JP5579358B2 - 頑丈なシャロー・トレンチ分離構造およびシャロー・トレンチ分離構造を形成する方法 - Google Patents

頑丈なシャロー・トレンチ分離構造およびシャロー・トレンチ分離構造を形成する方法 Download PDFInfo

- Publication number

- JP5579358B2 JP5579358B2 JP2006345124A JP2006345124A JP5579358B2 JP 5579358 B2 JP5579358 B2 JP 5579358B2 JP 2006345124 A JP2006345124 A JP 2006345124A JP 2006345124 A JP2006345124 A JP 2006345124A JP 5579358 B2 JP5579358 B2 JP 5579358B2

- Authority

- JP

- Japan

- Prior art keywords

- dielectric material

- conformal

- isolation structure

- semiconductor layer

- depositing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H10P50/283—

-

- H10W10/011—

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3105—After-treatment

- H01L21/311—Etching the insulating layers by chemical or physical means

- H01L21/31105—Etching inorganic layers

- H01L21/31111—Etching inorganic layers by chemical means

- H01L21/31116—Etching inorganic layers by chemical means by dry-etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/76—Making of isolation regions between components

- H01L21/762—Dielectric regions, e.g. EPIC dielectric isolation, LOCOS; Trench refilling techniques, SOI technology, use of channel stoppers

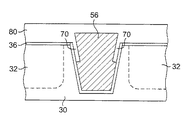

- H01L21/76224—Dielectric regions, e.g. EPIC dielectric isolation, LOCOS; Trench refilling techniques, SOI technology, use of channel stoppers using trench refilling with dielectric materials

- H01L21/76232—Dielectric regions, e.g. EPIC dielectric isolation, LOCOS; Trench refilling techniques, SOI technology, use of channel stoppers using trench refilling with dielectric materials of trenches having a shape other than rectangular or V-shape, e.g. rounded corners, oblique or rounded trench walls

-

- H10W10/0145—

-

- H10W10/10—

-

- H10W10/17—

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02123—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon

- H01L21/02126—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material containing Si, O, and at least one of H, N, C, F, or other non-metal elements, e.g. SiOC, SiOC:H or SiONC

- H01L21/0214—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material containing Si, O, and at least one of H, N, C, F, or other non-metal elements, e.g. SiOC, SiOC:H or SiONC the material being a silicon oxynitride, e.g. SiON or SiON:H

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02123—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon

- H01L21/02164—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material being a silicon oxide, e.g. SiO2

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02123—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon

- H01L21/02167—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material being a silicon carbide not containing oxygen, e.g. SiC, SiC:H or silicon carbonitrides

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02123—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon

- H01L21/0217—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material being a silicon nitride not containing oxygen, e.g. SixNy or SixByNz

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02225—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer

- H01L21/0226—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process

- H01L21/02263—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase

- H01L21/02271—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase deposition by decomposition or reaction of gaseous or vapour phase compounds, i.e. chemical vapour deposition

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02225—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer

- H01L21/0226—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process

- H01L21/02263—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase

- H01L21/02271—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase deposition by decomposition or reaction of gaseous or vapour phase compounds, i.e. chemical vapour deposition

- H01L21/02274—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase deposition by decomposition or reaction of gaseous or vapour phase compounds, i.e. chemical vapour deposition in the presence of a plasma [PECVD]

-

- H10P14/6334—

-

- H10P14/6336—

-

- H10P14/6905—

-

- H10P14/69215—

-

- H10P14/6927—

-

- H10P14/69433—

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Physics & Mathematics (AREA)

- Power Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Element Separation (AREA)

- Formation Of Insulating Films (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/321,206 | 2005-12-29 | ||

| US11/321,206 US7514336B2 (en) | 2005-12-29 | 2005-12-29 | Robust shallow trench isolation structures and a method for forming shallow trench isolation structures |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007184588A JP2007184588A (ja) | 2007-07-19 |

| JP2007184588A5 JP2007184588A5 (enExample) | 2011-01-13 |

| JP5579358B2 true JP5579358B2 (ja) | 2014-08-27 |

Family

ID=38068283

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006345124A Active JP5579358B2 (ja) | 2005-12-29 | 2006-12-22 | 頑丈なシャロー・トレンチ分離構造およびシャロー・トレンチ分離構造を形成する方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US7514336B2 (enExample) |

| EP (1) | EP1806780A3 (enExample) |

| JP (1) | JP5579358B2 (enExample) |

| KR (1) | KR101292025B1 (enExample) |

| CN (1) | CN100501968C (enExample) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7514336B2 (en) * | 2005-12-29 | 2009-04-07 | Agere Systems Inc. | Robust shallow trench isolation structures and a method for forming shallow trench isolation structures |

| US20110244683A1 (en) * | 2010-04-01 | 2011-10-06 | Michiaki Sano | Fabricating Voids Using Slurry Protect Coat Before Chemical-Mechanical Polishing |

| CN103531519B (zh) * | 2012-07-02 | 2016-03-23 | 中芯国际集成电路制造(上海)有限公司 | 半导体结构及其形成方法 |

| US9768055B2 (en) | 2012-08-21 | 2017-09-19 | Stmicroelectronics, Inc. | Isolation regions for SOI devices |

| US10468529B2 (en) | 2017-07-11 | 2019-11-05 | Taiwan Semiconductor Manufacturing Co., Ltd. | Structure and formation method of semiconductor device structure with etch stop layer |

| KR102661930B1 (ko) | 2018-08-13 | 2024-04-29 | 삼성전자주식회사 | 집적회로 소자 |

| CN109273532B (zh) * | 2018-09-12 | 2022-03-11 | 上海华力微电子有限公司 | 应用于高压电路防静电保护的无回滞效应硅控整流器 |

| CN116053211A (zh) * | 2022-12-30 | 2023-05-02 | 联合微电子中心有限责任公司 | 一种防止源漏区漏电的结构及其制备方法 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08330410A (ja) * | 1995-05-31 | 1996-12-13 | Sony Corp | 素子分離方法、素子分離構造、及び半導体装置 |

| TW388100B (en) * | 1997-02-18 | 2000-04-21 | Hitachi Ulsi Eng Corp | Semiconductor deivce and process for producing the same |

| US6228741B1 (en) * | 1998-01-13 | 2001-05-08 | Texas Instruments Incorporated | Method for trench isolation of semiconductor devices |

| WO1999044223A2 (en) * | 1998-02-27 | 1999-09-02 | Lsi Logic Corporation | Process of shallow trench isolating active devices to avoid sub-threshold kinks arising from corner effects without additional processing |

| KR100280107B1 (ko) * | 1998-05-07 | 2001-03-02 | 윤종용 | 트렌치 격리 형성 방법 |

| KR100286127B1 (ko) * | 1998-06-24 | 2001-04-16 | 윤종용 | 반도체 장치의 트렌치 격리 형성 방법 |

| TW398053B (en) * | 1998-07-31 | 2000-07-11 | United Microelectronics Corp | Manufacturing of shallow trench isolation |

| US6319794B1 (en) * | 1998-10-14 | 2001-11-20 | International Business Machines Corporation | Structure and method for producing low leakage isolation devices |

| JP2000223704A (ja) * | 1999-01-29 | 2000-08-11 | Sony Corp | 半導体装置およびその製造方法 |

| US6255194B1 (en) * | 1999-06-03 | 2001-07-03 | Samsung Electronics Co., Ltd. | Trench isolation method |

| US6500729B1 (en) * | 2000-06-02 | 2002-12-31 | Agere Systems Guardian Corp. | Method for reducing dishing related issues during the formation of shallow trench isolation structures |

| US6921947B2 (en) * | 2000-12-15 | 2005-07-26 | Renesas Technology Corp. | Semiconductor device having recessed isolation insulation film |

| KR100568100B1 (ko) * | 2001-03-05 | 2006-04-05 | 삼성전자주식회사 | 트렌치형 소자 분리막 형성 방법 |

| JP2003151956A (ja) * | 2001-11-19 | 2003-05-23 | Sony Corp | 半導体装置製造工程における窒化シリコン膜のエッチング方法 |

| TW540135B (en) * | 2002-04-24 | 2003-07-01 | Nanya Technology Corp | Method of forming shallow trench isolation region |

| KR20040002147A (ko) * | 2002-06-29 | 2004-01-07 | 주식회사 하이닉스반도체 | 반도체 소자의 소자분리막 형성방법 |

| JP2004311487A (ja) * | 2003-04-02 | 2004-11-04 | Hitachi Ltd | 半導体装置の製造方法 |

| KR100505419B1 (ko) * | 2003-04-23 | 2005-08-04 | 주식회사 하이닉스반도체 | 반도체 소자의 소자분리막 제조방법 |

| JP2004363486A (ja) * | 2003-06-06 | 2004-12-24 | Renesas Technology Corp | トレンチ分離を有する半導体装置およびその製造方法 |

| JP2005166700A (ja) * | 2003-11-28 | 2005-06-23 | Toshiba Corp | 半導体装置及びその製造方法 |

| KR100538811B1 (ko) * | 2003-12-29 | 2005-12-23 | 주식회사 하이닉스반도체 | 반도체 소자의 제조방법 |

| US7514336B2 (en) | 2005-12-29 | 2009-04-07 | Agere Systems Inc. | Robust shallow trench isolation structures and a method for forming shallow trench isolation structures |

-

2005

- 2005-12-29 US US11/321,206 patent/US7514336B2/en not_active Expired - Fee Related

-

2006

- 2006-09-06 EP EP06254630A patent/EP1806780A3/en not_active Withdrawn

- 2006-09-13 CN CNB2006101542012A patent/CN100501968C/zh not_active Expired - Fee Related

- 2006-12-22 JP JP2006345124A patent/JP5579358B2/ja active Active

- 2006-12-29 KR KR1020060137758A patent/KR101292025B1/ko not_active Expired - Fee Related

-

2009

- 2009-01-21 US US12/356,600 patent/US8022481B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US8022481B2 (en) | 2011-09-20 |

| KR20070072408A (ko) | 2007-07-04 |

| US20090127651A1 (en) | 2009-05-21 |

| JP2007184588A (ja) | 2007-07-19 |

| CN1992194A (zh) | 2007-07-04 |

| CN100501968C (zh) | 2009-06-17 |

| EP1806780A2 (en) | 2007-07-11 |

| US7514336B2 (en) | 2009-04-07 |

| KR101292025B1 (ko) | 2013-08-01 |

| EP1806780A3 (en) | 2011-06-01 |

| US20070152294A1 (en) | 2007-07-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7906407B2 (en) | Shallow trench isolation structures and a method for forming shallow trench isolation structures | |

| US8022481B2 (en) | Robust shallow trench isolation structures and a method for forming shallow trench isolation structures | |

| CN107342259A (zh) | 半导体装置的形成方法 | |

| US6727150B2 (en) | Methods of forming trench isolation within a semiconductor substrate including, Tshaped trench with spacers | |

| KR100845103B1 (ko) | 반도체소자의 제조방법 | |

| JP4401156B2 (ja) | 半導体素子の製造方法 | |

| KR100935760B1 (ko) | 반도체 소자의 제조 방법 | |

| KR100932336B1 (ko) | 플래시 메모리 소자의 소자 분리막 형성 방법 | |

| KR100831671B1 (ko) | 반도체 소자의 소자 분리막 형성 방법 | |

| KR100474863B1 (ko) | 반도체 소자의 소자 분리막 형성 방법 | |

| KR100923760B1 (ko) | 반도체 소자의 소자분리막 형성방법 | |

| KR100552852B1 (ko) | 얕은 트렌치 소자 분리 제조 방법 | |

| KR100519517B1 (ko) | 반도체 소자의 소자 분리막 형성 방법 | |

| KR100763679B1 (ko) | 반도체 소자의 포토레지스트 패턴 제거 방법 | |

| KR20060075402A (ko) | 반도체 소자의 소자 분리막 형성 방법 | |

| KR100905163B1 (ko) | 반도체소자의 제조방법 | |

| KR100984854B1 (ko) | 반도체 소자의 소자분리막 형성방법 | |

| KR100967672B1 (ko) | 반도체 소자의 얕은 트랜치 소자분리막 형성방법 | |

| KR20050014166A (ko) | 반도체소자의 제조방법 | |

| KR20040050554A (ko) | 반도체 소자의 소자 분리막 형성 방법 | |

| KR20040001544A (ko) | 반도체 소자의 소자분리막 형성방법 | |

| KR20040042562A (ko) | 얕은 트렌치 격리 공정 | |

| KR20010065187A (ko) | 반도체 소자의 패턴 단차 완화 방법 | |

| JP2002313906A (ja) | 半導体装置の製造方法及び半導体装置 | |

| KR20100073463A (ko) | Mim 커패시터 형성 방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091130 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20091130 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101115 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120911 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121025 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130117 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130822 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20131122 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20131127 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131220 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20140227 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140624 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140709 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5579358 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20140807 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20140812 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D02 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |