WO2017057415A1 - パターン描画装置およびパターン描画方法 - Google Patents

パターン描画装置およびパターン描画方法 Download PDFInfo

- Publication number

- WO2017057415A1 WO2017057415A1 PCT/JP2016/078541 JP2016078541W WO2017057415A1 WO 2017057415 A1 WO2017057415 A1 WO 2017057415A1 JP 2016078541 W JP2016078541 W JP 2016078541W WO 2017057415 A1 WO2017057415 A1 WO 2017057415A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- scanning

- substrate

- light source

- unit

- pattern

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/70216—Mask projection systems

- G03F7/70283—Mask effects on the imaging process

- G03F7/70291—Addressable masks, e.g. spatial light modulators [SLMs], digital micro-mirror devices [DMDs] or liquid crystal display [LCD] patterning devices

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B26/00—Optical devices or arrangements for the control of light using movable or deformable optical elements

- G02B26/08—Optical devices or arrangements for the control of light using movable or deformable optical elements for controlling the direction of light

- G02B26/10—Scanning systems

- G02B26/12—Scanning systems using multifaceted mirrors

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B26/00—Optical devices or arrangements for the control of light using movable or deformable optical elements

- G02B26/08—Optical devices or arrangements for the control of light using movable or deformable optical elements for controlling the direction of light

- G02B26/10—Scanning systems

- G02B26/12—Scanning systems using multifaceted mirrors

- G02B26/124—Details of the optical system between the light source and the polygonal mirror

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B26/00—Optical devices or arrangements for the control of light using movable or deformable optical elements

- G02B26/08—Optical devices or arrangements for the control of light using movable or deformable optical elements for controlling the direction of light

- G02B26/10—Scanning systems

- G02B26/12—Scanning systems using multifaceted mirrors

- G02B26/125—Details of the optical system between the polygonal mirror and the image plane

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/29—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the position or the direction of light beams, i.e. deflection

- G02F1/33—Acousto-optical deflection devices

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

- G03F7/2051—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source

- G03F7/2057—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source using an addressed light valve, e.g. a liquid crystal device

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

- G03F7/24—Curved surfaces

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/70216—Mask projection systems

- G03F7/70358—Scanning exposure, i.e. relative movement of patterned beam and workpiece during imaging

Definitions

- the present invention relates to a pattern drawing apparatus and a pattern drawing method for drawing a pattern by scanning spot light irradiated on an irradiated object.

- a beam from a laser diode (LD) is repeatedly deflected by a polygon mirror, and the deflected beam is an f ⁇ lens.

- LD laser diode

- An electrophotographic image forming apparatus that scans on a photoconductor via a photoconductor is known.

- the temperature change in the writing unit including the laser diode (LD), the rotating polygon mirror, the f ⁇ lens, and the like is changed according to the change in the drive current of the laser diode (LD). Predict from.

- a write-use that becomes a reference when controlling the lighting of the laser diode (LD) in response to an image signal.

- the frequency of the clock signal is changed.

- the pattern of the image to be drawn is a pattern for an electronic device, even if the magnification error is corrected only by changing the frequency of the clock signal as disclosed in Japanese Patent Application Laid-Open No. 2009-220489, high accuracy is achieved. Cannot handle magnification correction finely.

- the first aspect of the present invention forms a pattern on the substrate by projecting the beam onto the substrate and scanning in the main scanning direction while modulating the intensity of the beam from the light source according to the pattern information.

- a pattern writing apparatus comprising: a plurality of scanning units including a deflecting member that deflects the beam from the light source for scanning the beam in the main scanning direction; In order to supply the beam from the light source in a time-sharing manner to each of the plurality of scanning units, the beam from the light source is set in a deflected state or a non-deflected state.

- An electro-optic deflecting device capable of adjusting the deflection angle of the beam in order to switch and shift the scanning locus of the beam in the sub-scanning direction intersecting the main scanning direction; Equipped with a.

- the second aspect of the present invention forms a pattern on the substrate by projecting the beam onto the substrate and scanning in the main scanning direction while modulating the intensity of the beam from the light source according to the pattern information.

- each of a plurality of scanning units arranged so that scanning trajectories of the beam projected on the substrate are shifted from each other uses the deflecting member to scan the beam from the light source in the main scanning.

- the drawing beam modulated according to the pattern information is projected onto the substrate and scanned in the main scanning direction, and the substrate and the drawing beam intersect with the main scanning direction.

- a pattern drawing apparatus for forming a pattern on the substrate by relatively moving in a direction, wherein a plurality of scanning units including a scanning member that scans the drawing beam are shifted from each other so that scanning trajectories by the drawing beam are shifted from each other.

- a scanning device arranged; a beam switching device including a plurality of first electro-optic members for selectively supplying a beam from a light source device for generating the drawing beam to each of the plurality of scanning units; and the main scanning.

- the scanning beam of the drawing beam scanned in the direction is displaced in the sub-scanning direction so that the light source device from the light source device that enters each of the plurality of scanning units.

- the chromatography beam and a beam deflection device comprising a second electro-optical element that deflects in the direction corresponding to the sub-scanning direction.

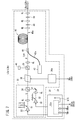

- FIG. 1 It is a figure which shows schematic structure of the device manufacturing system containing the exposure apparatus which performs the exposure process to the board

- FIG. 7 generate

- FIG. 7 shows the structure of the signal generation part shown in FIG. 7 which has the function to expand / contract a correction pixel.

- FIG. 9 shows the truth value table of the preset value which the preset part shown in FIG. 9 outputs.

- FIG. 3 is a block diagram showing an electrical configuration of the exposure apparatus shown in FIG. 2.

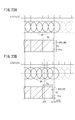

- FIG. 13 is a time chart showing an origin signal output from the origin sensor of FIG. 5 provided in each scanning unit and an incident permission signal generated by the selection element drive control unit shown in FIG. 12 according to the origin signal. It is a figure which shows the structure of the drawing data output part shown in FIG.

- FIG. 15 is a time chart showing a pixel permission pulse generated by the drawing permission signal generated by the drawing permission signal generating unit shown in FIG. 14 and a pixel shift pulse output from the transmission timing switching unit of FIG. 9 during a period when the drawing permission signal is high. It is a figure which shows the relationship between the position of the drawing line expanded / contracted within the range of the maximum scanning length, and delay time. It is a figure which shows the structure of the light source device in the modification of 1st Embodiment.

- FIG. 18 is a diagram illustrating a configuration of a clock signal generation unit illustrated in FIG. 17.

- FIG. 19 is a timing chart for explaining the operation of the clock signal generation unit of FIG. 18.

- FIG. It is a figure which shows the structure of the signal generation part provided in the inside of the light source device in 2nd Embodiment.

- 21A is a diagram showing a first example of the configuration of the delay circuit shown in FIG. 20, and

- FIG. 21B is a diagram showing a second example of the configuration of the delay circuit shown in FIG.

- It is a time chart which shows the signal output from each part of the signal generation part shown in FIG.

- FIG. 23A is a diagram for describing a pattern drawn when local magnification correction is not performed, and FIG.

- FIG. 23B is a drawing when local magnification correction (reduction) is performed according to the time chart shown in FIG. It is a figure explaining the pattern to be performed.

- FIG. 11 is an explanatory diagram of Modification 1 of each of the above-described embodiments, and drawing optics instead of the electro-optic element that modulates the intensity of the spot light according to the pattern data described in each of the above-described embodiments (including the modification) It is a figure which shows the example of arrangement

- FIG. 6 It is a figure showing a part of schematic structure of the drawing apparatus of the tandem system in the modification of 3rd Embodiment. It is a figure which shows the structure of the beam switching member provided corresponding to one scanning unit in the beam switching part by 4th Embodiment. It is a figure which shows the structure which replaced the optical element for selection and the unit side incident mirror which comprise the beam switching part shown in FIG. 6 or FIG. 24 with the structure of FIG. It is a figure which shows an example of a structure of the beam shifter part shown in FIG. FIG.

- FIG. 37A is a diagram showing an example of a beam deflecting member using an electro-optic element in which electrodes are formed on opposite parallel side surfaces of a transparent crystal medium formed in a prism shape (triangle) with a predetermined thickness.

- FIG. 37B is a diagram showing an example of a beam deflection member using an electro-optic element made of a KTN (KTa 1-x Nb x O 3 ) crystal.

- a pattern drawing apparatus and a pattern drawing method according to an aspect of the present invention will be described in detail below with reference to the accompanying drawings by listing preferred embodiments.

- the aspect of this invention is not limited to these embodiment, What added the various change or improvement is included. That is, the constituent elements described below include those that can be easily assumed by those skilled in the art and substantially the same elements, and the constituent elements described below can be appropriately combined. In addition, various omissions, substitutions, or changes of the components can be made without departing from the scope of the present invention.

- FIG. 1 is a diagram showing a schematic configuration of a device manufacturing system 10 including an exposure apparatus EX that performs an exposure process on a substrate (irradiated body) P according to the first embodiment.

- EX an exposure apparatus

- FIG. 1 an XYZ orthogonal coordinate system in which the gravity direction is the Z direction is set, and the X direction, the Y direction, and the Z direction will be described according to the arrows shown in the drawing.

- the device manufacturing system 10 is a system (substrate processing apparatus) that manufactures an electronic device by performing predetermined processing (exposure processing or the like) on the substrate P.

- a manufacturing line for manufacturing a flexible display as an electronic device for example, a film-like touch panel, a film-like color filter for a liquid crystal display panel, a flexible wiring, or a flexible sensor is constructed. It is a manufacturing system. The following description is based on the assumption that a flexible display is used as the electronic device. Examples of the flexible display include an organic EL display and a liquid crystal display.

- the device manufacturing system 10 sends out the substrate P from a supply roll FR1 obtained by winding a flexible sheet-like substrate (sheet substrate) P in a roll shape, and continuously performs various processes on the delivered substrate P. After that, the substrate P after various treatments is wound up by the recovery roll FR2, and has a so-called roll-to-roll (Roll To Roll) structure.

- the substrate P has a belt-like shape in which the moving direction (transport direction) of the substrate P is the longitudinal direction (long) and the width direction is the short direction (short).

- the film-like substrate P includes at least a processing apparatus (first processing apparatus) PR1, a processing apparatus (second processing apparatus) PR2, an exposure apparatus (third processing apparatus) EX, An example of winding up to the collection roll FR2 through the processing device (fourth processing device) PR3 and the processing device (fifth processing device) PR4 is shown.

- the X direction is a direction (conveying direction) in which the substrate P is directed from the supply roll FR1 to the collection roll FR2 in the horizontal plane.

- the Y direction is a direction orthogonal to the X direction in the horizontal plane, and is the width direction (short direction) of the substrate P.

- the Z direction is a direction (upward direction) orthogonal to the X direction and the Y direction, and is parallel to the direction in which gravity acts.

- a resin film or a foil (foil) made of a metal or alloy such as stainless steel is used.

- the material of the resin film include polyethylene resin, polypropylene resin, polyester resin, ethylene vinyl copolymer resin, polyvinyl chloride resin, cellulose resin, polyamide resin, polyimide resin, polycarbonate resin, polystyrene resin, and vinyl acetate resin. Among them, one containing at least one or more may be used. Further, the thickness and rigidity (Young's modulus) of the substrate P may be in a range that does not cause folds or irreversible wrinkles due to buckling in the substrate P when passing through the conveyance path of the device manufacturing system 10. .

- a film such as PET (polyethylene terephthalate) or PEN (polyethylene naphthalate) having a thickness of about 25 ⁇ m to 200 ⁇ m is typical of a suitable sheet substrate.

- the substrate P may receive heat in each process performed by the processing apparatus PR1, the processing apparatus PR2, the exposure apparatus EX, the processing apparatus PR3, and the processing apparatus PR4, the substrate P is made of a material whose thermal expansion coefficient is not remarkably large. It is preferable to select the substrate P.

- the thermal expansion coefficient can be suppressed by mixing an inorganic filler with a resin film.

- the inorganic filler may be, for example, titanium oxide, zinc oxide, alumina, or silicon oxide.

- the substrate P may be a single layer of ultrathin glass having a thickness of about 100 ⁇ m manufactured by a float process or the like, or a laminate in which the above resin film, foil, or the like is bonded to the ultrathin glass. It may be.

- the flexibility of the substrate P means the property that the substrate P can be bent without being sheared or broken even when a force of its own weight is applied to the substrate P. .

- flexibility includes a property of bending by a force of about its own weight.

- the degree of flexibility varies depending on the material, size and thickness of the substrate P, the layer structure formed on the substrate P, the environment such as temperature or humidity, and the like. In any case, when the substrate P is correctly wound around the conveyance direction changing members such as various conveyance rollers and rotating drums provided in the conveyance path in the device manufacturing system 10 according to the first embodiment, If the substrate P can be smoothly transported without being bent and creased or damaged (breaking or cracking), it can be said to be a flexible range.

- the processing apparatus PR1 applies the coating process to the substrate P while transporting the substrate P transported from the supply roll FR1 toward the processing apparatus PR2 in a transport direction (+ X direction) along the longitudinal direction at a predetermined speed. It is the coating device which performs.

- the processing apparatus PR1 selectively or uniformly applies the photosensitive functional liquid to the surface of the substrate P.

- the substrate P having the photosensitive functional liquid applied on the surface thereof is conveyed toward the processing apparatus PR2.

- the processing apparatus PR2 is a drying apparatus that performs a drying process on the substrate P while transporting the substrate P transported from the processing apparatus PR1 toward the exposure apparatus EX in the transport direction (+ X direction) at a predetermined speed. .

- the processing apparatus PR2 removes the solvent or water contained in the photosensitive functional liquid with a blower, an infrared light source, a ceramic heater, or the like that blows drying air (hot air) such as hot air or dry air onto the surface of the substrate P, and performs photosensitivity. Dry sexual function liquid.

- a film to be a photosensitive functional layer photosensitive layer

- the photosensitive functional layer may be formed on the surface of the substrate P by attaching a dry film to the surface of the substrate P.

- a pasting apparatus for sticking the dry film to the substrate P may be provided instead of the processing apparatus PR1 and the processing apparatus PR2.

- a typical one of the photosensitive functional liquid (layer) is a photoresist (liquid or dry film).

- a photoresist liquid or dry film

- the lyophilic property of the part that has been irradiated with ultraviolet rays There is a photosensitive silane coupling agent (SAM) that is modified, or a photosensitive reducing agent in which a plating reducing group is exposed in a portion irradiated with ultraviolet rays.

- SAM photosensitive silane coupling agent

- the pattern portion exposed to ultraviolet rays on the substrate P is modified from lyophobic to lyophilic.

- conductive ink ink containing conductive nanoparticles such as silver or copper

- a liquid containing a semiconductor material on the lyophilic portion, a thin film transistor (TFT) or the like

- a pattern layer to be an electrode, a semiconductor, insulation, or a wiring for connection can be formed.

- a photosensitive reducing agent is used as the photosensitive functional liquid (layer)

- the plating reducing group is exposed to the pattern portion exposed to ultraviolet rays on the substrate P. Therefore, after exposure, the substrate P is immediately immersed in a plating solution containing palladium ions or the like for a certain period of time, so that a pattern layer of palladium is formed (deposited).

- Such a plating process is an additive process, but may be based on an etching process as a subtractive process.

- the substrate P sent to the exposure apparatus EX is made of PET or PEN as a base material, and a metal thin film such as aluminum (Al) or copper (Cu) is deposited on the entire surface or selectively, and further, It may be a laminate of a photoresist layer thereon.

- a photosensitive reducing agent is used as the photosensitive functional liquid (layer).

- the exposure apparatus EX is a processing apparatus that performs exposure processing on the substrate P while transporting the substrate P transported from the processing apparatus PR2 toward the processing apparatus PR3 in the transport direction (+ X direction) at a predetermined speed.

- the exposure apparatus EX uses a light corresponding to a pattern for an electronic device (for example, a pattern of an electrode or wiring of a TFT constituting the electronic device) on the surface of the substrate P (the surface of the photosensitive functional layer, that is, the photosensitive surface). Irradiate the pattern. Thereby, a latent image (modified portion) corresponding to the pattern is formed on the photosensitive functional layer.

- the exposure apparatus EX is a direct drawing type exposure apparatus that does not use a mask, that is, a so-called raster scan type exposure apparatus (pattern drawing apparatus).

- the exposure apparatus EX transmits the spot light SP of the pulsed beam LB (pulse beam) for exposure to the substrate P while conveying the substrate P in the + X direction (sub-scanning direction).

- the intensity of the spot light SP is modulated at high speed according to the pattern data (drawing data, pattern information) while one-dimensionally scanning (main scanning) in the predetermined scanning direction (Y direction) on the irradiated surface (photosensitive surface). (ON / OFF).

- a light pattern corresponding to a predetermined pattern such as an electronic device, a circuit, or a wiring is drawn and exposed on the irradiated surface of the substrate P. That is, the spot light SP is relatively two-dimensionally scanned on the irradiated surface of the substrate P by the sub-scanning of the substrate P and the main scanning of the spot light SP, and a predetermined pattern is drawn and exposed on the substrate P. . Further, since the substrate P is transported along the transport direction (+ X direction), the exposure region W where the pattern is exposed by the exposure apparatus EX is spaced at a predetermined interval along the longitudinal direction of the substrate P. A plurality are provided (see FIG. 4).

- the exposure area W is also a device formation area. Since the electronic device is configured by superimposing a plurality of pattern layers (layers on which patterns are formed), a pattern corresponding to each layer may be exposed by the exposure apparatus EX.

- the processing apparatus PR3 is a wet processing apparatus that performs wet processing on the substrate P while transporting the substrate P transported from the exposure apparatus EX toward the processing apparatus PR4 in the transport direction (+ X direction) at a predetermined speed. is there.

- the processing apparatus PR3 performs a plating process which is a kind of wet process on the substrate P. That is, the substrate P is immersed in a plating solution stored in the processing tank for a predetermined time. As a result, a pattern layer corresponding to the latent image is deposited (formed) on the surface of the photosensitive functional layer.

- a predetermined material for example, palladium

- a predetermined material for example, palladium

- a coating process or a plating process of a liquid which is a kind of wet process is performed by the processing apparatus PR3.

- a pattern layer corresponding to the latent image is formed on the surface of the photosensitive functional layer. That is, a predetermined material (for example, conductive ink or palladium) is selectively formed on the substrate P according to the difference between the irradiated portion of the spot light SP of the photosensitive functional layer of the substrate P and the irradiated portion, This is the pattern layer.

- photosensitive functional layer when a photoresist is employed as the photosensitive functional layer, development processing which is a kind of wet processing is performed by the processing apparatus PR3. In this case, a pattern corresponding to the latent image is formed on the photosensitive functional layer (photoresist) by this development processing.

- the processing apparatus PR4 performs cleaning / drying processing on the substrate P while transporting the substrate P transported from the processing apparatus PR3 toward the recovery roll FR2 in the transport direction (+ X direction) at a predetermined speed. It is a drying device.

- the processing apparatus PR4 cleans the substrate P that has been subjected to the wet processing with pure water, and then dries until the moisture content of the substrate P is equal to or lower than a predetermined value at a glass transition temperature or lower.

- the processing apparatus PR4 may be an annealing / drying apparatus that performs an annealing process and a drying process on the substrate P.

- the substrate P is irradiated with, for example, high-intensity pulsed light from a strobe lamp in order to strengthen the electrical coupling between the nanoparticles contained in the applied conductive ink.

- a processing apparatus (wet processing apparatus) PR5 that performs an etching process between the processing apparatus PR4 and the recovery roll FR2, and a substrate P that has been subjected to the etching process.

- a processing apparatus (cleaning / drying apparatus) PR6 for performing the cleaning / drying process may be provided.

- a photoresist is adopted as the photosensitive functional layer

- a pattern layer is formed on the substrate P by performing an etching process. That is, a predetermined material (for example, aluminum (Al) or copper (Cu)) is selectively formed on the substrate P according to the difference between the irradiated portion of the spot light SP of the photosensitive functional layer of the substrate P and the irradiated portion. This is a pattern layer.

- the processing apparatuses PR5 and PR6 have a function of transporting the substrate P sent in the transport direction (+ X direction) at a predetermined speed toward the collection roll FR2.

- the function of the plurality of processing apparatuses PR1 to PR4 (including processing apparatuses PR5 and PR6 as necessary) to transfer the substrate P in the + X direction is configured as a substrate transfer apparatus.

- One pattern layer is formed on the substrate P through at least each process of the device manufacturing system 10.

- each process of the device manufacturing system 10 as illustrated in FIG. 1 is performed at least twice in order to generate the electronic device. Have to go through. Therefore, a pattern layer can be laminated

- the processed substrate P is in a state in which a plurality of electronic devices are connected along the longitudinal direction of the substrate P with a predetermined interval. That is, the substrate P is a multi-sided substrate.

- the collection roll FR2 that collects the substrate P formed in a state where the electronic devices are connected may be mounted on a dicing apparatus (not shown).

- the dicing apparatus to which the recovery roll FR2 is attached divides (dices) the processed substrate P into electronic devices (exposure regions W that are device formation regions) to form electronic devices that are a plurality of single wafers.

- the dimension in the width direction (short direction) is about 10 cm to 2 m

- the dimension in the length direction (long direction) is 10 m or more.

- substrate P is not limited to an above-described dimension.

- FIG. 2 is a block diagram showing the configuration of the exposure apparatus EX.

- the exposure apparatus EX is stored in the temperature control chamber ECV.

- This temperature control chamber ECV keeps the inside at a predetermined temperature and a predetermined humidity, thereby suppressing a change in shape due to the temperature of the substrate P transported inside, and occurring along with the hygroscopicity and transport of the substrate P.

- the humidity is set in consideration of static charge.

- the temperature control chamber ECV is arranged on the installation surface E of the manufacturing factory via passive or active vibration isolation units SU1, SU2.

- the anti-vibration units SU1 and SU2 reduce vibration from the installation surface E.

- the installation surface E may be the floor surface of the factory itself, or may be a surface on an installation base (pedestal) that is exclusively installed on the floor surface in order to obtain a horizontal surface.

- the control device (control unit) 16 controls each part of the exposure apparatus EX.

- the control device 16 includes a computer and a recording medium on which the program is recorded, and functions as the control device 16 of the first embodiment when the computer executes the program.

- the substrate transport mechanism 12 constitutes a part of the substrate transport apparatus of the device manufacturing system 10, and after the substrate P transported from the processing apparatus PR2 is transported at a predetermined speed in the exposure apparatus EX, the processing is performed. It sends out to the apparatus PR3 at a predetermined speed.

- the substrate transport mechanism 12 defines a transport path for the substrate P transported in the exposure apparatus EX.

- the substrate transport mechanism 12 includes an edge position controller EPC, a driving roller R1, a tension adjusting roller RT1, a rotating drum (cylindrical drum) DR, a tension adjusting roller RT2, in order from the upstream side ( ⁇ X direction side) in the transport direction of the substrate P.

- a driving roller R2 and a driving roller R3 are provided.

- the edge position controller EPC adjusts the position in the width direction (the Y direction and the short direction of the substrate P) of the substrate P transported from the processing apparatus PR2.

- the edge position controller EPC has a position at the end (edge) in the width direction of the substrate P that is transported in a state of a predetermined tension, which is about ⁇ 10 ⁇ m to several tens ⁇ m with respect to the target position.

- the position of the substrate P in the width direction is adjusted by moving the substrate P in the width direction so that it falls within this range (allowable range).

- the edge position controller EPC includes a roller on which the substrate P is stretched in a state where a predetermined tension is applied, and an edge sensor (end detection unit) (not shown) that detects the position of the end portion (edge) in the width direction of the substrate P. And have.

- the edge position controller EPC adjusts the position of the substrate P in the width direction by moving the roller of the edge position controller EPC in the Y direction based on the detection signal detected by the edge sensor.

- the driving roller (nip roller) R1 rotates while holding both front and back surfaces of the substrate P conveyed from the edge position controller EPC, and conveys the substrate P toward the rotating drum DR.

- the edge position controller EPC appropriately adjusts the position in the width direction of the substrate P so that the longitudinal direction of the substrate P wound around the rotating drum DR is always orthogonal to the central axis AXo of the rotating drum DR.

- the parallelism between the rotation axis of the roller and the Y axis of the edge position controller EPC may be appropriately adjusted so as to correct the tilt error in the traveling direction of the substrate P.

- the rotary drum DR has a central axis AXo extending in the Y direction and extending in a direction intersecting with the direction in which gravity works, and a cylindrical outer peripheral surface having a constant radius from the central axis AXo.

- the rotating drum DR rotates around the central axis AXo while supporting (holding) a part of the substrate P by bending the outer surface (circumferential surface) into a cylindrical surface in the longitudinal direction. Transport P in the + X direction.

- the rotating drum DR supports an area (portion) on the substrate P onto which the beam LB (spot light SP) from the exposure head 14 is projected on its outer peripheral surface.

- the rotating drum DR supports (holds and holds) the substrate P from the surface (back surface) opposite to the surface on which the electronic device is formed (surface on which the photosensitive surface is formed).

- shafts Sft supported by annular bearings are provided so that the rotating drum DR rotates around the central axis AXo.

- the shaft Sft rotates at a constant rotational speed around the central axis AXo by receiving a rotational torque from a rotational drive source (not shown) (for example, a motor or a speed reduction mechanism) controlled by the control device 16.

- a rotational drive source not shown

- a plane including the central axis AXo and parallel to the YZ plane is referred to as a central plane Poc.

- the driving rollers (nip rollers) R2 and R3 are arranged at a predetermined interval along the transport direction (+ X direction) of the substrate P, and give a predetermined slack (play) to the substrate P after exposure.

- the drive rollers R2 and R3 rotate while holding both front and back surfaces of the substrate P, and transport the substrate P toward the processing apparatus PR3.

- the tension adjusting rollers RT1 and RT2 are urged in the ⁇ Z direction, and apply a predetermined tension in the longitudinal direction to the substrate P that is wound around and supported by the rotary drum DR. As a result, the longitudinal tension applied to the substrate P applied to the rotating drum DR is stabilized within a predetermined range.

- the control device 16 rotates the driving rollers R1 to R3 by controlling a rotation driving source (not shown) (for example, a motor, a speed reducer, etc.).

- a rotation driving source for example, a motor, a speed reducer, etc.

- the rotation axes of the drive rollers R1 to R3 and the rotation axes of the tension adjustment rollers RT1 and RT2 are parallel to the center axis AXo of the rotation drum DR.

- the light source device LS (LSa, LSb) generates and emits a pulsed beam (pulse beam, pulsed light, laser) LB.

- the beam LB is ultraviolet light having a peak wavelength in a wavelength band of 370 nm or less, and the light emission frequency (oscillation frequency, predetermined frequency) of the beam LB is Fa.

- the beam LB emitted from the light source device LS (LSa, LSb) is incident on the exposure head 14 via the beam switching unit BDU.

- the light source device LS (LSa, LSb) emits and emits the beam LB at the emission frequency Fa according to the control of the control device 16.

- the configuration of the light source device LS (LSa, LSb) will be described later in detail.

- a semiconductor laser element that generates pulsed light in the infrared wavelength region, a fiber amplifier, an amplified red light, and the like. Consists of a wavelength conversion element (harmonic generation element) that converts pulsed light in the outer wavelength range to pulsed light in the ultraviolet wavelength range, with an oscillation frequency Fa of several hundred MHz, and an emission time of one pulsed light of about picoseconds It is assumed that a fiber amplifier laser light source (harmonic laser light source) capable of obtaining high-intensity ultraviolet pulsed light is used.

- the beam LB from the light source device LSa may be represented by LBa and the beam LB from the light source device LSb may be represented by LBb.

- the beam switching unit BDU switches the scanning unit Un on which the beams LBa and LBb are incident so that the beam LBn is incident on the scanning unit Un that scans the spot light SP. That is, the beam switching unit BDU causes the beam LBa from the light source device LSa to enter one of the scanning units U1 to U3 that scans the spot light SP. Similarly, the beam switching unit BDU causes the beam LBb from the light source device LSb to enter one scanning unit Un that scans the spot light SP among the scanning units U4 to U6.

- the beam switching unit BDU will be described in detail later.

- the scanning unit Un that scans the spot light SP is switched in the order of U1 ⁇ U2 ⁇ U3, and for the scanning units U4 to U6, the scanning that scans the spot light SP. Assume that the unit Un is switched in the order of U4 ⁇ U5 ⁇ U6.

- the exposure head 14 is a so-called multi-beam type exposure head in which a plurality of scanning units Un (U1 to U6) having the same configuration are arranged.

- the exposure head 14 draws a pattern on a part of the substrate P supported by the outer peripheral surface (circumferential surface) of the rotary drum DR by a plurality of scanning units Un (U1 to U6). Since the exposure head 14 repeatedly performs pattern exposure for an electronic device on the substrate P, an exposure region (electronic device formation region) W where the pattern is exposed is a predetermined interval along the longitudinal direction of the substrate P.

- a plurality are provided (see FIG. 4).

- the plurality of scanning units Un (U1 to U6) are arranged in a predetermined arrangement relationship.

- the plurality of scanning units Un are arranged in a staggered arrangement in two rows in the transport direction of the substrate P with the center plane Poc interposed therebetween.

- the odd-numbered scanning units U1, U3, U5 are arranged in a line on the upstream side ( ⁇ X direction side) in the transport direction of the substrate P with respect to the center plane Poc and at a predetermined interval along the Y direction.

- the even-numbered scanning units U2, U4, U6 are arranged in a line at a predetermined interval along the Y direction on the downstream side (+ X direction side) in the transport direction of the substrate P with respect to the center plane Poc.

- the odd-numbered scanning units U1, U3, and U5 and the even-numbered scanning units U2, U4, and U6 are provided symmetrically with respect to the center plane Poc.

- Each scanning unit Un projects the beam LB from the light source device LS (LSa, LSb) so as to converge on the spot light SP on the irradiated surface of the substrate P.

- One-dimensional scanning is performed by the rotating polygon mirror PM (see FIG. 5).

- the spot light SP is one-dimensionally scanned on the irradiated surface of the substrate P by the polygon mirror (deflecting member) PM of each of the scanning units Un (U1 to U6).

- the configuration of the scanning unit Un will be described in detail later.

- the scanning unit U1 scans the spot light SP along the drawing line SL1, and similarly, the scanning units U2 to U6 scan the spot light SP along the drawing lines SL2 to SL6.

- the drawing lines SLn (SL1 to SL6) of the plurality of scanning units Un (U1 to U6) are not separated from each other in the Y direction (the width direction of the substrate P, the main scanning direction), as shown in FIGS. , Are set to be spliced.

- the beam LB from the light source device LS (LSa, LSb) that enters the scanning unit Un via the beam switching unit BDU may be represented as LBn.

- the beam LBn incident on the scanning unit U1 may be represented by LB1, and similarly, the beam LBn incident on the scanning units U2 to U6 may be represented by LB2 to LB6.

- the drawing lines SLn (SL1 to SL6) indicate the scanning trajectory of the spot light SP of the beam LBn (LB1 to LB6) scanned by the scanning unit Un (U1 to U6).

- the beam LBn incident on the scanning unit Un may be a linearly polarized beam (P-polarized light or S-polarized light) polarized in a predetermined direction, and is a P-polarized beam in the first embodiment.

- each of the scanning units Un (U1 to U6) shares the scanning area so that the plurality of scanning units Un (U1 to U6) cover all of the exposure area W in the width direction. ing. Accordingly, each scanning unit Un (U1 to U6) can draw a pattern for each of a plurality of regions (drawing ranges) divided in the width direction of the substrate P.

- the width in the Y direction that can be drawn is increased to about 120 to 360 mm.

- the length of each drawing line SLn (SL1 to SL6) (length of the drawing range) is the same. That is, the scanning distance of the spot light SP of the beam LBn scanned along each of the drawing lines SL1 to SL6 is basically the same. Note that it is possible to increase the width of the exposure region W by increasing the length of the drawing line SLn itself or increasing the number of scanning units Un arranged in the Y direction.

- the actual drawing lines SLn are set slightly shorter than the maximum length (maximum scanning length) that the spot light SP can actually scan on the irradiated surface.

- the scanning length of the drawing line SLn on which pattern drawing is possible is 30 mm when the drawing magnification in the main scanning direction (Y direction) is an initial value (no magnification correction)

- the maximum scanning on the irradiated surface of the spot light SP The length is set to about 31 mm with a margin of about 0.5 mm on each of the drawing start point (scanning start point) side and the drawing end point (scanning end point) side of the drawing line SLn.

- the maximum scanning length of the spot light SP is not limited to 31 mm, and is mainly determined by the aperture of the f ⁇ lens FT (see FIG. 5) provided after the polygon mirror (rotating polygon mirror) PM in the scanning unit Un.

- the plurality of drawing lines SLn are arranged in a staggered arrangement in two rows in the circumferential direction of the rotary drum DR with the center surface Poc interposed therebetween.

- the odd-numbered drawing lines SL1, SL3, and SL5 are positioned on the irradiated surface of the substrate P on the upstream side ( ⁇ X direction side) in the transport direction of the substrate P with respect to the center plane Poc.

- the even-numbered drawing lines SL2, SL4, and SL6 are positioned on the irradiated surface of the substrate P on the downstream side (+ X direction side) in the transport direction of the substrate P with respect to the center plane Poc.

- the drawing lines SL1 to SL6 are substantially parallel to the width direction of the substrate P, that is, the central axis AXo of the rotary drum DR.

- the drawing lines SL1, SL3, and SL5 are arranged in a line on a straight line at a predetermined interval along the width direction (main scanning direction) of the substrate P.

- the drawing lines SL2, SL4, and SL6 are arranged in a line on the straight line at a predetermined interval along the width direction (main scanning direction) of the substrate P.

- the drawing line SL2 is arranged between the drawing line SL1 and the drawing line SL3 in the width direction of the substrate P.

- the drawing line SL3 is arranged between the drawing line SL2 and the drawing line SL4 in the width direction of the substrate P.

- the drawing line SL4 is arranged between the drawing line SL3 and the drawing line SL5 with respect to the width direction of the substrate P, and the drawing line SL5 is arranged between the drawing line SL4 and the drawing line SL6 with respect to the width direction of the substrate P.

- the plurality of drawing lines SLn (SL1 to SL6) are arranged so as to be shifted from each other in the Y direction (main scanning direction).

- the main scanning direction of the spot light SP of the beams LB1, LB3, LB5 scanned along each of the odd-numbered drawing lines SL1, SL3, SL5 is a one-dimensional direction and is the same direction.

- the main scanning direction of the spot light SP of the beams LB2, LB4, and LB6 scanned along the even-numbered drawing lines SL2, SL4, and SL6 is a one-dimensional direction and is the same direction.

- the main scanning direction of the spot light SP may be opposite to each other.

- the main scanning direction of the spot light SP of the beams LB1, LB3, LB5 scanned along the drawing lines SL1, SL3, SL5 is the -Y direction.

- the main scanning direction of the spot light SP of the beams LB2, LB4, and LB6 scanned along the drawing lines SL2, SL4, and SL6 is the + Y direction.

- the end of the drawing lines SL3 and SL5 on the drawing end point side and the end of the drawing lines SL2 and SL4 on the drawing end point side are adjacent or partially overlap in the Y direction.

- each drawing line SLn so that the ends of the drawing lines SLn adjacent in the Y direction partially overlap, for example, the drawing start point or the drawing end with respect to the length of each drawing line SLn It is preferable to overlap within a range of several percent or less in the Y direction including points.

- joining the drawing lines SLn in the Y direction means that the ends of the drawing lines SLn are adjacent to each other or partially overlap in the Y direction.

- the width (dimension in the X direction) of the drawing line SLn in the sub-scanning direction is a thickness corresponding to the size (diameter) ⁇ of the spot light SP.

- the width of the drawing line SLn is also 3 ⁇ m.

- the spot light SP may be projected along the drawing line SLn so as to overlap by a predetermined length (for example, 7/8 of the size ⁇ of the spot light SP).

- drawing lines SLn for example, the drawing line SL1 and the drawing line SL2 adjacent in the Y direction are connected to each other, they are overlapped by a predetermined length (for example, 7/8 of the size ⁇ of the spot light SP). It is good.

- the spot light SP projected onto the drawing line SLn during main scanning Is discrete according to the oscillation frequency Fa (for example, 400 MHz) of the beam LB (LBa, LBb). Therefore, it is necessary to overlap the spot light SP projected by one pulse light of the beam LB and the spot light SP projected by the next one pulse light in the main scanning direction.

- the amount of overlap is set by the size ⁇ of the spot light SP, the scanning speed (main scanning speed) Vs of the spot light SP, and the oscillation frequency Fa of the beam LB.

- the effective size ⁇ of the spot light SP is determined by 1 / e 2 (or 1/2) of the peak intensity of the spot light SP when the intensity distribution of the spot light SP is approximated by a Gaussian distribution.

- the scanning speed Vs and the oscillation frequency Fa of the spot light SP are set so that the spot light SP overlaps the effective size (dimension) ⁇ by about ⁇ ⁇ 7/8. Is done. Accordingly, the projection interval of the spot light SP along the main scanning direction is ⁇ / 8. Therefore, also in the sub-scanning direction (direction orthogonal to the drawing line SLn), the substrate P is effective for the spot light SP between one scanning of the spot light SP along the drawing line SLn and the next scanning.

- the exposure amount to the photosensitive functional layer on the substrate P can be set by adjusting the peak value of the beam LB (pulse light). However, the exposure amount can be increased in a situation where the intensity of the beam LB cannot be increased.

- the spot light SP is caused to fall by the decrease in the scanning speed Vs of the spot light SP in the main scanning direction, the increase in the oscillation frequency Fa of the beam LB, or the decrease in the transport speed Vt of the substrate P in the sub scanning direction.

- the overlap amount in the main scanning direction or the sub-scanning direction may be increased.

- the scanning speed Vs of the spot light SP in the main scanning direction increases in proportion to the rotational speed (rotational speed Vp) of the polygon mirror PM.

- Each scanning unit Un (U1 to U6) irradiates each beam LBn toward the substrate P so that each beam LBn travels toward the central axis AXo of the rotating drum DR at least in the XZ plane.

- the optical path (beam central axis) of the beam LBn traveling from each scanning unit Un (U1 to U6) toward the substrate P becomes parallel to the normal line of the irradiated surface of the substrate P in the XZ plane.

- each scanning unit Un (U1 to U6) is configured such that the beam LBn irradiated to the drawing line SLn (SL1 to SL6) is perpendicular to the irradiated surface of the substrate P in a plane parallel to the YZ plane.

- the beam LBn is irradiated toward the substrate P. That is, the beam LBn (LB1 to LB6) projected onto the substrate P is scanned in a telecentric state with respect to the main scanning direction of the spot light SP on the irradiated surface.

- a line perpendicular to the irradiated surface of the substrate P also called an optical axis

- SLn SL1 to SL6

- Un U1 to U6

- Each irradiation center axis Len (Le1 to Le6) is a line connecting the drawing lines SL1 to SL6 and the center axis AXo on the XZ plane.

- the irradiation center axes Le1, Le3, Le5 of the odd-numbered scanning units U1, U3, U5 are in the same direction in the XZ plane, and the irradiation center axes Le2 of the even-numbered scanning units U2, U4, U6. , Le4 and Le6 are in the same direction in the XZ plane.

- irradiation center axes Le1, Le3, Le5 and the irradiation center axes Le2, Le4, Le6 are set such that the angle is ⁇ ⁇ 1 with respect to the center plane Poc in the XZ plane (see FIG. 2).

- a plurality of alignment microscopes AM1m (AM11 to AM14) and AM2m (AM21 to AM24) shown in FIG. 2 are for detecting a plurality of alignment marks MKm (MK1 to MK4) formed on the substrate P shown in FIG. And a plurality (four in the first embodiment) are provided along the Y direction.

- the plurality of alignment marks MKm (MK1 to MK4) are reference marks for relatively aligning (aligning) the predetermined pattern drawn in the exposure area W on the irradiated surface of the substrate P with the substrate P. It is.

- a plurality of alignment microscopes AM1m (AM11 to AM14) and AM2m (AM21 to AM24) are arranged on the substrate P supported by the outer peripheral surface (circumferential surface) of the rotating drum DR, and a plurality of alignment marks MKm (MK1 to MK4). Is detected.

- the plurality of alignment microscopes AM1m (AM11 to AM14) are more than the irradiated area (area surrounded by the drawing lines SL1 to SL6) on the substrate P by the spot light SP of the beam LBn (LB1 to LB6) from the exposure head 14. It is provided on the upstream side ( ⁇ X direction side) in the transport direction of the substrate P.

- the plurality of alignment microscopes AM2m are irradiated from an irradiation area (area surrounded by the drawing lines SL1 to SL6) on the substrate P by the spot light SP of the beam LBn (LB1 to LB6) from the exposure head 14. Is also provided on the downstream side (+ X direction side) in the transport direction of the substrate P.

- the alignment microscopes AM1m (AM11 to AM14) and AM2m (AM21 to AM24) are a local region (observation region) Vw1m (Vw11) including a light source that projects illumination light for alignment onto the substrate P and an alignment mark MKm on the surface of the substrate P.

- Vw1m Vw11

- Vw2m Vw21 to Vw24

- an observation optical system including an objective lens

- the transport speed Vt of the substrate P is increased.

- an image pickup device such as a CCD or a CMOS for picking up an image with a corresponding high-speed shutter.

- Imaging signals (image data) captured by each of the plurality of alignment microscopes AM1m (AM11 to AM14) and AM2m (AM21 to AM24) are sent to the control device 16.

- the mark position detection unit 106 (see FIG. 12) of the control device 16 performs image analysis of the plurality of image signals that have been sent, so that the position of the alignment mark MKm (MK1 to MK4) on the substrate P (mark position). Information).

- the illumination light for alignment is light in a wavelength region that has little sensitivity to the photosensitive functional layer on the substrate P, for example, light having a wavelength of about 500 to 800 nm.

- a plurality of alignment marks MK1 to MK4 are provided around each exposure area W.

- a plurality of alignment marks MK1 and MK4 are formed on both sides of the exposure region W in the width direction of the substrate P at a constant interval Dh along the longitudinal direction of the substrate P.

- the alignment mark MK1 is formed on the ⁇ Y direction side in the width direction of the substrate P

- the alignment mark MK4 is formed on the + Y direction side in the width direction of the substrate P.

- Such alignment marks MK1 and MK4 are located at the same position in the longitudinal direction (X direction) of the substrate P when the substrate P is not deformed due to a large tension or a thermal process. Be placed.

- the alignment marks MK2 and MK3 are between the alignment mark MK1 and the alignment mark MK4, and extend in the width direction (short direction) of the substrate P in the margin part between the + X direction side and the ⁇ X direction side of the exposure region W. Is formed.

- the alignment marks MK2 and MK3 are formed between the exposure area W and the exposure area W.

- the alignment mark MK2 is formed on the ⁇ Y direction side in the width direction of the substrate P

- the alignment mark MK3 is formed on the + Y direction side of the substrate P.

- the Y-direction interval between the alignment mark MK1 and the margin alignment mark MK2 arranged at the ⁇ Y direction end of the substrate P, the Y-direction interval between the margin alignment mark MK2 and the alignment mark MK3, and The interval in the Y direction between the alignment mark MK4 arranged at the end on the + Y direction side of the substrate P and the alignment mark MK3 in the blank portion is set to the same distance.

- These alignment marks MKm (MK1 to MK4) may be formed together when forming the first pattern layer. For example, when the pattern of the first layer is exposed, the alignment mark pattern may be exposed around the exposure area W where the pattern is exposed.

- the alignment mark MKm may be formed in the exposure area W. For example, it may be formed in the exposure area W along the outline of the exposure area W. Further, a pattern portion at a specific position or a specific shape portion in the pattern of the electronic device formed in the exposure region W may be used as the alignment mark MKm.

- Alignment microscopes AM11 and AM21 are arranged so as to image alignment marks MK1 existing in observation regions (detection regions) Vw11 and Vw21 by the objective lens, as shown in FIG.

- the alignment microscopes AM12 to AM14 and AM22 to AM24 are arranged so as to image the alignment marks MK2 to MK4 existing in the observation areas Vw12 to Vw14 and Vw22 to Vw24 by the objective lens.

- the plurality of alignment microscopes AM11 to AM14 and AM21 to AM24 correspond to the positions of the plurality of alignment marks MK1 to MK4, and the substrates P in the order of AM11 to AM14 and AM21 to AM24 from the ⁇ Y direction side of the substrate P. It is provided along the width direction.

- the observation region Vw2m (Vw21 to Vw24) of the alignment microscope AM2m (AM21 to AM24) is not shown.

- the distance between the exposure position (drawing lines SL1 to SL6) and the observation region Vw1m (Vw11 to Vw14) in the X direction is shorter than the length of the exposure region W in the X direction. It is provided to become.

- the distance between the exposure position (drawing lines SL1 to SL6) and the observation region Vw2m (Vw21 to Vw24) with respect to the X direction is longer than the length of the exposure region W in the X direction. Is also provided to be shorter.

- the number of alignment microscopes AM1m and AM2m provided in the Y direction can be changed according to the number of alignment marks MKm formed in the width direction of the substrate P. Further, the sizes of the observation regions Vw1m (Vw11 to Vw14) and Vw2m (Vw21 to Vw24) on the irradiated surface of the substrate P are set according to the size of the alignment marks MK1 to MK4 and the alignment accuracy (position measurement accuracy). However, it is about 100 to 500 ⁇ m square.

- scale portions SDa and SDb having scales formed in an annular shape over the entire circumferential direction of the outer peripheral surface of the rotary drum DR are provided at both ends of the rotary drum DR.

- the scale portions SDa and SDb are diffraction gratings in which concave or convex lattice lines are engraved at a constant pitch (for example, 20 ⁇ m) in the circumferential direction of the outer peripheral surface of the rotary drum DR, and are configured as incremental scales.

- the scale portions SDa and SDb rotate integrally with the rotary drum DR around the central axis AXo.

- Encoders ENja and ENjb optically detect the rotational angle position of the rotary drum DR.

- Four encoders ENja (EN1a, EN2a, EN3a, EN4a) are provided so as to face the scale part SDa provided at the end of the rotary drum DR on the ⁇ Y direction side.

- four encoders ENjb (EN1b, EN2b, EN3b, EN4b) are provided so as to face the scale part SDb provided at the end on the + Y direction side of the rotary drum DR.

- the encoders EN1a and EN1b are provided on the upstream side ( ⁇ X direction side) in the transport direction of the substrate P with respect to the center plane Poc, and are disposed on the installation direction line Lx1 (see FIGS. 2 and 3).

- the installation azimuth line Lx1 is a line connecting the projection positions (reading positions) of the measurement light beams on the scale portions SDa and SDb of the encoders EN1a and EN1b and the central axis AXo on the XZ plane.

- the installation orientation line Lx1 is a line connecting the observation region Vw1m (Vw11 to Vw14) of each alignment microscope AM1m (AM11 to AM14) and the central axis AXo on the XZ plane. That is, a plurality of alignment microscopes AM1m (AM11 to AM14) are also arranged on the installation direction line Lx1.

- the encoders EN2a and EN2b are provided on the upstream side ( ⁇ X direction side) in the transport direction of the substrate P with respect to the center plane Poc, and further downstream in the transport direction of the substrate P (+ X direction) from the encoders EN1a and EN1b. Side).

- the encoders EN2a and EN2b are disposed on the installation direction line Lx2 (see FIGS. 2 and 3).

- the installation azimuth line Lx2 is a line connecting the projection positions (reading positions) of the measurement light beams on the scale portions SDa and SDb of the encoders EN2a and EN2b and the central axis AXo on the XZ plane.

- the installation azimuth line Lx2 overlaps with the irradiation center axes Le1, Le3, Le5 at the same angular position in the XZ plane.

- the encoders EN3a and EN3b are provided on the downstream side (+ X direction side) in the transport direction of the substrate P with respect to the center plane Poc, and are disposed on the installation direction line Lx3 (see FIGS. 2 and 3).

- the installation azimuth line Lx3 is a line connecting the projection positions (reading positions) of the measurement light beams on the scale portions SDa and SDb of the encoders EN3a and EN3b and the central axis AXo on the XZ plane.

- This installation orientation line Lx3 overlaps with the irradiation center axes Le2, Le4, and Le6 at the same angular position in the XZ plane. Therefore, the installation azimuth line Lx2 and the installation azimuth line Lx3 are set so that the angle is ⁇ ⁇ 1 with respect to the center plane Poc in the XZ plane (see FIG. 2).

- Encoders EN4a and EN4b are provided on the downstream side (+ X direction side) in the transport direction of the substrate P from the encoders EN3a and EN3b, and are arranged on the installation direction line Lx4 (see FIG. 2).

- the installation azimuth line Lx4 is a line connecting the projection positions (reading positions) of the measurement light beams on the scale portions SDa and SDb of the encoders EN4a and EN4b and the central axis AXo on the XZ plane.

- the installation orientation line Lx4 is a line connecting the observation region Vw2m (Vw21 to Vw24) of each alignment microscope AM2m (AM21 to AM24) and the central axis AXo on the XZ plane.

- a plurality of alignment microscopes AM2m are also arranged on the installation direction line Lx4.

- the installation azimuth line Lx1 and the installation azimuth line Lx4 are set such that the angle is ⁇ ⁇ 2 with respect to the center plane Poc in the XZ plane (see FIG. 2).

- Each encoder ENja (EN1a to EN4a), ENjb (EN1b to EN4b) projects a measurement light beam toward the scale portions SDa and SDb, and detects the reflected light beam (diffracted light) to detect a pulse signal. Is output to the control device 16.

- the rotational position detector 108 (see FIG. 12) of the control device 16 counts the detection signal (pulse signal), thereby measuring the rotational angular position and angular change of the rotary drum DR with submicron resolution. From the change in the angle of the rotating drum DR, the transport speed Vt of the substrate P can also be measured.

- the rotational position detector 108 individually counts detection signals from the encoders ENja (EN1a to EN4a) and ENjb (EN1b to EN4b).

- the rotational position detection unit 108 includes a plurality of counter circuits CNja (CN1a to CN4a) and CNjb (CN1b to CN4b).

- the counter circuit CN1a counts the detection signal from the encoder EN1a

- the counter circuit CN1b counts the detection signal from the encoder EN1b.

- the counter circuits CN2a to CN4a and CN2b to CN4b count detection signals from the encoders EN2a to EN4a and EN2b to EN4b.

- Each of the counter circuits CNja (CN1a to CN4a) and CNjb (CN1b to CN4b) has encoders ENja (EN1a to EN4a) and ENjb (EN1b to EN4b) formed in a part of the circumferential direction of the scale portions SDa and SDb.

- the count values corresponding to the encoders ENja and ENjb that have detected the origin mark ZZ are reset to zero.

- One of the count values of the counter circuits CN1a and CN1b or the average value thereof is used as the rotation angle position of the rotary drum DR on the installation direction line Lx1, and either one of the count values of the counter circuits CN2a and CN2b or the average The value is used as the rotation angle position of the rotary drum DR on the installation direction line Lx2.

- one or the average value of the count values of the counter circuits CN3a and CN3b is used as the rotation angle position of the rotary drum DR on the installation direction line Lx3, and either one of the count values of the counter circuits CN4a and CN4b or The average value is used as the rotation angle position of the rotary drum DR on the installation direction line Lx4.

- the count values of the counter circuits CN1a and CN1b are the same except when the rotary drum DR rotates eccentrically with respect to the central axis AXo due to a manufacturing error of the rotary drum DR.

- the count values of the counter circuits CN2a and CN2b are the same, and the count values of the counter circuits CN3a and CN3b and the count values of the counter circuits CN4a and CN4b are also the same.

- alignment microscope AM1m (AM11 to AM14) and encoders EN1a and EN1b are arranged on installation orientation line Lx1

- alignment microscope AM2m (AM21 to AM24) and encoders EN4a and EN4b are installation orientation lines Lx4. Is placed on top. Therefore, the position detection of the alignment mark MKm (MK1 to MK4) by the image analysis of the mark position detection unit 106 of the plurality of imaging signals picked up by the plurality of alignment microscopes AM1m (AM11 to AM14) and the moment when the alignment microscope AM1m picks up the image.

- the position of the substrate P on the installation orientation line Lx1 can be measured with high accuracy based on the information on the rotational angle position of the rotary drum DR (the count value based on the encoders EN1a and EN1b).

- the position detection of the alignment mark MKm MK1 to MK4 by the image analysis of the mark position detection unit 106 of the plurality of imaging signals captured by the plurality of alignment microscopes AM2m (AM21 to AM24), and the moment when the alignment microscope AM2m images

- the position of the substrate P on the installation orientation line Lx4 can be measured with high accuracy based on the information on the rotational angle position of the rotary drum DR (the count value based on the encoders EN4a and EN4b).

- the count values of the detection signals from the encoders EN1a and EN1b, the count values of the detection signals from the encoders EN2a and EN2b, the count values of the detection signals from the encoders EN3a and EN3b, and the detection signals from the encoders EN4a and EN4b The count value is reset to zero at the moment when each encoder ENja, ENjb detects the origin mark ZZ. Therefore, when the position on the installation orientation line Lx1 of the substrate P wound around the rotary drum DR when the count value based on the encoders EN1a and EN1b is the first value (for example, 100) is the first position.

- the count value based on the encoders EN2a, EN2b is the first value (for example, , 100).

- the count value of the detection signal based on the encoders EN3a, EN3b is the first. (For example, 100).

- the count value of the detection signal based on the encoders EN4a and EN4b becomes the first value (for example, 100).

- the substrate P is wound inside the scale portions SDa and SDb at both ends of the rotary drum DR.

- the radius from the central axis AXo of the outer peripheral surface of the scale portions SDa and SDb is set smaller than the radius from the central axis AXo of the outer peripheral surface of the rotary drum DR.

- the outer peripheral surfaces of the scale portions SDa and SDb may be set so as to be flush with the outer peripheral surface of the substrate P wound around the rotary drum DR.

- the radius (distance) from the central axis AXo of the outer peripheral surfaces of the scale portions SDa and SDb and the radius (distance) from the central axis AXo of the outer peripheral surface (irradiated surface) of the substrate P wound around the rotary drum DR May be set to be the same.

- each of the encoders ENja (EN1a to EN4a) and ENjb (EN1b to EN4b) can detect the scale portions SDa and SDb at the same radial position as the irradiated surface of the substrate P wound around the rotary drum DR. . Therefore, the Abbe error caused by the difference between the measurement positions by the encoders ENja and ENjb and the processing positions (drawing lines SL1 to SL6) in the radial direction of the rotary drum DR can be reduced.

- the radius of the outer peripheral surface of the scale portions SDa and SDb and the outer peripheral surface of the substrate P wound around the rotary drum DR are different. It is difficult to always make the radius the same. Therefore, in the case of the scale portions SDa and SDb shown in FIG. 3, the radius of the outer peripheral surface (scale surface) is set to coincide with the radius of the outer peripheral surface of the rotary drum DR. Furthermore, the scale portions SDa and SDb can be formed of individual disks, and the disks (scale disks) can be coaxially attached to the shaft Sft of the rotary drum DR. Even in this case, it is preferable to align the radius of the outer peripheral surface (scale surface) of the scale disk and the radius of the outer peripheral surface of the rotary drum DR so that the Abbe error falls within the allowable value.

- the start position of the drawing exposure of the exposure region W in the longitudinal direction (X direction) of the substrate P is determined by the control device 16 based on any one of these or the average value. Since the length of the exposure area W in the X direction is known in advance, the control device 16 determines the drawing exposure start position every time a predetermined number of alignment marks MKm (MK1 to MK4) are detected.

- the drawing exposure start position of the exposure region W in the longitudinal direction of the substrate P is located on the drawing lines SL1, SL3, SL5. Accordingly, the scanning units U1, U3, and U5 can start scanning the spot light SP based on the count values of the encoders EN2a and EN2b.

- the drawing exposure start position of the exposure region W in the longitudinal direction of the substrate P is positioned on the drawing lines SL2, SL4, and SL6. To do. Therefore, the scanning units U2, U4, and U6 can start scanning the spot light SP based on the count values of the encoders EN3a and EN3b.

- the tension adjusting rollers RT1 and RT2 apply a predetermined tension to the substrate P in the longitudinal direction, so that the substrate P is conveyed along with the rotation of the rotating drum DR while being in close contact with the rotating drum DR. .

- the rotational speed Vp of the rotating drum DR is high, or the tension applied to the substrate P by the tension adjusting rollers RT1 and RT2 is too low or too high, the substrate P slips with respect to the rotating drum DR. May occur.

- the encoders EN1a and EN1b at the moment when the alignment microscope AM1m images the alignment mark MKmA (a specific alignment mark MKm) based on the count value based on the encoders EN4a and 4b.

- the count value is the same as the count value based on (for example, 150)

- this alignment mark MKmA is detected by the alignment microscope AM2m.

- the count value based on the encoders EN4a and EN4b is a count value based on the encoders EN1a and EN1b at the moment when the alignment mark AMKm images the alignment mark MKmA (for example, , 150), the alignment mark MKmA is not detected by the alignment microscope AM2m.

- the count value based on the encoders EN4a and EN4b exceeds 150, for example, the alignment mark MKmA is detected by the alignment microscope AM2m.

- the slip amount of the substrate P can be measured by additionally installing the alignment microscope AM2m and the encoders EN4a and EN4b.

- each scanning unit Un (U1 to U6) has the same configuration, only the scanning unit U1 will be described, and the description of the other scanning units Un will be omitted.

- the direction parallel to the irradiation center axis Len (Le1) is the Zt direction

- the substrate P is on the plane orthogonal to the Zt direction

- the substrate P passes from the processing apparatus PR2 through the exposure apparatus EX to the processing apparatus PR3.

- the direction going to the Xt direction is defined as the Yt direction

- the direction perpendicular to the Xt direction on the plane orthogonal to the Zt direction is defined as the Yt direction.

- the three-dimensional coordinates of Xt, Yt, and Zt in FIG. 5 are the same as the three-dimensional coordinates of X, Y, and Z in FIG. 2, and the Z-axis direction is parallel to the irradiation center axis Len (Le1).

- the three-dimensional coordinates rotated as described above.

- a reflection mirror M10 As shown in FIG. 5, in the scanning unit U1, along the traveling direction of the beam LB1 from the incident position of the beam LB1 to the irradiated surface (substrate P), a reflection mirror M10, a beam expander BE, a reflection mirror M11, Polarization beam splitter BS1, reflection mirror M12, shift optical member (parallel plate) SR, deflection adjustment optical member (prism) DP, field aperture FA, reflection mirror M13, ⁇ / 4 wavelength plate QW, cylindrical lens CYA, reflection mirror M14, A polygon mirror PM, an f ⁇ lens FT, a reflection mirror M15, and a cylindrical lens CYb are provided.

- an origin sensor (origin detector) OP1 that detects the timing at which the scanning unit U1 can start drawing, and reflected light from the irradiated surface (substrate P) are detected via the polarization beam splitter BS1.

- An optical lens system G10 and a photodetector DT are provided.

- the beam LB1 incident on the scanning unit U1 travels in the ⁇ Zt direction and enters the reflection mirror M10 inclined by 45 ° with respect to the XtYt plane.

- the axis of the beam LB1 incident on the scanning unit U1 is incident on the reflection mirror M10 so as to be coaxial with the irradiation center axis Le1.

- the reflection mirror M10 functions as an incident optical member that causes the beam LB1 to enter the scanning unit U1, and the incident beam LB1 is moved from the reflection mirror M10 to the ⁇ Xt direction along the optical axis AXa set parallel to the Xt axis. Reflected in the -Xt direction toward the distant reflecting mirror M11.

- the optical axis AXa is orthogonal to the irradiation center axis Le1 in a plane parallel to the XtZt plane.

- the beam LB1 reflected by the reflection mirror M10 passes through the beam expander BE arranged along the optical axis AXa and enters the reflection mirror M11.

- the beam expander BE expands the diameter of the transmitted beam LB1.

- the beam expander BE includes a condensing lens Be1 and a collimator lens Be2 that collimates the beam LB1 diverged after being converged by the condensing lens Be1.

- the reflection mirror M11 is disposed with an inclination of 45 ° with respect to the YtZt plane, and reflects the incident beam LB1 (optical axis AXa) toward the polarization beam splitter BS1 in the ⁇ Yt direction.