EP1595990A1 - Schiffchenstickmaschine - Google Patents

Schiffchenstickmaschine Download PDFInfo

- Publication number

- EP1595990A1 EP1595990A1 EP04405732A EP04405732A EP1595990A1 EP 1595990 A1 EP1595990 A1 EP 1595990A1 EP 04405732 A EP04405732 A EP 04405732A EP 04405732 A EP04405732 A EP 04405732A EP 1595990 A1 EP1595990 A1 EP 1595990A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- driver

- shuttle

- embroidery

- drive

- embroidery machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05C—EMBROIDERING; TUFTING

- D05C11/00—Devices for guiding, feeding, handling, or treating the threads in embroidering machines; Machine needles; Operating or control mechanisms therefor

- D05C11/18—Shuttles ; Shuttle holders; Shuttle driving arrangements

Definitions

- the invention relates to a shuttle embroidery machine with a driver bar for common movement of boats and with a drive shaft for the driver bar.

- Shuttle embroidery machines operate on the two-thread system, i. with a Needle thread and a shuttle thread, the needle thread at each stitch is swallowed up with the shuttle thread.

- a front with an oehr provided needle transports the needle thread through the fabric on the Back of the fabric, where the thread when returning the needle a Loop forms. Through this loop then the boat, in which the Shuttles thread is included, passed.

- a shuttle embroidery machine contains a large number of arranged in a row embroidery and accordingly many needles and boats. To the float the shuttle serves a driver bar.

- Newer machines like them For example, in EP-A-0 638 681, have a Driver bar, which consists of a hollow profile. For each boat is one lower driver nail and an upper driver nail provided between which the shuttle is arranged. With these driver nails the boat is in the shuttle of the so-called Stöcklis moved up and down.

- EP-A-1 055 761 proposes that the driver bar be made of one Produce aluminum profile. This profile has holes in which Plastic driver nails are used. In addition to other benefits thereby creating a driver device with a relatively low mass, which increases the number of turns up to 600 revolutions per minute allowed.

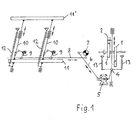

- FIG. 1 which was taken from the cited work, shows this Schiffchenantrieb.

- the cam 1 consists of two parts.

- the two Casters 2 are firmly connected to the slider 3 and move it at Turn the cam up and down. From the bolt 4 is doing the Schiffchenherz 5 offset in a swinging motion.

- the shuttle shaft is running outside the front main machine wall along and has the task to transfer the movement to the back of the machine.

- the angle lever 7 is driven.

- the angle lever 7 converts the oblique up and down movement in a horizontal movement of Driver cable 8 um.

- On this hinges 9 are attached, which have a and cause movement of the guide rods 10.

- a commercially available newer embroidery machine has a shuttle drive on, in which a drive shaft on the rear or Schiffchenseite the Machine extends parallel to the driver bar and at intervals from each other arranged cams to a roller lever parallel to the To pivot drive shaft extending pivot shaft.

- the pivot shaft has at intervals from each other levers, which via rods to the Driver beams are hinged to this with the shuttle up and down move.

- the GB 800 240 published in 1958 describes a sewing machine, which serves with a variety of needles and little boats in small To create distances between parallel seams when the fabric is straight is guided through the machine (Fig. 4, claim 1).

- This document is located

- a problem that is not in shuttle embroidery machines of Meaning is, namely, that the distance between the parallel seams the Size of usable boat limited.

- the construction of the described sewing machine differs significantly from Shuttle embroidery.

- the needles are in two rows distributed over the fabric area.

- the sewing machine thus has no driver bar with linearly arranged over the machine length and drivers powered boats on.

- the boats are in two Rows arranged in cages on a cart, which are driven by a crank and is movable.

- the crank is via a connecting rod to a lever hinged.

- This is in turn via a connecting rod to a Angle lever hinged, which engages the slide bar of the car to to move it back and forth with the boats.

- This Reference is not to be found, as in the case of embroidery machines because of Torsion of a pivot shaft occurring resonant vibrations avoided could become.

- an embroidery machine with a Driver bar or the like for common movement of boat and to provide with a drive shaft for the driver bar the is inexpensive to manufacture and has higher embroidery speeds than previously allowed.

- the embroidery machine according to the invention is characterized in that the Drive shaft arranged over a plurality of spaced apart Crank gear is coupled to the driver bar.

- Cam disc gears are cheap to produce in crank gears. This allowed to dispense with the hitherto necessary pivot shafts and allows it, with relatively low cost in short distances from each other such Provide crank mechanism for the reciprocation of the driver bar. As a result, an impermissible deformation of the driver bar at high Embroidery speeds avoided. Because no pivot shaft more necessary is, also accounts for this pivot shaft inherent torsional and Vibration problems. This allows an increase in the embroidery speed.

- crank gears also run substantially vibration-free and quieter and subject to only minor Wear. By eliminating the pivot shaft is also a Weight savings of the order of several hundred kilos achieved.

- Driver bars are usually provided with guide bars, which in stationary guides are back and forth.

- An advantageous Embodiment of the invention provides that the respective crank gear on such a guide rod or in the immediate vicinity of the guide rod on Driver bar is docked. This will be at the back and forth Deformation of the driver bar by the moving mass of the Guide rods avoided.

- the respective crank mechanism comprises one to the crankshaft articulated connecting rod, a rocker and a rod, the connecting rod to the Rocker, the rocker to the rod and the rod to the driver device is articulated.

- a direct linkage of a connecting rod to the Driver device can by appropriate arrangement and Dimensioning of the mentioned parts a waveform for the Schiffchen Gay be achieved, which is virtually the previously with the Cam achieved waveform corresponds.

- the drive of the drive shaft takes place at both ends thereof.

- the torsion of the drive shaft can be reduced. It is on it but also possible to drive the drive shaft in the middle to the torsion to keep low.

- FIGs 2 to 4 show both the driver device 21 and the for the Driver device 21 provided drive device 23.

- Die Driver device 21 consists essentially of the driver bar 25, which is supported by the guide rods 26.

- the guide rods 26 are stored in guides 27 of the machine frame.

- the drive device has a plurality of crank gears 30. In figure 3 is only one of these crank mechanism 30 is shown. All crank gears 30 are from a common crankshaft 31 driven. The crankshaft 31 is in Machine frame stored. Each crank gear 30 has a to the Crankshaft 31 hinged connecting rod 35. The connecting rod 35 is connected to the rocker 37, the Rocker 37 to the rod 39 and the rod 39 to the driver device 21st hinged. The bearing 41 of the rocker 37 is arranged on the machine frame.

- the respective guide rod 26 is according to the inclination the Schiffchenbahn arranged inclined by fifteen degrees to the vertical.

- the Linkage of the rod 39 to the driver device 21 therefore takes place in such a way that the axis 43 with respect to the bearing bore 45 of the guide rod 39 axially can move.

- FIG. 6 shows the path of the shuttle in millimeters during one revolution the crankshaft 31.

- the embroidery machine has for reciprocating the shuttle 24 a Driver device 21, the driver bar 25 for each boat 24 a lower driver 28 and an upper driver 29 has.

- the driver bar 25 is provided by spaced apart guide rods 26, which in Guides 27 slide, guided.

- the drive device 23 has a number of crank gears 30 which are connected to the guide rods 26 or in the immediate Close to the same coupled to the driver bar 25 and by a common Crankshaft 31 are driven.

- the power transmission takes place from the Crankshaft 31 on the connecting rod 35, from the connecting rod 35, the rocker 37 and from this via the rod 39 to the driver 21.

- the embroidery machine needed for the up and down movement of the shuttle no expensive cams and long linkage and also no vibration problems causing Pivot shaft.

- the shuttle drive is virtually free of play and also allows at high speed a quiet run.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Sewing Machines And Sewing (AREA)

- Knitting Machines (AREA)

- Impact Printers (AREA)

Abstract

Description

- Figur 1

- die schematische Darstellung einer bekannten Antriebsvorrichtung für die Treibereinrichtung,

- Figur 2

- eine schematische Darstellung eines Ausführungsbeispiels der erfindungsgemässen Antriebsvorrichtung für den Treiberbalken einer Schiffchenstickmaschine,

- Figur 3

- eine Ausführungsform eines der Kurbelgetriebe und dessen Anlenkung an den Treiberbalken der Schiffchenstickmaschine,

- Figur 4

- eine Seitenansicht des Kurbelgetriebes und des Treiberbalkens von Figur 3,

- Figur 5

- eine schematische Darstellung des Kurbelgetriebes und des Treiberbalkens gemäss Figur 4, und

- Figur 6

- die Schiffchenbewegungskurve, welche mit der Antriebsvorrichtung erzielbar ist.

Claims (5)

- Schiffchenstickmaschine mit einem Treiberbalken (25) zur gemeinsamen Bewegung von Schiffchen und mit einer Antriebswelle (31) für den Treiberbalken (25), dadurch gekennzeichnet, dass die Antriebswelle (31) über mehrere in Abständen voneinander angeordnete Kurbelgetriebe (30) mit dem Treiberbalken (25) gekuppelt ist.

- Schiffchenstickmaschine, bei welcher der Treiberbalken (25) mehrere Führungsstäbe (26) aufweist, welche in stationären Führungen (27) hin- und herverschiebbar sind, dadurch gekennzeichnet, dass das jeweilige Kurbelgetriebe (30) an einen Führungsstab (26) oder in der Nähe des Führungsstabes an den Treiberbalken (25) angekoppelt ist.

- Schiffchenstickmaschine nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass das jeweilige Kurbelgetriebe (30) einen an die Kurbelwelle (31) angelenkten Pleuel (35), eine Wippe (37) und eine Stange umfasst, wobei der Pleuel (35) an die Wippe (37), die Wippe (37) an die Stange (39) und die Stange (39) an die Treibereinrichtung (21) angelenkt ist.

- Schiffchenstickmaschine nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass der Antrieb der Kurbelwelle (31) an beiden Enden derselben erfolgt.

- Schiffchenstickmaschine nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass der Antrieb der Kurbelwelle (31) in der Mitte derselben erfolgt.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH7552004 | 2004-04-29 | ||

| CH7552004 | 2004-04-29 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1595990A1 true EP1595990A1 (de) | 2005-11-16 |

| EP1595990B1 EP1595990B1 (de) | 2006-05-24 |

Family

ID=34932382

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04405732A Not-in-force EP1595990B1 (de) | 2004-04-29 | 2004-11-24 | Schiffchenstickmaschine |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP1595990B1 (de) |

| KR (1) | KR101149386B1 (de) |

| CN (1) | CN1693572B (de) |

| AT (1) | ATE327362T1 (de) |

| DE (1) | DE502004000633D1 (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2330242A1 (de) | 2009-12-02 | 2011-06-08 | Lässer AG | Mehrkopf- Stickmaschine und Unterfadeneinheit für Mehrkopf- Stickmaschine |

| DE102010019704A1 (de) * | 2010-05-07 | 2011-11-10 | Oerlikon Saurer Arbon Ag | Schiffchen-Stickmaschine mit Antrieb des Treiberbalkens |

| WO2015027349A1 (de) | 2013-08-28 | 2015-03-05 | Lässer Ag | Schiffchenstickmaschine |

| WO2015066825A1 (de) * | 2013-11-08 | 2015-05-14 | Lässer Ag | Vorrichtung zur überwachung des schifflifadens auf einer gross- oder klein-schifflistickmaschine |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH705472A1 (de) * | 2011-09-08 | 2013-03-15 | Laesser Ag | Stickmaschine. |

| CN112921476B (zh) * | 2021-01-22 | 2023-07-04 | 佛山市华连达智能科技有限公司 | 一种斜推式半寸有梭机 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US876975A (en) * | 1906-07-09 | 1908-01-21 | Firm Of Adolph Saurer | Shuttle-embroidering machine. |

| GB800240A (en) * | 1955-05-18 | 1958-08-20 | Pathe Tool Mfg Co Inc | Multi-needle shuttle sewing machines, embroidery machines and the like |

| US3104635A (en) * | 1962-06-29 | 1963-09-24 | Bohus Theodore | Shuttle-moving mechanism for schiffli embroidery apparatus |

| US4627368A (en) * | 1981-08-22 | 1986-12-09 | Aktiengesellschaft Adolph Saurer | Embroidering station with schiffli-shuttles |

| EP0638681A1 (de) * | 1993-08-10 | 1995-02-15 | Franz Lässer AG | Schiffchenstickmaschine |

| EP1055761A1 (de) * | 1999-05-28 | 2000-11-29 | Franz Lässer AG | Schiffchenstickmaschine mit einer Treiberbalkeneinheit |

-

2004

- 2004-11-24 DE DE502004000633T patent/DE502004000633D1/de active Active

- 2004-11-24 EP EP04405732A patent/EP1595990B1/de not_active Not-in-force

- 2004-11-24 AT AT04405732T patent/ATE327362T1/de active

-

2005

- 2005-04-29 KR KR1020050035856A patent/KR101149386B1/ko not_active IP Right Cessation

- 2005-04-29 CN CN200510067795.9A patent/CN1693572B/zh not_active Expired - Fee Related

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US876975A (en) * | 1906-07-09 | 1908-01-21 | Firm Of Adolph Saurer | Shuttle-embroidering machine. |

| GB800240A (en) * | 1955-05-18 | 1958-08-20 | Pathe Tool Mfg Co Inc | Multi-needle shuttle sewing machines, embroidery machines and the like |

| US3104635A (en) * | 1962-06-29 | 1963-09-24 | Bohus Theodore | Shuttle-moving mechanism for schiffli embroidery apparatus |

| US4627368A (en) * | 1981-08-22 | 1986-12-09 | Aktiengesellschaft Adolph Saurer | Embroidering station with schiffli-shuttles |

| EP0638681A1 (de) * | 1993-08-10 | 1995-02-15 | Franz Lässer AG | Schiffchenstickmaschine |

| EP1055761A1 (de) * | 1999-05-28 | 2000-11-29 | Franz Lässer AG | Schiffchenstickmaschine mit einer Treiberbalkeneinheit |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2330242A1 (de) | 2009-12-02 | 2011-06-08 | Lässer AG | Mehrkopf- Stickmaschine und Unterfadeneinheit für Mehrkopf- Stickmaschine |

| CH702330A1 (de) * | 2009-12-02 | 2011-06-15 | Laesser Ag | Mehrkopf-Mehrnadel-Stickmaschine und Unterfadeneinheit für Mehrkopf-Mehrnadel-Stickmaschine. |

| DE102010019704A1 (de) * | 2010-05-07 | 2011-11-10 | Oerlikon Saurer Arbon Ag | Schiffchen-Stickmaschine mit Antrieb des Treiberbalkens |

| DE102010019704B4 (de) * | 2010-05-07 | 2013-11-07 | Oerlikon Saurer Arbon Ag | Schiffchen-Stickmaschine mit Antrieb des Treiberbalkens |

| WO2015027349A1 (de) | 2013-08-28 | 2015-03-05 | Lässer Ag | Schiffchenstickmaschine |

| CH708496A1 (de) * | 2013-08-28 | 2015-03-13 | Lässer Ag | Schiffchenstickmaschine. |

| EP3039178B1 (de) | 2013-08-28 | 2018-08-01 | Lässer AG | Schiffchenstickmaschine |

| EP3409821A1 (de) | 2013-08-28 | 2018-12-05 | Lässer AG | Schiffchenstickmaschine |

| WO2015066825A1 (de) * | 2013-11-08 | 2015-05-14 | Lässer Ag | Vorrichtung zur überwachung des schifflifadens auf einer gross- oder klein-schifflistickmaschine |

| TWI627323B (zh) * | 2013-11-08 | 2018-06-21 | 拉瑟股份公司 | 用以監督大或小的席弗里刺繡機上的席弗里纖維的裝置 |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE327362T1 (de) | 2006-06-15 |

| DE502004000633D1 (de) | 2006-06-29 |

| CN1693572B (zh) | 2012-03-21 |

| KR20060047617A (ko) | 2006-05-18 |

| KR101149386B1 (ko) | 2012-06-01 |

| CN1693567A (zh) | 2005-11-09 |

| EP1595990B1 (de) | 2006-05-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60225061T2 (de) | Fräsblechabstandsverstellung für doppelnadelbarrige raschelmaschinen | |

| EP1595990B1 (de) | Schiffchenstickmaschine | |

| DE683535C (de) | Antriebsvorrichtung fuer die Wirkwerkzeuge von Kettenwirkmaschinen | |

| DE102006050019A1 (de) | Einfassnähmaschine | |

| DE102004020433A1 (de) | Zuführvorrichtung einer Nähmaschine | |

| EP1881098B1 (de) | Schiffchenstickmaschine oder Steppmaschine | |

| DE4231834A1 (de) | Abnehmbarer nocken fuer eine tufting-maschine | |

| DE3226942A1 (de) | Schuettelmaschine | |

| DE68920572T2 (de) | Antriebsvorrichtung zur Steuerung von Nadelbar und von Legeschienen an schnell laufenden Strickmaschinen. | |

| DD242645A5 (de) | Kettelmaschine | |

| DE3034253A1 (de) | Schusssteuervorrichtung fuer haekelmaschinen | |

| EP0193625A1 (de) | Schiffchenstickmaschine | |

| CH691688A5 (de) | Stickmaschine. | |

| DE2507486A1 (de) | Jacquardmaschine | |

| DE2933660A1 (de) | Kettenwirkmaschine, insbesondere raschelmaschine mit in schwingrichtung festen legeschienen | |

| DE10241106B4 (de) | Pressmaschine | |

| DE4032302A1 (de) | Kurvenscheibeneinheit und naehmaschine zur verwendung derselben | |

| EP1162298B1 (de) | Stickmaschine | |

| DE1290653B (de) | Raschelmaschine | |

| DE611422C (de) | Stoffvorschubvorrichtung fuer Naehmaschinen | |

| DE249759C (de) | ||

| CH282702A (de) | Häkelmaschine. | |

| DE204891C (de) | ||

| DE1635760A1 (de) | Raschelwirkstuhl | |

| DE582866C (de) | Tragarmnaehmaschine mit Differentialstoffvorschub |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20041126 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060524 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: RIEDERER HASLER & PARTNER PATENTANWAELTE AG Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004000633 Country of ref document: DE Date of ref document: 20060629 Kind code of ref document: P |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060824 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060824 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060904 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061024 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20060524 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070227 |

|

| EN | Fr: translation not filed | ||

| BERE | Be: lapsed |

Owner name: LASSER A.G. Effective date: 20061130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060825 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070309 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060824 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061124 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061125 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060524 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20171121 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20171121 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004000633 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 327362 Country of ref document: AT Kind code of ref document: T Effective date: 20181124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181124 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190601 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20211125 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221130 |