EP0906458B1 - Vorspinnmaschine mit spulenwechselvorrichtung - Google Patents

Vorspinnmaschine mit spulenwechselvorrichtung Download PDFInfo

- Publication number

- EP0906458B1 EP0906458B1 EP97934426A EP97934426A EP0906458B1 EP 0906458 B1 EP0906458 B1 EP 0906458B1 EP 97934426 A EP97934426 A EP 97934426A EP 97934426 A EP97934426 A EP 97934426A EP 0906458 B1 EP0906458 B1 EP 0906458B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roving

- bobbin

- flyers

- machine

- suspended

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01H—SPINNING OR TWISTING

- D01H9/00—Arrangements for replacing or removing bobbins, cores, receptacles, or completed packages at paying-out or take-up stations ; Combination of spinning-winding machine

- D01H9/02—Arrangements for replacing or removing bobbins, cores, receptacles, or completed packages at paying-out or take-up stations ; Combination of spinning-winding machine for removing completed take-up packages and replacing by bobbins, cores, or receptacles at take-up stations; Transferring material between adjacent full and empty take-up elements

- D01H9/04—Doffing arrangements integral with spinning or twisting machines

- D01H9/046—Doffing arrangements integral with spinning or twisting machines for flyer type machines

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D31/00—Materials specially adapted for outerwear

- A41D31/04—Materials specially adapted for outerwear characterised by special function or use

- A41D31/08—Heat resistant; Fire retardant

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D31/00—Materials specially adapted for outerwear

- A41D31/04—Materials specially adapted for outerwear characterised by special function or use

- A41D31/08—Heat resistant; Fire retardant

- A41D31/085—Heat resistant; Fire retardant using layered materials

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62D—CHEMICAL MEANS FOR EXTINGUISHING FIRES OR FOR COMBATING OR PROTECTING AGAINST HARMFUL CHEMICAL AGENTS; CHEMICAL MATERIALS FOR USE IN BREATHING APPARATUS

- A62D5/00—Composition of materials for coverings or clothing affording protection against harmful chemical agents

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/83—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with metals; with metal-generating compounds, e.g. metal carbonyls; Reduction of metal compounds on textiles

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/21—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/244—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of halogenated hydrocarbons

- D06M15/256—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of halogenated hydrocarbons containing fluorine

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/21—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/263—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of unsaturated carboxylic acids; Salts or esters thereof

- D06M15/277—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of unsaturated carboxylic acids; Salts or esters thereof containing fluorine

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/37—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/564—Polyureas, polyurethanes or other polymers having ureide or urethane links; Precondensation products forming them

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/0002—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by the substrate

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N7/00—Flexible sheet materials not otherwise provided for, e.g. textile threads, filaments, yarns or tow, glued on macromolecular material

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M2101/00—Chemical constitution of the fibres, threads, yarns, fabrics or fibrous goods made from such materials, to be treated

- D06M2101/16—Synthetic fibres, other than mineral fibres

- D06M2101/30—Synthetic polymers consisting of macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2331/00—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products

- D10B2331/02—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products polyamides

- D10B2331/021—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products polyamides aromatic polyamides, e.g. aramides

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S428/00—Stock material or miscellaneous articles

- Y10S428/92—Fire or heat protection feature

- Y10S428/921—Fire or flameproofing

Definitions

- the invention relates to a roving machine with on a wing bench in at least one Row mounted wings and full with a device for automatic replacement Roving bobbins against empty roving tubes in the form of at least one on guide means moveable hanging wagon train with hanging brackets into which the roving bobbins and Roving sleeves by a relative stroke movement between the roving bobbins and the Hanging carriage train can be hooked in, the guide means as each row of wings assigned guide rails are formed and the bobbin of the bobbin and the Guide rails are movable relative to each other so that they are in a common vertical plane come to rest.

- Such devices are known from DE-A-39 36 518 and US-A-5222350.

- the guideways are widened Wing bench arranged on the back of the roving machine. So that the coil bank under the transport device can be pushed, the wing bench and that on it mounted drafting system in the spindle area are not supported. You are therefore resting self-supporting on two columns at the beginning and end of the machine.

- This construction requires a great technical effort.

- the great distance between wing area and Transport equipment requires long transport times and extends the downtime of the Machine when changing bobbins.

- JP-A-04352824 the guideways are high above and in front of the roving machine arranged.

- the transport of the full spools and empty tubes is particularly necessary long time.

- the object of the invention was accordingly to arrange the guideways in specify the immediate vicinity of the wing, the wing bench in a known manner on one side can be supported. It solves this problem by the features of claims 1 and 2.

- the embodiment according to claim 1, wherein the guide rails are preferably on the The underside of the wing bench are arranged directly next to the wings, has the advantage that the Guide rails can remain stationary and that there is a particularly short Travel of the coil bank results.

- it does require the ability to record the Roving bobbins or roving sleeves in the bobbin bank of the roving machine with the arranged between the rows of wings, i.e. standing between these recordings Bring guide rails into a common vertical plane.

- the coil bank can be designed to be movable by a corresponding distance. But it is also possible to design the wing bench or both units to be displaceable.

- EP 0310 568 A1 describes a device with vertically movable guide rails known, the bobbin bank for doffing from the spinning area of the roving machine is brought out.

- a disadvantage of this arrangement is that it is several meters in size Distance between the coil bench and guide rails. This long distance takes a long time Doff times.

- the embodiment according to claim 2 has the advantage that both the wing bench and the bobbin cannot be displaced transversely to the longitudinal direction of the roving machine have to. the transverse movement is placed here in the guideways. Here also arise very short transport routes and times.

- Claim 3 represents an advantageous combination of the embodiments of claims 1 and 2 in terms of transverse mobility in that both the guideways and the spindle bank can be displaced transversely to the longitudinal axis of the prespinning machine.

- the guide rails can be moved straight out of the machine frame. However, they can also be pivoted about axes running along the roving machine be, with two guide rails one axis lies on the machine frame, the other on the front of the leader.

- the pre-spinning machines which are usually equipped with two rows of wings, are advantageous one of the guide rails between the rows of wings, the other can - from the Looking at the front of the machine - lying in front of or behind the rows of wings.

- Corresponding the spool bank or the guide rails must move forward when changing or be relocatable to the rear.

- the spool bank can be moved in that it is horizontal on trusses is led to the raising and lowering of the coil bank when building the coil winding and are movable and on which the bobbin can be moved back and forth. After the rotary drive on the bobbin in the bobbin usually anyway is transmitted by means of cardan shafts, the additional possibility of movement Coil bank no constructive problems.

- the bobbins are usually guided by spindles that are on the bobbin Coil spindles are arranged.

- spindles that are on the bobbin

- Coil spindles are arranged.

- a machine frame 1 enters Drafting system 2 and a wing bench 3, on which the in two rows arranged wings 4 are rotatably mounted.

- the wing bench contains the common, not shown drive of the wing.

- a coil bank 5 is also vertical movably guided, in which the coils 6 are rotatably mounted.

- the Coil bank 5 contains the common, not shown Driving the coils 6.

- the spool bank 6 is on several, over the length of the roving machine distributed trusses 7 stored. On these trusses 7 racks 8 are arranged vertically, with which pinions 9 mesh, by the one driving the common shaft of these pinions Motor 10 can be driven to move the bobbin 5 up and down are.

- the coil bank 5 also back and forth across the longitudinal direction of the roving machine guided in the traverses 7. She points to this Purpose preferably 7 gears 11 on each traverse, in engage the pinion 12 (Fig. le). These pinions 12 sit on a common, extending over the length of the spindle bank 5 Shaft that rotates back and forth via a motor 13 is.

- Hanging carriage trains 15 can be of common construction and articulated interconnected trolleys are made by means of Run rollers on or in the guide rails 14 and, for example. by means of known friction wheel drives from driven against Side surfaces of the hanging trolley pressing friction rollers are movable.

- the hanging trolleys carry hanging holders 16, on full roving bobbins 6 or empty roving sleeves 18 can be attached. In the described Embodiment carry the hanging car trains hanging holder 16 in half mutual distance between the wings 4 and 6 coils of the roving machine.

- Fig. 1a shows the starting position for the replacement of the full Spools 6 in the spool bank 5 of the roving machine against empty ones Sleeves 18.

- the bobbins 6 are finished, the pre-spinning machine has come to a standstill in a position where the arms the wing 4 stand in the longitudinal direction of the roving machine and in the guide rails 14 are suspension trolley trains 15 with sleeves 18 been retracted. Between those equipped with sleeves 18 Hanging brackets 16 each leave a hanging bracket empty.

- the coil bank 5 is carried out according to FIG. 1b corresponding control of the motor 10 by the control device 20 via the pinion 9 and the racks 8 according to the Arrows only lowered so far that the upper edges of the coils 6 stand below the hanging bracket 16.

- the coil bank 5 by appropriate control of the motor 13 via the pinion 12 and the toothing 11 retracted against the roving machine so that the bobbins 6 to stand under empty hanging brackets 16 in the hanging car trains 15 come.

- the coil bank 5 is raised again according to FIG. 1d, until the coils 6 latch into this hanging holder 16.

- the bobbin 5 is lowered so far according to FIG. 1e that the Coil spindles 19 allow the hanging trolley trains 15 to be moved, to hangers 16 equipped with sleeves 18 over the spool spindles 19 to bring.

- the coil bank 5 is raised again according to FIG. 1f, to release the sleeves 18 from the hangers 16 and to put on the spindles 19.

- the coil bank 5 By lifting (Fig. 1i) the coil bank 5 is has reached the starting position for restarting the roving machine.

- the hanging trolley trains 15 with the coils 6 the area the wing 4 have left, the roving machine again start up.

- FIGS. 2a and 2b An embodiment is shown in FIGS. 2a and 2b, in which the bobbin 5 is not transverse to the longitudinal axis of the roving machine is movable.

- the relative relocation required of guide rails and spool bank is here in the displaceability the guide rails.

- the function of the guide rails 14 of FIGS. 1a to 1i corresponding guide rails 21, 22 are movably guided, that they are transverse to the longitudinal direction of the roving machine below the wing 4 in a vertical plane through the wing 4 and the bobbin can be moved in the bobbin 5.

- the guide rails 21, 22 in a plurality over the length of the guide rails distributed push rods 23, 24 can be moved horizontally back and forth.

- Moving the Push rods 23, 24 are made by means of teeth 25, 26 on the Push rods and pinions engaging in the toothing 27, 28, which can be driven by motors 29, 30.

- it can also fluidic (pneumatic or hydraulic) working elements be provided.

- Fig. 2a shows the starting position for the change process: the coil bank 5 with the coils 6 is lowered, the guide rails 21, 22 are still in the retracted position, in which they Rotation of the wings 4 and the lifting movement of the coil bank 5 are not hinder.

- a first step of Fig. 2b they are through appropriate control of the motors 29, 30 via the pinion 27, 28 and the teeth 25, 26 moved so far forward that the front guide rail 21 between the rows of coils 6, the rear guide rail 22 just behind the rear row the coils are standing.

- the sleeves 18 equipped hanging trolley trains 15 so far into the guide rails retracted that their sleeves in gap to the coils 6 and their empty hangers 16 stand next to the coils: Fig. 4a.

- Fig. 4a shows the starting position for the change process: the coil bank 5 with the coils 6 is lowered, the guide rails 21, 22 are still in the retracted position, in which they Rotation of the wings 4 and the lifting movement of the coil bank 5 are not hinder.

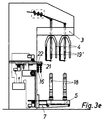

- Figures 3 a to 3e show an embodiment in which both the coil bank 5 can be moved back and forth, as well as the Guide rails 21, 22 arranged below the wing 4 and on the ways already described are shiftable.

- the guide rails 21, 22 after lowering and retracting the coil bank 5 from its initial position shown in FIG. 3a by means of motors 29, 30 via pinions 27, 28 and the teeth 25, 26 to different degrees forward between move the rows of lowered coils 6.

- This position lies in the vertical plane of the wing 4.

- the distance of the guide rails 21, 22 in the withdrawn Position can be such that in this position already Hanging carriage trains 15 equipped with sleeves 18 can retract.

- the guide rails 21, 22 also parallel to the longitudinal direction of the roving machine Axes can be pivoted.

- the sequence of the change process corresponds to that described above.

- Guide rails 21, 22 are the spindles that guide the coils 19 'advantageously arranged on the wings 4, because otherwise the spool bank 5 can be lowered so far or the wing bank so should be high that the 15 hanging coils 6 and sleeves 18 over the from the coil bank could move towering coil spindles away.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Toxicology (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Business, Economics & Management (AREA)

- Emergency Management (AREA)

- Spinning Or Twisting Of Yarns (AREA)

- Unwinding Of Filamentary Materials (AREA)

- Replacing, Conveying, And Pick-Finding For Filamentary Materials (AREA)

- Looms (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19631445 | 1996-08-03 | ||

| DE19631445A DE19631445A1 (de) | 1996-08-03 | 1996-08-03 | Vorspinnmaschine mit Spulenwechselvorrichtung |

| PCT/DE1997/001486 WO1998005810A1 (de) | 1996-08-03 | 1997-07-08 | Vorspinnmaschine mit spulenwechselvorrichtung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0906458A1 EP0906458A1 (de) | 1999-04-07 |

| EP0906458B1 true EP0906458B1 (de) | 2001-12-12 |

Family

ID=7801741

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97934426A Expired - Lifetime EP0906458B1 (de) | 1996-08-03 | 1997-07-08 | Vorspinnmaschine mit spulenwechselvorrichtung |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US5970699A (zh) |

| EP (1) | EP0906458B1 (zh) |

| JP (1) | JP2000508388A (zh) |

| CN (1) | CN1090256C (zh) |

| DE (2) | DE19631445A1 (zh) |

| ES (1) | ES2169867T3 (zh) |

| IT (1) | IT1293813B1 (zh) |

| WO (1) | WO1998005810A1 (zh) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101153415B (zh) * | 2006-09-30 | 2010-08-18 | 天津宏大纺织机械有限公司 | 用于粗纱机的输送导轨系统 |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006024553B4 (de) * | 2006-05-23 | 2008-05-08 | Oerlikon Textile Gmbh & Co. Kg | Vorspinnmaschine mit selbstständiger Spulenwechselvorrichtung |

| CN100590239C (zh) * | 2006-10-16 | 2010-02-17 | 天津宏大纺织机械有限公司 | 在粗纱机上从锭翼两侧自动取满纱放空管的方法 |

| DE102007007864A1 (de) * | 2007-02-14 | 2008-08-21 | Oerlikon Textile Gmbh & Co. Kg | Ringspinnmaschine mit Gatter |

| JP4872788B2 (ja) * | 2007-05-09 | 2012-02-08 | 株式会社豊田自動織機 | 粗紡機におけるボビンレール昇降装置 |

| ITMI20072352A1 (it) * | 2007-12-17 | 2009-06-18 | Savio Macchine Tessili Spa | Dispositivo e procedimento per la levata delle spoledai filatoi ad anello |

| DE102009035393A1 (de) * | 2009-07-30 | 2011-02-03 | Oerlikon Textile Gmbh & Co. Kg | Spulenwechseleinrichtung für eine Vorspinnmaschine |

| DE102009035384A1 (de) * | 2009-07-30 | 2011-02-03 | Oerlikon Textile Gmbh & Co. Kg | Vorspinnmaschine mit Spulenwechseleinrichtung |

| CN102330216B (zh) * | 2011-06-19 | 2013-07-03 | 无锡市新康纺机有限公司 | 用于粗纱机上的导轨罩壳结合件 |

| CN102373518A (zh) * | 2011-10-14 | 2012-03-14 | 无锡集聚智能纺织机械有限公司 | 改装的细纱机导轨机构及其改装方法 |

| CN102493049B (zh) * | 2011-12-31 | 2014-01-29 | 无锡宏源机电科技有限公司 | 电脑粗纱机自动落纱控制系统及其使用方法 |

| CN102789175A (zh) * | 2012-07-02 | 2012-11-21 | 山东宏业纺织股份有限公司 | 粗纱机精密定长装置控制电路 |

| CN105483875A (zh) * | 2016-01-19 | 2016-04-13 | 太平洋机电集团上海纺织机械有限公司 | 粗纱机下龙筋与机架的脱离及复位连接结构及方法 |

| JP6601325B2 (ja) * | 2016-06-29 | 2019-11-06 | 株式会社豊田自動織機 | 粗紡機の管替装置 |

| CN106245169A (zh) * | 2016-09-28 | 2016-12-21 | 青岛国邦工业科技发展有限公司 | 粗纱机自动落纱装置 |

| CN106757581A (zh) * | 2016-12-28 | 2017-05-31 | 无锡诚本纺机有限公司 | 一种带有筒管挂卸机构的上锭杆悬锭锭翼 |

| CN111876865B (zh) * | 2020-08-13 | 2021-10-22 | 东台远欣机械有限公司 | 一种捻线机用结构可调式预警装置 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE936518C (de) * | 1948-10-02 | 1955-12-15 | Siemens Ag | Anordnung fuer Traegerfrequenz-Fernsprechuebertragungsanlagen |

| JPH0663150B2 (ja) * | 1985-09-06 | 1994-08-17 | 豊和工業株式会社 | 粗紡機の管替装置 |

| IT1222821B (it) * | 1987-10-02 | 1990-09-12 | Marzoli & C Spa | Apparecchiatura atta ad effettuare,in modo automatico,il prelievo delle spole e la loro sostituzione con tubi vuoti,su banchi a fusi |

| DE3936518C2 (de) * | 1989-11-02 | 2001-10-11 | Rieter Ag Maschf | Vorspinnmaschine |

| US5222350A (en) * | 1990-12-06 | 1993-06-29 | Platt Saco Lowell Corporation | Roving frame and method |

| JP2906735B2 (ja) * | 1991-05-27 | 1999-06-21 | 株式会社豊田自動織機製作所 | 粗紡機における玉揚装置 |

| DE4229296A1 (de) * | 1992-09-02 | 1994-03-03 | Zinser Textilmaschinen Gmbh | Vorspinnmaschine mit einer Einrichtung zum selbsttätigen Auswechseln voller Vorgarnspulen gegen leere Vorgarnhülsen |

| DE4436277A1 (de) * | 1993-10-21 | 1995-04-27 | Rieter Ag Maschf | Flyer |

| DE4406488C1 (de) * | 1994-02-28 | 1995-08-10 | Zinser Textilmaschinen Gmbh | Vorspinnmaschine |

| US5797255A (en) * | 1994-10-14 | 1998-08-25 | Kabushiki Kaisha Toyoda Jidoshokki Seisakusho | Bobbin changing method and apparatus |

| JP3718274B2 (ja) * | 1995-01-27 | 2005-11-24 | ザウラー・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツング・ウント・コンパニー・コマンディトゲゼルシャフト | 満粗紡ボビンを空粗紡チューブと自動的に交換するための装置を備えたフライヤ粗紡機 |

-

1996

- 1996-08-03 DE DE19631445A patent/DE19631445A1/de not_active Withdrawn

-

1997

- 1997-07-08 EP EP97934426A patent/EP0906458B1/de not_active Expired - Lifetime

- 1997-07-08 JP JP10507451A patent/JP2000508388A/ja active Pending

- 1997-07-08 CN CN97191022A patent/CN1090256C/zh not_active Expired - Fee Related

- 1997-07-08 US US09/029,562 patent/US5970699A/en not_active Expired - Fee Related

- 1997-07-08 WO PCT/DE1997/001486 patent/WO1998005810A1/de active IP Right Grant

- 1997-07-08 ES ES97934426T patent/ES2169867T3/es not_active Expired - Lifetime

- 1997-07-08 DE DE59705779T patent/DE59705779D1/de not_active Expired - Fee Related

- 1997-08-01 IT IT97MI001870A patent/IT1293813B1/it active IP Right Grant

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101153415B (zh) * | 2006-09-30 | 2010-08-18 | 天津宏大纺织机械有限公司 | 用于粗纱机的输送导轨系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| IT1293813B1 (it) | 1999-03-10 |

| ES2169867T3 (es) | 2002-07-16 |

| US5970699A (en) | 1999-10-26 |

| EP0906458A1 (de) | 1999-04-07 |

| WO1998005810A1 (de) | 1998-02-12 |

| CN1090256C (zh) | 2002-09-04 |

| ITMI971870A1 (it) | 1999-02-01 |

| DE19631445A1 (de) | 1998-02-05 |

| CN1198785A (zh) | 1998-11-11 |

| JP2000508388A (ja) | 2000-07-04 |

| DE59705779D1 (de) | 2002-01-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0906458B1 (de) | Vorspinnmaschine mit spulenwechselvorrichtung | |

| EP0709501B1 (de) | Verfahren zum Kannenwechsel zwischen einem Transportwagen für Flachkannen und einer OE-Spinnmaschine und Transportwagen zur Durchführung des Verfahrens | |

| EP0585827B1 (de) | Vorspinnmaschine mit einer Einrichtung zum selbsttätigen Auswechseln voller Vorgarnspulen gegen leere Vorgarnhülsen | |

| EP0062063B1 (de) | Spinnmaschine, insbesondere ringspinnmaschine | |

| CH662586A5 (de) | Spinnanlage zur herstellung von garn aus vorgarn. | |

| EP0311862B1 (de) | Verfahren und Vorrichtung zum Wechseln von Vorgarnspulen an einer Textilmaschine | |

| EP0912781B1 (de) | Vorspinnmaschine mit einer vorrichtung zum selbsttätigen auswechseln voller vorgarnspulen gegen leere vorgarnhülsen | |

| DE3146170A1 (de) | Gatter | |

| EP0310870A1 (de) | Verfahren und Vorrichtung zum Einwechseln von vollen Vorgarnspulen | |

| WO2007134806A1 (de) | Vorspinnmaschine mit selbsttätiger spulenwechselvorrichtung | |

| CH687026A5 (de) | Verfahren und Vorrichtung zum Ver- und Entsorgen mit Garnkoerpern und Leerhuelsen an Textilmaschinen | |

| DE10130467B4 (de) | Anordnung von Service-Positionen für Wartungseinrichtungen an einer Textilmaschine | |

| DE19505050C2 (de) | Transport- und Umsetzsystem zwischen mindestens einer Vorspinnmaschine und einem nachgeordneten Lager- oder Verarbeitungsbereich | |

| CH691489A5 (de) | Vorspinnmaschine mit einer Vorrichtung zum selbsttätigen Auswechseln voller Vorgarnspulen gegen leere Hülsen. | |

| CH667677A5 (de) | Verfahren zum spulenwechsel in einer spinnmaschine. | |

| DE2521370A1 (de) | Einrichtung zum selbsttaetigen spulen- oder huelsenwechsel an spinn- oder zwirnmaschinen | |

| DE3876397T2 (de) | Vorrichtung zum beschicken von spinnmaschinen mit vorlagespulen. | |

| WO2017001297A1 (de) | Vorrichtung zum aufnehmen und abtransportieren von gewickelten spulen | |

| DE19502586C2 (de) | Vorspinnmaschine mit einer Vorrichtung zum selbsttätigen Auswechseln voller Vorgarnspulen gegen leere Hülsen | |

| DE19651783C1 (de) | Ringspinnmaschine, mit mindestens einer selbsttätigen Kopswechselvorrichtung | |

| DE3246463A1 (de) | Bediengeraet, insbesondere fadenansetzgeraet fuer eine ringspinnmaschine | |

| DE4312073C2 (de) | Spinnanlage mit einer an einer Kranbahn verfahrbaren Laufkatze zum Aufnehmen und Transportieren von Vorgarnspulen enthaltenden Hängewagenzügen | |

| CH412656A (de) | Verfahren und Vorrichtung zum selbsttätigen Kannenwechsel an Spinnereivorbereitungsmaschinen, insbesondere Strecken | |

| DE4445263C2 (de) | Transport- und Umsetzsystem für Vorgarnspulen und leere Hülsen | |

| DE4004043C1 (en) | Textile machine - comprises winding stations with winding spindle for package(s) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19980401 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR IT LI |

|

| 17Q | First examination report despatched |

Effective date: 20010202 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 20011212 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59705779 Country of ref document: DE Date of ref document: 20020124 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2169867 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20040721 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20060331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20070724 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080729 Year of fee payment: 12 Ref country code: CH Payment date: 20080730 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20080709 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080709 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100202 |