WO2015005049A1 - ポリ(メタ)アクリルイミドフィルム、その易接着性フィルム及びそれらの製造方法 - Google Patents

ポリ(メタ)アクリルイミドフィルム、その易接着性フィルム及びそれらの製造方法 Download PDFInfo

- Publication number

- WO2015005049A1 WO2015005049A1 PCT/JP2014/065440 JP2014065440W WO2015005049A1 WO 2015005049 A1 WO2015005049 A1 WO 2015005049A1 JP 2014065440 W JP2014065440 W JP 2014065440W WO 2015005049 A1 WO2015005049 A1 WO 2015005049A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- meth

- film

- poly

- acrylimide

- hard coat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/001—Combinations of extrusion moulding with other shaping operations

- B29C48/0019—Combinations of extrusion moulding with other shaping operations combined with shaping by flattening, folding or bending

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/07—Flat, e.g. panels

- B29C48/08—Flat, e.g. panels flexible, e.g. films

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/30—Extrusion nozzles or dies

- B29C48/305—Extrusion nozzles or dies having a wide opening, e.g. for forming sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/395—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders

- B29C48/40—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders

- B29C48/402—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders the screws having intermeshing parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/395—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders

- B29C48/40—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders

- B29C48/405—Intermeshing co-rotating screws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/395—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders

- B29C48/40—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders

- B29C48/41—Intermeshing counter-rotating screws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/911—Cooling

- B29C48/9135—Cooling of flat articles, e.g. using specially adapted supporting means

- B29C48/9145—Endless cooling belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/92—Measuring, controlling or regulating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C59/00—Surface shaping of articles, e.g. embossing; Apparatus therefor

- B29C59/10—Surface shaping of articles, e.g. embossing; Apparatus therefor by electric discharge treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C71/00—After-treatment of articles without altering their shape; Apparatus therefor

- B29C71/04—After-treatment of articles without altering their shape; Apparatus therefor by wave energy or particle radiation, e.g. for curing or vulcanising preformed articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/28—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42

- B32B27/281—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42 comprising polyimides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/042—Coating with two or more layers, where at least one layer of a composition contains a polymer binder

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/0427—Coating with only one layer of a composition containing a polymer binder

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/043—Improving the adhesiveness of the coatings per se, e.g. forming primers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/046—Forming abrasion-resistant coatings; Forming surface-hardening coatings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/06—Coating with compositions not containing macromolecular substances

- C08J7/065—Low-molecular-weight organic substances, e.g. absorption of additives in the surface of the article

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/12—Chemical modification

- C08J7/123—Treatment by wave energy or particle radiation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92504—Controlled parameter

- B29C2948/92704—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/022—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the choice of material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/27—Cleaning; Purging; Avoiding contamination

- B29C48/2715—Cleaning; Purging; Avoiding contamination of plasticising units

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/911—Cooling

- B29C48/9135—Cooling of flat articles, e.g. using specially adapted supporting means

- B29C48/914—Cooling drums

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/918—Thermal treatment of the stream of extruded material, e.g. cooling characterized by differential heating or cooling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2079/00—Use of polymers having nitrogen, with or without oxygen or carbon only, in the main chain, not provided for in groups B29K2061/00 - B29K2077/00, as moulding material

- B29K2079/08—PI, i.e. polyimides or derivatives thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2007/00—Flat articles, e.g. films or sheets

- B29L2007/008—Wide strips, e.g. films, webs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/20—Displays, e.g. liquid crystal displays, plasma displays

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/24—Homopolymers or copolymers of amides or imides

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/24—Homopolymers or copolymers of amides or imides

- C08J2333/26—Homopolymers or copolymers of acrylamide or methacrylamide

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2433/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2433/04—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters

- C08J2433/06—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters of esters containing only carbon, hydrogen, and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C08J2433/08—Homopolymers or copolymers of acrylic acid esters

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2475/00—Characterised by the use of polyureas or polyurethanes; Derivatives of such polymers

- C08J2475/04—Polyurethanes

Definitions

- the present invention relates to a poly (meth) acrylimide film, an easily adhesive film thereof, and a production method thereof.

- the present invention is excellent in surface smoothness, transparency, appearance, low retardation poly (meth) acrylimide film, excellent adhesion strength with hard coat, base of touch panel display face plate and transparent conductive substrate.

- the present invention relates to an easily-adhesive poly (meth) acrylimide film suitable as a material, and a method for producing them.

- touch panels that have been installed on image display devices such as liquid crystal displays, plasma displays, and electroluminescence displays and that allow input by touching with a finger or a pen while watching the display have become widespread.

- glass-based materials have been used for display faceplates and transparent conductive substrates for touch panels because they meet required characteristics such as heat resistance, dimensional stability, high transparency, high surface hardness, and high rigidity. It has been.

- glass has problems such as low impact resistance and easy cracking, low workability, difficult handling, high specific gravity and heavy, and difficulty in meeting the demands for curved display and flexibility. Therefore, materials that replace glass have been actively studied, and the surface of a transparent resin film substrate such as triacetylcellulose, polyethylene terephthalate, polycarbonate, polymethyl methacrylate, and norbornene-based polymer has excellent surface hardness and scratch resistance.

- a large number of hard coat laminated films formed with a hard coat have been proposed (for example, JP-A-2013-208896). However, its heat resistance and dimensional stability are insufficient.

- the process temperature high when forming the transparent conductive film to increase the crystallinity of the transparent conductive film and to reduce the surface resistance.

- the process temperature cannot be increased; since the heat resistance of the transparent resin film substrate is insufficient, a thin film transistor is further formed on the transparent conductive laminated film.

- the adoption of a hard coat laminated film formed from a transparent resin film base material has not been promoted for the reason that it cannot be formed.

- glass is exclusively used for transparent conductive substrates.

- poly (meth) acrylimide introduces the characteristics of heat resistance and dimensional stability of polyimide resin, while maintaining the characteristics of acrylic resin, such as high transparency, high surface hardness, and high rigidity. It is a thermoplastic resin that has improved the disadvantage of coloring.

- Such poly (meth) acrylimide is disclosed, for example, in JP-T-2011-519999.

- a normal T-die extrusion method could not obtain a poly (meth) acrylimide film excellent in surface smoothness, transparency and appearance. Further, the adhesion strength between the poly (meth) acrylimide film and the hard coat was not always satisfactory.

- Japanese Patent Application Laid-Open No. 2009-292871 discloses “an acrylic film having a thin film thickness and good die line, surface roughness and film wrinkle and a method for producing the same”. Since poly (meth) acrylimide also has properties as an acrylic resin, the present inventors tried to apply the technique of the document, but poly (meth) which is also excellent in surface smoothness, transparency and appearance. An acrylimide film could not be obtained.

- the present invention has been made in view of the circumstances as described above, and is excellent in surface smoothness, transparency, appearance, poly (meth) acrylimide film with small retardation, excellent adhesion strength with a hard coat, An easy-adhesive poly (meth) acrylimide film suitable as a base material for a transparent conductive substrate, a hard-coated laminated poly (meth) acrylimide film formed from these films, and an image display device member including these films The purpose is to provide.

- the “image display device” mentioned here includes an image display device having a touch panel function and an image display device not having a touch panel function.

- the first embodiment (items [1] to [11]), the second embodiment (items [12] to [26]), the third embodiment (item [27]).

- [34]) are as follows. [1].

- a poly (meth) acrylimide film characterized by satisfying the following properties (i) and (ii): (I) a total light transmittance of greater than 90%; and (ii) a haze of 2.0% or less. [2].

- the poly (meth) acrylimide film according to the above [1] which satisfies the following property (iii): (Iii) Retardation of less than 50 nm. [3].

- the easily adhesive film as described in [4] above, wherein the anchor coat contains a silane coupling agent having an amino group.

- the easily adhesive film as described in [4] above, wherein the anchor coat is a thermoplastic urethane anchor coat. [7].

- a hard coat laminated film wherein a hard coat is formed on at least one surface of the poly (meth) acrylimide film according to the above [1] or [2]. [8]. A hard coat laminated film, wherein a hard coat is formed on a surface of the poly (meth) acrylimide film described in [3] above having a wetness index of 50 mN / m or more. [9]. The hard coat laminated film according to any one of the above [4] to [6], wherein a hard coat is further formed on the anchor coat. [10]. The hard coat laminated film according to any one of [7] to [9], wherein the hard coat surface has a pencil hardness of 7H or more. [11].

- An image display device member comprising the film according to any one of [1] to [10] above. [12].

- a method for producing a poly (meth) acrylimide film (A) A step of continuously extruding a molten film of poly (meth) acrylimide from a T die using an apparatus including an extruder and a T die; (B) including supplying and pressing the molten film of the poly (meth) acrylimide between the rotating or circulating first mirror body and the rotating or circulating second mirror body; Where (C) the surface temperature of the first mirror body is 100 to 200 ° C .; (D) The method wherein the surface temperature of the second mirror body is 20 to 200 ° C. [13].

- a poly (meth) acrylimide film obtained by the method according to any one of [12] to [14] above. [16].

- the poly (meth) acrylimide film according to [15] which satisfies the following characteristics (i) and (ii): (I) a total light transmittance of greater than 90%; and (ii) a haze of 2.0% or less. [17].

- a method for producing an easily adhesive poly (meth) acrylimide film (1) A step of subjecting at least one surface of the poly (meth) acrylimide film to a corona discharge treatment; (2) including a step of forming an anchor coat containing a silane coupling agent having an amino group as an easy-adhesion surface on the treated surface of the poly (meth) acrylimide film subjected to the corona discharge treatment in the step (1).

- An easy-adhesive poly (meth) acrylimide film obtained by the method described in [27] above. [29].

- a poly (meth) acrylimide film having excellent surface smoothness, transparency and appearance and a small retardation can be obtained.

- This poly (meth) acrylimide film often has high surface hardness and rigidity, and is excellent in color tone, heat resistance and dimensional stability.

- the easily-adhesive film excellent in the adhesive strength with a hard coat can be obtained.

- These films are suitably used as a display face plate of a touch panel and a base material of a transparent conductive substrate due to the above characteristics.

- These films can also be suitably used as members of image display devices such as liquid crystal displays, plasma displays and electroluminescence displays.

- the poly (meth) acrylimide film according to the first aspect of the present invention satisfies the following characteristics (i) and (ii).

- This poly (meth) acrylimide film preferably satisfies (i) to (iii). Therefore, it can be suitably used as a base plate for a display face plate of a touch panel or a transparent conductive substrate.

- Haze 2.0% or less

- Retardation less than 50 nm

- the total light transmittance of the poly (meth) acrylimide film is more than 90%, it can be suitably used as a display face plate of a touch panel or a base material of a transparent conductive substrate.

- the total light transmittance of the poly (meth) acrylimide film is preferably as high as possible, and more preferably 92% or more.

- the total light transmittance here can be measured according to JIS K7361-1: 1997.

- the haze of the poly (meth) acrylimide film is 2.0% or less, it can be suitably used as a display face plate of a touch panel or a base material of a transparent conductive substrate.

- the haze of the poly (meth) acrylimide film is preferably as low as possible, and more preferably 1.5% or less.

- the haze can be measured according to JIS K7136-2000.

- the retardation of the poly (meth) acrylimide film is less than 50 nm, it can be very suitably used as a display face plate of a touch panel or a base material of a transparent conductive substrate.

- the retardation of the poly (meth) acrylimide film is preferably as small as possible, more preferably 40 nm or less, and even more preferably 30 nm or less.

- the retardation here can be measured based on the parallel Nicol rotation method.

- Poly (meth) acrylimide is colored from light yellow to reddish brown by introducing the characteristics of the heat resistance and dimensional stability of polyimide resin while maintaining the characteristics of acrylic resin with high transparency, high surface hardness and high rigidity. This resin improves the above-mentioned drawback and has thermoplasticity.

- poly (meth) acrylimide means polyacrylimide or polymethacrylamide.

- the poly (meth) acrylimide used for obtaining the film of the present invention is not particularly limited except that it has high transparency and is not colored for the purpose of use as a transparent resin film substrate.

- Poly (meth) acrylimide can be used.

- Preferred examples of the poly (meth) acrylimide include those having a yellowness index (measured according to JIS K7105: 1981) of 3 or less.

- the yellowness index of poly (meth) acrylimide is more preferably 2 or less, and still more preferably 1 or less.

- the melt mass flow rate (measured in accordance with ISO 1133 at 260 ° C. and 98.07 N) is 0.1 to 20 g / 10 min. Things can be mentioned.

- the melt mass flow rate of poly (meth) acrylimide is more preferably 0.5 to 10 g / 10 min.

- the glass transition temperature of poly (meth) acrylimide is preferably 150 ° C. or higher.

- the glass transition temperature of poly (meth) acrylimide is more preferably 170 ° C. or higher.

- Examples of commercially available poly (meth) acrylimide include “ACRYMID TT70 (trade name)” manufactured by Evonik.

- the poly (meth) acrylimide may have a thermoplastic resin other than poly (meth) acrylimide; a pigment, an inorganic filler, an organic filler, a resin filler; a lubricant, as long as it is not contrary to the object of the present invention.

- An additive such as an antioxidant, a weather resistance stabilizer, a heat stabilizer, a mold release agent, an antistatic agent, and a surfactant may be further included.

- the blending amount of these optional components is usually about 0.01 to 10 parts by mass when poly (meth) acrylimide is 100 parts by mass.

- the method for producing the poly (meth) acrylimide film according to the first aspect of the present invention is not particularly limited, for example, it can be produced by the method of the second aspect described later.

- the thickness of the poly (meth) acrylimide film is not particularly limited, and can be any thickness as desired.

- the thickness thereof is usually 20 ⁇ m or more, preferably 50 ⁇ m or more, from the viewpoint of handleability. From the viewpoint of economy, the thickness is usually 250 ⁇ m or less, preferably 150 ⁇ m or less.

- the thickness thereof is usually 100 ⁇ m or more, preferably 200 ⁇ m or more, more preferably 300 ⁇ m or more from the viewpoint of maintaining rigidity.

- the thickness thereof is usually 1500 ⁇ m or less, preferably 1200 ⁇ m or less, more preferably 1000 ⁇ m or less.

- the poly (meth) acrylimide film can be formed as an easily adhesive film by forming an anchor coat as an easily adhesive surface on at least one surface thereof. Furthermore, a hard coat can be formed on the anchor coat to form a hard coat laminated film.

- the poly (meth) acrylimide film of the present invention can be formed into a hard coat laminated film by forming a hard coat on at least one surface thereof.

- the anchor coat or the hard coat it is preferable to subject the laminated surface of the poly (meth) acrylimide film to a corona discharge treatment so that the wetting index (measured in accordance with JISK6768: 1999) is 50 mN / m or more.

- An anchor coat or hard coat may be formed without any treatment, but by performing a corona discharge treatment, a good interlayer adhesion strength can be obtained regardless of the type of paint for forming the anchor coat or hard coat. Will be able to.

- the wetting index is preferably 60 mN / m or more.

- the method of the corona discharge treatment is not particularly limited, and for example, the method described later for the third aspect can be used.

- an anchor coat agent for forming the anchor coat for the purpose of using the easily adhesive film obtained as a display face plate of a touch panel or a transparent conductive substrate, other than having high transparency and no coloring.

- the anchor coating agent for example, known materials such as polyester, acrylic, polyurethane, acrylic urethane, and polyester urethane can be used. Of these, a thermoplastic urethane anchor coating agent is preferred from the viewpoint of improving the adhesive strength with the hard coat.

- thermoplastic urethane anchor coating agent for example, “Washin Coat (trade name)” of Washin Chemical Industry Co., Ltd. can be mentioned.

- a paint containing a silane coupling agent can be used as the anchor coating agent.

- Suitable examples of the silane coupling agent include hydrolyzable groups (for example, alkoxy groups such as methoxy group and ethoxy group; acyloxy groups such as acetoxy group; halogen groups such as chloro group) and organic functional groups (for example, A silane compound having at least two different reactive groups (amino group, vinyl group, epoxy group, methacryloxy group, acryloxy group, isocyanate group, etc.).

- the silane coupling agent functions to improve the adhesive strength with the hard coat. Of these, a silane coupling agent having an amino group is preferred from the viewpoint of improving the adhesive strength with the hard coat.

- the paint containing the silane coupling agent may be a paint mainly containing a silane coupling agent (50% by mass or more as a solid content). Preferably, 75% by mass or more of the solid content of the paint is a silane coupling agent. A more desirable ratio is 90% by mass or more.

- silane coupling agent having an amino group examples include N-2- (aminoethyl) -3-aminopropylmethyldimethoxysilane, N-2- (aminoethyl) -3-aminopropyltrimethoxysilane, and N-2.

- silane coupling agent having an amino group examples include commercially available products such as Shin-Etsu Chemical Co., Ltd., Toray Dow Corning Co., Ltd., and Tokyo Chemical Industry Co., Ltd.

- the anchor coating agent includes an antioxidant, a weather resistance stabilizer, a light resistance stabilizer, an ultraviolet absorber, a heat stabilizer, an antistatic agent, a surfactant, and a colorant as long as the object of the present invention is not adversely affected.

- one or more additives such as an infrared shielding agent, a leveling agent, a thixotropic agent, and a filler may be included.

- the method for applying the anchor coating agent is not particularly limited, and for example, the method described later for the third aspect can be used.

- the dry thickness of the anchor coat is usually about 0.01 to 5 ⁇ m, preferably 0.1 to 2 ⁇ m.

- the coating material for forming the hard coat from the purpose of using the obtained hard coat laminated film as a display face plate or a transparent conductive substrate of a touch panel, except that it has high transparency and is not colored, It is not limited, Arbitrary paints can be used.

- Preferred examples of the hard coat forming coating material include those capable of forming a hard coat excellent in surface hardness and scratch resistance.

- the active energy ray-curable resin composition described below can be exemplified.

- the active energy ray-curable resin composition here is a resin composition that can be polymerized and cured by active energy rays such as ultraviolet rays and electron beams to form a hard coat.

- active energy ray-curable resin composition include an active energy ray-curable resin together with a compound having two or more isocyanate groups (—N ⁇ C ⁇ O) in one molecule and / or a photopolymerization initiator.

- a composition can be mentioned.

- the active energy ray-curable resin examples include polyurethane (meth) acrylate, polyester (meth) acrylate, polyacryl (meth) acrylate, polyepoxy (meth) acrylate, polyalkylene glycol poly (meth) acrylate, and poly (Meth) acryloyl group-containing prepolymer or oligomer such as ether (meth) acrylate; methyl (meth) acrylate, ethyl (meth) acrylate, n-butyl (meth) acrylate, hexyl (meth) acrylate, 2-ethylhexyl (meth) Acrylate, lauryl (meth) acrylate, isobornyl (meth) acrylate, dicyclopentenyl (meth) acrylate, dicyclopentenyloxyethyl (meth) acrylate, phenyl (meth) acrylate , Phenyl cellosolve (meth)

- (meth) acrylate means acrylate or methacrylate.

- Examples of the compound having two or more isocyanate groups in one molecule include methylene bis-4-cyclohexyl isocyanate; trimethylol propane adduct of tolylene diisocyanate, trimethylol propane adduct of hexamethylene diisocyanate, trimethylol of isophorone diisocyanate.

- Polyisocyanates such as propane adduct, isocyanurate of tolylene diisocyanate, isocyanurate of hexamethylene diisocyanate, isocyanurate of isophorone diisocyanate, biuret of hexamethylene diisocyanate; and urethanes such as block isocyanates of the above polyisocyanates

- a crosslinking agent etc. can be mentioned. These may be used alone or in combination of two or more. Further, at the time of crosslinking, a catalyst such as dibutyltin dilaurate or dibutyltin diethylhexoate may be added as necessary.

- photopolymerization initiator examples include benzophenone, methyl-o-benzoylbenzoate, 4-methylbenzophenone, 4,4′-bis (diethylamino) benzophenone, methyl o-benzoylbenzoate, 4-phenylbenzophenone, 4-benzoyl.

- Benzophenone compounds such as -4'-methyldiphenyl sulfide, 3,3 ', 4,4'-tetra (tert-butylperoxycarbonyl) benzophenone, 2,4,6-trimethylbenzophenone; benzoin, benzoin methyl ether, benzoin Benzoin compounds such as ethyl ether, benzoin isopropyl ether, benzyl methyl ketal; acetophenone, 2,2-dimethoxy-2-phenylacetophenone, 1-hydroxycyclohexyl phenyl ketone Acetophenone compounds; methylanthraquinone, 2-ethylanthraquinone, 2-amylanthraquinone and other anthraquinone compounds; thioxanthone, 2,4-diethylthioxanthone, thioxanthone compounds such as 2,4-diisopropylthioxanthone; alkyl such as

- the active energy ray-curable resin composition includes an antistatic agent, a surfactant, a leveling agent, a thixotropic agent, a stain prevention agent, a printability improving agent, an antioxidant, and a weather resistance stabilizer as necessary.

- one or more additives such as a light resistance stabilizer, an ultraviolet absorber, a heat stabilizer, a colorant, and a filler may be contained.

- fine particles having an average particle diameter of 1 nm to 300 nm.

- the fine particles in an amount of 1 to 300 parts by weight, preferably 20 to 100 parts by weight, based on 100 parts by weight of the active energy ray-curable resin component, the hardness of the hard coat can be increased.

- Both inorganic fine particles and organic fine particles can be used as the fine particles.

- the inorganic fine particles include silica (silicon dioxide); metal oxide fine particles such as aluminum oxide, zirconia, titania, zinc oxide, germanium oxide, indium oxide, tin oxide, indium tin oxide, antimony oxide, and cerium oxide; Examples thereof include metal fluoride fine particles such as magnesium fluoride and sodium fluoride; metal fine particles; metal sulfide fine particles; metal nitride fine particles.

- the organic fine particles include resin beads such as a styrene resin, an acrylic resin, a polycarbonate resin, an ethylene resin, and a cured resin of an amino compound and formaldehyde. These may be used alone or in combination of two or more.

- the surface of the fine particles is treated with a silane coupling agent such as vinylsilane or aminosilane; a titanate coupling agent; aluminum Nate coupling agents; Organic compounds having an ethylenically unsaturated bond group such as (meth) acryloyl group, vinyl group and allyl group and reactive functional groups such as epoxy group; Surface treatment agents such as fatty acids and fatty acid metal salts You may use what was processed by.

- a silane coupling agent such as vinylsilane or aminosilane

- a titanate coupling agent such as aluminum Nate coupling agents

- Organic compounds having an ethylenically unsaturated bond group such as (meth) acryloyl group, vinyl group and allyl group and reactive functional groups such as epoxy group

- Surface treatment agents such as fatty acids and fatty acid metal salts You may use what was processed by.

- silica and aluminum oxide fine particles are preferable for obtaining a hard coat layer with higher hardness, and silica fine particles are more preferable.

- examples of commercially available silica fine particles include Snowtex (trade name) manufactured by Nissan Chemical Industries, Ltd. and Quattron (trade name) manufactured by Fuso Chemical Industries, Ltd.

- the average particle diameter of the fine particles is preferably 300 nm or less in order to maintain the transparency of the hard coat layer and to obtain a sufficient hardness improvement effect.

- the average particle diameter of the fine particles is preferably 200 nm or less, more preferably 120 nm or less.

- there is no particular lower limit to the average particle size of the fine particles but usually available particles are at most about 1 nm even if they are fine.

- the average particle diameter of the fine particles is the particle diameter distribution curve measured using a laser diffraction / scattering particle size analyzer “MT3200II” (trade name) manufactured by Nikkiso Co., Ltd. It is the particle diameter at which the accumulation is 50% by mass.

- the said active energy ray curable resin composition is diluted to the density

- the solvent is not particularly limited as long as it does not react with the components of the curable resin composition and other optional components and does not catalyze (promote) the self-reaction (including deterioration reaction) of these components.

- the solvent include 1-methoxy-2-propanol, ethyl acetate, nbutyl acetate, toluene, methyl ethyl ketone, methyl isobutyl ketone, diacetone alcohol, acetone and the like.

- the active energy ray-curable resin composition can be obtained by mixing and stirring these components.

- the method for applying the coating material such as the active energy ray-curable resin composition is not particularly limited, and for example, the method described later for the third aspect can be used.

- the thickness of the hard coat is preferably 17 ⁇ m or more, more preferably 20 ⁇ m or more, and further preferably 25 ⁇ m or more.

- the thickness of the hard coat is preferably 100 ⁇ m or less, and more preferably 50 ⁇ m or less.

- the poly (meth) acrylimide film, the easily adhesive film, and the hard coat laminated film according to the first aspect of the present invention include an image display device (an image display device having a touch panel function and an image display device not having a touch panel function). ) Is preferably used as a member.

- the second aspect of the present invention is a method for producing a poly (meth) acrylimide film, wherein (A) an apparatus including an extruder and a T die is used, and the poly (meth) acrylimide is melted from the T die. A step of continuously extruding the film.

- the characteristics of the raw material poly (meth) acrylimide used in this production method and the product poly (meth) acrylimide film are not particularly limited, but are preferably those described for the first aspect. It may be.

- extruder an arbitrary one can be used, and examples thereof include a single-screw extruder, a same-direction rotating twin-screw extruder, and a different-direction rotating twin-screw extruder.

- poly (meth) acrylimide is a highly hygroscopic resin, it is preferably dried before being used for film formation. It is also preferred that the poly (meth) acrylimide dried by the dryer is directly transported from the dryer to the extruder and charged.

- the set temperature of the dryer is preferably 100 to 150 ° C.

- the T-die is not particularly limited, and an arbitrary one may be used.

- a manifold die, a fish tail die, a coat hanger die and the like can be mentioned.

- the temperature of the T die is preferably set to at least 260 ° C. or higher in order to stably perform the process of continuously extruding a poly (meth) acrylimide molten film.

- the temperature of the T die is more preferably 270 ° C. or higher.

- the temperature of the T die is preferably set to 350 ° C. or lower.

- the ratio (R / T) between the lip opening (R) and the thickness (T) of the obtained poly (meth) acrylimide film is preferably 1 to 5. From the viewpoint of preventing an increase in retardation, the ratio (R / T) is preferably 5 or less. On the other hand, from the viewpoint of suppressing the extrusion load, the ratio (R / T) is preferably 1 or more. The ratio (R / T) is more preferably 1.1 to 2.5.

- the method for producing a poly (meth) acrylimide film according to the second aspect of the present invention includes (B) a first mirror body that rotates or circulates and a second mirror body that rotates or circulates, The method includes supplying and pressing the molten film of poly (meth) acrylimide.

- Examples of the first mirror body include a mirror roll and a mirror belt.

- a mirror roll As said 2nd mirror surface body, a mirror surface roll, a mirror surface belt, etc. can be mentioned, for example.

- the mirror roll is a roll having a mirror-finished surface, and is made of metal, ceramic, silicon rubber, or the like. Further, the surface of the mirror roll can be subjected to chrome plating, iron-phosphorus alloy plating, hard carbon treatment by PVD method or CVD method for the purpose of protection from corrosion and scratches.

- the “mirror finish” is not particularly limited, and may be processed into a mirror finish by a known means such as polishing with fine abrasive grains.

- the first and / or second mirror body may have an arithmetic average roughness (Ra) of preferably 100 nm or less, more preferably 50 nm or less.

- the first and / or second mirror body may have a ten-point average roughness (Rz) of preferably 500 nm or less, and more preferably 200 nm or less.

- the mirror surface belt is a seamless belt, usually made of metal, whose surface is mirror-finished.

- the mirror belt is circulated between a pair of belt rollers.

- the surface of the mirror belt can be subjected to chrome plating, iron-phosphorus alloy plating, hard carbon treatment by PVD method or CVD method, etc. for the purpose of protection from corrosion and scratches.

- this production method can provide a poly (meth) acrylimide film excellent in surface smoothness, transparency and appearance because the surface temperature is 100 to 200 ° C.

- the poly (meth) acrylimide molten film By pressing the poly (meth) acrylimide molten film with the mirror body and the second mirror body with a surface temperature of 20 to 200 ° C., the first mirror body and the second mirror body are highly smooth. It is considered that this is because the surface state is transferred to the film and a defective portion such as a die stripe is corrected.

- the surface temperature of the first mirror body may be at least 100 ° C. or higher, preferably 120 ° C. or higher, more preferably 140 ° C. or higher.

- the surface temperature of the first mirror body is 200 ° C. or less, preferably 160 ° C. or less, in order to prevent appearance defects (peeling traces) associated with peeling from the first mirror body from appearing on the film.

- the surface temperature of the second mirror body may be at least 20 ° C. or higher, preferably 60 ° C. or higher, more preferably 100 ° C. or higher.

- the surface temperature of the second mirror body is 200 ° C. or lower, preferably 160 ° C. or lower. .

- the surface temperature of the first mirror body is preferably higher than the surface temperature of the second mirror body. This is because the film is held in the first mirror body and sent to the next transfer roll.

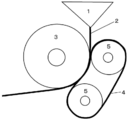

- FIG. 1 is a conceptual diagram showing an example of the manufacturing method according to the second embodiment of the present invention.

- the illustrated apparatus includes a T die 1, a molten film 2, a mirror roll 3, a mirror belt 4, and a pair of belt rollers 5.

- the mirror belt 4 is looped between a pair of belt rollers 5 and circulated.

- the molten film 2 of poly (meth) acrylimide continuously extruded from the T-die 1 is supplied and fed between the rotating mirror surface roll 3 and the mirror surface belt 4 circulating along the outer peripheral surface of the mirror surface roll 3.

- the highly smooth surface state of the mirror roll 3 and the mirror belt 4 is transferred to the film, and defective portions such as die lines are corrected to form a film having excellent surface smoothness, transparency, and appearance. Is done.

- the mirror belt 4 circulates along the outer peripheral surface of the mirror roll 3 when pressed against the mirror roll 3. Therefore, by using the mirror roll 3 and the mirror belt 4, the molten film can be pressed by the surface, and the transfer of the surface state and the correction of the defective portion can be surely performed.

- the pair of belt rollers 5 are usually suspended on a support base that can finely adjust the distance between the upper and lower sides in order to keep the mirror roll 3 and the mirror belt 4 parallel.

- the tension of the mirror belt 4 can be adjusted by the distance between the pair of belt rollers 5.

- the thickness of the poly (meth) acrylimide film produced by the production method of the second aspect of the present invention is not particularly limited, but is preferably as described for the first aspect.

- the 3rd aspect of this invention is a manufacturing method of an easily-adhesive poly (meth) acrylimide film, Comprising: (1) At least one surface of a poly (meth) acrylimide film includes the process of carrying out a corona discharge process.

- a film is passed between an insulated electrode and a dielectric roll, a high frequency high voltage is applied to generate a corona discharge, and the film surface is treated.

- Oxygen and the like are ionized by this corona discharge and collide with the film surface, so that the resin molecular chain is broken or the oxygen-containing functional group is added to the resin molecular chain on the film surface, thereby improving the adhesive strength with the hard coat. be able to.

- the wetting index with which sufficient adhesive strength can be expected is usually 50 mN / m or more, preferably 60 mN / m or more.

- the processing amount (S) required to obtain the above wetting index is usually 80 W ⁇ min / m 2 or more, preferably 120 W ⁇ min / m 2 or more.

- the throughput (S) of the corona discharge treatment it is preferable to suppress the throughput (S) of the corona discharge treatment to 500 W ⁇ min / m 2 or less.

- the processing amount (S) is more preferably 400 W ⁇ min / m 2 or less.

- S P / (L ⁇ V) here, S: throughput (W ⁇ min / m 2 ); P: Discharge power (W); L: length of discharge electrode (m); V: Line speed (m / min).

- the production method according to the third aspect of the present invention includes (2) a silane cup having an amino group as an easy-adhesion surface on the treated surface of the poly (meth) acrylimide film subjected to the corona discharge treatment in the step (1). Forming an anchor coat containing a ring agent.

- the amino group-containing silane coupling agent includes a hydrolyzable group (for example, an alkoxy group such as a methoxy group and an ethoxy group; an acyloxy group such as an acetoxy group; a halogen group such as a chloro group; and the like) and at least an amino group It is a silane compound having two different reactive groups.

- This silane coupling agent having an amino group functions to improve the adhesive strength with the hard coat.

- silane coupling agent which has an amino group

- Preferably what was illustrated about the said 1st aspect can be used.

- the paint for forming an anchor coat containing a silane coupling agent having an amino group is preferably a paint mainly containing a silane coupling agent having an amino group (50% by mass or more as a solid content). It is more preferable that 75% by mass or more of the solid content of the coating material is a silane coupling agent having an amino group. More preferably, 90% by mass or more of the solid content of the coating material is a silane coupling agent having an amino group.

- the paint for forming an anchor coat containing a silane coupling agent having an amino group includes a silane coupling agent having no amino group, such as a vinyl silane coupling agent, an epoxy silane coupling agent, and a methacryloxy silane. Coupling agents, acryloxy silane coupling agents, mercapto silane coupling agents, isocyanate silane coupling agents, ureido silane coupling agents, and the like may also be included. From the viewpoint of improving the adhesive strength with the hard coat, the proportion of the silane coupling agent having no amino group in the paint is preferably as small as possible, and is usually less than 50% by mass of the solid content, more preferably the solid content. Of less than 25% by weight.

- the above-mentioned paint is an adhesive resin, an antioxidant, a weather resistance stabilizer, a light resistance stabilizer, an ultraviolet absorber, a heat stabilizer, an antistatic agent, a surfactant, a colorant, as long as it does not contradict the purpose of the present invention.

- one or more additives such as an infrared shielding agent, a leveling agent, a thixotropic agent, and a filler may be included.

- the method for applying the paint is not particularly limited, and a known web application method can be used. Specific examples include roll coating, gravure coating, reverse coating, roll brushing, spray coating, air knife coating, and die coating.

- an optional diluting solvent such as methanol, ethanol, isopropyl alcohol, 1-methoxy-2-propanol, n-butyl acetate, toluene, methyl ethyl ketone, methyl isobutyl ketone, ethyl acetate, acetone or the like should be used. Can do.

- the above paint can be obtained by mixing and stirring a silane coupling agent having an amino group and other components.

- the method for drying the wet coating film of the paint is not particularly limited, and a known method can be used.

- the dry thickness of the anchor coat containing the silane coupling agent having an amino group is usually about 0.01 to 5 ⁇ m, preferably 0.1 to 2 ⁇ m.

- the poly (meth) acrylimide film used in the production method according to the third aspect of the present invention in particular, it has high transparency and is not colored for the purpose of use as a transparent resin film substrate. It is not limited, The film which formed arbitrary poly (meth) acrylimide by the arbitrary methods can be used.

- This poly (meth) acrylimide film may preferably be the one described for the first aspect. Further, this poly (meth) acrylimide film may preferably be produced by the method described for the second embodiment.

- the thickness of the poly (meth) acrylimide film used in the production method according to the third aspect of the present invention is not particularly limited, and can be any thickness as desired.

- the thickness of the poly (meth) acrylimide film is usually 20 ⁇ m or more, preferably 50 ⁇ m or more, from the viewpoint of web handling properties. Moreover, from an economical viewpoint, it may be 250 micrometers or less normally, Preferably it may be 150 micrometers or less.

- the easy-adhesive poly (meth) acrylimide film obtained by the production method of the third aspect of the present invention as a display faceplate

- it is usually 100 ⁇ m or more, preferably 200 ⁇ m or more, More preferably, it may be 300 ⁇ m or more.

- it may be 1500 micrometers or less normally, Preferably it is 1200 micrometers or less, More preferably, it may be 1000 micrometers or less.

- a hard coat can be laminated on the easy-adhesion surface of the easy-adhesive poly (meth) acrylimide film obtained by the production method according to the third aspect of the present invention.

- the paint for forming the hard coat is not particularly limited, except that it is excellent in transparency and not colored, for the purpose of use as a base plate for a display face plate of a touch panel or a transparent conductive substrate. The paint can be used.

- Preferred examples of the hard coat forming paint in this embodiment include those capable of forming a hard coat having excellent surface hardness and scratch resistance.

- the active energy ray-curable resin composition described for the first aspect can be given.

- a hydroxyl group-containing silicon-modified acrylic surface modifier is preferable. be able to.

- the touch face side hard coat contains a hydroxyl group-containing silicon-modified acrylic surface conditioner, thereby improving the sliding property.

- the method of applying a hard coat forming coating material such as an active energy ray-curable resin composition is not particularly limited, and a known web coating method can be used. Specific examples include roll coating, gravure coating, reverse coating, roll brushing, spray coating, air knife coating, and die coating.

- the thickness of the hard coat is not particularly limited, but is preferably as described for the first aspect.

- Pencil hardness In accordance with JIS K5600-5-4, evaluation was performed using a pencil “Uni” (trade name) manufactured by Mitsubishi Pencil Co., Ltd. under a load of 200 g or 750 g. For the hard coat laminated poly (meth) acrylimide film, the hard coat surface was evaluated.

- thermomechanical analyzer “EXSTAR6000 (trade name)” manufactured by Seiko Instruments Inc. was used.

- the test piece was 20 mm long and 10 mm wide, and the film was collected so that the machine direction (MD) of the film was the vertical direction of the test piece.

- Conditioning of the test piece was performed at a temperature of 23 ° C. ⁇ 2 ° C. and a relative humidity of 50 ⁇ 5% for 24 hours.

- the condition adjustment at the maximum measurement temperature was not performed. .

- the distance between chucks was 10 mm, and the temperature program was a program in which the temperature was maintained at 20 ° C. for 3 minutes and then the temperature was increased to 270 ° C. at a temperature increase rate of 5 ° C./min. From the obtained temperature-test piece length curve, the poly (meth) acrylimide film has a low temperature side temperature of 30 ° C. and a high temperature side temperature of 200 ° C., and the hard coat laminated poly (meth) acrylimide film has a low temperature side temperature of 30 ° C. The linear expansion coefficient was calculated at a high temperature side temperature of 250 ° C.

- the hard coat surface of the hard coat laminated film was traced up and down, left and right or in a circle with an index finger, and was evaluated based on the impression whether or not it was traced as intended. Each test was conducted by 10 people, and 2 points were given if they were traced as expected, 1 point was given if they were traced almost as expected, and 0 points were given if they were not traced as expected due to a finger being caught. Were evaluated and evaluated according to the following criteria. ⁇ : 16-20 points ⁇ : 10-15 points ⁇ : 0-9 points

- the raw materials used are as follows.

- Raw materials used The raw materials used in the following examples, comparative examples, and reference examples are as follows.

- (B-2) 90 parts by weight of a thermoplastic urethane anchor coating agent “WASIN COAT VH KE-21 CLEAR (trade name)” manufactured by Washin Chemical Industry Co., Ltd .; 10 parts by weight of Washincoat VHKE-21B mat (trade name); and 100 parts by weight of propylene glycol monomethyl ether were mixed and stirred to obtain an anchor coat agent (B-2).

- a thermoplastic urethane anchor coating agent “WASIN COAT VH KE-21 CLEAR (trade name)” manufactured by Washin Chemical Industry Co., Ltd .

- 10 parts by weight of Washincoat VHKE-21B mat trade name

- propylene glycol monomethyl ether 100 parts by weight

- Silane coupling agent having no amino group (b-1): Vinyl-based silane coupling agent “Shin-Etsu Silicone KBE-1003 (trade name)” from Shin-Etsu Chemical Co., Ltd. Vinyl triethoxysilane (b-2) : Shin-Etsu Chemical Co., Ltd. epoxy-based silane coupling agent “Shin-Etsu Silicone KBE-403 (trade name)” 3-glycidoxypropyltriethoxysilane (b-3): Shin-Etsu Chemical Co., Ltd.

- Hard coat forming coating (C-1): 30 parts by mass of the following (c1), 70 parts by mass of the following (c2), 4 parts by mass of the following (c4), and 30 parts by mass of methyl ethyl ketone are mixed and stirred. A coating-forming coating material (C-1) was obtained.

- C-3) 65 parts by mass (c1) below, 65 parts by mass (c3) below, 6.5 parts by mass (c4) below, 0.55 parts by mass (c6) below, and 25 parts by mass methyl ethyl ketone and methyl isobutyl

- C-3 65 parts by mass (c1) below, 65 parts by mass (c3) below, 6.5 parts by mass (c4) below, 0.55 parts by mass (c7) below, and 25 parts by mass methyl ethyl ketone and methyl isobutyl

- C-4 65 parts by mass (c1) below, 65 parts by mass (c3) below, 6.5 parts by mass (c4) below, 0.55 parts by mass (c7) below, and 25 parts by mass methyl ethyl ketone and methyl isobutyl

- C-5 65 parts by mass (c1) below, 65 parts by mass (c3) below, 6.5 parts by mass (c4) below, 0.55 parts by mass (c8) below, and 25 parts by mass methyl ethyl ketone and methyl isobutyl 10 parts by mass of ketone was mixed and stirred to obtain a hard coat forming coating (C-5).

- C1 Nippon Kayaku Co., Ltd. dipentaerythritol hexaacrylate

- c2 BASF polyether acrylate and nano silica (average particle size 20 nm) 50:50 (mass ratio) mixed paint “LaromerPO9026 (trade name) ) "

- C3 50:50 (mass ratio) mixed paint “NANOBYK-3605 (trade name)” of hexanediol diacrylate of Big Chemie Japan Co., Ltd.

- C4 Phenylketone-based photopolymerization initiator (1-hydroxycyclohexyl phenyl ketone) “SB-PI714 (trade name)” by Soho Sangyo Co., Ltd.

- C5 Hydroxy group-containing silicon-modified acrylic surface modifier “BYK-SILCLEAN3700 (trade name)” of Big Chemie Japan, Inc.

- C6 Big Chemie Japan Co., Ltd. acrylic surface modifier “BYK-352 (trade name)”

- C7 Big Chemie Japan Co., Ltd. acrylic surface modifier “BYK-358N (trade name)”

- C8 Kyoeisha Chemical Co., Ltd. modified silicon surface modifier “Polyflow KL-403 (trade name)”

- Examples 2-5, Comparative Examples 1-2 Film formation was performed in the same manner as in Example 1 except that the mirror surface temperature and the mirror belt surface temperature were changed as shown in Table 1 or 2.

- the physical property measurement / evaluation results are shown in Table 1 or 2.

- Comparative Example 3 Film formation was performed in the same manner as in Example 1 except that the mirror roll surface temperature was changed to 220 ° C. The appearance was remarkably poor due to the peeling marks accompanying peeling with the mirror roll. Therefore, physical properties other than the appearance could not be evaluated (not shown in the table).

- Comparative Example 4 A film was formed in the same manner as in Example 1 except that the mirror belt surface temperature was changed to 220 ° C. The appearance was remarkably poor due to peeling marks accompanying peeling with the mirror belt. Therefore, physical properties other than the appearance could not be evaluated (not shown in the table).

- the obtained film was subjected to measurement tests for total light transmittance, haze, retardation, surface appearance, color tone, pencil hardness (750 g load), and linear expansion coefficient (thermal dimensional stability) by the above methods. The results are shown in Table 2.

- Example 8 A film was formed in the same manner as Example 3 except that the take-up speed was 2.6 m / min and the film thickness was changed to 550 ⁇ m.

- the physical property measurement / evaluation results are shown in Table 2.

- Example 9 A film was formed in the same manner as in Example 7 except that the take-up speed was 2.6 m / min and the film thickness was changed to 550 ⁇ m.

- the physical property measurement / evaluation results are shown in Table 2.

- Example 10 Corona discharge treatment was performed on one side of the poly (meth) acrylimide film obtained in Example 3 above under the conditions of a throughput of 167 W ⁇ min / m 2 (discharge power 500 W, discharge electrode length 1 m, line speed 3 m / min). Went.

- the anchor coating agent (B-1) is applied to the corona discharge treated surface using a film Mayer bar type coating device so that the dry film thickness becomes 0.5 ⁇ m, and the easy adhesion property A poly (meth) acrylimide film was obtained.

- the measurement test of the total light transmittance, haze, surface appearance, and color tone was done by the said method.

- the paint (C-1) was applied to the easy-adhesion surface of the easy-adhesive poly (meth) acrylimide film using a die-type coating device so that the dry thickness was 25 ⁇ m.

- a hard coat laminated film was obtained.

- the total light transmittance, haze, surface appearance, color tone, pencil hardness (750 g load), linear expansion coefficient (thermal dimensional stability), cross-cut test (with hard coat) A measurement test of adhesion was performed. The results are shown in Table 3.

- Examples 11-13 Except that the amount of corona discharge treatment was changed to the values shown in Table 3, all as in Example 10, corona discharge treatment, easy-adhesive poly (meth) acrylimide film and hard coat laminated film formation, and their Physical properties were measured. The results are shown in Table 3.

- Example 14 Except that the above (B-2) was used instead of the above (B-1) as the anchor coating agent, all the same as in Example 10, corona discharge treatment, easy-adhesive poly (meth) acrylimide film and hard Formation of a coated laminated film and measurement of physical properties thereof were performed. The results are shown in Table 3.

- Example 15 Except that the above (B-3) was used instead of the above (B-1) as an anchor coating agent, all the same as in Example 10, corona discharge treatment, easy-adhesive poly (meth) acrylimide film and hard Formation of a coated laminated film and measurement of physical properties thereof were performed. The results are shown in Table 3.

- Example 16 Corona discharge treatment on both sides of the poly (meth) acrylimide film obtained in Example 3 under the conditions of a throughput of 167 W ⁇ min / m 2 (discharge power 500 W, discharge electrode length 1 m, line speed 3 m / min). Went. The wetness index on both sides was 64 mN / m.

- the above-mentioned anchor coating agent (B-2) is applied to both surfaces subjected to corona discharge treatment using a film Mayer bar type coating apparatus so that the dry film thickness becomes 0.5 ⁇ m.

- An adhesive poly (meth) acrylimide film was obtained.

- the measurement test of the total light transmittance, haze, surface appearance, and color tone was done by the said method.

- the total light transmittance was 92%

- the haze was 0.2%

- the surface appearance was ⁇ on both sides

- the yellowness index was 0.5.

- a die-type coating apparatus is used to dry the above-mentioned (C-2) as a touch surface side hard coat forming coating material.

- the test on the surface of the hard coat is described in the table column as “evaluation result of touch surface side hard coat / evaluation result of print surface side hard coat”.

- the pencil hardness of the touch surface side hard coat is 9H

- the pencil hardness of the print surface side hard coat is 9H, so it is described as “9H / 9H”.

- “ ⁇ ” means that the test is omitted because the characteristic is not required on the touch surface side or the print surface side.

- Example 17 All except that the paint (C-4) was used in place of the paint (C-3) as a paint for forming the printing surface side hard coat on the easily adhesive film obtained in Example 16 A hard coat laminated film was obtained in the same manner as in Example 16. The physical property measurement / evaluation results are shown in Table 4.

- Example 18 All except that the paint (C-5) was used in place of the paint (C-3) as a paint for forming the print side hard coat on the easy-adhesive film obtained in Example 16 A hard coat laminated film was obtained in the same manner as in Example 16. The physical property measurement / evaluation results are shown in Table 4.

- Example 19 A hard coat laminated film was obtained in the same manner as in Example 16 except that the dry thickness of the touch surface side hard coat was 20 ⁇ m and the dry thickness of the print side hard coat was 15 ⁇ m.

- the physical property measurement / evaluation results are shown in Table 4.

- Examples 1 to 5 and 7 to 19 according to the present invention exhibited physical properties suitable as a display face plate of a touch panel and a base material of a transparent conductive substrate.

- Comparative Example 1 was slightly inferior in total light transmittance and surface appearance was not sufficiently good.

- Comparative Example 2 was inferior in total light transmittance and transparency.

- Examples 21-24 Film formation was performed in the same manner as in Example 20 except that the mirror roll surface temperature and the mirror belt surface temperature were changed as shown in Table 5.

- the physical property measurement / evaluation results are shown in Table 5.

- Comparative Examples 5 and 6 Film formation was performed in the same manner as in Example 20 except that the mirror roll surface temperature and the mirror belt surface temperature were changed as shown in Table 6.

- Table 6 shows the physical property measurement / evaluation results.

- Comparative Examples 7 and 8 Except that the mirror surface temperature of Comparative Example 7 was changed to 220 ° C., everything was the same as Example 20, and that of Comparative Example 8 was the same as Example 20 except that the mirror belt surface temperature was changed to 220 ° C. Then, film formation was performed. In any of these examples, the appearance was remarkably poor due to peeling marks accompanying peeling with a mirror roll. Therefore, physical properties other than the appearance could not be evaluated (not shown in the table).

- the obtained film was subjected to measurement tests for surface appearance, total light transmittance, haze, pencil hardness (200 g load), color tone, coefficient of linear expansion (thermal dimensional stability), and retardation by the above methods. The results are shown in Table 5.

- Example 26 A film was formed in the same manner as in Example 22 except that the take-up speed was 2.6 m / min and the film thickness was changed to 550 ⁇ m. Table 6 shows the physical property measurement / evaluation results.

- Example 27 A film was formed in the same manner as in Example 25 except that the take-up speed was 2.6 m / min and the film thickness was changed to 550 ⁇ m. Table 6 shows the physical property measurement / evaluation results.

- the poly (meth) acrylimide film obtained by the production method of the present invention is excellent in surface smoothness, transparency and appearance, has high surface hardness, excellent color tone, heat resistance and dimensional stability, and also has low retardation. I understood that.

- Comparative Examples 5 and 6 had insufficient surface conditions, and transparency, dimensional stability, and retardation were also inferior to those of the Examples.

- the comparative examples 7 and 8 had the peeling trace accompanying peeling with a mirror surface on a film, and the external appearance was remarkably bad.

- a film (A) was formed.

- the processing amount 167W ⁇ min / m 2 discharge power 500 W, length 1m discharge electrode, line speed 3m / min

- the paint diluted to a concentration of 1% by mass with a “mixed solvent” is applied using a film Mayer bar type coating device so that the dry film thickness becomes 0.5 ⁇ m, and an easily adhesive poly (meta ) An acrylic imide film was obtained.

- the measurement test of the surface appearance, the total light transmittance, haze, and color tone was done by the said method.

- the paint (C-1) was applied to the easy-adhesion surface of the easy-adhesive poly (meth) acrylimide film using a die-type coating apparatus so that the dry thickness was 25 ⁇ m.

- a hard coat laminated film was obtained.

- Reference examples 3-8 Corona discharge treatment, easy-adhesive poly (meth) acrylimide film, and hard coat, all in the same manner as in Example 28 except that those shown in Table 8 were used instead of the anchor coat agent of (B-1) above. Formation of laminated films and measurement of their physical properties were performed. The results are shown in Table 8.

- Examples 32-34 Except that the dry thickness of the hard coat formed on the easy-adhesive film obtained in Example 28 was changed to the values shown in Table 9, all the same as in Example 28, corona discharge treatment, easy-adhesive poly (meta ) Formation of acrylic imide film and hard coat laminate film, and measurement of physical properties of the hard coat laminate film. The results are shown in Table 9.

- the examples of the present invention were found to be excellent in appearance, transparency, color tone, pencil hardness, adhesion to the hard coat, and dimensional stability.

- a silane coupling agent having an amino group is not used as an anchor coating agent, and other silane couplings are used instead.

- adhesion to the hard coat was inferior to that of the Examples.

- Example 35 Corona discharge treatment was performed on both surfaces of the film (A) under the conditions of a throughput of 167 W ⁇ min / m 2 (discharge power 500 W, discharge electrode length 1 m, line speed 3 m / min). The wetness index on both sides was 64 mN / m.

- the coating solution diluted to a concentration of 1% by mass with a “mixed solvent” is applied to a dry film thickness of 0.5 ⁇ m using a film Mayer bar type coating device.