KR20180097136A - 기판의 연마 장치 및 연마 방법 - Google Patents

기판의 연마 장치 및 연마 방법 Download PDFInfo

- Publication number

- KR20180097136A KR20180097136A KR1020180019296A KR20180019296A KR20180097136A KR 20180097136 A KR20180097136 A KR 20180097136A KR 1020180019296 A KR1020180019296 A KR 1020180019296A KR 20180019296 A KR20180019296 A KR 20180019296A KR 20180097136 A KR20180097136 A KR 20180097136A

- Authority

- KR

- South Korea

- Prior art keywords

- substrate

- polishing

- polishing pad

- movement

- driving mechanism

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000005498 polishing Methods 0.000 title claims abstract description 724

- 239000000758 substrate Substances 0.000 title claims abstract description 389

- 238000000034 method Methods 0.000 title claims description 40

- 230000007246 mechanism Effects 0.000 claims abstract description 104

- 238000012545 processing Methods 0.000 claims abstract description 71

- 238000004140 cleaning Methods 0.000 claims description 54

- 239000007788 liquid Substances 0.000 claims description 34

- 230000003750 conditioning effect Effects 0.000 claims description 29

- 238000009826 distribution Methods 0.000 claims description 19

- 238000003825 pressing Methods 0.000 claims description 15

- 238000001035 drying Methods 0.000 claims description 11

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 5

- 230000008859 change Effects 0.000 claims description 4

- 238000003754 machining Methods 0.000 claims description 4

- 238000001514 detection method Methods 0.000 description 23

- 238000007517 polishing process Methods 0.000 description 13

- 239000000463 material Substances 0.000 description 11

- 230000000694 effects Effects 0.000 description 8

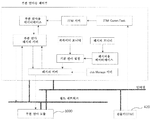

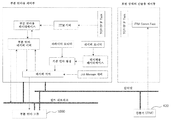

- 238000010586 diagram Methods 0.000 description 7

- 230000008569 process Effects 0.000 description 7

- 238000012546 transfer Methods 0.000 description 5

- 239000000523 sample Substances 0.000 description 4

- 239000002002 slurry Substances 0.000 description 4

- 229910003460 diamond Inorganic materials 0.000 description 3

- 239000010432 diamond Substances 0.000 description 3

- 239000003550 marker Substances 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000004065 semiconductor Substances 0.000 description 3

- 230000007723 transport mechanism Effects 0.000 description 3

- 238000011109 contamination Methods 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 238000009877 rendering Methods 0.000 description 2

- 238000001179 sorption measurement Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 230000002159 abnormal effect Effects 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000008094 contradictory effect Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000003303 reheating Methods 0.000 description 1

- 238000012958 reprocessing Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/005—Control means for lapping machines or devices

- B24B37/013—Devices or means for detecting lapping completion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

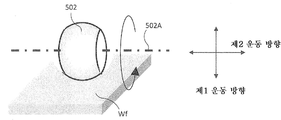

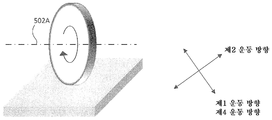

- B24B37/07—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67092—Apparatus for mechanical treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B21/00—Machines or devices using grinding or polishing belts; Accessories therefor

- B24B21/04—Machines or devices using grinding or polishing belts; Accessories therefor for grinding plane surfaces

- B24B21/12—Machines or devices using grinding or polishing belts; Accessories therefor for grinding plane surfaces involving a contact wheel or roller pressing the belt against the work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B27/00—Other grinding machines or devices

- B24B27/0084—Other grinding machines or devices the grinding wheel support being angularly adjustable

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/005—Control means for lapping machines or devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

- B24B37/07—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool

- B24B37/10—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool for single side lapping

- B24B37/105—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool for single side lapping the workpieces or work carriers being actively moved by a drive, e.g. in a combined rotary and translatory movement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

- B24B37/07—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool

- B24B37/10—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool for single side lapping

- B24B37/105—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool for single side lapping the workpieces or work carriers being actively moved by a drive, e.g. in a combined rotary and translatory movement

- B24B37/107—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool for single side lapping the workpieces or work carriers being actively moved by a drive, e.g. in a combined rotary and translatory movement in a rotary movement only, about an axis being stationary during lapping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/34—Accessories

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B53/00—Devices or means for dressing or conditioning abrasive surfaces

- B24B53/017—Devices or means for dressing, cleaning or otherwise conditioning lapping tools

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B57/00—Devices for feeding, applying, grading or recovering grinding, polishing or lapping agents

- B24B57/02—Devices for feeding, applying, grading or recovering grinding, polishing or lapping agents for feeding of fluid, sprayed, pulverised, or liquefied grinding, polishing or lapping agents

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02041—Cleaning

- H01L21/02043—Cleaning before device manufacture, i.e. Begin-Of-Line process

- H01L21/02052—Wet cleaning only

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/304—Mechanical treatment, e.g. grinding, polishing, cutting

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Physics & Mathematics (AREA)

- Power Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Constituent Portions Of Griding Lathes, Driving, Sensing And Control (AREA)

- Grinding-Machine Dressing And Accessory Apparatuses (AREA)

- Grinding And Polishing Of Tertiary Curved Surfaces And Surfaces With Complex Shapes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JPJP-P-2017-031243 | 2017-02-22 | ||

| JP2017031243A JP2018134710A (ja) | 2017-02-22 | 2017-02-22 | 基板の研磨装置および研磨方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20180097136A true KR20180097136A (ko) | 2018-08-30 |

Family

ID=63166818

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020180019296A Ceased KR20180097136A (ko) | 2017-02-22 | 2018-02-19 | 기판의 연마 장치 및 연마 방법 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20180236630A1 (enExample) |

| JP (1) | JP2018134710A (enExample) |

| KR (1) | KR20180097136A (enExample) |

| CN (1) | CN108453618A (enExample) |

| SG (1) | SG10201801373RA (enExample) |

| TW (1) | TW201900338A (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20200087674A (ko) * | 2019-01-11 | 2020-07-21 | 가부시키가이샤 에바라 세이사꾸쇼 | 기판 처리 장치 및 기판 처리 장치에서 부분 연마되어야 할 영역을 특정하는 방법 |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6884015B2 (ja) * | 2017-03-22 | 2021-06-09 | 株式会社荏原製作所 | 基板の研磨装置および研磨方法 |

| CN109227388A (zh) * | 2018-09-19 | 2019-01-18 | 大连理工大学 | 一种环抛机盘面修整系统及其工作方法 |

| US11235454B2 (en) * | 2019-01-14 | 2022-02-01 | Dynabrade, Inc. | Spring loaded adjustable head |

| JP7317532B2 (ja) * | 2019-03-19 | 2023-07-31 | キオクシア株式会社 | 研磨装置及び研磨方法 |

| TWI771668B (zh) * | 2019-04-18 | 2022-07-21 | 美商應用材料股份有限公司 | Cmp期間基於溫度的原位邊緣不對稱校正 |

| TWI826280B (zh) | 2019-11-22 | 2023-12-11 | 美商應用材料股份有限公司 | 在拋光墊中使用溝槽的晶圓邊緣不對稱校正 |

| JP7442314B2 (ja) * | 2019-12-24 | 2024-03-04 | 東京エレクトロン株式会社 | 基板処理装置、および基板処理方法 |

| JP7387471B2 (ja) * | 2020-02-05 | 2023-11-28 | 株式会社荏原製作所 | 基板処理装置および基板処理方法 |

| JP7341918B2 (ja) * | 2020-02-06 | 2023-09-11 | 株式会社荏原製作所 | 基板処理装置および基板処理方法 |

| CN111482891A (zh) * | 2020-04-20 | 2020-08-04 | 北京烁科精微电子装备有限公司 | 一种化学机械平坦化设备 |

| JP7530237B2 (ja) * | 2020-08-17 | 2024-08-07 | キオクシア株式会社 | 研磨装置および研磨方法 |

| WO2022187259A1 (en) | 2021-03-05 | 2022-09-09 | Applied Materials, Inc. | Roller for location-specific wafer polishing |

| JP7733487B2 (ja) * | 2021-07-07 | 2025-09-03 | 株式会社荏原製作所 | 研磨装置および研磨方法 |

| JP7764215B2 (ja) * | 2021-11-22 | 2025-11-05 | 株式会社ディスコ | クリープフィード研削装置 |

| CN114012605B (zh) * | 2022-01-05 | 2022-05-17 | 杭州众硅电子科技有限公司 | 一种抛光垫修整装置 |

| KR20250038724A (ko) * | 2022-07-14 | 2025-03-19 | 어플라이드 머티어리얼스, 인코포레이티드 | 페이스-업 연마에서의 두께 모니터링 |

| CN116460667B (zh) * | 2022-12-30 | 2023-11-07 | 北京创思工贸有限公司 | 氟化钙光学零件的加工方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150352686A1 (en) | 2012-02-14 | 2015-12-10 | Taiwan Semiconductor Manufacturing Co., Ltd. | Chemical mechanical polishing (cmp) platform for local profile control |

Family Cites Families (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3943666A (en) * | 1974-07-31 | 1976-03-16 | Dysan Corporation | Method and apparatus for burnishing flexible recording material |

| US4347689A (en) * | 1980-10-20 | 1982-09-07 | Verbatim Corporation | Method for burnishing |

| JPS59173555U (ja) * | 1984-01-17 | 1984-11-20 | 株式会社ノリタケカンパニーリミテド | 研削砥石を傾斜させた研削装置に用いられる傾斜フランジ |

| US4958463A (en) * | 1988-06-06 | 1990-09-25 | United Technologies Corporation | Optical surface quality improving arrangement |

| JPH033765A (ja) * | 1989-05-29 | 1991-01-09 | Sony Corp | 剛性基板の表面処理方法 |

| JPH04322964A (ja) * | 1991-04-22 | 1992-11-12 | Amada Washino Co Ltd | 研削制御装置 |

| JPH074750B2 (ja) * | 1992-12-03 | 1995-01-25 | 株式会社松田精機 | フイルム研磨材を用いた平面研磨装置 |

| JP3020800B2 (ja) * | 1994-05-16 | 2000-03-15 | 株式会社ノリタケカンパニーリミテド | 疵取り用研削装置 |

| JPH0811042A (ja) * | 1994-06-30 | 1996-01-16 | Nippondenso Co Ltd | 平面研削加工方法 |

| JPH0947947A (ja) * | 1994-08-30 | 1997-02-18 | Seiko Seiki Co Ltd | 研削装置、並びに研削方法、並びに半導体装置及び半導体基板の製造方法 |

| JPH08108360A (ja) * | 1994-10-11 | 1996-04-30 | Fuji Photo Film Co Ltd | ガラス基板の研磨装置 |

| JPH10329015A (ja) * | 1997-03-24 | 1998-12-15 | Canon Inc | 研磨装置および研磨方法 |

| JPH11285978A (ja) * | 1998-04-03 | 1999-10-19 | Ebara Corp | 砥石の保持構造及び研磨装置 |

| JP3652163B2 (ja) * | 1999-03-15 | 2005-05-25 | キヤノン株式会社 | 研磨方法 |

| JP2001353659A (ja) * | 2000-06-16 | 2001-12-25 | Okamoto Machine Tool Works Ltd | 研磨ウエハの研磨合否判定方法 |

| US6811680B2 (en) * | 2001-03-14 | 2004-11-02 | Applied Materials Inc. | Planarization of substrates using electrochemical mechanical polishing |

| JP2003282493A (ja) * | 2001-08-14 | 2003-10-03 | Sony Corp | 研磨装置および研磨方法 |

| US6875086B2 (en) * | 2003-01-10 | 2005-04-05 | Intel Corporation | Surface planarization |

| CN1822905A (zh) * | 2003-06-06 | 2006-08-23 | P.C.T.系统公司 | 用兆频声波能量处理基片的方法和设备 |

| JP2005177925A (ja) * | 2003-12-19 | 2005-07-07 | Olympus Corp | 研磨加工方法 |

| JP4406772B2 (ja) * | 2005-04-01 | 2010-02-03 | 株式会社サンシン | 板状部材表面傷修復装置 |

| JP2009190109A (ja) * | 2008-02-13 | 2009-08-27 | Lasertec Corp | 基板保持装置及び基板加工装置 |

| JP5369478B2 (ja) * | 2008-04-11 | 2013-12-18 | 株式会社ニコン | 研磨装置 |

| US9393669B2 (en) * | 2011-10-21 | 2016-07-19 | Strasbaugh | Systems and methods of processing substrates |

| CN103231303B (zh) * | 2013-05-15 | 2016-02-24 | 清华大学 | 化学机械抛光设备 |

-

2017

- 2017-02-22 JP JP2017031243A patent/JP2018134710A/ja active Pending

-

2018

- 2018-02-12 TW TW107104944A patent/TW201900338A/zh unknown

- 2018-02-14 CN CN201810151773.8A patent/CN108453618A/zh active Pending

- 2018-02-19 KR KR1020180019296A patent/KR20180097136A/ko not_active Ceased

- 2018-02-20 US US15/900,140 patent/US20180236630A1/en not_active Abandoned

- 2018-02-20 SG SG10201801373RA patent/SG10201801373RA/en unknown

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150352686A1 (en) | 2012-02-14 | 2015-12-10 | Taiwan Semiconductor Manufacturing Co., Ltd. | Chemical mechanical polishing (cmp) platform for local profile control |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20200087674A (ko) * | 2019-01-11 | 2020-07-21 | 가부시키가이샤 에바라 세이사꾸쇼 | 기판 처리 장치 및 기판 처리 장치에서 부분 연마되어야 할 영역을 특정하는 방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20180236630A1 (en) | 2018-08-23 |

| JP2018134710A (ja) | 2018-08-30 |

| TW201900338A (zh) | 2019-01-01 |

| CN108453618A (zh) | 2018-08-28 |

| SG10201801373RA (en) | 2018-09-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20180097136A (ko) | 기판의 연마 장치 및 연마 방법 | |

| JP2018134710A5 (enExample) | ||

| CN107186612B (zh) | 基板的研磨装置、研磨方法及记录介质 | |

| US11396082B2 (en) | Substrate holding device and substrate processing apparatus including the same | |

| JP6000643B2 (ja) | 被加工物の加工方法と、該加工方法によって加工された光学素子、金型及び半導体基板 | |

| KR102482181B1 (ko) | 기판의 연마 장치 및 연마 방법 | |

| CN110732943A (zh) | 用于对基板的周缘部进行研磨的研磨装置及研磨方法 | |

| CN113211299A (zh) | 基板处理装置及基板处理方法 | |

| JP6539467B2 (ja) | 研削加工装置 | |

| JP5654365B2 (ja) | 研削装置 | |

| JP6736728B2 (ja) | 研削加工装置 | |

| JP2019024053A (ja) | 基板処理装置、および基板に形成された切り欠きを検出する方法 | |

| JP7015139B2 (ja) | 被加工物の研削方法及び研削装置 | |

| KR20010040249A (ko) | 연마장치 및 그 장치를 사용한 반도체제조방법 | |

| TW202133996A (zh) | 基板處理裝置及基板處理方法及基板研磨方法 | |

| US20250114906A1 (en) | Method of processing workpiece | |

| JP2001239457A (ja) | ポリッシング装置 | |

| TW202446555A (zh) | 被加工物的研削方法 | |

| JP2024101818A (ja) | 研削方法 | |

| JP2025086509A (ja) | ウェーハの研削方法 | |

| JP2025126568A (ja) | 加工装置及び研磨面整形方法 | |

| JP2021126739A (ja) | 基板処理方法および基板処理装置 | |

| JP2022083110A (ja) | 異物除去装置及びチャックテーブルの洗浄方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 20180219 |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20201221 Comment text: Request for Examination of Application Patent event code: PA02011R01I Patent event date: 20180219 Comment text: Patent Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20220421 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20220629 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20220421 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |