JP2008032335A - ミニエンバイロメント装置、検査装置、製造装置、及び空間の清浄化方法 - Google Patents

ミニエンバイロメント装置、検査装置、製造装置、及び空間の清浄化方法 Download PDFInfo

- Publication number

- JP2008032335A JP2008032335A JP2006207774A JP2006207774A JP2008032335A JP 2008032335 A JP2008032335 A JP 2008032335A JP 2006207774 A JP2006207774 A JP 2006207774A JP 2006207774 A JP2006207774 A JP 2006207774A JP 2008032335 A JP2008032335 A JP 2008032335A

- Authority

- JP

- Japan

- Prior art keywords

- housing

- pressure

- chamber

- clean

- measuring means

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

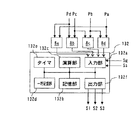

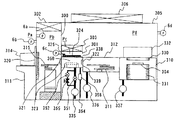

- F24F11/00—Control or safety arrangements

- F24F11/30—Control or safety arrangements for purposes related to the operation of the system, e.g. for safety or monitoring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/12—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling

- F24F3/16—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by purification, e.g. by filtering; by sterilisation; by ozonisation

- F24F3/167—Clean rooms, i.e. enclosed spaces in which a uniform flow of filtered air is distributed

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/70—Control systems characterised by their outputs; Constructional details thereof

- F24F11/72—Control systems characterised by their outputs; Constructional details thereof for controlling the supply of treated air, e.g. its pressure

- F24F11/74—Control systems characterised by their outputs; Constructional details thereof for controlling the supply of treated air, e.g. its pressure for controlling air flow rate or air velocity

- F24F11/77—Control systems characterised by their outputs; Constructional details thereof for controlling the supply of treated air, e.g. its pressure for controlling air flow rate or air velocity by controlling the speed of ventilators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2110/00—Control inputs relating to air properties

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2110/00—Control inputs relating to air properties

- F24F2110/40—Pressure, e.g. wind pressure

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02B—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO BUILDINGS, e.g. HOUSING, HOUSE APPLIANCES OR RELATED END-USER APPLICATIONS

- Y02B30/00—Energy efficient heating, ventilation or air conditioning [HVAC]

- Y02B30/70—Efficient control or regulation technologies, e.g. for control of refrigerant flow, motor or heating

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

- Ventilation (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006207774A JP2008032335A (ja) | 2006-07-31 | 2006-07-31 | ミニエンバイロメント装置、検査装置、製造装置、及び空間の清浄化方法 |

| US11/882,063 US7925390B2 (en) | 2006-07-31 | 2007-07-30 | Mini environment apparatus, inspection apparatus, manufacturing apparatus and cleaning method of space |

| US13/040,350 US20110153114A1 (en) | 2006-07-31 | 2011-03-04 | Mini Environment Apparatus, Inspection Apparatus, Manufacturing Apparatus and Cleaning Method of Space |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006207774A JP2008032335A (ja) | 2006-07-31 | 2006-07-31 | ミニエンバイロメント装置、検査装置、製造装置、及び空間の清浄化方法 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012118914A Division JP5385425B2 (ja) | 2012-05-24 | 2012-05-24 | 検査装置及びミニエンバイロメント構造 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008032335A true JP2008032335A (ja) | 2008-02-14 |

| JP2008032335A5 JP2008032335A5 (enExample) | 2008-12-04 |

Family

ID=39102417

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006207774A Pending JP2008032335A (ja) | 2006-07-31 | 2006-07-31 | ミニエンバイロメント装置、検査装置、製造装置、及び空間の清浄化方法 |

Country Status (2)

| Country | Link |

|---|---|

| US (2) | US7925390B2 (enExample) |

| JP (1) | JP2008032335A (enExample) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010092950A (ja) * | 2008-10-06 | 2010-04-22 | Hitachi High-Technologies Corp | 試料測定装置 |

| JP2012149817A (ja) * | 2011-01-19 | 2012-08-09 | Nippon Spindle Mfg Co Ltd | 温調装置 |

| CN107101346A (zh) * | 2017-06-19 | 2017-08-29 | 芜湖美智空调设备有限公司 | 室外风机控制方法、空调器以及计算机可读存储介质 |

| JP2018011448A (ja) * | 2016-07-14 | 2018-01-18 | Ckd株式会社 | アクチュエータ |

| JP2019134678A (ja) * | 2019-04-24 | 2019-08-08 | Ckd株式会社 | アクチュエータ |

| JP2021158222A (ja) * | 2020-03-27 | 2021-10-07 | 国立研究開発法人産業技術総合研究所 | カプセル化クリーンルームシステム |

| WO2024142563A1 (ja) * | 2022-12-27 | 2024-07-04 | 株式会社Sumco | 半導体ウェーハの処理装置 |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008032335A (ja) * | 2006-07-31 | 2008-02-14 | Hitachi High-Technologies Corp | ミニエンバイロメント装置、検査装置、製造装置、及び空間の清浄化方法 |

| JP5056143B2 (ja) * | 2007-04-25 | 2012-10-24 | ダイキン工業株式会社 | ファン制御システム |

| JP2009002634A (ja) * | 2007-06-25 | 2009-01-08 | Unitec Inc | ユニット型クリーンルーム |

| US8202145B2 (en) * | 2009-03-20 | 2012-06-19 | Maintainer Corporation Of Iowa | Service truck body pressurized storage system |

| JP5085716B2 (ja) * | 2010-11-02 | 2012-11-28 | 株式会社東芝 | サーバ室管理用の空調システム、およびこれを利用したサーバ管理用システム、空調制御方法 |

| US8834582B2 (en) * | 2011-12-26 | 2014-09-16 | Beijing Sevenstar Electronics Co., Ltd. | Apparatus for manufacturing semiconductor wafer |

| CN103177985B (zh) * | 2011-12-26 | 2016-08-03 | 北京七星华创电子股份有限公司 | 半导体晶圆制造装置 |

| US10646734B2 (en) * | 2014-05-05 | 2020-05-12 | Wayne Fueling Systems Sweden Ab | Purge and pressurization system with feedback control |

| CN105135603A (zh) * | 2015-08-12 | 2015-12-09 | 武汉华星光电技术有限公司 | 腔室气流控制系统及方法 |

| DE102018106751B4 (de) * | 2017-07-31 | 2025-02-27 | Taiwan Semiconductor Manufacturing Co. Ltd. | Automatisiertes inspektionswerkzeug |

| KR102385366B1 (ko) | 2017-09-20 | 2022-04-08 | 삼성전자주식회사 | 반도체 제조 설비의 제어 시스템 및 방법과, 이를 이용한 집적 회로의 제조 방법 및 프로세서의 제조 방법 |

| CN109855205A (zh) * | 2018-12-07 | 2019-06-07 | 青岛海尔空调器有限总公司 | 空调自清洁控制的方法、装置及计算机存储介质 |

| CN114247225B (zh) * | 2021-11-17 | 2023-05-16 | 江苏百维能源科技有限公司 | 一种电能计量器具柜 |

| BE1031344B1 (nl) * | 2023-02-15 | 2024-09-16 | Abn Cleanroom Tech N V | Inrichting en werkwijze voor het ventileren van een klimaatkamer |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11278604A (ja) * | 1998-03-27 | 1999-10-12 | Toyota Autom Loom Works Ltd | 清浄保管装置 |

| JP2000082731A (ja) * | 1998-09-04 | 2000-03-21 | Hitachi Plant Eng & Constr Co Ltd | クリーンルーム設備 |

| JP2000257909A (ja) * | 1999-03-09 | 2000-09-22 | Daikin Plant Kk | 空調設備 |

| JP2002022227A (ja) * | 2000-07-04 | 2002-01-23 | Hitachi Plant Eng & Constr Co Ltd | クリーンルーム設備 |

| JP2002231782A (ja) * | 2001-02-01 | 2002-08-16 | Toshiba Corp | 半導体ウエハの移送方法、半導体装置の製造方法およびプロセス装置 |

| JP2005019739A (ja) * | 2003-06-26 | 2005-01-20 | Tokyo Electron Ltd | 被処理体の搬送方法 |

| JP2006125812A (ja) * | 2004-09-29 | 2006-05-18 | Matsushita Electric Ind Co Ltd | クリーンルーム設備及びクリーンルームの室圧制御方法 |

Family Cites Families (79)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6346328A (ja) * | 1986-08-12 | 1988-02-27 | Sekisui Chem Co Ltd | クリ−ンル−ム付き建物の排気方法 |

| DE3634920A1 (de) * | 1986-10-14 | 1988-04-21 | Hoelter Heinz | Reinluftschrank fuer sterilgut zur lagerung und als schleuse |

| DE3637880C2 (de) * | 1986-11-06 | 1994-09-01 | Meissner & Wurst | Transportierbares Behältnis zur Handhabung von Halbleiterelementen während ihrer Herstellung sowie Verfahren zur partikelfreien Übergabe von Produkten |

| JPH0756879B2 (ja) * | 1988-03-31 | 1995-06-14 | 日鉄セミコンダクター株式会社 | 半導体の無塵化製造装置 |

| JPH03291436A (ja) * | 1990-04-05 | 1991-12-20 | N M B Semiconductor:Kk | 半導体製造工場のクリーンルーム |

| US5401212A (en) * | 1990-08-29 | 1995-03-28 | Intelligent Enclosures Corporation | Environmental control system |

| US5219464A (en) * | 1990-10-09 | 1993-06-15 | Tokyo Electron Limited | Clean air apparatus |

| US5261935A (en) * | 1990-09-26 | 1993-11-16 | Tokyo Electron Sagami Limited | Clean air apparatus |

| US5326316A (en) * | 1991-04-17 | 1994-07-05 | Matsushita Electric Industrial Co., Ltd. | Coupling type clean space apparatus |

| DE4121006A1 (de) * | 1991-06-21 | 1992-12-24 | Elpro Ag | Entsorgungseinrichtung zur durchfuehrung von vorerkundungen, erkundungen und sanierungsarbeiten |

| GB9202154D0 (en) * | 1992-01-31 | 1992-03-18 | Challenger John G | Clean room construction |

| JPH05248677A (ja) * | 1992-03-03 | 1993-09-24 | Fujitsu Ltd | クリーンブース |

| US5259812A (en) * | 1992-09-23 | 1993-11-09 | Kleinsek Don A | Clean room and clean room containment center |

| DK85093D0 (da) * | 1993-07-16 | 1993-07-16 | Landsforeningen Til Kraeftens | Method and apparatus for performing operations |

| US5810657A (en) * | 1994-11-22 | 1998-09-22 | Lighthouse Associates, Inc. | Controller to maintain a certain set of environmental parameters in an environment |

| US5549512A (en) * | 1994-11-30 | 1996-08-27 | Lucent Technologies Inc. | Minienvironment for hazardous process tools |

| SE508807C2 (sv) * | 1996-04-01 | 1998-11-09 | Flaekt Ab | Anordning för tillförsel av luft till renrum indelat i zoner med olika klimatkrav |

| WO1998000676A1 (en) * | 1996-06-28 | 1998-01-08 | Intelligent Enclosures Corporation | Environmentally enhanced enclosure for managing cmp contamination |

| JP3654612B2 (ja) * | 1996-09-24 | 2005-06-02 | 株式会社ルネサステクノロジ | クリーンルーム |

| US6082949A (en) * | 1996-10-11 | 2000-07-04 | Asyst Technologies, Inc. | Load port opener |

| KR100238945B1 (ko) * | 1997-01-09 | 2000-01-15 | 윤종용 | 반도체장치 제조용 클린룸의 팬 필터 유니트 구동 감시장치 |

| WO1998050134A1 (en) * | 1997-05-09 | 1998-11-12 | Szatmary Michael A | Isolation chamber air curtain apparatus |

| JP3425592B2 (ja) * | 1997-08-12 | 2003-07-14 | 東京エレクトロン株式会社 | 処理装置 |

| US6183358B1 (en) * | 1997-11-17 | 2001-02-06 | Texas Instruments Incorporated | Isolated multilevel fabricating facility with two way clean tunnel transport system with each tool having adjacent support skid |

| US7658891B1 (en) * | 1997-11-21 | 2010-02-09 | Barnes Ronald L | Air purification and decontamination for hazmat suits |

| TW343377B (en) * | 1997-12-03 | 1998-10-21 | United Microelectronics Corp | Via structure and production process thereof |

| KR100259984B1 (ko) * | 1997-12-08 | 2000-06-15 | 윤종용 | 클린룸의공조용팬필터유니트구동상태체크시스템 |

| JP3911904B2 (ja) * | 1999-04-21 | 2007-05-09 | 株式会社日立プラントテクノロジー | クリーンルーム構造 |

| US6050891A (en) * | 1998-02-06 | 2000-04-18 | Applied Materials, Inc. | Vacuum processing system with turbo-axial fan in clean-air supply system of front end environment |

| KR100626857B1 (ko) * | 1998-03-16 | 2006-09-22 | 어사이스트 테크놀로지스, 인코포레이티드 | 지능적 소형 환경 |

| JP2947272B1 (ja) * | 1998-06-05 | 1999-09-13 | 日本電気株式会社 | クリーンルーム室圧調整方法及びその装置 |

| US6056797A (en) * | 1998-06-12 | 2000-05-02 | Richard; Kenneth L. | Dust collector filter cleaning control system |

| JP2000002456A (ja) * | 1998-06-17 | 2000-01-07 | Daiichi Shisetsu Kogyo Kk | クリーンコンテナ |

| US6358128B1 (en) * | 1999-03-05 | 2002-03-19 | Ebara Corporation | Polishing apparatus |

| TW463207B (en) * | 1999-03-17 | 2001-11-11 | Fujitsu Ltd | Double-sealed work conveying and transferring apparatus and container inspecting method |

| JP2000294615A (ja) * | 1999-04-09 | 2000-10-20 | Miyagi Oki Electric Co Ltd | 搬送システムおよび搬送方法 |

| JP2000297953A (ja) * | 1999-04-13 | 2000-10-24 | Taikisha Ltd | クリーンルームのポッド用インターフェースチャンバ |

| US6135698A (en) * | 1999-04-30 | 2000-10-24 | Asyst Technologies, Inc. | Universal tool interface and/or workpiece transfer apparatus for SMIF and open pod applications |

| US6612797B1 (en) * | 1999-05-18 | 2003-09-02 | Asyst Technologies, Inc. | Cassette buffering within a minienvironment |

| JP3916380B2 (ja) * | 1999-07-06 | 2007-05-16 | 株式会社荏原製作所 | 基板搬送容器待機ステーション |

| JP3476395B2 (ja) * | 1999-09-24 | 2003-12-10 | Necエレクトロニクス株式会社 | クリーンルーム及びクリーンルームの空調方法 |

| DE19947781C1 (de) * | 1999-10-02 | 2000-12-21 | Bosch Gmbh Robert | Verfahren und Vorrichtung zur Luftführung in einem Bearbeitungsraum |

| US6547953B2 (en) * | 2000-01-28 | 2003-04-15 | Ebara Corporation | Substrate container and method of dehumidifying substrate container |

| JP3939101B2 (ja) * | 2000-12-04 | 2007-07-04 | 株式会社荏原製作所 | 基板搬送方法および基板搬送容器 |

| CN1193193C (zh) * | 2000-12-21 | 2005-03-16 | 松下电器产业株式会社 | 净化室及半导体装置的制造方法 |

| US6585470B2 (en) * | 2001-06-19 | 2003-07-01 | Brooks Automation, Inc. | System for transporting substrates |

| JP2003017376A (ja) * | 2001-07-02 | 2003-01-17 | Sanki Eng Co Ltd | 半導体製造装置および半導体製造方法 |

| JP4038352B2 (ja) * | 2001-08-24 | 2008-01-23 | 株式会社日立産機システム | クリーンルーム |

| US7066707B1 (en) * | 2001-08-31 | 2006-06-27 | Asyst Technologies, Inc. | Wafer engine |

| US7217076B2 (en) * | 2001-08-31 | 2007-05-15 | Asyst Technologies, Inc. | Semiconductor material handling system |

| JP3765748B2 (ja) * | 2001-11-27 | 2006-04-12 | 富士写真フイルム株式会社 | 電子機器の内気圧調節システム |

| US7536940B2 (en) * | 2001-12-20 | 2009-05-26 | Fujifilm Corporation | Clean booth and sheet conveyor device |

| DE10164175B4 (de) * | 2001-12-27 | 2004-02-12 | Infineon Technologies Ag | Prozeßgerät mit zwei Raumeinheiten und einer die zwei Raumeinheiten verbindenden dritten Raumeinheit mit jeweils einer gegenüber der Umgebung verminderten Dichte kontaminierter Teilchen und Verfahren zum Betrieb des Prozeßgerätes |

| US6969497B2 (en) * | 2002-07-08 | 2005-11-29 | Giuseppe Sacca | Decontamination system for use with a rapid transfer port |

| US7156898B2 (en) * | 2002-07-12 | 2007-01-02 | Jaisinghani Rajan A | Low pressure drop deep electrically enhanced filter |

| JP2004126427A (ja) * | 2002-10-07 | 2004-04-22 | Fuji Photo Film Co Ltd | 電子画像形成方法 |

| KR100486690B1 (ko) * | 2002-11-29 | 2005-05-03 | 삼성전자주식회사 | 기판 이송 모듈의 오염을 제어할 수 있는 기판 처리 장치및 방법 |

| JP4344593B2 (ja) | 2002-12-02 | 2009-10-14 | ローツェ株式会社 | ミニエンバイロメント装置、薄板状物製造システム及び清浄容器の雰囲気置換方法 |

| JP4440654B2 (ja) * | 2003-01-08 | 2010-03-24 | 三機工業株式会社 | ファンフィルタユニットおよび既設加圧チャンバ方式クリーンルームをffu方式クリーンルームに改修する方法ならびにffu方式クリーンルームをffu方式クリーンルームと一部空調機方式クリーンルームとの併用型クリーンルームに改修する方法 |

| KR100483428B1 (ko) * | 2003-01-24 | 2005-04-14 | 삼성전자주식회사 | 기판 가공 장치 |

| JP2004327561A (ja) * | 2003-04-22 | 2004-11-18 | Ebara Corp | 基板処理方法及び基板処理装置 |

| JP4860102B2 (ja) * | 2003-06-26 | 2012-01-25 | ルネサスエレクトロニクス株式会社 | 半導体装置 |

| KR100524875B1 (ko) * | 2003-06-28 | 2005-10-31 | 엘지.필립스 엘시디 주식회사 | 청정시스템 |

| JP4429313B2 (ja) * | 2004-06-03 | 2010-03-10 | 株式会社トーショー | クリーンルームユニット |

| TW200540922A (en) * | 2004-06-04 | 2005-12-16 | Kondoh Ind Ltd | Air-purifying equipment in a semiconductor wafer container |

| KR100583730B1 (ko) * | 2004-06-29 | 2006-05-26 | 삼성전자주식회사 | 기판 이송 시스템 및 상기 시스템의 프레임 내 압력을조절하는 방법 |

| JP4523803B2 (ja) * | 2004-06-30 | 2010-08-11 | 富士通株式会社 | ファンシステム、ファン装置、及びファン装置の制御方法 |

| US7197883B2 (en) * | 2005-05-06 | 2007-04-03 | Praxair Technology, Inc. | Cooling or heating with multi-pass fluid flow |

| US7539601B2 (en) * | 2005-10-11 | 2009-05-26 | Jaisinghani Rajan A | Energy efficient air handling system for cleanrooms |

| JP2007123523A (ja) * | 2005-10-27 | 2007-05-17 | Ebara Corp | 研磨方法及び研磨装置、並びに電解研磨装置 |

| US20070135024A1 (en) * | 2005-12-08 | 2007-06-14 | Itsuki Kobata | Polishing pad and polishing apparatus |

| US20070155300A1 (en) * | 2006-01-04 | 2007-07-05 | Chih-Ching Hsieh | Safety device for controlling ventilation of a vehicle compartment |

| SG136834A1 (en) * | 2006-04-28 | 2007-11-29 | Kyodo Allied Ind Ltd | A method and apparatus for maintaining air characteristics in an air ventilated facility using fan filter units |

| AU2007255044B2 (en) * | 2006-05-24 | 2012-03-22 | American Innovative Research Corp. | Positive air pressure isolation system |

| JP4268624B2 (ja) * | 2006-06-02 | 2009-05-27 | 株式会社日立製作所 | 培養システム、培養装置、及び培養容器箱、並びに空気清浄化方法 |

| US7819934B2 (en) * | 2006-07-14 | 2010-10-26 | Xcellerex, Inc. | Environmental containment systems |

| JP2008032335A (ja) * | 2006-07-31 | 2008-02-14 | Hitachi High-Technologies Corp | ミニエンバイロメント装置、検査装置、製造装置、及び空間の清浄化方法 |

| US20080076343A1 (en) * | 2006-09-15 | 2008-03-27 | Vectech Pharmaceutical Consultants | Portable clean air cart |

| JP2009297953A (ja) * | 2008-06-11 | 2009-12-24 | Seiko Epson Corp | 静電アクチュエータの製造方法、静電アクチュエータ、液滴吐出ヘッドの製造方法、液滴吐出ヘッド、液滴吐出装置の製造方法及び液滴吐出装置 |

-

2006

- 2006-07-31 JP JP2006207774A patent/JP2008032335A/ja active Pending

-

2007

- 2007-07-30 US US11/882,063 patent/US7925390B2/en active Active

-

2011

- 2011-03-04 US US13/040,350 patent/US20110153114A1/en not_active Abandoned

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11278604A (ja) * | 1998-03-27 | 1999-10-12 | Toyota Autom Loom Works Ltd | 清浄保管装置 |

| JP2000082731A (ja) * | 1998-09-04 | 2000-03-21 | Hitachi Plant Eng & Constr Co Ltd | クリーンルーム設備 |

| JP2000257909A (ja) * | 1999-03-09 | 2000-09-22 | Daikin Plant Kk | 空調設備 |

| JP2002022227A (ja) * | 2000-07-04 | 2002-01-23 | Hitachi Plant Eng & Constr Co Ltd | クリーンルーム設備 |

| JP2002231782A (ja) * | 2001-02-01 | 2002-08-16 | Toshiba Corp | 半導体ウエハの移送方法、半導体装置の製造方法およびプロセス装置 |

| JP2005019739A (ja) * | 2003-06-26 | 2005-01-20 | Tokyo Electron Ltd | 被処理体の搬送方法 |

| JP2006125812A (ja) * | 2004-09-29 | 2006-05-18 | Matsushita Electric Ind Co Ltd | クリーンルーム設備及びクリーンルームの室圧制御方法 |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010092950A (ja) * | 2008-10-06 | 2010-04-22 | Hitachi High-Technologies Corp | 試料測定装置 |

| JP2012149817A (ja) * | 2011-01-19 | 2012-08-09 | Nippon Spindle Mfg Co Ltd | 温調装置 |

| JP2018011448A (ja) * | 2016-07-14 | 2018-01-18 | Ckd株式会社 | アクチュエータ |

| CN107101346A (zh) * | 2017-06-19 | 2017-08-29 | 芜湖美智空调设备有限公司 | 室外风机控制方法、空调器以及计算机可读存储介质 |

| JP2019134678A (ja) * | 2019-04-24 | 2019-08-08 | Ckd株式会社 | アクチュエータ |

| JP2021158222A (ja) * | 2020-03-27 | 2021-10-07 | 国立研究開発法人産業技術総合研究所 | カプセル化クリーンルームシステム |

| JP7410565B2 (ja) | 2020-03-27 | 2024-01-10 | 国立研究開発法人産業技術総合研究所 | カプセル化クリーンルームシステム |

| WO2024142563A1 (ja) * | 2022-12-27 | 2024-07-04 | 株式会社Sumco | 半導体ウェーハの処理装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20080046133A1 (en) | 2008-02-21 |

| US7925390B2 (en) | 2011-04-12 |

| US20110153114A1 (en) | 2011-06-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2008032335A (ja) | ミニエンバイロメント装置、検査装置、製造装置、及び空間の清浄化方法 | |

| JP2731950B2 (ja) | 露光方法 | |

| TW201921566A (zh) | 用於移動基板的方法和系統 | |

| JP5385425B2 (ja) | 検査装置及びミニエンバイロメント構造 | |

| WO2002080236A2 (en) | An apparatus and method for creating an ultra-clean mini-environment through lozalized air flow augmentation | |

| US8353986B2 (en) | Substrate processing apparatus | |

| US6592679B2 (en) | Clean method for vacuum holding of substrates | |

| US7428850B2 (en) | Integrated in situ scanning electronic microscope review station in semiconductor wafers and photomasks optical inspection system | |

| US20070130738A1 (en) | Vacuum processing apparatus and zonal airflow generating unit | |

| JPH0888155A (ja) | 局所クリーン化におけるインターフェイスボックス及びそのクリーンルーム | |

| TWM527792U (zh) | 潔淨系統及其晶圓盒 | |

| JP2003264219A (ja) | 局所クリーン装置 | |

| JP5456804B2 (ja) | 搬送容器 | |

| TW202430287A (zh) | 用於清潔基板的整合清潔和乾燥模組 | |

| WO2013129196A1 (ja) | 荷電粒子線装置及び荷電粒子線照射方法 | |

| JP6977557B2 (ja) | 検査装置 | |

| JP2020047807A (ja) | 給排気制御装置、ウェーハ処理装置、ウェーハ処理方法、圧力制御装置、及び圧力制御方法 | |

| JP2010262214A (ja) | マスク検査装置及びマスク検査装置の管理方法 | |

| KR20230076960A (ko) | 기판 이송 모듈 및 그 습도 제어 방법 | |

| JPH0364477A (ja) | 常圧処理装置 | |

| JP5465979B2 (ja) | 半導体製造装置 | |

| JP2009087992A (ja) | プラズマ処理装置 | |

| JPH1097962A (ja) | 処理装置及び処理システム | |

| JP2002164408A (ja) | 半導体製造装置および半導体装置の製造方法 | |

| JP2000015198A (ja) | 洗浄装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081022 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081022 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110322 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110412 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110722 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120228 |