WO2017169207A1 - 組織状蛋白素材の製造方法 - Google Patents

組織状蛋白素材の製造方法 Download PDFInfo

- Publication number

- WO2017169207A1 WO2017169207A1 PCT/JP2017/005294 JP2017005294W WO2017169207A1 WO 2017169207 A1 WO2017169207 A1 WO 2017169207A1 JP 2017005294 W JP2017005294 W JP 2017005294W WO 2017169207 A1 WO2017169207 A1 WO 2017169207A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- protein material

- textured protein

- textured

- meat

- cutting blade

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23J—PROTEIN COMPOSITIONS FOR FOODSTUFFS; WORKING-UP PROTEINS FOR FOODSTUFFS; PHOSPHATIDE COMPOSITIONS FOR FOODSTUFFS

- A23J3/00—Working-up of proteins for foodstuffs

- A23J3/14—Vegetable proteins

- A23J3/16—Vegetable proteins from soybean

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23J—PROTEIN COMPOSITIONS FOR FOODSTUFFS; WORKING-UP PROTEINS FOR FOODSTUFFS; PHOSPHATIDE COMPOSITIONS FOR FOODSTUFFS

- A23J3/00—Working-up of proteins for foodstuffs

- A23J3/14—Vegetable proteins

- A23J3/18—Vegetable proteins from wheat

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23J—PROTEIN COMPOSITIONS FOR FOODSTUFFS; WORKING-UP PROTEINS FOR FOODSTUFFS; PHOSPHATIDE COMPOSITIONS FOR FOODSTUFFS

- A23J3/00—Working-up of proteins for foodstuffs

- A23J3/22—Working-up of proteins for foodstuffs by texturising

- A23J3/225—Texturised simulated foods with high protein content

- A23J3/227—Meat-like textured foods

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23J—PROTEIN COMPOSITIONS FOR FOODSTUFFS; WORKING-UP PROTEINS FOR FOODSTUFFS; PHOSPHATIDE COMPOSITIONS FOR FOODSTUFFS

- A23J3/00—Working-up of proteins for foodstuffs

- A23J3/22—Working-up of proteins for foodstuffs by texturising

- A23J3/26—Working-up of proteins for foodstuffs by texturising using extrusion or expansion

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23P—SHAPING OR WORKING OF FOODSTUFFS, NOT FULLY COVERED BY A SINGLE OTHER SUBCLASS

- A23P30/00—Shaping or working of foodstuffs characterised by the process or apparatus

- A23P30/20—Extruding

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23B—PRESERVATION OF FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES; CHEMICAL RIPENING OF FRUIT OR VEGETABLES

- A23B2/00—Preservation of foods or foodstuffs, in general

- A23B2/90—Preservation of foods or foodstuffs, in general by drying or kilning; Subsequent reconstitution

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23B—PRESERVATION OF FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES; CHEMICAL RIPENING OF FRUIT OR VEGETABLES

- A23B7/00—Preservation of fruit or vegetables; Chemical ripening of fruit or vegetables

- A23B7/02—Dehydrating; Subsequent reconstitution

- A23B7/0205—Dehydrating; Subsequent reconstitution by contact of the material with fluids, e.g. drying gas or extracting liquids

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES, NOT OTHERWISE PROVIDED FOR; PREPARATION OR TREATMENT THEREOF

- A23L5/00—Preparation or treatment of foods or foodstuffs, in general; Food or foodstuffs obtained thereby; Materials therefor

- A23L5/10—General methods of cooking foods, e.g. by roasting or frying

- A23L5/13—General methods of cooking foods, e.g. by roasting or frying using water or steam

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES, NOT OTHERWISE PROVIDED FOR; PREPARATION OR TREATMENT THEREOF

- A23L5/00—Preparation or treatment of foods or foodstuffs, in general; Food or foodstuffs obtained thereby; Materials therefor

- A23L5/10—General methods of cooking foods, e.g. by roasting or frying

- A23L5/17—General methods of cooking foods, e.g. by roasting or frying in a gaseous atmosphere with forced air or gas circulation, in vacuum or under pressure

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2002/00—Food compositions, function of food ingredients or processes for food or foodstuffs

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2250/00—Food ingredients

- A23V2250/54—Proteins

- A23V2250/548—Vegetable protein

- A23V2250/5486—Wheat protein, gluten

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2250/00—Food ingredients

- A23V2250/54—Proteins

- A23V2250/548—Vegetable protein

- A23V2250/5488—Soybean protein

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2300/00—Processes

- A23V2300/16—Extrusion

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2300/00—Processes

- A23V2300/24—Heat, thermal treatment

Definitions

- the present invention relates to a method for producing a textured protein material.

- the textured protein material produced by extrusion is not in a state with a flesh-like fiber feeling as it is, but has been subjected to various processing treatments to give a fiber feeling (for example, Patent Documents 1 and 2). .

- Patent Document 1 is a technique using a defibrating roll, in which a number of file teeth such as a sheet cutter are arranged on the surface, or an orientation obtained by extrusion onto a defibrating roll having a needle like a brush.

- a technique is described in which a sheet or rod-like material is subdivided into thin fibers in a softened state.

- the structured protein material is subdivided into thin fibers, so as it is, it cannot be used as a meat-like protein processed food, or mixed with meat, It is necessary to remold the subdivided fibrous material.

- Patent Document 2 is a technique using a roll, and by passing a textured protein material through two or more rolls having different circumferential speeds, a shear stress generated due to a difference in circumferential speed is applied to the textured protein material, whereby water is added.

- a shear stress generated due to a difference in circumferential speed is applied to the textured protein material, whereby water is added.

- it describes a method for producing a protein food material having a structure, appearance, and texture similar to natural meat when reconstituted with hot water.

- the entire textured protein material is crushed, so that a flesh-like elasticity can be obtained, but there is a problem that the fiber feel is lacking.

- An object of the present invention is to provide a method for producing a textured protein material having a flesh-like fiber feeling.

- the inventors do not perform processing using a roll that is normally performed on a textured protein material, but are opposed to each other, called cutting blade rolls that are used to cut noodles and the like.

- cutting blade rolls that are used to cut noodles and the like.

- the textured protein material is produced by passing through a cutting blade roll, and the upper and lower surfaces of the textured protein material are provided with grooves cut in the same direction as the extruded direction.

- the pitch width of the adjacent annular blades is preferably 0.8 to 1.5 mm, and the clearance width between the pair of rolls when passing the structured protein material is a textured shape. It is preferably 10 to 30% with respect to the thickness of the protein material.

- the textured protein material prepared in the present invention can be seasoned and dried to obtain a meat-like dried protein processed food that is an ingredient for instant food.

- a method for producing a textured protein material having a flesh-like fiber feeling can be provided.

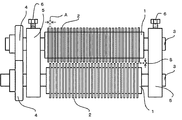

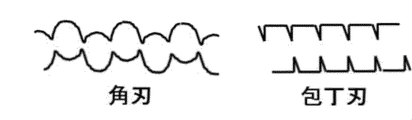

- FIG. 1 It is a schematic diagram of the cutting blade roll (square blade) which concerns on embodiment of this invention. It is an image figure of a section of a textured protein material when a textured protein material is cut with a cutting blade roll having a square blade and a knife blade.

- the textured protein material according to the present invention is prepared by kneading plant-derived powder material such as defatted soybean powder, soybean protein powder, wheat protein powder and starch with water, and using a twin screw extruder at high temperature and high pressure. It is made by being extruded through a die under normal pressure. At this time, the textured protein material has a porous structure by being released at once from high pressure to normal pressure.

- Various sheet-like textured protein materials can be obtained by changing the shape of the die.

- the thickness of the sheet-like tissue protein is preferably 10 mm or less, and more preferably adjusted to a thickness of about 2 to 5 mm.

- the obtained textured protein material may be used as it is after being cut to an appropriate length, but it can be stored for a long time by drying or freezing. Further, the extruded sheet-like textured protein material may be directly processed by a cutting blade roll, which will be described later, and then cut to an appropriate length and used as it is or after being dried or frozen. .

- the tissue-like protein material is completely moisturized and has an appropriate elasticity.

- the rehydrated tissue protein material is dehydrated to remove unnecessary moisture. By dehydrating, not only can unnecessary components be removed, but also odors such as soybean odor and wheat protein odor can be reduced. Moreover, when the process by the cutting blade roll mentioned later is already performed, after dehydrating, it can spin-dry

- the dehydrated textured protein material is cut into grooves by pressing with a cutting blade roll.

- the textured protein material has fiber properties and fiber orientation, resulting in a more meaty texture.

- it is easy to season the textured protein material evenly, and the restorability at the time of eating is also improved.

- the structured protein material When the structured protein material is cut with a cutting blade roll, it is preferably passed through the cutting blade roll so that the cutting groove is attached in the same direction as the textured protein material extruded by the biaxial extruder. It is not preferable to pass through a cutting blade roll so that a cut groove is formed in a direction perpendicular to the extruded direction, because the directionality of the fibers is destroyed.

- the cutting blade roll according to the present invention is composed of a pair of rolls 1 having a plurality of annular blades 2 facing each other and arranged in parallel as shown in FIG.

- the pair of rolls 1 are installed in parallel so that the roll shaft 3 penetrates the housing 5, receives the rotation from the drive unit, and the pair of rolls 1 are rotated by the gear 4 around the roll shaft 3. To do.

- the annular blade 2 is an annular blade having a flat surface called a square blade and the corners of both sides sharpened at right angles, and a cutting blade roll having many annular blades (square blades) 2 as shown in FIG.

- a cutting blade roll having many annular blades (square blades) 2 as shown in FIG.

- the pitch A which is the interval between the annular blades (square blades) 2 is preferably 0.8 mm to 1.5 mm.

- the interval is narrower than 0.8 mm pitch, the surface of the noodle strings is too rough and cracks are likely to occur.

- the interval is wider than 1.5 mm pitch, the fiber feeling is reduced.

- the clearance B which is the distance between the tips of the annular blades (square blades) 2 attached to the pair of rolls 1, depends on the thickness of the tissue protein material, but the thickness of the tissue protein material is about 3 to 10 mm.

- the clearance B is preferably 10 to 30% with respect to the thickness of the tissue protein material.

- the clearance B may be adjusted by adjusting the adjustment screw 6.

- the textured protein material with a kerf may be boiled or boiled after seasoning, and processed into a meat-like protein processed food. It is good also as a meat-like dry protein processed food used as an ingredient of the instant food cooked by microwave oven cooking.

- soy sauce As a specific method of manufacturing a meat-like dried protein processed food used as an ingredient for instant foods, soy sauce, sugar, salt, mirin, sake, sodium glutamate, protein Add or mix hydrolyzate, livestock meat extract, juice or powder such as ginger and onion, spices, fragrances, and pigments, or immerse or boil them in a seasoning solution containing these ingredients. If necessary, add edible oils such as sesame oil, palm oil, lard, beef tallow, etc., and perform hot-air drying, microwave drying or freeze-drying, or dry without adding edible oils and fats. Then, the meat-like dried protein processed food may be used.

- soy sauce sugar, salt, mirin, sake, sodium glutamate

- protein Add or mix hydrolyzate, livestock meat extract, juice or powder such as ginger and onion, spices, fragrances, and pigments, or immerse or boil them in a seasoning solution containing these ingredients.

- edible oils such as sesame oil, palm oil, lard, beef tallow,

- hot air drying is preferable because it is inexpensive and the texture can be controlled, and the fat content after drying is 10 to 20% by weight, more preferably 12 to 16% by weight in the seasoned textured protein material.

- the fat content after drying is 10 to 20% by weight, more preferably 12 to 16% by weight in the seasoned textured protein material.

- After adding the edible oil / fat it is preferably dried with hot air at 100 to 120 ° C., more preferably 105 to 115 ° C. until the water content becomes 5 to 12 wt%, more preferably 6 to 10 wt%.

- a pair of flat sheet-like textured protein materials produced by being pressurized and heated by an extruder and having a plurality of square blade-like annular blades that face each other and are arranged side by side.

- the textured protein material has a flesh-like fiber feeling by attaching cut grooves cut in the same direction as the extruded direction on the upper and lower surfaces of the textured protein material by passing it through a cutting blade roll made of Can be manufactured.

- Example 1 Raw material powder consisting of 80% by weight of defatted soybeans, 10% by weight of separated soy protein, 9.6% by weight of corn starch and 0.4% by weight of calcium sulfate is mixed, and water is added to 5% by weight with respect to the weight of the raw material powder. While adding water and mixing, saturated steam flows in 1.5% by weight with respect to the weight of the raw material powder, and the diameter of the outlet is 110 ° C with a biaxial extruder under the heating and pressurizing conditions of 3.5 Maps. A flat sheet-like textured protein material was prepared by extrusion from a slit die having a thickness of 1 mm and a width of 30 mm.

- the prepared textured protein material was cut to a length of about 25 mm and dried with hot air at 60 ° C. so that the water content was 8 wt%.

- the dried textured protein material is soaked in water overnight, dehydrated, dehydrated, and dehydrated 3-4 mm thick textured protein material as shown in FIG.

- a textured protein material is formed by passing a textured protein material through a textured protein material so that the groove is inserted in the direction of extrusion into a bladed roll adjusted so that the clearance between the upper and lower rolls is 0.5 mm.

- the fiber was oriented.

- the textured protein material passed through the cutting blade roll is immersed in a seasoning solution consisting of 20% by weight of soy sauce, 35% by weight of sugar, 5% by weight of salt, 2% by weight of caramel pigment, and 38% by weight of water, and heated until boiling. After boiling, the fire was turned off, left to stand for 5 minutes, drained and seasoned.

- a seasoning solution consisting of 20% by weight of soy sauce, 35% by weight of sugar, 5% by weight of salt, 2% by weight of caramel pigment, and 38% by weight of water

- the textured protein material is put into a mixer, and 50 ° C. beef tallow (melting point: 40 ° C.), which is 20% by weight with respect to the weight of the textured protein material seasoned therein, is mixed and mixed homogeneously. Thereafter, the textured protein material was taken out.

- the textured protein material to which beef tallow was added was heated and dried with a hot air dryer at 110 ° C. until the water content became 8% by weight, and then cooled to obtain a meat-like dried protein processed food sample (oil content 14% by weight).

- the measuring method of fats and oils was performed by the ether extraction method described in the food labeling standard attachment (analytical methods such as nutrients, etc. 2 lipid (1)).

- the method for measuring moisture is the atmospheric pressure drying method described in the food labeling standard attachment (analytical methods for nutrients, etc. 5 carbohydrates, moisture (3)), the heating temperature is 105 ° C., and the time is 4 Went in time.

- Example 2 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that the pitch width of the cutting blade roll was 0.6 mm.

- Example 3 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that the pitch width of the cutting blade roll was 1.2 mm.

- Example 4 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that the pitch width of the cutting blade roll was 1.5 mm.

- Example 5 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that the clearance width of the cutting blade roll was 0.4 mm.

- Example 6 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that the clearance width of the cutting blade roll was 0.6 mm.

- Example 7 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that the clearance width of the cutting blade roll was 0.8 mm.

- Example 1 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that the annular blade of the cutting blade roll was changed to a sharp blade with a sharp tip.

- Example 2 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that a kerf was made to be perpendicular to the extrusion direction.

- Example 3 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that one of the cutting blade rolls was changed to a flat roll without an annular blade and a groove was cut only on one side.

- Example 5 A meat-like dried protein processed food sample was produced according to the method of Example 1 except that the pitch width of the cutting blade roll was 0.4 mm.

- the prepared meat-like dried protein processed food was evaluated. Evaluation was performed about the meat-like fiber feeling after hot water cooking, and the crack of the meat-like dried protein processed food in manufacture. The evaluation method was carried out by five skilled panelists using a four-level evaluation for meat-like fiber feeling and a three-level evaluation for cracking of meat pieces during production. Hot water cooking was performed by putting 10 processed meat-like dried protein products into a cup container and restoring a pre-prepared 400 ml hot water bath for 3 minutes.

- Table 1 shows the evaluation results of the test examples.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Polymers & Plastics (AREA)

- Nutrition Science (AREA)

- Biochemistry (AREA)

- Molecular Biology (AREA)

- Manufacturing & Machinery (AREA)

- Meat, Egg Or Seafood Products (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/082,455 US11224236B2 (en) | 2016-03-28 | 2017-02-14 | Method for producing textured protein material |

| BR112018069815A BR112018069815B8 (pt) | 2016-03-28 | 2017-02-14 | Método para produção de material proteico texturizado e de um produto alimentar processado proteico seco semelhante a carne para um produto alimentar instantâneo |

| HK19101433.2A HK1258953B (zh) | 2016-03-28 | 2017-02-14 | 组织状蛋白材料的制造方法 |

| CN201780029280.0A CN109152390B (zh) | 2016-03-28 | 2017-02-14 | 组织状蛋白材料的制造方法 |

| EP17773755.8A EP3437482B1 (en) | 2016-03-28 | 2017-02-14 | Method for producing textured protein material |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016063718A JP6382250B2 (ja) | 2016-03-28 | 2016-03-28 | 組織状蛋白素材の製造方法 |

| JP2016-063718 | 2016-03-28 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017169207A1 true WO2017169207A1 (ja) | 2017-10-05 |

Family

ID=59962922

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/005294 Ceased WO2017169207A1 (ja) | 2016-03-28 | 2017-02-14 | 組織状蛋白素材の製造方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US11224236B2 (enExample) |

| EP (1) | EP3437482B1 (enExample) |

| JP (1) | JP6382250B2 (enExample) |

| CN (1) | CN109152390B (enExample) |

| BR (1) | BR112018069815B8 (enExample) |

| HU (1) | HUE051940T2 (enExample) |

| WO (1) | WO2017169207A1 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019191809A1 (en) * | 2018-04-04 | 2019-10-10 | ProForm Innovation Pty Limited | Shredding device for textured protein foodstuff |

| WO2023171304A1 (ja) * | 2022-03-11 | 2023-09-14 | 富士フイルム株式会社 | タンパク質食品素材の製造方法及びタンパク質食品素材 |

| WO2023171303A1 (ja) * | 2022-03-11 | 2023-09-14 | 富士フイルム株式会社 | タンパク質食品素材及び代替成形肉 |

| WO2023232974A1 (en) | 2022-06-02 | 2023-12-07 | Plant Meat Limited | Meat analogues |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11550558B2 (en) | 2016-02-12 | 2023-01-10 | Nutanix, Inc. | Virtualized file server deployment |

| JP6965172B2 (ja) * | 2018-02-06 | 2021-11-10 | 日清食品ホールディングス株式会社 | 組織状蛋白素材の製造方法 |

| WO2020208104A1 (en) * | 2019-04-10 | 2020-10-15 | Société des Produits Nestlé S.A. | Meat analogues and meat analogue extrusion devices and methods |

| JP6844736B1 (ja) * | 2020-07-13 | 2021-03-17 | 不二製油株式会社 | 組織状蛋白素材の製造方法及び組織状蛋白素材 |

| GB2605746A (en) * | 2021-01-20 | 2022-10-19 | Bevo Biotehnoloske Resitve D O O | Method of producing a meat analogue |

| US20240074454A1 (en) * | 2021-01-20 | 2024-03-07 | Bevo, Biotehnološke Rešitve D.O.O. | Method of producing a meat analogue |

| US12004539B2 (en) * | 2022-01-31 | 2024-06-11 | The Livekindly Company Switzerland GmbH | Methods for creating of high fibrousness, high moisture extrudates |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5427888B2 (enExample) * | 1976-06-10 | 1979-09-12 | ||

| JPS581905B2 (ja) * | 1980-10-31 | 1983-01-13 | 備南ハイフ−ズ株式会社 | 乾燥蟹風ほぐし身製品 |

| JPH045413B2 (enExample) * | 1983-06-14 | 1992-01-31 |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1976751A (en) * | 1932-12-16 | 1934-10-16 | Lillie A Short | Meat-tenderer |

| US2223466A (en) * | 1937-08-25 | 1940-12-03 | Cube Steak Machine Company Inc | Meat-slitting machine |

| US2243492A (en) * | 1939-07-20 | 1941-05-27 | Harry T Floyd | Meat tenderizer |

| US2420549A (en) * | 1941-12-05 | 1947-05-13 | Ind Patents Corp | Meat treatment |

| US3962751A (en) * | 1975-02-07 | 1976-06-15 | Hollymatic Corporation | Scoring apparatus |

| JPS5834338B2 (ja) | 1977-08-02 | 1983-07-26 | 東洋製罐株式会社 | 罐と樹脂容器との一体成形容器及びその製造法 |

| US4313963A (en) * | 1980-08-19 | 1982-02-02 | Beatrice Foods Co. | Method for tenderizing cut meat portions |

| JPS581905A (ja) | 1981-06-26 | 1983-01-07 | 市光工業株式会社 | 車輛用灯具 |

| JPH045413A (ja) | 1990-04-20 | 1992-01-09 | Agency Of Ind Science & Technol | 排ガス浄化装置 |

| US5145453A (en) * | 1990-09-26 | 1992-09-08 | Oscar Mayer Foods Crporation | Apparatus for macerating meat |

| US5234705A (en) * | 1990-12-27 | 1993-08-10 | Simon Mani | Method of making pita bread with reinforced surfaces |

| US5738578A (en) * | 1993-10-27 | 1998-04-14 | Mister Tenderizer, Inc. | Modular food processing assembly |

| CH689102A5 (fr) | 1995-04-06 | 1998-10-15 | Nestle Sa | Fabrication de protéines texturées. |

| US6257132B1 (en) * | 1998-07-27 | 2001-07-10 | Phil Bifulco | Method and apparatus for preparing meat |

| US6902754B1 (en) * | 1999-02-01 | 2005-06-07 | The Pillsbury Company | Blunt edge dough cutter |

| US6379738B1 (en) | 1999-11-16 | 2002-04-30 | Nestec S.A. | Meat emulsion product |

| US7736686B2 (en) | 2000-11-08 | 2010-06-15 | Nestec S.A. | Meat emulsion products and methods of making same |

| JP2004135592A (ja) * | 2002-10-18 | 2004-05-13 | Michinobu Oka | スリット入り麺 |

| US20070128340A1 (en) * | 2005-12-13 | 2007-06-07 | Andrews Stanley J | Food Products, Methods of Producing the Food Products, and Methods of Distributing the Food Products and Ingredients Thereof |

| US20090155448A1 (en) * | 2007-12-12 | 2009-06-18 | Solae, Llc | Organic Protein Extrudates and Preparation Thereof |

| RU2010137628A (ru) * | 2008-02-12 | 2012-03-20 | Марс Инкорпорейтед (US) | Продукт-аналог мяса |

| CN201345888Y (zh) | 2009-01-07 | 2009-11-18 | 黄孝礼 | 高水分组织蛋白生产设备 |

| CN101455304B (zh) | 2009-01-07 | 2011-09-21 | 黄孝礼 | 高水分组织蛋白生产设备 |

| US8764523B2 (en) * | 2009-10-08 | 2014-07-01 | Wolf-Tec, Inc. | Macerator having automated roller spacing control |

| EP2689670B1 (en) * | 2011-03-23 | 2018-03-21 | House Foods Group Inc. | Method for producing a meat-like foodstuff |

| CA2775473C (en) * | 2011-04-27 | 2018-10-09 | Kraft Foods Global Brands Llc | Apparatus and method for macerating meat-type products |

| HUE039003T2 (hu) * | 2011-05-13 | 2018-12-28 | Ojah B V | Módszer a strukturált fehérjekészítmények elõállítására |

| US20150289542A1 (en) * | 2012-11-23 | 2015-10-15 | Proviand B.V. | Method for Texturing Vegetable Fibres and Proteins |

| US20150296834A1 (en) * | 2014-04-17 | 2015-10-22 | Savage River, Inc. dba Beyond Meat, Inc. | Plant based meat structured protein products |

| US10477882B1 (en) * | 2014-04-25 | 2019-11-19 | Sophie's Kitchen, Inc. | Vegan meat replacement food product |

| US9914229B2 (en) * | 2014-08-29 | 2018-03-13 | Prince Castle LLC | Produce slicer |

| CN104273461A (zh) | 2014-10-23 | 2015-01-14 | 项城市菱花面粉有限公司 | 一种素肉及其生产方法 |

| US9351497B1 (en) * | 2015-01-13 | 2016-05-31 | Phillip L. Parkman | Meat tenderizer |

| US10918117B2 (en) * | 2015-01-19 | 2021-02-16 | General Mills, Inc. | Extruded protein product and methods of making |

| WO2016167749A1 (en) * | 2015-04-14 | 2016-10-20 | General Mills, Inc. | Heat stable extruded protein composition and related food products |

-

2016

- 2016-03-28 JP JP2016063718A patent/JP6382250B2/ja active Active

-

2017

- 2017-02-14 EP EP17773755.8A patent/EP3437482B1/en active Active

- 2017-02-14 WO PCT/JP2017/005294 patent/WO2017169207A1/ja not_active Ceased

- 2017-02-14 BR BR112018069815A patent/BR112018069815B8/pt active IP Right Grant

- 2017-02-14 HU HUE17773755A patent/HUE051940T2/hu unknown

- 2017-02-14 US US16/082,455 patent/US11224236B2/en active Active

- 2017-02-14 CN CN201780029280.0A patent/CN109152390B/zh active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5427888B2 (enExample) * | 1976-06-10 | 1979-09-12 | ||

| JPS581905B2 (ja) * | 1980-10-31 | 1983-01-13 | 備南ハイフ−ズ株式会社 | 乾燥蟹風ほぐし身製品 |

| JPH045413B2 (enExample) * | 1983-06-14 | 1992-01-31 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3437482A4 * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019191809A1 (en) * | 2018-04-04 | 2019-10-10 | ProForm Innovation Pty Limited | Shredding device for textured protein foodstuff |

| WO2023171304A1 (ja) * | 2022-03-11 | 2023-09-14 | 富士フイルム株式会社 | タンパク質食品素材の製造方法及びタンパク質食品素材 |

| WO2023171303A1 (ja) * | 2022-03-11 | 2023-09-14 | 富士フイルム株式会社 | タンパク質食品素材及び代替成形肉 |

| WO2023232974A1 (en) | 2022-06-02 | 2023-12-07 | Plant Meat Limited | Meat analogues |

Also Published As

| Publication number | Publication date |

|---|---|

| BR112018069815A2 (pt) | 2019-01-29 |

| EP3437482A1 (en) | 2019-02-06 |

| EP3437482B1 (en) | 2020-08-19 |

| BR112018069815B1 (pt) | 2022-06-07 |

| CN109152390A (zh) | 2019-01-04 |

| CN109152390B (zh) | 2020-05-12 |

| HK1258953A1 (zh) | 2019-11-22 |

| BR112018069815B8 (pt) | 2022-09-20 |

| EP3437482A4 (en) | 2019-08-21 |

| US20190082716A1 (en) | 2019-03-21 |

| JP2017175943A (ja) | 2017-10-05 |

| US11224236B2 (en) | 2022-01-18 |

| HUE051940T2 (hu) | 2021-03-29 |

| JP6382250B2 (ja) | 2018-08-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6382250B2 (ja) | 組織状蛋白素材の製造方法 | |

| JP6227693B2 (ja) | 肉様乾燥蛋白加工食品の製造方法 | |

| JP7161019B2 (ja) | 組織状蛋白素材の製造方法 | |

| JP6439679B2 (ja) | 組織状植物性蛋白素材及びこれを利用した薄切り代用肉 | |

| RU2765875C1 (ru) | Способ получения лапши быстрого приготовления, содержащей лактат калия | |

| JP2018164459A (ja) | 組織状蛋白素材の製造方法 | |

| CN101095507A (zh) | 组合仿生肉干的生产方法和产品 | |

| JP2015228836A (ja) | 真空凍結乾燥食品およびその製造方法 | |

| JP4840134B2 (ja) | 肉様加工食品の製造法 | |

| JPS6112254A (ja) | 加工食品の製造法 | |

| HK1258953B (zh) | 组织状蛋白材料的制造方法 | |

| KR101295634B1 (ko) | 부유성과 조직감이 우수한 건조어묵의 제조방법 | |

| JP2023063029A (ja) | 肉様食品 | |

| JP7705249B2 (ja) | 畜肉様食品の製造方法 | |

| JP6495990B2 (ja) | 肉様乾燥蛋白加工食品の製造方法 | |

| JP5402609B2 (ja) | 蛋白膨化食品の製造法 | |

| JP5978488B1 (ja) | 鳥を原料とした出汁用食材の製造方法及び製造された食材 | |

| JP2007244217A (ja) | 油揚げ即席麺及びその製造方法 | |

| JPS60199351A (ja) | ハンバ−グ様食品の製造法 | |

| JP2023038738A (ja) | 組織状大豆蛋白素材 | |

| WO2022202884A1 (ja) | 組織状蛋白素材の製造方法及び組織状蛋白素材 | |

| JPH0811050B2 (ja) | カニ足かまぼこの製造方法 | |

| JP2022179150A (ja) | 畜肉様食品 | |

| JPS5911146A (ja) | 佃煮の製造法 | |

| JP2018033359A (ja) | 抽出適性を向上させた削り節製品 並びにその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112018069815 Country of ref document: BR |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2017773755 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 2017773755 Country of ref document: EP Effective date: 20181029 |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17773755 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 112018069815 Country of ref document: BR Kind code of ref document: A2 Effective date: 20180927 |