KR101078552B1 - 촉매 재료 - Google Patents

촉매 재료 Download PDFInfo

- Publication number

- KR101078552B1 KR101078552B1 KR1020097019476A KR20097019476A KR101078552B1 KR 101078552 B1 KR101078552 B1 KR 101078552B1 KR 1020097019476 A KR1020097019476 A KR 1020097019476A KR 20097019476 A KR20097019476 A KR 20097019476A KR 101078552 B1 KR101078552 B1 KR 101078552B1

- Authority

- KR

- South Korea

- Prior art keywords

- catalyst

- silver

- alumina

- delafossite

- catalyst material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/38—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals

- B01J23/48—Silver or gold

- B01J23/50—Silver

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/944—Simultaneously removing carbon monoxide, hydrocarbons or carbon making use of oxidation catalysts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J21/00—Catalysts comprising the elements, oxides, or hydroxides of magnesium, boron, aluminium, carbon, silicon, titanium, zirconium, or hafnium

- B01J21/02—Boron or aluminium; Oxides or hydroxides thereof

- B01J21/04—Alumina

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/002—Mixed oxides other than spinels, e.g. perovskite

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

- B01J23/72—Copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/30—Catalysts, in general, characterised by their form or physical properties characterised by their physical properties

- B01J35/391—Physical properties of the active metal ingredient

- B01J35/395—Thickness of the active catalytic layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/50—Catalysts, in general, characterised by their form or physical properties characterised by their shape or configuration

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/50—Catalysts, in general, characterised by their form or physical properties characterised by their shape or configuration

- B01J35/56—Foraminous structures having flow-through passages or channels, e.g. grids or three-dimensional monoliths

- B01J35/57—Honeycombs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/70—Catalysts, in general, characterised by their form or physical properties characterised by their crystalline properties, e.g. semi-crystalline

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/0215—Coating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/024—Multiple impregnation or coating

- B01J37/0244—Coatings comprising several layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/08—Heat treatment

- B01J37/10—Heat treatment in the presence of water, e.g. steam

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/01—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics

- C04B35/44—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on aluminates

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B38/00—Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof

- C04B38/0006—Honeycomb structures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/28—Construction of catalytic reactors

- F01N3/2803—Construction of catalytic reactors characterised by structure, by material or by manufacturing of catalyst support

- F01N3/2807—Metal other than sintered metal

- F01N3/281—Metallic honeycomb monoliths made of stacked or rolled sheets, foils or plates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/10—Noble metals or compounds thereof

- B01D2255/104—Silver

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/209—Other metals

- B01D2255/2092—Aluminium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/90—Physical characteristics of catalysts

- B01D2255/92—Dimensions

- B01D2255/9202—Linear dimensions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2279/00—Filters adapted for separating dispersed particles from gases or vapours specially modified for specific uses

- B01D2279/30—Filters adapted for separating dispersed particles from gases or vapours specially modified for specific uses for treatment of exhaust gases from IC Engines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2235/00—Indexing scheme associated with group B01J35/00, related to the analysis techniques used to determine the catalysts form or properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2235/00—Indexing scheme associated with group B01J35/00, related to the analysis techniques used to determine the catalysts form or properties

- B01J2235/15—X-ray diffraction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2523/00—Constitutive chemical elements of heterogeneous catalysts

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2111/00—Mortars, concrete or artificial stone or mixtures to prepare them, characterised by specific function, property or use

- C04B2111/00474—Uses not provided for elsewhere in C04B2111/00

- C04B2111/0081—Uses not provided for elsewhere in C04B2111/00 as catalysts or catalyst carriers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2510/00—Surface coverings

- F01N2510/06—Surface coverings for exhaust purification, e.g. catalytic reaction

- F01N2510/068—Surface coverings for exhaust purification, e.g. catalytic reaction characterised by the distribution of the catalytic coatings

- F01N2510/0682—Surface coverings for exhaust purification, e.g. catalytic reaction characterised by the distribution of the catalytic coatings having a discontinuous, uneven or partially overlapping coating of catalytic material, e.g. higher amount of material upstream than downstream or vice versa

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/02—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust

- F01N3/021—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters

- F01N3/033—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters in combination with other devices

- F01N3/035—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters in combination with other devices with catalytic reactors

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Health & Medical Sciences (AREA)

- Combustion & Propulsion (AREA)

- Structural Engineering (AREA)

- Analytical Chemistry (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- General Chemical & Material Sciences (AREA)

- Biomedical Technology (AREA)

- Environmental & Geological Engineering (AREA)

- Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Toxicology (AREA)

- Catalysts (AREA)

- Exhaust Gas Treatment By Means Of Catalyst (AREA)

- Processes For Solid Components From Exhaust (AREA)

- Filtering Materials (AREA)

- Exhaust Gas After Treatment (AREA)

Abstract

Description

Claims (12)

- 탄소를 연소시키는데 사용되는 촉매 재료이며,은과 알루미나를 구성요소로 하는 촉매에 있어서 아령 형상의 O-Ag-O 구조를 갖고,상기 촉매 재료는 금속 은 또는 은 이온과 알루미나가 교호식으로 적층되어 있고, 그 적층 주기가 5nm 이하인 것을 특징으로 하는, 촉매 재료.

- 삭제

- 삭제

- 삭제

- 삭제

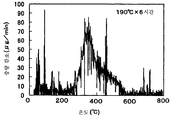

- 제1항에 있어서, 상기 촉매 재료의 라만 스펙트럼이 측정될 때, 200 내지 400㎝-1, 600 내지 800㎝-1, 1000 내지 1200㎝-1의 세 개 이상의 피크를 갖는, 촉매 재료

- 제6항에 있어서, 상기 촉매 재료가 델라포사이트-타입 AgAlO2인, 촉매 재료.

- 제1항에 있어서, 상기 촉매 재료는 Cu-Kα를 사용한 X선 회절에서 적어도 14.5°, 29.2°, 36.1°, 37.2° 및 41.6°에 회절 피크를 갖는 3R 대칭성을 구비한 X선 회절 스펙트럼을 갖는, 촉매 재료.

- 제1항 또는 제6항에 있어서, 상기 알루미나는 Ag-β 알루미나인, 촉매 재료.

- 삭제

- 삭제

- 제1항, 제6항 내지 제8항 중 어느 한 항에 있어서, 알루미나에 대한 은의 원소비가 0.25 이상인, 촉매 재료.

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007072627 | 2007-03-20 | ||

| JPJP-P-2007-072627 | 2007-03-20 | ||

| JP2007284949 | 2007-11-01 | ||

| JPJP-P-2007-284949 | 2007-11-01 | ||

| JPJP-P-2008-038489 | 2008-02-20 | ||

| JP2008038489 | 2008-02-20 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20090115872A KR20090115872A (ko) | 2009-11-09 |

| KR101078552B1 true KR101078552B1 (ko) | 2011-11-01 |

Family

ID=39808164

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020097019476A Expired - Fee Related KR101078552B1 (ko) | 2007-03-20 | 2008-03-19 | 촉매 재료 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US8501662B2 (ko) |

| EP (1) | EP2127730B1 (ko) |

| JP (1) | JP4992773B2 (ko) |

| KR (1) | KR101078552B1 (ko) |

| CN (1) | CN101636221B (ko) |

| WO (1) | WO2008120582A1 (ko) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009219971A (ja) * | 2007-03-20 | 2009-10-01 | Denso Corp | セラミックハニカム構造体 |

| JP2009219972A (ja) * | 2007-03-20 | 2009-10-01 | Denso Corp | 触媒材料の製造方法 |

| JP5051093B2 (ja) * | 2008-10-14 | 2012-10-17 | 株式会社デンソー | 触媒担持体の製造方法 |

| JP5434474B2 (ja) * | 2009-10-26 | 2014-03-05 | 株式会社デンソー | 触媒構造体の製造方法 |

| JP5545167B2 (ja) * | 2010-10-21 | 2014-07-09 | 株式会社デンソー | 触媒材料およびその製造方法 |

| CN103619439B (zh) * | 2011-07-01 | 2015-08-19 | 丰田自动车株式会社 | 用于内燃机的排气净化系统 |

| CN103566920B (zh) | 2012-08-01 | 2016-05-25 | 通用电气公司 | 物质和使用其的排气装置及方法 |

| JP6281439B2 (ja) * | 2014-08-04 | 2018-02-21 | 株式会社デンソー | 排ガス浄化フィルタ及びその製造方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000027637A (ja) * | 1998-07-10 | 2000-01-25 | Mitsubishi Motors Corp | 燃焼排ガス用NOx還元システム |

Family Cites Families (50)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3974255A (en) | 1973-03-12 | 1976-08-10 | Atlantic Richfield Company | Method for treatment of engine exhaust gases |

| JPS5067294A (ko) | 1973-10-19 | 1975-06-05 | ||

| JPS5095188A (ko) | 1973-12-27 | 1975-07-29 | ||

| JPS58128128A (ja) * | 1982-01-27 | 1983-07-30 | Toyota Motor Corp | 内燃機関の排出ガス浄化用フイルタ |

| JPS6186944A (ja) * | 1984-10-02 | 1986-05-02 | Matsushita Electric Ind Co Ltd | 排ガス浄化用触媒体 |

| JPS6220613A (ja) * | 1985-07-19 | 1987-01-29 | Cataler Kogyo Kk | パテイキユレ−ト除去用触媒フイルタ |

| JPS6320028A (ja) | 1986-07-12 | 1988-01-27 | Nissan Motor Co Ltd | 排ガス浄化用触媒 |

| JPH02261511A (ja) * | 1989-03-31 | 1990-10-24 | Komatsu Ltd | ディーゼル排気中の微粒子除去用触媒及びそのフィルタ |

| JP2968615B2 (ja) | 1991-06-25 | 1999-10-25 | 株式会社神戸製鋼所 | ボルトの自動締緩方法 |

| JP2506598B2 (ja) | 1992-03-12 | 1996-06-12 | 工業技術院長 | 窒素酸化物の除去方法 |

| JPH08173806A (ja) | 1994-12-26 | 1996-07-09 | Nissan Motor Co Ltd | 排気ガス浄化用触媒及びその製造方法 |

| US5834395A (en) | 1995-03-24 | 1998-11-10 | Next Generation Catalyst Research Institute, Co., Ltd. | Catalyst for controlling emissions |

| JP3453239B2 (ja) * | 1995-08-18 | 2003-10-06 | 財団法人石油産業活性化センター | 窒素酸化物接触還元用触媒 |

| DE69730764T2 (de) * | 1996-02-08 | 2006-01-19 | Sakai Chemical Industry Co., Ltd., Sakai | Katalysator und Verfahren zur katalytischen Reduzierung von Stickstoffoxiden |

| JP3777696B2 (ja) | 1997-02-07 | 2006-05-24 | トヨタ自動車株式会社 | 金属微粒子担持酸化物触媒 |

| JPH11123330A (ja) | 1997-08-20 | 1999-05-11 | Hino Motors Ltd | 排ガス浄化触媒及びその製法 |

| JPH11169717A (ja) | 1997-12-09 | 1999-06-29 | Tokyo Gas Co Ltd | 希薄燃焼エンジン用触媒 |

| JPH11200849A (ja) * | 1998-01-08 | 1999-07-27 | Mitsubishi Motors Corp | エンジンの排気ガス浄化装置 |

| JP2000015097A (ja) | 1998-06-30 | 2000-01-18 | Toyota Motor Corp | 触媒の製造方法 |

| JP2000025548A (ja) | 1998-07-16 | 2000-01-25 | Tokai Rika Co Ltd | エアバッグ装置 |

| JP2000350933A (ja) | 1999-06-11 | 2000-12-19 | Suzuki Motor Corp | 排気ガス浄化触媒およびその製造方法 |

| US6314722B1 (en) | 1999-10-06 | 2001-11-13 | Matros Technologies, Inc. | Method and apparatus for emission control |

| JP3736242B2 (ja) | 1999-12-02 | 2006-01-18 | 松下電器産業株式会社 | 排ガス浄化材、及びその製造方法 |

| JP4540785B2 (ja) * | 2000-01-11 | 2010-09-08 | 日揮触媒化成株式会社 | 排ガス浄化用触媒成型体 |

| US6606856B1 (en) | 2000-03-03 | 2003-08-19 | The Lubrizol Corporation | Process for reducing pollutants from the exhaust of a diesel engine |

| JP3494114B2 (ja) | 2000-03-28 | 2004-02-03 | トヨタ自動車株式会社 | 排気ガス浄化方法および排気ガス浄化装置 |

| ATE296160T1 (de) | 2000-04-11 | 2005-06-15 | Accentus Plc | Plasmaunterstützte gasbehandlung |

| GB0020287D0 (en) * | 2000-08-17 | 2000-10-04 | Aea Technology Plc | The catalytic treatment of gases |

| JP2002255548A (ja) | 2001-02-26 | 2002-09-11 | Japan Science & Technology Corp | 混合層積層不整結晶構造デラフォサイト型酸化物とその製造方法 |

| JP2002370030A (ja) * | 2001-06-13 | 2002-12-24 | Sumitomo Metal Mining Co Ltd | 排ガス浄化用触媒およびこれを使用する排ガス浄化方法 |

| JP2002370032A (ja) | 2001-06-13 | 2002-12-24 | Sumitomo Metal Mining Co Ltd | 排ガス浄化用触媒、並びにそれを使用する触媒成形体、触媒被覆構造体及び排ガス浄化方法 |

| JP2004066106A (ja) | 2002-08-06 | 2004-03-04 | Hino Motors Ltd | 排気浄化装置 |

| JP2005009454A (ja) | 2003-06-20 | 2005-01-13 | Tokyo Yogyo Co Ltd | 排ガス浄化用フィルタ |

| JP2005007360A (ja) * | 2003-06-20 | 2005-01-13 | Tokyo Yogyo Co Ltd | 排ガス浄化用フィルタ |

| JP2005097642A (ja) | 2003-09-22 | 2005-04-14 | Tanaka Kikinzoku Kogyo Kk | 貴金属−金属酸化物複合クラスター |

| US20050135977A1 (en) | 2003-12-19 | 2005-06-23 | Caterpillar Inc. | Multi-part catalyst system for exhaust treatment elements |

| US7541010B2 (en) * | 2003-12-19 | 2009-06-02 | Caterpillar Inc. | Silver doped catalysts for treatment of exhaust |

| US7146802B2 (en) | 2004-10-07 | 2006-12-12 | General Motors Corporation | Reducing NOx emissions with a staged catalyst |

| JP4525909B2 (ja) | 2004-10-28 | 2010-08-18 | 戸田工業株式会社 | 水性ガスシフト反応用触媒及びその製造方法、並びに水性ガスの製造方法 |

| JP2006239544A (ja) | 2005-03-02 | 2006-09-14 | Denso Corp | 触媒体およびその製造方法 |

| JP4265561B2 (ja) | 2005-04-04 | 2009-05-20 | 株式会社デンソー | 自動車の排ガス浄化用触媒体 |

| JP4739870B2 (ja) | 2005-09-05 | 2011-08-03 | アイシン精機株式会社 | サングラス検出装置及び顔中心位置検出装置 |

| JP2007196135A (ja) * | 2006-01-26 | 2007-08-09 | Honda Motor Co Ltd | 排ガス浄化触媒及びその製造方法 |

| JP5085176B2 (ja) | 2006-04-07 | 2012-11-28 | 本田技研工業株式会社 | 排ガス浄化触媒および排ガス浄化装置 |

| JP4989096B2 (ja) | 2006-04-14 | 2012-08-01 | ケイミュー株式会社 | 屋根の棟役物及び屋根の棟構造 |

| JP2008038489A (ja) | 2006-08-07 | 2008-02-21 | Calsonic Kansei Corp | ドア開閉アシスト装置 |

| JP4828358B2 (ja) | 2006-09-04 | 2011-11-30 | カヤバ工業株式会社 | 運行管理装置 |

| JP5095188B2 (ja) | 2006-11-28 | 2012-12-12 | 株式会社ブラザーエンタープライズ | 球発射装置 |

| JP2008229608A (ja) * | 2007-11-01 | 2008-10-02 | Denso Corp | 触媒材料及びセラミックハニカム構造体 |

| JP5067294B2 (ja) | 2008-07-17 | 2012-11-07 | パナソニック株式会社 | 電波受信装置 |

-

2008

- 2008-03-14 JP JP2008065361A patent/JP4992773B2/ja not_active Expired - Fee Related

- 2008-03-19 KR KR1020097019476A patent/KR101078552B1/ko not_active Expired - Fee Related

- 2008-03-19 US US12/530,910 patent/US8501662B2/en not_active Expired - Fee Related

- 2008-03-19 WO PCT/JP2008/055103 patent/WO2008120582A1/ja not_active Ceased

- 2008-03-19 CN CN2008800089234A patent/CN101636221B/zh not_active Expired - Fee Related

- 2008-03-19 EP EP08722478.8A patent/EP2127730B1/en not_active Not-in-force

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000027637A (ja) * | 1998-07-10 | 2000-01-25 | Mitsubishi Motors Corp | 燃焼排ガス用NOx還元システム |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2127730B1 (en) | 2015-07-08 |

| US8501662B2 (en) | 2013-08-06 |

| JP2009219970A (ja) | 2009-10-01 |

| EP2127730A4 (en) | 2011-04-06 |

| WO2008120582A1 (ja) | 2008-10-09 |

| CN101636221B (zh) | 2013-07-10 |

| KR20090115872A (ko) | 2009-11-09 |

| CN101636221A (zh) | 2010-01-27 |

| JP4992773B2 (ja) | 2012-08-08 |

| US20100093529A1 (en) | 2010-04-15 |

| EP2127730A1 (en) | 2009-12-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20090115871A (ko) | 촉매 재료의 제조 방법 | |

| KR101078552B1 (ko) | 촉매 재료 | |

| KR20090113380A (ko) | 세라믹 벌집형 구조체 | |

| JP4907860B2 (ja) | フィルタ触媒 | |

| KR102018484B1 (ko) | 배기 가스를 처리하기 위한 백금족 금속(pgm) 촉매 | |

| ES2391991T3 (es) | Catalizadores para reducir NOx en una corriente de gas de escape y métodos de preparación | |

| JP3936238B2 (ja) | 触媒体および触媒体の製造方法 | |

| JP2001327818A (ja) | セラミックフィルター及びフィルター装置 | |

| WO2008035652A1 (en) | Catalyst for burning carbon-containing substance, process for production of the catalyst, material having catalyst carried thereon, and process for production of the material | |

| US11731111B2 (en) | Porous ceramic structure and method of producing porous ceramic structure | |

| WO2008035651A1 (en) | Catalyst for burning carbon-containing substance, process for production of the catalyst, material having catalyst carried thereon, and process for production of the material | |

| JP5805603B2 (ja) | 排気ガス浄化用触媒 | |

| KR20140061353A (ko) | 세라믹 담체, 및 상기 담체에 화학적 및 기계적으로 고정된 활성 상을 포함하는, 열기관으로부터의 배기 가스의 정화를 위한 장치 | |

| KR20140082632A (ko) | 세라믹 담체, 및 상기 담체에 기계적으로 고정된 활성 상을 포함하는, 열기관으로부터의 배기 가스의 정화를 위한 장치 | |

| CN113441149A (zh) | 多孔质陶瓷结构体及多孔质陶瓷结构体的制造方法 | |

| JP5051093B2 (ja) | 触媒担持体の製造方法 | |

| JP2008229608A (ja) | 触媒材料及びセラミックハニカム構造体 | |

| Zhang et al. | In situ growth of ZnO nanorods on monolithic diesel particulate filters and supporting potassium for catalytic soot combustion | |

| JP2011074882A (ja) | 排ガス浄化装置 | |

| WO2014083869A1 (ja) | 排気ガス浄化用触媒 | |

| JP2008100208A (ja) | 触媒材料及びその製造方法、並びにハニカム構造体 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PA0105 | International application |

St.27 status event code: A-0-1-A10-A15-nap-PA0105 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| E13-X000 | Pre-grant limitation requested |

St.27 status event code: A-2-3-E10-E13-lim-X000 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U12-oth-PR1002 Fee payment year number: 1 |

|

| PG1601 | Publication of registration |

St.27 status event code: A-4-4-Q10-Q13-nap-PG1601 |

|

| FPAY | Annual fee payment |

Payment date: 20141017 Year of fee payment: 4 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| FPAY | Annual fee payment |

Payment date: 20151016 Year of fee payment: 5 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 5 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 6 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 7 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-5-5-R10-R18-oth-X000 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 8 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 9 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 10 |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: A-4-4-U10-U13-oth-PC1903 Not in force date: 20211026 Payment event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date: 20211026 |

|

| P22-X000 | Classification modified |

St.27 status event code: A-4-4-P10-P22-nap-X000 |

|

| P22-X000 | Classification modified |

St.27 status event code: A-4-4-P10-P22-nap-X000 |