling the spray area for controlling the spray area using fluids, e.g. gas streams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B12/00—Arrangements for controlling delivery; Arrangements for controlling the spray area

- B05B12/16—Arrangements for controlling delivery; Arrangements for controlling the spray area for controlling the spray area

- B05B12/20—Masking elements, i.e. elements defining uncoated areas on an object to be coated

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B14/00—Arrangements for collecting, re-using or eliminating excess spraying material

- B05B14/10—Arrangements for collecting, re-using or eliminating excess spraying material the excess material being particulate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/08—Plant for applying liquids or other fluent materials to objects

- B05B5/082—Plant for applying liquids or other fluent materials to objects characterised by means for supporting, holding or conveying the objects

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D1/00—Processes for applying liquids or other fluent materials

- B05D1/02—Processes for applying liquids or other fluent materials performed by spraying

- B05D1/12—Applying particulate materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D1/00—Processes for applying liquids or other fluent materials

- B05D1/32—Processes for applying liquids or other fluent materials using means for protecting parts of a surface not to be coated, e.g. using stencils, resists

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D3/00—Pretreatment of surfaces to which liquids or other fluent materials are to be applied; After-treatment of applied coatings, e.g. intermediate treating of an applied coating preparatory to subsequent applications of liquids or other fluent materials

- B05D3/02—Pretreatment of surfaces to which liquids or other fluent materials are to be applied; After-treatment of applied coatings, e.g. intermediate treating of an applied coating preparatory to subsequent applications of liquids or other fluent materials by baking

- B05D3/0254—After-treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/02—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work

- B05B13/0221—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work characterised by the means for moving or conveying the objects or other work, e.g. conveyor belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/06—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00 specially designed for treating the inside of hollow bodies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D1/00—Processes for applying liquids or other fluent materials

- B05D1/02—Processes for applying liquids or other fluent materials performed by spraying

- B05D1/04—Processes for applying liquids or other fluent materials performed by spraying involving the use of an electrostatic field

- B05D1/06—Applying particulate materials

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D55/00—Brakes with substantially-radial braking surfaces pressed together in axial direction, e.g. disc brakes

- F16D2055/0004—Parts or details of disc brakes

- F16D2055/0016—Brake calipers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2250/00—Manufacturing; Assembly

- F16D2250/0038—Surface treatment

- F16D2250/0046—Coating

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Electrostatic Spraying Apparatus (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Details Or Accessories Of Spraying Plant Or Apparatus (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013244106A JP2015100761A (ja) | 2013-11-26 | 2013-11-26 | 支持具、粉体塗布システム、粉体塗布方法、及びキャリパ |

| US14/888,464 US20160082464A1 (en) | 2013-11-26 | 2014-11-26 | Insulated support tool |

| EP14810001.9A EP3074143A1 (en) | 2013-11-26 | 2014-11-26 | Insulated support tool |

| PCT/JP2014/005916 WO2015079685A1 (en) | 2013-11-26 | 2014-11-26 | Insulated support tool |

| CN201480024555.8A CN105163864A (zh) | 2013-11-26 | 2014-11-26 | 绝缘支撑工具 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013244106A JP2015100761A (ja) | 2013-11-26 | 2013-11-26 | 支持具、粉体塗布システム、粉体塗布方法、及びキャリパ |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015100761A true JP2015100761A (ja) | 2015-06-04 |

| JP2015100761A5 JP2015100761A5 (enExample) | 2016-12-15 |

Family

ID=52021401

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013244106A Pending JP2015100761A (ja) | 2013-11-26 | 2013-11-26 | 支持具、粉体塗布システム、粉体塗布方法、及びキャリパ |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20160082464A1 (enExample) |

| EP (1) | EP3074143A1 (enExample) |

| JP (1) | JP2015100761A (enExample) |

| CN (1) | CN105163864A (enExample) |

| WO (1) | WO2015079685A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105772363A (zh) * | 2016-04-07 | 2016-07-20 | 华蓥市正大汽配有限公司 | 一种使用喷涂工装对汽车灯罩进行防雾喷漆的方法 |

| JP2017104786A (ja) * | 2015-12-08 | 2017-06-15 | 株式会社大気社 | 静電塗装設備 |

| JP2022097440A (ja) * | 2020-12-18 | 2022-06-30 | エクセル インダストリー | 静電粉末コーティングのためのロボット、システム及び方法 |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3060693B1 (en) * | 2013-10-25 | 2018-06-27 | United Technologies Corporation | Plasma spraying system with adjustable coating medium nozzle |

| ITUB20160922A1 (it) * | 2016-02-22 | 2017-08-22 | Varnish Tech S R L | Impianto e metodo di verniciatura. |

| EP3499072A1 (en) * | 2017-12-15 | 2019-06-19 | Meritor Heavy Vehicle Braking Systems (UK) Limited | Brake caliper |

| IT201900001321A1 (it) * | 2019-01-30 | 2020-07-30 | Ima Spa | Metodo per la realizzazione di un dispositivo operatore automatico articolato e relativo dispositivo operatore automatico articolato. |

| CN114472019A (zh) * | 2022-02-23 | 2022-05-13 | 扬州京隆科技有限公司 | 智能电网变电站制造用柜体表面高精度处理装置及方法 |

| CN116020675B (zh) * | 2022-12-31 | 2023-07-25 | 山东鼎诚塑粉新材料有限公司 | 一种基于二分法的塑粉小样机 |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS51143048A (en) * | 1975-06-04 | 1976-12-09 | Moon Star Co | A powder coating method |

| JPS5216547B2 (enExample) * | 1972-08-25 | 1977-05-10 | ||

| JPS6430674A (en) * | 1987-07-01 | 1989-02-01 | Herberts Gmbh | Method of electrostatic-coating or spray-coating product with electric-insulating surface and device used for said method |

| JPH0567361U (ja) * | 1992-02-19 | 1993-09-07 | 株式会社ユニシアジェックス | 塗装用マスキング装置 |

| JPH09122569A (ja) * | 1995-10-27 | 1997-05-13 | Anest Iwata Corp | ロボット塗装における塗装方法 |

| JPH10165881A (ja) * | 1996-12-05 | 1998-06-23 | Nippon Parkerizing Co Ltd | ロードホイールの静電粉体塗装方法 |

| JPH11253876A (ja) * | 1998-03-10 | 1999-09-21 | Nippon Parkerizing Co Ltd | ロードホイールの吹き付け塗装方法 |

| JP2001212479A (ja) * | 2000-02-04 | 2001-08-07 | Tokai Rika Co Ltd | 静電塗装装置及び静電塗装方法 |

| JP2002346464A (ja) * | 2001-05-28 | 2002-12-03 | Chuo Motor Wheel Co Ltd | 自動車用ホイールの粉体塗料吸引装置 |

| JP2004130254A (ja) * | 2002-10-11 | 2004-04-30 | Tdk Corp | マスキング冶具および粉体塗装方法ならびにカード型電子機器 |

| JP2005013931A (ja) * | 2003-06-27 | 2005-01-20 | Nisca Corp | 粉体塗装装置 |

| JP2005013932A (ja) * | 2003-06-27 | 2005-01-20 | Nisca Corp | 粉体塗装装置 |

| JP2009233510A (ja) * | 2008-03-26 | 2009-10-15 | Akebono Brake Ind Co Ltd | 塗装用支持装置、塗装用支持具、及び塗装方法 |

| JP2011161395A (ja) * | 2010-02-12 | 2011-08-25 | Seiko Epson Corp | 液滴吐出装置および液滴吐出方法 |

Family Cites Families (40)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2517220A (en) * | 1947-02-10 | 1950-08-01 | Lister John Samuel | Guard for use in painting and cleaning operations |

| US3618929A (en) * | 1969-04-03 | 1971-11-09 | Sperry Rand Corp | Holding and masking fixture for applying a coating of thermosetting material to selected surfaces of a part |

| US3866567A (en) * | 1969-11-25 | 1975-02-18 | Gen Electric | Masking apparatus for use in coating an article of manufacture |

| US4273505A (en) * | 1978-09-22 | 1981-06-16 | The United States Of America As Represented By The Administrator Of The National Aeronautics And Space Administration | Pneumatic inflatable end effector |

| DE3220796C2 (de) * | 1982-06-03 | 1987-04-09 | Ransburg-Gema AG, St. Gallen | Zerstäubervorrichtung zum Beschichten mit Pulver |

| US5567239A (en) * | 1991-05-18 | 1996-10-22 | Ribic, Jr.; Harald | Masking profile for use in painting car bodies |

| FR2718130B1 (fr) * | 1994-04-05 | 1996-06-21 | Europ Propulsion | Procédé pour l'application d'une protection anti-oxydation sur des disques de frein en matériau composite contenant du carbone. |

| DE4412084C1 (de) * | 1994-04-08 | 1996-01-11 | Fraunhofer Ges Forschung | Werkstückträger zur Verwendung bei elektrostatischen Beschichtungsverfahren |

| US5786028A (en) * | 1996-09-05 | 1998-07-28 | Cantwell; Jay S. | Masking tape and method |

| JP2001521989A (ja) * | 1997-11-03 | 2001-11-13 | シーメンス アクチエンゲゼルシヤフト | 被膜形成方法及びこの方法を実施するための装置 |

| US6136374A (en) * | 1999-10-14 | 2000-10-24 | Reuscher; Craig J. | Method and apparatus for coating vented brake rotors |

| DE10115376B4 (de) * | 2001-03-28 | 2006-03-16 | EISENMANN Fördertechnik GmbH & Co. KG | Anlage zum Pulverlackieren von Gegenständen |

| DE10249999B3 (de) * | 2002-10-26 | 2004-04-15 | EISENMANN Maschinenbau KG (Komplementär: Eisenmann-Stiftung) | Vorrichtung zur Absaugung bestimmter Flächenbereiche an bepulverten Fahrzeugrädern |

| DE10321700A1 (de) * | 2003-05-14 | 2004-12-09 | Pro-Tech Beratungs- Und Entwicklungs Gmbh | Maskierungsmittel zur Abdeckung eines Stahl- oder Eisenteilabschnittes in einem Beschichtungsverfahren |

| US7667157B2 (en) * | 2004-09-29 | 2010-02-23 | General Electric Company | Portable plenum laser forming |

| JP4676220B2 (ja) * | 2005-03-03 | 2011-04-27 | 曙ブレーキ工業株式会社 | ディスクブレーキ用キャリパ |

| DE102005033972A1 (de) * | 2005-07-20 | 2007-01-25 | Dürr Systems GmbH | Beschichtungsverfahren und zugehörige Beschichtungseinrichtung |

| JP5044138B2 (ja) * | 2006-04-17 | 2012-10-10 | 川崎重工業株式会社 | 搬送システムおよび加工設備 |

| US7655271B2 (en) * | 2006-06-08 | 2010-02-02 | General Electric Company | Apparatus and method for masking |

| JP2008095179A (ja) * | 2006-08-08 | 2008-04-24 | Sulzer Metco Ag | 基体の被覆用の方法および装置 |

| DE102007010312A1 (de) * | 2007-02-23 | 2008-08-28 | Wurster, Gerd | Vorrichtung und Verfahren zum Lackieren von Felgen |

| JP4725543B2 (ja) * | 2007-03-26 | 2011-07-13 | トヨタ自動車株式会社 | 溶射装置 |

| US8039052B2 (en) * | 2007-09-06 | 2011-10-18 | Intermolecular, Inc. | Multi-region processing system and heads |

| US8960382B2 (en) * | 2008-04-18 | 2015-02-24 | GM Global Technology Operations LLC | Chamber with filler material to dampen vibrating components |

| US9375746B2 (en) * | 2008-06-05 | 2016-06-28 | Durr Systems Gmbh | Compact paint booth |

| US8167605B2 (en) * | 2008-06-20 | 2012-05-01 | Oria Collapsibles, Llc | Production assembly and process for mass manufacture of a thermoplastic pallet incorporating a stiffened insert |

| CN101994097B (zh) * | 2009-08-25 | 2013-08-21 | 鸿富锦精密工业(深圳)有限公司 | 镀膜装置 |

| US20110064888A1 (en) * | 2009-09-11 | 2011-03-17 | Whitley Jeffery G | Portable heating apparatus for powder coating |

| US20110094443A1 (en) * | 2009-10-22 | 2011-04-28 | Steve Karaga | Masking apparatus for household paint job |

| TWI458557B (zh) * | 2009-11-26 | 2014-11-01 | Hon Hai Prec Ind Co Ltd | 噴塗遮蔽結構及採用該結構之噴塗遮蔽方法 |

| DE102009060649A1 (de) * | 2009-12-22 | 2011-06-30 | EISENMANN Anlagenbau GmbH & Co. KG, 71032 | Anlage zur Oberflächenbehandlung von Gegenständen |

| FR2954716B1 (fr) * | 2009-12-29 | 2012-02-10 | Plastic Omnium Cie | Procede de traitement surfacique de pieces de grandes dimensions, prehenseur de pieces adapte pour la mise en oeuvre d'un tel procede, utilisation de ce prehenseur et cabine de traitement |

| US20120037073A1 (en) * | 2010-08-12 | 2012-02-16 | Miguel Linares | Assembly and process incorporating a conveyed template surface for receiving a sprayable powderized foam in order to create a plurality of flexible parts |

| JP4975870B1 (ja) * | 2011-02-09 | 2012-07-11 | ファナック株式会社 | マスキング治具を用いたマスキング装置 |

| US8646404B2 (en) * | 2011-09-26 | 2014-02-11 | Todd E. Hendricks, SR. | Modular system with platformed robot, booth, and fluid delivery system for tire spraying |

| US8726833B2 (en) * | 2012-03-07 | 2014-05-20 | Adam G. Logan | Painting system having a vehicle with lift structure, table actuator, and spray head |

| JP5712955B2 (ja) * | 2012-03-21 | 2015-05-07 | 株式会社デンソー | 粉体塗装装置 |

| CN102896059B (zh) * | 2012-10-31 | 2014-09-17 | 深圳崇达多层线路板有限公司 | 一种防止静电喷涂上下板边聚油的装置 |

| EP3060693B1 (en) * | 2013-10-25 | 2018-06-27 | United Technologies Corporation | Plasma spraying system with adjustable coating medium nozzle |

| US9861998B2 (en) * | 2014-04-07 | 2018-01-09 | Oria Collapsibles, Llc | Assembly for coating an article incorporating robotic subassemblies utilizing articulating spray arms and carousel conveyor with inlet and outlet locations for the article |

-

2013

- 2013-11-26 JP JP2013244106A patent/JP2015100761A/ja active Pending

-

2014

- 2014-11-26 EP EP14810001.9A patent/EP3074143A1/en not_active Withdrawn

- 2014-11-26 CN CN201480024555.8A patent/CN105163864A/zh active Pending

- 2014-11-26 US US14/888,464 patent/US20160082464A1/en not_active Abandoned

- 2014-11-26 WO PCT/JP2014/005916 patent/WO2015079685A1/en not_active Ceased

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5216547B2 (enExample) * | 1972-08-25 | 1977-05-10 | ||

| JPS51143048A (en) * | 1975-06-04 | 1976-12-09 | Moon Star Co | A powder coating method |

| JPS6430674A (en) * | 1987-07-01 | 1989-02-01 | Herberts Gmbh | Method of electrostatic-coating or spray-coating product with electric-insulating surface and device used for said method |

| JPH0567361U (ja) * | 1992-02-19 | 1993-09-07 | 株式会社ユニシアジェックス | 塗装用マスキング装置 |

| JPH09122569A (ja) * | 1995-10-27 | 1997-05-13 | Anest Iwata Corp | ロボット塗装における塗装方法 |

| JPH10165881A (ja) * | 1996-12-05 | 1998-06-23 | Nippon Parkerizing Co Ltd | ロードホイールの静電粉体塗装方法 |

| JPH11253876A (ja) * | 1998-03-10 | 1999-09-21 | Nippon Parkerizing Co Ltd | ロードホイールの吹き付け塗装方法 |

| JP2001212479A (ja) * | 2000-02-04 | 2001-08-07 | Tokai Rika Co Ltd | 静電塗装装置及び静電塗装方法 |

| JP2002346464A (ja) * | 2001-05-28 | 2002-12-03 | Chuo Motor Wheel Co Ltd | 自動車用ホイールの粉体塗料吸引装置 |

| JP2004130254A (ja) * | 2002-10-11 | 2004-04-30 | Tdk Corp | マスキング冶具および粉体塗装方法ならびにカード型電子機器 |

| JP2005013931A (ja) * | 2003-06-27 | 2005-01-20 | Nisca Corp | 粉体塗装装置 |

| JP2005013932A (ja) * | 2003-06-27 | 2005-01-20 | Nisca Corp | 粉体塗装装置 |

| JP2009233510A (ja) * | 2008-03-26 | 2009-10-15 | Akebono Brake Ind Co Ltd | 塗装用支持装置、塗装用支持具、及び塗装方法 |

| JP2011161395A (ja) * | 2010-02-12 | 2011-08-25 | Seiko Epson Corp | 液滴吐出装置および液滴吐出方法 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017104786A (ja) * | 2015-12-08 | 2017-06-15 | 株式会社大気社 | 静電塗装設備 |

| CN105772363A (zh) * | 2016-04-07 | 2016-07-20 | 华蓥市正大汽配有限公司 | 一种使用喷涂工装对汽车灯罩进行防雾喷漆的方法 |

| JP2022097440A (ja) * | 2020-12-18 | 2022-06-30 | エクセル インダストリー | 静電粉末コーティングのためのロボット、システム及び方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20160082464A1 (en) | 2016-03-24 |

| EP3074143A1 (en) | 2016-10-05 |

| WO2015079685A1 (en) | 2015-06-04 |

| CN105163864A (zh) | 2015-12-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

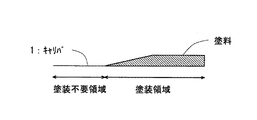

| JP2015100761A (ja) | 支持具、粉体塗布システム、粉体塗布方法、及びキャリパ | |

| JP2015100761A5 (enExample) | ||

| CN101939462A (zh) | 气缸孔喷涂装置和喷涂薄膜形成方法 | |

| WO2006030991A1 (ja) | 静電塗装装置 | |

| JP2015127047A (ja) | 粉体塗布システム、粉体塗布方法、キャリパの製造方法、及びキャリパ | |

| JP2010138440A (ja) | 溶射マスキング装置と同装置に使用する溶射膜除去装置及び溶射膜除去方法 | |

| CN110813588A (zh) | 用于喷涂工件的方法和设备 | |

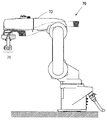

| JPS5858147B2 (ja) | 塗装用ロボツト | |

| JP5325964B2 (ja) | マスキング治具を用いたマスキング装置 | |

| JP5209805B1 (ja) | マスキング治具を用いたマスキング方法 | |

| CN103029988A (zh) | 机械手以及基板搬送装置 | |

| CN115335155A (zh) | 用于多轴的空心腕关节涂装机器人的雾化器更换系统 | |

| JP5442957B2 (ja) | 塗装用支持装置、塗装用支持具、及び塗装方法 | |

| JP2018103117A (ja) | 塗装ブース | |

| JP2008049281A (ja) | 粉体塗料塗着システムおよび粉体塗料塗着方法 | |

| JP2015189293A (ja) | ガラス位置決め装置及びガラス取付装置、 | |

| CN114932024B (zh) | 一种用于轮毂的静电喷涂装置及其静电喷涂工艺 | |

| JPS6133253A (ja) | ロボット用回転霧化静電塗装装置 | |

| CN105562273A (zh) | 一种钣金件自动化喷涂装置 | |

| JP2012232222A (ja) | 粉体塗装装置 | |

| JPH0611859U (ja) | 塗装用マスキング部材の自動取付装置 | |

| CN212309926U (zh) | 一种异形零件的化工喷涂设备 | |

| JP3043230U (ja) | 塗装用螺子穴遮蔽具 | |

| CN205684218U (zh) | 一种静电粉末喷涂设备 | |

| CN216137462U (zh) | 白车身涂装防护工装 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161031 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20161031 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170911 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20171107 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20180508 |