EP0343150B1 - Weiche mit einem Herzstück mit beweglicher Haupt- und Beispitze - Google Patents

Weiche mit einem Herzstück mit beweglicher Haupt- und Beispitze Download PDFInfo

- Publication number

- EP0343150B1 EP0343150B1 EP89890147A EP89890147A EP0343150B1 EP 0343150 B1 EP0343150 B1 EP 0343150B1 EP 89890147 A EP89890147 A EP 89890147A EP 89890147 A EP89890147 A EP 89890147A EP 0343150 B1 EP0343150 B1 EP 0343150B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- nose

- tip

- main

- rail

- profiles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B7/00—Switches; Crossings

- E01B7/10—Frogs

- E01B7/14—Frogs with movable parts

Definitions

- the invention relates to a switch with a centerpiece with a movable main and example.

- Frogs with a movable frog tip which have a main tip and an example that slidably abuts the main tip, have become known, for example, from German Utility Model 69 08 819 (DE-B-1911 160).

- German Utility Model 69 08 819 DE-B-1911 160

- large lengths are required for such designs and the previously known designs have a relatively low load-bearing capacity and stability of the tip.

- restrictions had to be accepted with regard to the use of materials or also for the use of different switch geometries and a further disadvantage of known designs was that welding and adhesive shocks in the carriageway were sometimes required in the unclamped area.

- An additional problem with the known designs is the susceptibility to errors in the running edge course and a relatively complicated design and a complicated locking system was required for previously known movable tips.

- the invention now aims to provide a switch of the type mentioned with a movable centerpiece, in which common materials can be used without restrictions in rail and switch construction and which is characterized by greater load-bearing capacity and stability, especially in the tip area.

- the switch according to the invention essentially consists in the fact that the main and exemplary tips are formed using thick web control rail profiles and that lower outer rails compared to the thick web control rail profiles are lower, at least partially fixed on base plates, asymmetrical tongue profiles are arranged.

- the same material can be selected for both the main and the example, so that uniform wear and thus less maintenance is achieved.

- the choice of thick web control rail profiles gives the main and example the necessary stability while simultaneously improving the possibility of elastic bracing of the wing rail parts and by the measure of making the outer wing rails lower than the thick web control rail profiles of the centerpiece and at least partially fixing them on base plates.

- the possibility is created that the Dicksteg control rail profiles can be secured against rising when the tip of the heart is pivoted with its foot part below the wing rails.

- the required strength is ensured by the thick web control rail profiles of the heart tip and the special design of the outer wing rails prevents the tip of the heart from rising.

- Such a design is particularly advantageous for high-speed switches, in which the required joints or road connections cannot be produced without great effort when using different materials, such as manganese hard steel castings.

- the design is advantageously made such that the height of the lower asymmetrical tongue profiles is lower by at least the height of the rail foot of the thick web control rail profiles of the frog tip than the height of the thick web control rail profiles of the frog tip.

- the centerpiece tip can be inserted in the respective end position with the foot part of the thick web control rail profile below the outer wing rails, whereby a locking is achieved.

- the design is advantageously made such that the end faces of the base plates facing the frog tip have recesses for engaging over the foot of the frog tip in the abutting position of the frog tip.

- the design is advantageously made such that the foot of the frog tip in the area at least part of the base plates of the wing rails is formed except for a smaller width.

- the use of thick web control rail profiles for the main and the tip now also enables a particularly stable sliding fixing of the tip at the main tip in the outlet area of the frog.

- a sliding connection is advantageously provided at this point and the design can be made in a particularly simple manner in such a way that the main tip and the tip point through their abutting surfaces are screwed together and that the opening for the screw, in particular provided with a support sleeve and spring elements, is formed in the main and / or example as an elongated hole extending in the longitudinal direction of the rail profile.

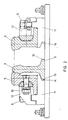

- FIG. 1 shows the detail of a plan view of a switch according to the invention with a centerpiece with a movable main and example tip; 2 shows a section along the line II-II of Figure 1, the tongue rail is shown in a different position, and Figure 3 shows a section along the line III-III of Figure 1.

- 1 denotes a frog, which has a frog tip 2 with a main tip 3 and an example 4.

- the wing rails of the centerpiece 1 are designated 5 and 6.

- the wing rails 5 and 6 are fixed to sleepers 7 by means of screws 8, as will be explained in more detail below.

- the foot 9 of the main tip 3 has, in the area of the fixing of the wing rail 5 on a threshold 7, recesses 10, the functioning of which will be explained in more detail below.

- the main tip 3 is shown in contact with the wing rail 5.

- the main tip is made of a thick web control rail profile, for example UIC60 according to UIC 861-3V but with 30 mm web thickness or UIC54 "Profile A” according to UIC 861-2V with 28 mm web thickness.

- the asymmetrical and lower height wing rail parts 5 and 6 are adapted to the rail profile used for the tip, for which purpose, for example, an asymmetrical tongue profile for UIC rail 60 kg / m according to UIC 861-2V or a "profile B 68.5 kg / m "according to UIC 861-2V can be used.

- the wing rails 5 and 6 are each fixed on base plates 11, the height of which is dimensioned such that the total height of the base plate 11 with the lower wing rail 5 or 6 corresponds to the height of the main tip 3.

- the wing rails 5 are fixed on the base plate 11 in a known manner via supports 12 which are connected to the wing rail by means of a screw connection 13 and to the base plate 11 by means of the screw connection 8.

- the base plates 11 have recesses 14 on their end faces facing the tip 3, into which recesses part 10 of the rail foot 9 of the tip 3 can engage in the position in contact with the wing rail. Overlapping of the base plate 11 in this way prevents the tip 3 from rising and the base plate 11 thus acts as a hold-down device in the position in contact with the wing rail.

- connection according to FIG. 3 shows the connection between the main tip 3 and the example tip 4.

- the example 4 like the main tip 3, is formed using thick-web control rail profiles, as explained above.

- the wing rails 5 and 6 in turn have a lower height and an asymmetrical tongue profile and are in turn fixed on base plates 11 on the sleepers 7.

- the main tip 3 and the example tip 4 are connected to one another by a screw connection 15, the opening 16 for the screw 15 in the example 4 is designed as an elongated hole running in the longitudinal direction of the rail profile.

- the screw is screwed together with a high-strength screw on the screw head and on the rail web of the main tip, while the tip is pressed against the main tip with spring elements.

- the opening in the main tip 3 is designed as a simple bore 17.

- the example tip 4 also has a rail foot 18 for a more stable design of the centerpiece with less risk of tipping.

- the transmission of lateral forces from the tips 3 and 4 to the respective wing rails 5 and 6 takes place via supports 19 and 20 which can be attached to the wing rail or to the apex of the heart. These supports are also indicated in Fig.1 and also designated 19 and 20 respectively.

- Spacers 21 which are indicated schematically in FIG. 1, are also provided for support between the main tip and the tip 3 at a large distance from the tip region. These spacers can alternately be attached on one side to the main and at the tip, so that the opposite contact surface on the thick bar control rail profile of the other tip can slide during the changeover due to the relative displacement between the main and the tip on the rail profile.

- main and example tips Due to the design of the main and example tips as a thick web control rail profile, these components are superior to known movable tips in terms of load capacity. Furthermore, by using such frogs, their overall length can be shortened considerably, since the relative displacement of the changeover process can be placed in the area between the main and the example, since the machined thick web profiles have a sufficient load-bearing capacity.

- thick web control profiles for the main and example 3 or 4 This can be designed to run continuously from the start of the tip to the end of the switch, so that during a changeover process, bending lines or running edge profiles are created which can be exactly predetermined.

- the main tip 3 and example 4 are thus continuous elastic switch elements without rigid interference areas.

- the use of a thick web control rail profile for the main tip 3 and example 4 makes it possible to keep spring points in the rail foot, which are not shown for the sake of clarity, relatively short and to be arranged relatively far forward without making the changeover forces unacceptably high. Such a shortening also has a favorable effect on the overall length of the centerpiece tip 2. Due to the elastic design of the entire centerpiece with thick web control rail profiles as tips 3 and 4 or asymmetrical profiles for the wing rails 5 and 6, the centerpiece fits into the elastic behavior of the track and does not represent a foreign body in the elastic track.

- the main tip 3 and example 4 from the thick web control rail profile are either guided to the end of the crosspiece tip 2 and adapted there to the control rail profile or they end in the clamped area 2 to 3 threshold fields before the end of the crosspiece and are welded to a control rail after adaptation to the control rail profile , which extends to the centerpiece.

- the wing rail parts designed as an asymmetrical tongue profile of low height in the area of the frog 1 are either forged in the area immediately in front of the tip of the heart from the lower asymmetrical tongue profile to the standard rail profile or mutually adapted and welded to a standard rail which extends to the beginning of the frog.

- the asymmetrical tongue profile can also extend to the beginning of the centerpiece and can only be adapted to the standard rail profile there.

- the wing rail parts are either guided up to the wing rail end as an asymmetrical tongue profile or after the overflow area behind the zone after the cardiac tips also forged onto the control rail profile or adapted to one another and welded to a control rail which extends to the end of the wing rail.

- either naturally hard untreated rail steels, special grade steels, heat-treated steels or hard manganese steel can be rolled or cast, which can also be pre-consolidated.

- the adjoining control rail which connects at the beginning or end of the heart or end of the wing rail, is connected to the respective road section of the centerpiece tip or the wing rail according to special methods for welding hard manganese steel to rail steel.

- a fastening can also be used, which is referred to as the inner stock rail bracing.

- the cardiac tips 3 and 4 can also be fastened in the clamped area and in the area of the wing rails made of standard rail profile by means of elastic clamping plates attached on the inside.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Railway Tracks (AREA)

- Gears, Cams (AREA)

- Investigating Or Analysing Biological Materials (AREA)

- Sampling And Sample Adjustment (AREA)

- Escalators And Moving Walkways (AREA)

- Mounting, Exchange, And Manufacturing Of Dies (AREA)

- Train Traffic Observation, Control, And Security (AREA)

- Harvester Elements (AREA)

- Keying Circuit Devices (AREA)

- Switches With Compound Operations (AREA)

- Percussion Or Vibration Massage (AREA)

- Thermotherapy And Cooling Therapy Devices (AREA)

- Passenger Equipment (AREA)

- Preliminary Treatment Of Fibers (AREA)

- Finger-Pressure Massage (AREA)

- Massaging Devices (AREA)

- Toys (AREA)

- Adjustable Resistors (AREA)

- Mutual Connection Of Rods And Tubes (AREA)

- Pens And Brushes (AREA)

- Mechanical Pencils And Projecting And Retracting Systems Therefor, And Multi-System Writing Instruments (AREA)

- Machines For Laying And Maintaining Railways (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0134088A AT390084B (de) | 1988-05-20 | 1988-05-20 | Weiche mit einem herzstueck mit beweglicher haupt- und beispitze |

| AT1340/88 | 1988-05-20 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0343150A2 EP0343150A2 (de) | 1989-11-23 |

| EP0343150A3 EP0343150A3 (en) | 1990-06-13 |

| EP0343150B1 true EP0343150B1 (de) | 1992-12-30 |

Family

ID=3511783

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89890147A Expired - Lifetime EP0343150B1 (de) | 1988-05-20 | 1989-05-18 | Weiche mit einem Herzstück mit beweglicher Haupt- und Beispitze |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US4953814A (ru) |

| EP (1) | EP0343150B1 (ru) |

| AT (2) | AT390084B (ru) |

| CA (1) | CA1323013C (ru) |

| DE (1) | DE58903144D1 (ru) |

| ES (1) | ES2038001T3 (ru) |

| FI (1) | FI92504C (ru) |

| GR (1) | GR3007447T3 (ru) |

| NO (1) | NO173748C (ru) |

| SU (1) | SU1724020A3 (ru) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3828921C3 (de) * | 1988-08-26 | 2000-10-26 | Weichenbau Laeis Gmbh & Co Kg | Verfahren zum Herstellen einer Weiche mit Herzstück mit federndbeweglicher Spitze sowie eine Weiche mit Herzstück |

| CA1324364C (fr) * | 1988-10-14 | 1993-11-16 | Gerard Testart | Coeur de croisement a pointe mobile et procede de fabrication d'un tel coeur de croisement |

| LU87721A1 (fr) * | 1990-04-11 | 1990-12-11 | Kihn Sarl | Aiguillage pour rails a gorge |

| DE4014346C2 (de) * | 1990-05-04 | 2002-03-21 | Butzbacher Weichenbau Gmbh | Relativ zu Flügelschienen verstellbare Herzstückspitze |

| FR2662450B1 (fr) * | 1990-05-23 | 1992-09-11 | Cogifer | Aiguillage pour voie de guidage a orniere. |

| FR2672316B1 (fr) * | 1991-02-05 | 1993-05-28 | Cogifer Cie Cle Installat Ferr | Appareil de voie pour vehicules ferroviaires sur pneumatiques a galet de guidage median et procede pour sa fabrication. |

| FR2695662B1 (fr) * | 1992-09-11 | 1994-11-18 | Cogifer | Encastrement de la pointe mobile dans le berceau d'un cÓoeur de croisement incorporé dans les longs rails soudés et procédé de réalisation d'un tel encastrement. |

| DE4412806A1 (de) * | 1994-04-14 | 1994-09-01 | Guenter Andres | Gleisweiche für den Eisenbahn- und Schienenverkehr |

| RO119241B1 (ro) * | 1996-08-21 | 2004-06-30 | Hubmann Hans Peter | Inimă de schimbător de cale pentru macazuri şi intersecţii şi procedeu de realizare |

| DE19901949C2 (de) * | 1999-01-20 | 2002-10-31 | Thyssen Krupp Materials & Serv | Bewegliche zwei- oder mehrstückige Herzstückspitze |

| US6286791B1 (en) * | 2000-03-09 | 2001-09-11 | Abc-Naco Inc. | Railroad spring wing frog with hold-open and shock dampening elements |

| DE10310043A1 (de) * | 2003-03-06 | 2004-09-16 | Schreck-Mieves Gmbh | Herzstück |

| AT506269B1 (de) * | 2008-01-14 | 2010-02-15 | Vae Eisenbahnsysteme Gmbh | Weiche mit beweglicher herzstückspitze |

| ES1072245Y (es) * | 2010-04-09 | 2010-09-09 | Amurrio Ferrocarril Y Equipos | Dispositivo de encerrojamiento para corazon de punta movil |

| ES2399735B1 (es) * | 2010-06-15 | 2013-11-13 | Jez Sistemas Ferroviarios, S.L. | Corazon agudo de punta movil para aparatos de via de carril garganta |

| EP2479080A3 (de) * | 2011-01-19 | 2015-10-28 | Siemens Schweiz AG | Klinkenverschluss mit Verschlussklammerschraube |

| US8424812B1 (en) | 2011-01-25 | 2013-04-23 | Cleveland Track Material, Inc. | Elevated frog and rail track assembly |

| EP2487293B1 (en) * | 2011-02-08 | 2014-05-07 | Jez Sistemas Ferroviarios, S.l. | Acute swing nose crossing for railways |

| US8556217B1 (en) | 2011-05-24 | 2013-10-15 | Cleveland Track Material, Inc. | Elevated frog and rail crossing track assembly |

| AT513323B1 (de) * | 2012-08-28 | 2014-08-15 | Voestalpine Hytronics Gmbh | Weiche für Schienen |

| DE102012017982A1 (de) * | 2012-09-12 | 2014-03-13 | Schwihag Ag | Herzstückrollvorrichtung |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE211594C (ru) * | ||||

| US487957A (en) * | 1892-12-13 | Railroad-frog | ||

| DE488452C (de) * | 1928-10-05 | 1930-01-06 | Fried Krupp Akt Ges | Einfaches Herzstueck |

| US2377273A (en) * | 1942-07-29 | 1945-05-29 | George J H Siebert | Railway track assembly |

| FR1547338A (fr) * | 1966-12-21 | 1968-11-22 | Kloeckner Werke Ag | Pointe-de-coeur simple avec pointe élastique |

| AT288463B (de) * | 1967-02-17 | 1971-03-10 | Oeesterreichisch Alpine Montan | Weichen-Herzstück |

| DE6908819U (de) * | 1969-03-05 | 1974-06-06 | Krupp Ag Huettenwerke | Herzstueck mit beweglicher herzstueckspitze. |

| DE1911160B1 (de) * | 1969-03-05 | 1970-07-16 | Krupp Ag Huettenwerke | Herzstueck mit beweglicher Herzstueckspitze |

| FR2339706A1 (fr) * | 1976-02-02 | 1977-08-26 | Abbaye Atel Const | Dispositif d'aiguillage pour voies de roulement et de guidage |

| FR2551106B1 (fr) * | 1983-03-30 | 1985-12-06 | Renaud Christian | Appareil de fixation de contre-aiguille a coussinet de glissement pour aiguillage de voie de chemin de fer |

| DE3411122A1 (de) * | 1984-03-26 | 1985-10-03 | BWG Butzbacher Weichenbau GmbH, 6308 Butzbach | Vorrichtung zum befestigen von schienen |

-

1988

- 1988-05-20 AT AT0134088A patent/AT390084B/de not_active IP Right Cessation

-

1989

- 1989-05-17 SU SU894614008A patent/SU1724020A3/ru active

- 1989-05-17 US US07/353,022 patent/US4953814A/en not_active Expired - Lifetime

- 1989-05-18 AT AT89890147T patent/ATE84089T1/de not_active IP Right Cessation

- 1989-05-18 EP EP89890147A patent/EP0343150B1/de not_active Expired - Lifetime

- 1989-05-18 DE DE8989890147T patent/DE58903144D1/de not_active Expired - Fee Related

- 1989-05-18 ES ES198989890147T patent/ES2038001T3/es not_active Expired - Lifetime

- 1989-05-19 FI FI892447A patent/FI92504C/fi not_active IP Right Cessation

- 1989-05-19 NO NO892031A patent/NO173748C/no not_active IP Right Cessation

- 1989-05-19 CA CA000600214A patent/CA1323013C/en not_active Expired - Fee Related

-

1993

- 1993-03-23 GR GR930400634T patent/GR3007447T3/el unknown

Also Published As

| Publication number | Publication date |

|---|---|

| NO173748C (no) | 1994-01-26 |

| SU1724020A3 (ru) | 1992-03-30 |

| CA1323013C (en) | 1993-10-12 |

| NO892031D0 (no) | 1989-05-19 |

| NO173748B (no) | 1993-10-18 |

| DE58903144D1 (de) | 1993-02-11 |

| FI892447A (fi) | 1989-11-21 |

| US4953814A (en) | 1990-09-04 |

| ATE84089T1 (de) | 1993-01-15 |

| NO892031L (no) | 1989-11-21 |

| FI92504C (fi) | 1994-11-25 |

| FI92504B (fi) | 1994-08-15 |

| GR3007447T3 (ru) | 1993-07-30 |

| ES2038001T3 (es) | 1993-07-01 |

| AT390084B (de) | 1990-03-12 |

| FI892447A0 (fi) | 1989-05-19 |

| EP0343150A3 (en) | 1990-06-13 |

| ATA134088A (de) | 1989-08-15 |

| EP0343150A2 (de) | 1989-11-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0343150B1 (de) | Weiche mit einem Herzstück mit beweglicher Haupt- und Beispitze | |

| DE4011523C2 (de) | Verfahren zum Herstellen von Profilkörpern für Weichen für Rillenschienen durch maschinelle Bearbeitung zur Herstellung von Weichen | |

| DE3339442C1 (de) | Herzstueck fuer Weichen oder Kreuzungen und Verfahren zur Herstellung eines solchen Herzstueckes | |

| AT6220U2 (de) | Stopfaggregat zum unterstopfen eines gleises | |

| DE102016120200A1 (de) | Flügelschiene eines Herzstücks sowie Verfahren zum Herstellen eines Herzstücks | |

| DE3941937C2 (ru) | ||

| DE2508739B2 (de) | Gelenkige schienenverbindung fuer eine einschienenhaengebahn im bergbau | |

| DD289568A5 (de) | Herzstueck mit herzspitze aus gegossenem hartmanganstahl | |

| DE29602463U1 (de) | Zweiblock-Schwelle | |

| DE8105454U1 (de) | "herzstueck" | |

| EP1516091A1 (de) | Weiche mit verstärkter zungenschiene | |

| AT506269B1 (de) | Weiche mit beweglicher herzstückspitze | |

| DE2239653A1 (de) | Kombinierte lauf- und schutzschiene | |

| EP3284863B1 (de) | Zungenschiene und zungenvorrichtung | |

| DE2831285C2 (de) | Laufschiene aus einem Doppel-T-Profil für eine Einschienenhängebahn | |

| DE1284439B (de) | Herzstueck mit blockartiger Herzstueckspitze | |

| DE1658316B1 (de) | Einfaches Herzstück für Weichen und Kreuzungen | |

| DE1048938B (de) | Federzungenvorrichtung, insbesondere fuer Rillenschienenweichen, in Blockkonstruktion | |

| DE2061264A1 (de) | Herzstueck fuer Weichen und Kreuzungen | |

| DE10310042B4 (de) | Herzstück | |

| LU81085A1 (de) | Zur befestigung von eisenbahnschienen auf stahlschwellen geeignetes befestigungssystem | |

| DD285390A5 (de) | Herzstueck | |

| DE2429921C3 (de) | Herzstück | |

| DE2415418C3 (de) | Auflaufkreuzung von Geleisen und Verfahren zur Herstellung | |

| AT5558U1 (de) | Verfahren zur montage von weichen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900828 |

|

| 17Q | First examination report despatched |

Effective date: 19910729 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: VOEST-ALPINE EISENBAHNSYSTEME GESELLSCHAFT M.B.H. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 84089 Country of ref document: AT Date of ref document: 19930115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 58903144 Country of ref document: DE Date of ref document: 19930211 |

|

| ITF | It: translation for a ep patent filed |

Owner name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19930330 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3007447 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2038001 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 89890147.5 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: VOEST-ALPINE EISENBAHNSYSTEME GESELLSCHAFT M.B.H. TRANSFER- VAE AKTIENGESELLSCHAFT |

|

| NLS | Nl: assignments of ep-patents |

Owner name: VOEST-ALPINE EISENBAHNSYSTEME AG |

|

| NLT1 | Nl: modifications of names registered in virtue of documents presented to the patent office pursuant to art. 16 a, paragraph 1 |

Owner name: VAE AKTIENGESELLSCHAFT;VAE EISENBAHNSYSTEME AG |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Ref country code: FR Ref legal event code: CA |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20030422 Year of fee payment: 15 Ref country code: CH Payment date: 20030422 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030428 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20030502 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20030505 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20030506 Year of fee payment: 15 Ref country code: AT Payment date: 20030506 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030512 Year of fee payment: 15 Ref country code: BE Payment date: 20030512 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20030514 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20030516 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040518 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040518 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040519 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040519 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 |

|

| BERE | Be: lapsed |

Owner name: *VAE A.G. Effective date: 20040531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041201 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041203 |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20040518 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050131 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20041201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050518 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20040519 |