JP4635167B2 - 被制御プロセスにおける異常の根本原因診断装置 - Google Patents

被制御プロセスにおける異常の根本原因診断装置 Download PDFInfo

- Publication number

- JP4635167B2 JP4635167B2 JP2003535005A JP2003535005A JP4635167B2 JP 4635167 B2 JP4635167 B2 JP 4635167B2 JP 2003535005 A JP2003535005 A JP 2003535005A JP 2003535005 A JP2003535005 A JP 2003535005A JP 4635167 B2 JP4635167 B2 JP 4635167B2

- Authority

- JP

- Japan

- Prior art keywords

- model

- detection

- industrial

- signal

- root cause

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B23/00—Testing or monitoring of control systems or parts thereof

- G05B23/02—Electric testing or monitoring

- G05B23/0205—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults

- G05B23/0218—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults characterised by the fault detection method dealing with either existing or incipient faults

- G05B23/0243—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults characterised by the fault detection method dealing with either existing or incipient faults model based detection method, e.g. first-principles knowledge model

- G05B23/0254—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults characterised by the fault detection method dealing with either existing or incipient faults model based detection method, e.g. first-principles knowledge model based on a quantitative model, e.g. mathematical relationships between inputs and outputs; functions: observer, Kalman filter, residual calculation, Neural Networks

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B13/00—Adaptive control systems, i.e. systems automatically adjusting themselves to have a performance which is optimum according to some preassigned criterion

- G05B13/02—Adaptive control systems, i.e. systems automatically adjusting themselves to have a performance which is optimum according to some preassigned criterion electric

- G05B13/0265—Adaptive control systems, i.e. systems automatically adjusting themselves to have a performance which is optimum according to some preassigned criterion electric the criterion being a learning criterion

- G05B13/0275—Adaptive control systems, i.e. systems automatically adjusting themselves to have a performance which is optimum according to some preassigned criterion electric the criterion being a learning criterion using fuzzy logic only

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B21/00—Systems involving sampling of the variable controlled

- G05B21/02—Systems involving sampling of the variable controlled electric

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B23/00—Testing or monitoring of control systems or parts thereof

- G05B23/02—Electric testing or monitoring

- G05B23/0205—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults

- G05B23/0218—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults characterised by the fault detection method dealing with either existing or incipient faults

- G05B23/0243—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults characterised by the fault detection method dealing with either existing or incipient faults model based detection method, e.g. first-principles knowledge model

- G05B23/0245—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults characterised by the fault detection method dealing with either existing or incipient faults model based detection method, e.g. first-principles knowledge model based on a qualitative model, e.g. rule based; if-then decisions

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B23/00—Testing or monitoring of control systems or parts thereof

- G05B23/02—Electric testing or monitoring

- G05B23/0205—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults

- G05B23/0259—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults characterized by the response to fault detection

- G05B23/0275—Fault isolation and identification, e.g. classify fault; estimate cause or root of failure

- G05B23/0278—Qualitative, e.g. if-then rules; Fuzzy logic; Lookup tables; Symptomatic search; FMEA

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B23/00—Testing or monitoring of control systems or parts thereof

- G05B23/02—Electric testing or monitoring

- G05B23/0205—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults

- G05B23/0259—Electric testing or monitoring by means of a monitoring system capable of detecting and responding to faults characterized by the response to fault detection

- G05B23/0275—Fault isolation and identification, e.g. classify fault; estimate cause or root of failure

- G05B23/0281—Quantitative, e.g. mathematical distance; Clustering; Neural networks; Statistical analysis

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B9/00—Safety arrangements

- G05B9/02—Safety arrangements electric

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N5/00—Computing arrangements using knowledge-based models

- G06N5/02—Knowledge representation; Symbolic representation

- G06N5/022—Knowledge engineering; Knowledge acquisition

- G06N5/025—Extracting rules from data

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/31—From computer integrated manufacturing till monitoring

- G05B2219/31464—Select between different models corresponding to diff process control configurations

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Automation & Control Theory (AREA)

- Artificial Intelligence (AREA)

- Mathematical Physics (AREA)

- Evolutionary Computation (AREA)

- Software Systems (AREA)

- General Engineering & Computer Science (AREA)

- Fuzzy Systems (AREA)

- Theoretical Computer Science (AREA)

- Medical Informatics (AREA)

- Algebra (AREA)

- Quality & Reliability (AREA)

- Mathematical Analysis (AREA)

- Health & Medical Sciences (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Probability & Statistics with Applications (AREA)

- Mathematical Optimization (AREA)

- Computational Linguistics (AREA)

- Data Mining & Analysis (AREA)

- Computing Systems (AREA)

- Pure & Applied Mathematics (AREA)

- Testing And Monitoring For Control Systems (AREA)

- Feedback Control In General (AREA)

Description

4……プロセスパイプ

6……2線プロセス制御ループ

8……送信機

10……コントローラ

12……通信機

14……制御室

16……センサ

18……バルブ

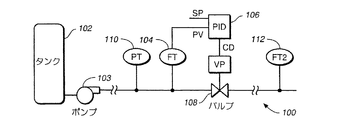

100……プロセス装置

102……根本原因分析ブロック

104……制御信号入力

106……プロセス変数入力

108……設定ポイント入力

110,111……プロセス信号入力

112……プロセス形成モデル

116……モデル選択入力

118……表示出力

120……根本原因出力

Claims (21)

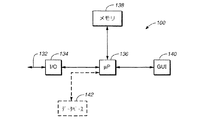

- 工業プロセスにおける異常の根本原因を特定するための工業プロセス診断装置において、

複数のプロセス形成モデルを記憶するメモリであって、各々のプロセス形成モデルが、工業プロセスの、タイプが異なる複数のプロセス制御ループの各々での基本的なプロセス処理用および検出用の構成要素の物理的な接続関係、さらにプロセス処理用および検出用のオプションの構成要素が追加された場合には該プロセス処理用および検出用のオプションの構成要素の物理的な接続関係も表すモデルと、前記基本的な検出用の各構成要素で検出されるプロセス信号に基づいて異常の根本原因を決定するために使用されるルールベース、さらに前記プロセス処理用および検出用のオプションの構成要素が追加された場合に該検出用のオプションの構成要素で検出されるプロセス信号をも用いて異常の根本原因を決定するために使用されるルールベースを含んでいる複数のプロセス形成モデルを記憶するメモリと、

前記基本的なプロセス処理用および検出用の構成要素の物理的な接続関係を表すモデルに前記プロセス処理用および検出用のオプションの構成要素を追加するように構成され、また、前記メモリに記憶された複数のプロセス形成モデルのうちの唯一のプロセス形成モデルを特定し、該プロセス形成モデルを前記メモリから読み出すように構成された選択入力手段と、

前記選択入力手段により読み出されたプロセス形成モデルに含まれるモデルの、検出用の各構成要素で検出されるプロセス信号を入力するように構成された信号入力手段と、

前記選択入力手段により読み出されたプロセス形成モデルに含まれるモデルの工業プロセスにおける異常の根本原因を示す根本原因出力を出力する根本原因分析手段であって、前記選択入力手段により読み出されたプロセス形成モデルに含まれるモデルの、検出用の各構成要素で検出されるプロセス信号に基づいて異常の根本原因を決定するルールベースと前記信号入力手段によって入力されたプロセス信号を入力として異常の根本原因を判定し、その判定結果を異常の根本原因出力として送出する根本原因分析手段とからなる工業プロセス診断装置。 - PC内に実装される請求項1記載の工業プロセス診断装置。

- プロセス装置内に実装される請求項1記載の工業プロセス診断装置。

- 前記プロセス装置が送信機を含む請求項3記載の工業プロセス診断装置。

- 前記プロセス装置がコントローラを含む請求項3記載の工業プロセス診断装置。

- 前記モデルが、プロセス処理用および検出用の構成要素の物理的な接続関係を表すグラフィック表現を提供するグラフィックモデルを含む請求項1記載の工業プロセス診断装置。

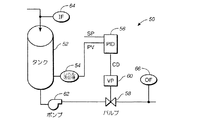

- 前記プロセス信号が、液体レベルまたは液体流速を表すプロセス変数(PV)、前記プロセス変数に従って構成要素を制御するための制御要求(CD)信号、および前記プロセス変数の所望値を示す設定ポイント(SP)を含む請求項1記載の工業プロセス診断装置。

- 前記プロセス信号が、前記制御要求(CD)信号に応答して提供される実際の制御値を表すプロセス信号をさらに含む請求項7記載の工業プロセス診断装置。

- 前記プロセス信号が、その他のプロセス変数をさらに含む請求項7記載の工業プロセス診断装置。

- 前記複数のプロセス形成モデルの少なくとも一つが、液体レベルプロセス制御ループを採用した工業プロセスのプロセス処理用および検出用の構成要素の物理的な接続関係を表すモデルを含む請求項1記載の工業プロセス診断装置。

- 前記複数のプロセス形成モデルが、プロセス流体流量制御ループを採用した工業プロセスのプロセス処理用および検出用の構成要素の物理的な接続関係を表すモデルを含む請求項1記載の工業プロセス診断装置。

- 工業プロセスにおける異常の根本原因を特定するための工業プロセス診断方法において、

各々のプロセス形成モデルが、工業プロセスの、タイプが異なる複数のプロセス制御ループでの基本的なプロセス処理用および検出用の構成要素の物理的な接続関係、さらに選択入力手段によりプロセス処理用および検出用のオプションの構成要素が追加された場合には該プロセス処理用および検出用のオプションの構成要素の物理的な接続関係も表すモデルと、前記基本的な検出用の各構成要素で検出されるプロセス信号に基づいて異常の根本原因を決定するために使用されるルールベース、さらに前記選択入力手段により前記プロセス処理用および検出用のオプションの構成要素が追加された場合に該検出用のオプションの構成要素で検出されるプロセス信号をも用いて異常の根本原因を決定するために使用される複数のルールベースを含んでいる複数のプロセス形成モデルを記憶しているメモリから、前記基本的なプロセス処理用および検出用の構成要素の物理的な接続関係を表すモデルあるいは前記選択入力手段により前記プロセス処理用および検出用のオプションの構成要素が追加された場合には該プロセス処理用および検出用のオプションの構成要素の物理的な接続関係も表すモデルを含む唯一のプロセス形成モデルを、前記選択入力手段によりから送出されるモデル選択入力によって特定して読み出し、

該プロセス形成モデルに含まれるモデルの検出用の各構成要素で検出されるプロセス信号を受信し、

前記メモリから読み出されたプロセス形成モデルに含まれるモデルの、検出用の各構成要素で検出されるプロセス信号に基づいて異常の根本原因を決定するルールベースと受信されたプロセス信号を入力として異常の根本原因を判定し、その判定結果を異常の根本原因出力として送出する工業プロセス診断方法。 - 請求項12記載の工業プロセス診断方法を設備したPC。

- 請求項12記載の工業プロセス診断方法を設備した処理装置。

- 前記モデルが、プロセス処理用および検出用の構成要素の物理的な接続関係を表すグラフィック表現を提供するグラフィックモデルを含む請求項12記載の工業プロセス診断方法。

- 前記プロセス信号が、液体レベルまたは液体流速を表すプロセス変数(PV)、前記プロセス変数に従って構成要素を制御するための制御要求(CD)信号、および前記プロセス変数の所望値を示す設定ポイント(SP)を含む請求項12記載の工業プロセス診断方法。

- 前記プロセス信号が、前記制御要求(CD)信号に応答して提供される実際の制御値を表すプロセス信号をさらに含む請求項16記載の工業プロセス診断方法。

- 前記記プロセス信号が、その他のプロセス変数をさらに含む請求項16記載の工業プロセス診断方法。

- 前記複数のプロセス形成モデルの少なくとも一つが、液体レベルプロセス制御ループを採用した工業プロセスのプロセス処理用および検出用の構成要素の物理的な接続関係を表すモデルを含む請求項12記載の工業プロセス診断方法。

- 前記複数のプロセス形成モデルが、プロセス流体流量制御ループを採用した工業プロセスのプロセス処理用および検出用の構成要素の物理的な接続関係を表すモデルを含む請求項12記載の工業プロセス診断方法。

- 請求項12記載の工業プロセス診断方法を実施するために形成されたコンピュータ命令を記憶する記憶媒体。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/972,078 US7085610B2 (en) | 1996-03-28 | 2001-10-05 | Root cause diagnostics |

| PCT/US2002/030465 WO2003032100A1 (en) | 2001-10-05 | 2002-09-25 | Root cause diagnostics of aberrations in a controlled process |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008170413A Division JP2008269640A (ja) | 2001-10-05 | 2008-06-30 | 工業プロセス診断装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005505822A JP2005505822A (ja) | 2005-02-24 |

| JP4635167B2 true JP4635167B2 (ja) | 2011-02-16 |

Family

ID=25519134

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003535005A Expired - Lifetime JP4635167B2 (ja) | 2001-10-05 | 2002-09-25 | 被制御プロセスにおける異常の根本原因診断装置 |

| JP2008170413A Pending JP2008269640A (ja) | 2001-10-05 | 2008-06-30 | 工業プロセス診断装置 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008170413A Pending JP2008269640A (ja) | 2001-10-05 | 2008-06-30 | 工業プロセス診断装置 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US7085610B2 (ja) |

| EP (1) | EP1436678B1 (ja) |

| JP (2) | JP4635167B2 (ja) |

| CN (1) | CN1260626C (ja) |

| DE (1) | DE60226757D1 (ja) |

| WO (1) | WO2003032100A1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014531598A (ja) * | 2011-09-28 | 2014-11-27 | ローズマウント インコーポレイテッド | 診断機能を有する圧力トランスミッタ |

Families Citing this family (87)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8290721B2 (en) | 1996-03-28 | 2012-10-16 | Rosemount Inc. | Flow measurement diagnostics |

| US7623932B2 (en) * | 1996-03-28 | 2009-11-24 | Fisher-Rosemount Systems, Inc. | Rule set for root cause diagnostics |

| CN100409129C (zh) * | 2000-02-25 | 2008-08-06 | 西门子公司 | 用于监控技术设备的装置及操作方法 |

| US7389204B2 (en) * | 2001-03-01 | 2008-06-17 | Fisher-Rosemount Systems, Inc. | Data presentation system for abnormal situation prevention in a process plant |

| US7720727B2 (en) * | 2001-03-01 | 2010-05-18 | Fisher-Rosemount Systems, Inc. | Economic calculations in process control system |

| US8073967B2 (en) * | 2002-04-15 | 2011-12-06 | Fisher-Rosemount Systems, Inc. | Web services-based communications for use with process control systems |

| US20020191102A1 (en) * | 2001-05-31 | 2002-12-19 | Casio Computer Co., Ltd. | Light emitting device, camera with light emitting device, and image pickup method |

| EP1599712B1 (en) * | 2003-02-14 | 2008-04-09 | Dresser, Inc. | Method, system and storage medium for performing online valve diagnostics |

| JP4636428B2 (ja) * | 2003-12-05 | 2011-02-23 | 横河電機株式会社 | 多変数伝送器及び多変数伝送器の演算処理方法 |

| WO2005078544A1 (en) * | 2004-02-05 | 2005-08-25 | Rosemount Inc. | Emergency shutdown valve diagnostics using a pressure transmitter |

| US7058089B2 (en) * | 2004-02-18 | 2006-06-06 | Rosemount, Inc. | System and method for maintaining a common sense of time on a network segment |

| US7234084B2 (en) | 2004-02-18 | 2007-06-19 | Emerson Process Management | System and method for associating a DLPDU received by an interface chip with a data measurement made by an external circuit |

| US7079984B2 (en) * | 2004-03-03 | 2006-07-18 | Fisher-Rosemount Systems, Inc. | Abnormal situation prevention in a process plant |

| US7676287B2 (en) * | 2004-03-03 | 2010-03-09 | Fisher-Rosemount Systems, Inc. | Configuration system and method for abnormal situation prevention in a process plant |

| US7515977B2 (en) * | 2004-03-30 | 2009-04-07 | Fisher-Rosemount Systems, Inc. | Integrated configuration system for use in a process plant |

| US7799273B2 (en) | 2004-05-06 | 2010-09-21 | Smp Logic Systems Llc | Manufacturing execution system for validation, quality and risk assessment and monitoring of pharmaceutical manufacturing processes |

| US7545531B2 (en) * | 2004-05-18 | 2009-06-09 | Xerox Corporation | Method and apparatus for implementing statistical process control (SPC) in a printing environment |

| US7536274B2 (en) * | 2004-05-28 | 2009-05-19 | Fisher-Rosemount Systems, Inc. | System and method for detecting an abnormal situation associated with a heater |

| US20050267709A1 (en) * | 2004-05-28 | 2005-12-01 | Fisher-Rosemount Systems, Inc. | System and method for detecting an abnormal situation associated with a heater |

| RU2007101229A (ru) | 2004-06-12 | 2008-07-20 | Фишер-Роузмаунт Системз | Система и способ для обнаружения аномальной ситуации, связанной с развитием процесса контура управления |

| US7349746B2 (en) * | 2004-09-10 | 2008-03-25 | Exxonmobil Research And Engineering Company | System and method for abnormal event detection in the operation of continuous industrial processes |

| US7424395B2 (en) * | 2004-09-10 | 2008-09-09 | Exxonmobil Research And Engineering Company | Application of abnormal event detection technology to olefins recovery trains |

| US20060074598A1 (en) * | 2004-09-10 | 2006-04-06 | Emigholz Kenneth F | Application of abnormal event detection technology to hydrocracking units |

| US7567887B2 (en) * | 2004-09-10 | 2009-07-28 | Exxonmobil Research And Engineering Company | Application of abnormal event detection technology to fluidized catalytic cracking unit |

| US7181654B2 (en) * | 2004-09-17 | 2007-02-20 | Fisher-Rosemount Systems, Inc. | System and method for detecting an abnormal situation associated with a reactor |

| BRPI0610522A2 (pt) * | 2005-04-04 | 2017-01-31 | Fisher Rosemount Systems Inc | métodos para detectar uma situação anormal associada com uma instalação de processo, uma situação anormal em um craqueador catalítico fluido e em uma coluna de destilação, para processar dados coletados em uma instalação de processo, e para adaptar uma onda senoidal aos dados coletados dentro de uma instalação de processo |

| US8112565B2 (en) | 2005-06-08 | 2012-02-07 | Fisher-Rosemount Systems, Inc. | Multi-protocol field device interface with automatic bus detection |

| US20070068225A1 (en) | 2005-09-29 | 2007-03-29 | Brown Gregory C | Leak detector for process valve |

| US7444191B2 (en) * | 2005-10-04 | 2008-10-28 | Fisher-Rosemount Systems, Inc. | Process model identification in a process control system |

| CN101305327A (zh) * | 2005-10-14 | 2008-11-12 | 费舍-柔斯芒特系统股份有限公司 | 与多元统计分析一起用于过程中的故障检测和隔离及异常情况预防的统计特征 |

| US8509926B2 (en) * | 2005-12-05 | 2013-08-13 | Fisher-Rosemount Systems, Inc. | Self-diagnostic process control loop for a process plant |

| US7761172B2 (en) * | 2006-03-21 | 2010-07-20 | Exxonmobil Research And Engineering Company | Application of abnormal event detection (AED) technology to polymers |

| US7720641B2 (en) * | 2006-04-21 | 2010-05-18 | Exxonmobil Research And Engineering Company | Application of abnormal event detection technology to delayed coking unit |

| US7869888B2 (en) * | 2006-05-31 | 2011-01-11 | Tokyo Electron Limited | Information processing apparatus, semiconductor manufacturing system, information processing method, and storage medium |

| US7657399B2 (en) * | 2006-07-25 | 2010-02-02 | Fisher-Rosemount Systems, Inc. | Methods and systems for detecting deviation of a process variable from expected values |

| US7912676B2 (en) * | 2006-07-25 | 2011-03-22 | Fisher-Rosemount Systems, Inc. | Method and system for detecting abnormal operation in a process plant |

| US8606544B2 (en) | 2006-07-25 | 2013-12-10 | Fisher-Rosemount Systems, Inc. | Methods and systems for detecting deviation of a process variable from expected values |

| US8145358B2 (en) * | 2006-07-25 | 2012-03-27 | Fisher-Rosemount Systems, Inc. | Method and system for detecting abnormal operation of a level regulatory control loop |

| WO2008018805A2 (en) | 2006-08-09 | 2008-02-14 | Auckland Uniservices Limited | Process control of an industrial plant |

| US20080065705A1 (en) * | 2006-09-12 | 2008-03-13 | Fisher-Rosemount Systems, Inc. | Process Data Collection for Process Plant Diagnostics Development |

| US20080125877A1 (en) * | 2006-09-12 | 2008-05-29 | Fisher-Rosemount Systems, Inc. | Process data collection system configuration for process plant diagnostics development |

| US20080065706A1 (en) * | 2006-09-12 | 2008-03-13 | Fisher-Rosemount Systems, Inc. | Process Data Storage For Process Plant Diagnostics Development |

| US7953501B2 (en) | 2006-09-25 | 2011-05-31 | Fisher-Rosemount Systems, Inc. | Industrial process control loop monitor |

| US8788070B2 (en) | 2006-09-26 | 2014-07-22 | Rosemount Inc. | Automatic field device service adviser |

| CN101529354A (zh) * | 2006-09-28 | 2009-09-09 | 费舍-柔斯芒特系统股份有限公司 | 焦化加热器中的异常情况预防 |

| CN101535909B (zh) | 2006-09-28 | 2012-08-29 | 费舍-柔斯芒特系统股份有限公司 | 热交换器中的异常情况预防 |

| US7778797B2 (en) * | 2006-09-28 | 2010-08-17 | Fisher-Rosemount Systems, Inc. | Method and system for detecting abnormal operation in a stirred vessel |

| US8010292B2 (en) * | 2006-09-28 | 2011-08-30 | Fisher-Rosemount Systems, Inc. | Method and system for detecting abnormal operation in a hydrocracker |

| US7917240B2 (en) * | 2006-09-29 | 2011-03-29 | Fisher-Rosemount Systems, Inc. | Univariate method for monitoring and analysis of multivariate data |

| US7750642B2 (en) | 2006-09-29 | 2010-07-06 | Rosemount Inc. | Magnetic flowmeter with verification |

| US7321846B1 (en) | 2006-10-05 | 2008-01-22 | Rosemount Inc. | Two-wire process control loop diagnostics |

| US20080188972A1 (en) * | 2006-10-11 | 2008-08-07 | Fisher-Rosemount Systems, Inc. | Method and System for Detecting Faults in a Process Plant |

| US8032340B2 (en) | 2007-01-04 | 2011-10-04 | Fisher-Rosemount Systems, Inc. | Method and system for modeling a process variable in a process plant |

| US8032341B2 (en) * | 2007-01-04 | 2011-10-04 | Fisher-Rosemount Systems, Inc. | Modeling a process using a composite model comprising a plurality of regression models |

| US7539560B2 (en) | 2007-01-05 | 2009-05-26 | Dresser, Inc. | Control valve and positioner diagnostics |

| US7827006B2 (en) * | 2007-01-31 | 2010-11-02 | Fisher-Rosemount Systems, Inc. | Heat exchanger fouling detection |

| JP4834580B2 (ja) * | 2007-03-06 | 2011-12-14 | 株式会社東芝 | プラント状態指標管理装置とその実現用コンピュータプログラム |

| US8046086B2 (en) * | 2007-05-15 | 2011-10-25 | Fisher-Rosemount Systems, Inc. | Methods and systems for batch processing and execution in a process system |

| US7770459B2 (en) * | 2007-07-20 | 2010-08-10 | Rosemount Inc. | Differential pressure diagnostic for process fluid pulsations |

| CN101802314B (zh) * | 2007-07-20 | 2013-05-29 | 罗斯蒙德公司 | 过程流体脉动的差压诊断 |

| US8898036B2 (en) | 2007-08-06 | 2014-11-25 | Rosemount Inc. | Process variable transmitter with acceleration sensor |

| US8301676B2 (en) * | 2007-08-23 | 2012-10-30 | Fisher-Rosemount Systems, Inc. | Field device with capability of calculating digital filter coefficients |

| US7702401B2 (en) | 2007-09-05 | 2010-04-20 | Fisher-Rosemount Systems, Inc. | System for preserving and displaying process control data associated with an abnormal situation |

| US7590511B2 (en) | 2007-09-25 | 2009-09-15 | Rosemount Inc. | Field device for digital process control loop diagnostics |

| US8055479B2 (en) | 2007-10-10 | 2011-11-08 | Fisher-Rosemount Systems, Inc. | Simplified algorithm for abnormal situation prevention in load following applications including plugged line diagnostics in a dynamic process |

| US7996161B2 (en) * | 2007-11-29 | 2011-08-09 | Rosemount Inc. | Process fluid pressure transmitter with pressure transient detection |

| US8159358B2 (en) * | 2008-05-12 | 2012-04-17 | Enraf B.V. | Apparatus and method for storage tank hatch monitoring in an inventory management system |

| US9674976B2 (en) | 2009-06-16 | 2017-06-06 | Rosemount Inc. | Wireless process communication adapter with improved encapsulation |

| US8228946B2 (en) * | 2009-07-29 | 2012-07-24 | General Electric Company | Method for fail-safe communication |

| US8862250B2 (en) | 2010-05-07 | 2014-10-14 | Exxonmobil Research And Engineering Company | Integrated expert system for identifying abnormal events in an industrial plant |

| US10761524B2 (en) | 2010-08-12 | 2020-09-01 | Rosemount Inc. | Wireless adapter with process diagnostics |

| US9207670B2 (en) | 2011-03-21 | 2015-12-08 | Rosemount Inc. | Degrading sensor detection implemented within a transmitter |

| US9927788B2 (en) | 2011-05-19 | 2018-03-27 | Fisher-Rosemount Systems, Inc. | Software lockout coordination between a process control system and an asset management system |

| US8762301B1 (en) | 2011-10-12 | 2014-06-24 | Metso Automation Usa Inc. | Automated determination of root cause |

| US9052240B2 (en) | 2012-06-29 | 2015-06-09 | Rosemount Inc. | Industrial process temperature transmitter with sensor stress diagnostics |

| US20140180658A1 (en) * | 2012-09-04 | 2014-06-26 | Schlumberger Technology Corporation | Model-driven surveillance and diagnostics |

| US9602122B2 (en) | 2012-09-28 | 2017-03-21 | Rosemount Inc. | Process variable measurement noise diagnostic |

| US9423050B2 (en) * | 2013-04-09 | 2016-08-23 | Fisher Controls International Llc | Intelligent actuator and method of monitoring actuator health and integrity |

| TWI648609B (zh) * | 2013-06-07 | 2019-01-21 | Scientific Design Company, Inc. | 程序監控系統及方法 |

| CN104298225B (zh) * | 2014-09-25 | 2017-07-04 | 中国石油化工股份有限公司 | 化工过程异常工况因果关系推理模型建模与图形化展示方法 |

| EP3384355B1 (en) * | 2015-12-03 | 2020-02-12 | ABB Schweiz AG | Root cause analysis of failure to meet communication requirements in a process control system |

| CN109901544A (zh) | 2017-12-07 | 2019-06-18 | 开利公司 | 制冷系统、用于其的故障诊断系统、故障诊断方法及控制器与存储介质 |

| CN110230727B (zh) * | 2019-06-26 | 2021-07-23 | 玉环大地铜业股份有限公司 | 一种可自我检查并在阀门损坏时进行报警和自动关闭的阀门 |

| JP7526571B2 (ja) * | 2020-03-06 | 2024-08-01 | ナブテスコ株式会社 | 状態推定装置、制御弁、状態推定プログラム、および状態推定方法 |

| DE102020118556A1 (de) | 2020-07-14 | 2022-03-10 | Samson Aktiengesellschaft | Ventilstellgerät, prozesstechnische Anlage mit Ventilstellgerät, Diagnoseverfahren und Verwendung eines Ventilstellgeräts |

| DE102020121890A1 (de) | 2020-08-20 | 2022-02-24 | Samson Aktiengesellschaft | Verfahren zur Diagnose eines Steuer- und/oder Regelungssystems sowie Steuer- und/oder Regelungssystem |

| EP4084416B1 (en) * | 2021-04-30 | 2025-10-15 | ABB Schweiz AG | Monitoring a communication system that is used for control and/or surveillance of an industrial process |

Family Cites Families (283)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US893144A (en) * | 1907-04-24 | 1908-07-14 | Herman Casler | Variable-speed power-transmission mechanism. |

| BE610970A (ja) | 1960-12-02 | |||

| US3096434A (en) | 1961-11-28 | 1963-07-02 | Daniel Orifice Fitting Company | Multiple integration flow computer |

| US3404264A (en) | 1965-07-19 | 1968-10-01 | American Meter Co | Telemetering system for determining rate of flow |

| US3468164A (en) | 1966-08-26 | 1969-09-23 | Westinghouse Electric Corp | Open thermocouple detection apparatus |

| GB1224904A (en) | 1968-08-09 | 1971-03-10 | John Stewart Simpson Stewart | Improvements in and relating to electromedical apparatus |

| US3590370A (en) | 1969-04-09 | 1971-06-29 | Leeds & Northrup Co | Method and apparatus for detecting the open-circuit condition of a thermocouple by sending a pulse through the thermocouple and a reactive element in series |

| US3701280A (en) | 1970-03-18 | 1972-10-31 | Daniel Ind Inc | Method and apparatus for determining the supercompressibility factor of natural gas |

| US3691842A (en) | 1970-09-08 | 1972-09-19 | Beckman Instruments Inc | Differential pressure transducer |

| US3688190A (en) | 1970-09-25 | 1972-08-29 | Beckman Instruments Inc | Differential capacitance circuitry for differential pressure measuring instruments |

| US3849637A (en) | 1973-05-22 | 1974-11-19 | Combustion Eng | Reactor megawatt demand setter |

| US3855858A (en) | 1973-08-01 | 1974-12-24 | V Cushing | Self synchronous noise rejection circuit for fluid velocity meter |

| USRE29383E (en) | 1974-01-10 | 1977-09-06 | Process Systems, Inc. | Digital fluid flow rate measurement or control system |

| US3952759A (en) | 1974-08-14 | 1976-04-27 | M & J Valve Company | Liquid line break control system and method |

| US3973184A (en) | 1975-01-27 | 1976-08-03 | Leeds & Northrup Company | Thermocouple circuit detector for simultaneous analog trend recording and analog to digital conversion |

| GB1534280A (en) | 1975-02-28 | 1978-11-29 | Solartron Electronic Group | Method and apparatus for testing thermocouples |

| ZA761634B (en) | 1975-07-17 | 1977-04-27 | Unit Rig & Equip | Transverse oscillation for excavating and loading system |

| US4058975A (en) | 1975-12-08 | 1977-11-22 | General Electric Company | Gas turbine temperature sensor validation apparatus and method |

| US4099413A (en) | 1976-06-25 | 1978-07-11 | Yokogawa Electric Works, Ltd. | Thermal noise thermometer |

| US4102199A (en) | 1976-08-26 | 1978-07-25 | Megasystems, Inc. | RTD measurement system |

| US4122719A (en) | 1977-07-08 | 1978-10-31 | Environmental Systems Corporation | System for accurate measurement of temperature |

| JPS54111050A (en) | 1978-02-21 | 1979-08-31 | Toyota Motor Corp | Automatic speed changer |

| US4250490A (en) | 1979-01-19 | 1981-02-10 | Rosemount Inc. | Two wire transmitter for converting a varying signal from a remote reactance sensor to a DC current signal |

| JPS6230915Y2 (ja) | 1979-03-08 | 1987-08-08 | ||

| US4249164A (en) | 1979-05-14 | 1981-02-03 | Tivy Vincent V | Flow meter |

| US4279013A (en) | 1979-10-31 | 1981-07-14 | The Valeron Corporation | Machine process controller |

| US4337516A (en) | 1980-06-26 | 1982-06-29 | United Technologies Corporation | Sensor fault detection by activity monitoring |

| DE3213866A1 (de) | 1980-12-18 | 1983-10-27 | Siemens AG, 1000 Berlin und 8000 München | Verfahren und schaltungsanordnung zur bestimmung des wertes des ohmschen widerstandes eines messobjekts |

| US4417312A (en) | 1981-06-08 | 1983-11-22 | Worcester Controls Corporation | Electronic controller for valve actuators |

| US4399824A (en) | 1981-10-05 | 1983-08-23 | Air-Shields, Inc. | Apparatus for detecting probe dislodgement |

| JPS58129316U (ja) | 1982-02-24 | 1983-09-01 | 古田 雅夫 | ボルト頭部の押え板 |

| US4571689A (en) | 1982-10-20 | 1986-02-18 | The United States Of America As Represented By The Secretary Of The Air Force | Multiple thermocouple testing device |

| JPS59116811U (ja) | 1983-01-28 | 1984-08-07 | 株式会社日立製作所 | 厚み測定装置 |

| DE3464661D1 (en) | 1983-04-13 | 1987-08-13 | Omron Tateisi Electronics Co | Electronic thermometer |

| JPS59163520U (ja) | 1983-04-19 | 1984-11-01 | トヨタ自動車株式会社 | 自動車のドア構造 |

| US4668473A (en) | 1983-04-25 | 1987-05-26 | The Babcock & Wilcox Company | Control system for ethylene polymerization reactor |

| JPS59211896A (ja) | 1983-05-17 | 1984-11-30 | 三菱重工業株式会社 | 検出器応答異常診断装置 |

| JPS59211196A (ja) | 1983-05-17 | 1984-11-29 | 三菱重工業株式会社 | 検出器応答異常診断装置 |

| US4530234A (en) | 1983-06-30 | 1985-07-23 | Mobil Oil Corporation | Method and system for measuring properties of fluids |

| JPH0619666B2 (ja) | 1983-06-30 | 1994-03-16 | 富士通株式会社 | 故障診断処理方式 |

| US4707796A (en) | 1983-10-19 | 1987-11-17 | Calabro Salvatore R | Reliability and maintainability indicator |

| JPS6076619U (ja) | 1983-10-31 | 1985-05-29 | 株式会社押上紙器印刷 | 組立紙容器 |

| JPS60131495U (ja) | 1984-02-14 | 1985-09-03 | 日立造船株式会社 | 張出軸受の海水潤滑装置 |

| EP0158192B1 (de) | 1984-03-31 | 1991-06-05 | B a r m a g AG | Verfahren zur zentralen Erfassung von Messwerten einer Vielzahl von Messstellen |

| JPS60158987U (ja) | 1984-04-02 | 1985-10-22 | スズキ株式会社 | 鞍乗型車両の泥よけ装置 |

| JPS60174915U (ja) | 1984-04-26 | 1985-11-20 | 花井 安五郎 | エアブリ−ザ−の圧力調整装置 |

| US4517468A (en) | 1984-04-30 | 1985-05-14 | Westinghouse Electric Corp. | Diagnostic system and method |

| US4649515A (en) | 1984-04-30 | 1987-03-10 | Westinghouse Electric Corp. | Methods and apparatus for system fault diagnosis and control |

| US4644479A (en) | 1984-07-31 | 1987-02-17 | Westinghouse Electric Corp. | Diagnostic apparatus |

| US4642782A (en) | 1984-07-31 | 1987-02-10 | Westinghouse Electric Corp. | Rule based diagnostic system with dynamic alteration capability |

| JPH0734162B2 (ja) | 1985-02-06 | 1995-04-12 | 株式会社日立製作所 | 類推制御方法 |

| JPH025105Y2 (ja) | 1985-05-21 | 1990-02-07 | ||

| US5179540A (en) | 1985-11-08 | 1993-01-12 | Harris Corporation | Programmable chip enable logic function |

| DE3540204C1 (de) | 1985-11-13 | 1986-09-25 | Daimler-Benz Ag, 7000 Stuttgart | Vorrichtung in einem Kraftfahrzeug zur Anzeige der Aussentemperatur |

| US4807151A (en) | 1986-04-11 | 1989-02-21 | Purdue Research Foundation | Electrical technique for correcting bridge type mass air flow rate sensor errors resulting from ambient temperature variations |

| GB8611360D0 (en) | 1986-05-09 | 1986-06-18 | Eaton Williams Raymond H | Air condition monitor unit |

| JPS6340825A (ja) | 1986-08-07 | 1988-02-22 | Terumo Corp | 電子体温計 |

| US4736367A (en) | 1986-12-22 | 1988-04-05 | Chrysler Motors Corporation | Smart control and sensor devices single wire bus multiplex system |

| JPH0693204B2 (ja) * | 1987-01-28 | 1994-11-16 | 三菱電機株式会社 | プラント監視制御システム |

| US5005142A (en) | 1987-01-30 | 1991-04-02 | Westinghouse Electric Corp. | Smart sensor system for diagnostic monitoring |

| US4736763A (en) | 1987-02-26 | 1988-04-12 | Britton George L | Automatic device for the detection and shutoff of unwanted liquid flow in pipes |

| JPH01502848A (ja) | 1987-04-02 | 1989-09-28 | エフターク エンツタウブングス ― ウント フエルダーテヒニーク アクチエンゲゼルシヤフト | 半導体ガスセンサから発生される信号を評価するための回路装置 |

| JPS63313208A (ja) * | 1987-06-17 | 1988-12-21 | Nippon Atom Ind Group Co Ltd | プラント診断方法 |

| JPS6421510A (en) * | 1987-07-16 | 1989-01-24 | Mitsubishi Electric Corp | Process abnormality diagnosing device |

| JP2650914B2 (ja) * | 1987-07-16 | 1997-09-10 | 三菱電機株式会社 | プロセス異常診断装置 |

| JP2645017B2 (ja) * | 1987-07-23 | 1997-08-25 | 株式会社東芝 | プラント診断方法及びその装置 |

| US4988990A (en) | 1989-05-09 | 1991-01-29 | Rosemount Inc. | Dual master implied token communication system |

| US5122794A (en) | 1987-08-11 | 1992-06-16 | Rosemount Inc. | Dual master implied token communication system |

| US4873655A (en) | 1987-08-21 | 1989-10-10 | Board Of Regents, The University Of Texas System | Sensor conditioning method and apparatus |

| JPS6472699A (en) | 1987-09-12 | 1989-03-17 | Sony Corp | Speaker diaphragm and its manufacture |

| US4907167A (en) | 1987-09-30 | 1990-03-06 | E. I. Du Pont De Nemours And Company | Process control system with action logging |

| US4818994A (en) | 1987-10-22 | 1989-04-04 | Rosemount Inc. | Transmitter with internal serial bus |

| US4831564A (en) | 1987-10-22 | 1989-05-16 | Suga Test Instruments Co., Ltd. | Apparatus for estimating and displaying remainder of lifetime of xenon lamps |

| US5274572A (en) | 1987-12-02 | 1993-12-28 | Schlumberger Technology Corporation | Method and apparatus for knowledge-based signal monitoring and analysis |

| US5488697A (en) | 1988-01-12 | 1996-01-30 | Honeywell Inc. | Problem state monitoring system |

| US5193143A (en) | 1988-01-12 | 1993-03-09 | Honeywell Inc. | Problem state monitoring |

| US4841286A (en) | 1988-02-08 | 1989-06-20 | Honeywell Inc. | Apparatus and method for detection of an open thermocouple in a process control network |

| US4924418A (en) | 1988-02-10 | 1990-05-08 | Dickey-John Corporation | Universal monitor |

| JPH0763586B2 (ja) | 1988-03-04 | 1995-07-12 | 川崎製鉄株式会社 | コークス炉ガス脱硫液の再生における廃空気の処理方法 |

| JPH0774961B2 (ja) | 1988-04-07 | 1995-08-09 | 株式会社日立製作所 | オートチユーニングpid調節計 |

| US4964125A (en) | 1988-08-19 | 1990-10-16 | Hughes Aircraft Company | Method and apparatus for diagnosing faults |

| US5197328A (en) | 1988-08-25 | 1993-03-30 | Fisher Controls International, Inc. | Diagnostic apparatus and method for fluid control valves |

| US5099436A (en) | 1988-11-03 | 1992-03-24 | Allied-Signal Inc. | Methods and apparatus for performing system fault diagnosis |

| US5067099A (en) | 1988-11-03 | 1991-11-19 | Allied-Signal Inc. | Methods and apparatus for monitoring system performance |

| EP0369489A3 (en) | 1988-11-18 | 1991-11-27 | Omron Corporation | Sensor controller system |

| JP2714091B2 (ja) | 1989-01-09 | 1998-02-16 | 株式会社日立製作所 | フィールド計器 |

| US5098197A (en) | 1989-01-30 | 1992-03-24 | The United States Of America As Represented By The United States Department Of Energy | Optical Johnson noise thermometry |

| US5089979A (en) | 1989-02-08 | 1992-02-18 | Basic Measuring Instruments | Apparatus for digital calibration of detachable transducers |

| US5081598A (en) | 1989-02-21 | 1992-01-14 | Westinghouse Electric Corp. | Method for associating text in automatic diagnostic system to produce recommended actions automatically |

| US4939753A (en) | 1989-02-24 | 1990-07-03 | Rosemount Inc. | Time synchronization of control networks |

| DE4008560C2 (de) | 1989-03-17 | 1995-11-02 | Hitachi Ltd | Verfahren und Vorrichtung zum Bestimmen einer Restlebensdauer eines Aggregats |

| JPH0692914B2 (ja) * | 1989-04-14 | 1994-11-16 | 株式会社日立製作所 | 機器/設備の状態診断システム |

| US5089984A (en) | 1989-05-15 | 1992-02-18 | Allen-Bradley Company, Inc. | Adaptive alarm controller changes multiple inputs to industrial controller in order for state word to conform with stored state word |

| US4934196A (en) | 1989-06-02 | 1990-06-19 | Micro Motion, Inc. | Coriolis mass flow rate meter having a substantially increased noise immunity |

| JPH0650557B2 (ja) | 1989-07-04 | 1994-06-29 | 株式会社日立製作所 | フィールド計器の通信方式 |

| US5269311A (en) | 1989-08-29 | 1993-12-14 | Abbott Laboratories | Method for compensating errors in a pressure transducer |

| US5293585A (en) | 1989-08-31 | 1994-03-08 | Kabushiki Kaisha Toshiba | Industrial expert system |

| JP2712625B2 (ja) | 1989-09-19 | 1998-02-16 | 横河電機株式会社 | 信号伝送器 |

| JP2656637B2 (ja) | 1989-11-22 | 1997-09-24 | 株式会社日立製作所 | プロセス制御システム及び発電プラントプロセス制御システム |

| JPH03166601A (ja) | 1989-11-27 | 1991-07-18 | Hitachi Ltd | 制御支援装置 |

| US5019760A (en) | 1989-12-07 | 1991-05-28 | Electric Power Research Institute | Thermal life indicator |

| CA2031765C (en) | 1989-12-08 | 1996-02-20 | Masahide Nomura | Method and system for performing control conforming with characteristics of controlled system |

| US5633809A (en) | 1989-12-22 | 1997-05-27 | American Sigma, Inc. | Multi-function flow monitoring apparatus with area velocity sensor capability |

| US5111531A (en) | 1990-01-08 | 1992-05-05 | Automation Technology, Inc. | Process control using neural network |

| JP2753592B2 (ja) | 1990-01-18 | 1998-05-20 | 横河電機株式会社 | 2線式計器 |

| JP2712701B2 (ja) | 1990-02-02 | 1998-02-16 | 横河電機株式会社 | 圧力伝送器 |

| US5235527A (en) | 1990-02-09 | 1993-08-10 | Toyota Jidosha Kabushiki Kaisha | Method for diagnosing abnormality of sensor |

| US5134574A (en) | 1990-02-27 | 1992-07-28 | The Foxboro Company | Performance control apparatus and method in a processing plant |

| US5122976A (en) | 1990-03-12 | 1992-06-16 | Westinghouse Electric Corp. | Method and apparatus for remotely controlling sensor processing algorithms to expert sensor diagnoses |

| US5053815A (en) | 1990-04-09 | 1991-10-01 | Eastman Kodak Company | Reproduction apparatus having real time statistical process control |

| JPH043203A (ja) * | 1990-04-20 | 1992-01-08 | Mitsubishi Electric Corp | プロセス監視制御装置 |

| EP0460892B1 (en) | 1990-06-04 | 1996-09-04 | Hitachi, Ltd. | A control device for controlling a controlled apparatus, and a control method therefor |

| US5224203A (en) | 1990-08-03 | 1993-06-29 | E. I. Du Pont De Nemours & Co., Inc. | On-line process control neural network using data pointers |

| US5142612A (en) | 1990-08-03 | 1992-08-25 | E. I. Du Pont De Nemours & Co. (Inc.) | Computer neural network supervisory process control system and method |

| US5121467A (en) | 1990-08-03 | 1992-06-09 | E.I. Du Pont De Nemours & Co., Inc. | Neural network/expert system process control system and method |

| US5212765A (en) | 1990-08-03 | 1993-05-18 | E. I. Du Pont De Nemours & Co., Inc. | On-line training neural network system for process control |

| US5282261A (en) | 1990-08-03 | 1994-01-25 | E. I. Du Pont De Nemours And Co., Inc. | Neural network process measurement and control |

| US5167009A (en) | 1990-08-03 | 1992-11-24 | E. I. Du Pont De Nemours & Co. (Inc.) | On-line process control neural network using data pointers |

| US5197114A (en) | 1990-08-03 | 1993-03-23 | E. I. Du Pont De Nemours & Co., Inc. | Computer neural network regulatory process control system and method |

| US5175678A (en) | 1990-08-15 | 1992-12-29 | Elsag International B.V. | Method and procedure for neural control of dynamic processes |

| US5130936A (en) | 1990-09-14 | 1992-07-14 | Arinc Research Corporation | Method and apparatus for diagnostic testing including a neural network for determining testing sufficiency |

| EP0480654B1 (en) | 1990-10-10 | 1998-03-04 | Honeywell Inc. | Process system identification |

| US5367612A (en) | 1990-10-30 | 1994-11-22 | Science Applications International Corporation | Neurocontrolled adaptive process control system |

| JP3189326B2 (ja) | 1990-11-21 | 2001-07-16 | セイコーエプソン株式会社 | 生産管理装置および該装置を用いた生産管理方法 |

| US5265031A (en) | 1990-11-26 | 1993-11-23 | Praxair Technology, Inc. | Diagnostic gas monitoring process utilizing an expert system |

| US5214582C1 (en) | 1991-01-30 | 2001-06-26 | Edge Diagnostic Systems | Interactive diagnostic system for an automobile vehicle and method |

| US5143452A (en) | 1991-02-04 | 1992-09-01 | Rockwell International Corporation | System for interfacing a single sensor unit with multiple data processing modules |

| EP0570505B1 (en) | 1991-02-05 | 1999-03-31 | Storage Technology Corporation | Knowledge based machine initiated maintenance system and method |

| JPH07112299B2 (ja) | 1991-03-07 | 1995-11-29 | 横河電機株式会社 | プロセス信号受信装置 |

| US5137370A (en) | 1991-03-25 | 1992-08-11 | Delta M Corporation | Thermoresistive sensor system |

| US5357449A (en) | 1991-04-26 | 1994-10-18 | Texas Instruments Incorporated | Combining estimates using fuzzy sets |

| AU1893392A (en) | 1991-05-03 | 1992-12-21 | Storage Technology Corporation | Knowledge based resource management |

| US5114664A (en) | 1991-05-06 | 1992-05-19 | General Electric Company | Method for in situ evaluation of capacitive type pressure transducers in a nuclear power plant |

| US5671335A (en) | 1991-05-23 | 1997-09-23 | Allen-Bradley Company, Inc. | Process optimization using a neural network |

| US5317520A (en) | 1991-07-01 | 1994-05-31 | Moore Industries International Inc. | Computerized remote resistance measurement system with fault detection |

| JP3182807B2 (ja) | 1991-09-20 | 2001-07-03 | 株式会社日立製作所 | 多機能流体計測伝送装置及びそれを用いた流体量計測制御システム |

| US5365787A (en) | 1991-10-02 | 1994-11-22 | Monitoring Technology Corp. | Noninvasive method and apparatus for determining resonance information for rotating machinery components and for anticipating component failure from changes therein |

| US5414645A (en) | 1991-10-25 | 1995-05-09 | Mazda Motor Corporation | Method of fault diagnosis in an apparatus having sensors |

| US5327357A (en) | 1991-12-03 | 1994-07-05 | Praxair Technology, Inc. | Method of decarburizing molten metal in the refining of steel using neural networks |

| JP3203560B2 (ja) | 1991-12-13 | 2001-08-27 | ハネウエル・インコーポレーテッド | 圧電抵抗シリコン圧力センサ設計 |

| US5365423A (en) | 1992-01-08 | 1994-11-15 | Rockwell International Corporation | Control system for distributed sensors and actuators |

| US5282131A (en) | 1992-01-21 | 1994-01-25 | Brown And Root Industrial Services, Inc. | Control system for controlling a pulp washing system using a neural network controller |

| US5349541A (en) | 1992-01-23 | 1994-09-20 | Electric Power Research Institute, Inc. | Method and apparatus utilizing neural networks to predict a specified signal value within a multi-element system |

| EP0565761B1 (en) | 1992-04-15 | 1997-07-09 | Mita Industrial Co. Ltd. | An image forming apparatus provided with self-diagnosis system |

| GB9208704D0 (en) | 1992-04-22 | 1992-06-10 | Foxboro Ltd | Improvements in and relating to sensor units |

| JP2783059B2 (ja) | 1992-04-23 | 1998-08-06 | 株式会社日立製作所 | プロセス状態検出装置、及び半導体センサおよびその状態表示装置 |

| ES2046114B1 (es) | 1992-05-08 | 1995-08-01 | Iberditan Sa | Sistema de control automatico de compactacion en prensas. |

| JP3100757B2 (ja) | 1992-06-02 | 2000-10-23 | 三菱電機株式会社 | 監視診断装置 |

| FR2692037B1 (fr) | 1992-06-03 | 1997-08-08 | Thomson Csf | Procede de diagnostic d'un processus evolutif. |

| CA2097558C (en) | 1992-06-16 | 2001-08-21 | William B. Kilgore | Directly connected display of process control system in an open systems windows environment |

| EP0655887B1 (de) | 1992-08-22 | 1996-05-22 | CLAAS KGaA | Vorrichtung zur messung eines massestromes |

| US5384699A (en) | 1992-08-24 | 1995-01-24 | Associated Universities, Inc. | Preventive maintenance system for the photomultiplier detector blocks of pet scanners |

| US5477444A (en) | 1992-09-14 | 1995-12-19 | Bhat; Naveen V. | Control system using an adaptive neural network for target and path optimization for a multivariable, nonlinear process |

| US5347843A (en) | 1992-09-23 | 1994-09-20 | Korr Medical Technologies Inc. | Differential pressure flowmeter with enhanced signal processing for respiratory flow measurement |

| US5469070A (en) | 1992-10-16 | 1995-11-21 | Rosemount Analytical Inc. | Circuit for measuring source resistance of a sensor |

| US5228780A (en) | 1992-10-30 | 1993-07-20 | Martin Marietta Energy Systems, Inc. | Dual-mode self-validating resistance/Johnson noise thermometer system |

| US5388465A (en) | 1992-11-17 | 1995-02-14 | Yamatake-Honeywell Co., Ltd. | Electromagnetic flowmeter |

| AT399235B (de) | 1992-12-24 | 1995-04-25 | Vaillant Gmbh | Verfahren zur funktionskontrolle eines temperaturfühlers |

| US5486996A (en) | 1993-01-22 | 1996-01-23 | Honeywell Inc. | Parameterized neurocontrollers |

| JP3170381B2 (ja) | 1993-02-12 | 2001-05-28 | オムロン株式会社 | 電池の寿命判定装置 |

| US5394341A (en) | 1993-03-25 | 1995-02-28 | Ford Motor Company | Apparatus for detecting the failure of a sensor |

| US5774378A (en) | 1993-04-21 | 1998-06-30 | The Foxboro Company | Self-validating sensors |

| AU6669594A (en) | 1993-04-30 | 1994-11-21 | Pavilion Technologies, Inc. | Method and apparatus for determining the sensitivity of inputs to a neural network on output parameters |

| FR2705155A1 (fr) | 1993-05-12 | 1994-11-18 | Philips Laboratoire Electroniq | Dispositif et méthode pour générer une fonction d'approximation. |

| US5510779A (en) | 1993-06-04 | 1996-04-23 | Drexelbrook Controls, Inc. | Error compensating instrument system with digital communications |

| US5361628A (en) | 1993-08-02 | 1994-11-08 | Ford Motor Company | System and method for processing test measurements collected from an internal combustion engine for diagnostic purposes |

| JP2546159B2 (ja) | 1993-08-05 | 1996-10-23 | 日本電気株式会社 | 生産管理システム |

| US5386373A (en) | 1993-08-05 | 1995-01-31 | Pavilion Technologies, Inc. | Virtual continuous emission monitoring system with sensor validation |

| US5539638A (en) | 1993-08-05 | 1996-07-23 | Pavilion Technologies, Inc. | Virtual emissions monitor for automobile |

| US5549137A (en) | 1993-08-25 | 1996-08-27 | Rosemount Inc. | Valve positioner with pressure feedback, dynamic correction and diagnostics |

| US5404064A (en) | 1993-09-02 | 1995-04-04 | The United States Of America As Represented By The Secretary Of The Navy | Low-frequency electrostrictive ceramic plate voltage sensor |

| CA2169721A1 (en) | 1993-09-07 | 1995-03-16 | David A. Broden | Multivariable transmitter |

| US5489831A (en) | 1993-09-16 | 1996-02-06 | Honeywell Inc. | Pulse width modulating motor controller |

| US5481199A (en) | 1993-09-24 | 1996-01-02 | Anderson; Karl F. | System for improving measurement accuracy of transducer by measuring transducer temperature and resistance change using thermoelectric voltages |

| US5408406A (en) | 1993-10-07 | 1995-04-18 | Honeywell Inc. | Neural net based disturbance predictor for model predictive control |

| US5442639A (en) | 1993-10-12 | 1995-08-15 | Ship Star Associates, Inc. | Method and apparatus for monitoring a communications network |

| CH687047A5 (de) | 1993-11-30 | 1996-08-30 | Hler Ag B | Verfahren zur Regelung einer Arbeitsmaschine |

| JP2893233B2 (ja) | 1993-12-09 | 1999-05-17 | 株式会社ユニシアジェックス | 筒内圧センサの診断装置 |

| US5526293A (en) | 1993-12-17 | 1996-06-11 | Texas Instruments Inc. | System and method for controlling semiconductor wafer processing |

| JPH07225530A (ja) | 1994-02-15 | 1995-08-22 | Canon Inc | 画像記録用熱定着器の診断装置および画像記録装置 |

| US5440478A (en) | 1994-02-22 | 1995-08-08 | Mercer Forge Company | Process control method for improving manufacturing operations |

| JPH07234988A (ja) | 1994-02-23 | 1995-09-05 | Mitsubishi Heavy Ind Ltd | 異常診断装置 |

| US5434774A (en) | 1994-03-02 | 1995-07-18 | Fisher Controls International, Inc. | Interface apparatus for two-wire communication in process control loops |

| US5436705A (en) | 1994-04-18 | 1995-07-25 | Xerox Corporation | Adaptive process controller for electrophotographic printing |

| US5528516A (en) | 1994-05-25 | 1996-06-18 | System Management Arts, Inc. | Apparatus and method for event correlation and problem reporting |

| FR2720498B1 (fr) | 1994-05-27 | 1996-08-09 | Schlumberger Services Petrol | Débitmètre multiphasique. |

| US5483387A (en) | 1994-07-22 | 1996-01-09 | Honeywell, Inc. | High pass optical filter |

| JPH0854923A (ja) | 1994-08-10 | 1996-02-27 | Idemitsu Material Kk | プロセスデータ診断方法および診断装置 |

| US5608650A (en) | 1994-08-19 | 1997-03-04 | Spectrel Partners, L.L.C. | Systems and methods for testing pump flow rates |

| US5623605A (en) | 1994-08-29 | 1997-04-22 | Lucent Technologies Inc. | Methods and systems for interprocess communication and inter-network data transfer |

| US5669713A (en) | 1994-09-27 | 1997-09-23 | Rosemount Inc. | Calibration of process control temperature transmitter |

| WO1996011389A1 (en) | 1994-10-08 | 1996-04-18 | Honeywell S.A. | Transmitter sensor |

| DE69529180T2 (de) | 1994-10-24 | 2003-09-25 | Fisher-Rosemount Systems, Inc. | Feldgeräte zur Verwendung in einem verteilten Steuerungssystem |

| US5704011A (en) | 1994-11-01 | 1997-12-30 | The Foxboro Company | Method and apparatus for providing multivariable nonlinear control |

| JP3129121B2 (ja) | 1994-11-10 | 2001-01-29 | 横河電機株式会社 | 管路閉塞検出装置 |

| JPH08166309A (ja) | 1994-12-13 | 1996-06-25 | Yokogawa Electric Corp | 導圧管の詰まり診断機構付き差圧測定装置 |

| US5600148A (en) | 1994-12-30 | 1997-02-04 | Honeywell Inc. | Low power infrared scene projector array and method of manufacture |

| DE19502499A1 (de) | 1995-01-27 | 1996-08-01 | Pepperl & Fuchs | Bussystem zur Steuerung und Aktivierung von miteinander vernetzten ASI-Slaves, vorzugsweise binäre Sensoren oder Eingangsmodule und/oder Ausgangsmodule oder Aktuatoren eines Aktuator-Sensor-Interface |

| US5637802A (en) | 1995-02-28 | 1997-06-10 | Rosemount Inc. | Capacitive pressure sensor for a pressure transmitted where electric field emanates substantially from back sides of plates |

| JP3746089B2 (ja) | 1995-03-14 | 2006-02-15 | 松下冷機株式会社 | 圧縮機の性能劣化診断装置 |

| US5708585A (en) | 1995-03-20 | 1998-01-13 | General Motors Corporation | Combustible gas measurement |

| US6151560A (en) | 1995-03-27 | 2000-11-21 | Jones; Thaddeus M. | Open circuit failure monitoring apparatus for controlled electrical resistance heaters |

| US5572420A (en) | 1995-04-03 | 1996-11-05 | Honeywell Inc. | Method of optimal controller design for multivariable predictive control utilizing range control |

| JP3574909B2 (ja) * | 1995-04-07 | 2004-10-06 | 株式会社日立製作所 | プラント監視装置 |

| GB2301901B (en) | 1995-06-05 | 1999-04-07 | Nippon Denso Co | Apparatus and method for diagnosing degradation or malfunction of oxygen sensor |

| US5741074A (en) | 1995-06-06 | 1998-04-21 | Thermo Electrioc Corporation | Linear integrated sensing transmitter sensor |

| CN1047442C (zh) | 1995-06-06 | 1999-12-15 | 罗斯蒙德公司 | 用于过程控制系统中的温度变送器的传感器开路诊断系统 |

| US5561599A (en) | 1995-06-14 | 1996-10-01 | Honeywell Inc. | Method of incorporating independent feedforward control in a multivariable predictive controller |

| US5742845A (en) | 1995-06-22 | 1998-04-21 | Datascape, Inc. | System for extending present open network communication protocols to communicate with non-standard I/O devices directly coupled to an open network |

| US5736649A (en) | 1995-08-23 | 1998-04-07 | Tokico Ltd. | Vortex flowmeter |

| US5705978A (en) | 1995-09-29 | 1998-01-06 | Rosemount Inc. | Process control transmitter |

| JP3263296B2 (ja) | 1995-10-26 | 2002-03-04 | 株式会社東芝 | 電磁流量計 |

| US5956484A (en) | 1995-12-13 | 1999-09-21 | Immersion Corporation | Method and apparatus for providing force feedback over a computer network |

| US5940290A (en) | 1995-12-06 | 1999-08-17 | Honeywell Inc. | Method of predictive maintenance of a process control system having fluid movement |

| WO1997021157A1 (en) | 1995-12-06 | 1997-06-12 | Honeywell Inc. | A method of predictive maintenance of a process control system haivng fluid movement |

| CA2165400C (en) | 1995-12-15 | 1999-04-20 | Jean Serodes | Method of predicting residual chlorine in water supply systems |

| US6014902A (en) | 1995-12-28 | 2000-01-18 | The Foxboro Company | Magnetic flowmeter with diagnostics |

| US5746511A (en) | 1996-01-03 | 1998-05-05 | Rosemount Inc. | Temperature transmitter with on-line calibration using johnson noise |

| US5700090A (en) | 1996-01-03 | 1997-12-23 | Rosemount Inc. | Temperature sensor transmitter with sensor sheath lead |

| US5817950A (en) | 1996-01-04 | 1998-10-06 | Rosemount Inc. | Flow measurement compensation technique for use with an averaging pitot tube type primary element |

| JP3181601B2 (ja) | 1996-01-17 | 2001-07-03 | シーメンス アクチエンゲゼルシヤフト | 自動化装置 |

| DE29600609U1 (de) | 1996-01-17 | 1997-02-13 | Siemens AG, 80333 München | Automatisierungsgerät |

| US5801689A (en) | 1996-01-22 | 1998-09-01 | Extended Systems, Inc. | Hypertext based remote graphic user interface control system |

| US6209048B1 (en) | 1996-02-09 | 2001-03-27 | Ricoh Company, Ltd. | Peripheral with integrated HTTP server for remote access using URL's |

| US5764891A (en) | 1996-02-15 | 1998-06-09 | Rosemount Inc. | Process I/O to fieldbus interface circuit |

| US5665899A (en) | 1996-02-23 | 1997-09-09 | Rosemount Inc. | Pressure sensor diagnostics in a process transmitter |

| US6017143A (en) | 1996-03-28 | 2000-01-25 | Rosemount Inc. | Device in a process system for detecting events |

| US5909368A (en) | 1996-04-12 | 1999-06-01 | Fisher-Rosemount Systems, Inc. | Process control system using a process control strategy distributed among multiple control elements |

| IE76714B1 (en) | 1996-04-19 | 1997-10-22 | Auro Environmental Ltd | Apparatus for measuring the velocity of a fluid flowing in a conduit |

| US5710370A (en) | 1996-05-17 | 1998-01-20 | Dieterich Technology Holding Corp. | Method for calibrating a differential pressure fluid flow measuring system |

| US5752008A (en) | 1996-05-28 | 1998-05-12 | Fisher-Rosemount Systems, Inc. | Real-time process control simulation method and apparatus |

| US5708211A (en) | 1996-05-28 | 1998-01-13 | Ohio University | Flow regime determination and flow measurement in multiphase flow pipelines |

| US5805442A (en) | 1996-05-30 | 1998-09-08 | Control Technology Corporation | Distributed interface architecture for programmable industrial control systems |

| US5728947A (en) | 1996-06-12 | 1998-03-17 | Asahi/America, Inc. | Ultrasonic vortex flowmeter having clamp-on housing |

| US5680109A (en) | 1996-06-21 | 1997-10-21 | The Foxboro Company | Impulse line blockage detector systems and methods |

| EP0825506B1 (en) | 1996-08-20 | 2013-03-06 | Invensys Systems, Inc. | Methods and apparatus for remote process control |

| US5713668A (en) | 1996-08-23 | 1998-02-03 | Accutru International Corporation | Self-verifying temperature sensor |

| US6023399A (en) | 1996-09-24 | 2000-02-08 | Hitachi, Ltd. | Decentralized control system and shutdown control apparatus |

| US5857777A (en) | 1996-09-25 | 1999-01-12 | Claud S. Gordon Company | Smart temperature sensing device |

| US5936514A (en) | 1996-09-27 | 1999-08-10 | Rosemount Inc. | Power supply input circuit for field instrument |

| US5970430A (en) | 1996-10-04 | 1999-10-19 | Fisher Controls International, Inc. | Local device and process diagnostics in a process control network having distributed control functions |

| AU4663497A (en) | 1996-10-04 | 1998-04-24 | Fisher Controls International Inc. | A network accessible interface for a process control network |

| US6047222A (en) | 1996-10-04 | 2000-04-04 | Fisher Controls International, Inc. | Process control network with redundant field devices and buses |

| US5859964A (en) | 1996-10-25 | 1999-01-12 | Advanced Micro Devices, Inc. | System and method for performing real time data acquisition, process modeling and fault detection of wafer fabrication processes |

| US5956487A (en) | 1996-10-25 | 1999-09-21 | Hewlett-Packard Company | Embedding web access mechanism in an appliance for user interface functions including a web server and web browser |

| US5956663A (en) | 1996-11-07 | 1999-09-21 | Rosemount, Inc. | Signal processing technique which separates signal components in a sensor for sensor diagnostics |

| US5828567A (en) | 1996-11-07 | 1998-10-27 | Rosemount Inc. | Diagnostics for resistance based transmitter |

| US6601005B1 (en) | 1996-11-07 | 2003-07-29 | Rosemount Inc. | Process device diagnostics using process variable sensor signal |

| US5719378A (en) | 1996-11-19 | 1998-02-17 | Illinois Tool Works, Inc. | Self-calibrating temperature controller |

| IT1286007B1 (it) | 1996-11-28 | 1998-06-26 | Sgs Thomson Microelectronics | Misuratore di flusso di un fluido |

| WO1998029785A1 (en) | 1996-12-31 | 1998-07-09 | Rosemount Inc. | Device in a process system for validating a control signal from a field device |

| JPH10198657A (ja) | 1997-01-08 | 1998-07-31 | Toshiba Corp | 信号処理装置 |

| DE19703359A1 (de) | 1997-01-30 | 1998-08-06 | Telefunken Microelectron | Verfahren zur Temperaturkompensation bei Meßsystemen |

| JPH10232170A (ja) | 1997-02-20 | 1998-09-02 | Chino Corp | 熱電対劣化予測装置 |

| WO1998039718A1 (en) | 1997-03-04 | 1998-09-11 | Emerson Electric Co. | Distributed diagnostic system |

| JPH10261185A (ja) | 1997-03-19 | 1998-09-29 | Hitachi Ltd | 入出力混在形信号変換器 |

| US5848383A (en) | 1997-05-06 | 1998-12-08 | Integrated Sensor Solutions | System and method for precision compensation for the nonlinear offset and sensitivity variation of a sensor with temperature |

| DE19724167C2 (de) | 1997-06-07 | 1999-07-15 | Deutsch Zentr Luft & Raumfahrt | Verfahren und Vorrichtung zum Ermitteln eines Meßwerts einer Zielmeßgröße einer Mehr-Phasen-Strömung |

| US5923557A (en) | 1997-08-01 | 1999-07-13 | Hewlett-Packard Company | Method and apparatus for providing a standard interface to process control devices that are adapted to differing field-bus protocols |

| JP3326714B2 (ja) | 1997-09-10 | 2002-09-24 | 株式会社山武 | 電磁流量計 |

| DE19742716C5 (de) | 1997-09-26 | 2005-12-01 | Phoenix Contact Gmbh & Co. Kg | Steuer- und Datenübertragungsanlage und Verfahren zum Übertragen von sicherheitsbezogenen Daten |

| JP4611517B2 (ja) | 1997-10-13 | 2011-01-12 | ローズマウント インコーポレイテッド | 流体のプロセス装置 |

| US6311136B1 (en) | 1997-11-26 | 2001-10-30 | Invensys Systems, Inc. | Digital flowmeter |

| US6112131A (en) | 1998-02-06 | 2000-08-29 | Zellweger Uster, Inc. | Gin process control |

| US6199018B1 (en) | 1998-03-04 | 2001-03-06 | Emerson Electric Co. | Distributed diagnostic system |

| US6016523A (en) | 1998-03-09 | 2000-01-18 | Schneider Automation, Inc. | I/O modular terminal having a plurality of data registers and an identification register and providing for interfacing between field devices and a field master |

| US6139180A (en) | 1998-03-27 | 2000-10-31 | Vesuvius Crucible Company | Method and system for testing the accuracy of a thermocouple probe used to measure the temperature of molten steel |

| US6072150A (en) | 1998-05-27 | 2000-06-06 | Beamworks Ltd. | Apparatus and method for in-line soldering |

| FI114745B (fi) | 1998-06-01 | 2004-12-15 | Metso Automation Oy | Kenttälaitteiden hallintajärjestelmä |

| US6360277B1 (en) | 1998-07-22 | 2002-03-19 | Crydom Corporation | Addressable intelligent relay |

| US6327914B1 (en) | 1998-09-30 | 2001-12-11 | Micro Motion, Inc. | Correction of coriolis flowmeter measurements due to multiphase flows |

| GB9821972D0 (en) | 1998-10-08 | 1998-12-02 | Abb Kent Taylor Ltd | Flowmeter logging |

| IT1304079B1 (it) | 1998-12-31 | 2001-03-07 | Abb Research Ltd | Dispositivo di collaudo per sistemi di controllo industriali |

| US6298454B1 (en) | 1999-02-22 | 2001-10-02 | Fisher-Rosemount Systems, Inc. | Diagnostics in a process control system |

| US6564268B1 (en) | 1999-03-17 | 2003-05-13 | Rosemount Inc. | Fieldbus message queuing method and apparatus |

| WO2000070531A2 (en) | 1999-05-17 | 2000-11-23 | The Foxboro Company | Methods and apparatus for control configuration |

| EP1058093B1 (de) | 1999-05-29 | 2003-01-29 | MTL Instruments GmbH | Verfahren und Schaltungsanordnung zur Spannungsversorgung und Funktionsüberwachung zumindest eines Messwertumformers |

| DE19930660A1 (de) | 1999-07-02 | 2001-01-11 | Siemens Ag | Verfahren zur Überwachung oder zur Installation neuer Programmcodes in einer industriellen Anlage |

| US6425038B1 (en) | 1999-09-28 | 2002-07-23 | Rockwell Automation Technologies, Inc. | Conversion of desk-top operating system for real-time control using installable interrupt service routines |

| DE29917651U1 (de) | 1999-10-07 | 2000-11-09 | Siemens AG, 80333 München | Meßumformer sowie Prozeßleitsystem |

| FI110425B (fi) | 2000-04-12 | 2003-01-31 | Metso Paper Inc | Menetelmä kiinnirullaimen toimintavarmuuden parantamiseksi |

| DE10036971A1 (de) | 2000-07-28 | 2002-02-28 | Siemens Ag | Verfahren zur Ferndiagnose eines technologischen Prozesses |

| WO2002027418A2 (en) | 2000-09-25 | 2002-04-04 | Motorwiz, Inc. | Model-based machine diagnostics and prognostics using theory of noise and communications |

-

2001

- 2001-10-05 US US09/972,078 patent/US7085610B2/en not_active Expired - Fee Related

-

2002

- 2002-09-25 JP JP2003535005A patent/JP4635167B2/ja not_active Expired - Lifetime

- 2002-09-25 CN CNB028197593A patent/CN1260626C/zh not_active Expired - Lifetime

- 2002-09-25 EP EP02768898A patent/EP1436678B1/en not_active Expired - Lifetime

- 2002-09-25 DE DE60226757T patent/DE60226757D1/de not_active Expired - Lifetime

- 2002-09-25 WO PCT/US2002/030465 patent/WO2003032100A1/en not_active Ceased

-

2008

- 2008-06-30 JP JP2008170413A patent/JP2008269640A/ja active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014531598A (ja) * | 2011-09-28 | 2014-11-27 | ローズマウント インコーポレイテッド | 診断機能を有する圧力トランスミッタ |

Also Published As

| Publication number | Publication date |

|---|---|

| US7085610B2 (en) | 2006-08-01 |

| JP2005505822A (ja) | 2005-02-24 |

| CN1260626C (zh) | 2006-06-21 |

| JP2008269640A (ja) | 2008-11-06 |

| US20020038156A1 (en) | 2002-03-28 |

| DE60226757D1 (de) | 2008-07-03 |

| CN1564971A (zh) | 2005-01-12 |

| EP1436678B1 (en) | 2008-05-21 |

| EP1436678A1 (en) | 2004-07-14 |

| WO2003032100A1 (en) | 2003-04-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4635167B2 (ja) | 被制御プロセスにおける異常の根本原因診断装置 | |

| US7917240B2 (en) | Univariate method for monitoring and analysis of multivariate data | |

| CN1138193C (zh) | 在处理系统用于确认来自现场装置的控制信号的装置 | |

| WO2005124491A1 (en) | System and method for detecting an abnormal situation associated with a process gain of a control loop | |

| US7623932B2 (en) | Rule set for root cause diagnostics | |

| WO2008014344A2 (en) | Model based method for detecting abnormal operation of a level regulatory control loop and associated apparatus | |

| WO2008042739A2 (en) | On-line monitoring and diagnostics of a process using multivariate statistical analysis | |

| WO2008042758A2 (en) | Multivariate monitoring and diagnostics of process variable data | |

| WO2008042759A2 (en) | On-line multivariate analysis in a distributed process control system | |

| WO2008042757A2 (en) | Univariate method for monitoring and analysis of multivariate data |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20050822 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20050822 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050913 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20050822 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070815 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20071114 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20071212 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080305 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20080402 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100427 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100831 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101026 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131203 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4635167 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |