WO2011078298A1 - ポリアクリル酸系吸水性樹脂粉末及びその製造方法 - Google Patents

ポリアクリル酸系吸水性樹脂粉末及びその製造方法 Download PDFInfo

- Publication number

- WO2011078298A1 WO2011078298A1 PCT/JP2010/073254 JP2010073254W WO2011078298A1 WO 2011078298 A1 WO2011078298 A1 WO 2011078298A1 JP 2010073254 W JP2010073254 W JP 2010073254W WO 2011078298 A1 WO2011078298 A1 WO 2011078298A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- water

- resin powder

- absorbent resin

- polymerization

- aqueous solution

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/12—Powdering or granulating

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L15/00—Chemical aspects of, or use of materials for, bandages, dressings or absorbent pads

- A61L15/16—Bandages, dressings or absorbent pads for physiological fluids such as urine or blood, e.g. sanitary towels, tampons

- A61L15/42—Use of materials characterised by their function or physical properties

- A61L15/48—Surfactants

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L15/00—Chemical aspects of, or use of materials for, bandages, dressings or absorbent pads

- A61L15/16—Bandages, dressings or absorbent pads for physiological fluids such as urine or blood, e.g. sanitary towels, tampons

- A61L15/42—Use of materials characterised by their function or physical properties

- A61L15/60—Liquid-swellable gel-forming materials, e.g. super-absorbents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J20/00—Solid sorbent compositions or filter aid compositions; Sorbents for chromatography; Processes for preparing, regenerating or reactivating thereof

- B01J20/22—Solid sorbent compositions or filter aid compositions; Sorbents for chromatography; Processes for preparing, regenerating or reactivating thereof comprising organic material

- B01J20/26—Synthetic macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2/00—Processes of polymerisation

- C08F2/001—Multistage polymerisation processes characterised by a change in reactor conditions without deactivating the intermediate polymer

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2/00—Processes of polymerisation

- C08F2/12—Polymerisation in non-solvents

- C08F2/16—Aqueous medium

- C08F2/22—Emulsion polymerisation

- C08F2/24—Emulsion polymerisation with the aid of emulsifying agents

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2/00—Processes of polymerisation

- C08F2/12—Polymerisation in non-solvents

- C08F2/16—Aqueous medium

- C08F2/22—Emulsion polymerisation

- C08F2/24—Emulsion polymerisation with the aid of emulsifying agents

- C08F2/30—Emulsion polymerisation with the aid of emulsifying agents non-ionic

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F20/00—Homopolymers and copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride, ester, amide, imide or nitrile thereof

- C08F20/02—Monocarboxylic acids having less than ten carbon atoms, Derivatives thereof

- C08F20/04—Acids, Metal salts or ammonium salts thereof

- C08F20/06—Acrylic acid; Methacrylic acid; Metal salts or ammonium salts thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/04—Acids; Metal salts or ammonium salts thereof

- C08F220/06—Acrylic acid; Methacrylic acid; Metal salts or ammonium salts thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F6/00—Post-polymerisation treatments

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F6/00—Post-polymerisation treatments

- C08F6/26—Treatment of polymers prepared in bulk also solid polymers or polymer melts

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/24—Crosslinking, e.g. vulcanising, of macromolecules

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2810/00—Chemical modification of a polymer

- C08F2810/20—Chemical modification of a polymer leading to a crosslinking, either explicitly or inherently

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/04—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters

- C08J2333/06—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters of esters containing only carbon, hydrogen, and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C08J2333/08—Homopolymers or copolymers of acrylic acid esters

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/04—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters

- C08J2333/06—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters of esters containing only carbon, hydrogen, and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C08J2333/10—Homopolymers or copolymers of methacrylic acid esters

Definitions

- the present invention relates to a polyacrylic acid-based water absorbent resin powder and a method for producing the same. More particularly, the present invention relates to a water-absorbing resin powder used for sanitary goods such as paper diapers and sanitary napkins, and has excellent water absorption performance (especially high water absorption speed). It is about.

- Water-absorbing resin (SAP / Super Absorbent Polymer) is a water-swellable, water-insoluble polymer gelling agent, absorbent articles such as paper diapers and sanitary napkins, water retaining agents for agriculture and horticulture, and industrial waterstops. As a material etc., it is frequently used mainly for disposable use.

- a water-absorbing resin many monomers and hydrophilic polymers have been proposed as raw materials, and in particular, a polyacrylic acid-based water-absorbing material using acrylic acid and / or a salt thereof as a monomer. Resins are most commonly used industrially due to their high water absorption performance (Non-patent Document 1).

- Such a water-absorbent resin is produced through a polymerization process, a drying process, if necessary, a removal process of undried material, a pulverization process, a classification process, a surface crosslinking process, and the like (Patent Documents 1 to 5).

- water-absorbing resins are also required to have many functions. Specifically, the gel strength, water-soluble content, water absorption speed, water absorption capacity under pressure, liquid permeability, particle size distribution, urine resistance, antibacterial properties, impact resistance (resistance to resistance) Many physical properties such as damage property), powder flowability, deodorant property, coloring resistance (whiteness), and low dust are required for the water-absorbent resin. For this reason, many proposals have been made in the above and below patent documents, such as many surface cross-linking techniques, additives, and manufacturing process changes.

- liquid permeability has been seen as a more important factor as the amount of water-absorbent resin used in paper diapers increases in recent years (for example, 50% by weight or more).

- improvement methods and improvement techniques for under-load liquid permeability and under-load liquid permeability such as SFC (Saline Flow Conductivity / Patent Document 6) and GBP (Gel Bed Permeability / Patent Documents 7 to 9) have been proposed. Yes.

- the water absorption rate is also an important basic physical property of the water-absorbent resin, and as a method for improving the water absorption rate, a technique for improving the water absorption rate by increasing the specific surface area is known.

- a technique for finely controlling the particle diameter Patent Document 10

- a technique for granulating fine particles having a large surface area Patent Documents 11 to 13

- a technique for freeze-drying a hydrous gel to make it porous Patent Document 14

- techniques for surface cross-linking of particles simultaneously with granulation Patent Documents 15 to 17

- techniques for foam polymerization Patent Documents 18 to 35

- techniques for foaming and cross-linking after polymerization Patent Document 36

- Patent Documents 10 to 36 the water absorption speed is improved to some extent by increasing the surface area of the water absorbent resin, but it still does not show a sufficient effect, and a special apparatus or an expensive raw material (a large amount of surfactant or Foaming agent) was required. Furthermore, problems such as deterioration of other physical properties such as liquid permeability (Patent Documents 6 to 9), impact resistance (Patent Document 37), bulk specific gravity (Patent Documents 38 and 39) and the like, which are required in recent years. Had.

- the water-absorbing resin is used in absorbent articles such as paper diapers and sanitary napkins, and is often combined with white pulp.

- Many color improvement techniques have been proposed for the whiteness of patents (Patent Documents 40 to 42).

- Patent Documents 40 to 42 Many color improvement techniques have been proposed for the whiteness of patents (Patent Documents 40 to 42).

- the present situation is that these are not sufficient in terms of the cost and safety of the coloring inhibitor, the complexity of the process, and the effect.

- the problem to be solved by the present invention is to maintain the other physical properties of the water-absorbent resin (liquid permeability, bulk specific gravity, surface tension, water absorption capacity under pressure, impact resistance, etc.) or more expensive raw materials. It is to provide a white water-absorbent resin powder having an improved water absorption speed (for example, FSR) without using any device. In particular, it is to provide a white water-absorbent resin powder having both high liquid permeability (for example, SFC) and water absorption speed (for example, FSR).

- SFC high liquid permeability

- FSR water absorption speed

- the present inventor paid attention to a method of dispersing bubbles in monomers during polymerization, and solved the above problems by using a specific method, and reduced bulk specific gravity and surface tension. Further, it was found that a water-absorbing resin powder excellent in whiteness, liquid permeability, and impact resistance (also known as damage resistance) was obtained, and the present invention was completed.

- a water-absorbing resin powder excellent in whiteness, liquid permeability, and impact resistance also known as damage resistance

- the present invention was completed.

- techniques for increasing the surface area, foaming polymerization, and making porous to improve the water absorption rate have been proposed in the above-mentioned patent documents, but the present invention is the first to use closed cells (also known as internal bubbles) that have not been focused on. Attention has been paid to find out that the above problems can be solved by controlling the internal cell ratio (Closed-Cell Rate) of the water-absorbent resin within a specific range, and the present invention has been completed.

- the method for producing a water-absorbent resin of the present invention (first method) is obtained by polymerizing an aqueous acrylic acid monomer solution containing bubbles and the polymerization step.

- a method for producing a polyacrylic acid-based water-absorbent resin powder comprising a step of drying a hydrogel crosslinked polymer, wherein the solubility of dissolved gas in an aqueous monomer solution in the presence of a surfactant and / or a dispersant It is characterized by including a bubble generation and containing step of generating and containing bubbles in the aqueous acrylic acid monomer solution by reducing.

- the method for producing a water-absorbent resin of the present invention (second method) is obtained by polymerizing an aqueous acrylic acid monomer solution containing bubbles and the polymerization step.

- a method for producing a polyacrylic acid-based water-absorbing resin powder comprising a step of drying a hydrogel crosslinked polymer, wherein the temperature of the acrylic acid-based monomer aqueous solution is increased in the presence of a surfactant and / or a dispersant. It is characterized by including the process to make.

- the manufacturing method (3rd method) of the water absorbing resin of this invention is obtained by the process of superposing

- a method for producing a polyacrylic acid-based water-absorbent resin powder comprising a step of drying a water-containing gel-like cross-linked polymer, which is water-soluble in an acrylic acid-based monomer aqueous solution in the presence of a surfactant and / or a dispersant. It includes a step of mixing organic substances.

- the water absorbent resin of the present invention has a particle size of 850 to 150 ⁇ m with a ratio of 95 weight.

- % of polyacrylic acid-based water-absorbent resin powder characterized in that the internal cell ratio defined by the following formula is 2.8 to 6.6%.

- the water-absorbent resin (second water-absorbent resin) of the present invention is a polyacrylic acid-based water-absorbent containing a surfactant and / or a dispersant therein.

- the resin powder is characterized in that the surface tension is 60 [mN / m] or more and the powder surface is coated with a surfactant.

- the method for producing a water-absorbent resin powder according to the present invention a water-absorbent resin powder having a high water absorption rate can be produced efficiently and efficiently without using a large amount of a surfactant.

- the water-absorbent resin powder of the present invention obtained by the production method of the present invention is a novel water-absorbent resin that has both water absorption speed and liquid permeability and excellent impact resistance. It is a powder.

- FIG. 1 is a perspective view showing an example of an apparatus used in a continuous temperature raising method by heating an acrylic acid monomer aqueous solution to which the first method and the second method of the present invention are applied.

- FIG. 2 is a flow diagram showing an outline of a method of raising temperature and generating bubbles by neutralization of an acrylic acid monomer aqueous solution to which the first method and the second method of the present invention are applied.

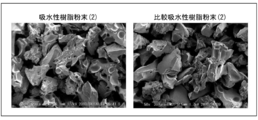

- FIG. 3 is an electron micrograph (50 times magnification) of the water-absorbent resin powder obtained in Example 2 and Comparative Example 2. In Examples and Comparative Examples, which will be described later, after the polymerization and drying, the water-absorbent resin powder is in an irregularly crushed shape as shown in the photograph.

- FIG. 1 is a perspective view showing an example of an apparatus used in a continuous temperature raising method by heating an acrylic acid monomer aqueous solution to which the first method and the second method of the present invention are applied.

- FIG. 2 is a flow diagram showing an outline of a method of

- FIG. 4 is a flowchart showing an outline of a method for raising temperature and generating bubbles by neutralization of an aqueous acrylic acid monomer solution in the presence of a surfactant in Example 2.

- FIG. 5 is a flowchart showing an outline of a temperature raising method by neutralization of an acrylic acid monomer aqueous solution in Comparative Example 3.

- FIG. 6 shows a preferred embodiment of the present invention that can be applied to the first method and the second method of the present invention.

- an inert gas for example, nitrogen

- FIG. 7 shows a preferred embodiment of the present invention that can be applied to the first method and the second method of the present invention.

- an inert gas for example, nitrogen

- FIG. 8 shows a preferred embodiment of the present invention that can be applied to the first method and the second method of the present invention.

- an inert gas for example, nitrogen It is a flowchart which shows the outline of the embodiment which deoxygenates before superposition

- FIG. 9 shows a preferred embodiment of the present invention that can be applied to the first method and the second method of the present invention.

- an inert gas for example, nitrogen It is a flowchart which shows the outline of the embodiment which deoxygenates before superposition

- an inert gas for example, nitrogen It is a flowchart which shows the outline of the embodiment which deoxygenates before superposition

- FIG. 10 is a flowchart showing an outline of gas solubility reduction and bubble generation by mixing a water-soluble organic compound in an acrylic acid monomer aqueous solution, which can be applied to the first method and the third method of the present invention. is there.

- FIG. 11 is a flowchart showing an outline of gas solubility reduction and bubble generation by mixing a water-soluble organic compound in an acrylic acid monomer aqueous solution, which can be applied to the first method and the third method of the present invention. is there.

- FIG. 12 is a cross-sectional view schematically showing closed cells (Opened Cell) and open cells (Closed Cell) in the water absorbent resin powder.

- the water-absorbent resin (described later) of the present invention has a characteristic of having an internal cell ratio (also known as closed cells) controlled within a specific range.

- FIG. 13 is a cross-sectional view schematically showing an operation for finely pulverizing a water-absorbent resin powder (for example, the ratio of the particle size of 850 to 150 ⁇ m is 95% by weight or more) for measuring the true density of the present invention to less than 45 ⁇ m. is there.

- the true density [g / cm 3 ] of the water-absorbent resin powder is measured by performing dry density measurement with helium gas after the closed cells are substantially broken or formed into open cells by finely pulverizing the water-absorbent resin powder. it can.

- FIG. 14 shows a preferred embodiment of the present invention that can be applied to the first method and the second method of the present invention.

- a hydrated gel-like cross-linked polymer is charged into a screw extruder using a belt polymerizer to obtain a crushed gel. It is sectional drawing which shows the outline of the process to obtain.

- FIG. 15 shows a preferred embodiment of the present invention that can be applied to the first method and the second method of the present invention.

- an inert gas for example, nitrogen

- the present invention is not limited to the following embodiments, and various modifications are possible within the scope of the claims, and technical means disclosed in different embodiments are appropriately combined. Embodiments obtained in this manner are also included in the technical scope of the present invention.

- Water absorbent resin powder The “water-absorbent resin powder” in the present invention means a water-swellable water-insoluble polymer gelling agent. “Water swellability” means that the CRC (water absorption capacity under no pressure) specified by ERT441.2-02 is 5 [g / g] or more, and “water-insoluble” means ERT470. Ext (water soluble content) specified in 2-02 is 0 to 50% by weight.

- the water-absorbent resin powder can be designed as appropriate according to its use, and is not particularly limited, and is not limited to a form in which the total amount (100% by weight) is a polymer, and maintains the above performance. Within the range, an additive or the like may be contained, and the water absorbent resin composition containing a small amount of the additive is also collectively referred to as a water absorbent resin powder in the present invention. Moreover, the presence or absence of surface cross-linking does not matter.

- the shape of the water-absorbing resin include a sheet shape, a fiber shape, a film shape, a gel shape, and the like, preferably a powder shape, and particularly preferably a powdered water-absorbing resin having a particle size and moisture content described below.

- the “polyacrylic acid-based water-absorbent resin powder” in the present invention optionally contains a graft component, and contains, as a repeating unit, acrylic acid and / or a salt thereof (hereinafter referred to as acrylic acid (salt)) as a main component. It means a polymer.

- polyacrylate type (neutralization type) polymers are also collectively referred to as polyacrylic acid.

- CRC is an abbreviation for Centrifugation Retention Capacity (centrifuge retention capacity), and means water absorption capacity without pressure (hereinafter also referred to as “water absorption capacity”). Specifically, the water absorption capacity (unit: [g / g] after 30 minutes of free swelling of 0.200 g of the water-absorbing resin in the nonwoven fabric with respect to a 0.9 wt% sodium chloride aqueous solution and further draining with a centrifuge ).

- AAP is an abbreviation for Absorption against Pressure, which means water absorption capacity under pressure. Specifically, it is the water absorption capacity (unit: [g / g]) after swelling under a load of 2.06 kPa for 1 hour with respect to 0.900 g of a 0.9 wt% aqueous sodium chloride solution.

- ERT442.2-02 “Absorption Under Pressure” is described, but the contents are substantially the same. Further, the load condition may be changed to 4.83 kPa (0.7 psi) for measurement.

- Ext is an abbreviation for Extractables and means a water-soluble component (water-soluble component amount). Specifically, it is a value (unit:% by weight) measured by pH titration of 1 g of water absorbent resin powder for 16 hours with respect to 200 g of 0.9 wt% sodium chloride aqueous solution for 16 hours.

- PSD is an abbreviation for Particle Size Distribution and means a particle size distribution measured by sieve classification.

- the weight average particle size (D50) and the particle size distribution width are measured by the same method as “(1) Average Particle Diameter and Distribution of Particle Diameter” described in US Pat. No. 2006-204755.

- liquid permeability The flow of liquid flowing between particles of the swollen water-absorbent resin powder under load or no load is referred to as “liquid permeability”.

- Typical measurement methods for this “liquid permeability” include SFC (Saline Flow Conductivity / Saline Flow Inductivity) and GBP (Gel Bed Permeability / Gel Bed Permeability).

- SFC saline flow inductivity

- GBP liquid permeability of a 0.69 wt% sodium chloride aqueous solution to the water absorbent resin powder under load or free expansion. It is measured according to the GBP test method described in International Publication No. 2005/016393 pamphlet.

- X to Y indicating a range means “X or more and Y or less”.

- t (ton) which is a unit of weight means “Metric ton”

- ppm means “ppm by weight” unless otherwise noted.

- weight and “mass”, “wt%” and “mass%”, “part by weight” and “part by mass” are treated as synonyms.

- ⁇ acid (salt) means “ ⁇ acid and / or salt thereof”

- (meth) acryl means “acryl and / or methacryl”.

- the manufacturing method of the water-absorbing resin powder according to the present invention is a method of foaming in the method of foam polymerization for improving the water absorption speed. Has characteristics.

- air bubbles are uniformly dispersed in the monomer aqueous solution before polymerization, not only the water absorption speed of the resulting water absorbent resin powder is improved, but also the whiteness is improved.

- other expensive physical properties and equipment can be maintained without maintaining or almost damaging other physical properties (liquid permeability, bulk specific gravity, surface tension, water absorption capacity under pressure, impact resistance (damage resistance), etc.) of the water absorbent resin powder. There is no need to use it.

- the production method (first method) of the present invention comprises a polymerization step of an aqueous acrylic acid monomer solution containing air bubbles, and if necessary, gel refinement of a hydrogel crosslinked polymer during or after polymerization.

- the method for producing a polyacrylic acid-based water-absorbent resin powder comprising a step and a drying step of a hydrogel crosslinked polymer, in the presence of a surfactant and / or a dispersant, It includes a bubble generation and containing step of generating and containing bubbles by lowering the solubility of dissolved gas.

- the surfactant may be added before the bubble generation-containing step, it may be performed after the polymerization step, but is preferably performed before the polymerization step.

- the aqueous acrylic acid monomer solution during or after adjustment before the polymerization step contains a surfactant and / or a dispersant, and the aqueous acrylic acid monomer solution

- a method for reducing the solubility of the dissolved gas for example, a method of increasing the temperature of an acrylic acid-based monomer aqueous solution and / or a method of mixing a water-soluble organic substance in an acrylic acid-based monomer aqueous solution. Is mentioned.

- the bubble generation and containing step may be performed after the polymerization step is started because it may be performed until the polymerization step is completed, but it is preferably performed before the polymerization step.

- the method for producing the water-absorbent resin powder of the present invention preferably comprises a step of polymerizing an aqueous acrylic acid monomer solution containing bubbles and, if necessary, a gel of a hydrogel crosslinked polymer after or after polymerization.

- a method for producing a polyacrylic acid-based water-absorbent resin powder comprising a fine graining step and a drying step of a hydrogel crosslinked polymer, wherein an acrylic acid monomer aqueous solution during or after adjustment before the polymerization step Contains a surfactant and / or a dispersant, and includes a step of raising the temperature of the aqueous acrylic acid monomer solution before the polymerization step, and / or a polymerization step A step of mixing a water-soluble organic substance into the acrylic acid monomer aqueous solution before the polymerization step, wherein the acrylic acid monomer aqueous solution before or after adjustment contains a surfactant and / or a dispersant. Including a manufacturing method (third manufacturing method).

- the water-soluble organic substance is acrylic acid, particularly unneutralized acrylic acid, and its water content is preferably 20% by weight or less, more preferably 2% by weight or less, and still more preferably 0. .5% by weight or less.

- the mixing ratio of the aqueous acrylic acid monomer solution containing the surfactant and / or dispersant and the water-soluble organic substance is appropriately determined, and is preferably 1: 9 to 9: 1 by weight, and preferably 2: 8 to 8: 2 is more preferable, and 3: 7 to 7: 3 is particularly preferable.

- the step of reducing the solubility of dissolved gas to generate bubbles, the step of raising the temperature of the acrylic acid monomer aqueous solution, and the step of mixing the water-soluble organic matter are under pressure and under reduced pressure, respectively.

- the atmosphere is substantially atmospheric pressure because of the simplicity of operation, processes and equipment.

- substantially normal pressure means a state of ⁇ 10% with respect to atmospheric pressure, preferably ⁇ 5%, more preferably ⁇ 2%, still more preferably ⁇ 1%, particularly preferably 0. % (Same as atmospheric pressure).

- the range is substantially 0%.

- bubbles are contained by these methods, but preferably, before or after the step of reducing the solubility of the dissolved gas, a step of mixing the inert gas into the acrylic acid monomer aqueous solution is performed. Including.

- the time from the end of the step of reducing the solubility of dissolved gas (the step of generating bubbles) to the start of polymerization in the polymerization step exceeds 0 due to the stability of the generated bubbles. It is preferably within 300 seconds, more preferably within 120 seconds, still more preferably within 60 seconds, and particularly preferably within 30 seconds.

- the above time exceeds 300 seconds, the generated bubbles are united or disappeared before polymerization, and the effect of improving the water absorption rate tends to be small, which is not preferable.

- the “acrylic acid monomer aqueous solution” is an aqueous solution of a monomer mainly composed of acrylic acid and / or a salt thereof described later, and if necessary, a crosslinking agent or other graft component described later, This refers to a composition in which constituents of a water-absorbent resin such as components (chelating agent, surfactant, dispersant) and the like are prepared. In this state, a polymerization initiator is added to be used for polymerization.

- the acrylic acid may be unneutralized or may be a salt type (completely neutralized type or partially neutralized type).

- the monomer aqueous solution may exceed the saturation concentration, and so-called supersaturated aqueous solution of acrylic acid (salt) and aqueous slurry solution (aqueous dispersion) are also included in the category of the acrylic acid-based monomer aqueous solution in the present invention.

- an acrylic acid monomer aqueous solution having a saturated concentration or less is preferably used from the viewpoint of the physical properties of the resulting water-absorbent resin powder.

- the monomer polymerization solvent is water, and the acrylic acid monomer is an aqueous solution.

- the aqueous solution is not limited when 100% by weight of the solvent is water, preferably Even if another water-soluble organic solvent (for example, alcohol) is used in combination with 0 to 30% by weight, more preferably 0 to 5% by weight, it is referred to as an aqueous solution in the present invention.

- the solubility of the gas is reduced (first method), preferably the temperature is increased (second method) or the water-soluble organic substance is mixed (third method) with respect to the aqueous acrylic acid solution.

- a basic aqueous solution for example, caustic soda aqueous solution

- an aqueous acrylic acid solution (acrylic acid + NaOH aqueous solution) is generated at the start of mixing, 100% by weight acrylic acid (water

- neutralization is carried out for no acrylic acid or acrylic acid containing a small amount of water (for example, acrylic acid having a water content of 2% by weight or less) is also included in the first to third methods of the present invention. .

- the adjusted acrylic acid-based monomer aqueous solution before the polymerization step is an acrylic acid-based monomer aqueous solution before being introduced into the polymerization apparatus or acrylic acid before being introduced into the polymerization apparatus and starting polymerization. Refers to an aqueous monomer solution.

- the acrylic acid-based monomer aqueous solution under adjustment (also known as adjustment in the present invention) in the present invention is a mixture of all components in the above-mentioned monomer aqueous solution mainly composed of acrylic acid and / or a salt thereof. It refers to an aqueous solution of the previous acrylic acid or a salt thereof, typically an aqueous solution of an acrylic acid aqueous solution, a partially neutralized or completely neutralized acrylate, or the like.

- the final acrylic acid monomer aqueous solution can be further neutralized, mixed with water as a solvent, or mixed with the above-mentioned trace components with respect to the acrylic acid monomer aqueous solution being adjusted. It is said.

- the acrylic acid monomer aqueous solution in the step of reducing the solubility of dissolved gas to generate and contain bubbles, that is, the step of raising the temperature of the acrylic acid monomer aqueous solution, the acrylic acid monomer aqueous solution

- the solubility of the gas decreases as the temperature rises.

- the temperature increase width is preferably + 5 ° C. or more, more preferably +10 to + 100 ° C., still more preferably +20 to + 90 ° C., and particularly preferably +30 to + 80 ° C. from the amount of bubbles generated.

- the temperature of the monomer aqueous solution before the temperature rise is preferably 0 to 60 ° C., more preferably 20 to 50 ° C.

- the temperature of the aqueous monomer solution after the temperature rise (width) after the temperature rise is preferably 40 to 100 ° C., more preferably in the range described later.

- FIG. 2 and FIG. 4 are schematic flow charts showing temperature rise and bubble generation by typical heat of neutralization.

- the heat of neutralization of acrylic acid is 13.9 [kcal / mol] (25 ° C.)

- the specific heat of water is 1 [cal / ° C./g] (25 ° C.)

- the specific heat of acrylic acid is 0.66 [cal / mol].

- ° C / g] 25 ° C

- the temperature of the acrylic acid aqueous solution is preferably raised by the heat of neutralization of the acrylic acid.

- the range of temperature rise can also be predicted from the heat of neutralization and specific heat.

- the temperature when the temperature is raised by the heat of neutralization of acrylic acid 13.9 [kcal / mol] (25 ° C.), it may be appropriately heated or cooled during the neutralization reaction in order to control the range of the temperature rise.

- the reaction system may be insulated from the neutralization reaction.

- the solubility of the gas is reduced by the temperature rise, and bubbles are generated in the aqueous acrylic acid solution. Bubbles generated by such a mechanism (not particularly limiting the present invention) are very fine compared to the conventional foaming methods described in Patent Documents 18 to 35 and the like, and are further increased by a surfactant and / or a dispersant. It is presumed that the problem of the present invention is solved by stabilization.

- thermo raising method other than the temperature raising method utilizing the heat of neutralization, there is a method of raising the temperature by heating an acrylic acid monomer aqueous solution. What is necessary is just to heat.

- FIG. 1 shows an apparatus diagram (schematic diagram) of a continuous temperature raising method by heating an acrylic acid monomer aqueous solution to which the first method and the second method of the present invention can be applied.

- the apparatus shown in FIG. 1 is an apparatus that can be used in one method for generating bubbles by raising the temperature of an aqueous acrylic acid monomer solution.

- FIG. 6 to FIG. 9 are flowcharts showing the outline of the embodiment of the gas solubility decrease and bubble generation included in the embodiment of the present invention due to the temperature rise. These temperature raising methods may be used in combination, or may be other methods.

- the method for producing a water-absorbent resin powder of the present invention provides a water-absorbent resin powder that improves the water absorption rate (for example, FSR) and maintains liquid permeability (for example, SFC). Therefore, it is preferably provided in a method for producing a water-absorbent resin powder excellent in FSR and SFC, which will be described later, and there is no decrease in other physical properties. Although preferable physical properties are in the ranges described later, the water-absorbing resin powder has a saline flow conductivity (SFC) of 20 [ ⁇ 10 ⁇ 7 ⁇ cm 3 ⁇ sec ⁇ g ⁇ 1 ] or more and a water absorption rate (FSR).

- SFC saline flow conductivity

- FSR and SFC are those described in “(3-3) SFC (saline flow inductivity)” and “(3-5) FSR (water absorption rate)” described later.

- the acrylic acid-based monomer aqueous solution adjusting step is a step of obtaining an acrylic acid-based monomer aqueous solution in which a gas is dispersed. This will be specifically described below.

- the acrylic acid monomer used in the present invention is not particularly limited as long as acrylic acid is used and can be made into a water absorbent resin powder by polymerization.

- Anionic unsaturated monomers such as sulfonic acid, 2- (meth) acryloylethanesulfonic acid, 2- (meth) acryloylpropanesulfonic acid, 2-hydroxyethyl (meth) acryloyl phosphate and salts thereof; Saturated monomers; phenolic hydroxyl group-containing unsaturated monomers; amide group-containing unsaturated monomers such

- the amount of acrylic acid and / or its salt used is 50 mol% or more, preferably 70 mol% or more, based on the total monomer components (excluding internal cross-linking agents described later). More preferably, it is 80 mol% or more, More preferably, it is 90 mol% or more, Most preferably, it is 95 mol% or more (an upper limit is 100 mol%).

- polyacrylic acid is a concept including polyacrylate (especially monovalent salt).

- the neutralization rate of the monomer or polymer thereof is not particularly limited, but the polymerization gel may be neutralized after polymerization, if necessary. In applications that may come into contact with the human body, such as sanitary products, neutralization after polymerization is not required.

- the neutralization rate is preferably 40 to 90 mol%, more preferably 50 to 80 mol%, and still more preferably 60 to 74 mol%. Also from the viewpoint of solving the problems of the present invention, when the neutralization rate is low, the water absorption rate (for example, FSR) tends to decrease, and when the neutralization rate is high, the reactivity of the surface cross-linking agent is decreased.

- an acid group monomer such as acrylic acid or a polymer thereof may be partially or entirely salt type in terms of water absorption capacity without load (CRC) or water absorption rate (FSR), such as sodium salt, lithium salt, Monovalent salts such as potassium salts, ammonium salts and amines, especially alkali metal salts, sodium salts and / or potassium salts are preferred, and sodium salts are more preferred from the viewpoint of cost and physical properties.

- CRC water absorption capacity without load

- FSR water absorption rate

- Monovalent salts such as potassium salts, ammonium salts and amines, especially alkali metal salts, sodium salts and / or potassium salts are preferred, and sodium salts are more preferred from the viewpoint of cost and physical properties.

- an internal cross-linking agent is used as necessary.

- an internal crosslinking agent a conventionally known internal crosslinking agent can be used. Specifically, for example, N, N′-methylenebis (meth) acrylamide, (poly) ethylene glycol di (meth) acrylate, (poly) propylene glycol di (meth) acrylate, trimethylolpropane tri (meth) acrylate, glycerin Tri (meth) acrylate, glycerin acrylate methacrylate, ethylene oxide modified trimethylolpropane tri (meth) acrylate, pentaerythritol hexa (meth) acrylate, triallyl cyanurate, triallyl isocyanurate, triallyl phosphate, triallylamine, poly (meta ) Allyloxyalkane, (Poly) ethylene glycol diglycidyl ether, glycerol diglycidyl ether,

- the amount of the internal cross-linking agent used can be appropriately determined depending on the desired properties of the water-absorbent resin, but is usually preferably 0.001 to 5 mol% with respect to the total amount of the acrylic acid-based monomer. 0.005 to 2 mol% is more preferable, and 0.01 to 1 mol% is still more preferable.

- the amount of the internal cross-linking agent used is less than 0.001 mol%, the water-soluble content of the resulting water-absorbent resin powder is increased, so that there is a possibility that a sufficient amount of water absorption cannot be secured under pressure.

- the amount of the internal cross-linking agent used exceeds 5 mol%, the cross-linking density becomes high, and the water absorption amount of the resulting water-absorbent resin powder may be insufficient.

- the internal crosslinking agent may be added all at once to the reaction system or may be added in portions.

- Bubble dispersion In the method of dispersing bubbles in an aqueous acrylic acid monomer solution, dissolved gas contained in the aqueous solution is generated in the presence of a surfactant and / or a dispersant, and these are effectively made into fine bubbles (microbubbles). Bubbles or nanobubbles).

- a gas for example, an inert gas

- At least one of the following methods (a) and (b) is used as a method for dispersing bubbles in the acrylic acid-based monomer aqueous solution.

- a method for dispersing bubbles in an acrylic acid monomer aqueous solution the temperature of the acrylic acid monomer aqueous solution prepared by mixing the monomer and / or salt thereof, and an internal cross-linking agent and water as required is increased.

- a method of decreasing the solubility of the gas in the aqueous solution by raising the temperature in the adjustment step of the acrylic monomer aqueous solution.

- the temperature of the heated monomer aqueous solution is preferably a high temperature at which the solubility of the gas is lowered, specifically, 40 ° C. to the boiling point of the aqueous solution, more preferably 50 to 100 ° C., and still more preferably 60 ° C. ⁇ 98 ° C, most preferably 70-95 ° C.

- the time required for the temperature rise is preferably 60 seconds or less, more preferably 30 seconds or less, and even more preferably 10 seconds or less, and it is preferable to rapidly warm the monomer aqueous solution in order to generate as many bubbles as possible.

- the heat of neutralization (13.9 [kcal / mol] (25 ° C.)) in the step of increasing the degree of neutralization of the monomer (neutralization) And the like may be used in one-step neutralization or multiple steps (two-step neutralization).

- neutralization may be performed continuously or in batch. Further, it may be performed in one stage up to a predetermined neutralization rate, or may be performed in multiple stages (for example, two stages).

- Two-step neutralization involves adding a base in two steps, and is shown in FIG. 4, Example 2 and the like.

- the gas may be dissolved or dispersed in advance in the aqueous monomer solution before the temperature increase.

- a method for dispersing bubbles in an aqueous acrylic acid monomer solution when the monomer and / or salt thereof, and if necessary, an internal cross-linking agent and water are mixed, the gas is not dissolved, or Examples include a method for reducing the solubility of gas by mixing water-soluble organic substances that are hardly dissolved, aqueous acrylic acid monomers to be mixed, or water-soluble organic substances that do not dissolve in gas compared to water. It is done.

- a compound is used.

- a gas-free monomer solution for example, acrylic acid

- a gas-containing (dissolved) acrylic acid-based monomer aqueous solution a gas that cannot be dissolved in the mixed aqueous solution is generated. It can be dispersed in the aqueous solution as fine bubbles.

- the number average diameter (volume average particle diameter) of the bubbles introduced into the acrylic acid monomer aqueous solution by the method (a) or (b) is preferably 50 ⁇ m or less, and preferably 50 nm (more preferably 10 ⁇ m) to 500 ⁇ m. Is more preferable, and 100 nm (more preferably 10 ⁇ m) to 100 ⁇ m is even more preferable.

- the average diameter of the bubbles is less than 50 nm, the surface area does not increase, so that the water absorption rate may be inferior. Moreover, when an average diameter exceeds 500 micrometers, there exists a possibility that the intensity

- the solubility of gas in water is determined by the type and temperature of the gas. For example, for water at 25 ° C., carbon dioxide (1.05 [ml / ml]), oxygen (0.0285 [ml / ml]) ), Nitrogen (0.0147 [ml / ml]), and the solubility of these gases is reduced by increasing the temperature or mixing with a water-soluble organic substance (preferably acrylic acid). What is necessary is just to make it disperse

- the amount of bubbles is appropriately determined depending on the type of gas and the method of decreasing the solubility (temperature rise range and mixing ratio of water-soluble organic substances).

- the volume of the monomer aqueous solution is preferably 1.01 to 1. It is preferable to disperse the bubbles in the acrylic acid monomer aqueous solution so as to be 1 time, more preferably 1.02 to 1.08 times.

- the bubbles are dispersed by lowering the solubility of the dissolved gas in the aqueous acrylic acid monomer solution. It may be dispersed. That is, the bubbles may be dispersed in the aqueous acrylic acid monomer solution by bubbles dispersed with a reduced solubility, or bubbles dispersed with a gas introduced from the outside if necessary.

- examples of the gas constituting the bubbles dispersed in the aqueous acrylic acid monomer solution include oxygen, air, nitrogen, carbon dioxide, ozone, and mixtures thereof. Preferably, nitrogen, carbon dioxide, etc. An inert gas is used.

- air and nitrogen are particularly preferable in view of polymerizability and cost.

- the pressure at the time of introducing the gas or after the introduction is appropriately determined by normal pressure, pressurization, and decompression.

- a preferable introduction method when introducing gas from the outside is the method described in Japanese Patent Application No. 2009-292318 (application date: December 24, 2009) and its priority application PCT / JP2010 / 001004. In the following, “(2-1-4) Gas introduction method”.

- such gas dissolution and / or dispersion may be performed before or after the bubble generation and inclusion process described above.

- bubbles can be introduced more stably through a step of reducing the solubility of the present invention.

- the method of introducing microbubbles includes (a) a monomer aqueous solution and gas pressurization method, (b) monomer aqueous solution and gas swirl flow formation method, (c) Examples thereof include at least one method selected from a method of mixing a gas through a pore with a monomer aqueous solution.

- a monomer aqueous solution and gas pressurization method includes (a) a monomer aqueous solution and gas pressurization method, (b) monomer aqueous solution and gas swirl flow formation method, (c) Examples thereof include at least one method selected from a method of mixing a gas through a pore with a monomer aqueous solution.

- each method will be described.

- (A) Pressurization of monomer aqueous solution and gas As a method for introducing microbubbles, a pressure dissolution method by pressurization of the monomer aqueous solution and gas is preferably used.

- the gas is preferably pressurized and dissolved in the liquid at an absolute pressure of about 100 to 1000 kPa (absolute pressure), more preferably about 200 to 400 kPa, and particularly preferably about 250 to 350 kPa.

- absolute pressure absolute pressure

- p HC

- a shearing force to the monomer aqueous solution and gas mixture before or during pressurization, if necessary.

- a high speed rotating pump or the like is used to apply the shearing force.

- the gas is finely dispersed by a shearing force and is preferably further pressurized. After applying the shearing force to the monomer aqueous solution and the gas, the gas is pressurized to 0.1 to 1 MPa, and further released under pressure as described later. .

- the concentration of the gas component in the acrylic acid monomer aqueous solution in which the gas is dissolved and / or dispersed as described above is 1.01 to 10 times the saturation solubility of the gas at a predetermined temperature. Preferably, it is 1.05 to 5 times, more preferably 1.06 to 3 times.

- (B) Formation of monomer aqueous solution and gas swirl flow As another method for introducing microbubbles, formation of monomer aqueous solution and gas swirl flow is preferable.

- This method is a method in which gas-liquid two-phase fluid is swirled and bubbles are dispersed at the outlet (discharge port of the mixer), and the ratio of gas flow rate to liquid flow rate is preferably 1/7 to 1/15.

- the speed is preferably 10 to 10,000 revolutions per second, more preferably 100 to 1,000 revolutions.

- swirling microbubble generator examples include, for example, International Publication No. 00/69550, Japanese Patent Publication “JP 2003-205228”, “JP 2000-447”, and “JP 2006-”. No. 116365 ”etc., but is not particularly limited.

- (C) Mixing of gas through pores into monomer aqueous solution

- a method of introducing microbubbles a method of generating bubbles from pores of various porous materials, membranes, filters, etc. 2 O—CaO—Al 2 O 3 —B 2 O 3 —SiO 2 -based glass) or the like is used, and a surfactant in the range described later such as higher than 0 and 0.03% by weight or less is preferably used.

- the said method can be performed using Kinoshita Rika Kogyo Co., Ltd. Kinoshita type

- Microbubble generator In order to introduce microbubbles, a microbubble generator having a function of pressurizing an aqueous monomer solution and an inert gas or generating a swirling flow may be used. By this operation, the generated microbubbles can be suspended and held in the monomer aqueous solution until the start of polymerization.

- microbubble generator that can be used in the method according to the present invention is not particularly limited, and commercially available devices can be used. An example of a commercial product is illustrated below.

- OHR line mixer OHR Fluid Engineering Laboratory Co., Ltd.

- M-type microbubble generator Na planet Research Laboratories

- Microbubble generator for business use SMB-450 type Ishimaru Trading Co., Ltd.

- Microbubble generator Mbelife Kansai Autome Equipment Co., Ltd.

- Sphere built-in type bubble generator MBG type Nishida Tekko Co., Ltd.

- Pomparator Teikoku Electric Manufacturing Co., Ltd.

- the microbubble generator has a water inlet and a water outlet. When liquid (water or monomer) flows into the water inlet at a certain pressure or higher, the gas mixed inside the water Are collected in the center due to the density difference, and a gas axis is formed.

- the number average diameter of the microbubbles generated by the microbubble generator is preferably 50 nm (more preferably 10 ⁇ m) to 500 ⁇ m, more preferably 100 nm (more preferably 10 ⁇ m) to 100 ⁇ m.

- the average diameter of the bubbles is less than 50 nm, the surface area does not increase, so that the water absorption rate may be inferior.

- an average diameter exceeds 500 micrometers there exists a possibility that the intensity

- the throughput of the microbubble generator can be set as appropriate depending on the desired properties of the water-absorbent resin powder, but it is desirable to increase the flow rate of the aqueous monomer solution.

- the flow rate of the monomer aqueous solution is preferably 500 [kg / hr], more preferably 1000 [kg / hr], and still more preferably 2000 [kg / hr].

- the production amount per hour is not limited to the use of the microbubble generator, and the production method of the present invention is generally suitably applicable for industrial huge scale production. Although an upper limit is determined suitably, Preferably it is the said range (for example, 300 ton / hr or less). Therefore, the production method of the present invention is preferably applicable to continuous production, particularly continuous production of the production amount.

- Static mixer system Static mixer that has no moving parts and is mixed when fluid passes through an element fixed inside the tube, or a mushroom-like shape attached to the spiral flow guide and tube inside the circular tube

- An OHR mixer in which microbubbles are generated by crushing a gas-liquid two-phase flow that flows in a swirling manner by the protrusions of the above-mentioned projections.

- Cavitation method There is a method of generating microbubbles by deforming the flow path so that cavitation is intentionally generated in the gas distributor.

- Venturi method There is a method in which, when gas and liquid are simultaneously flowed through the straw section (throttle), large bubbles are blasted by shock waves generated by a sudden change in the liquid flow velocity, and microbubbles are generated.

- Rotating type A method in which a stirring blade is rotated at a high speed, gas is self-supplied, and microbubbles are generated can be mentioned.

- Ultrasonic method A method of generating microbubbles by appropriately setting an ultrasonic frequency, a pressure amplitude and the like can be mentioned.

- Electrolytic decomposition method There is a method of generating micro-order bubbles by electrolysis of water.

- the gas-liquid consisting of the monomer aqueous solution and gas is sheared, and the shearing method includes (3) centrifugal pump And a static mixer having a combination of shearing and swirling flow represented by an OHR mixer.

- one or more of the methods (a) to (c) and (1) to (8) can be applied, preferably (a) or (b), more preferably (a). If necessary, a shearing force generated by a microbubble generator may be applied.

- the gas and the monomer aqueous solution are pressurized beyond the atmospheric pressure (preferably, the range described in (a) above, the absolute pressure).

- the amount and size of the bubbles are controlled by opening to atmospheric pressure (or reduced pressure, in particular, slightly reduced pressure within ⁇ 10 mmHg). It is preferable to control the bubbles by controlling the pressure, temperature and opening time, particularly the opening time. With such control, it is possible to obtain a water-absorbing resin having high liquid permeability and high impact resistance at a target high water absorption speed.

- the above-mentioned (a) to (c) and various microbubbles may be used when preparing an aqueous monomer solution by mixing the acrylic acid or a salt thereof, a solvent, a crosslinking agent, and a polymerization initiator. What is necessary is just to set it as a pressurized state in a generator, ie, the pressure which exceeds atmospheric pressure in piping or an apparatus, and supply the said monomer aqueous solution to a superposition

- T1 is the time from the release of atmospheric pressure to the start of polymerization.

- T is the time from when atmospheric pressure is released until the kaolin turbidity returns to the value before the gas is dissolved or dispersed in the monomer aqueous solution.

- T1 is defined by the white turbidity of the monomer aqueous solution (derived from the formation of the polymer) or the temperature rise (1 ° C. or more) due to the heat of polymerization, and T is the initiator using a 100 ml graduated cylinder as described later. It can be defined by the time (T) until bubbles are dispersed in an aqueous monomer solution not contained and allowed to stand at room temperature under atmospheric pressure until the cloudiness derived from the bubbles disappears.

- the white turbidity is usually derived from a large bubble having a wavelength longer than that of visible light, and the fact that the inclusion of nanobubbles does not substantially affect the white turbidity is also described in the following turbidity (kaolin turbidity).

- the lower limit of T1 is appropriately determined, but is preferably a defoaming time described later (preferably 5 seconds or more, more preferably 10 to 3600 seconds), and the upper limit is a monomer composition including the amount of surfactant. Determined by the method of bubble inclusion.

- a gas can be introduced from the outside into the acrylic acid monomer aqueous solution as necessary.

- the present invention is not limited to the step of reducing the solubility of the gas. It is important that the dissolved gas becomes bubbles.

- the solubility of the gas is lowered by raising the temperature of the acrylic monomer aqueous solution or mixing the water-soluble organic substance, and bubbles are dispersed or dissolved in the monomer aqueous solution.

- the amount of dissolved gas before the operation for reducing the solubility of the gas is large.

- the dissolved gas in the aqueous monomer solution is preferably more than 1 ppm before the operation for reducing the solubility of the gas, more preferably 2 to 50,000 ppm, more preferably 3 to 30,000 ppm, most preferably 3 to 10,000 ppm.

- the amount of these gases is appropriately determined depending on the type of gas, temperature, composition of the acrylic monomer aqueous solution, and the like.

- bubbles can be stably suspended by using a surfactant and / or a dispersant.

- the water absorbing resin powder which has a desired physical property can be obtained by adjusting suitably the kind and quantity of surfactant and / or a dispersing agent.

- the surfactant is a non-polymer surfactant and the dispersant is a polymer dispersant.

- the amount of the surfactant and / or dispersant used is appropriately determined depending on the type, but preferably the surface tension of the water-absorbent resin powder obtained is 60 [mN / m] or more, and further described in “(3 The amount is preferably within the range indicated by “-7) surface tension”.

- the surface tension of the water-absorbent resin powder obtained is less than 60 [mN / m], the amount of return tends to increase when used with paper diapers, which is not preferable.

- reactive or polymerizable surfactants such as water-absorbent resin powder and its monomers, such as unsaturated polymerizable groups (particularly ⁇ , ⁇ -unsaturated double bonds) and reactions

- a surfactant having a functional group hydroxyl group or amino group

- a hydrophilic surfactant having high solubility in water for example, HLB is 1 to 18, particularly preferably 8 to 15 is also suitable.

- the type of the surfactant used in the present invention is not particularly limited.

- anionic surfactants, nonionic surfactants, cationic surfactants, amphoteric surfactants, fluorine-based surfactants examples thereof include organic metal surfactants, and specific examples include surfactants described in Patent Document 28 (International Publication No. WO 97/017397) or Patent Document 30 (US Pat. No. 6,107,358).

- the amount of these surfactants used is typically greater than 0 based on the monomers used, although it depends on the type of surfactant used and the desired physical properties (especially water absorption rate and surface tension). 2% by weight or less, preferably 0.03% by weight or less, more preferably more than 0 and 0.015% by weight, more preferably more than 0 and 0.01% by weight or less, most preferably more than 0 and 0.008% by weight % Or less.

- the amount of the surfactant used can be applied to the water-absorbent resin powder, and if necessary, as a final product obtained after coating with the surfactant described in “(2-7) Surface coating step” described later.

- the present invention can also be applied to water absorbent resin powder.

- the surfactant is too much, it may be difficult to control foaming, and the surface tension of the resulting water-absorbent resin powder will be excessively lowered, resulting in an increase in the amount of return. It is not preferred for actual use in diapers.

- a very small amount of surfactant improves the transportability and damage resistance of the resulting water-absorbent resin powder, and as a result, improves the physical properties of the water-absorbent resin powder after surface cross-linking and after powder transport.

- the surfactant is preferably used in an amount of more than 0 ppm, more preferably 0.1 ppm or more, and even more preferably 1 ppm or more.

- usable surfactants are not particularly limited including those exemplified in Patent Document 28 and Patent Document 30, but nonionic surfactants, anionic surfactants, and cationic surfactants.

- Various agents and amphoteric surfactants can be used, and they may have a polymerizable or reactive group with the monomer of the water absorbent resin powder.

- Nonionic surfactants include, for example, polyoxyalkylene alkyl ethers such as polyoxyethylene lauryl ether, polyoxyethylene cetyl ether, polyoxyethylene stearyl ether, polyoxyethylene oleyl ether; polyoxyethylene octyl phenyl ether, polyoxy Polyoxyalkylene alkyl phenyl ethers such as ethylene nonyl phenyl ether; polyoxyalkylene alkyl amino ethers such as polyoxyethylene lauryl amino ether and polyoxyethylene stearyl amino ether; sorbitan monolaurate, sorbitan monopalmitate, sorbitan monostearate, Sorbitan fatty acid esters such as sorbitan monooleate; polyoxyethylene sorbitan monolaurate Polyoxyalkylene sorbitan monopalmitate, polyoxyethylene sorbitan monostearate, polyoxyalkylene sorbitan fatty acid ester such as polyoxyethylene sorbitan monoole

- anionic surfactant examples include sodium polyoxyethylene lauryl ether sulfate, sodium polyoxyethylene octylphenyl ether sulfate, sodium polyoxyethylene nonylphenyl ether sulfate, triethanolamine lauryl sulfate, sodium lauryl sulfate, potassium lauryl sulfate.

- Sulfate salts such as ammonium lauryl sulfate; sulfonates such as sodium dodecylbenzene sulfonate, sodium alkylnaphthalene sulfonate and sodium dialkylsulfosuccinate; anionic surfactants represented by phosphate ester salts such as potassium alkyl phosphate Agents.

- cationic surfactant examples include cationic surfactants represented by quaternary ammonium salts such as lauryltrimethylammonium chloride, stearyltrimethylammonium chloride, cetyltrimethylammonium chloride, and stearyltrimethylammonium chloride. .

- silicone surfactants include anionic, nonionic, and cationic silicone surfactants, and polyoxyalkylene-modified silicone surfactants. Specifically, modified with polyoxyethylene-modified dimethylpolysiloxane, polyoxyethylene / polyoxypropylene block or random copolymer-modified dimesyl polysiloxane, and polyoxyethylene having an alkyl group having 1 to 12 carbon atoms at the terminal Dimethylpolysiloxane modified, dimethylpolysiloxane modified with block or random copolymer of polyoxyethylene / polyoxypropylene having an alkyl group having 1 to 12 carbon atoms at the end, end of dimethylpolysiloxane and / or inside of molecule And the above-mentioned polyoxyalkylene-modified products of dimethylpolysiloxane derivatives having amino groups, epoxy groups and the like.

- Polyoxyethylene-modified dimethylpolysiloxane, polyoxyethylene / polyoxypropylene block or random copolymer-modified dimesyl polysiloxane are preferable, and polyoxyethylene-modified dimethylpolysiloxane is more preferable because it can be obtained industrially at low cost. Oxyethylene-modified dimethylpolysiloxane.

- surfactants may be used alone or in combination of two or more thereof, or may be used in combination with a dispersant described below (particularly, a polymer dispersant).

- a dispersant described below (particularly, a polymer dispersant).

- anionic surfactants, nonionic surfactants or silicone surfactants, and further, nonionic surfactants or silicone surfactants may be used from the viewpoint of effects. preferable.

- the acrylic monomer aqueous solution during or after adjustment before the polymerization step includes a dispersant, and the dispersant is a hydrophilic polymer dispersant exhibiting water absorption. More preferably, it is a water-soluble polymer dispersant, and its weight average molecular weight is appropriately determined depending on the type of the dispersant, but is preferably 500 to 10 million, more preferably 5,000 to 500. 10,000, particularly preferably about 10,000 to 3,000,000.

- dispersants are not particularly limited.

- starch, starch derivatives, cellulose, cellulose derivatives, polyvinyl alcohol, carboxymethyl cellulose (sodium), hydroxyethyl cellulose, polyacrylic acid (salt), polyacrylic acid (Salt) Hydrophilic polymers such as cross-linked products are exemplified, and among these, a water-soluble polymer dispersant selected from starch, cellulose, and PVA is preferable from the viewpoint of the effect of the present invention.

- the amount of the dispersant used is preferably more than 0 parts by weight and 50 parts by weight or less, more preferably 0.01 to 20 parts by weight, still more preferably 0.05 to 10 parts by weight with respect to 100 parts by weight of the monomer. Parts, most preferably 0.1 to 5 parts by weight.

- the amount of the dispersant is similarly applied to the water-absorbent resin powder as a hydrophilic polymer dispersant used in place of the water-soluble polymer. If the amount of the dispersant is too large, it may be difficult to control foaming, and the absorbent capacity of the resulting water-absorbent resin powder is lowered, which is not preferable for actual use in a paper diaper.

- a polymerization inhibitor is preferably contained during the polymerization.

- the polymerization inhibitor include N-oxyxyl compounds, manganese compounds and substituted phenol compounds exemplified in International Publication No. 2008/096713, preferably substituted phenols, particularly methoxyphenols.

- methoxyphenols that can be preferably used include o, m, p-methoxyphenol and methoxy having one or more substituents such as a methyl group, a t-butyl group, and a hydroxyl group.

- Phenols are exemplified, and in the present invention, p-methoxyphenol is particularly preferable.

- the content of methoxyphenols may be 10 to 200 ppm, preferably 5 to 160 ppm, more preferably 10 to 160 ppm, still more preferably 10 to 100 ppm, particularly preferably 10 to 80 ppm, and most preferably 10 to 70 ppm. It is.

- the monomer aqueous solution preferably contains 10 to 200 ppm, more preferably p-methoxyphenol within the above range. It is preferable.

- bubbles generated by such a mechanism are very fine, and further stabilized by a surfactant and / or a dispersing agent, so that the liquid can be further passed at a high water absorption rate. It is possible to provide a white water-absorbing resin powder having excellent properties.

- the degassing (deoxygenation) of the aqueous monomer solution described in Patent Documents 1 and 3 with a simple inert gas does not stabilize the bubbles during polymerization, and does not solve the problem of the present invention.

- reducing the solubility of a gas refers to an operation for reducing the solubility of the same gas, and is a different concept from a degassing operation for removing dissolved oxygen (substituting oxygen with an inert gas).

- the aqueous solution in the presence of a surfactant and / or a dispersant, the aqueous solution is heated or mixed with a poor solvent (preferably acrylic acid) in the aqueous solution to lower the solubility of the dissolved gas and generate bubbles to disperse. This is a completely new foaming method.

- degassing substitution of dissolved oxygen and inert gas

- the dissolved oxygen is preferably 1 ppm or less, more preferably 0.5 ppm or less.

- a gas introduction step shown in “(2-1-3) Gas” may be provided separately.

- polymerization with a monomer slurry is a physical property (water absorption capacity, water-soluble content). , Residual monomer, etc.) may decrease. Therefore, preferably, when the monomer is an acid group-containing monomer, the neutralization rate is such that the neutralized salt does not precipitate in the aqueous monomer solution. That is, not an aqueous dispersion of an acrylic acid monomer, but preferably an aqueous acrylic acid monomer solution is polymerized in the present invention. Precipitation of the neutralized salt is determined by the solubility of the neutralized salt in water, such as the monomer concentration, neutralization rate, temperature, pressure, and neutralizing base. It depends on the conditions and is appropriately determined.

- the present invention preferably further includes a defoaming step.

- a defoaming step By including the defoaming step, large bubbles are sequentially removed from the monomer, and excessive foaming and a decrease in bulk specific gravity are suppressed.

- the defoaming time is preferably 5 seconds or more, more preferably 10 seconds to 60 minutes, further preferably 30 seconds to 30 minutes, and particularly preferably 60 seconds to 20 minutes. It is adjusted so as to leave the desired fine bubbles in the monomer aqueous solution.

- the size of bubbles in the aqueous monomer solution after the defoaming step is preferably 100 ⁇ m or less, more preferably 50 ⁇ m or less, still more preferably 20 ⁇ m or less, and particularly preferably 5 ⁇ m or less in terms of volume average diameter.

- the expansion ratio of the monomer aqueous solution after the defoaming step relative to the monomer aqueous solution before the bubble dispersion step is preferably 1.1 times or less, more preferably 1.05 or less, and still more preferably 1.02 or less. Particularly preferably, it is 1.01 or less, and usually the lower limit exceeds 1.

- the defoaming step used in the present invention may be a known technique, such as the method described in US Pat. No. 6,667,372 or the method described in Techno Systems Publishing Co., Ltd. “Foam Engineering First Edition”, pages 759-774. Etc.

- the defoaming step is preferably performed by circulating a monomer aqueous solution containing a circulating air flow to the circulation tank.

- the upper space of the circulation tank preferably contains 1% by volume or more of oxygen.

- at least a part of the monomer aqueous solution is supplied to the polymerization step through the neutralization step or the neutralization step from the step of circulating the monomer aqueous solution containing the air flow and the circulation line, and is polymerized.

- the aqueous monomer solution may be degassed by accumulating bubbles by allowing the monomer aqueous solution to stand by for a certain period of time in the pipe or in the polymerization apparatus until the start of polymerization.

- the monomer aqueous solution preferentially containing fine bubbles obtained

- a polymerization initiator or irradiation with ultraviolet rays may be performed.

- the resulting water-absorbent resin powder is scale-like or the bulk specific gravity is excessively reduced (for example, 0.5 [g / cm 3 ] or less).

- liquid permeability and impact resistance are also reduced.

- any of these defoaming methods may be used, but the purpose is to obtain an aqueous monomer solution preferentially containing fine bubbles after defoaming mainly on large bubbles. Not intended. In this way, the water-absorbent resin powder obtained through the defoaming step becomes a porous polymer having fine and uniform pores.

- microbubbles (fine bubbles) generated through the defoaming step are performed by the concentrated ions acting on the bubble interface, generating a repulsive force of static electricity, and preventing the gas from escaping.

- Nanobubbles may be generated by crushing microbubbles by a self-pressurizing effect or an adiabatic compression effect.

- the rising speed is 5400 [ ⁇ m / s] and the internal pressure is 1.04 ⁇ 10 5 Pa.

- the rising speed is 54 [ ⁇ m / s]

- the internal pressure is 1.31 ⁇ 10 5 Pa

- the rising speed is 0.54 [ ⁇ m / s] and the internal pressure is 3.95 ⁇ 10 5 Pa.

- the expansion ratio of the volume of the aqueous monomer solution in the polymerization step relative to the volume of the aqueous monomer solution before the bubble generation-containing step is preferably 1.1 times or less, more preferably 1.05 times or less, and still more preferably 1. It is 02 times or less, particularly preferably 1.01 times or less, and most preferably 1.00 times (preferably more than 1).

- a method for polymerizing by dispersing a large amount of bubbles has been known.

- polymerization is performed without excessively dispersing bubbles by using the above technique, so that there is almost no decrease in bulk specific gravity.