JP2007508698A - 有機ケイ酸塩ガラスについての一酸化二窒素剥脱方法 - Google Patents

有機ケイ酸塩ガラスについての一酸化二窒素剥脱方法 Download PDFInfo

- Publication number

- JP2007508698A JP2007508698A JP2006534260A JP2006534260A JP2007508698A JP 2007508698 A JP2007508698 A JP 2007508698A JP 2006534260 A JP2006534260 A JP 2006534260A JP 2006534260 A JP2006534260 A JP 2006534260A JP 2007508698 A JP2007508698 A JP 2007508698A

- Authority

- JP

- Japan

- Prior art keywords

- layer

- photoresist

- osg

- stripping

- organic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76801—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing

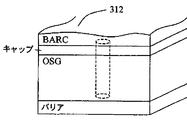

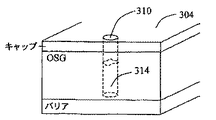

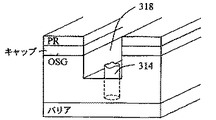

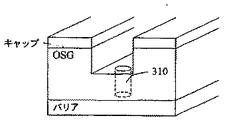

- H01L21/76802—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics

- H01L21/76807—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics for dual damascene structures

- H01L21/76808—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics for dual damascene structures involving intermediate temporary filling with material

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/26—Processing photosensitive materials; Apparatus therefor

- G03F7/42—Stripping or agents therefor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3105—After-treatment

- H01L21/311—Etching the insulating layers by chemical or physical means

- H01L21/31127—Etching organic layers

- H01L21/31133—Etching organic layers by chemical means

- H01L21/31138—Etching organic layers by chemical means by dry-etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76801—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing

- H01L21/76802—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics

- H01L21/76807—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics for dual damascene structures

- H01L21/76811—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics for dual damascene structures involving multiple stacked pre-patterned masks

Landscapes

- Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Power Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

- Drying Of Semiconductors (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/680,895 US7202177B2 (en) | 2003-10-08 | 2003-10-08 | Nitrous oxide stripping process for organosilicate glass |

| PCT/US2004/032793 WO2005038892A1 (en) | 2003-10-08 | 2004-10-05 | A nitrous oxide stripping process for organosilicate glass |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007508698A true JP2007508698A (ja) | 2007-04-05 |

| JP2007508698A5 JP2007508698A5 (enExample) | 2007-10-18 |

Family

ID=34422202

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006534260A Pending JP2007508698A (ja) | 2003-10-08 | 2004-10-05 | 有機ケイ酸塩ガラスについての一酸化二窒素剥脱方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7202177B2 (enExample) |

| EP (1) | EP1671363A4 (enExample) |

| JP (1) | JP2007508698A (enExample) |

| KR (1) | KR101197070B1 (enExample) |

| CN (1) | CN100426469C (enExample) |

| TW (1) | TW200523689A (enExample) |

| WO (1) | WO2005038892A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190070859A (ko) * | 2017-12-13 | 2019-06-21 | 도쿄엘렉트론가부시키가이샤 | 반도체 장치의 제조 방법 |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050136681A1 (en) * | 2003-12-23 | 2005-06-23 | Tokyo Electron Limited | Method and apparatus for removing photoresist from a substrate |

| KR100666881B1 (ko) * | 2005-06-10 | 2007-01-10 | 삼성전자주식회사 | 포토레지스트 제거 방법 및 이를 이용한 반도체 소자의제조 방법. |

| JP5005702B2 (ja) * | 2005-11-17 | 2012-08-22 | エヌエックスピー ビー ヴィ | 湿度センサー |

| US7932181B2 (en) * | 2006-06-20 | 2011-04-26 | Lam Research Corporation | Edge gas injection for critical dimension uniformity improvement |

| US8283255B2 (en) * | 2007-05-24 | 2012-10-09 | Lam Research Corporation | In-situ photoresist strip during plasma etching of active hard mask |

| US20110226280A1 (en) * | 2008-11-21 | 2011-09-22 | Axcelis Technologies, Inc. | Plasma mediated ashing processes |

| US20100130017A1 (en) * | 2008-11-21 | 2010-05-27 | Axcelis Technologies, Inc. | Front end of line plasma mediated ashing processes and apparatus |

| CN101996934B (zh) * | 2009-08-20 | 2012-07-18 | 中芯国际集成电路制造(上海)有限公司 | 半导体器件的制作方法 |

| CN115799028B (zh) * | 2021-09-10 | 2025-12-05 | 长鑫存储技术有限公司 | 半导体结构的制备方法及半导体结构 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000183040A (ja) * | 1998-12-15 | 2000-06-30 | Canon Inc | 有機層間絶縁膜エッチング後のレジストアッシング方法 |

| WO2002003426A2 (en) * | 2000-06-30 | 2002-01-10 | Lam Research Corporation | Process for the post etch stripping of photoresist with hydrogen |

| JP2003045969A (ja) * | 2001-07-12 | 2003-02-14 | Samsung Electronics Co Ltd | デュアルダマシン工程を利用した配線形成方法 |

| JP2003092349A (ja) * | 2001-09-18 | 2003-03-28 | Mitsubishi Electric Corp | 半導体装置およびその製造方法 |

| US6617257B2 (en) * | 2001-03-30 | 2003-09-09 | Lam Research Corporation | Method of plasma etching organic antireflective coating |

| JP2003303880A (ja) * | 2002-04-10 | 2003-10-24 | Nec Corp | 積層層間絶縁膜構造を利用した配線構造およびその製造方法 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US111041A (en) * | 1871-01-17 | Improvement in hay-tedders | ||

| US5126231A (en) * | 1990-02-26 | 1992-06-30 | Applied Materials, Inc. | Process for multi-layer photoresist etching with minimal feature undercut and unchanging photoresist load during etch |

| US5910453A (en) * | 1996-01-16 | 1999-06-08 | Advanced Micro Devices, Inc. | Deep UV anti-reflection coating etch |

| US5970376A (en) * | 1997-12-29 | 1999-10-19 | Taiwan Semiconductor Manufacturing Company, Ltd. | Post via etch plasma treatment method for forming with attenuated lateral etching a residue free via through a silsesquioxane spin-on-glass (SOG) dielectric layer |

| JP4221847B2 (ja) * | 1999-10-25 | 2009-02-12 | パナソニック電工株式会社 | プラズマ処理装置及びプラズマ点灯方法 |

| US6323121B1 (en) * | 2000-05-12 | 2001-11-27 | Taiwan Semiconductor Manufacturing Company | Fully dry post-via-etch cleaning method for a damascene process |

| JP2002118087A (ja) * | 2000-06-29 | 2002-04-19 | Dms Co Ltd | 紫外線照査装置 |

| US6413877B1 (en) * | 2000-12-22 | 2002-07-02 | Lam Research Corporation | Method of preventing damage to organo-silicate-glass materials during resist stripping |

| US6514860B1 (en) * | 2001-01-31 | 2003-02-04 | Advanced Micro Devices, Inc. | Integration of organic fill for dual damascene process |

| US6777344B2 (en) | 2001-02-12 | 2004-08-17 | Lam Research Corporation | Post-etch photoresist strip with O2 and NH3 for organosilicate glass low-K dielectric etch applications |

| US6566283B1 (en) * | 2001-02-15 | 2003-05-20 | Advanced Micro Devices, Inc. | Silane treatment of low dielectric constant materials in semiconductor device manufacturing |

| US20020139771A1 (en) * | 2001-02-22 | 2002-10-03 | Ping Jiang | Gas switching during an etch process to modulate the characteristics of the etch |

| US6498112B1 (en) * | 2001-07-13 | 2002-12-24 | Advanced Micro Devices, Inc. | Graded oxide caps on low dielectric constant (low K) chemical vapor deposition (CVD) films |

| US6696222B2 (en) * | 2001-07-24 | 2004-02-24 | Silicon Integrated Systems Corp. | Dual damascene process using metal hard mask |

| US7253112B2 (en) * | 2002-06-04 | 2007-08-07 | Taiwan Semiconductor Manufacturing Co., Ltd. | Dual damascene process |

| JP2004079901A (ja) * | 2002-08-21 | 2004-03-11 | Nec Electronics Corp | 半導体装置及びその製造方法 |

| US6720256B1 (en) * | 2002-12-04 | 2004-04-13 | Taiwan Semiconductor Manufacturing Company | Method of dual damascene patterning |

| US6916697B2 (en) * | 2003-10-08 | 2005-07-12 | Lam Research Corporation | Etch back process using nitrous oxide |

-

2003

- 2003-10-08 US US10/680,895 patent/US7202177B2/en not_active Expired - Lifetime

-

2004

- 2004-10-04 TW TW093130026A patent/TW200523689A/zh unknown

- 2004-10-05 WO PCT/US2004/032793 patent/WO2005038892A1/en not_active Ceased

- 2004-10-05 CN CNB2004800291641A patent/CN100426469C/zh not_active Expired - Fee Related

- 2004-10-05 JP JP2006534260A patent/JP2007508698A/ja active Pending

- 2004-10-05 KR KR1020067008588A patent/KR101197070B1/ko not_active Expired - Fee Related

- 2004-10-05 EP EP04794216A patent/EP1671363A4/en not_active Withdrawn

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000183040A (ja) * | 1998-12-15 | 2000-06-30 | Canon Inc | 有機層間絶縁膜エッチング後のレジストアッシング方法 |

| WO2002003426A2 (en) * | 2000-06-30 | 2002-01-10 | Lam Research Corporation | Process for the post etch stripping of photoresist with hydrogen |

| US6617257B2 (en) * | 2001-03-30 | 2003-09-09 | Lam Research Corporation | Method of plasma etching organic antireflective coating |

| JP2003045969A (ja) * | 2001-07-12 | 2003-02-14 | Samsung Electronics Co Ltd | デュアルダマシン工程を利用した配線形成方法 |

| JP2003092349A (ja) * | 2001-09-18 | 2003-03-28 | Mitsubishi Electric Corp | 半導体装置およびその製造方法 |

| JP2003303880A (ja) * | 2002-04-10 | 2003-10-24 | Nec Corp | 積層層間絶縁膜構造を利用した配線構造およびその製造方法 |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190070859A (ko) * | 2017-12-13 | 2019-06-21 | 도쿄엘렉트론가부시키가이샤 | 반도체 장치의 제조 방법 |

| JP2019106490A (ja) * | 2017-12-13 | 2019-06-27 | 東京エレクトロン株式会社 | 半導体装置の製造方法 |

| CN110034063A (zh) * | 2017-12-13 | 2019-07-19 | 东京毅力科创株式会社 | 半导体装置的制造方法 |

| US11495490B2 (en) | 2017-12-13 | 2022-11-08 | Tokyo Electron Limited | Semiconductor device manufacturing method |

| CN110034063B (zh) * | 2017-12-13 | 2023-10-20 | 东京毅力科创株式会社 | 半导体装置的制造方法 |

| KR102642184B1 (ko) * | 2017-12-13 | 2024-03-04 | 도쿄엘렉트론가부시키가이샤 | 반도체 장치의 제조 방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR101197070B1 (ko) | 2012-11-06 |

| US20050079710A1 (en) | 2005-04-14 |

| WO2005038892A1 (en) | 2005-04-28 |

| EP1671363A1 (en) | 2006-06-21 |

| CN1864249A (zh) | 2006-11-15 |

| CN100426469C (zh) | 2008-10-15 |

| US7202177B2 (en) | 2007-04-10 |

| EP1671363A4 (en) | 2010-01-13 |

| TW200523689A (en) | 2005-07-16 |

| KR20060107758A (ko) | 2006-10-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100849707B1 (ko) | 탄소-도우핑된 저유전체들의 선택적 식각 | |

| KR100883291B1 (ko) | 유기 반사 방지막 플라즈마 식각 방법 | |

| US6805139B1 (en) | Systems and methods for photoresist strip and residue treatment in integrated circuit manufacturing | |

| KR100778260B1 (ko) | 수소로 포토레지스트를 포스트 에칭 박리하기 위한 프로세스 | |

| JP6049871B2 (ja) | エッチング及びアッシング中での低誘電率材料の側壁保護 | |

| US6583065B1 (en) | Sidewall polymer forming gas additives for etching processes | |

| US6991739B2 (en) | Method of photoresist removal in the presence of a dielectric layer having a low k-value | |

| US6686293B2 (en) | Method of etching a trench in a silicon-containing dielectric material | |

| US20050022839A1 (en) | Systems and methods for photoresist strip and residue treatment in integrated circuit manufacturing | |

| US7129171B2 (en) | Selective oxygen-free etching process for barrier materials | |

| US6849193B2 (en) | Highly selective process for etching oxide over nitride using hexafluorobutadiene | |

| TWI514516B (zh) | 保護外露式低k表面的方法 | |

| US20070193602A1 (en) | Systems and Methods for Photoresist Strip and Residue Treatment in Integrated Circuit Manufacturing | |

| JP2007537602A (ja) | フルオロカーボン化学エッチングにおけるh2添加物を使用しての炭素ドープ酸化ケイ素エッチング | |

| JP4451934B2 (ja) | 導電層をエッチングする方法及び集積回路 | |

| US6647994B1 (en) | Method of resist stripping over low-k dielectric material | |

| KR20060123144A (ko) | 포토레지스트 스트립 동안의 배리어 재료의 손실 최소화 | |

| KR101197070B1 (ko) | 유기실리케이트 유리용 아산화질소 스트립 프로세스 | |

| KR101276043B1 (ko) | 아산화질소를 사용하는 에치백 프로세스 | |

| US6969685B1 (en) | Etching a dielectric layer in an integrated circuit structure having a metal hard mask layer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070829 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070829 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100817 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100819 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20101119 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20101129 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20101220 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20101228 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20110119 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20110126 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110221 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110414 |