EP2127775B1 - Procédé et maschine de fluotournage pour la fabrication de pièces - Google Patents

Procédé et maschine de fluotournage pour la fabrication de pièces Download PDFInfo

- Publication number

- EP2127775B1 EP2127775B1 EP08009558A EP08009558A EP2127775B1 EP 2127775 B1 EP2127775 B1 EP 2127775B1 EP 08009558 A EP08009558 A EP 08009558A EP 08009558 A EP08009558 A EP 08009558A EP 2127775 B1 EP2127775 B1 EP 2127775B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- preform

- mandrel

- tailstock

- pressure rolling

- rolling machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D22/00—Shaping without cutting, by stamping, spinning, or deep-drawing

- B21D22/14—Spinning

- B21D22/16—Spinning over shaping mandrels or formers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D51/00—Making hollow objects

- B21D51/02—Making hollow objects characterised by the structure of the objects

- B21D51/10—Making hollow objects characterised by the structure of the objects conically or cylindrically shaped objects

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21H—MAKING PARTICULAR METAL OBJECTS BY ROLLING, e.g. SCREWS, WHEELS, RINGS, BARRELS, BALLS

- B21H5/00—Making gear wheels, racks, spline shafts or worms

- B21H5/02—Making gear wheels, racks, spline shafts or worms with cylindrical outline, e.g. by means of die rolls

- B21H5/025—Internally geared wheels

Definitions

- the invention relates to a method for the production of workpieces according to the preamble of claim 1.

- a method according to the preamble of claim 1 is made DE 10 2005 057 945 A1 known.

- rotationally symmetric preforms are processed by spin forming, for example, to produce support rollers, automotive parts or gas cylinders.

- Particularly preferred here are moldings with concave or conical inner surfaces, which were not produced with the previously known flow-forming process.

- the object of the invention is therefore to provide a method of the type mentioned, with which can be produced from a preform workpieces with concave or conical inner surface.

- the preform preferably a cylindrical tube, is clamped onto the mandrels of a main spindle box and a tailstock.

- Main spindle box and tailstock each have a tool housing, which are each arranged concentrically around the respective mandrel and provide for external centering of the preform.

- Mandrels and tool housing are each movable parallel to the machine axis or to the longitudinal axis of the preform.

- the mandrels each have outer surfaces which taper in one direction so as to form a negative mold of the concave or conical inner surface to be formed in the preform.

- pressure is now exerted on the outer surface of the preform by one or preferably a plurality of pressure rollers. During machining, the facing sides of the two mandrels are held in contact with each other.

- the mandrels and tool housing are moved so that initially a material flow of the material of the preform takes place in a space between the tailstock mandrel and associated tool housing. Subsequently, a movement of the tool housing of the main spindle box and the associated mandrel is such that the material flow takes place substantially in the direction of the main spindle box in the region of the outer surface of the associated mandrel and so the workpiece is finished with concave or conical inner surface.

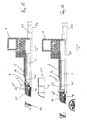

- FIGS. 1 to 6 is a schematically illustrated flow-forming machine, with which the inventive method can be performed.

- the device shown has a main spindle box 1 and an associated tool housing 6 with a mandrel 4 guided axially displaceably therein.

- Tool housing 6 and mandrel 4 lie on a common longitudinal axis MA which passes through the center of the main spindle S1 and tailstock spindle S2.

- a hydraulic cylinder H1 By a hydraulic cylinder H1, the mandrel 4 can be moved axially relative to the tool housing 6.

- the mandrel 4, as well as the mandrel 3, is each equipped with the negative mold of the inner surface of the finished part 8.2 a and 8.2 b. In this case, the smallest diameter in the plane of the mutually facing end faces 3c and 4c of the mandrels 3 and 4.

- the tool housing 6 has opposite the main spindle receiving a receiving bore 6b with a driver 6a.

- the receiving bore 6b has the outer diameter of the preform 8, so that the preform 8 centered by the receiving bore 6b can be added to the longitudinal axis MA.

- the driver 6a takes this with rotation of the main spindle S1 on the tool housing 6 with.

- the axial contact pressure of the preform is taken over by the axial forming force of the spinning rollers 7.

- Tailstock 2 with the tailstock spindle S2 and the tool housing 5, depending on the size of the preform to be reshaped 8 also be equipped with a synchronous to the main spindle S1 drive.

- Tailstock spindle and tool housing 5 lie in the center of the common longitudinal axis MA and rotate around them.

- the mandrel 3 in the tool housing 5 is arranged axially displaceable by a hydraulic cylinder H2.

- main spindle box 1 and tailstock 2 can be moved relative to and independently of each other to the axially positioned pressure rollers 7.

- the pressure rollers 7 to be arranged displaceable together via an axial feed, in which case the main spindle 1 fixed and the tailstock 2 are arranged movable.

- the latter solution is in the Figures 1-6 shown.

- the mandrel 3 has an axial stop surface 3d and in the negative mold direction an outer diameter 3e which corresponds to the inner diameter of the preform 8. If a preform 8 is received, the mandrel 3 moves into the preform 8 by advancing the hydraulic cylinder H2, centering the outer diameter 3e on the side of the preform 8 facing the mandrel 3, and pushing it into the previously described outer center 6b of the tool holder 6 to press them against the driver 6a with an axial pressure. In this workflow phase, FIG. 2 , the preform is kept centered by hand or by an automatic loading device until the clamping is ensured.

- the tool housing 5, as in the Figures 1-6 shown, is required only when the tailstock S2 is driven. If the tailstock spindle is not driven, the mandrel 3 with the hydraulic cylinder H2 assumes the function of a tailstock quill. A corresponding embodiment is in the FIGS. 7 to 12 shown.

- the mandrel 4 moves axially towards the tailstock 2 by the advance of the hydraulic cylinder H1 to form a unit with the mandrel 3.

- both sides 3c and 4c of the mandrels 3 and 4 are pressed against each other, wherein the centering projection 3a of the mandrel 3 is inserted into the centering hole 4a of the mandrel 4.

- the length of the two proportional negative forms 3b, 4b together corresponds to the length of the finished part, which is formed from the preform 8. If a cylindrical shape 8c with the diameter of the separating surface 3c or 4c is provided between the proportionate negative mold 3b, 4b and separating surface 3c and / or parting surface 4c, then the length of the finished part increases by these amounts.

- the spinning rollers 7 move radially outside the clamped preform 8 in their positions, and then together in the axial direction to drive against the rotating preform 8, FIG. 3 ,

- the rotation of the unit preform 8, tool housing 5, 6 with the spines 3, 4, the main spindle S1 and tailstock S2 is done by the drive of the main spindle S1 and, depending on the version, also on the synchronisedden- drive the tailstock S2.

- one or preferably a plurality of pressure rollers 7 are arranged on the circumference of the preform 8.

- the pressure rollers 7 are provided on the circumference in the axial direction in each case with an inlet slope. Radially, the pressure rollers 7 are in position to the outer diameter of the finished part 8.2, which achieved by flow-forming the preform 8 shall be. If the pressure rollers 7 positioned around the center of the longitudinal axis MA of the main spindle S1 are driven jointly in the axial direction x by a common feed on the rotating preform 8, they are rotated by contact with the preform 8 in rotation.

- the material is set in a flow state by the axial and radial pressure of the pressure rollers 7 in the region between the pressure rollers 7 and first of all the respective, axial cross-sectional plane of the mandrel 3, FIG. 4 .

- the material penetrates into the existing free space 9 between the mandrel 3 and the pressure roller 7 in order, after filling the volume of the free space 9, FIG. 5 , in the direction of tailstock 2, with the set outer diameter of the finished part 8.2 and given by the mandrel 3 inner diameter, to evade.

- the axial stop 3d on the mandrel 3 of the tailstock 2 of this mandrel 3 is taken by the back-flowing material, as long as material flows back through the displacement. Tolerances in the diameters of the preform 8 are therefore noticeable only in the length of the formed workpiece 8.2.

- the two mandrels 3, 4 are coupled in the composite, they are pushed together by the displaced material in the tailstock 2, while the spinning rollers 7 move together in the direction of the main spindle box 1. This results from the material displacement from the preform 8, the finished part 8.2, which is reduced in outer diameter relative to the preform 8, with an imprint of the two mandrels 3, 4 as an inner diameter.

- the forming is completed when the spinning rollers 7 come close to the outer center 6b of the preform, FIG. 5 , Thereafter, the individual flow-forming rollers 7 return to their radial starting position and together in their axial starting position.

- the mandrel 4 of the main spindle side is decoupled and retracted, the mandrel 3 of the tailstock side also from the shaped workpiece 8.2. For this purpose, if necessary, provided an externally acting scraper. With the withdrawal of the tailstock 2, the shaped workpiece 8.2 is released, FIG. 6 ,

- the shaped workpiece 8.2 is characterized by a reduced outer diameter, and in the inner diameter by the impression of the contour of the two mandrels 3, 4th

- concave, conical and cylindrical contours are used on the mandrels. Since the mandrel or the composite of two mandrels during the deformation, in which the material flows, is displaced by the excess material, which forms from the reduction of the cross section of the preform on the cross section of the finished part form, there is no relative movement between the workpiece inner surface and Mandrel.

- the mandrel moves axially only in the direction of freedom when a material abundance is present. This means that the reshaped material rolls axially on the mandrel and this pushes further only if enough material is there. There is thus no relative movement between mandrel and material, but only a rolling according to the contour in the axial direction. This rolling of the material in the area of the spinning rollers can be assisted or made more difficult by a hydraulic pressure regulation in the cylinders H1 and H2.

- Tolerances in the preform area are absorbed by the extruded material without affecting the nature of the finished workpiece, ie different wall thicknesses of the preforms have no influence on the formed by the spin forming wall thickness of the finished workpiece; the material continues to flow only when the predetermined wall thickness of the finished workpiece is reached in the relevant axial plane. Only the length of the shaped workpiece is therefore predominantly subject to tolerances.

- the flow rate of the material from the Quer4.000reduzi für in the relevant axial plane of the preform, in the cross section of the relevant axial plane of the finished part is formed from the excess material and the feed rate of the spinning rollers. This means that the axial speed of the displacement of the unit of the two mandrels is dependent on the cross-sectional reduction in the respective axial plane of the preform, at a constant feed rate of the spinning rollers.

- the method is applicable when only a part of the rotationally symmetrical body in the longitudinal direction, using one or two mandrels, reshaped and thereby applied.

- the properties of the cylindrical preformed workpieces produced by the process are particularly suitable for gas cylinders and idlers.

- FIGS. 7 to 12 a second erfindungsegzeße embodiment of the flow-forming machine is shown.

- the mandrel 3 is pushed back by material flow in the direction of the tailstock side 2 'against the force of the hydraulic cylinder.

- the method is analogous to that described above with reference to FIGS. 1 to 6 described method.

- FIGS. 13 to 17 An alternative variant is in the FIGS. 13 to 17 shown. In contrast to the embodiments described above, this device comes with only one main spindle side provided expanding mandrel 4 'from. This variant is provided in particular for forming cylindrical preforms 8, in which one end is closed, such as in gas cylinders.

- the expanding mandrel 4 ' has a section approximately corresponding to the mandrel 4 of the above embodiments with a conical or conical outer surface 4b' and an adjoining spreading section 4d which has outer surface sections 4b "which act against the machine axis MA via a spreading mechanism 4e can be so that this section is replaced by the shape of the mandrel 3 of the above embodiments.

- the preform 8 is pushed with its open side on the expanding mandrel 4 ', wherein a mandrel 4' opposite slider 10 engages the closed end of the preform 8 and this deferred until the stop 6a on the tool housing 6 of the main spindle box 1, FIG.

- the slider 10 holds the preform 8 against the stop 6a, so that the portion 4f of the mandrel 4 'by means of the spreading mechanism 4e can be spread so that the above-described clearance 9, which corresponds to the negative shape of the inner surface to be formed, is formed by the surfaces 4b 'and 4b "between the inner wall of the preform 8 and the mandrel 4' Material from the preform 8 is forced into the space 9, wherein the mandrel 4 'is moved, FIGS. 15 and 16 .

- the finished form 8.2 is removed after retraction of the mandrel 4 ', FIG. 17 , and the open end of the mold 8.2 can be further processed, for example, to produce a gas cylinder 8.3.

- the forming by spin forming takes place in the described embodiments in two directions, namely in the radial direction by reducing the outer diameter of the preform 8 and in the axial direction by shaping a cylindrical shape with the new, reduced outer diameter.

- the spinning rollers 7 advance in the direction of the main spindle box 1 while rotating the preform 8.

- This causes the material displacement takes place in a spiral shape and thus the displaced material distributed both axially and in the circumferential direction of the mandrel 3, 4, 4 '(tangentially).

- the reason for this lies in the material displacement from a larger to a smaller diameter with simultaneous rotation of the material.

- the material flows radially to the smaller diameter of the mandrel 3, 4, 4 'and fills the cavity; tangential, due to the rolling displacement by the rotation, with simultaneous feed movement in the axial direction; such as axially, opposite to the feed movement, if a sufficient excess material is present.

- the mandrel 3, 4, 4 'in the circumferential direction and axially freely movable This allows it to adapt to the movement in the two directions mentioned by the contact with the deformed material unhindered. In this case, takes place in the circumferential direction relative movement in the non-contact region of the preform 8 to the mandrel 4, 4 'on the main spindle side.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Forging (AREA)

- Electrical Discharge Machining, Electrochemical Machining, And Combined Machining (AREA)

- Threshing Machine Elements (AREA)

Claims (16)

- Procédé de fluotournage pour la fabrication de pièces, dans lequel une préforme (8) essentiellement cylindrique est transformée en une pièce finie (8.2) au moyen d'au moins un rouleau de pression (7), ledit procédé consistant àa) glisser une section de la préforme (8) sur au moins un premier mandrin (3, 4'), qui est monté, déplaçable parallèlement à l'axe longitudinal (A) de la préforme (8),b) ajuster le premier mandrin (3, 4') de sorte que sa surface (3b, 4b ; 4b'), placée dans la préforme (8), forme approximativement une impression négative de la surface intérieure à former sur la préforme (8),c) exécuter un mouvement relatif entre la préforme (8) et le rouleau de pression (7) dans une direction parallèle à l'axe longitudinal (A), tout en pressant simultanément le rouleau de pression (7) contre la préforme (8),caractérisé en ce que

l'étape c) est effectuée de sorte que de la matière de la préforme (8) soit refoulée par le rouleau de pression (7) et que le mandrin (3, 4') soit ainsi poussé par la matière refoulée. - Procédé selon la revendication 1,

caractérisé en ce que,

lorsque l'étape a) a été exécutée, l'autre section de la préforme (8), située à l'opposé de la première section, est glissée sur un deuxième mandrin (4), qui est monté de manière à pouvoir être déplacé parallèlement à l'axe longitudinal (A) de la préforme (8), et que le premier mandrin (4) et le deuxième mandrin (3) sont ensuite réunis de sorte que leurs surfaces (3b, 4b), placées dans la préforme (8), forment approximativement une impression négative de la surface intérieure à former sur la préforme (8). - Procédé selon la revendication 2,

caractérisé en ce que

les mandrins (3, 4) sont couplés pendant le processus de pression. - Procédé selon l'une des revendications précédentes,

caractérisé en ce que

le ou les mandrin(s) (3, 4, 4') est / sont, tout au moins par moments, poussés axialement par translation et / ou par rotation hors de la préforme (8) par la matière refoulée. - Procédé selon la revendication 4,

caractérisé en ce que

le déplacement est effectué en direction du premier logement d'outil (5), qui est relié à la contre-poupée (2) et dans lequel le premier mandrin (3) est montée, mobile. - Procédé selon l'une des revendications précédentes,

caractérisé en ce que

la préforme (8) est glissée sur le premier mandrin (3) au moyen d'un entraîneur (6a), qui équipe un logement d'outil (5, 6). - Procédé selon la revendication 6,

caractérisé en ce que

la préforme (8) est centrée au moyen d'un dispositif de centrage (3e), lorsqu'elle est glissée sur le premier mandrin (3). - Procédé selon l'une des revendications précédentes,

caractérisé en ce que

l'on utilise au moins un premier mandrin (3, 4) avec une surface extérieure en forme de cône ou de double cône ou en forme de cône effilé ou de double cône effilé (3b, 4b, 4b'). - Procédé selon l'une des revendications précédentes,

caractérisé en ce que

l'on ne transforme qu'une seule section d'une préforme (8) symétrique en rotation. - Machine de fluotournage, en particulier pour l'exécution du procédé selon l'une des revendications précédentes, avec au moins un mandrin (3, 4, 4'), déplaçable parallèlement à l'axe de la machine (MA), pour la mise en place d'une préforme (8) à transformer, et avec au moins un rouleau de formage (7) pour le formage de la préforme (8), la surface extérieure du mandrin (3, 4, 4') au moins prévu étant configurée de sorte qu'elle présente, dans la région d'une préforme (8) mise en place, une section amincie, qui forme essentiellement l'impression négative d'une surface intérieure devant être formée sur la préforme (8),

caractérisé en ce que

le mandrin (3, 4, 4') au moins prévu est monté de sorte que, lors de la transformation, il soit déplacé en translation ou en rotation par la matière, qui est refoulée hors de la préforme (8) lors du fluotournage. - Machine de fluotournage selon la revendication 10,

caractérisée en ce que

celle-ci présente, en outre, une boîte à mandrins principale (1) avec un logement d'outil (6) et un autre mandrin (4) y afférent, qui est monté, mobile parallèlement à l'axe de la machine (MA). - Machine de fluotournage selon la revendication 11,

caractérisée en ce

qu'est prévu, en outre, une contre-poupée (2), mobile parallèlement à l'axe de la machine (MA) avec le mandrin (3) y associé, les deux mandrins (3, 4) étant disposés concentriquement, et que lesdits deux mandrins (3, 4) sont orientés l'un vers l'autre avec leur côtés frontaux (3c, 4c) et s'effilent chacun en direction de leurs côtés frontaux (3c, 4c). - Machine de fluotournage selon la revendication 12,

caractérisée en ce que

l'on prévoit, en outre, un logement d'outil (5), qui est associé à la contre-poupée (2) et est monté déplaçable parallèlement à l'axe de la machine (MA). - Machine de fluotournage selon l'une des revendications 11 à 13,

caractérisée en ce que

l'un des mandrins (3) présente une pointe (3a), qui, lors du centrage par rapport à l'autre mandrin (4), peut être introduite dans un alésage (4a), pratiqué à cette fin dans ce dernier. - Machine de fluotournage selon l'une des revendications 10 à 14,

caractérisée en ce que

le mandrin (3, 4, 4') au moins prévu présente un système de centrage pour la préforme (8) à recevoir. - Machine de fluotournage selon l'une des revendications 10 à 15,

caractérisée en ce

qu'un mandrin (4') pourvu d'un dispositif d'expansion est prévu.

Priority Applications (12)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP08009558A EP2127775B1 (fr) | 2008-05-26 | 2008-05-26 | Procédé et maschine de fluotournage pour la fabrication de pièces |

| AT08009558T ATE458564T1 (de) | 2008-05-26 | 2008-05-26 | Verfahren zur fertigung von werkstücken und drückwalzmaschine dazu |

| DE502008000404T DE502008000404D1 (de) | 2008-05-26 | 2008-05-26 | Verfahren zur Fertigung von Werkstücken und Drückwalzmaschine dazu |

| ES08009558T ES2341683T3 (es) | 2008-05-26 | 2008-05-26 | Procedimiento para la fabricacion de piezas de trabajo y maquina de laminacion a presion para ello. |

| ES08013579T ES2386504T3 (es) | 2008-05-26 | 2008-07-29 | Dispositivo y método para fabricar o mecanizar piezas de trabajo a partir de una preforma, en particular para el conformado de perfiles interiores o dentados interiores |

| EP08013579A EP2127777B1 (fr) | 2008-05-26 | 2008-07-29 | Dispositif et procédé de fabrication ou de traitement de pièces à usiner à partir d'une ébauche, en particulier pour former des profils internes ou des dentures intérieures |

| AT08013579T ATE553864T1 (de) | 2008-05-26 | 2008-07-29 | Vorrichtung und verfahren zum herstellen oder bearbeiten von werkstücken aus einer vorform, insbesondere zum anformen von innenprofilen oder innenverzahnungen |

| CNA2009101417656A CN101590510A (zh) | 2008-05-26 | 2009-05-25 | 用于制造工件的方法 |

| JP2009125380A JP5527875B2 (ja) | 2008-05-26 | 2009-05-25 | 工作物の仕上げ方法 |

| KR1020090046094A KR101540814B1 (ko) | 2008-05-26 | 2009-05-26 | 공작물 제조 방법 |

| US12/471,737 US8161788B2 (en) | 2008-05-26 | 2009-05-26 | Method for producing workpieces |

| US13/056,358 US8984921B2 (en) | 2008-05-26 | 2009-07-29 | Device and process for producing or processing workpieces from a preform, in particular for integrally forming internal profiles or internal tooth systems |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP08009558A EP2127775B1 (fr) | 2008-05-26 | 2008-05-26 | Procédé et maschine de fluotournage pour la fabrication de pièces |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2127775A1 EP2127775A1 (fr) | 2009-12-02 |

| EP2127775B1 true EP2127775B1 (fr) | 2010-02-24 |

Family

ID=39846654

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08009558A Active EP2127775B1 (fr) | 2008-05-26 | 2008-05-26 | Procédé et maschine de fluotournage pour la fabrication de pièces |

| EP08013579A Active EP2127777B1 (fr) | 2008-05-26 | 2008-07-29 | Dispositif et procédé de fabrication ou de traitement de pièces à usiner à partir d'une ébauche, en particulier pour former des profils internes ou des dentures intérieures |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08013579A Active EP2127777B1 (fr) | 2008-05-26 | 2008-07-29 | Dispositif et procédé de fabrication ou de traitement de pièces à usiner à partir d'une ébauche, en particulier pour former des profils internes ou des dentures intérieures |

Country Status (8)

| Country | Link |

|---|---|

| US (2) | US8161788B2 (fr) |

| EP (2) | EP2127775B1 (fr) |

| JP (1) | JP5527875B2 (fr) |

| KR (1) | KR101540814B1 (fr) |

| CN (1) | CN101590510A (fr) |

| AT (2) | ATE458564T1 (fr) |

| DE (1) | DE502008000404D1 (fr) |

| ES (2) | ES2341683T3 (fr) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8230597B2 (en) * | 2008-10-03 | 2012-07-31 | Ford Global Technologies, Llc | Forming preforms and parts therefrom |

| PL2210682T3 (pl) | 2009-07-09 | 2012-07-31 | Leifeld Metal Spinning Ag | Sposób wyoblania z walcowaniem oraz urządzenia do wyoblania z walcowaniem półwyrobu w kształcie rury |

| ES2543005T3 (es) * | 2010-01-12 | 2015-08-13 | Repkon Machine and Tool Industry and Trade Inc. | Dispositivo y procedimiento para el moldeado de piezas de trabajo |

| CN102500699A (zh) * | 2011-12-21 | 2012-06-20 | 厦门捷讯汽车零部件有限公司 | 一种无轮辐汽车解耦电机皮带轮制造模具及工艺 |

| EP2716377B1 (fr) | 2012-10-05 | 2016-03-02 | Zaklad Produkcji Sprzetu Oswietleniowego "ROSA"-Stanislaw ROSA | Méthode de fabrication d'un élément tubulaire conique |

| PL224268B1 (pl) | 2013-06-12 | 2016-12-30 | Lubelska Polt | Sposób przepychania obrotowego z regulowanym rozstawem osi stopniowanych odkuwek osiowosymetrycznych |

| EP3025802B1 (fr) | 2014-11-28 | 2021-05-12 | REPKON Machine and Tool Industry and Trade Inc. | Dispositif et procédé pour le fluotournage des pièces à usiner |

| CN104959440B (zh) * | 2015-05-15 | 2017-03-29 | 航天特种材料及工艺技术研究所 | 一种反旋旋压方法 |

| CN104858285B (zh) * | 2015-05-15 | 2017-03-29 | 航天特种材料及工艺技术研究所 | 一种旋压方法 |

| CN104858284B (zh) * | 2015-05-15 | 2017-05-17 | 航天特种材料及工艺技术研究所 | 一种正旋旋压方法 |

| CN104858286B (zh) * | 2015-05-15 | 2017-03-08 | 航天特种材料及工艺技术研究所 | 一种旋压设备 |

| ES2665845T3 (es) | 2015-10-20 | 2018-04-27 | Leifeld Metal Spinning Ag | Máquina de conformación para presionar/laminar a presión y procedimiento para presionar/laminar a presión |

| DE102019109183A1 (de) * | 2019-04-08 | 2020-10-08 | Winkelmann Powertrain Components GmbH & Co. KG. | Verfahren zur Herstellung einer Hohlwelle |

| CN115090803B (zh) * | 2022-06-17 | 2023-05-23 | 华南理工大学 | 一种线齿轮自动搓齿机 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2230554B2 (de) * | 1972-06-22 | 1974-08-22 | Leifeld & Co, 4730 Ahlen | Verfahren zur Herstellung eines Anlenkgehäuses für einen Drehfederstab durch Drücken aus einem rohrförmigen Körper |

| US3908421A (en) * | 1973-10-19 | 1975-09-30 | Aspro Inc | Apparatus for making multi-groove pulleys |

| JPS58202927A (ja) * | 1982-05-21 | 1983-11-26 | Hitachi Ltd | くら形吸込コ−ンの製作方法 |

| JPS603922A (ja) * | 1983-06-20 | 1985-01-10 | Mitsubishi Heavy Ind Ltd | スピニング加工方法及びその装置 |

| JPS60145226A (ja) * | 1984-01-10 | 1985-07-31 | Mitsubishi Heavy Ind Ltd | 管の絞り加工方法 |

| JP3197647B2 (ja) * | 1993-01-19 | 2001-08-13 | ブリヂストンサイクル株式会社 | 自転車用フレームパイプの製造方法 |

| JPH08300070A (ja) * | 1995-04-27 | 1996-11-19 | Mitsubishi Electric Corp | 管端成形機及び被成形管の加工方法 |

| DE19532951A1 (de) * | 1995-09-07 | 1997-03-13 | Dynamit Nobel Ag | Verfahren und Vorrichtung zur Herstellung von drückgewalzten Rohren mit inneren Wandverdickungen an den Enden |

| DE19532953A1 (de) * | 1995-09-07 | 1997-03-13 | Dynamit Nobel Ag | Verfahren und Vorrichtung zur Herstellung von drückgewalzten Rohren mit inneren Wandverdickungen |

| DE19722359A1 (de) * | 1997-05-28 | 1998-12-03 | Dynamit Nobel Ag | Drückwalzvorrichtung und Verfahren zur Herstellung von Hohlrädern mit zwei Innenverzahnungen |

| DE19830817B4 (de) * | 1998-07-09 | 2011-06-09 | Leifeld Metal Spinning Gmbh | Verfahren zum Umformen eines Werkstücks durch Drückwalzen |

| DE19854481C2 (de) * | 1998-11-25 | 2002-06-20 | Leico Werkzeugmaschb Gmbh & Co | Verfahren und Vorrichtung zum Drückwalzen |

| DE10039706B4 (de) * | 2000-08-14 | 2007-11-29 | Leifeld Metal Spinning Gmbh | Verfahren zum Einbringen einer Sicke und Drückwalzmaschine |

| DE10062002B4 (de) | 2000-12-13 | 2006-11-09 | Leifeld Metal Spinning Gmbh | Verfahren zum Drückwalzen sowie Drückwalzvorrichtung |

| JP3991188B2 (ja) * | 2001-03-26 | 2007-10-17 | 株式会社ジェイテクト | パイプ状の段付部品の成形方法および装置 |

| DE102005057945A1 (de) | 2005-12-05 | 2007-06-21 | Reichhardt, Hans H. | Verfahren, Maschine und Werkzeuge zur spanlosen Herstellung von Rohrabschnitten und rohrförmigen Werkstücken mit reduziertem Innendurchmesser in Form eines Absatzes |

| JP4393470B2 (ja) * | 2006-04-14 | 2010-01-06 | 日本スピンドル製造株式会社 | 絞り加工方法及びその装置 |

-

2008

- 2008-05-26 EP EP08009558A patent/EP2127775B1/fr active Active

- 2008-05-26 ES ES08009558T patent/ES2341683T3/es active Active

- 2008-05-26 AT AT08009558T patent/ATE458564T1/de active

- 2008-05-26 DE DE502008000404T patent/DE502008000404D1/de active Active

- 2008-07-29 EP EP08013579A patent/EP2127777B1/fr active Active

- 2008-07-29 ES ES08013579T patent/ES2386504T3/es active Active

- 2008-07-29 AT AT08013579T patent/ATE553864T1/de active

-

2009

- 2009-05-25 JP JP2009125380A patent/JP5527875B2/ja active Active

- 2009-05-25 CN CNA2009101417656A patent/CN101590510A/zh active Pending

- 2009-05-26 US US12/471,737 patent/US8161788B2/en active Active

- 2009-05-26 KR KR1020090046094A patent/KR101540814B1/ko active IP Right Grant

- 2009-07-29 US US13/056,358 patent/US8984921B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN101590510A (zh) | 2009-12-02 |

| ATE458564T1 (de) | 2010-03-15 |

| US8984921B2 (en) | 2015-03-24 |

| DE502008000404D1 (de) | 2010-04-08 |

| EP2127777A1 (fr) | 2009-12-02 |

| US8161788B2 (en) | 2012-04-24 |

| EP2127775A1 (fr) | 2009-12-02 |

| ATE553864T1 (de) | 2012-05-15 |

| US20110126606A1 (en) | 2011-06-02 |

| ES2386504T3 (es) | 2012-08-22 |

| KR20090122889A (ko) | 2009-12-01 |

| JP2009285730A (ja) | 2009-12-10 |

| US20090288464A1 (en) | 2009-11-26 |

| ES2341683T3 (es) | 2010-06-24 |

| KR101540814B1 (ko) | 2015-07-30 |

| JP5527875B2 (ja) | 2014-06-25 |

| EP2127777B1 (fr) | 2012-04-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2127775B1 (fr) | Procédé et maschine de fluotournage pour la fabrication de pièces | |

| EP2210682B1 (fr) | Méthode et appareil de fluotournage | |

| DE3433515C2 (fr) | ||

| DE2419854C3 (de) | Verfahren und Drückmaschine zum Herstellen einer mehrrilligen Keilriemenscheibe aus Blech | |

| DE102005057945A1 (de) | Verfahren, Maschine und Werkzeuge zur spanlosen Herstellung von Rohrabschnitten und rohrförmigen Werkstücken mit reduziertem Innendurchmesser in Form eines Absatzes | |

| DE19830817A1 (de) | Verfahren zum Umformen eines Werkstücks durch Drückwalzen | |

| EP1017518B1 (fr) | Dispositif de fluotournage et procede pour la fabrication d'engrenages a deux dentures interieures | |

| DE19960582A1 (de) | Verfahren und Vorrichtung zum Drückwalzen | |

| DE1906574A1 (de) | Verfahren und Vorrichtung zur Herstellung von Riemenscheiben | |

| EP0955110B1 (fr) | Procédé et dispositif pour le fluotournage | |

| EP1656225B1 (fr) | Procede de fabrication d'anneaux profiles a l'interieur et/ou a l'exterieur et dispositif destine a cet effet | |

| DE10039706B4 (de) | Verfahren zum Einbringen einer Sicke und Drückwalzmaschine | |

| DE10054399A1 (de) | Verfahren und Vorrichtung zur Herstellung eines Werkstückes mit Innenverzahnung, insbesondere eines Hohlrades | |

| DE4032424C2 (de) | Verfahren und Vorrichtung zur Herstellung von gefalzten Rohren | |

| DE19725453C2 (de) | Verfahren zur Herstellung einer Hohlwelle | |

| EP1660257A1 (fr) | Procede et dispositif pour realiser des tubes au moins partiellement profiles | |

| WO2004035243A1 (fr) | Procede et dispositif pour produire une jante pour pneumatiques | |

| EP3221068B2 (fr) | Procédé de fabrication d'un élément moulé à symétrie de révolution | |

| EP0997210B1 (fr) | Procédé de fabrication d'objets en forme de disque avec moyeu et rouleau de pression pour exécuter ledit procédé | |

| EP1611973B1 (fr) | Procédé de formage de tubes et de fabrication d'arbres creux | |

| DE19716383C2 (de) | Verfahren zur Herstellung von rotationssymmetrischen Hohlkörpern | |

| DE2418104A1 (de) | Hydraulische presse | |

| DE19830816C2 (de) | Verfahren zum Drückwalzen und Drückwalzvorrichtung | |

| DE19632279C2 (de) | Verfahren zur Herstellung eines scheibenförmigen Teiles | |

| DE4431500C2 (de) | Verfahren zur Herstellung eines rotationssymmetrischen Werkstückes aus Metall durch Drücken sowie Vorrichtung zur Durchführung des Verfahrens |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| 17P | Request for examination filed |

Effective date: 20081108 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REF | Corresponds to: |

Ref document number: 502008000404 Country of ref document: DE Date of ref document: 20100408 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: SCHMAUDER & PARTNER AG PATENT- UND MARKENANWAELTE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2341683 Country of ref document: ES Kind code of ref document: T3 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20100224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100524 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100624 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100525 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| BERE | Be: lapsed |

Owner name: REPKON MACHINE AND TOOL INDUSTRY & TRADE LTD. Effective date: 20100531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100524 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100531 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| 26N | No opposition filed |

Effective date: 20101125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502008000404 Country of ref document: DE Representative=s name: THIELKING & ELBERTZHAGEN PATENTANWAELTE, DE Effective date: 20110908 Ref country code: DE Ref legal event code: R082 Ref document number: 502008000404 Country of ref document: DE Representative=s name: PATENTANWAELTE THIELKING & ELBERTZHAGEN, DE Effective date: 20110908 Ref country code: DE Ref legal event code: R081 Ref document number: 502008000404 Country of ref document: DE Owner name: REPKON MACHINE AND TOOL INDUSTRY & TRADE INC., TR Free format text: FORMER OWNER: REPKON MACHINE AND TOOL INDUSTRY & TRADE LTD., KALAMIS, TR Effective date: 20110908 Ref country code: DE Ref legal event code: R082 Ref document number: 502008000404 Country of ref document: DE Representative=s name: THIELKING & ELBERTZHAGEN PATENTANWAELTE PARTNE, DE Effective date: 20110908 Ref country code: DE Ref legal event code: R081 Ref document number: 502008000404 Country of ref document: DE Owner name: REPKON MACHINE AND TOOL INDUSTRY & TRADE INC., TR Free format text: FORMER OWNER: REPKON MACHINE AND TOOL INDUSTRY & TRADE LTD., KALAMIS, ISTANBUL, TR Effective date: 20110908 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120618 Year of fee payment: 5 Ref country code: GB Payment date: 20120508 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100526 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100724 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100825 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130526 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20140131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130531 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 458564 Country of ref document: AT Kind code of ref document: T Effective date: 20130526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130526 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230519 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20230519 Year of fee payment: 16 Ref country code: IT Payment date: 20230531 Year of fee payment: 16 Ref country code: ES Payment date: 20230621 Year of fee payment: 16 Ref country code: DE Payment date: 20230628 Year of fee payment: 16 Ref country code: CH Payment date: 20230605 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20230523 Year of fee payment: 16 |