JP4602869B2 - 複合成形品の成形方法とそれに用いる型締装置 - Google Patents

複合成形品の成形方法とそれに用いる型締装置 Download PDFInfo

- Publication number

- JP4602869B2 JP4602869B2 JP2005236668A JP2005236668A JP4602869B2 JP 4602869 B2 JP4602869 B2 JP 4602869B2 JP 2005236668 A JP2005236668 A JP 2005236668A JP 2005236668 A JP2005236668 A JP 2005236668A JP 4602869 B2 JP4602869 B2 JP 4602869B2

- Authority

- JP

- Japan

- Prior art keywords

- mold part

- molding

- mold

- movable

- cavity

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/04—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles using movable moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/03—Injection moulding apparatus

- B29C45/04—Injection moulding apparatus using movable moulds or mould halves

- B29C45/0441—Injection moulding apparatus using movable moulds or mould halves involving a rotational movement

- B29C45/045—Injection moulding apparatus using movable moulds or mould halves involving a rotational movement mounted on the circumference of a rotating support having a rotating axis perpendicular to the mould opening, closing or clamping direction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/16—Making multilayered or multicoloured articles

- B29C45/1615—The materials being injected at different moulding stations

- B29C45/1628—The materials being injected at different moulding stations using a mould carrier rotatable about an axis perpendicular to the opening and closing axis of the moulding stations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/46—Means for plasticising or homogenising the moulding material or forcing it into the mould

- B29C45/56—Means for plasticising or homogenising the moulding material or forcing it into the mould using mould parts movable during or after injection, e.g. injection-compression moulding

- B29C45/561—Injection-compression moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2011/00—Optical elements, e.g. lenses, prisms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/30—Vehicles, e.g. ships or aircraft, or body parts thereof

- B29L2031/3055—Cars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/778—Windows

- B29L2031/7782—Glazing

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

Description

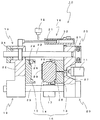

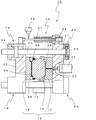

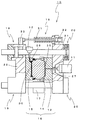

11 第1射出装置

12 第2射出装置

13 第1型部

14 可動型部

15 第2型部

16 金型

18 型開閉装置

19 圧締装置

21 固定盤

22 可動盤

25 第1クランパ

26 第2クランパ

29 1次成形品

30 2次成形品

35 第1キャビティ

36 第2キャビティ

G 間隙

Claims (4)

- 固定盤に取付けられた第1型部と可動盤に取付けられた第2型部との間に回転・移動装置により回転かつ型開閉方向に移動可能な可動型部が設けられ、

前記第1型部または前記第2型部のいずれか一方により1次成形品を1次成形し、前記1次成形品を保持した前記可動型部を回転させて前記1次成形した前記第1型部または前記第2型部とは異なる前記第2型部または前記第1型部のいずれか他方に型合わせされていた前記可動型部と入替え前記1次成形品をインサートした後、前記1次成形品がインサートされた前記第2型部または前記第1型部のいずれか他方により2次成形品を2次成形する複合成形品の成形方法であって、

前記可動盤及び前記可動型部が移動して前記第1型部または前記第2型部のいずれか一方と前記可動型部との間に第1キャビティが形成され前記可動型部と前記第1キャビティを形成した前記第2型部または前記第1型部のいずれか他方との間に第2キャビティが形成されて型閉じが完了した後に、前記1次成形は第1射出装置から溶融材料を前記第1キャビティへ射出する成形であるとともに前記2次成形は第2射出装置から溶融材料を前記第2キャビティへ射出する成形であり、前記1次成形及び前記2次成形は、互いに異なった時点の連続しない別個の工程で実行され、

前記1次成形または前記2次成形の少なくとも一方は、前記第1キャビティまたは前記第2キャビティのいずれかの該当するキャビティの容積を縮小させる圧縮成形で行われる

ことを特徴とする複合成形品の成形方法。 - 前記圧縮成形を行うとき、複数の圧締装置を制御して前記可動型部と前記第1型部または前記第2型部とを平行に保って圧縮制御する請求項1に記載の複合成形品の成形方法。

- 固定盤に取付けられた第1型部と可動盤に取付けられた第2型部との間に回転・移動装置により回転かつ型開閉方向に移動可能な可動型部が設けられ、

前記第1型部または前記第2型部のいずれか一方により1次成形品を1次成形し、前記1次成形品を保持した前記可動型部を回転させて前記1次成形した前記第1型部または前記第2型部とは異なる前記第2型部または前記第1型部のいずれか他方に型合わせされていた前記可動型部と入替え前記1次成形品をインサートした後、前記1次成形品がインサートされた前記第2型部または前記第1型部のいずれか他方により2次成形品を2次成形する複合成形品の型締装置であって、

前記可動盤及び前記可動型部が移動して前記第1型部または前記第2型部のいずれか一方と前記可動型部との間に第1キャビティが形成され前記可動型部と前記第1キャビティを形成した前記第2型部または前記第1型部のいずれか他方との間に第2キャビティが形成されて型閉じが完了した後に、前記1次成形は第1射出装置から溶融材料を前記第1キャビティへ射出する成形であるとともに前記2次成形は第2射出装置から溶融材料を前記第2キャビティへ射出する成形であり、前記1次成形及び前記2次成形は、互いに異なった時点の連続しない別個の工程で実行され、

前記1次成形または前記2次成形の少なくとも一方は、前記第1キャビティまたは前記第2キャビティのいずれかの該当するキャビティの容積を縮小させる圧縮成形を行う

ことを特徴とする複合成形品の型締装置。 - 前記圧縮成形を行うとき、複数の圧締装置を制御して前記可動型部と前記第1型部または前記第2型部とを平行に保って圧縮制御する請求項3に記載の複合成形品の型締装置。

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005236668A JP4602869B2 (ja) | 2005-08-17 | 2005-08-17 | 複合成形品の成形方法とそれに用いる型締装置 |

| PCT/JP2006/315720 WO2007020844A1 (ja) | 2005-08-17 | 2006-08-09 | 複合成形品の成形方法とそれに用いる金型装置 |

| EP06782536.4A EP1916082B1 (en) | 2005-08-17 | 2006-08-09 | Method of molding composite molded article |

| US11/990,398 US8408890B2 (en) | 2005-08-17 | 2006-08-09 | Mold system for composite molding |

| CN2006800296574A CN101242942B (zh) | 2005-08-17 | 2006-08-09 | 复合成形品的成形方法及其所使用的模具装置 |

| CN201210465011.8A CN103009549B (zh) | 2005-08-17 | 2006-08-09 | 复合成形品的成形方法 |

| US13/749,964 US9321196B2 (en) | 2005-08-17 | 2013-01-25 | Method of molding composite molded article |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005236668A JP4602869B2 (ja) | 2005-08-17 | 2005-08-17 | 複合成形品の成形方法とそれに用いる型締装置 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010018539A Division JP4880045B2 (ja) | 2010-01-29 | 2010-01-29 | 複合成形用の型締装置及び複合成形品の成形方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007050585A JP2007050585A (ja) | 2007-03-01 |

| JP2007050585A5 JP2007050585A5 (ja) | 2010-03-18 |

| JP4602869B2 true JP4602869B2 (ja) | 2010-12-22 |

Family

ID=37757506

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005236668A Expired - Lifetime JP4602869B2 (ja) | 2005-08-17 | 2005-08-17 | 複合成形品の成形方法とそれに用いる型締装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US8408890B2 (ja) |

| EP (1) | EP1916082B1 (ja) |

| JP (1) | JP4602869B2 (ja) |

| CN (2) | CN103009549B (ja) |

| WO (1) | WO2007020844A1 (ja) |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4410192B2 (ja) * | 2005-12-07 | 2010-02-03 | 株式会社名機製作所 | 射出成形機 |

| WO2010115954A1 (en) * | 2009-04-08 | 2010-10-14 | Photon B.V. | Method for producing a cover plate for a photovoltaic device |

| KR101355419B1 (ko) * | 2009-05-28 | 2014-01-27 | 우베 고산 기카이 가부시키가이샤 | 적층 성형장치 및 적층 성형방법 |

| JP5440046B2 (ja) * | 2009-09-09 | 2014-03-12 | 宇部興産機械株式会社 | 積層成形装置 |

| CN102211408A (zh) * | 2011-05-24 | 2011-10-12 | 常熟市汽车饰件有限公司 | 汽车内饰件pu喷涂二次成型方法 |

| US9242418B2 (en) * | 2011-11-16 | 2016-01-26 | Essilor International | Ophthalmic lens containing a fresnel surface and method for manufacturing same |

| JP5613720B2 (ja) * | 2012-05-08 | 2014-10-29 | 日精樹脂工業株式会社 | 液状樹脂材料用成形設備 |

| TWI489179B (zh) * | 2012-12-14 | 2015-06-21 | Wistron Corp | 製造導光板的方法、治具以及相關的導光板 |

| DE102012025132A1 (de) * | 2012-12-21 | 2014-06-26 | Ferromatik Milacron Gmbh | Verfahren zum Herstellen eines Kunststoff-Formteils sowie Spritzgießmaschine |

| ITAN20130073A1 (it) * | 2013-04-10 | 2014-10-11 | Fintema S R L | Struttura integrata di stampo di formatura, in multi-iniezione, di manufatti plastici. |

| ITAN20130072A1 (it) * | 2013-04-10 | 2014-10-11 | Fintema S R L | Struttura di stampo di formatura, in multi-iniezione, di manufatti plastici |

| DE102013216008A1 (de) * | 2013-08-13 | 2015-02-19 | Otto Männer Innovation GmbH | Spritzgießmaschine für mehrere Spritzgießvorgänge |

| CN104552747B (zh) * | 2013-10-14 | 2017-02-01 | 玉晶光电(厦门)有限公司 | 光学组件的制造方法 |

| JP6300510B2 (ja) * | 2013-12-18 | 2018-03-28 | キヤノン株式会社 | トランスファ成形方法および成形金型 |

| US10946570B2 (en) | 2014-06-06 | 2021-03-16 | Mitsubishi Heavy Industries Plastic Technology Co., Ltd. | Injection molding method and injection molding machine |

| FR3028796B1 (fr) * | 2014-11-24 | 2017-05-19 | Jp Grosfilley | Moule d’injection rotatif et procede d’injection relatif audit moule d’injection rotatif |

| KR101568701B1 (ko) * | 2015-05-13 | 2015-11-12 | 주식회사 제이피씨오토모티브 | R2k 사출 금형 및 방법 |

| WO2017051383A1 (en) * | 2015-09-25 | 2017-03-30 | Sabic Global Technologies B.V. | Method of molding using mold inserts and apparatus therefor |

| DE102015117266B4 (de) * | 2015-10-09 | 2017-07-13 | Trw Automotive Electronics & Components Gmbh | Linsenbauteil eines Regensensors sowie Baukastensystem, Verfahren und Werkzeug zur Herstellung |

| CN106217897B (zh) * | 2016-09-19 | 2018-09-28 | 福州福耀模具科技有限公司 | 通过压注复合工艺来成型纤维板产品的装置和方法 |

| CN106945244B (zh) * | 2017-04-13 | 2023-04-21 | 厦门捷信达精密科技股份有限公司 | 双色模利用牛顿力学摆钩控制开模顺序模具 |

| CN109483800A (zh) * | 2019-01-09 | 2019-03-19 | 青岛佳友模具科技有限公司 | 一种超厚透明双色包覆件注塑成型方法 |

| CN112045925A (zh) * | 2019-06-06 | 2020-12-08 | 苏州汉扬精密电子有限公司 | 一种仿金属质感塑胶制品的制造方法及塑胶制品 |

| KR102726701B1 (ko) * | 2019-12-13 | 2024-11-07 | 현대자동차주식회사 | 도광판 일체형 차량용 트림 패널 및 그 제조방법 |

| JP7341112B2 (ja) * | 2020-10-06 | 2023-09-08 | Towa株式会社 | 樹脂成形品の製造方法 |

| JP7328395B1 (ja) * | 2022-04-21 | 2023-08-16 | 株式会社ソディック | 射出成形機、射出成形機の制御方法及びプログラム |

| CN115319999A (zh) * | 2022-10-14 | 2022-11-11 | 赫比(成都)精密塑胶制品有限公司 | 立方体注塑模具及注塑方法 |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3319300A (en) * | 1963-11-02 | 1967-05-16 | Hehl & Soehne Arburg Masch | Injection molding machine for producing two-color or two-material molded products |

| CA978712A (en) * | 1971-06-15 | 1975-12-02 | Katashi Aoki | Multicolor injection molding machine |

| JPS60110415A (ja) * | 1983-11-22 | 1985-06-15 | Nippon Sekisoo Kogyo Kk | グロメットの製造法 |

| GB8517073D0 (en) * | 1985-07-05 | 1985-08-14 | Hepworth Iron Co Ltd | Pipe pipe couplings &c |

| JPH0615186B2 (ja) * | 1987-01-30 | 1994-03-02 | 株式会社高橋精機工業所 | 合成樹脂製品の成形法 |

| JPH069850Y2 (ja) * | 1987-06-15 | 1994-03-16 | 日本板硝子株式会社 | 車両用窓ガラス |

| KR960007863B1 (ko) * | 1987-08-28 | 1996-06-13 | 스미도모쥬기가이고오교오 가부시기가이샤 | 사출 성형기 |

| US5049343A (en) * | 1990-06-18 | 1991-09-17 | Sorensen Jens Ole | Sequentially injected multi-component core-back injection molding |

| US5030406A (en) * | 1989-08-14 | 1991-07-09 | Sorensen Jens Ole | Sequentially injected multi-component shuttle-stack-molding |

| JP2661432B2 (ja) * | 1991-09-06 | 1997-10-08 | ヤマハ株式会社 | 複合成形品の製法 |

| US5863479A (en) * | 1991-09-06 | 1999-01-26 | Yamaha Corporation | Production method for a composite molded article |

| JP3189394B2 (ja) | 1992-07-01 | 2001-07-16 | 井関農機株式会社 | 籾摺ロ−ルの間隙調節装置 |

| JP2908176B2 (ja) * | 1993-05-18 | 1999-06-21 | 株式会社小糸製作所 | 車輌用灯具の合成樹脂製積層レンズ及びその成形方法 |

| AR002773A1 (es) * | 1995-07-07 | 1998-04-29 | Continental Pet Technologies | Metodo para el moldeado por inyeccion de un articulo plastico y aparato para llevarlo a cabo. |

| JPH09280345A (ja) * | 1996-02-15 | 1997-10-28 | Bridgestone Corp | プーリー及びその製造方法 |

| JPH09220745A (ja) * | 1996-02-16 | 1997-08-26 | Mitsubishi Heavy Ind Ltd | 射出圧縮成形機 |

| JPH1016002A (ja) * | 1996-07-05 | 1998-01-20 | Shin Etsu Polymer Co Ltd | 複合成形品の成形装置および製造方法 |

| DE69824650T2 (de) * | 1997-01-22 | 2005-08-11 | Chisso Corp. | Verfahren zur Herstellung eines Verbundformgegenstandes aus thermoplastischen Harzen |

| DE19733667C2 (de) | 1997-08-04 | 2002-02-07 | Ferromatik Milacron Maschb Gmb | Vorrichtung zur Herstellung von Spritzgießartikeln aus mindestens zwei Kunststoffschmelzen |

| JP3944984B2 (ja) * | 1998-01-05 | 2007-07-18 | 住友化学株式会社 | 樹脂成形体製造用金型 |

| US6468458B1 (en) * | 1998-10-23 | 2002-10-22 | Textron Automotive Company Inc, | Method for forming a composite product |

| SE520529C2 (sv) * | 2000-12-27 | 2003-07-22 | Ericsson Telefon Ab L M | Metod för tillverkning av avskärmningslåda och avskärmningslåda |

| EP1226916A1 (de) * | 2001-01-29 | 2002-07-31 | FOBOHA GmbH | Vorrichtung und Verfahren zur Herstellung von Objekten aus Kunststoff |

| JP3783201B2 (ja) | 2001-01-31 | 2006-06-07 | 日精樹脂工業株式会社 | 異材質樹脂による複合製品の射出成形方法及び金型装置 |

| FR2821288B1 (fr) * | 2001-02-26 | 2004-01-16 | Cebal | Procede de fabrication d'assemblages de pieces en matiere plastique |

| AT5360U1 (de) | 2001-05-08 | 2002-06-25 | Engel Gmbh Maschbau | Spritzgiesseinrichtung |

| CN2678879Y (zh) * | 2003-12-16 | 2005-02-16 | 魏小兵 | 一种用于生产改性玻璃钢内衬复合管的成型设备 |

| ITTO20040696A1 (it) * | 2004-10-11 | 2005-01-11 | Incos Spa | Apparecchiatura e metodo per lo stampaggio mediante iniezione-compressione di articoli di materia plastica a due componenti |

| ITTO20040701A1 (it) * | 2004-10-11 | 2005-01-11 | Incos Spa | Procedimento per la produzione di lastre di materiale plastico con parti sovrastampate mediante inietto-compressione |

-

2005

- 2005-08-17 JP JP2005236668A patent/JP4602869B2/ja not_active Expired - Lifetime

-

2006

- 2006-08-09 CN CN201210465011.8A patent/CN103009549B/zh not_active Expired - Fee Related

- 2006-08-09 WO PCT/JP2006/315720 patent/WO2007020844A1/ja not_active Ceased

- 2006-08-09 CN CN2006800296574A patent/CN101242942B/zh not_active Expired - Fee Related

- 2006-08-09 EP EP06782536.4A patent/EP1916082B1/en not_active Ceased

- 2006-08-09 US US11/990,398 patent/US8408890B2/en not_active Expired - Fee Related

-

2013

- 2013-01-25 US US13/749,964 patent/US9321196B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN101242942A (zh) | 2008-08-13 |

| US8408890B2 (en) | 2013-04-02 |

| JP2007050585A (ja) | 2007-03-01 |

| US20130140735A1 (en) | 2013-06-06 |

| CN103009549B (zh) | 2016-06-29 |

| CN103009549A (zh) | 2013-04-03 |

| WO2007020844A1 (ja) | 2007-02-22 |

| US20100019411A1 (en) | 2010-01-28 |

| EP1916082B1 (en) | 2020-01-08 |

| US9321196B2 (en) | 2016-04-26 |

| EP1916082A4 (en) | 2010-09-22 |

| EP1916082A1 (en) | 2008-04-30 |

| CN101242942B (zh) | 2013-01-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4602869B2 (ja) | 複合成形品の成形方法とそれに用いる型締装置 | |

| JP2007050585A5 (ja) | ||

| JP3942945B2 (ja) | 射出圧縮成形装置、射出圧縮成形方法およびその方法による射出圧縮成形品 | |

| US6780365B2 (en) | Process for preparing composite molded articles by multicomponent injection molding | |

| US20090085235A1 (en) | Method and apparatus for making a microstructured or nanostructured article | |

| JP2007521158A (ja) | 多色射出成形方法及びその成形装置 | |

| US7458794B2 (en) | Injection moulding machine | |

| CN1820102B (zh) | 用于制造车辆部件的方法和装置 | |

| KR20010104220A (ko) | 열가소성 재료로 제작된 물품의 열간 성형 장치 및 방법 | |

| JP4880045B2 (ja) | 複合成形用の型締装置及び複合成形品の成形方法 | |

| JP2010105168A (ja) | 多材射出成形装置および多材射出成形方法ならびに多材射出成形金型 | |

| KR20130102753A (ko) | 멀티사출 및 멀티취출이 동시 가능한 큐브 사출 금형 및 그 제조방법 | |

| JPH07290485A (ja) | 樹脂成形品の成形方法及び成形用金型装置 | |

| JP7173861B2 (ja) | 自動車用インパネの成形方法、及び自動車用インパネ | |

| JP2025127300A (ja) | 車両用モジュールの製造方法、車両用モジュール、射出成形装置 | |

| JP2005329544A (ja) | 2色成形品及びその成形方法 | |

| KR100636803B1 (ko) | 휴대폰의 이형부재 사출성형장치 | |

| JP7173860B2 (ja) | 射出成形品の製造方法、及び射出成形金型 | |

| KR20000071757A (ko) | 사출성형기 | |

| JP7173862B2 (ja) | 射出成形品の製造方法 | |

| JP5172157B2 (ja) | 成形装置 | |

| JP2000229518A (ja) | 車両ルーフの可動プレート、この可動プレートの製造装置及び製造方法 | |

| WO2025197473A1 (ja) | 成形型及び樹脂製品の製造方法 | |

| JPH0615682A (ja) | 射出成形方法及び装置 | |

| JP2013233779A (ja) | 金型内塗装用金型、射出成形装置及び積層成形品の金型内塗装方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080509 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100129 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100629 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100826 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100928 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100930 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131008 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4602869 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313115 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |