JP5412759B2 - エピタキシャルウェーハの保持具及びそのウェーハの製造方法 - Google Patents

エピタキシャルウェーハの保持具及びそのウェーハの製造方法 Download PDFInfo

- Publication number

- JP5412759B2 JP5412759B2 JP2008197723A JP2008197723A JP5412759B2 JP 5412759 B2 JP5412759 B2 JP 5412759B2 JP 2008197723 A JP2008197723 A JP 2008197723A JP 2008197723 A JP2008197723 A JP 2008197723A JP 5412759 B2 JP5412759 B2 JP 5412759B2

- Authority

- JP

- Japan

- Prior art keywords

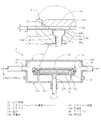

- wafer

- lift

- lift pin

- susceptor

- hole

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H10P72/7612—

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68742—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by a lifting arrangement, e.g. lift pins

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/24—Deposition of silicon only

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/458—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for supporting substrates in the reaction chamber

- C23C16/4582—Rigid and flat substrates, e.g. plates or discs

- C23C16/4583—Rigid and flat substrates, e.g. plates or discs the substrate being supported substantially horizontally

- C23C16/4586—Elements in the interior of the support, e.g. electrodes, heating or cooling devices

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/46—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for heating the substrate

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B25/00—Single-crystal growth by chemical reaction of reactive gases, e.g. chemical vapour-deposition growth

- C30B25/02—Epitaxial-layer growth

- C30B25/12—Substrate holders or susceptors

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B29/00—Single crystals or homogeneous polycrystalline material with defined structure characterised by the material or by their shape

- C30B29/02—Elements

- C30B29/06—Silicon

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67098—Apparatus for thermal treatment

- H01L21/67115—Apparatus for thermal treatment mainly by radiation

-

- H10P72/0436—

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1016—Apparatus with means for treating single-crystal [e.g., heat treating]

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Metallurgy (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Power Engineering (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Computer Hardware Design (AREA)

- Manufacturing & Machinery (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

- Chemical Vapour Deposition (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008197723A JP5412759B2 (ja) | 2008-07-31 | 2008-07-31 | エピタキシャルウェーハの保持具及びそのウェーハの製造方法 |

| DE112009001826.2T DE112009001826B4 (de) | 2008-07-31 | 2009-07-24 | Herstellungsverfahren für einen epitaktischen Wafer und die dabei zum Halten des Wafer verwendete Haltevorrichtung |

| PCT/JP2009/063243 WO2010013646A1 (ja) | 2008-07-31 | 2009-07-24 | エピタキシャルウェーハの製造方法及びそれに用いられるウェーハの保持具 |

| US13/003,440 US8980001B2 (en) | 2008-07-31 | 2009-07-24 | Method for manufacturing epitaxial wafer and wafer holder used in the method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008197723A JP5412759B2 (ja) | 2008-07-31 | 2008-07-31 | エピタキシャルウェーハの保持具及びそのウェーハの製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010034476A JP2010034476A (ja) | 2010-02-12 |

| JP2010034476A5 JP2010034476A5 (enExample) | 2011-09-15 |

| JP5412759B2 true JP5412759B2 (ja) | 2014-02-12 |

Family

ID=41610345

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008197723A Active JP5412759B2 (ja) | 2008-07-31 | 2008-07-31 | エピタキシャルウェーハの保持具及びそのウェーハの製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US8980001B2 (enExample) |

| JP (1) | JP5412759B2 (enExample) |

| DE (1) | DE112009001826B4 (enExample) |

| WO (1) | WO2010013646A1 (enExample) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5698043B2 (ja) * | 2010-08-04 | 2015-04-08 | 株式会社ニューフレアテクノロジー | 半導体製造装置 |

| CN102747418B (zh) * | 2012-07-25 | 2015-12-16 | 东莞市天域半导体科技有限公司 | 一种高温大面积碳化硅外延生长装置及处理方法 |

| JP6017328B2 (ja) * | 2013-01-22 | 2016-10-26 | 東京エレクトロン株式会社 | 載置台及びプラズマ処理装置 |

| JP5999511B2 (ja) * | 2013-08-26 | 2016-09-28 | 信越半導体株式会社 | 気相エピタキシャル成長装置及びそれを用いたエピタキシャルウェーハの製造方法 |

| JP6153095B2 (ja) * | 2014-12-19 | 2017-06-28 | 信越半導体株式会社 | エピタキシャルウェーハの製造方法 |

| KR101548903B1 (ko) * | 2015-03-19 | 2015-09-04 | (주)코미코 | 리프트 핀 및 이의 제조 방법 |

| JP6424726B2 (ja) | 2015-04-27 | 2018-11-21 | 株式会社Sumco | サセプタ及びエピタキシャル成長装置 |

| TWI615917B (zh) * | 2015-04-27 | 2018-02-21 | Sumco股份有限公司 | 承托器及磊晶生長裝置 |

| JP6539929B2 (ja) | 2015-12-21 | 2019-07-10 | 昭和電工株式会社 | ウェハ支持機構、化学気相成長装置およびエピタキシャルウェハの製造方法 |

| JP6500792B2 (ja) * | 2016-01-25 | 2019-04-17 | 株式会社Sumco | エピタキシャルウェーハの品質評価方法および製造方法 |

| KR20240145054A (ko) * | 2016-03-28 | 2024-10-04 | 어플라이드 머티어리얼스, 인코포레이티드 | 서셉터 지지부 |

| TWI729101B (zh) * | 2016-04-02 | 2021-06-01 | 美商應用材料股份有限公司 | 用於旋轉料架基座中的晶圓旋轉的設備及方法 |

| JP2018026503A (ja) * | 2016-08-12 | 2018-02-15 | 株式会社Sumco | サセプタ、エピタキシャル成長装置、及びエピタキシャルウェーハの製造方法 |

| US20180102247A1 (en) * | 2016-10-06 | 2018-04-12 | Asm Ip Holding B.V. | Substrate processing apparatus and method of manufacturing semiconductor device |

| CN106607320B (zh) * | 2016-12-22 | 2019-10-01 | 武汉华星光电技术有限公司 | 适用于柔性基板的热真空干燥装置 |

| KR102262311B1 (ko) * | 2017-02-02 | 2021-06-07 | 가부시키가이샤 사무코 | 리프트 핀, 당해 리프트 핀을 이용한 에피택셜 성장 장치 및 실리콘 에피택셜 웨이퍼의 제조 방법 |

| US10755955B2 (en) * | 2018-02-12 | 2020-08-25 | Applied Materials, Inc. | Substrate transfer mechanism to reduce back-side substrate contact |

| US11121019B2 (en) | 2018-06-19 | 2021-09-14 | Kla Corporation | Slotted electrostatic chuck |

| KR102640172B1 (ko) | 2019-07-03 | 2024-02-23 | 삼성전자주식회사 | 기판 처리 장치 및 이의 구동 방법 |

| JP7192756B2 (ja) * | 2019-12-19 | 2022-12-20 | 株式会社Sumco | 気相成長装置及び気相成長方法 |

| JP7519784B2 (ja) * | 2020-02-19 | 2024-07-22 | グローバルウェーハズ・ジャパン株式会社 | シリコンウェーハの製造方法 |

| FI130021B (en) | 2021-05-10 | 2022-12-30 | Picosun Oy | Substrate processing apparatus and method |

| US20220364263A1 (en) * | 2021-05-12 | 2022-11-17 | Applied Materials, Inc. | Low mass substrate support |

| TWI779896B (zh) * | 2021-10-22 | 2022-10-01 | 環球晶圓股份有限公司 | 晶圓治具、晶圓結構及晶圓的加工方法 |

| US20240363390A1 (en) * | 2023-04-26 | 2024-10-31 | Applied Materials, Inc. | Gas flow substrate supports, processing chambers, and related methods and apparatus, for semiconductor manufacturing |

| US20250259878A1 (en) * | 2024-02-14 | 2025-08-14 | Applied Materials, Inc. | Lift pin assembly for a susceptor of a processing chamber |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6596086B1 (en) * | 1998-04-28 | 2003-07-22 | Shin-Etsu Handotai Co., Ltd. | Apparatus for thin film growth |

| JP3092801B2 (ja) * | 1998-04-28 | 2000-09-25 | 信越半導体株式会社 | 薄膜成長装置 |

| JP4402763B2 (ja) * | 1999-05-13 | 2010-01-20 | Sumco Techxiv株式会社 | エピタキシャルウェーハ製造装置 |

| JP2001313329A (ja) * | 2000-04-28 | 2001-11-09 | Applied Materials Inc | 半導体製造装置におけるウェハ支持装置 |

| KR20040008193A (ko) * | 2001-05-30 | 2004-01-28 | 에이에스엠 아메리카, 인코포레이티드 | 저온 로딩 및 소성 |

| US20030178145A1 (en) * | 2002-03-25 | 2003-09-25 | Applied Materials, Inc. | Closed hole edge lift pin and susceptor for wafer process chambers |

| JP3908112B2 (ja) * | 2002-07-29 | 2007-04-25 | Sumco Techxiv株式会社 | サセプタ、エピタキシャルウェーハ製造装置及びエピタキシャルウェーハ製造方法 |

| EP1670044A4 (en) * | 2003-10-01 | 2007-03-21 | Shinetsu Handotai Kk | METHOD OF MANUFACTURING SILICON EPITAXIAL WAFERS AND SILICON EPITAXIAL WAFERS |

| JP2005311108A (ja) * | 2004-04-22 | 2005-11-04 | Shin Etsu Handotai Co Ltd | 気相成長装置 |

| US20070089836A1 (en) * | 2005-10-24 | 2007-04-26 | Applied Materials, Inc. | Semiconductor process chamber |

| CN101847574B (zh) * | 2006-01-31 | 2012-11-07 | 东京毅力科创株式会社 | 基板处理装置和暴露于等离子体的部件 |

| JP4861208B2 (ja) * | 2006-01-31 | 2012-01-25 | 東京エレクトロン株式会社 | 基板載置台および基板処理装置 |

| JP4868503B2 (ja) * | 2006-03-30 | 2012-02-01 | Sumco Techxiv株式会社 | エピタキシャルウェーハの製造方法 |

| US8021484B2 (en) * | 2006-03-30 | 2011-09-20 | Sumco Techxiv Corporation | Method of manufacturing epitaxial silicon wafer and apparatus therefor |

| JP2010016312A (ja) * | 2008-07-07 | 2010-01-21 | Sumco Corp | エピタキシャルウェーハの製造方法 |

| JP5141541B2 (ja) * | 2008-12-24 | 2013-02-13 | 株式会社Sumco | エピタキシャルウェーハの製造方法 |

-

2008

- 2008-07-31 JP JP2008197723A patent/JP5412759B2/ja active Active

-

2009

- 2009-07-24 US US13/003,440 patent/US8980001B2/en active Active

- 2009-07-24 DE DE112009001826.2T patent/DE112009001826B4/de active Active

- 2009-07-24 WO PCT/JP2009/063243 patent/WO2010013646A1/ja not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| DE112009001826T5 (de) | 2011-06-09 |

| JP2010034476A (ja) | 2010-02-12 |

| US20110114014A1 (en) | 2011-05-19 |

| DE112009001826B4 (de) | 2016-02-25 |

| WO2010013646A1 (ja) | 2010-02-04 |

| US8980001B2 (en) | 2015-03-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5412759B2 (ja) | エピタキシャルウェーハの保持具及びそのウェーハの製造方法 | |

| JP5092975B2 (ja) | エピタキシャルウェーハの製造方法 | |

| JP4798163B2 (ja) | エピタキシャル成長用サセプタ | |

| CN102144280B (zh) | 具有变化热阻的晶片载体 | |

| CN107851560B (zh) | 基座、外延生长装置、及外延晶圆 | |

| CN107851561B (zh) | 基座及外延生长装置 | |

| EP2037485B1 (en) | Fabrication apparatus and fabrication method of semiconductor device produced by heating a substrate | |

| TWI396250B (zh) | 晶座、半導體製造裝置及半導體製造方法 | |

| JP2024133383A (ja) | サセプタ | |

| US9708732B2 (en) | Susceptor with groove provided on back surface and method for manufacturing epitaxial wafer using the same | |

| JP5446760B2 (ja) | エピタキシャル成長方法 | |

| JP3092801B2 (ja) | 薄膜成長装置 | |

| KR20130097184A (ko) | 개선된 웨이퍼 캐리어 | |

| JP5161748B2 (ja) | 気相成長用サセプタ及び気相成長装置並びにエピタキシャルウェーハの製造方法 | |

| US10184193B2 (en) | Epitaxy reactor and susceptor system for improved epitaxial wafer flatness | |

| JP5098873B2 (ja) | 気相成長装置用のサセプタ及び気相成長装置 | |

| JP2005056984A (ja) | 気相成長装置及び気相成長方法 | |

| JP3594074B2 (ja) | シリコンエピタキシャルウェーハおよびその製造方法 | |

| JP2019096639A (ja) | サセプタ、エピタキシャルウェーハの製造方法 | |

| JP2002033284A (ja) | 縦型cvd用ウェハホルダー | |

| JP2006041028A (ja) | サセプタ、およびエピタキシャルウェーハの製造方法 | |

| TWI835249B (zh) | 一種用於晶圓磊晶生長的晶圓支撐桿裝置、設備及方法 | |

| JP2010034337A (ja) | 気相成長装置用のサセプタ | |

| KR20110087440A (ko) | 반도체 제조용 서셉터 및 이를 포함하는 반도체 제조 장치 | |

| KR102888301B1 (ko) | 서셉터 및 이를 포함하는 에피택셜층 성장 장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110801 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110801 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130806 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130925 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20131015 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20131028 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5412759 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |