JP2005031684A - プラズマディスプレイパネルの接続構造及び接続方法 - Google Patents

プラズマディスプレイパネルの接続構造及び接続方法 Download PDFInfo

- Publication number

- JP2005031684A JP2005031684A JP2004203508A JP2004203508A JP2005031684A JP 2005031684 A JP2005031684 A JP 2005031684A JP 2004203508 A JP2004203508 A JP 2004203508A JP 2004203508 A JP2004203508 A JP 2004203508A JP 2005031684 A JP2005031684 A JP 2005031684A

- Authority

- JP

- Japan

- Prior art keywords

- electrode

- panel

- connection

- substrate

- plasma display

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034 method Methods 0.000 title claims abstract description 16

- 239000000758 substrate Substances 0.000 claims abstract description 105

- 239000003822 epoxy resin Substances 0.000 claims description 12

- 229920000647 polyepoxide Polymers 0.000 claims description 12

- 229920005989 resin Polymers 0.000 claims description 7

- 239000011347 resin Substances 0.000 claims description 7

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 claims description 6

- 239000000463 material Substances 0.000 claims description 6

- 239000011521 glass Substances 0.000 claims description 5

- 239000005011 phenolic resin Substances 0.000 claims description 3

- 229920002050 silicone resin Polymers 0.000 claims description 3

- 229920002803 thermoplastic polyurethane Polymers 0.000 claims description 3

- 239000010949 copper Substances 0.000 abstract description 31

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 abstract description 30

- 229910052802 copper Inorganic materials 0.000 abstract description 30

- 230000006835 compression Effects 0.000 abstract 1

- 238000007906 compression Methods 0.000 abstract 1

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 229920002379 silicone rubber Polymers 0.000 description 2

- 239000004945 silicone rubber Substances 0.000 description 2

- 238000013459 approach Methods 0.000 description 1

- 238000003491 array Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000017525 heat dissipation Effects 0.000 description 1

- 230000010365 information processing Effects 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J11/00—Gas-filled discharge tubes with alternating current induction of the discharge, e.g. alternating current plasma display panels [AC-PDP]; Gas-filled discharge tubes without any main electrode inside the vessel; Gas-filled discharge tubes with at least one main electrode outside the vessel

- H01J11/20—Constructional details

- H01J11/46—Connecting or feeding means, e.g. leading-in conductors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J11/00—Gas-filled discharge tubes with alternating current induction of the discharge, e.g. alternating current plasma display panels [AC-PDP]; Gas-filled discharge tubes without any main electrode inside the vessel; Gas-filled discharge tubes with at least one main electrode outside the vessel

- H01J11/10—AC-PDPs with at least one main electrode being out of contact with the plasma

- H01J11/12—AC-PDPs with at least one main electrode being out of contact with the plasma with main electrodes provided on both sides of the discharge space

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J11/00—Gas-filled discharge tubes with alternating current induction of the discharge, e.g. alternating current plasma display panels [AC-PDP]; Gas-filled discharge tubes without any main electrode inside the vessel; Gas-filled discharge tubes with at least one main electrode outside the vessel

- H01J11/20—Constructional details

- H01J11/22—Electrodes, e.g. special shape, material or configuration

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/50—Fixed connections

- H01R12/51—Fixed connections for rigid printed circuits or like structures

- H01R12/52—Fixed connections for rigid printed circuits or like structures connecting to other rigid printed circuits or like structures

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/7076—Coupling devices for connection between PCB and component, e.g. display

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/02—Contact members

- H01R13/22—Contacts for co-operating by abutting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/26—Connections in which at least one of the connecting parts has projections which bite into or engage the other connecting part in order to improve the contact

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/36—Assembling printed circuits with other printed circuits

- H05K3/361—Assembling flexible printed circuits with other printed circuits

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/73—Means for bonding being of different types provided for in two or more of groups H01L2224/10, H01L2224/18, H01L2224/26, H01L2224/34, H01L2224/42, H01L2224/50, H01L2224/63, H01L2224/71

- H01L2224/732—Location after the connecting process

- H01L2224/73201—Location after the connecting process on the same surface

- H01L2224/73203—Bump and layer connectors

- H01L2224/73204—Bump and layer connectors the bump connector being embedded into the layer connector

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/03—Conductive materials

- H05K2201/0332—Structure of the conductor

- H05K2201/0364—Conductor shape

- H05K2201/0367—Metallic bump or raised conductor not used as solder bump

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/30—Assembling printed circuits with electric components, e.g. with resistor

- H05K3/32—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits

- H05K3/321—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits by conductive adhesives

- H05K3/323—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits by conductive adhesives by applying an anisotropic conductive adhesive layer over an array of pads

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Devices For Indicating Variable Information By Combining Individual Elements (AREA)

- Gas-Filled Discharge Tubes (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR10-2003-0046330A KR100512992B1 (ko) | 2003-07-09 | 2003-07-09 | 플라즈마 디스플레이 패널의 접속 구조 및 방법 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005031684A true JP2005031684A (ja) | 2005-02-03 |

| JP2005031684A5 JP2005031684A5 (enExample) | 2007-08-23 |

Family

ID=33448367

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004203508A Pending JP2005031684A (ja) | 2003-07-09 | 2004-07-09 | プラズマディスプレイパネルの接続構造及び接続方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7211951B2 (enExample) |

| EP (1) | EP1496537B1 (enExample) |

| JP (1) | JP2005031684A (enExample) |

| KR (1) | KR100512992B1 (enExample) |

| CN (1) | CN100350542C (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006227622A (ja) * | 2005-02-17 | 2006-08-31 | Lg Electronics Inc | コネクターを含むプラズマディスプレイ装置 |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100715877B1 (ko) * | 2005-09-14 | 2007-05-08 | (주)아이디에스 | 요철형상의 커버레이 필름이 적층된 아웃터리드를 구비한연성회로기판 |

| JP5128773B2 (ja) * | 2006-01-23 | 2013-01-23 | 日本電気株式会社 | 液晶表示装置の製造方法 |

| KR100777732B1 (ko) * | 2006-03-02 | 2007-11-19 | 삼성에스디아이 주식회사 | 플라즈마 디스플레이 패널 |

| KR20090057719A (ko) * | 2007-12-03 | 2009-06-08 | 엘지전자 주식회사 | 플라즈마 디스플레이 장치 |

| TW201123377A (en) * | 2009-12-16 | 2011-07-01 | Raydium Semiconductor Corp | Electronic chip and substrate with void |

| US10172241B2 (en) * | 2013-09-13 | 2019-01-01 | Korea Advanced Institute Of Science And Technology | Method for packaging flexible device using holding wafer, and flexible device manufactured by the same |

| CN104754866B (zh) * | 2013-12-27 | 2019-01-04 | 昆山国显光电有限公司 | 柔性印刷电路板及其制造方法和平板显示器 |

| EP3035117A1 (fr) * | 2014-12-16 | 2016-06-22 | Gemalto Sa | Procédé de fabrication d'un dispositif d'affichage |

| KR102662413B1 (ko) * | 2017-12-29 | 2024-04-30 | 엘지디스플레이 주식회사 | 표시 패널용 전극 접속 구조 |

| KR20200145877A (ko) * | 2019-06-19 | 2020-12-31 | 삼성디스플레이 주식회사 | 표시 장치, 칩온 필름의 제조 장치, 및 칩온 필름의 제조 방법 |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5085297A (enExample) * | 1973-11-29 | 1975-07-09 | ||

| JPH05190612A (ja) * | 1992-01-14 | 1993-07-30 | Matsushita Electric Ind Co Ltd | 熱圧着方法および圧着用部材 |

| JPH09223762A (ja) * | 1996-01-17 | 1997-08-26 | Internatl Business Mach Corp <Ibm> | 表面実装コンポーネントを交換するコンピュータ・システムおよびソケット |

| JPH1116502A (ja) * | 1997-04-30 | 1999-01-22 | Matsushita Electric Ind Co Ltd | プラズマディスプレイパネルの電極接合方法 |

| JPH1140064A (ja) * | 1997-07-25 | 1999-02-12 | Hitachi Ltd | ガス放電型表示パネルおよびそれを用いた表示装置 |

| JPH11202792A (ja) * | 1998-01-19 | 1999-07-30 | Enplas Corp | 表示パネル検査用ソケット |

| JPH11273577A (ja) * | 1998-03-20 | 1999-10-08 | Dainippon Printing Co Ltd | プラズマディスプレイパネルの電極端子部 |

| JP2000269475A (ja) * | 1999-01-14 | 2000-09-29 | Sharp Corp | 二次元画像検出器およびアクティブマトリクス基板並びに表示装置 |

| JP2002108231A (ja) * | 2000-09-27 | 2002-04-10 | Fujitsu Ltd | 接続部材とマトリックス型表示装置 |

| JP2006276881A (ja) * | 1997-04-30 | 2006-10-12 | Matsushita Electric Ind Co Ltd | プラズマディスプレイパネルの製造方法 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2896458B2 (ja) * | 1996-09-02 | 1999-05-31 | 株式会社日立製作所 | フラットパネル表示装置 |

| US6086441A (en) * | 1997-04-30 | 2000-07-11 | Matsushita Electric Industrial Co., Ltd. | Method for connecting electrodes of plasma display panel |

| JP3705914B2 (ja) * | 1998-01-27 | 2005-10-12 | 三菱電機株式会社 | 面放電型プラズマディスプレイパネル及びその製造方法 |

| JP3259771B2 (ja) * | 1999-01-25 | 2002-02-25 | 日本電気株式会社 | プラズマディスプレイパネル |

| JP2001305570A (ja) * | 2000-04-24 | 2001-10-31 | Nec Corp | 表示パネルモジュール及びその製造方法 |

| JP4107787B2 (ja) | 2000-06-09 | 2008-06-25 | パイオニア株式会社 | プラズマディスプレイパネル及びその製造方法 |

-

2003

- 2003-07-09 KR KR10-2003-0046330A patent/KR100512992B1/ko not_active Expired - Fee Related

-

2004

- 2004-07-08 US US10/885,695 patent/US7211951B2/en not_active Expired - Fee Related

- 2004-07-09 JP JP2004203508A patent/JP2005031684A/ja active Pending

- 2004-07-09 CN CNB2004100900054A patent/CN100350542C/zh not_active Expired - Fee Related

- 2004-07-09 EP EP04254128A patent/EP1496537B1/en not_active Expired - Lifetime

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5085297A (enExample) * | 1973-11-29 | 1975-07-09 | ||

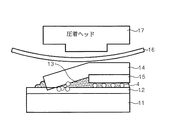

| JPH05190612A (ja) * | 1992-01-14 | 1993-07-30 | Matsushita Electric Ind Co Ltd | 熱圧着方法および圧着用部材 |

| JPH09223762A (ja) * | 1996-01-17 | 1997-08-26 | Internatl Business Mach Corp <Ibm> | 表面実装コンポーネントを交換するコンピュータ・システムおよびソケット |

| JPH1116502A (ja) * | 1997-04-30 | 1999-01-22 | Matsushita Electric Ind Co Ltd | プラズマディスプレイパネルの電極接合方法 |

| JP2006276881A (ja) * | 1997-04-30 | 2006-10-12 | Matsushita Electric Ind Co Ltd | プラズマディスプレイパネルの製造方法 |

| JPH1140064A (ja) * | 1997-07-25 | 1999-02-12 | Hitachi Ltd | ガス放電型表示パネルおよびそれを用いた表示装置 |

| JPH11202792A (ja) * | 1998-01-19 | 1999-07-30 | Enplas Corp | 表示パネル検査用ソケット |

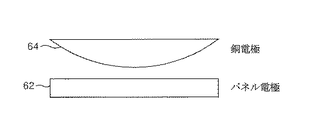

| JPH11273577A (ja) * | 1998-03-20 | 1999-10-08 | Dainippon Printing Co Ltd | プラズマディスプレイパネルの電極端子部 |

| JP2000269475A (ja) * | 1999-01-14 | 2000-09-29 | Sharp Corp | 二次元画像検出器およびアクティブマトリクス基板並びに表示装置 |

| JP2002108231A (ja) * | 2000-09-27 | 2002-04-10 | Fujitsu Ltd | 接続部材とマトリックス型表示装置 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006227622A (ja) * | 2005-02-17 | 2006-08-31 | Lg Electronics Inc | コネクターを含むプラズマディスプレイ装置 |

| US8011989B2 (en) | 2005-02-17 | 2011-09-06 | Lg Electronics Inc. | Method of making a plasma display panel with a novel connection structure |

Also Published As

| Publication number | Publication date |

|---|---|

| CN100350542C (zh) | 2007-11-21 |

| US7211951B2 (en) | 2007-05-01 |

| EP1496537B1 (en) | 2013-01-09 |

| EP1496537A2 (en) | 2005-01-12 |

| KR100512992B1 (ko) | 2005-09-05 |

| CN1599005A (zh) | 2005-03-23 |

| US20050006650A1 (en) | 2005-01-13 |

| EP1496537A3 (en) | 2007-07-25 |

| KR20050006496A (ko) | 2005-01-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7999341B2 (en) | Display driver integrated circuit device, film, and module | |

| EP2946643B1 (en) | Method and apparatus for coupling an active display portion and substrate | |

| KR101148467B1 (ko) | 전자종이 표시장치 | |

| CN101763186B (zh) | 触控面板 | |

| JP2003108017A (ja) | フラットパネル型表示装置 | |

| JP2005031684A (ja) | プラズマディスプレイパネルの接続構造及び接続方法 | |

| JP2005203745A (ja) | 駆動チップ及びこれを有する表示装置 | |

| CN109407358B (zh) | 一种显示面板的修复方法及显示面板 | |

| JP4174798B2 (ja) | 表示装置 | |

| CN111722745B (zh) | 显示装置 | |

| JP2002063958A (ja) | 電気光学装置および電子機器 | |

| KR20010012979A (ko) | 압착 접속 기판, 액정장치 및 전자기기 | |

| JP5068953B2 (ja) | コネクターを含むプラズマディスプレイ装置 | |

| JP2002344097A (ja) | 実装用基板及びこの基板を有する表示装置 | |

| CN100493313C (zh) | 平面显示器 | |

| KR100762700B1 (ko) | 테이프 캐리어 패키지가 구비된 평판표시장치 | |

| KR20040041937A (ko) | 착탈이 용이한 표시패널의 단자부 접속구조를 갖는 평판표시소자 | |

| TW200947028A (en) | Liquid crystal display panel | |

| JP4100315B2 (ja) | 電気光学装置の製造方法 | |

| KR100227840B1 (ko) | 액정 디스플레이 | |

| JP2006013007A (ja) | フレキシブル配線基板、電子機器およびその製造方法 | |

| JP2005252134A (ja) | フィルム基板の接合方法およびフィルム基板の接合構造 | |

| TWI311208B (en) | Flat display device | |

| CN116782689A (zh) | 一种显示面板、显示组件及电子设备 | |

| CN113169147A (zh) | 显示面板以及显示模组 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070709 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070709 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090724 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090811 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091111 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100511 |