EP2129270B1 - Verbesserungen bei oder im zusammenhang mit einer getränkezubereitungsmaschine - Google Patents

Verbesserungen bei oder im zusammenhang mit einer getränkezubereitungsmaschine Download PDFInfo

- Publication number

- EP2129270B1 EP2129270B1 EP08709510A EP08709510A EP2129270B1 EP 2129270 B1 EP2129270 B1 EP 2129270B1 EP 08709510 A EP08709510 A EP 08709510A EP 08709510 A EP08709510 A EP 08709510A EP 2129270 B1 EP2129270 B1 EP 2129270B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- reservoir

- beverage preparation

- preparation machine

- water

- module

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 235000013361 beverage Nutrition 0.000 title claims abstract description 64

- 238000002360 preparation method Methods 0.000 title claims abstract description 46

- 239000012736 aqueous medium Substances 0.000 claims abstract description 19

- 230000007246 mechanism Effects 0.000 claims description 12

- 238000010438 heat treatment Methods 0.000 claims description 9

- 238000004659 sterilization and disinfection Methods 0.000 claims description 7

- 241001122767 Theaceae Species 0.000 claims description 4

- 238000001914 filtration Methods 0.000 claims description 4

- 235000016213 coffee Nutrition 0.000 claims description 3

- 235000013353 coffee beverage Nutrition 0.000 claims description 3

- 239000012530 fluid Substances 0.000 claims description 3

- 235000013616 tea Nutrition 0.000 claims description 3

- 235000015116 cappuccino Nutrition 0.000 claims description 2

- 238000004891 communication Methods 0.000 claims description 2

- 235000020278 hot chocolate Nutrition 0.000 claims description 2

- 230000000249 desinfective effect Effects 0.000 claims 1

- 235000013399 edible fruits Nutrition 0.000 claims 1

- 235000013570 smoothie Nutrition 0.000 claims 1

- 235000020354 squash Nutrition 0.000 claims 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 139

- 235000020965 cold beverage Nutrition 0.000 description 7

- 235000012171 hot beverage Nutrition 0.000 description 5

- 239000000463 material Substances 0.000 description 4

- 230000006870 function Effects 0.000 description 3

- 230000002572 peristaltic effect Effects 0.000 description 3

- 238000001816 cooling Methods 0.000 description 2

- 230000033001 locomotion Effects 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 235000015114 espresso Nutrition 0.000 description 1

- XUCNUKMRBVNAPB-UHFFFAOYSA-N fluoroethene Chemical group FC=C XUCNUKMRBVNAPB-UHFFFAOYSA-N 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/44—Parts or details or accessories of beverage-making apparatus

- A47J31/4403—Constructional details

- A47J31/441—Warming devices or supports for beverage containers

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/40—Beverage-making apparatus with dispensing means for adding a measured quantity of ingredients, e.g. coffee, water, sugar, cocoa, milk, tea

- A47J31/407—Beverage-making apparatus with dispensing means for adding a measured quantity of ingredients, e.g. coffee, water, sugar, cocoa, milk, tea with ingredient-containing cartridges; Cartridge-perforating means

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/04—Coffee-making apparatus with rising pipes

- A47J31/057—Coffee-making apparatus with rising pipes with water container separated from beverage container, the hot water passing the filter only once i.e. classical type of drip coffee makers

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/44—Parts or details or accessories of beverage-making apparatus

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/44—Parts or details or accessories of beverage-making apparatus

- A47J31/4403—Constructional details

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/44—Parts or details or accessories of beverage-making apparatus

- A47J31/46—Dispensing spouts, pumps, drain valves or like liquid transporting devices

- A47J31/462—Dispensing spouts, pumps, drain valves or like liquid transporting devices with an intermediate liquid storage tank

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/44—Parts or details or accessories of beverage-making apparatus

- A47J31/54—Water boiling vessels in beverage making machines

- A47J31/542—Continuous-flow heaters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/0015—Apparatus or devices for dispensing beverages on draught the beverage being prepared by mixing at least two liquid components

- B67D1/0021—Apparatus or devices for dispensing beverages on draught the beverage being prepared by mixing at least two liquid components the components being mixed at the time of dispensing, i.e. post-mix dispensers

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/44—Parts or details or accessories of beverage-making apparatus

- A47J31/4403—Constructional details

- A47J31/441—Warming devices or supports for beverage containers

- A47J31/4425—Supports for beverage containers when filled or while being filled

- A47J31/4432—Supports for beverage containers when filled or while being filled with means for keeping the beverage warm

- A47J31/4435—Heated support plates

Definitions

- the present invention relates to improvements in or relating to a machine for the preparation of beverages.

- Beverage preparation systems for producing beverages such as coffee and tea are known in the art.

- One example is described in WO2004/064585 which teaches a beverage preparation system suitable for producing a wide range of beverages such as coffee, tea, hot chocolate, espresso and cappuccino.

- the present invention provides a beverage preparation machine for dispensing beverages comprising:

- the machine may further comprise a second reservoir station and a second reservoir for containing an aqueous medium, the second reservoir being connectable to said second reservoir station.

- the auxiliary module may be connected inbetween the second reservoir and second reservoir station:

- the auxiliary module may be selected from a chilling module, a pre-heating module, an aqueous medium filtration unit, a disinfection module and a telemetry unit.

- a heater may be provided in fluid communication with the first reservoir station and or the' second reservoir station.

- the first reservoir contains aqueous medium at ambient temperature.

- the second reservoir contains aqueous medium at a temperature of between 5 and 30 degrees Celsius below ambient temperature. More preferably, the aqueous medium is at a temperature of between 5 and 15 degrees Celsius below ambient temperature. The ambient temperature will vary according to the local climate in which the machine is used. Preferably, the second reservoir contains aqueous medium at a temperature of between 4 and 15 degrees Celsius.

- the chilling module may comprise a recirculation mechanism for diverting aqueous medium cooled by the chilling module back to the reservoir.

- the second reservoir may be thermally insulated.

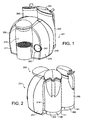

- FIGS 1 to 3 show a first embodiment of beverage preparation machine according to the present invention.

- the beverage preparation machine is of the general type described and shown in WO2004/064585 except for modifications as described below relating to the present invention as defined by the appended claims.

- WO2004/064585 describes fully the basic design and functioning of the beverage preparation machine and the design and function of the beverage cartridges used with the machine. These aspects will not be described in detail here except where relevant to the present invention.

- the contents of WO2004/064585 are incorporated herein by reference.

- beverage preparation machine for the purposes of the present invention there is no requirement for the beverage ingredients to be derived from cartridges or delivered in a single-dose format.

- the beverage preparation machine 201 generally comprises a housing 210 containing a water heater 225, a water pump 230, a dispensing valve 235 with an air inlet 236, a control processor, a user interface 240 and a cartridge head 250.

- the cartridge head 250 in turn generally comprises a cartridge holder for holding, in use, the beverage cartridge, cartridge recognition means and inlet and outlet piercers, for forming, in use, an inlet and an outlet in the beverage cartridge.

- the front half 211 of the housing 210 comprises a dispense station 270 where dispensation of the beverage takes place.

- the machine user interface 240 is located on the front of the housing 210 and comprises a start/stop button 241.

- the start/stop button 241 controls commencement of the operating cycle and is a manually operated push-button, switch or similar.

- the button 241 may also be used to manually stop the operating cycle.

- a rear half 212 of the housing 210 provides a recess 214 for the attachment of first and second water tanks 220, 280.

- the first water tank 220 may be made from a transparent or translucent material to allow a consumer to view the quantity of water remaining in the tank.

- the first water tank 220 may be made from an opaque material but have provided a viewing window therein.

- the first water tank 220 may be provided with a low level sensor which prevents operation of the water pump 230 and optionally triggers a warning indicator, such as an LED, when the water level in the tank descends to a preselected level.

- the first water tank 220 preferably has an internal capacity of approximately 1.5 litres.

- the first water tank 220 is connected in use to a first water tank station 120.

- the first water tank 220 comprises a generally cylindrical body 221 which may be right circular or a frustum as desired for aesthetic reasons.

- the tank comprises an open upper end forming an inlet for filling the tank with water which is closed off in use by a manually removable lid 222.

- An outlet is provided towards a lower end of the tank.

- the outlet contains a valve which is biased into a closed position when the first water tank is removed from the first water tank station 120.

- the outlet may also be provided with a filter to prevent ingress of solid particulates into the internal parts of the machine.

- the first water tank station 120 comprises a base plate 121 shaped to receive a lower end of the first water tank 220.

- the base plate 121 is provided with a valve connector 122 that matingly connects with the outlet valve of the first water tank 220 when the tank is placed on the base plate. Connection of the tank 220 to the station 120 opens the valve and allows for

- a conduit 123 extending internally from the valve connector 122 communicates with the water heater 225.

- the beverage preparation machine 201 is provided with a second water tank station 180.

- the second water tank station 180 comprises a base plate 181 having a valve connector 182 in the same manner as the first water tank station 120.

- the second water tank 280 is locatable on the second water tank station 180.

- the second water tank 280 is provided with an outlet valve of the same type as the first water tank and connects to the valve connector in the same manner as described above.

- the construction and materials of the second water tank 280 are preferable the same as those of the first water tank 220.

- the base plates 121 and 181 are preferable formed as one piece having separate indentations marking the locations of the first and second water tanks 220, 280.

- a conduit 183 extends internally from the valve connector 182 of the second water tank station to the dispensing valve 235.

- the water pump 230 is a volumetric displacement pump that creates sufficient suction head to draw water from the tanks through the heater and the dispensing valve 250.

- a peristaltic type pump is used such that each revolution delivers a known volume of water.

- the water pump 230 provides a maximum flow rate of 900 ml/min of water at a maximum pressure of.2.5 bar.

- the pressure will be limited to 2 bar.

- the flow rate of water through the machine can be controlled by the control processor to be a percentage of the maximum flow rate of the pump by speed control.

- the pump can be driven at any of 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90% or 100% of the maximum rated flow rate.

- the accuracy of the volume of water pumped is preferably + or - 5% leading to a + or - 5% accuracy in the final volume of the dispensed beverage where a peristaltic pump is used the volume delivered can be determined by the number of revolutions.

- a volumetric flow sensor (not shown) can be provided in the flow line either upstream or downstream of the water pump 230.

- the volumetric flow sensor would be a rotary sensor.

- the dispensing valve, 235 preferably comprises an assembly of two electrically operated solenoid change-over valves with associated non-return valves as shown schematically in Figure 3 .

- the respective solenoid valve of the dispensing valve 250 is selected by the control processor before flow commences.

- the water heater 225 has a power rating of 1550 W and is able to heat water received from the water pump 230 from a starting temperature of approximately 20°C to an operating temperature in the range of around 88 to 94°C in under 1 minute. Preferably the dwell time between the end of one operating cycle and the heater 225 being able to commence a subsequent operating cycle is less than 10 seconds.

- the heater maintains the selected temperature to within + or - 2 °C during the operating cycle.

- the water for the operating cycle may be delivered to the cartridge head 250 at 88°C, 91°C or 94°C.

- the heater 225 is able to quickly adjust the delivery temperature within the range 88°C or 94°C.

- the heater 225 comprises an over-temperature cut-off which shuts off the heater if the temperature exceeds 98 °C.

- the dispensing valve 235 receives water supply inlets from the water heater 225 and the second water tank 280 as shown in Figure 3 .

- the air inlet 236 allows air to be pumped to the cartridge head 250. If required a separate air compressor may be incorporated into the air supply route.

- the water/air outlet 237 from the dispensing valve 235 connects to the water pump 230. In turn, the water pump 230 connects to the cartridge head 250.

- the control processor of the beverage preparation machine comprises a processing module and a memory.

- the control processor is operatively connected to, and controls operation of, the water heater 225, water pump 230, dispensing valve 235 and user interface 240.

- the first water tank 220 is used to provide water for hot drinks and the water passes through the water heater 225 on the way to the cartridge head 250.

- the second water tank 280 is used to provide water for cold drinks or drinks served at ambient temperature and the water does not pass through the water heater 225.

- the water in the second water tank 280 may be chilled before it is poured into the tank.

- the tank, containing the water may be chilled in a refrigerator.

- the water in the second water tank 280 when connected to the secondary water tank station is at between 5 and 30 degrees Celsius below ambient or room temperature, more preferably at between 5 and 15 degrees Celsius below ambient.

- the shape and size of the tank allows the tank to be fitted into a domestic refrigerator door when disconnected from the beverage preparation machine.

- the first and second water tanks 220, 280 may be interchangeable on the first and second water tank stations 120, 180. In other words, one design of tank may be used for fitting to the first and second water tank stations 120, 180.

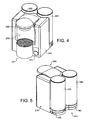

- FIGs 4 to 7 show a second embodiment of beverage preparation machine 201 according to the present invention.

- the machine comprises first and second water tanks 220, 280 and first and second water tank stations 120, 180.

- the design of the housing 210 is of a different shape but the function of the components of the machine is the same as that of the first embodiment described above except where noted differently below.

- the beverage preparation machine is provided with one or more auxiliary modules.

- two auxiliary modules are shown mounted to the first and second water tank stations 120, 180.

- a pre-heating module 320 is mounted on the first water tank station 120 between the first water tank 220 and the base plate 121.

- a chilling module 380 is mounted on the second water tank station 180 between the second water tank 280 and the base plate 180.

- Figure 6 shows an optional arrangement where the beverage preparation machine is provided with a single water tank 290 of double capacity which is located on both the first and second water tank stations.

- the auxiliary modules 320, 380 are mounted in line with the first and second water tanks.

- a lower face of each auxiliary module matches the interface of the water tanks stations, whilst an upper face of the auxiliary modules is shaped to receive the first or second water tanks.

- Both the upper and lower faces of the auxiliary module are provided with suitable valve connectors for mating with the valve connectors of the water tank stations and water tanks.

- This arrangement is particularly suitable where the auxiliary module comprises a chilling unit or a pre-heating unit.

- a filtration unit may also be used in this configuration.

- FIG. 7 illustrates schematically the internal configuration of the second embodiment.

- the arrangement of the pump, water heater and dispensing valve are the same as in the first embodiment.

- the pre-heating module 320 comprises a heater 321.

- the chilling module 380 comprises a thermoelectric cooler (TEC) 381 which receives water from the second tank 280 via a tank outlet 383, cools the water and then re-circulates the water back to the second tank 280 via a tank inlet 384.

- Motive force for the re-circulation is provided by a dedicated pump 382 within the chilling module 380.

- Other types of peltier heat pump or similar device may be used instead of the TEC 381.

- water is pumped from the second water tank 280 by the pump 230 to the cartridge head 250. Due to the presence of the chilling module 380 the water in the second tank 280 is maintained in a chilled state.

- the chilling module 380 may be used to chill water in the second tank 280 that is initially at ambient or room temperature or may be used to maintain the temperature of water in the second tank 280 which has previously been chilled in a refrigerator.

- the pre-heating module 320 may be used to heat water taken from the first tank 220 at ambient temperature by a set amount before passing the water to the main heater 225 in the machine housing.

- the second tank may itself comprise a chilling mechanism, such as a TEC, as an integral part of the tank.

- a chilling mechanism such as a TEC

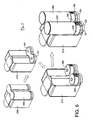

- FIG 8 shows a third embodiment of the present invention wherein the beverage preparation machine 201 is provided with an auxiliary module station 300 as well as the first and second water tank stations 120, 180.

- the auxiliary module station 300 is used to mount auxiliary modules in parallel to the first and second water tanks rather than in line with the tanks.

- the auxiliary module station 300 comprises power and fluid connections.

- the auxiliary module station 300 may be rotated in between a storage position, in which the station is hidden from view below the first and second water tank stations, and an operating position as shown in Figure 8 in which the station is accessible and is position rearward of the first and second tank stations.

- the auxiliary module station 300 may be moved between storage and operating positions by means of a translational movement, such as a sliding motion, or by being located on a flip-down panel which is lowered when the auxiliary module is to be used.

- the auxiliary module 300 may be any of a chilling module, a pre-heating module, a water filtration unit, a disinfection module, a telemetry device or similar as described above.

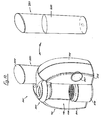

- FIG. 9 illustrates a modification to the system which can be utilised in any of the above embodiments.

- An ultra-violet (UV) chamber 501 is provided as part of a water recirculation system. As shown water is recirculated from the second tank 280 by means of pump 382 and three-way valve 500 back to the second tank 280 via the UV chamber 501. This recirculation continues when water is not required to be transferred to the cartridge head 250. When water is required to dispense a beverage then this is diverted to the cartridge head 250 by use of the three-way valve 500.

- UV ultra-violet

- the UV chamber 501 comprises a housing 503 and a plurality of UV emitting elements 502 which are focussed to illuminate the water passing through the chamber 501 with light in the UV range.

- the piping used for conveying the water through the chamber 501 is formed from fluoroethylene polymer (FEP) to allow for good UV transmission across the piping.

- the UV emitting elements 502 comprises UV-emitting light emitting diodes (LEDs).

- the LEDs emit UV in a chosen wavelength between 250 and 320 nanometres (nm).

- the LEDs may have a relatively low power output compared with low-pressure mercury discharge UV lamps since the recirculation of the water through the chamber 501 many times increases the total UV exposure time of the water.

- the LEDs may be arranged to have a small focus area by the use of a suitable lens arrangement to enhance the disinfection effect. This allows less expensive and smaller UV LEDs to be utilised.

- the tank 280 or the water contained therein may be illuminated by a portion of the UV output of the LEDs which has been filtered.

- the tank 280 may be formed, or contain, a material which fluoresces when exposed to UV light.

- the use of UV light to disinfect the water used in the system may be used for water recirculation in the first tank 220 and or the second water tank 280 irrespective of whether the water is also subject to chilling, heating or discharged at ambient temperature.

- the UV chamber 501 may be formed as part of the recirculation piping of a chilling module formed as part of the machine or as part of another auxiliary module connectable to one of the water or auxiliary module stations. Each reservoir station may be provided with an inline UV chamber 501 if required.

- the UV chamber 501 may be formed as part of the main housing of the machine or as part of a separate, connectable, auxiliary module.

- the UV chamber 501 and recirculation mechanism may be formed as part of a disinfection module per se or as part of a chilling module.

- FIG 10 illustrates a fourth embodiment of system.

- the beverage preparation machine 201 comprises a single reservoir station and two water tanks.

- the first water tank 220 contains water at ambient temperature and is to be used to prepare hot beverages.

- the second tank 280 contains water 400 at below ambient temperature and is used to prepare cold beverages.

- the tanks 220, 280 are interchangeable and swapped on and off the reservoir station as required.

- the second tank when not mounted to the beverage preparation machine 201 is preferably stored in a refrigerator in order to create and maintain a chilled volume of water. In this way the system can quickly be used to make both hot and cold beverages without the necessity for chilling apparatus within the housing of the beverage preparation machine.

- the second water tank 280 is thermally insulated and may be provided with a carrying handle. It may also be suitably shaped to fit within standard compartments of a refrigerator such as a door pocket.

- an auxiliary module as required is mounted to the auxiliary module station or the first or second water tank station as appropriate.

- one or other or both of the first and second water tanks are positioned on the respective first and second water tank stations as appropriate.

- the water for the beverage is sourced from the first or second water tank depending on the type of beverage to be dispensed. For example, where a chilled beverage is required the water is sourced from the second tank which may contain water pre-chilled in a refrigerator, or contain water chilled by a chilling module or integrated TEC. Where a hot beverage is required the water is sourced from the first tank and the water is passed to the heater 225, optionally via a pre-heating module.

- auxiliary modules where present may be positioned in line or parallel to one or more tanks containing water for forming beverages.

- One, two or more auxiliary modules may be used in combination with one, two or more water tanks depending on the desired combination of functions.

- auxiliary module described are given as examples only and may be used with one or more of the embodiments of beverage machine described above.

- the auxiliary modules and water tanks of the above embodiments may be used with beverage preparation machines having one, two or more reservoir stations.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Devices For Dispensing Beverages (AREA)

- Seal Device For Vehicle (AREA)

- Apparatus For Making Beverages (AREA)

- Devices That Are Associated With Refrigeration Equipment (AREA)

- Non-Alcoholic Beverages (AREA)

Claims (18)

- Getränke-Zubereitungsvorrichtung (201) zur Abgabe von Getränken, umfassend:ein Gehäuse (210);eine erste Behälterstation (120);einen ersten Behälter (220) zum Enthalten eines wasserhaltigen Mediums, wobei der erste Behälter (220) mit der ersten Behälterstation (120) verbindbar ist;dadurch gekennzeichnet, dass die Getränke-Zubereitungsvorrichtung (201) ferner ein Hilfsmodul (320) umfasst, wobei das Hilfsmodul eine erste Schnittstelle zum Verbinden des Hilfsmoduls (320) mit der ersten Behälterstation (120) und eine zweite Schnittstelle zum Verbinden des ersten Behälters (220) mit dem Hilfsmodul (320) umfasst, so dass im montierten Zustand das Hilfsmodul (320) zwischen dem ersten Behälter (220) und der ersten Behälterstation (120) angeordnet ist.

- Getränke-Zubereitungsvorrichtung (201) nach Anspruch 1, ferner umfassend eine zweite Behälterstation (180) und einen zweiten Behälter (280) zum Enthalten eines wasserhaltigen Mediums, wobei der zweite Behälter (280) mit der zweiten Behälterstation (180) verbindbar ist.

- Getränke-Zubereitungsvorrichtung (201) nach Anspruch 2, wobei das Hilfsmodul (320) zwischen dem zweiten Behälter (280) und der zweiten Behälterstation (180) verbindbar ist.

- Getränke-Zubereitungsvorrichtung (201) nach einem der vorhergehenden Ansprüche, wobei das Hilfsmodul (320) ausgewählt ist aus einem Kühlmodul, einem Vorheizmodul, einer Filtereinheit für ein wasserhaltiges Medium, einem Desinfektionsmodul und einer Telemetrieeinheit.

- Getränke-Zubereitungsvorrichtung (201) nach einem der vorhergehenden Ansprüche, ferner umfassend einen Heizer (321), welcher in Fluidverbindung mit der ersten Behälterstation (120) oder/und der zweiten Behälterstation (180) steht.

- Getränke-Zubereitungsvorrichtung (201) nach einem der vorhergehenden Ansprüche, wobei der erste Behälter (280) ein wasserhaltiges Medium bei Raumtemperatur enthält.

- Getränke-Zubereitungsvorrichtung (201) nach einem der vorhergehenden Ansprüche, wobei der zweite Behälter (280) ein wasserhaltiges Medium bei einer Temperatur von zwischen 5 und 30 Grad Celsius unterhalb von Raumtemperatur enthält.

- Getränke-Zubereitungsvorrichtung (201) nach Anspruch 7, wobei das wasserhaltige Medium bei einer Temperatur von zwischen 5 und 15 Grad Celsius unterhalb von Raumtemperatur ist.

- Getränke-Zubereitungsvorrichtung (201) nach einem der Ansprüche 2 bis 8, wobei der zweite Behälter (280) ein wasserhaltiges Medium bei einer Temperatur von zwischen 4 und 15 Grad Celsius enthält.

- Getränke-Zubereitungsvorrichtung (201) nach einem der Ansprüche 4 bis 9, wobei das Kühlmodul einen Rezirkulationsmechanismus umfasst zum Umleiten von von dem Kühlmodul gekühltem wasserhaltigem Medium zurück zum Behälter.

- Getränke-Zubereitungsvorrichtung (201) nach Anspruch 2 bis 10, wobei der zweite Behälter (280) thermisch isoliert ist.

- Getränke-Zubereitungsvorrichtung (201) nach einem der vorhergehenden Ansprüche, ferner umfassend einen Rezirkulationsmechanismus zum Umleiten von wasserhaltigem Medium aus dem ersten Behälter (220) zurück zu dem ersten Behälter (220) oder von dem Hilfsmodul (320) zurück zu dem Hilfsmodul (320), wobei der Rezirkulationsmechanismus eine UV-Quelle (501) umfasst zum Desinfizieren des wasserhaltigen Mediums, während es in dem Rezirkulationsmechanismus zirkuliert.

- Getränke-Zubereitungsvorrichtung (201) nach Anspruch 12, wobei die UV-Quelle UV-LEDs (502) sind.

- Getränke-Zubereitungsvorrichtung (201) nach Anspruch 13, wobei das von den UV-LEDs (502) emittierte Licht eine Wellenlänge von 250 und 320 nm aufweist.

- Getränke-Zubereitungsvorrichtung (201) nach einem der Ansprüche 12 bis 14, wobei der Rezirkulationsmechanismus und die UV-Quelle als Teil eines Desinfektionshilfsmoduls bereitgestellt sind.

- Getränke-Zubereitungsvorrichtung (201) nach einem der Ansprüche 12 bis 14, wobei der Rezirkulationsmechanismus auch einen Kühlmechanismus (381) umfasst.

- Getränke-Zubereitungsvorrichtung (201) nach Anspruch 15, wobei der Rezirkulationsmechanismus, der Kühlmechanismus und die UV-Quelle (501) alle als Teil eines Kühlmoduls (380) bereitgestellt sind.

- Getränke-Zubereitungsvorrichtung (201) nach einem der vorhergehenden Ansprüche, welche zur Abgabe einer Reihe von heißen und kalten, extrahierten/aufgegossenen oder verdünnten Getränken umfassend, aber nicht beschränkt auf Kaffee, Tee, Cappuccino, heiße Schokolade, Eistee, Fruchtsäften, Smoothies und Frappes, geeignet ist.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SI200830510T SI2129270T1 (sl) | 2007-02-27 | 2008-02-25 | Izboljšave pri napravi za pripravo pijač |

| PL08709510T PL2129270T5 (pl) | 2007-02-27 | 2008-02-25 | Ulepszenia urządzenia do przygotowywania napojów lub z nim związane |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB0703764A GB2447024A (en) | 2007-02-27 | 2007-02-27 | A dispensing machine for hot or cold drinks |

| PCT/GB2008/000628 WO2008104751A1 (en) | 2007-02-27 | 2008-02-25 | Improvements in or relating to a machine for the preparation of beverages |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2129270A1 EP2129270A1 (de) | 2009-12-09 |

| EP2129270B1 true EP2129270B1 (de) | 2011-12-14 |

| EP2129270B2 EP2129270B2 (de) | 2018-10-17 |

Family

ID=37945788

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08709510.5A Active EP2129270B2 (de) | 2007-02-27 | 2008-02-25 | Verbesserungen bei oder im zusammenhang mit einer getränkezubereitungsmaschine |

Country Status (15)

| Country | Link |

|---|---|

| US (5) | US8887622B2 (de) |

| EP (1) | EP2129270B2 (de) |

| JP (1) | JP5009379B2 (de) |

| KR (3) | KR101502181B1 (de) |

| CN (2) | CN101621949B (de) |

| AT (1) | ATE536779T1 (de) |

| BR (1) | BRPI0807381B1 (de) |

| CA (4) | CA2678050C (de) |

| DK (1) | DK2129270T3 (de) |

| ES (1) | ES2375179T5 (de) |

| GB (1) | GB2447024A (de) |

| PL (1) | PL2129270T5 (de) |

| RU (1) | RU2435508C2 (de) |

| SI (1) | SI2129270T1 (de) |

| WO (1) | WO2008104751A1 (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8887622B2 (en) | 2007-02-27 | 2014-11-18 | Kraft Foods R & D, Inc. | Machine for the preparation of beverages |

| DE102013109619A1 (de) * | 2013-09-04 | 2015-03-05 | Miele & Cie. Kg | Getränkebereiter zur Herstellung eines Kaltgetränkes und Verfahren hierzu |

| EP3610763B1 (de) | 2018-08-16 | 2021-04-07 | CUP&CINO Kaffeesystem-Vertrieb GmbH & Co. KG | Kaffeemaschine zum zubereiten eines heissgetränks |

| EP3705561B1 (de) * | 2017-06-26 | 2024-11-06 | LG Electronics Inc. | Getränkezubereiter |

Families Citing this family (121)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2189087B1 (de) | 2006-06-16 | 2014-03-05 | Nestec S.A. | Getränkeautomat mit Auflagesystem und Tropffänger für Behälter verschiedener Größen |

| US8677888B2 (en) | 2007-04-05 | 2014-03-25 | Primo Products, LLC | Select serving and flavored sparkling beverage maker |

| US8250972B2 (en) * | 2007-04-05 | 2012-08-28 | Primo Products, LLC | Select serving and flavored sparkling beverage maker |

| US20110020508A1 (en) * | 2007-04-05 | 2011-01-27 | Rising Phoenix Co. | Select Serving and Flavored Sparkling Beverage Maker |

| EP2070454B1 (de) | 2007-12-12 | 2015-07-15 | Nestec S.A. | Modulare Herstellung von Getränkeherstellungsmaschinen |

| EP2276380B1 (de) | 2008-05-07 | 2013-07-17 | Nestec S.A. | Gebrauchtkapselsammler für getränkegeräte |

| CN102118992B (zh) | 2008-08-08 | 2014-12-03 | 雀巢产品技术援助有限公司 | 带有携带手柄和可配置的外观及侧面功能的饮料机 |

| CA2736927A1 (en) | 2008-10-03 | 2010-04-08 | Nestec S.A. | User-friendly interface for a beverage machine |

| CA2748384C (en) | 2008-12-30 | 2017-03-28 | Nestec S.A. | Process of brewing tea leaves contained in a capsule |

| EP2208450A1 (de) * | 2009-01-14 | 2010-07-21 | Nestec S.A. | Modulsystem mit autonomem Modul mit kleinem Empfangsbereich |

| RU2526677C2 (ru) | 2009-05-06 | 2014-08-27 | Нестек С.А. | Машины для приготовления напитков с упрощенным обслуживанием |

| NL2003409C2 (nl) * | 2009-08-28 | 2011-03-01 | Dijk 3D Engineering B V Van | Inrichting en werkwijze voor het koppelen van een waterreservoir aan een koffiezetapparaat. |

| AU2010291241C1 (en) | 2009-09-02 | 2018-03-08 | Société des Produits Nestlé S.A. | Beverage machine for a network |

| US9138096B2 (en) | 2009-09-09 | 2015-09-22 | Nestec S.A. | Beverage machine in a network |

| CA2779980A1 (en) | 2009-11-05 | 2011-05-12 | Nestec S.A. | Remote diagnosis of beverage preparation machines |

| CA2782446C (en) | 2009-12-02 | 2018-01-16 | Nestec S.A. | Beverage preparation machine comprising a card reading arrangement |

| JP5809160B2 (ja) | 2009-12-02 | 2015-11-10 | ネステク ソシエテ アノニム | 拡張されたユーザ助言機能を有する飲料調製マシン |

| US9514595B2 (en) | 2009-12-02 | 2016-12-06 | Nestec S.A. | Beverage preparation machine with ambience emulation functionality |

| RU2555639C2 (ru) | 2009-12-02 | 2015-07-10 | Нестек С.А. | Машина для приготовления напитков с функциональной возможностью виртуальной покупки |

| US8876000B2 (en) | 2009-12-02 | 2014-11-04 | Nestec S.A. | Beverage preparation machine with touch menu functionality |

| RU2553081C2 (ru) | 2009-12-02 | 2015-06-10 | Нестек С.А. | Машина для приготовления напитков, поддерживающая функциональные возможности дистанционного обслуживания |

| WO2011095147A1 (de) * | 2010-02-04 | 2011-08-11 | SEVERIN ELEKTROGERÄTE GmbH | Elektrischer kaffeevollautomat |

| US8567767B2 (en) | 2010-05-03 | 2013-10-29 | Apiqe Inc | Apparatuses, systems and methods for efficient solubilization of carbon dioxide in water using high energy impact |

| US9309103B2 (en) | 2010-05-03 | 2016-04-12 | Cgp Water Systems, Llc | Water dispenser system |

| DK2571408T3 (da) | 2010-05-21 | 2014-06-23 | Nestec Sa | Drikmaskine med ergonomisk vandadministration |

| RU2578990C2 (ru) | 2010-05-21 | 2016-03-27 | Нестек С.А. | Эргономичный интерфейс раздаточного устройства |

| WO2011144719A1 (en) | 2010-05-21 | 2011-11-24 | Nestec S.A. | Ergonomic handle & user-interface |

| BR112013003295A2 (pt) * | 2010-08-13 | 2016-06-07 | Koninkl Philips Electronics Nv | recipiente de água para máquinas para preparar bebidas e máquina para preparar bebidas |

| US9661950B2 (en) | 2010-09-07 | 2017-05-30 | Nestec S.A. | Ergonomic handle with user-interface |

| CN103200850B (zh) | 2010-10-27 | 2016-06-08 | 雀巢产品技术援助有限公司 | 用于不同空间环境的饮料机 |

| RU2702253C2 (ru) * | 2010-11-11 | 2019-10-07 | Сосьете Де Продюи Нестле С.А. | Капсула, аппарат для приготовления напитков и система для приготовления продукта питания |

| WO2012072761A1 (en) | 2010-12-01 | 2012-06-07 | Nestec S.A. | Beverage machine with reliable user-indicator |

| AU2011334909A1 (en) | 2010-12-01 | 2013-06-13 | Nestec S.A. | Ergonomic user-interface for motorised ingredient chamber |

| EP2645912B2 (de) | 2010-12-01 | 2025-05-07 | Société des Produits Nestlé S.A. | Einfache benutzerschnittstelle für eine getränkemaschine |

| US8636174B1 (en) * | 2010-12-22 | 2014-01-28 | Food Equipment Technologies Company, Inc. | On-demand temperature controlled water dispenser and method |

| US10035979B2 (en) | 2015-07-23 | 2018-07-31 | Picobrew, Inc. | Beer making machine with direct steam injection |

| US11753610B2 (en) | 2011-03-03 | 2023-09-12 | PB Funding Group, LLC | Self healing controller for beer brewing system |

| US20150000531A1 (en) * | 2011-03-03 | 2015-01-01 | PicoBrew, LLC | Multiple Flow Path Recirculating Brewing System with Removable Reservoirs |

| US11678760B2 (en) | 2011-03-03 | 2023-06-20 | PB Funding Group, LLC | Multifunctional brewing system for coffee, beer, and other beverages |

| US9114902B2 (en) | 2011-03-22 | 2015-08-25 | Polyone Designed Structures And Solutions Llc | Methods and systems for use in forming an article from a multi-layer sheet structure |

| ITRM20110327A1 (it) * | 2011-06-23 | 2012-12-24 | Alfio Giovanni Torrisi | Procedimento di somministrazione di succo di frutta, in particolare di succo di agrumi, e dispositivo per l?uso secondo detto procedimento. |

| WO2012178106A2 (en) * | 2011-06-23 | 2012-12-27 | Apiqe, Inc. | Flow dispenser, flavor adapter, and flavor pack |

| WO2012178179A2 (en) | 2011-06-23 | 2012-12-27 | Apiqe Inc. | Disposable filter cartridge for water dispenser |

| EP2723481B1 (de) | 2011-06-23 | 2019-05-01 | Apiqe Inc. | Strömungskompensator |

| EP2734669B1 (de) * | 2011-07-19 | 2016-04-13 | Koninklijke Philips N.V. | Haushaltsgerät mit einem aktuator |

| RU2594968C2 (ru) * | 2011-07-19 | 2016-08-20 | Конинклейке Филипс Н.В. | Бытовое электрическое устройство, содержащее исполнительный механизм |

| AU2012307512A1 (en) * | 2011-09-16 | 2014-03-06 | Nestec S.A. | Multi-system beverage machine safe connector |

| ITVR20110179A1 (it) * | 2011-09-19 | 2013-03-20 | Caffita System Spa | Dispositivo di infusione per la produzione di bevande mediante l'utilizzo di cartucce, quali cartucce o cialde |

| US10080459B2 (en) | 2011-11-09 | 2018-09-25 | La Vit Technology Llc | Capsule-based system for preparing and dispensing a beverage |

| US10034570B2 (en) | 2011-11-09 | 2018-07-31 | LaVit Technology LLC | Capsule based system for preparing and dispensing a beverage |

| WO2013087996A1 (fr) * | 2011-12-13 | 2013-06-20 | FRYDMAN, Philippe | Machine multifonction de préparation de boisson par extraction de capsule |

| CH706133A1 (de) * | 2012-02-21 | 2013-08-30 | Schaerer Ag | Getränke-Zubereitungsmodul mit Zusatzmodulen für Selbstbedienungs-Getränkeautomaten. |

| US9161654B2 (en) | 2012-03-09 | 2015-10-20 | Primo Products Llc | Select serving and flavored sparkling beverage maker system |

| BR112014028905A2 (pt) * | 2012-05-23 | 2017-06-27 | Koninklijke Philips Nv | dispositivo de produção de bebidas |

| RU2751428C2 (ru) * | 2012-06-29 | 2021-07-13 | Конинклейке Дауве Егбертс Б.В. | Система для автоматизированного обнаружения в устройствах для розлива напитка |

| DE202012009076U1 (de) * | 2012-09-21 | 2012-11-16 | Eugster/Frismag Ag | Vorrichtung zur Bereitung von wahlweise kaltem oder warmem Milchschaum oder Abgabe wahlweise kalter oder warmer Milch |

| CN103860017A (zh) * | 2012-12-15 | 2014-06-18 | 苏州工业园区咖乐美电器有限公司 | 一种具有检测环境温度功能的咖啡机 |

| EP2981198A4 (de) * | 2013-04-03 | 2016-11-16 | 2266170 Ontario Inc | Kapselmaschine und komponenten |

| US9320382B2 (en) | 2013-07-15 | 2016-04-26 | La Vit Technology Llc | Capsule based system for preparing and dispensing a beverage |

| ITMO20130295A1 (it) * | 2013-10-17 | 2015-04-18 | Sarong Spa | Macchina erogatrice di bevande |

| CA2931215A1 (en) | 2013-12-23 | 2015-07-02 | Nestec S.A. | Simple ergonomic user-interface for a beverage machine |

| US9439532B2 (en) | 2014-03-11 | 2016-09-13 | Starbucks Corporation | Beverage production machines with multi-chambered basket units |

| US9504348B2 (en) | 2014-03-11 | 2016-11-29 | Starbucks Corporation | Cartridge ejection systems and methods for single-serve beverage production machines |

| US20150257586A1 (en) * | 2014-03-11 | 2015-09-17 | Starbucks Corporation Dba Starbucks Coffee Company | Single-serve beverage production machine |

| JP2017513583A (ja) * | 2014-04-08 | 2017-06-01 | レミントン デザインズ リミテッド ライアビリティ カンパニー | 飲料抽出システム及びシステムを使用するための方法 |

| CA2946084A1 (en) | 2014-05-13 | 2015-11-19 | Nestec S.A. | Beverage preparation device for hot and cold beverages |

| WO2015185286A1 (en) * | 2014-06-06 | 2015-12-10 | Arcelik Anonim Sirketi | A hot beverage preparation machine comprising a power plate |

| PT2959808T (pt) * | 2014-06-27 | 2019-02-04 | Gruppo Cimbali Spa | Dispositivo melhorado para humedecer uma dose de café moído em máquinas de café com um elemento de aquecimento na unidade doseadora e processo de humedecimento |

| US10414642B2 (en) | 2014-07-22 | 2019-09-17 | BIBO Barmaid LLC | Cold beverage dispenser and flexible pouch |

| US9932218B2 (en) | 2016-03-04 | 2018-04-03 | BIBO Barmaid LLC | Cold beverage dispenser and cutter assembly for cold beverage dispenser |

| EP3171747A4 (de) | 2014-07-22 | 2018-03-14 | Bibo Barmaid LLC | Ausgabevorrichtung für kalte getränke |

| KR102285134B1 (ko) * | 2014-09-12 | 2021-08-05 | 코웨이 주식회사 | 커피 추출장치 및 방법 |

| US10308903B2 (en) | 2014-09-17 | 2019-06-04 | Picobrew, Inc. | Foam reducing device |

| CA2960907C (en) * | 2014-09-19 | 2022-10-25 | Bogdan KRINITCHKO | Machine for brewing tea |

| US10874246B2 (en) * | 2014-10-06 | 2020-12-29 | Coffee Solutions, Llc | Beverage brewing systems and methods for using the same |

| AU2015330350A1 (en) * | 2014-10-08 | 2017-02-23 | Société des Produits Nestlé S.A. | Extraction unit of beverage preparation machine |

| AU2015330349A1 (en) * | 2014-10-08 | 2017-03-02 | Société des Produits Nestlé S.A. | Reconfigurable beverage preparation machine |

| GB2531780B (en) | 2014-10-30 | 2018-04-04 | Douwe Egberts Bv | Beverage preparation machine |

| WO2016115557A1 (en) | 2015-01-16 | 2016-07-21 | CocoTerra Company | Chocolate processing system and method |

| ES2579978B2 (es) * | 2015-02-16 | 2017-04-07 | Smart Spirits, S.L. | Infusor de bebidas alcohólicas |

| WO2016135681A1 (en) * | 2015-02-27 | 2016-09-01 | Anheuser-Bush Inbev S.A. | Appliances and containers for preparing a beverage in a transparent chamber |

| US10377981B2 (en) | 2015-03-17 | 2019-08-13 | Picobrew, Inc. | Software tuning of recipes for beer brewing system |

| US10336597B2 (en) | 2015-03-23 | 2019-07-02 | Altria Client Services Llc | Capsule-based alcoholic beverage forming apparatus and components thereof |

| JP6917672B2 (ja) * | 2015-04-15 | 2021-08-11 | タイガー魔法瓶株式会社 | 抽出式飲料製造装置 |

| US9968217B2 (en) | 2015-06-16 | 2018-05-15 | Starbucks Corporation | Beverage preparation systems with brew chamber securing mechanisms |

| US10342377B2 (en) | 2015-06-16 | 2019-07-09 | Starbucks Corporation | Beverage preparation systems with adaptable brew chambers |

| US10602874B2 (en) | 2015-06-16 | 2020-03-31 | Starbucks Corporation Dba Starbucks Coffee Company | Beverage preparation systems with brew chamber access mechanisms |

| US9932547B2 (en) | 2015-07-31 | 2018-04-03 | Picobrew, Inc. | Fermentation monitoring and management |

| US10161533B2 (en) | 2016-05-09 | 2018-12-25 | Picobrew, Inc. | Bi-stable electrically actuated valve |

| USD817061S1 (en) * | 2016-07-29 | 2018-05-08 | Illycaffe′ S.p.A. | Coffee machine |

| RU2759647C2 (ru) * | 2016-08-24 | 2021-11-16 | Инностим Свисс Са | Устройство и способ быстрого получения горячей воды |

| WO2018046400A1 (en) | 2016-09-09 | 2018-03-15 | Nestec Sa | Beverage machine with ergonomic handling |

| BR112019008836A2 (pt) | 2016-11-09 | 2019-07-09 | Pepsico Inc | conjuntos de fabricação de bebida carbonatada, métodos, e sistemas |

| US10238233B2 (en) * | 2016-11-15 | 2019-03-26 | Haier Us Appliance Solutions, Inc. | Filtration and liquid level control system |

| CA3053423C (en) | 2017-02-15 | 2021-04-27 | 2266170 Ontario Inc. | Beverage preparation and infusion system |

| US10463983B2 (en) | 2017-03-31 | 2019-11-05 | Picobrew, Inc. | Distillation and essence extractor insert for beer brewing machine |

| US10688451B1 (en) * | 2017-05-15 | 2020-06-23 | Carl Santoiemmo | Selected serving and flavored sparkling beverage maker |

| US11344149B2 (en) | 2017-06-01 | 2022-05-31 | Societe Des Produits Nestle S.A. | Beverage machine with ergonomic power switch |

| WO2018219989A1 (en) | 2017-06-01 | 2018-12-06 | Nestec Sa | Beverage machine with a stablizing foot |

| WO2018219985A1 (en) | 2017-06-01 | 2018-12-06 | Nestec Sa | Beverage machine with a storable dispensing head |

| US11700969B2 (en) | 2017-06-01 | 2023-07-18 | Societe Des Produits Nestle S.A. | Beverage machine with a collapsible interface |

| WO2018229102A1 (en) | 2017-06-13 | 2018-12-20 | Nestec Sa | Beverage preparation machine with capsule recognition |

| US20190000261A1 (en) * | 2017-07-03 | 2019-01-03 | Coffeeworks, Inc. | Method and apparatus for producing steeped coffee using cyclonic agitation |

| HUE070758T2 (hu) | 2018-02-09 | 2025-07-28 | Nestle Sa | Italkészítõ gép kapszula-felismeréssel |

| CN112638213B (zh) | 2018-09-27 | 2023-10-31 | 雀巢产品有限公司 | 具有致动分配装置的饮料机 |

| USD904817S1 (en) | 2018-10-03 | 2020-12-15 | LNJ Group, LLC | Beverage dispenser |

| JP7475348B2 (ja) | 2018-12-12 | 2024-04-26 | ソシエテ・デ・プロデュイ・ネスレ・エス・アー | カプセルを認識する飲料調製マシン |

| CA3130851A1 (en) * | 2019-02-21 | 2020-08-27 | The Coca-Cola Company | Beverage dispensing system with remote micro-ingredient storage systems |

| CN111595100A (zh) * | 2019-02-21 | 2020-08-28 | 佛山市顺德区美的饮水机制造有限公司 | 调温式可分离存储饮用液体制冷系统及制冷设备 |

| US11470853B2 (en) | 2019-03-15 | 2022-10-18 | CocoTerra Company | Interface and application for designing a chocolate-making experience |

| CN209951060U (zh) * | 2019-03-28 | 2020-01-17 | 张文丞 | 一种智能萃取饮料冷却机 |

| DE102019218722A1 (de) * | 2019-12-02 | 2021-06-02 | Wmf Group Gmbh | Kaffeemaschine mit Modul zur Inaktivierung von Mikroorganismen |

| BR112022013134A2 (pt) | 2020-02-05 | 2022-09-06 | Nestle Sa | Máquina para o preparo de bebidas com reconhecimento de cápsula |

| WO2021156268A1 (en) | 2020-02-05 | 2021-08-12 | Societe Des Produits Nestle S.A. | Beverage preparation machine with capsule recognition |

| US11261076B1 (en) * | 2020-08-13 | 2022-03-01 | Pepsico, Inc. | Beverage dispense monitoring with camera |

| CA3233465A1 (en) * | 2021-10-13 | 2023-04-20 | Laurent LAGOUCHE | Ergonomic beverage machine |

| KR102454113B1 (ko) * | 2021-11-02 | 2022-10-14 | (주)메디프레소 | Uv램프를 이용한 급수부 살균 시스템을 이용하는 캡슐음료 추출장치 및 이의 제어방법 |

| US11412878B1 (en) * | 2021-11-26 | 2022-08-16 | Mark Wolf | One touch cooker |

| US20230405539A1 (en) * | 2022-06-17 | 2023-12-21 | C18 Llc | Control method of carbonated water machine and carbonated water machine |

| US12005408B1 (en) | 2023-04-14 | 2024-06-11 | Sharkninja Operating Llc | Mixing funnel |

| WO2024254837A1 (en) | 2023-06-16 | 2024-12-19 | Sharkninja Operating Llc | Carbonation mixing nozzles |

Family Cites Families (270)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2899106A (en) | 1959-08-11 | Dry powder dispersing device | ||

| DE276991C (de) * | 1913-07-16 | 1914-07-24 | ||

| GB468248A (en) | 1936-01-29 | 1937-07-01 | Aveling Barford Ltd | Improvements relating to containers such as containers for cooking foodstuffs |

| US2243895A (en) | 1938-09-21 | 1941-06-03 | William F Brown | Beverage machine |

| CH276991A (de) * | 1949-11-11 | 1951-08-15 | Schmidt Fritz | Vorrichtung zum Sieden von Flüssigkeiten, insbesondere von Milch, speziell für Restaurationsbetriebe und Haushaltungen. |

| US2715868A (en) | 1951-11-23 | 1955-08-23 | Internat Coffee Corp | Coffee extracting and dispensing apparatus |

| GB828529A (en) | 1955-05-04 | 1960-02-17 | Jonas Geoffrey Jessel | Improvements in or relating to apparatus for dispensing beverages |

| US3149471A (en) * | 1962-02-09 | 1964-09-22 | Borg Warner | Water chiller |

| FR1364608A (fr) | 1963-03-04 | 1964-06-26 | Moyens nouveaux pour obtenir des boissons avec des cartouches pré-conditionnées | |

| US3336857A (en) | 1965-05-27 | 1967-08-22 | Corning Glass Works | Invertible drip coffee maker |

| US3380374A (en) * | 1966-08-24 | 1968-04-30 | William M. Lowerre Jr. | Liquid infusion device |

| FR1537031A (fr) | 1967-06-26 | 1968-08-23 | Procédé et dispositif pour obtenir une boisson à partir d'un produit de base pulvérulent ou liquide | |

| US3403617A (en) | 1967-11-20 | 1968-10-01 | Universal Oil Prod Co | Apparatus for piercing containers for use in beverage producing machines |

| GB1215840A (en) | 1968-05-09 | 1970-12-16 | Universal Oil Prod Co | Apparatus for piercing containers for use in beverage producing machines |

| US3607297A (en) | 1969-03-13 | 1971-09-21 | Osvaldo Fasano | Method for producing beverages |

| US3805999A (en) | 1972-03-27 | 1974-04-23 | M Syverson | Hot drink dispenser |

| US4147097A (en) * | 1976-09-23 | 1979-04-03 | The Procter & Gamble Company | Method of and apparatus for making drip-type coffee |

| USD255529S (en) | 1978-01-09 | 1980-06-24 | Salton, Inc. | Coffee maker |

| IT7821703U1 (it) | 1978-05-03 | 1979-11-03 | Illy Caffe S P A | Macchina per fare una tazza di caffe'. |

| US4206694A (en) | 1978-05-22 | 1980-06-10 | Salton, Inc. | Infuser primarily intended for use in making coffee |

| SU688175A1 (ru) | 1978-05-23 | 1979-09-30 | Киевский Филиал Всесоюзного Научно-Исследовательского Института Технической Эстетики | Кофеварка |

| US4382402A (en) | 1981-04-01 | 1983-05-10 | Alvarez Donald E | Portable coffee maker |

| US4384512A (en) * | 1981-05-11 | 1983-05-24 | Keith Glenn R | Beverage heater and cooler |

| US4389191A (en) | 1981-09-01 | 1983-06-21 | Lowe Richard L | Apparatus for moving a vessel heater cover |

| DE3138779A1 (de) | 1981-09-30 | 1983-04-21 | Peter Dipl.-Ing. 8034 Germering Klein | Elektrisch betriebene einrichtung zur herstellung von aufgussgetraenken. |

| US4744291A (en) | 1982-01-26 | 1988-05-17 | Hamilton Beach Inc. | Electric coffee maker |

| IT1152110B (it) | 1982-05-04 | 1986-12-31 | Illycaffe Spa | Macchina automatica per fare caffe' espresso |

| SE8302444L (sv) | 1982-05-13 | 1983-11-14 | Mars Ltd | Utmatningsanordning |

| US4448113A (en) * | 1982-09-29 | 1984-05-15 | Brabon David L | Coffee refreshener |

| JPS59156317A (ja) * | 1983-02-28 | 1984-09-05 | 金沢工業株式会社 | コ−ヒ−等の抽出装置 |

| IT8321543U1 (it) | 1983-04-14 | 1984-10-14 | Nuova Faema Spa | Macchina per il caffe' espresso con regolazione automatica della temperatura dell'acqua. |

| US4775048A (en) | 1983-05-05 | 1988-10-04 | Alfredo Baecchi | Dispensing unit for manually-operated hot drink dispensing machine with pre-manufactured throwaway capsules of two sizes |

| US4723688A (en) * | 1983-11-03 | 1988-02-09 | Munoz Edward A | Beverage container and dispenser |

| CH655234A5 (fr) | 1984-01-26 | 1986-04-15 | Nestle Sa | Machine a cafe. |

| DK151558C (da) | 1984-05-22 | 1988-08-15 | Douwe Egberts Tabaksfab | Engangsemballage til opbevaring og transport af et flydende eller viskoest produkt |

| JPS618259U (ja) | 1984-06-21 | 1986-01-18 | 宗裕 久井 | フアインセラミツクス・鍵 |

| CH664886A5 (fr) | 1985-04-30 | 1988-04-15 | Nestle Sa | Appareil pour la confection automatique d'une boisson. |

| GB8513531D0 (en) | 1985-05-29 | 1985-07-03 | Still & Sons Ltd W M | Apparatus for making tea/coffee |

| CH668544A5 (fr) | 1986-04-24 | 1989-01-13 | Nestle Sa | Dispositif d'extraction de cafe de cartouches. |

| US4728281A (en) * | 1986-07-21 | 1988-03-01 | Mcguffin George B | Key controlled beverage making device |

| US4704954A (en) * | 1986-11-10 | 1987-11-10 | Mollenhoff David V | Drip coffee maker |

| US4792059A (en) | 1987-02-04 | 1988-12-20 | United States Thermoelectric Corporation | Sealed hot, cold and room temperature pure water dispenser |

| FR2610502B1 (fr) | 1987-02-11 | 1991-02-08 | Levi Mario | Un dispositif de detection et d'affichage pour machine a cafe express a service automatique |

| JP2727319B2 (ja) | 1988-02-05 | 1998-03-11 | 富士写真フイルム株式会社 | 温度制御装置 |

| GB8806666D0 (en) | 1988-03-21 | 1988-04-20 | Gen Foods Ltd | Method for preparing beverages & beverage preparing machines |

| US4990352A (en) | 1988-03-21 | 1991-02-05 | General Foods Limited | Method for preparing beverages |

| GB8806670D0 (en) | 1988-03-21 | 1988-04-20 | Gen Foods Ltd | Beverage preparing machines |

| GB8806668D0 (en) | 1988-03-21 | 1988-04-20 | Gen Foods Ltd | Method for preparing beverages & beverage preparing machines |

| GB2219194B (en) | 1988-05-30 | 1992-08-05 | Toshiba Kk | Siphon coffee maker |

| US5080008A (en) | 1988-07-12 | 1992-01-14 | Edward Helbling | Coffee machine with product selectivity |

| US5072660A (en) | 1988-07-12 | 1991-12-17 | Edward Helbling | Automatic infusion-beverage apparatus |

| US4838152A (en) | 1988-07-21 | 1989-06-13 | Black & Decker | Auto-off coffee brewing system |

| US4921712A (en) | 1988-08-19 | 1990-05-01 | Malmquist Neil A | Automatic low volume beverage brewing system |

| JPH0287759A (ja) | 1988-09-26 | 1990-03-28 | Nippon Telegr & Teleph Corp <Ntt> | 情報伝送方式 |

| USD316795S (en) | 1988-12-19 | 1991-05-14 | Bunn-O-Matic Corporation | Beverage brewer |

| JPH0531085Y2 (de) | 1988-12-20 | 1993-08-10 | ||

| US5063836A (en) | 1989-01-25 | 1991-11-12 | Cafe 98 Industries Ltd. | Coffee making machine and components thereof |

| IT1235261B (it) | 1989-01-30 | 1992-06-26 | Illycaffe Spa | Macchina da caffe'. |

| US4875408A (en) | 1989-02-27 | 1989-10-24 | Mcgee Frank C | Beverage maker for use in automotive vehicles |

| CA1269690A (en) | 1989-03-14 | 1990-05-29 | Peter Klein | Electrical apparatus useful to prepare a hot beverage |

| US4917005A (en) | 1989-06-09 | 1990-04-17 | Bunn-O-Matic Corporation | Beverage brewer with brewing temperature interlock |

| IT1230290B (it) | 1989-07-05 | 1991-10-18 | Nuova Faema Spa | Macchina automatica per la erogazione di caffe', cappuccino e simili. |

| US5178058A (en) | 1989-07-13 | 1993-01-12 | Sara Lee/De N.V. | Filterpan ring for brewing prepackaged dry beverages |

| GB8924764D0 (en) | 1989-11-02 | 1989-12-20 | Mars G B Ltd | Dispensing machine |

| DE3937000C2 (de) | 1989-11-07 | 1995-05-04 | Willi Marco | Kaffeemaschine zur wahlweisen Zubereitung von Espresso-Kaffee oder Filterkaffee |

| JP2977224B2 (ja) * | 1990-03-28 | 1999-11-15 | 株式会社東芝 | 給湯装置 |

| US5134924A (en) | 1990-04-02 | 1992-08-04 | Wayne Vicker | Automatic coffee or like beverage making machine |

| US5183998A (en) | 1990-05-30 | 1993-02-02 | Mr. Coffee Inc. | Apparatus and method for heating water for infusion and the like |

| US5285717A (en) | 1990-07-19 | 1994-02-15 | Bunn-O-Matic Corporation | Brewer control |

| EP0468078B1 (de) | 1990-07-27 | 1993-08-25 | Societe Des Produits Nestle S.A. | Verfahren zum Aufbrühen von geschlossenen Portionspackungen und Vorrichtung zur Durchführung dieses Verfahrens |

| ATE97789T1 (de) | 1990-07-27 | 1993-12-15 | Nestle Sa | In einem patronenhalter anpassbarer einsatz. |

| ES2066058T3 (es) | 1990-07-27 | 1995-03-01 | Nestle Sa | Procedimiento de extraccion de cartuchos abiertos de cafe, cartucho de cafe y dispositivo de extraccion para efectuar el procedimiento. |

| DE69022847T2 (de) | 1990-07-27 | 1996-03-14 | Nestle Sa | Aufbrühvorrichtung für geschlossene Portionspackungen. |

| US5259295A (en) | 1990-10-04 | 1993-11-09 | Eberhard Timm | Container for the preparation of hot drinks |

| ES2085823B1 (es) | 1990-10-31 | 1997-01-01 | Coffea Sa | Conjunto de aparato y cartucho para preparar un producto liquido, tal como una bebida o un alimento liquido. |

| US5303639A (en) | 1991-04-10 | 1994-04-19 | Bunn-O-Matic Corporation | Automatic brewer |

| US5209069A (en) * | 1991-05-06 | 1993-05-11 | Grindmaster Corporation | Compact thermoelectrically cooled beverage dispenser |

| US5897899A (en) | 1991-05-08 | 1999-04-27 | Nestec S.A. | Cartridges containing substances for beverage preparation |

| EP0521187B1 (de) | 1991-07-05 | 1995-11-02 | Societe Des Produits Nestle S.A. | Gerät zum Extrahieren von Kartuschen, brauchbar für jede Espressomaschine |

| US5327815A (en) | 1991-07-05 | 1994-07-12 | Nestec S.A. | Device for use in beverage extraction machines |

| DE69114278T2 (de) | 1991-07-05 | 1996-06-27 | Nestle Sa | Gerät zum Extrahieren von Kartuschen. |

| US5440972A (en) | 1991-08-01 | 1995-08-15 | English; Philip H. | Portable beverage brewing device |

| CH682798A5 (de) * | 1991-11-15 | 1993-11-30 | Salvis Ag | Kaffeemaschine. |

| CA2083324A1 (en) | 1992-02-03 | 1993-08-04 | Shirdan J. Grykiewicz | Brew basket |

| JPH0730517Y2 (ja) | 1992-03-18 | 1995-07-12 | 全国学校用品株式会社 | 蓋付容器の閉止構造 |

| CA2116580C (en) | 1992-07-01 | 2000-11-07 | Andre Lussi | Appliance for preparation of hot drinks |

| JP3142960B2 (ja) | 1992-07-06 | 2001-03-07 | オリンパス光学工業株式会社 | 測距装置 |

| US5285718A (en) † | 1992-07-16 | 1994-02-15 | Newco Enterprises, Incorporated | Combination beverage brewer with cold water supply |

| DE69333428T2 (de) | 1992-07-20 | 2004-07-22 | Société des Produits Nestlé S.A. | Vorrichtung zur Extraktion undurchlässiger, verformbarer Portionspackungen |

| US5351604A (en) | 1992-09-01 | 1994-10-04 | Zuma Coffee Technologies, Inc. | Coffee brewer method and apparatus |

| US5840189A (en) | 1992-09-16 | 1998-11-24 | Keurig, Inc. | Beverage filter cartridge |

| US5305639A (en) | 1992-10-16 | 1994-04-26 | Scully Signal Company | LPG gauge sensor |

| DE4337425A1 (de) | 1992-12-03 | 1994-06-09 | Philips Electronics Nv | Kaffeemaschine |

| US5603254A (en) | 1993-06-02 | 1997-02-18 | Nestec S.A. | Apparatus for extracting substances contained in sealed pliant bags |

| FR2708452B1 (fr) | 1993-07-29 | 1997-09-05 | Moulinex Sa | Machine à infusion comportant un dispositif de purification d'eau. |

| GB9316717D0 (en) | 1993-08-11 | 1993-09-29 | Gen Foods Ltd | Cartridge and method for the preparation fo whipped beverages |

| DE9312009U1 (de) * | 1993-08-12 | 1993-10-07 | Robert Krups Gmbh & Co Kg, 42719 Solingen | Kaffeemaschine |

| JPH07108277A (ja) * | 1993-08-20 | 1995-04-25 | Suntory Ltd | 無菌化液体供給器 |

| FR2709655B1 (fr) | 1993-09-06 | 1995-11-24 | Cafes Cie Mediterraneenne | Machine à café express utilisant un conditionnement de café moulu du type pastille pré-dosée. |

| WO1995007648A1 (en) | 1993-09-17 | 1995-03-23 | Mars G.B. Limited | Beverage brewing |

| WO1995016377A1 (en) | 1993-12-13 | 1995-06-22 | Ferr-Max Kft. | Method of and apparatus for preparing a frothy coffee beverage, especially for household use |

| CN1056504C (zh) | 1993-12-20 | 2000-09-20 | 地中海咖啡公司 | 制备浸出式热饮料的自动机器 |

| US5375508A (en) | 1993-12-29 | 1994-12-27 | Bunn-O-Matic Corporation | Digital brewer control |

| US5549035A (en) | 1994-04-12 | 1996-08-27 | Simatelex Manufactory Co., Ltd. | Coffee making machines |

| AU3566095A (en) | 1994-09-22 | 1996-04-09 | Eugster/Frismag Ag | Brewing head for coffee portion capsules in an espresso machine |

| DE4435100A1 (de) | 1994-09-30 | 1996-04-04 | Braun Ag | Verfahren zur Regelung der Wassertemperatur in einer Brühgetränkemaschine |

| US5473972A (en) * | 1994-10-24 | 1995-12-12 | Conair Corporation | Milk container attachment for cappucino maker |

| US5967021A (en) | 1994-11-29 | 1999-10-19 | Yung; Simon K. C. | Food appliance and a coding system therefor |

| US5564601A (en) | 1994-12-05 | 1996-10-15 | Cleland; Robert K. | Beverage dispensing machine with improved liquid chiller |

| US5531152A (en) | 1995-01-05 | 1996-07-02 | Grimac Royal Falcon Corp. | Platen assembly for coffee maker using pre-dosaged coffee filter packets |

| US5463932A (en) | 1995-01-19 | 1995-11-07 | Olson; Allen W. | Coffee maker |

| DE19504839C1 (de) * | 1995-02-14 | 1996-04-04 | Braun Ag | Kaltwasservorratsbehälter für eine elektrische Haushaltsbrühgetränkemaschine |

| US5638740A (en) | 1995-02-24 | 1997-06-17 | Cai; Zhihua | Apparatus for brewing espresso and cappuccino |

| US5803320A (en) * | 1995-03-27 | 1998-09-08 | Abc Dispensing Technologies | Carbonated coffee beverage dispenser |

| US5479849A (en) | 1995-03-31 | 1996-01-02 | Vki Technologies, Inc. | Lower chamber vent for the lower chamber of a brewing machine |

| CN2234745Y (zh) * | 1995-05-26 | 1996-09-11 | 赖信雄 | 新型开水饮用机 |

| US5584229A (en) | 1995-08-14 | 1996-12-17 | Bunn-O-Matic Corporation | Reduced temperature coffee brewer |

| EP0761150B1 (de) * | 1995-08-30 | 1999-12-29 | Thermoplan Ag | Kaffeemaschine |

| EP0771542B1 (de) | 1995-10-31 | 1999-01-07 | ILLYCAFFE' S.p.A. | Verbesserte Kaffeemaschine |

| IT1282934B1 (it) | 1995-11-06 | 1998-04-01 | C M A Spa | Macchina per la preparazione del caffe', cappuccino o bevande infuse simili, in dosi singole o multiple |

| US6029562A (en) * | 1995-11-13 | 2000-02-29 | Kevin O'Donnell | Modular beverage brewing system with interlocking assembly |

| WO1997024052A1 (de) | 1995-12-28 | 1997-07-10 | Creaholic S.A. | Kaffeemaschine |

| US5638741A (en) | 1996-05-06 | 1997-06-17 | Cisaria; Salvatore | Group module for coffee machine |

| US5724883A (en) * | 1996-05-28 | 1998-03-10 | Franklin Industries, L.L.C. | Hot/cold beverage brewing device |

| GB9612234D0 (en) | 1996-06-12 | 1996-08-14 | Paul Claire C | Improvements in and relating to food preparation |

| US5772627A (en) * | 1996-07-19 | 1998-06-30 | Neuro Navigational Corp. | Ultrasonic tissue resector for neurosurgery |

| NL1003716C2 (nl) | 1996-07-31 | 1998-02-05 | Sara Lee De Nv | Werkwijze, systeem en inrichting voor het bereiden van een voor consumptie geschikte drank zoals koffie. |

| US5953981A (en) | 1996-09-18 | 1999-09-21 | Food Equipment Technologies Company, Inc | Brewing system with electrical controller and method |

| GB2318503B (en) * | 1996-10-28 | 2000-06-14 | Tsann Kuen Usa Inc | Tea making device |

| IT1286085B1 (it) | 1996-11-05 | 1998-07-07 | Illycaffe Spa | Perfezionamenti in una macchina da caffe' espresso |

| WO1998027854A1 (en) | 1996-12-23 | 1998-07-02 | Koninklijke Philips Electronics N.V. | Coffee maker |

| US5704275A (en) | 1996-12-31 | 1998-01-06 | Bloomfield Industries Canada, Limited | Electronic brew control system |

| US5862738A (en) | 1996-12-31 | 1999-01-26 | Bloomfield Industries Canada Limited | Electronic brew control system |

| US5899137A (en) | 1997-01-13 | 1999-05-04 | Weber Aircraft, Inc. | Beverage making apparatus with can piercer |

| USD389694S (en) | 1997-01-27 | 1998-01-27 | The Coca-Cola Company | Beverage dispenser |

| IT1290258B1 (it) | 1997-02-05 | 1998-10-22 | Marino Assunto Maver | Macchina per caffe' espresso caricabile a cialde |

| WO1998047418A1 (fr) | 1997-04-21 | 1998-10-29 | Compagnie Mediterraneenne Des Cafes S.A. | Procede de transformation d'une machine express a extraction verticale de cafe en une machine a extraction horizontale et appareil ainsi transforme |

| US5974950A (en) | 1997-09-24 | 1999-11-02 | Innovations Amk, Inc. | Electronic coded coffee packets sealed in a gas flushed envelope, a beverage brewing machine using same as well as a method for brewing |

| NL1007169C2 (nl) | 1997-09-30 | 1999-03-31 | Sara Lee De Nv | Inrichting voor het bereiden van koffie. |

| NL1007167C2 (nl) | 1997-09-30 | 1999-03-31 | Sara Lee De Nv | Werkwijze voor het bereiden van geschuimde melk of café-crème. |

| NL1007171C2 (nl) | 1997-09-30 | 1999-03-31 | Sara Lee De Nv | Samenstel voor gebruik in een koffiemachine voor het bereiden van koffie, houder en pouch van dat samenstel. |

| FR2771614B1 (fr) | 1997-12-01 | 2000-01-07 | Seb Sa | Porte-filtre pour cafetiere du type expresso |

| US6312589B1 (en) † | 1997-12-23 | 2001-11-06 | The Coca-Cola Company | Apparatus arranged to provide controllable water treatment customized to the conditions of water supplied to a beverage dispenser |

| WO1999039619A1 (en) | 1998-02-09 | 1999-08-12 | Koninklijke Philips Electronics N.V. | Apparatus for preparing beverages with end of brew phase detection |

| US6158328A (en) | 1998-04-17 | 2000-12-12 | Cai; Edward Zhihua | Apparatus and methods for making beverages |

| USD419821S (en) | 1998-05-07 | 2000-02-01 | Mars U.K. Limited | Beverage dispensing machine |

| US5875703A (en) * | 1998-08-10 | 1999-03-02 | Rolfes; Patrick J. | Coffee brewer and hot water dispenser |

| US6006653A (en) | 1998-09-14 | 1999-12-28 | Wing Shing Products (Bvi) Co., Ltd. | Coffee maker |

| EP1000574A1 (de) | 1998-11-16 | 2000-05-17 | Societe Des Produits Nestle S.A. | Verfahren und Gerät zum Extrahieren einer geschlossenen Kartusche |

| DK0951853T3 (da) | 1998-11-25 | 2002-07-22 | Pi Design Ag | Anordning til tilberedning af varme drikke og fremgangsmåde til tilberedning af varme drikke ved hjælp af anordningen |

| US6085638A (en) | 1998-12-04 | 2000-07-11 | Amway Corporation | Coffee maker |

| DE19856165C2 (de) | 1998-12-05 | 2001-09-20 | Eberspaecher J Gmbh & Co | Heizgeräte-Schaltung für ein mit Flüssigbrennstoff betriebenes Wasser- oder Luft-Heizgerät eines Kraftfahrzeuges |

| DE19857165C2 (de) | 1998-12-11 | 2000-11-30 | Braun Gmbh | Vorrichtung für die wahlweise Kaffee-, Tee-, Heißwasser- oder Brühwasserbereitung |

| US6095031A (en) | 1999-01-08 | 2000-08-01 | Bloomfield Industries Canada Limited | Computer controlled brewing apparatus |

| US6142063A (en) | 1999-01-19 | 2000-11-07 | Keurig, Inc. | Automated beverage brewing system |

| DE69906956T2 (de) | 1999-01-19 | 2004-02-26 | Keurig, Inc., Waltham | Automatisches brühsystem |

| US6079315A (en) | 1999-01-19 | 2000-06-27 | Keurig, Inc. | Beverage filter cartridge holder |

| DE69905234T2 (de) | 1999-02-12 | 2003-09-11 | Societe Des Produits Nestle S.A., Vevey | Nachfüllkartusche für eine Getränke-Abgabevorrichtung und an solche Kartuschen angepasste Vorrichtung |

| US6245371B1 (en) | 1999-03-02 | 2001-06-12 | The Procter & Gamble Company | Method and apparatus for brewing a fluid extract using an inclined filter pouch containing flavor extractable particles |

| EP1046366B2 (de) | 1999-04-23 | 2009-01-07 | Saeco IPR Limited | Einrichtung zum Zuführen von abgepackten Portionen gemahlenen Kaffees in eine Brüheinheit |

| EP1055386A1 (de) * | 1999-05-25 | 2000-11-29 | Roland Wolf | Heisswasseraufbereiter |

| JP2000355375A (ja) | 1999-06-09 | 2000-12-26 | Toyo Seikan Kaisha Ltd | 飲料調製用密封容器 |

| US6240833B1 (en) | 1999-08-04 | 2001-06-05 | John C. K. Sham | Automatic French Press beverage maker |

| US6062127A (en) | 1999-08-13 | 2000-05-16 | Klosinski; Boguslaw | Portable espresso maker |

| US6759072B1 (en) | 1999-08-14 | 2004-07-06 | The Procter + Gamble Co. | Methods and systems for utilizing delayed dilution, mixing and filtration for providing customized beverages on demand |

| NL1012847C2 (nl) | 1999-08-17 | 2001-02-20 | Sara Lee De Nv | Inrichting voor het bereiden van koffie. |

| DK1090574T3 (da) | 1999-08-31 | 2005-03-21 | Nestle Sa | Indretning til udtrækning af en substans til tilberedning af en drikkevare |

| US6173117B1 (en) | 1999-09-14 | 2001-01-09 | Bobbye L. Clubb | Heated beverage machine |

| ATE275852T1 (de) | 1999-10-28 | 2004-10-15 | Nestle Sa | Auswurfvorrichtung für kartusche |

| US6641719B1 (en) * | 1999-11-30 | 2003-11-04 | Yosuke Naito | Water purifier for use with bottle container |

| US6405637B1 (en) | 2000-01-13 | 2002-06-18 | Houseware Technology Group Llc | Fluid delivery system for generating pressure pulses to make beverages |

| USD452107S1 (en) | 2000-02-02 | 2001-12-18 | Societe Des Produits Nestle S.A. | Coffee machine |

| GB0003355D0 (en) | 2000-02-14 | 2000-04-05 | Kraft Jacobs Suchard Limited | Cartridge and method for the preparation of whipped beverages |

| FR2806606B1 (fr) | 2000-03-24 | 2002-10-25 | Moulinex Sa | Machine a cafe electrique avec reservoir d'eau pivotant |

| PT1151707E (pt) | 2000-05-04 | 2004-10-29 | Nestle Sa | Dipositivo para a extraccao de uma substancia com uma peca movel |

| PT1153561E (pt) | 2000-05-09 | 2005-09-30 | Nestle Sa | Dispositivo para a extraccao de uma substancia |

| US6499388B2 (en) | 2000-06-14 | 2002-12-31 | Fianara Interational B. V. | Coffee machine for brewing coffee power pre-packed in a cartridge |

| USD454467S1 (en) | 2000-06-16 | 2002-03-19 | Heineken Technical Services B.V. | Drink dispensing apparatus |

| CZ20012835A3 (cs) | 2000-08-30 | 2002-04-17 | Fianara International B. V. | Kávovar k vaření kávového práąku předbaleného v zásobníku |

| AU2001284273A1 (en) | 2000-09-06 | 2002-03-22 | Mars Uk Limited | Methods and apparatus for brewing beverages |

| US20020048621A1 (en) | 2000-10-06 | 2002-04-25 | Boyd David D. | Encoded coffee packet |

| USD454466S1 (en) | 2000-11-22 | 2002-03-19 | Atico International Usa, Inc. | Coffee maker |

| TR200402491T4 (tr) | 2000-11-28 | 2004-12-21 | Societe Des Produits Nestle S.A. | Süzme tertibatı. |

| US6740345B2 (en) | 2000-12-22 | 2004-05-25 | Edward Zhihua Cai | Beverage making cartridge |

| US6460735B1 (en) † | 2001-01-24 | 2002-10-08 | Shlomo Greenwald | Beverage dispenser having selectable temperature |

| US7418899B2 (en) | 2001-02-08 | 2008-09-02 | Kraft Foods R & D, Inc. | Cartridge for the preparation of beverages |

| CA2335420A1 (en) | 2001-02-12 | 2002-08-12 | Pierre Mercier | Method and apparatus for the preparation of hot beverages |

| WO2002074144A2 (en) | 2001-03-16 | 2002-09-26 | The Procter & Gamble Company | Beverage brewing system |

| DE10116239A1 (de) | 2001-03-31 | 2002-10-17 | Eugster Frismag Ag Romanshorn | Maschinell lesbare Kennung, System zu deren Erfassung sowie Prüfverfahren für die maschinell lesbare Kennung |

| DK1247481T3 (da) | 2001-04-03 | 2005-02-14 | Nestle Sa | Udtrækningsindretning med integreret system til indsætning af kapsler |

| US6606938B2 (en) | 2001-04-06 | 2003-08-19 | Keurig, Incorporated | Two step puncturing and venting of single serve filter cartridge in a beverage brewer |

| US6708600B2 (en) | 2001-04-06 | 2004-03-23 | Keurig, Incorporated | Puncturing and venting of single serve beverage filter cartridge |

| US6644173B2 (en) | 2001-04-11 | 2003-11-11 | Keuring, Incorporated | Beverage filter cartridge holder |

| US6655260B2 (en) | 2001-04-11 | 2003-12-02 | Keurig, Incorporated | Beverage filter cartridge holder |

| WO2002085170A2 (en) | 2001-04-18 | 2002-10-31 | Keurig, Incorporated | System for monitoring and controlling the operation of a single serve beverage brewer |

| GB2374795B (en) | 2001-04-27 | 2005-08-03 | Mars Inc | Multicomponent beverage making apparatus and method |

| GB2379624B (en) | 2001-09-18 | 2005-07-20 | Mars Inc | Berverage making appartus and method |

| GB2374856B (en) | 2001-04-27 | 2004-11-03 | Mars Uk Ltd | Production of edible foams |

| ATE420584T1 (de) | 2001-04-27 | 2009-01-15 | Mars Inc | Verfahren, apparat und system zur herstellung von geschäumten getränken |

| GB2374816B (en) | 2001-04-27 | 2004-12-15 | Mars Uk Ltd | Production of foamed drinks |

| AUPR538401A0 (en) * | 2001-06-01 | 2001-06-28 | Khoury, Edward Joseph | Cordless base |

| US7063238B2 (en) | 2001-06-29 | 2006-06-20 | Robert Hale | Cartridge ejector for a beverage dispensing machine |

| US7032818B2 (en) | 2001-07-03 | 2006-04-25 | Nestec S.A. | Method and system of setting and/or controlling of a food product dispensing machine using a tag-type communication device |

| CN2523331Y (zh) | 2001-07-24 | 2002-12-04 | 何进生 | 加热可移动分离式饮水机 |

| USD459628S1 (en) | 2001-08-07 | 2002-07-02 | Societe Des Produits Nestle, S.A. | Coffee machine |

| NL1019013C2 (nl) | 2001-09-21 | 2003-03-26 | Sara Lee De Nv | Bereiding van cappuccino. |

| WO2003030696A1 (en) | 2001-10-05 | 2003-04-17 | Hp Intellectual Corp. | Coffee maker |

| US6698228B2 (en) | 2001-11-02 | 2004-03-02 | Moobella, Llc | Method and apparatus for producing and dispensing an aerated and/or blended food product |

| DK1310199T3 (da) | 2001-11-09 | 2007-05-21 | Nestle Sa | Indretning og fremgangsmåde til udvælgelse og ekstraktion af en kapsel til fremstilling af en drik |

| NL1019449C2 (nl) | 2001-11-29 | 2003-06-03 | Sara Lee De Nv | Inrichting voor het bereiden van een voor consumptie geschikte drank, voorzien van tenminste één roerder. |

| GB2382976B (en) | 2001-12-11 | 2005-07-20 | Mars Inc | Beverage brewing method and apparatus |

| USD460653S1 (en) | 2002-01-02 | 2002-07-23 | Societe Des Produits Nestle S.A. | Coffee machine |

| ME00324B (me) | 2002-01-16 | 2011-05-10 | Nestle Sa | Zatvorena kapsula sa uređajem za otvaranje |

| USD461358S1 (en) | 2002-01-22 | 2002-08-13 | Societe Des Produits Nestle S.A. | Coffee machine |

| US6786134B2 (en) | 2002-02-07 | 2004-09-07 | The Coca-Cola Company | Coffee and tea dispenser |

| USD479939S1 (en) | 2002-02-13 | 2003-09-30 | Fatia Industrial Co., Ltd. | Coffee maker |

| RU2283016C2 (ru) | 2002-04-18 | 2006-09-10 | Туттоэспрессо С.П.А. | Машина для приготовления напитков |

| US6786136B2 (en) | 2002-06-25 | 2004-09-07 | Unilever Bestfoods, North America, Division Of Conopco, Inc. | Apparatus for preventing passing off of a brewed beverage |