EP1554176B1 - Formverfahren, insbesondere blas-und/oder vakuumformverfahren, zum herstellen eines mit einem abzugebenden medium gefüllten abgabebehälters - Google Patents

Formverfahren, insbesondere blas-und/oder vakuumformverfahren, zum herstellen eines mit einem abzugebenden medium gefüllten abgabebehälters Download PDFInfo

- Publication number

- EP1554176B1 EP1554176B1 EP03807746A EP03807746A EP1554176B1 EP 1554176 B1 EP1554176 B1 EP 1554176B1 EP 03807746 A EP03807746 A EP 03807746A EP 03807746 A EP03807746 A EP 03807746A EP 1554176 B1 EP1554176 B1 EP 1554176B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- jowls

- container

- mould

- header

- plates

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000465 moulding Methods 0.000 title claims abstract description 26

- 238000007664 blowing Methods 0.000 title claims abstract description 6

- 238000000034 method Methods 0.000 title claims description 30

- 238000004519 manufacturing process Methods 0.000 title description 8

- 230000007704 transition Effects 0.000 claims abstract description 3

- 239000003000 extruded plastic Substances 0.000 claims abstract 3

- 238000003780 insertion Methods 0.000 claims description 7

- 230000037431 insertion Effects 0.000 claims description 7

- 239000004033 plastic Substances 0.000 claims description 6

- 238000003466 welding Methods 0.000 claims 1

- 230000001681 protective effect Effects 0.000 abstract description 29

- 239000012530 fluid Substances 0.000 abstract description 5

- 238000001802 infusion Methods 0.000 description 7

- 238000000071 blow moulding Methods 0.000 description 6

- 238000005452 bending Methods 0.000 description 5

- 239000012528 membrane Substances 0.000 description 4

- 239000004480 active ingredient Substances 0.000 description 3

- 238000011109 contamination Methods 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 239000000654 additive Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 241001631457 Cannula Species 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000003750 conditioning effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000036512 infertility Effects 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000007666 vacuum forming Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B3/00—Packaging plastic material, semiliquids, liquids or mixed solids and liquids, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B3/02—Machines characterised by the incorporation of means for making the containers or receptacles

- B65B3/022—Making containers by moulding of a thermoplastic material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/02—Combined blow-moulding and manufacture of the preform or the parison

- B29C49/04—Extrusion blow-moulding

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61M—DEVICES FOR INTRODUCING MEDIA INTO, OR ONTO, THE BODY; DEVICES FOR TRANSDUCING BODY MEDIA OR FOR TAKING MEDIA FROM THE BODY; DEVICES FOR PRODUCING OR ENDING SLEEP OR STUPOR

- A61M5/00—Devices for bringing media into the body in a subcutaneous, intra-vascular or intramuscular way; Accessories therefor, e.g. filling or cleaning devices, arm-rests

- A61M5/178—Syringes

- A61M5/28—Syringe ampoules or carpules, i.e. ampoules or carpules provided with a needle

- A61M5/281—Syringe ampoules or carpules, i.e. ampoules or carpules provided with a needle using emptying means to expel or eject media, e.g. pistons, deformation of the ampoule, or telescoping of the ampoule

- A61M5/282—Syringe ampoules or carpules, i.e. ampoules or carpules provided with a needle using emptying means to expel or eject media, e.g. pistons, deformation of the ampoule, or telescoping of the ampoule by compression of deformable ampoule or carpule wall

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/20—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor of articles having inserts or reinforcements ; Handling of inserts or reinforcements

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61M—DEVICES FOR INTRODUCING MEDIA INTO, OR ONTO, THE BODY; DEVICES FOR TRANSDUCING BODY MEDIA OR FOR TAKING MEDIA FROM THE BODY; DEVICES FOR PRODUCING OR ENDING SLEEP OR STUPOR

- A61M5/00—Devices for bringing media into the body in a subcutaneous, intra-vascular or intramuscular way; Accessories therefor, e.g. filling or cleaning devices, arm-rests

- A61M5/178—Syringes

- A61M5/31—Details

- A61M2005/3117—Means preventing contamination of the medicament compartment of a syringe

- A61M2005/3118—Means preventing contamination of the medicament compartment of a syringe via the distal end of a syringe, i.e. syringe end for mounting a needle cannula

- A61M2005/312—Means preventing contamination of the medicament compartment of a syringe via the distal end of a syringe, i.e. syringe end for mounting a needle cannula comprising sealing means, e.g. severable caps, to be removed prior to injection by, e.g. tearing or twisting

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61M—DEVICES FOR INTRODUCING MEDIA INTO, OR ONTO, THE BODY; DEVICES FOR TRANSDUCING BODY MEDIA OR FOR TAKING MEDIA FROM THE BODY; DEVICES FOR PRODUCING OR ENDING SLEEP OR STUPOR

- A61M2207/00—Methods of manufacture, assembly or production

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61M—DEVICES FOR INTRODUCING MEDIA INTO, OR ONTO, THE BODY; DEVICES FOR TRANSDUCING BODY MEDIA OR FOR TAKING MEDIA FROM THE BODY; DEVICES FOR PRODUCING OR ENDING SLEEP OR STUPOR

- A61M5/00—Devices for bringing media into the body in a subcutaneous, intra-vascular or intramuscular way; Accessories therefor, e.g. filling or cleaning devices, arm-rests

- A61M5/178—Syringes

- A61M5/28—Syringe ampoules or carpules, i.e. ampoules or carpules provided with a needle

- A61M5/285—Syringe ampoules or carpules, i.e. ampoules or carpules provided with a needle with sealing means to be broken or opened

- A61M5/286—Syringe ampoules or carpules, i.e. ampoules or carpules provided with a needle with sealing means to be broken or opened upon internal pressure increase, e.g. pierced or burst

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61M—DEVICES FOR INTRODUCING MEDIA INTO, OR ONTO, THE BODY; DEVICES FOR TRANSDUCING BODY MEDIA OR FOR TAKING MEDIA FROM THE BODY; DEVICES FOR PRODUCING OR ENDING SLEEP OR STUPOR

- A61M5/00—Devices for bringing media into the body in a subcutaneous, intra-vascular or intramuscular way; Accessories therefor, e.g. filling or cleaning devices, arm-rests

- A61M5/178—Syringes

- A61M5/31—Details

- A61M5/32—Needles; Details of needles pertaining to their connection with syringe or hub; Accessories for bringing the needle into, or holding the needle on, the body; Devices for protection of needles

- A61M5/3205—Apparatus for removing or disposing of used needles or syringes, e.g. containers; Means for protection against accidental injuries from used needles

- A61M5/321—Means for protection against accidental injuries by used needles

- A61M5/3243—Means for protection against accidental injuries by used needles being axially-extensible, e.g. protective sleeves coaxially slidable on the syringe barrel

- A61M5/3275—Means for protection against accidental injuries by used needles being axially-extensible, e.g. protective sleeves coaxially slidable on the syringe barrel being connected to the needle hub or syringe by radially deflectable members, e.g. longitudinal slats, cords or bands

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/753—Medical equipment; Accessories therefor

- B29L2031/7544—Injection needles, syringes

Definitions

- the invention relates to a molding process, in particular blow molding and / or vacuum molding process, for producing a dispensing container filled with a medium to be dispensed.

- the invention is directed to the production of such dispensing containers, the main but not exclusive use of which is to introduce a desired volume of the medium, in particular a liquid medium in a receptacle.

- the medium to be introduced is preferably an additive which, for example, is introduced as an active ingredient admixture into a fluid in the receptacle.

- the receptacle can be an infusion container to whose contents the medium is to be added as an additional active ingredient.

- a syringe As a dispensing container for this purpose usually a syringe is used, with the cannula a perforable closure or plug of the receptacle, such as the infusion container, is pierced, after which the medium is injected into the receptacle by expressing the syringe.

- the preparatory step of filling the syringe is required by transferring the desired amount of the medium from a reservoir into the syringe or filling the syringe from a conventional vial containing the metered dose of the medium in question.

- the integrated cannula and its protruding end, ie the needle tip, covering the safety device which covers the medium are combined to form an overall unit in the dispensing container produced by the method according to the invention.

- the desired dose of the medium in question can be provided in the dispensing container before the dispensing operation . Since the needle tip is covered by the securing device, the container with secured cannula can be easily handled in its ready for the dispensing process state. Intermediate steps of transferring medium and preparing a syringe are not required for the dispensing operation. The desired simplification, time savings and increased security against contamination are thus achieved.

- containers produced by the method according to the invention not only the risk of contamination of the medium is greatly reduced, but also reduces the risk that the user, such as a nurse injured, because the cannula is protected again after use by the securing device.

- the securing means of the closure unit may be designed so that after removal of the protective cover of the cannula protection body when piercing the closure by conditioning at the same from its advanced protective position at the end of the cannula in the position of use can be pushed back and after pulling out of the cannula from the closure back into the protective position can be advanced.

- the handling during the dispensing process is particularly simplified.

- the steps of widening and filling the container in the mold are carried out jointly by means of a combined blowing filling mandrel which extends through the introduction opening. This allows a particularly efficient production of the filled containers with short cycle times.

- the protective hood as an integrated part of the container and as part of the protective device is preferably formed when closing the head jaws of the mold in the region of the transition between the closure unit and protective cover on the wall of a predetermined breaking point, which forms a removal of the protective cover facilitating separation point.

- At least one protruding handle piece is formed, which forms a twist-off knob for convenient manual separation of the protective hood.

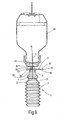

- an embodiment of a filled dispensing container produced by the method according to the invention is designated as a whole by 1.

- it is an ampoule-like plastic container whose wall 2 is provided with folds and bellows-shaped, so that the dispensing container 1 can be compressed from the configuration shown in FIGS. 6 to 9, see FIGS Neck is inserted into the dispensing container 1 as an insert part closure unit 3.

- the body 4 of the closure unit 3 is in the central region of FIG a cannula 11, the inner end 12 of which projects slightly inwardly over the body 4 of the closure unit 3.

- the body 4 of the closure unit 3 also has a first component 17 of a cannula securing device extending along the projecting part of the cannula.

- the second component of this securing device is a protective cover 5 surrounding the protruding part of the cannula 11, which is formed during the manufacture of the container 1 as an integral part thereof.

- the invention is explained below using the example of a blow molding process.

- the molding of the container with protective cover 5 could also be carried out by a vacuum molding process or a combined blow molding / vacuum molding process.

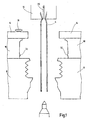

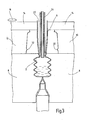

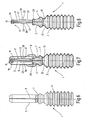

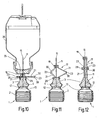

- FIGS. 1 to 5 The sequence of the molding process is illustrated in FIGS. 1 to 5, in which the essential parts of a molding device are shown in greatly simplified schematic form.

- the device comprises three pairs of movable mold jaws, namely main mold jaws 8 for forming the container to be dispensed receiving a main body, head jaws 10 for forming the closure unit 3 enclosing the upper container part, in the present example, the guard 5 of the securing device, and holding jaws 14 for stabilizing a

- This is extruded from a nozzle 18, which in a conventional manner has a terminal 20 for the supply of supporting air in the fully open in Fig.

- Fig. 3 shows that through the insertion opening 22 through which is formed by the severing of the tube 6, a movable, combined blowing filling mandrel 24 is retracted, through which the expansion of the tube 6 is effected by means of blown air, so that the container wall. 2 conforming to the walls of the main mold jaws 8 in a bellows-like configuration, and then, after the inside of the container has been shaped, the medium to be dispensed is filled in by means of the combined blow-filling mandrel 24, see FIG. 3.

- the next step is the insertion of the closure unit 3 by means of a retractable through the insertion 22, movable suction pad 28, see Fig. 4.

- the body 4 of the shutter unit 3 has a conical surface, which on a seat 27 abuts, which forms the inner wall of the tube 6 in the area in which the mold walls of the main mold jaws 8 adjacent to the head jaws 10.

- Fig. 5 shows that further.

- Course of the suction pads 28 is moved away after completion of loading process up and the mold is now closed by moving together the head jaws 10, whereby the extending in the region of the head jaws 10 section of the tube 6 is formed to the protective cover 5.

- the head jaws 10 have a shaping projection 32 which upon closing of the head jaws 10 on the hose 6 forms an annular notch, which forms a predetermined breaking point 7, at which the protective cover 5 is to be separated easily from the rest of the container.

- a rotary knob 9 is formed as a handle, which allows a comfortable manual twisting off of the protective hood 5.

- the head jaws 10 have at diametrically opposite locations recesses to form two opposing rotary knob 9. Of these depressions, only in FIG. 4 is a recess 34 indicated by a dashed line.

- the cannula 11 extends from the outer end of the body 4 of the closure unit 3 in a length which corresponds approximately to the length of a syringe cannula.

- FIGS. 6 and 7 show operating states in which the protruding outer end 15 of the cannula 11 is covered by both components of the securing device, that is to say both by the protective cover 5 and by the component denoted by 17 as a whole.

- This component 17 is integrally formed on the body 4 of the closure unit 3 and has an annular body 19 which is displaceable on the cannula 11 and in the protective position, see Figs. 7, 8 and 12, located at the outer end 15 of the cannula 11 to cover this cannula end, ie the needle tip.

- the annular body 19 is integrally connected via integrally molded support members 21 rod-like shape with the body 4 of the closure unit 3, wherein the joints with ring body 19 and body 4 of the closure unit 3 in the manner of bending joints are yielding. In addition, located on about half the length of the support members 21 bending joints 23, which divide the support members 21.

- FIGs. 10 and 9 show the container in the state where the cannula 11 has pierced with its front end 15 a perforable closure 25 of an infusion container 26.

- the annular body 19 is pushed back out of the protective position aligned with the end 15 of the cannula along the cannula 11 into the position of use.

- the pressure of the medium therein has been increased, so that the membrane 13 is pressed against the facing end 12 of the cannula 11 and pierced by this.

- the compression of the dispensing container 1 thereby leads to a squeezing of the medium therein into the infusion container 26, so that its content is added to the contents of the dispensing container 1 corresponding dose of an additive or active ingredient.

- the cannula 11 in the body 4 of the closure unit 3 could also be guided for a limited by stops (not shown) displacement movement that the cannula 11 is pushed back so far when piercing the shutter 25 that its end 12 the Membrane 13 perforated.

- Fig. 11 shows the operating state after the expressed dispensing container 1 is again withdrawn from the closure 25 of the infusion container 26. Due to the inherent elasticity of the carrier elements 21, the annular body has 19, which has previously been pushed back against the elasticity or holding force of the carrier elements 21 from the protective position during insertion of the cannula in the closure 25 by itself, partially by the elasticity force again partially against the end 15 of the cannula 11 pushed back.

- Fig. 12 shows the operating state of the container after the use thereof, wherein the protruding outer end 15 of the cannula 11, although the protective cover 5 is no longer attached, is secured again by the component 17 of the securing device.

- a removable on the body 4 of the shutter unit 3 locking ring 29 is removed from the body 4 of the shutter unit and advanced along the cannula 11, wherein it slides over the support members 21 and these from the position shown in Fig. 11 to the cannula 11, wherein the annular body 19 is advanced to the end 15 of the cannula 11.

- the support elements 21 have molded notches 30 into which the securing ring 29 engages, see FIG. 12.

- the dispensing container can not only be used to advantage for adding desired volumes of liquid media in infusion containers, but equally for the delivery of liquid, semi-solid or gaseous and / or particulate-laden media, as far as their delivery via cannulas is possible or necessary applied can be.

Landscapes

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Anesthesiology (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Hematology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Veterinary Medicine (AREA)

- General Health & Medical Sciences (AREA)

- Vascular Medicine (AREA)

- Manufacturing & Machinery (AREA)

- Environmental & Geological Engineering (AREA)

- Medical Preparation Storing Or Oral Administration Devices (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Basic Packing Technique (AREA)

- Infusion, Injection, And Reservoir Apparatuses (AREA)

- Tubes (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10245318A DE10245318A1 (de) | 2002-09-27 | 2002-09-27 | Formverfahren, insbesondere Blas- und/oder Vakuumformverfahren, zum Herstellen eines mit einem abzugebenden Medium gefüllten Abgabebehälters |

| DE10245318 | 2002-09-27 | ||

| PCT/EP2003/007452 WO2004033299A1 (de) | 2002-09-27 | 2003-07-10 | Formverfahren, insbesondere blas-und/oder vakuumformverfahren, zum herstellen eines mit einem abzugebenden medium gefüllten abgabebehälters |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1554176A1 EP1554176A1 (de) | 2005-07-20 |

| EP1554176B1 true EP1554176B1 (de) | 2007-09-12 |

Family

ID=31984192

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03807746A Expired - Lifetime EP1554176B1 (de) | 2002-09-27 | 2003-07-10 | Formverfahren, insbesondere blas-und/oder vakuumformverfahren, zum herstellen eines mit einem abzugebenden medium gefüllten abgabebehälters |

Country Status (14)

| Country | Link |

|---|---|

| US (2) | US7192549B2 (ja) |

| EP (1) | EP1554176B1 (ja) |

| JP (1) | JP4243590B2 (ja) |

| KR (1) | KR100964808B1 (ja) |

| CN (1) | CN100453405C (ja) |

| AT (1) | ATE372926T1 (ja) |

| AU (1) | AU2003250022B2 (ja) |

| CA (1) | CA2474907C (ja) |

| DE (2) | DE10245318A1 (ja) |

| DK (1) | DK1554176T3 (ja) |

| ES (1) | ES2290554T3 (ja) |

| MX (1) | MXPA04010654A (ja) |

| PT (1) | PT1554176E (ja) |

| WO (1) | WO2004033299A1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101596941B (zh) * | 2009-07-03 | 2011-07-27 | 阳江喜之郎果冻制造有限公司 | 一种带吸管包装袋的排气夹袋装置及应用该装置的包装方法 |

Families Citing this family (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1847242B1 (en) | 2005-02-08 | 2015-06-17 | Toyo Seikan Kaisha, Ltd. | Sterile package, process for producing the same, and production apparatus |

| ITBO20050468A1 (it) * | 2005-07-14 | 2007-01-15 | Brev Angela Srl | Macchina e metodo per realizzare un contenitore e contenitore cosi' ottenuto |

| DE102006026279B4 (de) * | 2006-06-02 | 2016-02-25 | Khs Gmbh | Verfahren sowie Vorrichtung zum Herstellen von Verpackungseinheiten oder Gebinden |

| JP4893932B2 (ja) * | 2006-07-12 | 2012-03-07 | 東洋製罐株式会社 | 無菌充填包装体の製造方法 |

| WO2008083209A2 (en) * | 2006-12-29 | 2008-07-10 | Amir Genosar | Hypodermic drug delivery reservoir and apparatus |

| US8663188B2 (en) * | 2007-12-28 | 2014-03-04 | Aktivpak, Inc. | Dispenser and therapeutic package suitable for administering a therapeutic substance to a subject, along with method relating to same |

| DE102008004088A1 (de) * | 2008-01-12 | 2009-07-16 | Bernd Hansen | Verfahren und Vorrichtung zum Herstellen von Behältern aus thermoplastischem Kunststoff sowie derart hergestellter Behälter |

| US20100107569A1 (en) * | 2008-11-06 | 2010-05-06 | Havemann Gregory L | Plastic tube sealing and test system |

| US9146184B1 (en) | 2008-11-06 | 2015-09-29 | AnC Precision Machining Inc. | Plastic tube sealing and test system |

| IT1398805B1 (it) * | 2009-06-11 | 2013-03-18 | Brev Angela Srl | Procedimento per la produzione di strumenti medicali |

| IT1394656B1 (it) * | 2009-07-03 | 2012-07-05 | Brev Angela Srl | Processo per la produzione e l'assemblaggio di una siringa per operazioni medicali |

| US8377368B2 (en) * | 2009-12-11 | 2013-02-19 | Ti Automotive Technology Center Gmbh | Component mounting arrangement |

| DE102010027617A1 (de) * | 2010-07-20 | 2012-01-26 | Bernd Hansen | Verfahren und Vorrichtung zum Herstellen und Befüllen von Behältern aus thermoplastischem Kunststoff sowie derart hergestellter Behälter |

| US9498570B2 (en) | 2010-10-25 | 2016-11-22 | Bayer Healthcare Llc | Bladder syringe fluid delivery system |

| WO2012061140A1 (en) | 2010-10-25 | 2012-05-10 | Medrad, Inc. | Bladder syringe fluid delivery system |

| US9180252B2 (en) | 2012-04-20 | 2015-11-10 | Bayer Medical Care Inc. | Bellows syringe fluid delivery system |

| BR112016024965B1 (pt) | 2014-04-25 | 2022-07-19 | Bayer Healthcare Llc | Diafragma de rolamento para receber um fluido medicinal no mesmo, seringa para um sistema de administração de fluido e sistema de administração de fluido |

| US10933190B2 (en) | 2015-04-24 | 2021-03-02 | Bayer Healthcare Llc | Syringe with rolling diaphragm |

| JP6989595B2 (ja) | 2016-09-16 | 2022-01-05 | バイエル・ヘルスケア・エルエルシーBayer HealthCare LLC | シリンジ保持要素を有する圧力ジャケット |

| CN114588394A (zh) | 2016-10-17 | 2022-06-07 | 拜耳医药保健有限公司 | 具有针筒接合机构的流体注射器 |

| WO2018075386A1 (en) | 2016-10-17 | 2018-04-26 | Bayer Healthcare Llc | Fluid injector with syringe engagement mechanism |

| EP3623338A4 (en) * | 2017-05-10 | 2021-04-07 | Dai Nippon Printing Co., Ltd. | ASEPTIC FILLING MACHINE AND PROCESS FOR ASEPTIC FILLING |

| WO2019055497A1 (en) | 2017-09-13 | 2019-03-21 | Bayer Healthcare Llc | SYRINGE SLIDE CAP FOR SEPARATE FILLING AND DISPENSING |

| CN107693903A (zh) * | 2017-11-16 | 2018-02-16 | 中国大冢制药有限公司 | 一种预灌封注射器及其制造方法 |

| US12083321B2 (en) | 2018-09-11 | 2024-09-10 | Bayer Healthcare Llc | Syringe retention feature for fluid injector system |

| CN114502214A (zh) | 2019-09-10 | 2022-05-13 | 拜耳医药保健有限公司 | 用于血管造影术流体注入器的压力护套和注射器保持特征 |

| CA3172757A1 (en) | 2020-02-21 | 2021-08-26 | Bayer Healthcare Llc | Fluid path connectors for medical fluid delivery |

| JP2023515625A (ja) | 2020-02-28 | 2023-04-13 | バイエル・ヘルスケア・エルエルシー | 液混合セット |

| DE102020002077A1 (de) | 2020-04-01 | 2021-10-07 | Kocher-Plastik Maschinenbau Gmbh | Verfahren zum Herstellen eines Behältererzeugnisses und Vorrichtung zur Durchfühung des Verfahrens |

| MX2022016123A (es) | 2020-06-18 | 2023-02-09 | Bayer Healthcare Llc | Aparato de suspension de burbujas de aire en linea para trayectorias de fluidos de inyectores de angiografia. |

| MX2023001722A (es) | 2020-08-11 | 2023-02-22 | Bayer Healthcare Llc | Caracteristicas para jeringa de angiografia. |

| CA3203474A1 (en) | 2020-12-01 | 2022-06-09 | Bayer Healthcare Llc | Cassette for retention of fluid path components for fluid injector system |

| DE102023000051A1 (de) | 2023-01-12 | 2024-07-18 | Kocher-Plastik Maschinenbau Gmbh | Vorrichtung |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2667165A (en) * | 1952-03-19 | 1954-01-26 | Arthur E Smith | Disposable syringe |

| US2667872A (en) * | 1952-03-19 | 1954-02-02 | Arthur E Smith | Syringe unit |

| US4707966A (en) * | 1981-08-26 | 1987-11-24 | Automatic Liquid Packaging, Inc. | Container with an encapsulated top insert and method and apparatus for making same |

| DE3834184C1 (ja) * | 1988-10-07 | 1989-12-28 | Bernd 7166 Sulzbach-Laufen De Hansen | |

| IT1262305B (it) * | 1993-02-23 | 1996-06-19 | Procedimento e impianto per confezionare prodotti fluidi o semifluidi entro contenitori in resina sintetica termoformabile. | |

| JP2714589B2 (ja) * | 1993-07-26 | 1998-02-16 | 株式会社日本製鋼所 | 中空成形による液体用容器の成形方法及び装置並びに医療用溶解液容器の成形方法 |

| US5538506A (en) * | 1993-11-03 | 1996-07-23 | Farris; Barry | Prefilled fluid syringe |

| DE4408394C2 (de) * | 1994-03-12 | 1999-06-24 | Bernd Hansen | Verpackungsmittel für Kontaktlinsen, insbesondere Einwegkontaktlinsen |

| DE4439231C1 (de) * | 1994-11-03 | 1996-04-25 | Bernd Hansen | Blasformverfahren zum Herstellen eines verschlossenen Behältnisses und nach diesem Verfahren hergestelltes Behältnis |

| JPH0957934A (ja) * | 1995-08-22 | 1997-03-04 | Aica Kogyo Co Ltd | 化粧シート及びその製造方法 |

| DE19707292A1 (de) * | 1995-08-23 | 1998-08-27 | Japan Steel Works Ltd | Simultan füllendes Blasform-Verfahren und -vorrichtung |

| JPH0970881A (ja) * | 1995-09-07 | 1997-03-18 | Japan Steel Works Ltd:The | 無菌充填容器の製造方法およびその装置 |

| US5779968A (en) * | 1996-08-22 | 1998-07-14 | Advanced Elastomer Systems, L.P. | Sports ball bladder and method of manufacture |

| DE19926329A1 (de) * | 1999-06-09 | 2000-12-21 | Bernd Hansen | Verfahren zum Herstellen von Behältern und Vorrichtung zum Durchführen des Verfahrens |

-

2002

- 2002-09-27 DE DE10245318A patent/DE10245318A1/de not_active Withdrawn

-

2003

- 2003-07-10 EP EP03807746A patent/EP1554176B1/de not_active Expired - Lifetime

- 2003-07-10 CA CA2474907A patent/CA2474907C/en not_active Expired - Fee Related

- 2003-07-10 DK DK03807746T patent/DK1554176T3/da active

- 2003-07-10 KR KR1020047014058A patent/KR100964808B1/ko active IP Right Grant

- 2003-07-10 US US10/502,748 patent/US7192549B2/en not_active Expired - Lifetime

- 2003-07-10 PT PT03807746T patent/PT1554176E/pt unknown

- 2003-07-10 ES ES03807746T patent/ES2290554T3/es not_active Expired - Lifetime

- 2003-07-10 AU AU2003250022A patent/AU2003250022B2/en not_active Ceased

- 2003-07-10 JP JP2004542261A patent/JP4243590B2/ja not_active Expired - Fee Related

- 2003-07-10 AT AT03807746T patent/ATE372926T1/de active

- 2003-07-10 WO PCT/EP2003/007452 patent/WO2004033299A1/de active IP Right Grant

- 2003-07-10 DE DE50308191T patent/DE50308191D1/de not_active Expired - Lifetime

- 2003-07-10 MX MXPA04010654A patent/MXPA04010654A/es active IP Right Grant

- 2003-07-10 CN CNB038051796A patent/CN100453405C/zh not_active Expired - Fee Related

-

2007

- 2007-03-19 US US11/723,276 patent/US7309463B2/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101596941B (zh) * | 2009-07-03 | 2011-07-27 | 阳江喜之郎果冻制造有限公司 | 一种带吸管包装袋的排气夹袋装置及应用该装置的包装方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10245318A1 (de) | 2004-04-08 |

| US7309463B2 (en) | 2007-12-18 |

| KR20050047504A (ko) | 2005-05-20 |

| KR100964808B1 (ko) | 2010-06-23 |

| CN1639005A (zh) | 2005-07-13 |

| EP1554176A1 (de) | 2005-07-20 |

| CN100453405C (zh) | 2009-01-21 |

| AU2003250022A1 (en) | 2004-05-04 |

| JP2006500259A (ja) | 2006-01-05 |

| WO2004033299A1 (de) | 2004-04-22 |

| AU2003250022B2 (en) | 2008-11-13 |

| CA2474907C (en) | 2010-04-20 |

| MXPA04010654A (es) | 2005-02-17 |

| JP4243590B2 (ja) | 2009-03-25 |

| ATE372926T1 (de) | 2007-09-15 |

| CA2474907A1 (en) | 2004-04-22 |

| US7192549B2 (en) | 2007-03-20 |

| ES2290554T3 (es) | 2008-02-16 |

| US20070187877A1 (en) | 2007-08-16 |

| PT1554176E (pt) | 2007-10-19 |

| US20050156360A1 (en) | 2005-07-21 |

| DK1554176T3 (da) | 2008-01-21 |

| DE50308191D1 (de) | 2007-10-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1554176B1 (de) | Formverfahren, insbesondere blas-und/oder vakuumformverfahren, zum herstellen eines mit einem abzugebenden medium gefüllten abgabebehälters | |

| EP1406686B1 (de) | Vorrichtung zur abgabe von medien | |

| EP0298227B1 (de) | Verfahren zum Befüllen und anschliessenden Verschweissen eines Behälters sowie Vorrichtung und Behälter zur Durchführung dieses Verfahrens | |

| EP0344476B1 (de) | Ampulle | |

| DE68928990T2 (de) | Vorrichtung zum Behandeln und Übertragen von Stoffen zwischen abgeschlossenen Räumen | |

| DE69725207T2 (de) | Hermetisch verschlossener Behälter mit zerbrechbarem Band und Verschlussansätzen sowie Verfahren und Vorrichtung zum Herstellen desselben | |

| DE69110112T2 (de) | Ausgabefläschchen mit Ärmeln. | |

| EP3375474B1 (de) | Inhalationstherapievorrichtung mit einer ampulle für die bevorratung eines zu vernebelnden medikaments | |

| EP0808148B1 (de) | Überleitungsgerät | |

| DE69031570T2 (de) | Vorrichtung zur blut-probenahme | |

| DE2258373A1 (de) | Fluessigkeitsspender sowie verfahren und vorrichtung zum fuellen desselben und zum ausbilden eines kolbens fuer diesen spender | |

| DE60130582T2 (de) | Vorgefüllte intradermalverabreichungsvorrichtung | |

| DE2258372A1 (de) | Fluessigkeitsspender sowie verfahren und vorrichtung zum fuellen desselben | |

| EP2080532B1 (de) | Kartusche für ein Autoinjektor und System bestehend aus einer solchen Kartusche und einem Autoinjektor | |

| WO2015185181A1 (de) | Abgabevorrichtung mit steuerkörper um abgabeelement axial zu verfahren | |

| DE69923706T2 (de) | Sicherheitsanordnung für spritze vorgefüllt mit flüssigem arzneimittel | |

| EP2826457B1 (de) | Ampulle für eine medizinische Flüssigkeit und Verfahren zum Herstellen einer Ampulle | |

| DE19904220A1 (de) | Injektor zum Implantieren einer gefalteten Intraokularlinse | |

| CH661664A5 (de) | Elastomerer fluessigkeitsbehaelter. | |

| CH662511A5 (de) | Verfahren zur herstellung einer zur verwendung mit einer subkutannadel bestimmten, mit medikamenten gefuellten ampulle. | |

| EP1726285A1 (de) | Behälter für die Abgabe eines Medikaments und zugehörige Verabreichungsvorrichtung | |

| EP2928811A1 (de) | Vorrichtung zum entleeren von behältnissen | |

| EP2595887B1 (de) | Verfahren und vorrichtung zum herstellen und befüllen von behältern aus thermoplastischem kunststoff | |

| DE4423261A1 (de) | Einmalspritzeinrichtung und Verfahren zu deren Herstellung | |

| DE202013103578U1 (de) | Einweg-Tube mit aufgesetztem Applikator |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20040505 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070924 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20071008 |

|

| REF | Corresponds to: |

Ref document number: 50308191 Country of ref document: DE Date of ref document: 20071025 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20070403432 Country of ref document: GR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2290554 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20080613 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080313 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20200521 Year of fee payment: 18 Ref country code: LU Payment date: 20200527 Year of fee payment: 18 Ref country code: IE Payment date: 20200619 Year of fee payment: 18 Ref country code: FR Payment date: 20200520 Year of fee payment: 18 Ref country code: PT Payment date: 20200519 Year of fee payment: 18 Ref country code: FI Payment date: 20200612 Year of fee payment: 18 Ref country code: GR Payment date: 20200520 Year of fee payment: 18 Ref country code: TR Payment date: 20200622 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20200617 Year of fee payment: 18 Ref country code: GB Payment date: 20200520 Year of fee payment: 18 Ref country code: SK Payment date: 20200602 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20200716 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20200804 Year of fee payment: 18 Ref country code: DK Payment date: 20200716 Year of fee payment: 18 Ref country code: DE Payment date: 20200731 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20200716 Year of fee payment: 18 Ref country code: CH Payment date: 20200713 Year of fee payment: 18 Ref country code: IT Payment date: 20200708 Year of fee payment: 18 Ref country code: AT Payment date: 20200722 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50308191 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20210731 |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MAE Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20210801 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 372926 Country of ref document: AT Kind code of ref document: T Effective date: 20210710 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210710 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20210731 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MM4A Ref document number: E 2603 Country of ref document: SK Effective date: 20210710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210731 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210710 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210710 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220201 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210731 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210710 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210711 Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220110 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210801 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210710 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220207 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210731 Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210710 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210710 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210731 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210731 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20220830 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210711 |