EP4350184A1 - Fluidsteuerventil - Google Patents

Fluidsteuerventil Download PDFInfo

- Publication number

- EP4350184A1 EP4350184A1 EP22815938.0A EP22815938A EP4350184A1 EP 4350184 A1 EP4350184 A1 EP 4350184A1 EP 22815938 A EP22815938 A EP 22815938A EP 4350184 A1 EP4350184 A1 EP 4350184A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- piston

- fluid control

- control valve

- pilot

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000012530 fluid Substances 0.000 title claims abstract description 115

- 238000011109 contamination Methods 0.000 abstract description 24

- 230000007257 malfunction Effects 0.000 abstract description 3

- 230000002093 peripheral effect Effects 0.000 description 41

- 239000006096 absorbing agent Substances 0.000 description 23

- 230000035939 shock Effects 0.000 description 17

- 230000007423 decrease Effects 0.000 description 12

- 238000013016 damping Methods 0.000 description 8

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical group [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 7

- 230000000052 comparative effect Effects 0.000 description 7

- 238000010586 diagram Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 3

- 239000007769 metal material Substances 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- 238000007789 sealing Methods 0.000 description 3

- 239000000314 lubricant Substances 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 229910000976 Electrical steel Inorganic materials 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 238000007792 addition Methods 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000000696 magnetic material Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K31/00—Actuating devices; Operating means; Releasing devices

- F16K31/12—Actuating devices; Operating means; Releasing devices actuated by fluid

- F16K31/36—Actuating devices; Operating means; Releasing devices actuated by fluid in which fluid from the circuit is constantly supplied to the fluid motor

- F16K31/40—Actuating devices; Operating means; Releasing devices actuated by fluid in which fluid from the circuit is constantly supplied to the fluid motor with electrically-actuated member in the discharge of the motor

- F16K31/406—Actuating devices; Operating means; Releasing devices actuated by fluid in which fluid from the circuit is constantly supplied to the fluid motor with electrically-actuated member in the discharge of the motor acting on a piston

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/32—Details

- F16K1/34—Cutting-off parts, e.g. valve members, seats

- F16K1/42—Valve seats

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/32—Details

- F16K1/34—Cutting-off parts, e.g. valve members, seats

- F16K1/36—Valve members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K17/00—Safety valves; Equalising valves, e.g. pressure relief valves

- F16K17/02—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side

- F16K17/04—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side spring-loaded

- F16K17/0466—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side spring-loaded with a special seating surface

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K17/00—Safety valves; Equalising valves, e.g. pressure relief valves

- F16K17/02—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side

- F16K17/04—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side spring-loaded

- F16K17/10—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side spring-loaded with auxiliary valve for fluid operation of the main valve

- F16K17/105—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side spring-loaded with auxiliary valve for fluid operation of the main valve using choking or throttling means to control the fluid operation of the main valve

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K25/00—Details relating to contact between valve members and seats

- F16K25/005—Particular materials for seats or closure elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16F—SPRINGS; SHOCK-ABSORBERS; MEANS FOR DAMPING VIBRATION

- F16F9/00—Springs, vibration-dampers, shock-absorbers, or similarly-constructed movement-dampers using a fluid or the equivalent as damping medium

- F16F9/32—Details

- F16F9/44—Means on or in the damper for manual or non-automatic adjustment; such means combined with temperature correction

- F16F9/46—Means on or in the damper for manual or non-automatic adjustment; such means combined with temperature correction allowing control from a distance, i.e. location of means for control input being remote from site of valves, e.g. on damper external wall

- F16F9/465—Means on or in the damper for manual or non-automatic adjustment; such means combined with temperature correction allowing control from a distance, i.e. location of means for control input being remote from site of valves, e.g. on damper external wall using servo control, the servo pressure being created by the flow of damping fluid, e.g. controlling pressure in a chamber downstream of a pilot passage

Definitions

- the present invention relates to a fluid control valve which controls a working fluid and, for example, the fluid control valve has a relief function or the like capable of discharging a working fluid.

- a valve used to control a working fluid in various industrial fields includes a valve body brought into contact with and separated from a valve seat and control a flow rate or pressure of a working fluid by adjusting a valve opening degree.

- Such a fluid control valve is largely classified into a valve (for example, a pressure reducing valve or the like) which detects a fluid pressure on a secondary side, adjusts a valve opening degree, and restricts a fluid introduction amount from a primary side to control a flow rate or pressure, or the like of a working fluid on the primary side and a valve which detect a fluid pressure of a working fluid and discharges the working fluid to the outside at a predetermined fluid pressure or more to control a flow rate or pressure of the working fluid, that is, a valve having a so-called relief function.

- a valve for example, a pressure reducing valve or the like

- the fluid control valve is fluidly connected to a piston chamber and a reservoir chamber of the shock absorber.

- a piston is disposed in the piston chamber. Accordingly, in the fluid control valve, the valve body is brought into contact with and separated from the valve seat in accordance with a fluid pressure of the piston chamber changing according to the movement of the piston. By using this movement, the shock absorber can control the damping force.

- the fluid control valve herein includes a valve housing, a valve body, a valve seat, and biasing means.

- the valve housing includes an inflow passage which communicates with the piston chamber of the shock absorber and a discharge passage which communicates with the reservoir chamber. That is, in the fluid control valve, the valve body and the valve seat are provided between the inflow passage and the discharge passage. Further, the valve body is biased in a valve closing direction by the biasing force of the biasing means and can maintain a valve closed state. Then, when a high-pressure working fluid flows into the inflow passage, the valve body is separated from the valve seat against the biasing of the biasing means in the fluid control valve. Accordingly, the fluid control valve is configured to discharge the working fluid from the discharge passage.

- Patent Citation 1 JP 2011-501798 A (Pages 6 and 7, FIG. 2 )

- the valve body moves while being guided by the valve housing in such a manner that a guide portion of the valve body comes into contact with an inner peripheral surface of the valve housing.

- contamination may be caught between the inner peripheral surface of the valve housing and the guide portion of the valve body. Accordingly, since resistance to the movement of the valve body is generated, the relief performance of the fluid control valve may deteriorate.

- the present invention has been made in view of such problems and an object thereof is to provide a fluid control valve that is less likely to malfunction due to contamination.

- a fluid control valve is a fluid control valve including: a valve housing which includes an inflow passage and a discharge passage; a valve seat which is disposed between the inflow passage and the discharge passage; and a valve body which includes a guide portion guided by an inner surface of the valve housing and a seal portion brought into contact with and separated from the valve seat, wherein the guide portion of the valve body includes a flat surface and a tapered surface tapered toward a side of the seal portion.

- an outer dimension of the valve body is larger at the tapered surface than at the seal portion. According to this preferable configuration, the valve body can be easily tilted largely, and the seal portion is less likely to be damaged by coming into contact with the inner surface of the valve housing.

- the tapered surface is an inclined surface with respect to an axial direction of the valve body. According to this preferable configuration, since the tapered surface is an inclined surface extending continuously in a linear or curved shape in a cross-sectional view, the valve body can smoothly move with respect to the valve housing.

- a concave portion extending from the flat surface to the tapered surface is formed in the valve body. According to this preferable configuration, contamination having flowed between the flat surface and the inner surface of the valve housing can be discharged from the tapered surface side through the concave portion.

- the concave portion is closed on the flat surface. According to this preferable configuration, the valve body can ensure sealing between the inner surface of the valve housing and the outer surface of the valve body.

- the concave portion is a spiral groove. According to this preferable configuration, the spiral groove that can be configured simply and have high contamination discharge performance is suitable as the concave portion.

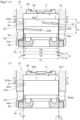

- a fluid control valve according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 4 . Additionally, this embodiment will be described by exemplifying a fluid control valve used in a shock absorber, but can also be applied to other uses.

- the top and bottom of the fluid control valve when viewed from the front in FIG. 1 will be described as the top and bottom of the fluid control valve. Specifically, a description will be made such that the lower side of the paper where a main valve 60 is disposed is the lower side of the fluid control valve and the upper side of the paper where a solenoid 80 is disposed as a drive source is the upper side of the fluid control valve.

- a fluid control valve V1 of the present invention is fluidly connected to an absorber piston chamber P and a reservoir chamber R of a shock absorber A.

- the fluid control valve V1 opens the main valve 60 so that the working fluid flows out from a discharge passage 12 to the reservoir chamber R. Accordingly, the fluid control valve V1 controls the flow rate of the working fluid flowing from the absorber piston chamber P toward the reservoir chamber R.

- the fluid control characteristic of the main valve 60 is adjusted by a pilot valve 50.

- the fluid control valve V1 controls the damping force of the shock absorber A.

- the fluid control valve V1 mainly includes a valve housing 10, the pilot valve 50, the main valve 60, and a solenoid 80.

- the pilot valve 50 is disposed at the upper end portion inside the valve housing 10. Further, the main valve 60 is disposed below the pilot valve 50 inside the valve housing 10.

- the pilot valve 50 includes a pilot valve body 51 and a pilot valve seat 40a.

- the pilot valve 50 is opened and closed in such a manner that the pilot valve body 51 is brought into contact with and separated from the pilot valve seat 40a.

- the main valve 60 includes a piston 61 which is a valve body and a main valve seat 45a which is a valve seat.

- the main valve 60 is opened and closed in such a manner that the piston 61 of the main valve 60 is brought into contact with and separated from the main valve seat 45a.

- the main valve 60 is illustrated with its left half closed and its right half open.

- valve housing 10 The components on the side of the valve housing 10 are the valve housing 10, the pilot valve 50, and the main valve 60.

- valve housing 10 is formed in a cylindrical shape with an inner step by a metal material or a resin material.

- the valve housing 10 is provided with a cylindrical portion 10a, a small-diameter bottomed cylindrical portion 10b, a medium-diameter bottomed cylindrical portion 10c, and a large-diameter bottomed cylindrical portion 10d in order from the top in the axial direction.

- the pilot valve body 51 is inserted into the cylindrical portion 10a from above in the axial direction.

- the pilot valve body 51 is formed to have a T-shaped cross-section having a cylindrical portion 52 and a flange portion 53.

- the cylindrical portion 52 has a cylindrical shape extending in the axial direction. The lower end portion of the cylindrical portion 52 is seated on the pilot valve seat 40a.

- a lower end surface of a rod 83 comes into contact with the upper end portion of the cylindrical portion 52. Accordingly, the pilot valve body 51 that receives a biasing force of a coil spring 85 comes into press-contact with the rod 83.

- the flange portion 53 has an annular plate shape extending radially outward from the upper end portion of the cylindrical portion 52.

- a communication passage 53a is formed in the flange portion 53 to penetrate in the axial direction.

- the communication passage 53a communicates the cylindrical portion 10a of the valve housing 10 with an opening portion 82b of a center post 82.

- the outer peripheral surface of the flange portion 53 is movably formed while being in sliding contact with the inner peripheral surface of the cylindrical portion 10a of the valve housing 10. Accordingly, the cylindrical portion 10a can guide the movement of the pilot valve body 51.

- the small-diameter bottomed cylindrical portion 10b is continuous to the cylindrical portion 10a and is recessed toward the axially upper side while the inner side of the cylindrical portion 10a is enlarged in diameter.

- a pilot valve seat member 40 which is press-inserted from below in the axial direction is integrally fixed to the small-diameter bottomed cylindrical portion 10b in a substantially sealed state.

- the pilot valve seat member 40 is formed in a circular plate shape having a plurality of communication passage 41 extending therethrough in the axial direction by a metal material or a resin material.

- annular convex portion 42 which protrudes in the axially upper side is formed at the center of the upper end portion of the pilot valve seat member 40.

- the upper end portion of the annular convex portion 42 is the pilot valve seat 40a.

- the medium-diameter bottomed cylindrical portion 10c is continuous to the small-diameter bottomed cylindrical portion 10b and is recessed toward the axially upper side while the inner side of the small-diameter bottomed cylindrical portion 10b is enlarged in diameter.

- the piston 61 and the main valve seat 45a are arranged on the medium-diameter bottomed cylindrical portion 10c.

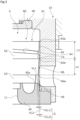

- the piston 61 includes a guide portion 62, a seal portion 63, and a spiral groove 64 (see FIG. 2A ) as a concave portion.

- the piston 61 is provided with a funnel-shaped hollow portion 61a which is recessed downward in the axial direction.

- the hollow portion 61a is opened upward in the axial direction. Further, the hollow portion 61a communicates with the inflow passage 11 through a communication passage 61b formed in the seal portion 63.

- the outer peripheral surface of the guide portion 62 is composed of a flat surface 65 and a tapered surface 66. Additionally, FIG. 2A illustrates only the configuration of the outer peripheral surface of the piston 61 in order to describe the configuration of the outer peripheral surface of the piston 61. This also applies to FIGS. 2B , 3 , 4A, and 4B .

- the flat surface 65 extends in the axial direction of the piston 61. Further, the flat surface 65 is continuous in the circumferential direction and has a circular cross-section in the axial direction.

- the tapered surface 66 is continuous to the lower end of the flat surface 65 and is tapered toward the seal portion 63. Further, the tapered surface 66 is continuous in the circumferential direction and has a circular cross-section in the axial direction.

- the tapered surface 66 of this embodiment is an inclined surface having a linear cross-section extending continuously in a direction inclined with respect to the axis. Additionally, the tapered surface may be an inclined surface having a curved cross-section.

- an inner diameter D1 of the medium-diameter bottomed cylindrical portion 10c of the valve housing 10 is slightly larger than a maximum outer diameter D2 of the guide portion 62 of the piston 61.

- a clearance C is formed between an inner peripheral surface 14 of the medium-diameter bottomed cylindrical portion 10c as the inner surface of the valve housing 10 (hereinafter, simply referred to as the "inner peripheral surface 14 of the valve housing 10") and the flat surface 65 and the tapered surface 66 of the guide portion 62.

- the flat surface 65 and the tapered surface 66 of the guide portion 62 are movable while being in sliding contact with the inner peripheral surface 14 of the valve housing 10. That is, the medium-diameter bottomed cylindrical portion 10c can guide the movement of the piston 61.

- the entire flat surface 65 of the guide portion 62 overlaps the inner peripheral surface 14 of the valve housing 10 in the radial direction.

- the entire flat surface 65 of the guide portion 62 overlaps the inner peripheral surface 14 of the valve housing 10 in the radial direction.

- the entire flat surface 65 radially overlaps the inner peripheral surface 14 of the valve housing 10 over the entire stroke area of the piston 61.

- the fluid control valve V1 can ensure sealing between the inner peripheral surface 14 of the valve housing 10 and the guide portion 62 of the piston 61.

- annular convex portion 63a which protrudes downward in the axial direction is formed at the outer diameter radial lower end portion of the seal portion 63.

- the annular convex portion 63a is seated on the main valve seat 45a in the valve closed state of the main valve 60.

- the spiral groove 64 extends continuously from the axial center portion of the flat surface 65 to the axial center portion of the tapered surface 66.

- spiral groove 64 extends obliquely downward in the circumferential and axial directions from an end portion 64a closed at the axial center of the flat surface 65. Then, the spiral groove 64 is closed at an end portion 64b located at the axial center portion of the tapered surface 66.

- the spiral groove 64 is axially closed in the piston 61. Accordingly, the piston 61 can ensure sealing between the inner peripheral surface 14 of the valve housing 10 and the guide portion 62 of the piston 61.

- the end portion 64a of the flat surface 65 and the end portion 64b of the tapered surface 66 axially overlap each other. That is, the spiral groove 64 extends substantially one turn in the circumferential direction.

- a coil spring 67 which serves as biasing means for biasing the piston 61 in the closing direction is disposed between the pilot valve seat member 40 and the piston 61. More specifically, the lower end portion of the coil spring 67 is inserted into the hollow portion 61a of the piston 61.

- a pilot control chamber S is formed in a space inside the small-diameter bottomed cylindrical portion 10b and the medium-diameter bottomed cylindrical portion 10c of the valve housing 10.

- the pilot control chamber S is defined by the small-diameter bottomed cylindrical portion 10b, the medium-diameter bottomed cylindrical portion 10c, the pilot valve seat member 40, the pilot valve body 51, and the piston 61.

- the large-diameter bottomed cylindrical portion 10d is continuous to the medium-diameter bottomed cylindrical portion 10c and is recessed toward the axially upper side while the inside of the medium-diameter bottomed cylindrical portion 10c is enlarged in diameter.

- a main valve seat member 45 is press-inserted into the large-diameter bottomed cylindrical portion 10d from below in the axial direction to be integrally fixed in a substantially sealed state.

- the main valve seat member 45 is formed in an annular plate shape having the inflow passage 11 extending therethrough in the axial direction by a metal material or a resin material.

- the main valve seat member 45 is press-inserted and fixed to the large-diameter bottomed cylindrical portion 10d from below in the axial direction through a gasket in a sealed state.

- the main valve seat member 45 includes a cylindrical portion 46 extending in the axial direction. The upper end portion of the cylindrical portion 46 is the main valve seat 45a.

- the outer surface of the valve housing 10 is provided with a communication groove 10e having a downward L-shaped cross-section from the upper end of the cylindrical portion 10a to the side surface thereof.

- the lower side end portion of the communication groove 10e is located below an opening portion 81b of a casing 81 and is opened in the outer radial direction.

- the communication groove 10e constitutes a pilot side discharge passage 13 of the pilot valve 50.

- the pilot side discharge passage 13 includes the cylindrical portion 10a, the small-diameter bottomed cylindrical portion 10b, and the communication groove 10e of the valve housing 10, the annular convex portion 42 of the pilot valve seat member 40, the opening portion 81b of the casing 81, and the opening portion 82b of the center post 82.

- valve housing 10 is provided with the discharge passage 12 which extends radially outward from the medium-diameter bottomed cylindrical portion 10c and communicates the inside of the medium-diameter bottomed cylindrical portion 10c with the reservoir chamber R.

- the solenoid 80 is connected to the valve housing 10 and applies a driving force to the pilot valve body 51.

- the solenoid 80 mainly includes the casing 81, the center post 82, the rod 83, a movable iron core 84, the coil spring 85, a coil 86, a sleeve 87, and bearings 88 and 89.

- the casing 81 includes a stepped cylindrical main body portion 81a into which the center post 82 is inserted and fixed from below in the axial direction.

- the opening portion 81b which is continuous to the lower end of the main body portion 81a and is opened downward is formed in the casing 81.

- the center post 82 is formed in a stepped cylindrical shape from a rigid body made of a magnetic material such as iron or silicon steel.

- the center post 82 includes a cylindrical main body portion 82a extending in the axial direction.

- the bearing 89 is inserted and fixed to the main body portion 82a from above in the axial direction.

- the opening portion 82b which is continuous to the lower end of the main body portion 82a and is opened toward the lower side of the center post 82 is formed in the center post 82.

- the rod 83 is inserted and fixed to the movable iron core 84. Accordingly, when the solenoid 80 is energized, the rod 83 moves to follow the movable iron core 84 moving in the valve closing direction. Accordingly, the rod 83 moves the pilot valve body 51 in the valve closing direction, that is, downward in the axial direction.

- the upper end portion is inserted through the bearing 88 and the lower end portion is inserted through the bearing 89.

- the axial movement of the rod 83 is guided. Therefore, the rod 83 is less likely to be tilted in the radial direction during the axial movement.

- the coil spring 85 is disposed between the pilot valve seat member 40 and the pilot valve body 51.

- the coil spring 85 biases the pilot valve body 51 in the valve opening direction of the pilot valve 50, that is, in the axially upper side.

- the coil 86 is an excitation coil wound around the center post 82 through a bobbin.

- the sleeve 87 is formed in a bottomed cylindrical shape. Further, the bearing 88 guiding the movement of the rod 83 is fitted and fixed to the sleeve 87.

- the fluid control valve V1 in the de-energized state will be described.

- the pilot valve body 51 of the pilot valve 50 is pressed toward the axially upper side by the biasing force of the coil spring 85 in the de-energized state. Accordingly, the pilot valve body 51 is separated from the pilot valve seat 40a and the pilot valve 50 is opened.

- the pilot valve opening degree at this time is the maximum in this embodiment.

- the shock absorber A When the shock absorber A is operated so that the pressure of the working fluid in the inflow passage 11 increases in the de-energized state, the working fluid passes through the communication passage 61b of the piston 61 and the pilot control chamber S and flows from the pilot side discharge passage 13 into the reservoir chamber R. Along with this, the working fluid may also flow into the reservoir chamber R from the discharge passage 12 depending on the pressure of the working fluid as will be described below.

- the cross-sectional area of the communication passage 61b in the piston 61 is formed to be narrow. Therefore, even when the pressure of the working fluid in the inflow passage 11 increases, the pressure of the working fluid in the pilot control chamber S is less likely to increase in response to the pressure of the working fluid in the inflow passage 11. Therefore, a differential pressure is generated between the pressure of the working fluid in the inflow passage 11 and the pressure of the working fluid in the pilot control chamber S. As this differential pressure increases, the main valve 60 becomes easier to open.

- the pressure of the working fluid in the inflow passage 11 is described as the "pressure Pin of the inflow passage 11" and the pressure of the working fluid in the pilot control chamber S is described as the “pressure Ps of the pilot control chamber S”.

- the factor that the differential pressure ⁇ P decreases is that the working fluid passes through the main valve 60 and flows from the discharge passage 12 into the reservoir chamber R so that the pressure Pin of the inflow passage 11 decreases, the working fluid flows from the communication passage 61b into the pilot control chamber S so that the pressure Pin of the inflow passage 11 decreases, the volume is narrowed due to the movement of the piston 61 so that the pressure Ps of the pilot control chamber S increases, and the like.

- the opening and closing operation of the main valve 60 will be described in more detail with specific examples.

- the piston 61 moves in the axially upper side against the biasing force of the coil spring 67.

- the seal portion 63 of the piston 61 is separated from the main valve seat 45a and the main valve 60 is opened. Accordingly, the working fluid flows from the discharge passage 12 into the reservoir chamber R.

- the valve opening degree of the main valve 60 increases as the pressure Pin (i.e., P2) of the inflow passage 11 approaches a large pressure value P3 (P3>P2).

- the main valve 60 since the main valve 60 is opened, the working fluid flows from the discharge passage 12 into the reservoir chamber R. Further, the extra working fluid in the pilot control chamber S flows from the pilot side discharge passage 13 into the reservoir chamber R.

- the rod 83 fixed to the movable iron core 84 moves downward in the axial direction together with the pilot valve body 51. Accordingly, the pilot valve 50 is closed when the pilot valve opening degree decreases and a current exceeding a predetermined level is energized.

- the working fluid in the inflow passage 11 flows from the pilot side discharge passage 13 into the reservoir chamber R in accordance with the operation of the shock absorber A as in the de-energized state. Further, as described above, the working fluid also flows from the discharge passage 12 into the reservoir chamber R depending on the pressure Pin of the inflow passage 11.

- the working fluid is less likely to flow from the pilot control chamber S into the pilot side discharge passage 13 as the pilot valve opening degree decreases. Therefore, the differential pressure ⁇ P between the pressure Pin of the inflow passage 11 and the pressure Ps of the pilot control chamber S is less likely to occur and the main valve 60 is less likely to open. That is, the damping force of the shock absorber A can be increased.

- the damping force of the shock absorber A is minimized. That is, the damping force is controlled to be minimized when the fluid control valve V1 is in the non-energized state.

- the differential pressure ⁇ P decreases in a short time as the pilot valve opening degree of the pilot valve 50 decreases. That is, the opening time of the main valve 60 is shortened as the pilot valve opening degree of the pilot valve 50 decreases.

- the fluid control characteristics of the main valve 60 are controlled according to the pilot valve opening degree of the pilot valve 50. Accordingly, the fluid control valve V1 can variably control the damping force of the shock absorber A.

- the fluid control valve V1 when the pilot valve 50 is closed in the energized state, the fluid control valve V1 is in a state in which the working fluid is most difficult to pass through the pilot valve 50 and the main valve 60 is difficult to open. Therefore, the fluid control valve V1 can maximize the damping force of the shock absorber A.

- a current value to be energized to the coil 86 constituting the solenoid 80 is set based on input parameters such as vehicle speed, vehicle acceleration/deceleration, steering angle, road surface condition, and sprung load.

- pilot valve 50 in the open state may be closed by setting a current value equal to or larger than a predetermined value.

- a normal state in which the piston 61 moves substantially parallel along the axis of the valve housing 10 (hereinafter, simply referred to as a "normal state") will be described.

- a state in which the piston 61 moves while being tilted (see FIG. 4 ) will be described.

- the clearance C having approximately the same dimension is formed over the circumferential direction between the inner peripheral surface 14 of the valve housing 10 and the flat surface 65 of the guide portion 62 of the piston 61 in the normal state.

- the piston 61 can smoothly move in the axial direction along the axis of the valve housing 10.

- the tapered surface 66 of the piston 61 is a smooth surface without unevenness. Therefore, the piston 61 can smoothly move with respect to the valve housing 10.

- the radial dimension L1 of the tapered surface 66 that is, sine length is smaller than the radial dimension L2 of the clearance C in the normal state (L1 ⁇ L2).

- the tapered surface 66 can guide the movement of the piston 61. Then, the tapered surface 66 of the piston 61 is a smooth surface without unevenness. Therefore, the piston 61 can smoothly slide on the valve housing 10.

- a piston 61A constituting a main valve 60A of a fluid control valve of a reference example (hereinafter, simply referred to as a "piston 61A" or a “piston 61A as a comparative object") will be described with reference to FIG. 2B .

- a guide portion 62A of the piston 61A includes only a flat surface 65A. Further, other configurations of the piston 61A are substantially the same as those of the piston 61.

- the clearance C into which oil as a lubricant, a working fluid, or the like flows exists between the inner peripheral surface 14 of the valve housing 10 and the flat surface 65A of the guide portion 62A of the piston 61A. Accordingly, the piston 61A is movable along the axis of the valve housing 10 similarly to the piston 61.

- the piston 61 is configured to move while being guided by the inner peripheral surface 14 of the valve housing 10 according to the urging force and differential pressure from the coil spring 67, the tilting becomes easier than the pilot valve body 51 that moves together with the rod 83 while being guided by the bearings 88 and 89.

- the radial dimension L1 of the tapered surface 66 is smaller than the dimension L2 of the clearance C in the normal state (L1 ⁇ L2).

- the piston 61 can be tilted until the upper end portion of the flat surface 65 and the lower end portion of the tapered surface 66 located on the diagonal line of the upper end portion come into contact with the inner peripheral surface 14 of the valve housing 10.

- the upper end portion of the flat surface 65 is the corner 65a and a portion in the vicinity thereof.

- the lower end portion of the tapered surface 66 is the corner 66a and a portion in the vicinity thereof.

- the corners 65a and 66a may be rounded as the R surface and in that case, the R surface or the vicinity thereof comes into contact with the inner peripheral surface 14 of the housing 10 when the piston 61 is tilted.

- an axis Ax2 of the piston 61 indicated by the one-dotted chain line in FIG. 4A can be tilted up to an angle ⁇ 1 with respect to an axis Ax1 of the valve housing 10 indicated by the one-dotted chain line in FIG. 4A .

- the corners 65a and 66a are less likely to come into angular-contact with the inner peripheral surface 14 of the valve housing 10. Accordingly, in the fluid control valve V1, the abrasion of the corners 65a and 66a, the damage due to the contact of the corners 65a and 66a with respect to the inner peripheral surface 14, and the like are prevented. Further, in this embodiment, since the tapered surface 66 follows the inner peripheral surface 14 of the valve housing 10 when the piston 61 is tilted, the angular contact is less likely to occur in the corner 66a than in the corner 65a.

- corner 65b between the flat surface 65 and the tapered surface 66 is difficult to come into angular-contact with the inner peripheral surface 14 of the valve housing 10. Accordingly, since the spiral groove 64 crossing a part of the corner 65b is less likely to come into contact with the inner peripheral surface 14, damage is suppressed.

- the corner 65b be separated from the flat surface 65 in order to prevent the angular contact of the corner 65b.

- the minimum outer diameter D3 of the tapered surface 66 is larger than the outer diameter D4 of the seal portion 63 (D3>D4).

- the outer radial end of the seal portion 63 is disposed on the inner radial side of a virtual extension line VL1 of the tapered surface 66 in the radial direction.

- the piston 61 prevents the seal portion 63 from contacting the inner peripheral surface 14 before the tapered surface 66 contacts the inner peripheral surface 14 of the valve housing 10. Therefore, the piston 61 is easily tilted within a range in which the seal portion 63 does not easily contact and damage the inner peripheral surface 14 of the valve housing 10.

- the tilting of the piston 61A as a comparative object will be described.

- the piston 61A as a comparative object can be tilted until the upper end portion of the flat surface 65A and the lower end portion of the flat surface 65A located on the diagonal line of the upper end portion contact the inner peripheral surface 14 of the valve housing 10.

- the upper end portion of the flat surface 65A is a portion which is continuous to a corner 62Aa between the flat surface 65A and the upper end surface of the piston 61A in the flat surface 65A.

- the lower end portion of the flat surface 65A is a portion which is continuous to a corner 62Ab between the flat surface 65A and the lower end surface of the guide portion 62A in the flat surface 65A.

- an axis Ax3 of the piston 61A indicated by the one-dotted chain line in FIG. 4B can be tilted up to an angle ⁇ 2 with respect to the axis Ax1 of the valve housing 10 indicated by the one-dotted chain line in FIG. 4B .

- the piston 61 of this embodiment can be tilted more than the piston 61A as a comparative object. That is, the tiltable angle ⁇ 1 of the piston 61 of this embodiment is larger than the tiltable angle ⁇ 2 of the piston 61A as a comparative example ( ⁇ 1> ⁇ 2).

- the piston 61 and the piston 61A may be tilted with the caught contamination as a base point in the caught state.

- the piston 61 of the present invention in which the tiltable angle ⁇ 1 is large, it is easy to obtain an opening that is sufficient to discharge contamination. Therefore, contamination caught in the piston 61 can be easily discharged.

- the piston 61 can slide smoothly with respect to the valve housing 10 as described above.

- the contamination may move relatively with respect to the pistons 61 and 61A as the pistons 61 and 61A move.

- the caught state continues until the contamination moves out of the flat surface 65A as the contamination moves relatively with respect to the piston 61A.

- the piston 61 of the present invention is provided with the spiral groove 64 which is recessed radially inward. Accordingly, contamination flows into the spiral groove 64 and the piston 61 is released from the caught state.

- the spiral groove 64 extends obliquely downward in the axial direction and extends substantially one turn in the circumferential direction.

- the spiral groove 64 has a wide area in which contamination can be collected in the circumferential direction and the axial direction.

- the spiral groove 64 can efficiently collect contamination that is displaced in the axial direction.

- the piston 61 is rotatable in the circumferential direction. Therefore, since the piston 61 rotates in accordance with the axial movement, the spiral groove 64 can efficiently collect contamination that is displaced in the circumferential direction.

- the spiral groove 64 that extends to the tapered surface 66 tends to introduce contamination into the gap G (see FIG. 2A ) between the inner peripheral surface 14 of the valve housing 10 and the tapered surface 66.

- the gap G is composed of the clearance C and the space H (G>C).

- the gap G (see FIG. 2A ) is opened toward the discharge passage 12.

- a main valve 160 includes a piston 161 which is a valve body, the main valve seat 45a, and a bellows 70.

- a hollow portion 161a which is recessed in a cylindrical shape downward in the axial direction is formed in the piston 161.

- the hollow portion 161a is opened upward in the axial direction. Further, the hollow portion 161a communicates with the inflow passage 11 through the communication passage 61b formed in the seal portion 63.

- the piston 161 includes a base portion 162 and the seal portion 63.

- the base portion 162 is formed in a cylindrical shape. Further, the outer diameter of the base portion 162 is smaller than the outer diameter of the seal portion 63. That is, the seal portion 63 protrudes radially outward in a flange shape from the outer peripheral surface of the base portion 162.

- the upper end portion of the bellows 70 is fixed to the corner portion of the medium-diameter bottomed cylindrical portion 10c of the valve housing 10. Further, the lower end portion of the bellows 70 is fixed to the outer radial end portion of the seal portion 63.

- a sufficient gap is formed between the bellows 70 and the inner peripheral surface 14 of the valve housing 10 so that the bellows 70 is less likely to come into contact with the inner peripheral surface 14 when the piston 161 moves.

- the piston 161 is movable in the axial direction while being prevented from tilting by the bellows 70.

- the fluid control valve includes the pilot valve and the main valve, but the present invention is not limited thereto. That is, the fluid control valve may include only the main valve.

- a configuration has been described in which the inflow passage and the discharge passage of the housing are formed so that the working fluid flows therethrough, but the present invention is not limited thereto. That is, a connector may be connected to the inflow passage and the discharge passage of the housing, and the working fluid may flow into the housing through the connector. That is, the present invention is not limited to a configuration in which the working fluid directly flows and the inflow passage, and the discharge passage may be formed for the inflow or discharge of the working fluid.

- valve seat is formed in the valve seat member separated from the valve housing, but the present invention is not limited thereto. That is, the valve seat may be integrally formed with the valve housing.

- valve housing is formed in a cylindrical shape

- present invention is not limited thereto.

- its shape may be appropriately changed such that the valve housing is formed in a polygonal cylindrical shape. That is, the inner surface of the valve housing is not limited to the circular inner peripheral surface when viewed in the axial direction and may be a polygonal inner surface when viewed in the axial direction.

- the inner surface of the valve housing may be divided in the circumferential direction by grooves or the like extending axially. That is, the inner surface of the valve housing may be discontinuous in the circumferential direction.

- valve body is the bottomed cylindrical piston

- present invention is not limited thereto.

- its shape may be appropriately changed such that the valve body has a polygonal bottomed cylindrical shape. That is, the flat surface and the tapered surface of the valve body are not limited to the circular shape when viewed in the axial direction and may be the polygonal shape when viewed in the axial direction.

- the flat surface and the tapered surface of the valve body are continuous in the circumferential direction, but the present invention is not limited thereto.

- the flat surface and the tapered surface may be divided in the circumferential direction by grooves or the like extending axially. That is, the flat surface and the tapered surface of the valve body may be discontinuous in the circumferential direction.

- the present invention is not limited thereto. That is, its shape may be appropriately changed such that another tapered surface is formed above the flat surface in the axial direction and a groove extending in the circumferential direction is formed between the flat surface and the tapered surface of the valve body.

- the tapered surface of the valve body is the inclined surface

- the present invention is not limited thereto. That is, the tapered surface may be appropriately changed such that the tapered surface is formed in a stepped shape consisting of a plurality of steps or may be a part of a spherical shape.

- the concave portion is the spiral groove, but the present invention is not limited thereto. That is, the concave portion may be appropriately changed to a groove which extends in the axial direction, a groove which extends in the radial direction, a concave portion which is recessed radially inward and is opened radially outward, or the like.

- the concave portion is one spiral groove, but the present invention is not limited thereto. That is, a plurality of concave portions may be formed.

- the spiral groove extends substantially one turn in the circumferential direction, but the present invention is not limited thereto.

- the spiral groove may extend over one or more turns.

- contamination can be collected in the entire area of the flat surface in the circumferential direction.

- the spiral groove extends substantially one turn in the circumferential direction, but the present invention is not limited thereto. That is, the spiral groove may extend less than one turn in the circumferential direction. In this case, it is preferable that a plurality of spiral grooves having less than one turn in the circumferential direction are formed in the circumferential direction.

- the biasing means for biasing the piston in the valve closing direction is the coil spring, but the present invention is not limited thereto. That is, a pull spring may be used, a pressure may be different from the pressure of the inflow passage, and various cylinders and the like may be used.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Magnetically Actuated Valves (AREA)

- Fluid-Driven Valves (AREA)

- Details Of Valves (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP25209820.7A EP4656916A2 (de) | 2021-05-31 | 2022-05-25 | Fluidsteuerventil |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2021091743 | 2021-05-31 | ||

| PCT/JP2022/021401 WO2022255188A1 (ja) | 2021-05-31 | 2022-05-25 | 流体制御弁 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP25209820.7A Division EP4656916A2 (de) | 2021-05-31 | 2022-05-25 | Fluidsteuerventil |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP4350184A1 true EP4350184A1 (de) | 2024-04-10 |

| EP4350184A4 EP4350184A4 (de) | 2025-05-07 |

Family

ID=84323145

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP25209820.7A Pending EP4656916A2 (de) | 2021-05-31 | 2022-05-25 | Fluidsteuerventil |

| EP22815938.0A Pending EP4350184A4 (de) | 2021-05-31 | 2022-05-25 | Fluidsteuerventil |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP25209820.7A Pending EP4656916A2 (de) | 2021-05-31 | 2022-05-25 | Fluidsteuerventil |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US12435794B2 (de) |

| EP (2) | EP4656916A2 (de) |

| JP (1) | JPWO2022255188A1 (de) |

| CN (1) | CN117355694A (de) |

| WO (1) | WO2022255188A1 (de) |

Family Cites Families (153)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1614002A (en) | 1923-12-05 | 1927-01-11 | Horton Spencer | Valve for automatic sprinkler apparatus for fire extinguishing |

| US2267515A (en) | 1940-01-19 | 1941-12-23 | California Cedar Prod | Fluid control valve |

| DE1147450B (de) * | 1962-03-23 | 1963-04-18 | Arap Armaturen Und App Ges Mit | Mehrstufiges Drosselventil mit einer Drosselkanaele aufweisenden Ventilspindel |

| US3360304A (en) | 1964-11-09 | 1967-12-26 | Abex Corp | Retarder systems |

| US3483888A (en) | 1967-12-15 | 1969-12-16 | Waldes Kohinoor Inc | Self-locking retaining rings and assemblies employing same |

| US3841354A (en) * | 1973-05-22 | 1974-10-15 | R Mcdonnell | Flow regulating device |

| US4085921A (en) | 1975-04-09 | 1978-04-25 | Matsushita Electric Industrial Co., Ltd. | Multiple-mode fluid-flow control valve arrangement |

| CH608580A5 (en) * | 1976-10-08 | 1979-01-15 | Sulzer Ag | Safety system hydraulic control valve for boiler - has valve piston with tapered sealing face retracted from seating by valve medium pressure (SW 2.5.78) |

| US4364615A (en) | 1980-09-08 | 1982-12-21 | The Bendix Corporation | Retaining ring |

| GB8315079D0 (en) | 1983-06-01 | 1983-07-06 | Sperry Ltd | Pilot valves for two-stage hydraulic devices |

| US4632359A (en) * | 1983-06-06 | 1986-12-30 | International Combustion Australia Limited | Low noise flow control valve |

| DE8322570U1 (de) | 1983-08-05 | 1985-01-17 | Robert Bosch Gmbh, 7000 Stuttgart | Druckregler |

| US4634434A (en) * | 1985-02-19 | 1987-01-06 | Biomedical Dynamics Corporation | Apparatus for regulating the flow of fluid in medical apparatus |

| US4895192A (en) | 1987-12-24 | 1990-01-23 | Sundstrand Corporation | Process and apparatus for filling a constant speed drive |

| DE3814156A1 (de) | 1988-04-27 | 1989-11-09 | Mesenich Gerhard | Pulsmoduliertes hydraulikventil |

| US4917150A (en) | 1988-07-29 | 1990-04-17 | Colt Industries Inc. | Solenoid operated pressure control valve |

| US4998559A (en) | 1988-09-13 | 1991-03-12 | Coltec Industries Inc. | Solenoid operated pressure control valve |

| US5060695A (en) | 1990-04-02 | 1991-10-29 | Coltec Industries Inc | Bypass flow pressure regulator |

| US5217047A (en) | 1991-05-30 | 1993-06-08 | Coltec Industries Inc. | Solenoid operated pressure regulating valve |

| US5263694A (en) | 1992-02-24 | 1993-11-23 | General Motors Corporation | Upper mount assembly for a suspension damper |

| JP2742001B2 (ja) | 1993-06-29 | 1998-04-22 | 川崎製鉄株式会社 | 微粉炭吹込み制御方法 |

| JPH08159320A (ja) | 1994-12-05 | 1996-06-21 | Fuji Koki Seisakusho:Kk | 電動流量制御弁 |

| US5702235A (en) | 1995-10-31 | 1997-12-30 | Tgk Company, Ltd. | Capacity control device for valiable-capacity compressor |

| US6010312A (en) | 1996-07-31 | 2000-01-04 | Kabushiki Kaisha Toyoda Jidoshokki Seiksakusho | Control valve unit with independently operable valve mechanisms for variable displacement compressor |

| JPH10220926A (ja) | 1997-02-03 | 1998-08-21 | Denso Corp | 電動式膨張弁 |

| US5778932A (en) | 1997-06-04 | 1998-07-14 | Vickers, Incorporated | Electrohydraulic proportional pressure reducing-relieving valve |

| JP4048512B2 (ja) | 1998-03-31 | 2008-02-20 | 株式会社日立製作所 | 減衰力調整式油圧緩衝器 |

| JP4106576B2 (ja) | 1998-08-31 | 2008-06-25 | 株式会社デンソー | 可変焦点レンズ |

| US6161585A (en) | 1999-03-26 | 2000-12-19 | Sterling Hydraulics, Inc. | High flow proportional pressure reducing valve |

| JP4075207B2 (ja) | 1999-04-22 | 2008-04-16 | 株式会社デンソー | 流量制御弁 |

| JP3583951B2 (ja) | 1999-06-07 | 2004-11-04 | 株式会社豊田自動織機 | 容量制御弁 |

| JP4161151B2 (ja) | 1999-06-30 | 2008-10-08 | 株式会社日立製作所 | 減衰力調整式油圧緩衝器 |

| JP2001153498A (ja) | 1999-12-01 | 2001-06-08 | Tgk Co Ltd | 過冷却度制御式膨張弁 |

| JP3840354B2 (ja) | 1999-12-01 | 2006-11-01 | 株式会社テージーケー | 電気制御膨張弁 |

| JP2001165055A (ja) | 1999-12-09 | 2001-06-19 | Toyota Autom Loom Works Ltd | 制御弁及び容量可変型圧縮機 |

| JP2002216803A (ja) | 2001-01-19 | 2002-08-02 | Sony Corp | 燃料電池及びその製法並びに使用方法 |

| JP2002286151A (ja) | 2001-03-26 | 2002-10-03 | Denso Corp | 電磁弁 |

| JP2003004160A (ja) | 2001-06-25 | 2003-01-08 | Fuji Koki Corp | 電動弁 |

| DE10139534A1 (de) * | 2001-08-10 | 2003-02-20 | Bosch Rexroth Ag | Schließkörper, insbesondere Ventilkegel für ein Stetigdruckventil |

| JP4246975B2 (ja) | 2002-02-04 | 2009-04-02 | イーグル工業株式会社 | 容量制御弁 |

| JP4162419B2 (ja) | 2002-04-09 | 2008-10-08 | サンデン株式会社 | 可変容量圧縮機 |

| JP4110512B2 (ja) | 2002-04-18 | 2008-07-02 | Smc株式会社 | 真空調圧弁 |

| US6939112B2 (en) | 2002-04-25 | 2005-09-06 | Sanden Corporation | Variable displacement compressors |

| JP4195633B2 (ja) | 2002-04-25 | 2008-12-10 | サンデン株式会社 | 容量制御弁を有する可変容量圧縮機 |

| JP2004190495A (ja) | 2002-12-06 | 2004-07-08 | Toyota Industries Corp | 容量可変型圧縮機の容量可変構造 |

| JP2004101163A (ja) | 2002-07-16 | 2004-04-02 | Tgk Co Ltd | 定流量膨張弁 |

| JP2004098757A (ja) | 2002-09-05 | 2004-04-02 | Toyota Industries Corp | 空調装置 |

| WO2004072524A1 (ja) | 2003-02-12 | 2004-08-26 | Isuzu Motors Limited | 流量制御弁 |

| JP4316955B2 (ja) | 2003-08-11 | 2009-08-19 | イーグル工業株式会社 | 容量制御弁 |

| US20050151310A1 (en) | 2004-01-14 | 2005-07-14 | Barnes Group, Inc., A Corp. Of Delaware | Spring washer |

| US6981689B2 (en) * | 2004-04-08 | 2006-01-03 | Gueorgui Milev Mihaylov | Hybrid flow metering valve |

| JP2005307817A (ja) | 2004-04-20 | 2005-11-04 | Toyota Industries Corp | 容量可変型圧縮機の容量制御装置 |

| JP2005351605A (ja) | 2004-06-14 | 2005-12-22 | Daikin Ind Ltd | 膨張弁及び冷凍装置 |

| JP4522833B2 (ja) | 2004-11-30 | 2010-08-11 | 株式会社キッツ | ニードルバルブ |

| JP2006194175A (ja) | 2005-01-14 | 2006-07-27 | Tgk Co Ltd | 可変容量圧縮機用制御弁 |

| JP4700048B2 (ja) | 2005-02-24 | 2011-06-15 | イーグル工業株式会社 | 容量制御弁 |

| AU2006219331C1 (en) * | 2005-02-28 | 2009-05-28 | Daikin Industries, Ltd. | Expansion valve and refrigeration device |

| JP4822735B2 (ja) | 2005-04-14 | 2011-11-24 | 株式会社タイカ | 機能顕示を兼ねた装飾部材並びにその製造方法並びに機能顕示を兼ねた装飾部材が組み込まれた要緩衝機材 |

| JP4928448B2 (ja) | 2005-06-03 | 2012-05-09 | イーグル工業株式会社 | 容量制御弁 |

| US10900539B2 (en) | 2005-12-30 | 2021-01-26 | Fox Factory, Inc. | Fluid damper having a damping profile favorable for absorbing the full range of compression forces, including low- and high-speed compression forces |

| JP5167121B2 (ja) | 2006-03-15 | 2013-03-21 | イーグル工業株式会社 | 容量制御弁 |

| JP2007247512A (ja) | 2006-03-15 | 2007-09-27 | Toyota Industries Corp | 可変容量型圧縮機における容量制御弁 |

| JP2008157031A (ja) | 2006-12-20 | 2008-07-10 | Toyota Industries Corp | クラッチレス可変容量型圧縮機における電磁式容量制御弁 |

| JP2008190574A (ja) | 2007-02-02 | 2008-08-21 | Nissin Kogyo Co Ltd | 電磁弁 |

| WO2008111840A1 (en) | 2007-03-09 | 2008-09-18 | Provinor As | Method for rotational moulding of a cylindrical product |

| JP2009030752A (ja) | 2007-07-30 | 2009-02-12 | Denso Corp | 電磁弁および電磁弁装置 |

| EP2180217B1 (de) | 2007-08-23 | 2017-10-11 | Eagle Industry Co., Ltd. | Steuerungsventil |

| US8434517B2 (en) | 2007-08-23 | 2013-05-07 | Eagle Industry Co. Ltd. | Control valve |

| SE531814C2 (sv) | 2007-10-17 | 2009-08-11 | Oehlins Racing Ab | Ventil med fjäderarrangemang för justering av en stötdämpares dämpmedieflöde |

| JP4861956B2 (ja) | 2007-10-24 | 2012-01-25 | 株式会社豊田自動織機 | 可変容量型圧縮機における容量制御弁 |

| JP5156339B2 (ja) | 2007-11-06 | 2013-03-06 | 株式会社不二工機 | 弁装置の製造方法及び弁組立体 |

| JP2009221965A (ja) | 2008-03-17 | 2009-10-01 | Sanden Corp | 可変容量圧縮機の容量制御弁及び往復動型可変容量圧縮機 |

| US8006719B2 (en) | 2008-04-15 | 2011-08-30 | Husco Automotive Holdings Llc | Electrohydraulic valve having a solenoid actuator plunger with an armature and a bearing |

| EP2276953B1 (de) | 2008-04-28 | 2018-05-23 | BorgWarner Inc. | Umspritzte oder einpressmuffe für hydraulische führung eines magnetventils |

| JP2009275550A (ja) | 2008-05-13 | 2009-11-26 | Toyota Industries Corp | 可変容量型圧縮機における容量制御弁 |

| SE532533C2 (sv) | 2008-06-25 | 2010-02-16 | Oehlins Racing Ab | Tryckregulator för stötdämpare |

| JP2010019406A (ja) | 2008-07-14 | 2010-01-28 | Fuji Koki Corp | 電動弁 |

| JP5535524B2 (ja) | 2009-05-25 | 2014-07-02 | 三菱重工業株式会社 | 弁装置 |

| JP5346276B2 (ja) | 2009-12-28 | 2013-11-20 | ユニ・チャーム株式会社 | 着用物品 |

| DE102010008773A1 (de) * | 2010-02-22 | 2011-08-25 | Schaeffler Technologies GmbH & Co. KG, 91074 | Betätigungselement einer elektromagnetischen Stelleinheit eines Hydraulikventils |

| WO2011108423A1 (ja) | 2010-03-03 | 2011-09-09 | イーグル工業株式会社 | ソレノイドバルブ |

| US8651826B2 (en) | 2010-03-16 | 2014-02-18 | Eagle Industry Co., Ltd. | Volume control valve |

| WO2011132438A1 (ja) | 2010-04-21 | 2011-10-27 | イーグル工業株式会社 | 圧力制御弁 |

| JP5680628B2 (ja) | 2010-04-29 | 2015-03-04 | イーグル工業株式会社 | 容量制御弁 |

| JP5878703B2 (ja) | 2010-09-06 | 2016-03-08 | 株式会社不二工機 | 可変容量型圧縮機用制御弁 |

| JP5740945B2 (ja) | 2010-12-06 | 2015-07-01 | Jfeスチール株式会社 | ルーパの可動ロール位置制御方法 |

| US9132714B2 (en) | 2010-12-09 | 2015-09-15 | Eagle Industry Co., Ltd. | Capacity control valve |

| JP5699259B2 (ja) | 2011-01-07 | 2015-04-08 | 株式会社テージーケー | 可変容量圧縮機用制御弁 |

| DE102011010474A1 (de) | 2011-02-05 | 2012-08-09 | Hydac Fluidtechnik Gmbh | Proportional-Druckregelventil |

| JP5682358B2 (ja) | 2011-02-15 | 2015-03-11 | 株式会社ニコン | 撮像装置 |

| US8225818B1 (en) | 2011-03-22 | 2012-07-24 | Incova Technologies, Inc. | Hydraulic valve arrangement with an annular check valve element |

| US9523987B2 (en) | 2011-06-15 | 2016-12-20 | Eagle Industry Co., Ltd. | Capacity control valve |

| ITFI20110145A1 (it) | 2011-07-19 | 2013-01-20 | Nuovo Pignone Spa | A differential pressure valve with parallel biasing springs and method for reducing spring surge |

| ITFI20110143A1 (it) | 2011-07-19 | 2013-01-20 | Nuovo Pignone Spa | A differential pressure valve with reduced spring-surge and method for reducing spring surge |

| JP2013024135A (ja) | 2011-07-21 | 2013-02-04 | Saginomiya Seisakusho Inc | 感圧制御弁 |

| JP5665722B2 (ja) | 2011-11-17 | 2015-02-04 | 株式会社豊田自動織機 | 容量制御弁 |

| JP6108673B2 (ja) | 2011-12-21 | 2017-04-05 | 株式会社不二工機 | 可変容量型圧縮機用制御弁 |

| JP6042411B2 (ja) | 2012-03-23 | 2016-12-14 | 日本発條株式会社 | 皿ばね |

| WO2013176012A1 (ja) | 2012-05-24 | 2013-11-28 | イーグル工業株式会社 | 容量制御弁 |

| ES2674812T3 (es) | 2012-07-11 | 2018-07-04 | Flextronics Ap, Llc | Accionador de solenoide de acción directa |

| JP6064132B2 (ja) | 2012-10-09 | 2017-01-25 | 株式会社テージーケー | 複合弁 |

| JP6064131B2 (ja) | 2012-10-17 | 2017-01-25 | 株式会社テージーケー | 可変容量圧縮機用制御弁 |

| JP6064123B2 (ja) | 2012-11-01 | 2017-01-25 | 株式会社テージーケー | 制御弁 |

| DE102012222399A1 (de) | 2012-12-06 | 2014-06-12 | Robert Bosch Gmbh | Stetig verstellbares hydraulisches Einbauventil |

| SE536848C2 (sv) * | 2012-12-20 | 2014-09-30 | Pmc Lubrication Ab | Ventil för styrning av fettförsörjning |

| US9777863B2 (en) | 2013-01-31 | 2017-10-03 | Eagle Industry Co., Ltd. | Capacity control valve |

| JP5600844B2 (ja) | 2013-02-12 | 2014-10-08 | 株式会社日本自動車部品総合研究所 | 電磁弁 |

| US20160053755A1 (en) | 2013-03-22 | 2016-02-25 | Sanden Holdings Corporation | Control Valve And Variable Capacity Compressor Provided With Said Control Valve |

| JP6136461B2 (ja) | 2013-03-29 | 2017-05-31 | 株式会社豊田自動織機 | 可変容量型圧縮機 |

| JP5983539B2 (ja) | 2013-06-13 | 2016-08-31 | 株式会社豊田自動織機 | 両頭ピストン型斜板式圧縮機 |

| JP5870971B2 (ja) | 2013-07-24 | 2016-03-01 | 株式会社デンソー | 電磁弁 |

| JP6115393B2 (ja) | 2013-08-08 | 2017-04-19 | 株式会社豊田自動織機 | 可変容量型斜板式圧縮機 |

| JP5918188B2 (ja) * | 2013-09-12 | 2016-05-18 | 株式会社鷺宮製作所 | 制御弁 |

| JP2015075054A (ja) | 2013-10-10 | 2015-04-20 | 株式会社豊田自動織機 | 可変容量型斜板式圧縮機 |

| JP6135521B2 (ja) | 2014-01-20 | 2017-05-31 | 株式会社豊田自動織機 | 可変容量型斜板式圧縮機 |

| JP2015152069A (ja) | 2014-02-13 | 2015-08-24 | 富士重工業株式会社 | 流量制御弁 |

| JP6206274B2 (ja) | 2014-03-19 | 2017-10-04 | 株式会社豊田自動織機 | 容量制御弁 |

| JP2015183614A (ja) | 2014-03-25 | 2015-10-22 | 株式会社豊田自動織機 | 可変容量型斜板式圧縮機 |

| US10337636B2 (en) | 2014-11-25 | 2019-07-02 | Eagle Industry Co., Ltd. | Displacement control valve |

| JP6495634B2 (ja) | 2014-12-02 | 2019-04-03 | サンデンホールディングス株式会社 | 可変容量圧縮機 |

| EP3239570B1 (de) | 2014-12-25 | 2020-05-13 | Eagle Industry Co., Ltd. | Volumensteuerungsventil |

| JP6500183B2 (ja) | 2015-04-02 | 2019-04-17 | 株式会社テージーケー | 可変容量圧縮機用制御弁 |

| US10830364B2 (en) | 2015-05-05 | 2020-11-10 | Eaton Intelligent Power Limited | Oil controlled valve |

| WO2016194388A1 (ja) * | 2015-06-03 | 2016-12-08 | 株式会社鷺宮製作所 | 絞り装置、および、それを備える冷凍サイクルシステム |

| JP6404191B2 (ja) | 2015-06-03 | 2018-10-10 | 株式会社鷺宮製作所 | 絞り装置、および、それを備える冷凍サイクルシステム |

| JP6715320B2 (ja) | 2015-07-31 | 2020-07-01 | 日産自動車株式会社 | 磁化状態制御方法及び磁化状態制御装置 |

| JP2017089832A (ja) | 2015-11-13 | 2017-05-25 | 株式会社テージーケー | 電磁弁 |

| JP6500186B2 (ja) | 2016-02-25 | 2019-04-17 | 株式会社テージーケー | 可変容量圧縮機用制御弁 |

| EP3431760B1 (de) | 2016-03-17 | 2020-09-23 | Eagle Industry Co., Ltd. | Ventil zur kapazitätssteuerung |

| JP6676432B2 (ja) | 2016-03-28 | 2020-04-08 | 株式会社不二工機 | 電動弁及びその組立方法 |

| ITUA20164408A1 (it) * | 2016-06-15 | 2017-12-15 | Dropsa Spa | Dispositivo di lubrificazione minimale con regolazione fine del flusso di olio |

| JP6802658B2 (ja) | 2016-07-29 | 2020-12-16 | タカオカ化成工業株式会社 | 水素水生成器 |

| US10781804B2 (en) | 2016-08-29 | 2020-09-22 | Eagle Industry Co., Ltd. | Displacement control valve |

| JP6461872B2 (ja) | 2016-08-30 | 2019-01-30 | 株式会社不二工機 | 電動弁 |

| CN110114573B (zh) | 2016-12-28 | 2021-06-29 | 伊格尔工业股份有限公司 | 容量控制阀 |

| JP6814644B2 (ja) | 2017-01-17 | 2021-01-20 | 日立オートモティブシステムズ株式会社 | 減衰力調整式緩衝器 |

| WO2018139476A1 (ja) | 2017-01-26 | 2018-08-02 | イーグル工業株式会社 | 容量制御弁 |

| JP6522023B2 (ja) | 2017-02-22 | 2019-05-29 | 株式会社不二工機 | 電動弁 |

| JP6924476B2 (ja) | 2017-04-07 | 2021-08-25 | 株式会社テージーケー | 可変容量圧縮機用制御弁 |

| EP3712433B1 (de) | 2017-11-15 | 2022-07-06 | Eagle Industry Co., Ltd. | Kapazitätssteuerventil und verfahren zur steuerung des kapazitätssteuerungsventils |

| JP7083844B2 (ja) | 2017-11-30 | 2022-06-13 | イーグル工業株式会社 | 容量制御弁及び容量制御弁の制御方法 |

| JP7190444B2 (ja) | 2017-12-14 | 2022-12-15 | イーグル工業株式会社 | 容量制御弁及び容量制御弁の制御方法 |

| EP3734068B1 (de) | 2017-12-25 | 2022-07-20 | Eagle Industry Co., Ltd. | Kapazitätssteuerungsventil |

| CN111465767B (zh) | 2017-12-27 | 2022-09-02 | 伊格尔工业股份有限公司 | 容量控制阀及容量控制阀的控制方法 |

| WO2019131693A1 (ja) | 2017-12-27 | 2019-07-04 | イーグル工業株式会社 | 容量制御弁及び容量制御弁の制御方法 |

| JP7194503B2 (ja) | 2018-01-31 | 2022-12-22 | 北越コーポレーション株式会社 | セルロースナノファイバーの製造方法 |

| JP7063453B2 (ja) | 2018-03-22 | 2022-05-09 | 株式会社不二工機 | 電動弁 |

| JP7242663B2 (ja) | 2018-05-23 | 2023-03-20 | イーグル工業株式会社 | 容量制御弁 |

| JP7262186B2 (ja) | 2018-07-04 | 2023-04-21 | 北越工業株式会社 | 気体制御弁 |

| JP7178837B2 (ja) | 2018-09-11 | 2022-11-28 | イーグル工業株式会社 | 流量制御弁 |

| CN113015853B (zh) | 2018-11-26 | 2022-12-23 | 伊格尔工业股份有限公司 | 容量控制阀 |

| JP6757996B2 (ja) | 2019-04-23 | 2020-09-23 | 株式会社不二工機 | 電動弁 |

| CN110260001A (zh) | 2019-07-08 | 2019-09-20 | 宁波国创机车装备有限公司 | 一种弹簧式止回阀 |

-

2022

- 2022-05-25 JP JP2023525755A patent/JPWO2022255188A1/ja active Pending

- 2022-05-25 US US18/563,717 patent/US12435794B2/en active Active

- 2022-05-25 CN CN202280036886.8A patent/CN117355694A/zh active Pending

- 2022-05-25 EP EP25209820.7A patent/EP4656916A2/de active Pending

- 2022-05-25 WO PCT/JP2022/021401 patent/WO2022255188A1/ja not_active Ceased

- 2022-05-25 EP EP22815938.0A patent/EP4350184A4/de active Pending

-

2025

- 2025-07-09 US US19/264,608 patent/US20250334185A1/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| EP4350184A4 (de) | 2025-05-07 |

| US20240271705A1 (en) | 2024-08-15 |

| CN117355694A (zh) | 2024-01-05 |

| WO2022255188A1 (ja) | 2022-12-08 |

| US20250334185A1 (en) | 2025-10-30 |

| US12435794B2 (en) | 2025-10-07 |

| JPWO2022255188A1 (de) | 2022-12-08 |

| EP4656916A2 (de) | 2025-12-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3835578B1 (de) | Kapazitätssteuerungsventil | |

| EP4224032B1 (de) | Ventil | |

| EP3961033B1 (de) | Kapazitätssteuerungsventil | |

| US12276346B2 (en) | Fluid control valve | |

| EP4350184A1 (de) | Fluidsteuerventil | |

| EP3822483A1 (de) | Kapazitätssteuerungsventil | |

| EP3835577B1 (de) | Kapazitätssteuerungsventil | |

| US11473683B2 (en) | Capacity control valve | |

| JP7391486B2 (ja) | 容量制御弁 | |

| US12435796B2 (en) | Fluid control valve | |

| EP4296552A1 (de) | Magnetventil | |

| EP3967911B1 (de) | Magnetventil | |

| EP4664495A1 (de) | Elektromagnetischer aktuator und elektromagnetisches ventil | |

| US20250084930A1 (en) | Solenoid valve | |

| US12146574B2 (en) | Flow rate control valve | |

| US20230059732A1 (en) | Spool valve | |

| JPH0587176A (ja) | 減衰力可変式シヨツクアブソーバ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20231127 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20250408 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F16K 31/40 20060101ALI20250402BHEP Ipc: F16K 25/00 20060101ALI20250402BHEP Ipc: F16K 17/10 20060101ALI20250402BHEP Ipc: F16K 1/42 20060101ALI20250402BHEP Ipc: F16K 1/36 20060101ALI20250402BHEP Ipc: F16K 51/00 20060101ALI20250402BHEP Ipc: F16K 17/04 20060101AFI20250402BHEP |