EP0792742B2 - Bogentransportvorrichtung und Verfahren zur Führung von bogenförmigem Material in einer Druckmaschine, insbesondere in einer Bogenrotations-Offsetdruckmaschine - Google Patents

Bogentransportvorrichtung und Verfahren zur Führung von bogenförmigem Material in einer Druckmaschine, insbesondere in einer Bogenrotations-Offsetdruckmaschine Download PDFInfo

- Publication number

- EP0792742B2 EP0792742B2 EP96118243A EP96118243A EP0792742B2 EP 0792742 B2 EP0792742 B2 EP 0792742B2 EP 96118243 A EP96118243 A EP 96118243A EP 96118243 A EP96118243 A EP 96118243A EP 0792742 B2 EP0792742 B2 EP 0792742B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- nozzles

- zone

- guide surface

- zones

- blowing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007639 printing Methods 0.000 title claims description 36

- 238000000034 method Methods 0.000 title claims description 4

- 238000007664 blowing Methods 0.000 claims description 39

- 238000007645 offset printing Methods 0.000 claims description 4

- 230000032258 transport Effects 0.000 description 11

- 238000005339 levitation Methods 0.000 description 5

- 230000002146 bilateral effect Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000007667 floating Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F21/00—Devices for conveying sheets through printing apparatus or machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/24—Delivering or advancing articles from machines; Advancing articles to or into piles by air blast or suction apparatus

- B65H29/245—Air blast devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H5/00—Feeding articles separated from piles; Feeding articles to machines

- B65H5/22—Feeding articles separated from piles; Feeding articles to machines by air-blast or suction device

- B65H5/228—Feeding articles separated from piles; Feeding articles to machines by air-blast or suction device by air-blast devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/30—Orientation, displacement, position of the handled material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2406/00—Means using fluid

- B65H2406/10—Means using fluid made only for exhausting gaseous medium

- B65H2406/11—Means using fluid made only for exhausting gaseous medium producing fluidised bed

- B65H2406/113—Details of the part distributing the air cushion

- B65H2406/1132—Multiple nozzles arrangement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2801/00—Application field

- B65H2801/03—Image reproduction devices

- B65H2801/21—Industrial-size printers, e.g. rotary printing press

Definitions

- the invention relates to a sheet transport device and a method of guiding arcuate Material in a printing press, in particular a sheet-fed rotary offset printing machine, according to the preamble of claims 1, 2 and 11.

- DE-OS 44 06 844 is a device for hovering sheets in a rotary printing machine known in the case of a guide surface in three in the direction of the sheet guide, arranged across the width of the sheet guide surface Zones are let in, both in the beautiful as well as in the beautiful and reverse printing of Blowing air must always be applied to the press and a reliable levitation of the bow in to ensure the two operating modes.

- nozzles have a blowing direction that essentially to the side and to the rear edge of the sheet is directed so that both a lateral tightening of the Bow, as well as a tightening of the bow in the longitudinal direction of the bow in these lateral guide zones.

- the scripture gives no indication of the blowing direction of the nozzles in the middle zone in the sheet transport direction and in the middle zone arranged nozzles in the perfecting mode to be blown with air and this in straight printing off.

- WO / A / 92/05467 describes a transport device for photographic films, which one Transport surface with rows of nozzles running in the longitudinal direction which has a total of three each Longitudinally assigned nozzle rows assigned Blow boxes are charged with blown air.

- the blowing direction of the in the middle of the film material Zone arranged blowing nozzles points in Film transport direction, whereas that on the side edges arranged on the transport surface Have blowing direction that the sheet transport direction is opposite.

- the object of the invention is to be achieved to create an apparatus and method with those during the perfecting operation a reliable levitation of the bilateral printed sheet is guaranteed and with which in straight printing at high printing speeds extremely short set-up times, as well also a reliable and effective tightening of the bow let achieve. It is also a task of Invention, the energy requirement and the device effort for sheet guiding in straight printing reduce.

- the invention has the particular advantage on that with her switching the sheet guide between straight printing and face and reverse printing the printing press without complex adjustment work is possible. Furthermore, the invention Device the advantage that they are particularly without problems in the area of dry sections, in which there is high heat development and in which the use of switchable in their direction of rotation Axial fans or axial fans are not possible is, can be used.

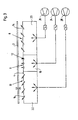

- the device 1 shown in Fig. 1 for Guiding sheet material 2 in a printing press has a guide surface 4, over the the bow 2 into the one marked by the arrow A. Sheet guiding direction is moved away.

- the leadership area 4 points in the preferred embodiment of the invention as shown in FIG. 1 and FIG. 2 as a whole three are in the longitudinal direction of the guide surface 4 extending zones 6, 8, 10, of which the zone 6 in the middle of the guide surface 4 and zones 8 and 10 corresponding to the side edges of the guide surface 4 are arranged.

- zones 6, 8, 10 are Blown air nozzles 12, 14, 16 arranged, which in the figures are shown only schematically and their blowing directions are indicated by associated arrows.

- the blowing direction in the middle or first zone 6 arranged blowing nozzles 12 points in the preferred Embodiment of the invention essentially in the transport direction A of the sheet 2, however, can also a component in the direction of Have sides of the sheet guide surface 4.

- the blowing direction which in the right or second zone 8 of Fig. 1 and 2 arranged on the right side of the guide surface 4 Blow nozzles 14 essentially have in Direction of the right side edge of the guide surface 4, and the blowing direction in the left or third zone 10 arranged blowing nozzles 16 essentially has to the left edge of the guide surface 4.

- the blowing direction the nozzles 14 and 16 preferably run at an angle of 90 ° to the transport direction A, can, however, also be in a range from 30 to 120 °.

- the nozzles 12, 14, 16 can each have any shape of nozzle and are preferred in the Embodiment of the invention by im State of the art, for example in the an existing guide surface 4 punched into a flat sheet Slot nozzles with preferably diverging Blown air jets formed.

- the blowing direction in relation on the guide surface 4 is at least in the lateral Nozzles 14, 16, as shown in FIGS. 3 and 4, essentially directed tangentially, but can also a component in the direction of the surface normal have the guide surface 4.

- the blowing direction of this lateral nozzles 14 and 16 is shown in Fig. 3 shown.

- the blowing direction in the middle zone 6 nozzles 12 is arranged with respect to the guide surface 4 preferably also essentially tangential directed, but can in the same way as in the nozzles 14 and 16 also have a vertical component to the guide surface 4. Furthermore, it can be provided be that to produce an improved Levitation around the nozzles 12 of the middle zone 6 around, not shown in the figures, by a round opening in the central zone 6 blow nozzles formed are provided, the blowing direction of which is only one Component in the direction of the surface normal of the Has guide surface 4.

- the distribution of the nozzles 14 and 16 over the side edge zones 8 and 10 is at preferred embodiment of the invention chosen such that the blowing jets of the near the middle zone 6 arranged nozzles between run through the outermost nozzles and not directly to the center of the farther outside lying nozzles are directed.

- This allows one uniform essentially vortex free flow of achieve side nozzles 14 and 16, which at Transport of a sheet 2 over the guide surface 4 for a lateral tightening of the arch both in the Schönals also ensures beautiful and reverse printing.

- the Occupancy density at nozzles in zones 6, 8 and 10 can be both homogeneous and uniform in one zone, as well as inhomogeneous, e.g. B. from the center of the guide surface 4 decreasing towards the side edges, his

- Fig. 1 As shown in Fig. 1 are below the zones 6, 8, 10 separate blow boxes 18, 20 assigned to them and 22 arranged, the unspecified Lines with associated fans 24, 26 and 28 in terms of flow are connected and the blow boxes 18, 20 and 22 during the perfecting mode supply blown air to the press.

- these Embodiments of the invention will be any blow box supplied by its own fan 24, 26, 28. The required amount of air is preferred by a correspondingly variable speed of the Blower 24, 26, 28 reached because of the effort for corresponding throttle valves.

- blowers 24, 26 and 28 can also be operated with throttle valves 30, 32 and 34 with the blow boxes 18, 20 and 22 be connected. The amount of air over the Throttle position of valves 30, 32 and 34 set.

- the blowing air generates in perfect and reverse printing mode under sheet 2 a constant air cushion on which the sheet 2 is secure and at a constant distance from the guide surface 4 passed over the guide surface 4 is, in which case the printed sheet underside does not come into contact with the guide surface 4.

- the fan speed accordingly or the valves

- the floating state between the sheet 2 and the guide surface 4 in the Zones 6, 8, 10 are adjusted accordingly, whereby depending on the production speed the printing press in perfecting mode reliable and trouble-free sheet guidance can be achieved.

- blow boxes 120 and 122 in terms of flow connected and are about a common fan 128 and an associated one Flow throttle 132 is charged with blown air. In this Traps are only two fans for the device 124, 128 sufficient.

- blow boxes 18, 118, 20, 120 and 22, 122 by only a, shown in Fig. 2 in dashed lines Blower 200 and corresponding flow restrictors 210 and 212 can be supplied with blown air.

- a Shut-off valve 214 included, with which the blown air supply interrupt to the middle blow box 18, 118 leaves, so that the blown air supply of the middle Blow box 18, 118 is turned off while the side Blow boxes 20, 120 and 22, 122 through the blower 200 continue to be blown with air.

- the shut-off function is also through Combination of valves 210 and 214 in a common Unity possible.

- the Lowering the arch 2 in the central zone 6 is based on the so-called ejector effect, which thereby is caused that the outward air flow the side nozzles 14 and 16 between the arch 2 and the guide surface 4 in the middle Zone 6 entrains air and transports it outside, so that this area is evacuated and a Vacuum occurs when the fan is off 24, 124 or closed shut-off valve 214 none or only a little air flows through the nozzles 12.

- the Sheet 2 is therefore with its underside in the area of Zone 6 sucked on the guide surface 4 and slides on this, which makes a

- the arch 2 is tightened in the longitudinal direction of the arch, which together with that through the outside directed air flow in the lateral zones 8 and 10 lateral tightening of the arch 2 in Fine printing operation of the printing press a trouble-free Guaranteed sheet travel.

- blowing air on or off in the middle zone 6 can thus be easier and more convenient Way between the perfecting and reverse printing the printing press, in which the blowing air is switched on and a clean levitation guide shown in Fig. 3 of the bow, and that shown in FIG. 4 Face printing, in which the unprinted Lower edge of the sheet in the area of the middle zone 6 slides on the guide surface 4, can be switched.

- the blowing air for a safe sheet run set once in perfecting mode the printer can switch between the two operating modes Face printing and perfecting through single and single Switch off the blown air in zone 6 inside switch over in the shortest possible time without further adjustments of air volumes and air routing.

- there is the advantage that for Sucking the sheet in zone 6 in straight printing no suction fan is required and therefore the equipment and the energy requirement of the invention Device 1 in the straight printing mode can be greatly reduced.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Delivering By Means Of Belts And Rollers (AREA)

- Feeding Of Articles By Means Other Than Belts Or Rollers (AREA)

- Supply, Installation And Extraction Of Printed Sheets Or Plates (AREA)

- Inking, Control Or Cleaning Of Printing Machines (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19607397 | 1996-02-28 | ||

| DE19607397A DE19607397A1 (de) | 1996-02-28 | 1996-02-28 | Vorrichtung und Verfahren zur Führung von bogenförmigem Material in einer Druckmaschine, insbesondere in einer Bogenrotations-Offsetdruckmaschine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0792742A1 EP0792742A1 (de) | 1997-09-03 |

| EP0792742B1 EP0792742B1 (de) | 2000-02-09 |

| EP0792742B2 true EP0792742B2 (de) | 2002-12-11 |

Family

ID=7786596

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96118243A Expired - Lifetime EP0792742B2 (de) | 1996-02-28 | 1996-11-14 | Bogentransportvorrichtung und Verfahren zur Führung von bogenförmigem Material in einer Druckmaschine, insbesondere in einer Bogenrotations-Offsetdruckmaschine |

Country Status (4)

| Country | Link |

|---|---|

| US (2) | US5797327A (enExample) |

| EP (1) | EP0792742B2 (enExample) |

| JP (1) | JP3924343B2 (enExample) |

| DE (2) | DE19607397A1 (enExample) |

Families Citing this family (59)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4406844C2 (de) * | 1994-03-03 | 1997-05-07 | Koenig & Bauer Albert Ag | Vorrichtung zum Führen von frisch beschichteten Bogen |

| US6378425B1 (en) * | 1995-02-01 | 2002-04-30 | Heidelberger Druckmaschinen Ag | Sheet-guiding device for printing presses |

| US6684774B2 (en) | 1997-05-09 | 2004-02-03 | Heidelberger Druckmaschinen Ag | Sheet-fed rotary printing press |

| DE19719624C1 (de) * | 1997-05-09 | 1998-06-10 | Heidelberger Druckmasch Ag | Bogenrotationsdruckmaschine |

| EP0899228B1 (de) * | 1997-08-28 | 2004-04-14 | Heidelberger Druckmaschinen Aktiengesellschaft | Luftpolsterführung |

| DE19747040A1 (de) * | 1997-08-28 | 1999-03-04 | Heidelberger Druckmasch Ag | Luftpolsterführung |

| US6039316A (en) * | 1998-03-02 | 2000-03-21 | Xerox Corporation | Multi-hierarchical control system for controlling object motion with smart matter |

| US6027112A (en) * | 1998-03-02 | 2000-02-22 | Xerox Corporation | Adaptive multiagent control system for controlling object motion with smart matter |

| US5947411A (en) * | 1998-03-26 | 1999-09-07 | Heidelberger Druckmaschinen Ag | Method and apparatus for air flotation |

| US6170819B1 (en) * | 1998-08-05 | 2001-01-09 | Baldwin Graphic Systems, Inc. | Non-contact sheet handling system and method of using same |

| GB9823383D0 (en) * | 1998-10-27 | 1998-12-23 | Spooner Ind Ltd | Improvements in or relating to web processing |

| US6125754A (en) * | 1998-10-30 | 2000-10-03 | Harris; J. C. | Web pressurizing channeled roller and method |

| US6250472B1 (en) | 1999-04-29 | 2001-06-26 | Advanced Sorting Technologies, Llc | Paper sorting system |

| WO2000066465A1 (en) * | 1999-04-29 | 2000-11-09 | Magnetic Separation Systems, Inc. | Paper sorting system |

| US6286655B1 (en) * | 1999-04-29 | 2001-09-11 | Advanced Sorting Technologies, Llc | Inclined conveyor |

| US6374998B1 (en) | 1999-04-29 | 2002-04-23 | Advanced Sorting Technologies Llc | “Acceleration conveyor” |

| US6369882B1 (en) | 1999-04-29 | 2002-04-09 | Advanced Sorting Technologies Llc | System and method for sensing white paper |

| DE10049809B4 (de) * | 1999-10-28 | 2014-02-13 | Heidelberger Druckmaschinen Ag | Leitvorrichtung für einen flächenhaften Bedruckstoff |

| DE10057570B4 (de) * | 1999-12-15 | 2005-11-24 | Heidelberger Druckmaschinen Ag | Leitvorrichtung einer flächige Bedruckstoffe verarbeitenden Maschine |

| US6585259B2 (en) * | 1999-12-17 | 2003-07-01 | Heidelberger Druckmaschinen Ag | Delivery of a machine for processing flat printing materials |

| US6585263B1 (en) * | 2000-02-02 | 2003-07-01 | Heidelberger Druckmaschinen Ag | Deceleration drum assembly containing air guides |

| DE10112759A1 (de) * | 2000-04-17 | 2001-10-18 | Heidelberger Druckmasch Ag | Verfahren und Vorrichtung zur berührungslosen Führung von Bogen |

| DE10133633A1 (de) * | 2000-08-31 | 2002-03-14 | Heidelberger Druckmasch Ag | Leit-und Tragelemente mit gedrosselter Blasluft |

| DE10042888A1 (de) * | 2000-08-31 | 2002-03-14 | Heidelberger Druckmasch Ag | Bogenleiteinrichtung |

| DE10151423B4 (de) * | 2000-10-26 | 2014-07-24 | Heidelberger Druckmaschinen Ag | Vorrichtung zur Einstellung eines einen Bogentransport beeinflussenden Luftstroms in einer Druckmaschine, und entsprechendes Verfahren |

| US6799514B2 (en) * | 2002-01-11 | 2004-10-05 | The Procter & Gamble Company | Cleaning apparatus for printing press |

| DE10304618B4 (de) * | 2002-03-25 | 2018-10-18 | Heidelberger Druckmaschinen Ag | Labyrinthdüse |

| DE102004012697A1 (de) * | 2003-04-11 | 2004-10-21 | Heidelberger Druckmaschinen Ag | Bogenglätteinrichtung |

| AU2003280219A1 (en) * | 2003-11-17 | 2004-06-06 | Silverbrook Research Pty Ltd | Blower box assembly for a printer |

| US7530179B2 (en) * | 2004-04-13 | 2009-05-12 | Megtec Systems, Inc. | Step air foil |

| WO2005099350A2 (en) * | 2004-04-14 | 2005-10-27 | Coreflow Scientific Solutions Ltd. | Non-contact support platforms for distance adjustment |

| US7513499B2 (en) * | 2004-05-04 | 2009-04-07 | Heidelberger Druckmaschinen Ag | Sheet brake using a partitioned blower nozzle array |

| DE102005015839A1 (de) * | 2005-04-07 | 2006-10-12 | Man Roland Druckmaschinen Ag | Bogenführungsvorrichtung einer Druckmaschine |

| DE102006017461B4 (de) | 2005-05-02 | 2022-06-09 | Heidelberger Druckmaschinen Ag | Verfahren und Vorrichtung zum Tragen eines Bedruckstoffbogens auf einem Luftpolster |

| US7311234B2 (en) * | 2005-06-06 | 2007-12-25 | The Procter & Gamble Company | Vectored air web handling apparatus |

| US7726649B2 (en) * | 2005-06-07 | 2010-06-01 | Xerox Corporation | Air drag cooler for sheet transport apparatus |

| US7419462B1 (en) * | 2005-06-13 | 2008-09-02 | Dixie Consumer Products Llc | Pressware die set with pneumatic blank feed |

| DE102005054995B4 (de) * | 2005-07-28 | 2014-03-13 | Otto Junker Gmbh | Düsensystem für die Behandlung von bahnförmigem Gut |

| DE102006012505A1 (de) * | 2006-03-18 | 2007-09-20 | Man Roland Druckmaschinen Ag | Leiteinrichtung für Bogenmaterial in einer Verarbeitungsmaschine |

| CN101269760B (zh) * | 2007-03-23 | 2011-11-16 | 海德堡印刷机械股份公司 | 收纸滚筒及双面印刷机 |

| JP2008247507A (ja) * | 2007-03-29 | 2008-10-16 | Fujifilm Corp | ウェブ搬送装置及び溶液製膜方法 |

| US8061055B2 (en) | 2007-05-07 | 2011-11-22 | Megtec Systems, Inc. | Step air foil web stabilizer |

| JP4798799B2 (ja) * | 2007-08-20 | 2011-10-19 | Necエンジニアリング株式会社 | 版給排装置及びそれを用いた刷版作成装置 |

| US7938764B2 (en) * | 2007-12-05 | 2011-05-10 | Greg Gale | Continuous feeder for paper folding machine and paper folding machine incorporating the same |

| DE102009012815A1 (de) * | 2008-04-14 | 2009-10-15 | Heidelberger Druckmaschinen Ag | Messvorrichtung mit beweglicher Messeinrichtung in einer Druckmaschine |

| EP2857199B8 (en) | 2009-06-05 | 2018-01-10 | Babcock & Wilcox MEGTEC, LLC | Method for infrared float bar |

| DE102009028738B4 (de) | 2009-08-20 | 2022-02-24 | manroland sheetfed GmbH | Bogentransportvorrichtung in einer Verarbeitungsmaschine und Verfahren zum Führen von Bogenmaterial |

| DE102010042928B4 (de) | 2009-12-10 | 2019-02-28 | manroland sheetfed GmbH | Bogentransportvorrichtung in einer Verarbeitungsmaschine und Verfahren zum Führen von Bogenmaterial |

| DE102011003962A1 (de) | 2011-02-11 | 2012-08-16 | manroland sheetfed GmbH | Bogentransportvorrichtung in einer Verarbeitungsmaschine und Verfahren zum Führen von Bogenmaterial |

| CN103224152A (zh) * | 2013-04-27 | 2013-07-31 | 朱光波 | 传输及输送气浮装置 |

| JP6287089B2 (ja) * | 2013-11-13 | 2018-03-07 | 村田機械株式会社 | 基板浮上装置、基板移載装置、および基板搬送装置 |

| DE102016207397A1 (de) * | 2016-04-29 | 2017-11-02 | Koenig & Bauer Ag | Vorrichtung zum Unterschuppen von Bogen |

| EP3507099B1 (en) * | 2016-09-02 | 2024-01-03 | Hewlett-Packard Development Company, L.P. | Vapor manager |

| CN107444938A (zh) * | 2017-09-01 | 2017-12-08 | 南京工业职业技术学院 | 一种相控气动送料工作台 |

| DE102018211588A1 (de) * | 2017-10-25 | 2019-04-25 | Heidelberger Druckmaschinen Ag | Vorrichtung zum Trocknen eines Bogens |

| TWI839413B (zh) * | 2018-12-21 | 2024-04-21 | 美商凱特伊夫公司 | 用於控制基材之漂浮的裝置、系統及方法 |

| JP7437186B2 (ja) * | 2020-02-26 | 2024-02-22 | Jswアクティナシステム株式会社 | 浮上搬送装置、及びレーザ処理装置 |

| CN111619221B (zh) * | 2020-04-21 | 2021-11-16 | 江苏扬中印刷有限公司 | 一种用于平板印刷的具有纸张定位结构的纸张张紧传送装置 |

| DE102023123942A1 (de) * | 2023-09-06 | 2025-03-06 | Canon Production Printing Holding B.V. | Vorrichtung und Verfahren zum Ausüben einer Streckung auf einen Aufzeichnungsträger |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29501537U1 (de) † | 1995-02-01 | 1995-03-09 | Heidelberger Druckmaschinen Ag, 69115 Heidelberg | Bogenleiteinrichtung mit Luftversorgungskästen |

| DE4427448A1 (de) † | 1994-08-03 | 1996-02-08 | Heidelberger Druckmasch Ag | Einrichtung zum berührungsfreien Führen bogenförmigen Materials |

| DE4209067C2 (de) † | 1992-03-20 | 1997-03-13 | Kba Planeta Ag | Bogenleiteinrichtung |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE310117B (enExample) * | 1965-07-08 | 1969-04-14 | Svenska Flaektfabriken Ab | |

| DE1499078B2 (de) * | 1966-11-23 | 1973-03-29 | Vits-Maschinenbau Gmbh, 4018 Langenfeld | Verfahren und einrichtung zur stabilisierung der lage einer warenbahn bei schwebender durchfuehrung dieser durch einen mindestens teilweise tragfluegelprofilbegrenzten behandlungsraum mittels eines blasmittels, mit dem wenigstens eine warenbahnflaeche im spitzen winkel zu ihrer bewegungsrichtung angeblasen wird |

| DE1761468A1 (de) * | 1968-05-24 | 1971-07-01 | Mabeg Maschb Gmbh Nachf Hense | Foerdervorrichtung fuer Bogen von Karton,Papier und Kunststoffolien |

| US4372550A (en) * | 1981-04-30 | 1983-02-08 | Woods Kenneth D | Air flow delivery system |

| DE3411029A1 (de) * | 1984-03-24 | 1985-10-03 | M.A.N.- Roland Druckmaschinen AG, 6050 Offenbach | Vorrichtung zum fuehren von ein- und beidseitig bedruckten bogen |

| US4901449A (en) * | 1988-06-07 | 1990-02-20 | W. R. Grace & Co.-Conn. | Tri-flotation air bar |

| US4913049A (en) * | 1989-04-19 | 1990-04-03 | Quad/Tech, Inc. | Bernoulli-effect web stabilizer |

| US5395029A (en) * | 1989-12-29 | 1995-03-07 | Somerset Technologies, Inc. | Flotation nozzle for web handling equipment |

| US5209387A (en) * | 1990-09-20 | 1993-05-11 | Eastman Kodak Company | Gas film conveyor for elongated strips of web material |

| US5553542A (en) * | 1991-11-06 | 1996-09-10 | Rockwell International Corporation | System for controlling a web in a printing press |

| DE4242730C2 (de) * | 1992-12-17 | 1997-01-30 | Heidelberger Druckmasch Ag | Bogenausleger einer Druckmaschine |

| DE4406844C2 (de) * | 1994-03-03 | 1997-05-07 | Koenig & Bauer Albert Ag | Vorrichtung zum Führen von frisch beschichteten Bogen |

| EP0701958B1 (de) * | 1994-09-02 | 1998-07-15 | Heidelberger Druckmaschinen Aktiengesellschaft | Leiteinrichtung für einen Bogen |

| DE9416106U1 (de) * | 1994-10-06 | 1994-11-24 | Heidelberger Druckmaschinen Ag, 69115 Heidelberg | Bogenleitblech für eine Wendeeinrichtung |

| US5634636A (en) * | 1996-01-11 | 1997-06-03 | Xerox Corporation | Flexible object handling system using feedback controlled air jets |

-

1996

- 1996-02-28 DE DE19607397A patent/DE19607397A1/de not_active Withdrawn

- 1996-11-14 EP EP96118243A patent/EP0792742B2/de not_active Expired - Lifetime

- 1996-11-14 DE DE59604421T patent/DE59604421D1/de not_active Expired - Lifetime

-

1997

- 1997-02-26 JP JP04205497A patent/JP3924343B2/ja not_active Expired - Fee Related

- 1997-02-28 US US08/808,783 patent/US5797327A/en not_active Expired - Lifetime

-

1998

- 1998-05-15 US US09/079,585 patent/US5927203A/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4209067C2 (de) † | 1992-03-20 | 1997-03-13 | Kba Planeta Ag | Bogenleiteinrichtung |

| DE4427448A1 (de) † | 1994-08-03 | 1996-02-08 | Heidelberger Druckmasch Ag | Einrichtung zum berührungsfreien Führen bogenförmigen Materials |

| DE29501537U1 (de) † | 1995-02-01 | 1995-03-09 | Heidelberger Druckmaschinen Ag, 69115 Heidelberg | Bogenleiteinrichtung mit Luftversorgungskästen |

Also Published As

| Publication number | Publication date |

|---|---|

| JP3924343B2 (ja) | 2007-06-06 |

| EP0792742A1 (de) | 1997-09-03 |

| US5927203A (en) | 1999-07-27 |

| JPH101238A (ja) | 1998-01-06 |

| DE59604421D1 (de) | 2000-03-16 |

| DE19607397A1 (de) | 1997-09-04 |

| EP0792742B1 (de) | 2000-02-09 |

| US5797327A (en) | 1998-08-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0792742B2 (de) | Bogentransportvorrichtung und Verfahren zur Führung von bogenförmigem Material in einer Druckmaschine, insbesondere in einer Bogenrotations-Offsetdruckmaschine | |

| DE4447963B4 (de) | Einrichtung zum berührungsfreien Führen bogenförmigen Materials | |

| DE2523986A1 (de) | Pneumatische blattransport- und ausrichtvorrichtung | |

| DE19549589B4 (de) | Bogenleiteinrichtung für Druckmaschinen | |

| DE4242730C2 (de) | Bogenausleger einer Druckmaschine | |

| DE4406848C2 (de) | Blaskasten zum schwebenden Führen von Bogen oder Bahnen | |

| DE3706058C2 (enExample) | ||

| DE69308064T2 (de) | Luftführungsvorrichtung mit einer Ablaufplatte zum Wenden einer bewegten Bahn | |

| EP0006522A1 (de) | Verfahren und Vorrichtung zum Öffnen gefalzter Druckbogen | |

| DE19817175A1 (de) | Vorrichtung zum Fördern eines insbesondere geschuppten Stroms von Bogen zu einer bogenverarbeitenden Maschine | |

| DE4424483A1 (de) | Ausleger einer bogenverarbeitenden Maschine | |

| EP1028077B1 (de) | Bogenführungseinrichtung für eine Druckmaschine | |

| DE10102221A1 (de) | Vorrichtung zum Verlangsamen von Signaturen | |

| DE3209259C1 (de) | Bogenanlegevorrichtung an bogenverarbeitenden Maschinen | |

| EP1344578A2 (de) | Schneidvorrichtung mit Entstaubungsvorrichtung im Falzapparat einer bahnverarbeitenden Druckmaschine | |

| EP0137065B1 (de) | Vorrichtung zum kontinuierlichen und spannungslosen Behandeln von textilen Warenbahnen | |

| DE4119068C2 (de) | Einrichtung zur Verbindung zweier Trockengruppen einer Papiermaschine | |

| EP1010525B1 (de) | Bogenführungseinrichtung für eine Druckmaschine | |

| DE3031309C2 (de) | Ablagevorrichtung für eine vorgefaltete Endlospapierbahn | |

| DD285072A5 (de) | Blaseinrichtung | |

| DE4421918C1 (de) | Vorrichtung zum Fördern und gleichzeitigen Ausrichten von bogenförmigem Material, insbesondere aus Papier, Karton oder Folien | |

| EP1184174A2 (de) | Maschine zur Verarbeitung von Bogen | |

| EP0945385A2 (de) | Falztrichter eines Falzapparats einer Rotationsdruckmaschine | |

| DE1774126B1 (de) | Einrichtung zur Stabilisierung der Lage bahn- oder bogenfoermiger Werkstuecke | |

| DE8207147U1 (de) | Bogenanlegevorrichtung an bogenverarbeitenden maschinen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19961114 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE FR GB LI |

|

| 17Q | First examination report despatched |

Effective date: 19980629 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RTI1 | Title (correction) |

Free format text: SHEET TRANSPORT DEVICE AND METHOD FOR GUIDING SHEETLIKE MATERIAL IN A PRINTING MACHINE, SPECIALLY IN AN OFFSET ROTARY PRINTING MACHINE FOR SHEETS |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB LI |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59604421 Country of ref document: DE Date of ref document: 20000316 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20000323 |

|

| ET | Fr: translation filed | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: KOENIG & BAUER AG Effective date: 20001109 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20021211 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): CH DE FR GB LI |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20061017 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20061127 Year of fee payment: 11 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20071114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071114 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20081117 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100730 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20131122 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59604421 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150602 |