JP5541732B2 - 液体吐出ヘッドの製造方法及び吐出口部材の製造方法 - Google Patents

液体吐出ヘッドの製造方法及び吐出口部材の製造方法 Download PDFInfo

- Publication number

- JP5541732B2 JP5541732B2 JP2010263680A JP2010263680A JP5541732B2 JP 5541732 B2 JP5541732 B2 JP 5541732B2 JP 2010263680 A JP2010263680 A JP 2010263680A JP 2010263680 A JP2010263680 A JP 2010263680A JP 5541732 B2 JP5541732 B2 JP 5541732B2

- Authority

- JP

- Japan

- Prior art keywords

- mask

- discharge port

- layer

- plating

- port member

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

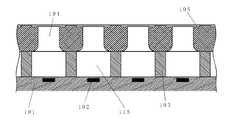

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1601—Production of bubble jet print heads

- B41J2/1603—Production of bubble jet print heads of the front shooter type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1631—Manufacturing processes photolithography

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/164—Manufacturing processes thin film formation

- B41J2/1643—Manufacturing processes thin film formation thin film formation by plating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/164—Manufacturing processes thin film formation

- B41J2/1646—Manufacturing processes thin film formation thin film formation by sputtering

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49401—Fluid pattern dispersing device making, e.g., ink jet

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Particle Formation And Scattering Control In Inkjet Printers (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010263680A JP5541732B2 (ja) | 2009-11-26 | 2010-11-26 | 液体吐出ヘッドの製造方法及び吐出口部材の製造方法 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009268758 | 2009-11-26 | ||

| JP2009268758 | 2009-11-26 | ||

| JP2010263680A JP5541732B2 (ja) | 2009-11-26 | 2010-11-26 | 液体吐出ヘッドの製造方法及び吐出口部材の製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011131590A JP2011131590A (ja) | 2011-07-07 |

| JP2011131590A5 JP2011131590A5 (enExample) | 2013-12-26 |

| JP5541732B2 true JP5541732B2 (ja) | 2014-07-09 |

Family

ID=44061220

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010263680A Expired - Fee Related JP5541732B2 (ja) | 2009-11-26 | 2010-11-26 | 液体吐出ヘッドの製造方法及び吐出口部材の製造方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US8499453B2 (enExample) |

| JP (1) | JP5541732B2 (enExample) |

| CN (1) | CN102139568B (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5901149B2 (ja) | 2011-06-01 | 2016-04-06 | キヤノン株式会社 | 液体吐出ヘッドおよびその製造方法 |

| JP6116198B2 (ja) | 2012-11-15 | 2017-04-19 | キヤノン株式会社 | 液体吐出ヘッドの製造方法 |

| JP6818436B2 (ja) * | 2016-05-27 | 2021-01-20 | キヤノン株式会社 | 記録素子基板、液体吐出ヘッドおよび液体吐出装置 |

Family Cites Families (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58124660A (ja) * | 1982-01-19 | 1983-07-25 | Ricoh Co Ltd | 液体噴射装置のマルチノズルプレ−トの製造方法 |

| US4675083A (en) * | 1986-04-02 | 1987-06-23 | Hewlett-Packard Company | Compound bore nozzle for ink jet printhead and method of manufacture |

| JPH0349960A (ja) | 1989-07-18 | 1991-03-04 | Seiko Epson Corp | インクジェットの製造方法 |

| US4972204A (en) * | 1989-08-21 | 1990-11-20 | Eastman Kodak Company | Laminate, electroformed ink jet orifice plate construction |

| JPH04338550A (ja) * | 1991-05-15 | 1992-11-25 | Brother Ind Ltd | オリフィスプレートの製造方法 |

| JPH08132625A (ja) | 1994-11-09 | 1996-05-28 | Ricoh Co Ltd | ノズルプレートの製造方法及びそのための母型構造 |

| MX9601409A (es) * | 1995-04-14 | 1997-08-30 | Canon Kk | Metodo para producir una cabeza de eyeccion de liquido y cabeza de eyeccion de liquido obtenida por dicho metodo. |

| JPH1016236A (ja) | 1996-06-28 | 1998-01-20 | Copal Co Ltd | インクジェットプリンタヘッド及びその製造方法 |

| JP3257960B2 (ja) * | 1996-12-17 | 2002-02-18 | 富士通株式会社 | インクジェットヘッド |

| JP3495218B2 (ja) | 1997-03-24 | 2004-02-09 | 株式会社リコー | ノズル形成部材の製造方法 |

| US5847725A (en) * | 1997-07-28 | 1998-12-08 | Hewlett-Packard Company | Expansion relief for orifice plate of thermal ink jet print head |

| US6449831B1 (en) * | 1998-06-19 | 2002-09-17 | Lexmark International, Inc | Process for making a heater chip module |

| RU2151066C1 (ru) * | 1998-11-03 | 2000-06-20 | Самсунг Электроникс Ко., Лтд. | Узел пластины сопла микроинжектора и способ его изготовления |

| EP1020291A3 (en) * | 1999-01-18 | 2001-04-11 | Canon Kabushiki Kaisha | Liquid discharge head and producing method therefor |

| JP3826608B2 (ja) * | 1999-03-17 | 2006-09-27 | 富士写真フイルム株式会社 | 液体吐出部表面の撥水膜形成 |

| EP1065059B1 (en) * | 1999-07-02 | 2007-01-31 | Canon Kabushiki Kaisha | Method for producing liquid discharge head, liquid discharge head, head cartridge, liquid discharging recording apparatus, method for producing silicon plate and silicon plate |

| JP2001038915A (ja) | 1999-08-02 | 2001-02-13 | Seiko Epson Corp | ノズルプレートの製造方法 |

| JP2002059551A (ja) | 2000-08-16 | 2002-02-26 | Ricoh Co Ltd | インクジェットノズル及びその製造方法 |

| JP2003025577A (ja) * | 2001-07-11 | 2003-01-29 | Canon Inc | 液体吐出ヘッド |

| JP4532785B2 (ja) * | 2001-07-11 | 2010-08-25 | キヤノン株式会社 | 構造体の製造方法、および液体吐出ヘッドの製造方法 |

| US20030143492A1 (en) * | 2002-01-31 | 2003-07-31 | Scitex Digital Printing, Inc. | Mandrel with controlled release layer for multi-layer electroformed ink jet orifice plates |

| JP4068892B2 (ja) * | 2002-05-20 | 2008-03-26 | 富士フイルム株式会社 | 画像形成材料 |

| US7086154B2 (en) * | 2002-06-26 | 2006-08-08 | Brother Kogyo Kabushiki Kaisha | Process of manufacturing nozzle plate for ink-jet print head |

| JP4298414B2 (ja) * | 2002-07-10 | 2009-07-22 | キヤノン株式会社 | 液体吐出ヘッドの製造方法 |

| JP4280574B2 (ja) * | 2002-07-10 | 2009-06-17 | キヤノン株式会社 | 液体吐出ヘッドの製造方法 |

| JP3862624B2 (ja) * | 2002-07-10 | 2006-12-27 | キヤノン株式会社 | 液体吐出ヘッドおよび、該ヘッドの製造方法 |

| US7022417B2 (en) * | 2002-12-02 | 2006-04-04 | Nitto Kogyo Co., Ltd. | Metal belt and coated belt |

| JP2004268359A (ja) * | 2003-03-07 | 2004-09-30 | Hitachi Printing Solutions Ltd | インクジェットヘッド及びその製造方法 |

| JP2004323642A (ja) * | 2003-04-23 | 2004-11-18 | Riso Kagaku Corp | カチオン重合性組成物及びインク |

| WO2005007411A1 (en) * | 2003-07-22 | 2005-01-27 | Canon Kabushiki Kaisha | Ink jet head and its manufacture method |

| DE60332288D1 (de) * | 2003-07-22 | 2010-06-02 | Canon Kk | Tintenstrahlkopf und herstellungsverfahren dafür |

| JP4776154B2 (ja) * | 2003-09-03 | 2011-09-21 | キヤノン株式会社 | 圧電体素子、インクジェット記録ヘッド、圧電体素子の製造方法 |

| JP4537246B2 (ja) * | 2004-05-06 | 2010-09-01 | キヤノン株式会社 | インクジェット記録ヘッド用基体の製造方法及び該方法により製造された前記基体を用いた記録ヘッドの製造方法 |

| CN1968815B (zh) | 2004-06-28 | 2013-05-01 | 佳能株式会社 | 排液头制造方法,和使用该方法得到的排液头 |

| JP4459037B2 (ja) * | 2004-12-01 | 2010-04-28 | キヤノン株式会社 | 液体吐出ヘッド |

| JP4667028B2 (ja) * | 2004-12-09 | 2011-04-06 | キヤノン株式会社 | 構造体の形成方法及びインクジェット記録ヘッドの製造方法 |

| JP4614383B2 (ja) * | 2004-12-09 | 2011-01-19 | キヤノン株式会社 | インクジェット記録ヘッドの製造方法、及びインクジェット記録ヘッド |

| KR100653088B1 (ko) * | 2005-12-06 | 2006-12-04 | 삼성전자주식회사 | 잉크젯 프린트 헤드의 제조방법 |

| JP5085272B2 (ja) * | 2007-02-09 | 2012-11-28 | 株式会社リコー | 液体吐出ヘッド及び画像形成装置 |

-

2010

- 2010-10-28 US US12/914,564 patent/US8499453B2/en not_active Expired - Fee Related

- 2010-11-23 CN CN201010556525.5A patent/CN102139568B/zh not_active Expired - Fee Related

- 2010-11-26 JP JP2010263680A patent/JP5541732B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN102139568A (zh) | 2011-08-03 |

| CN102139568B (zh) | 2013-07-10 |

| US8499453B2 (en) | 2013-08-06 |

| US20110120627A1 (en) | 2011-05-26 |

| JP2011131590A (ja) | 2011-07-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8429820B2 (en) | Method of manufacturing liquid discharge head | |

| CN100425447C (zh) | 液体喷射头,液体喷射装置,制造液体喷射头的方法 | |

| JP4455287B2 (ja) | インクジェット記録ヘッドの製造方法 | |

| KR101438267B1 (ko) | 액체 토출 헤드 및 그 제조 방법 | |

| JP5541732B2 (ja) | 液体吐出ヘッドの製造方法及び吐出口部材の製造方法 | |

| US7205097B2 (en) | Liquid ejection head and method of producing the same | |

| JP5541733B2 (ja) | 吐出口部材の製造方法および液体吐出ヘッドの製造方法 | |

| JP2000117981A (ja) | インクジェットプリンタヘッドアクチュエ―タ及びその製造方法 | |

| JP5679688B2 (ja) | 液体吐出ヘッド及びその製造方法 | |

| JP4015274B2 (ja) | インクジェットヘッド用ノズル板の製造方法 | |

| KR100289606B1 (ko) | 잉크젯 프린트헤드용 챔버판의 패터닝방법과 그에 의해 제조되는 액츄에이터 | |

| TWI273983B (en) | Liquid ejection element and manufacturing method therefor | |

| JP2000318163A (ja) | インクジェットヘッド及びその製造方法並びにノズル形成部材及びその製造方法 | |

| JP3672559B2 (ja) | インク噴射記録ヘッドチップの製造方法、インク噴射記録ヘッドの製造方法、および記録装置 | |

| JP2002059551A (ja) | インクジェットノズル及びその製造方法 | |

| JPH1120159A (ja) | インクジェットヘッド部品及びその製造方法 | |

| JPH11188880A (ja) | 電鋳支持基板及びその製造方法並びにインクジェットヘッド部品の製造方法 | |

| JP3780735B2 (ja) | インクジェットプリンタヘッドの製造方法 | |

| JP3862235B2 (ja) | インク噴射記録ヘッド、その製造方法および記録装置 | |

| JP2000313984A (ja) | 電鋳原版及びその製造方法並びに振動板の製造方法 | |

| JP2006175678A (ja) | ノズルシートの製造方法、ノズルシートの表面処理方法、ノズルシート、液体吐出ヘッドの製造方法、及び液体吐出ヘッド | |

| JP3568022B2 (ja) | インクジェットヘッドの製造方法 | |

| JP3166830B2 (ja) | 静電吸引型マルチノズルインクジェットヘッドの製造方法 | |

| JPH054346A (ja) | インクジエツトヘツドの製造方法 | |

| JPH11105283A (ja) | インクジェットヘッド及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131113 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20131113 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140311 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140408 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140430 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 5541732 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| LAPS | Cancellation because of no payment of annual fees |