EP0598705A2 - Dispositif de broyage et/ou compactage de composants d'aliments ou de fourrage - Google Patents

Dispositif de broyage et/ou compactage de composants d'aliments ou de fourrage Download PDFInfo

- Publication number

- EP0598705A2 EP0598705A2 EP94101739A EP94101739A EP0598705A2 EP 0598705 A2 EP0598705 A2 EP 0598705A2 EP 94101739 A EP94101739 A EP 94101739A EP 94101739 A EP94101739 A EP 94101739A EP 0598705 A2 EP0598705 A2 EP 0598705A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- bearing

- rollers

- foreign body

- bearing base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 235000013305 food Nutrition 0.000 title claims abstract description 4

- 238000003801 milling Methods 0.000 title description 2

- 238000000227 grinding Methods 0.000 claims abstract description 14

- 238000000034 method Methods 0.000 claims description 4

- 238000003825 pressing Methods 0.000 claims description 3

- 206010070245 Foreign body Diseases 0.000 abstract 3

- 235000013312 flour Nutrition 0.000 description 3

- GXCLVBGFBYZDAG-UHFFFAOYSA-N N-[2-(1H-indol-3-yl)ethyl]-N-methylprop-2-en-1-amine Chemical class CN(CCC1=CNC2=C1C=CC=C2)CC=C GXCLVBGFBYZDAG-UHFFFAOYSA-N 0.000 description 2

- 239000010903 husk Substances 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 235000012054 meals Nutrition 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000007873 sieving Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C4/00—Crushing or disintegrating by roller mills

- B02C4/28—Details

- B02C4/32—Adjusting, applying pressure to, or controlling the distance between, milling members

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C11/00—Other auxiliary devices or accessories specially adapted for grain mills

- B02C11/06—Arrangements for preventing fire or explosion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C23/00—Auxiliary methods or auxiliary devices or accessories specially adapted for crushing or disintegrating not provided for in preceding groups or not specially adapted to apparatus covered by a single preceding group

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C4/00—Crushing or disintegrating by roller mills

- B02C4/02—Crushing or disintegrating by roller mills with two or more rollers

- B02C4/06—Crushing or disintegrating by roller mills with two or more rollers specially adapted for milling grain

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C4/00—Crushing or disintegrating by roller mills

- B02C4/28—Details

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C9/00—Other milling methods or mills specially adapted for grain

- B02C9/04—Systems or sequences of operations; Plant

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/42—Drive mechanisms, regulating or controlling devices, or balancing devices, specially adapted for screens

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/46—Constructional details of screens in general; Cleaning or heating of screens

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B9/00—Combinations of apparatus for screening or sifting or for separating solids from solids using gas currents; General arrangement of plant, e.g. flow sheets

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05C—BOLTS OR FASTENING DEVICES FOR WINGS, SPECIALLY FOR DOORS OR WINDOWS

- E05C9/00—Arrangements of simultaneously actuated bolts or other securing devices at well-separated positions on the same wing

- E05C9/06—Arrangements of simultaneously actuated bolts or other securing devices at well-separated positions on the same wing with three or more sliding bars

- E05C9/063—Arrangements of simultaneously actuated bolts or other securing devices at well-separated positions on the same wing with three or more sliding bars extending along three or more sides of the wing or frame

Definitions

- the invention relates to a device for grinding and / or pressing food or feed components according to the preamble of patent claim 1.

- the arrangement of the pivotable bearing shell directly on the bearing base for the bearing of the other roller has the advantage that the path of the grinding forces within the joint frame is made as short as possible.

- a disadvantage of the known arrangement is that the fine adjustment can only be carried out manually by means of a nut-spindle arrangement which acts directly on the connection between the two bearing housings; this means that the required accuracy cannot be maintained and the threads have to absorb the full grinding pressure.

- a release device provided with an eccentric is provided, the adjustment linkage of which is supported on the roller stand and thus transmits part of the power flow and vibrations to the roller stand.

- a pressing device for the rolling of roller mills is already known (CH-PS 97 418), in which the fixed roller directly in the roller stand and the movable roller in a lever bearing pivotably arranged on the roller stand are rotatably mounted so that the power flow and vibrations are transmitted to the roll stand.

- the end of the lever bearing facing away from the pivot axis is held on the roller stand via a connection containing a foreign body lock and an eccentric, so that the rollers are held at a defined distance.

- the eccentric has an actuating lever which can be pivoted in a defined manner via a length-adjustable adjustment arrangement, as a result of which the roller spacing can be adjusted.

- the aim of the present invention is to provide a device of the type mentioned at the outset, which can be attached to other parts without disturbing the flow of force or being transmitted to these parts.

- the fine adjustment of the roller spacing is carried out by means of an eccentric provided at one end of the adjusting device, the special feature being that the actuating arrangement for the eccentric is located on a fixed bearing part, ie on a part of the bearing base which carries the roller attached to the roller stand, supports.

- the setting device is made an integral part of the roller package in a simple manner while maintaining the principle of fine adjustment by means of an eccentric, so that it can be completely prefabricated and attached to other lines.

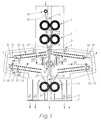

- the sieve units 7, 8 are symmetrical and each have two inclined, double-bottomed sieve compartments 10, 11 and 12, 13, respectively, in which two sieve frames 14, 14 'and 15, 15' are contained.

- Each sieve unit 7, 8 is articulated in the region of its side walls by means of a total of four articulation levers on supporting parts of the machine housing 3, so that they are activated by the drive 9 in the direction indicated by the arrows 16, 17 Can swing back and forth while doing sieving or separating work.

- the material to be ground is fed to the roller package 4 via a feed roller 18 and a baffle plate 19, where it is - as in the subsequent roller package 5 - crushed.

- the meal is evenly distributed by a distribution device 20 to the two sieve units 7 and 8 or their sieve compartments 10 and 12, where semolina and flour portions are already sieved, while the husks remain above the sieve surface.

- This process continues in the lower sieve compartments 11 and 13, after which flour is finally drawn off through the outlet shafts 21 and 22 and through the shafts 23 and 24 husks.

- the semolina reaches the lowest roller pack 6 via guide devices 25, 26, where they are also ground to flour.

- the arrangement of the sieve units is such that the sieve unit 7 is suspended on the one hand on two identical articulation levers, which in turn are firmly connected to corresponding drive levers 27 'and are pivotably mounted in an enlarged area 2' of the columns 2 of the machine housing 3; on the other hand, the sieve unit is supported by two further articulation levers 29 such that it can swing in relation to support arms (not shown) extending from the extended area 2 'of the columns 2 (not shown).

- the articulation of the sieve unit 8 is designed in an analogous manner, that is to say with corresponding articulation levers and drive levers 31 ′ assigned to them and articulated levers 33 arranged “standing”.

- each of the sieve units 7, 8 is approximately the same distance from all of their articulation points and in one plane with them. All of these levers have, due to their storage in rubber spring elements, to be described, restoring forces which, in the rest position, that is to say when the drive 9 is not switched on, bring about a vertical position of all the levers.

- the two-sided deflection from this rest position is relatively small due to the design of the drive 9 or the opposite oscillating movement generated by it; in connection with the likewise short effective lengths of all articulation levers, which is preferably only about eight to ten times the vibration range of the sieve units, this leads to a practically horizontal oscillating movement of the sieve units 7 and 8, so that disturbing vertical forces practically do not occur at all.

- the drive 9 which causes the oscillating movement of the sieve units 7, 8 essentially consists of a drive shaft which is equipped at both ends with two eccentrics, so that the two sieve units 7, 8 execute an opposite oscillating movement.

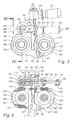

- FIGS. 3, 4 and 5 shows the roller package 4 designed as a closed structural unit with the roller pair 145, 146, which is described as representative of the roller packages 5 and 6 of the same design.

- the roller package 4 containing the rollers 145, 146 has a bearing base 147 which forms the one bearing shell for the roller 146.

- a removable bearing shell 149 is fixedly connected to this by screws 148.

- a spherical roller bearing 150 (FIGS. 4 and 5) is clamped between the two, in which the stub shaft end 151 of the roller 146 is rotatably mounted.

- the spherical roller bearing 150 is secured laterally by a lock nut 152 and covered by bearing covers 153, 154 screwed together.

- the second stub shaft of the roller 146 is mounted in the same way.

- the roller 146 is therefore removed by loosening the screws 148 and removing the bearing shell 149, whereupon the roller is free to be removed horizontally to one side of the column 2.

- the spherical roller bearing 150, the bearing caps 153, 154 and the lock nut 152 can then be removed from the stub shaft 151.

- the bearing base 147 overlaps the column 2 against the movable roller 145 with a bracket 155 and has an axle journal 156 on the free bracket end, to which a movable bearing shell 157 is articulated, in such a way that it can be pivoted against the bearing base 147 or away from it .

- a bearing shell 159 is detachably fastened to this movable bearing shell 157 by means of screws 158.

- a spherical roller bearing 160 is clamped, which is laterally covered by bearing caps 161.

- the stub axle 162 of the roller 145 is rotatably mounted in the spherical roller bearing 160.

- the rollers 145, 146 are mounted in the same way and are also equipped with drive means which drive them at different speeds.

- each pair of rollers 145, 146 has a drive pulley on the axis of the high-speed, fixed roller 146.

- the overdrive from the roller 146 to the slow-moving, movable roller 145 is effected by chain drives or spur gears.

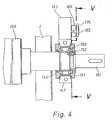

- the bearing base 147 has a bearing eye 163 at both ends of the roller, in which a shaft 164 with an eccentric pin 165 is freely rotatably mounted.

- a clamp 166 is pivotally mounted on the eccentric pin 165, in which a screw 167 is firmly clamped with the screw head 168.

- the screw 167 passes through a nut 169 which is rotatably mounted in a bearing head 170 of the bearing shell 157.

- a nut 171 which is supported against the nut 169, is screwed onto the screw 167.

- a spring 174 is located between a spring bearing 172 bearing against the screw head 168 and a spring bearing 173 supported on the bearing head 170.

- the pretensioning of the spring 174 is set by adjusting the nut 171. This serves as an overload protection if a hard foreign body gets between the rollers 145 and 146 during the grinding process. In this case, the bearing shell 157 together with the roller 145 can pivot outwards against the action of the spring 174, thereby preventing mechanical damage to the pair of rollers.

- the roller 145 is installed and removed in the same way as for the roller 146. After the screws 158 have been loosened, the bearing shells 159 are removed at both roller ends and the stub axles 162 are exposed. The roller can then be removed horizontally (away from column 2).

- the roller gap is adjusted at both roller ends by rotating the shaft 164.

- the end of a lever 175 is articulated on the eccentric pin 165, in the other forked end of which a pivot pin 176 is rotatably mounted.

- a nut thread runs diametrically in the pivot pin 176, into which a spindle 177 is screwed.

- the lower end of the spindle is freely rotatably mounted in a bearing 178 which is firmly connected to the journal 156, so that the spindle 177 can be pivoted with the journal 156.

- the spindle 177 is non-rotatably and axially connected to the output shaft of an angular gear 179, which is flanged to a brake motor 180 on the drive side.

- the angular gear 179 is supported by a torque arm 181. On the one hand it can follow a pivoting movement of the spindle 177 and on the other hand the torque generated by the brake motor 180 is compensated for by the machine housing.

- the pivot pin 176 follows an arc around the center of the shaft 164 and rotates it.

- the clamp 166 and the screw 167 move and pivot the bearing shell 157 or the roller 145 about the axle pin 156 at both roller ends.

- the bearing base 147 has a comparatively large extension in the vertical direction of the column 2 and forms a long lever parallel to the column 2. At their upper and lower ends there is a screw connection 4 'with which they are attached to the column 2 is.

- the connecting straight line of the two screw connections 4 ' runs essentially parallel to the column 2 and is roughly approximated centrally between the rollers 145, 146.

- the distance between the fastening points is preferably equal to or greater than the center distance of the rollers 145, 146 Roller drive and the forces transmitted by the rollers 145, 146 rotating at different speeds to the column 2 are comparatively small, and the smaller the greater the mutual distance between the screw connections 4 ', that is, the longer the effective lever is.

- rollers 145, 146 on opposite sides of the column 2 also causes (at least in rough approximation) a symmetrical loading of the column 2, so that it can be made slim and light.

- the tab 155 with the journal 156 are preferably arranged alternately in the bearing housing of the fixed rollers 146, what also favors a symmetrical loading of the columns 2.

- Such multiple roller mills also have the advantage that each roller can be unhindered by other machine parts and removed to the side.

- roller packs 4, 5, 6 each form a closed joint frame within which the forces and bending moments that occur during grinding are in equilibrium. These are therefore not to be taken up by the columns 2. They are only subjected to a load due to the weight of the roller packs and the drive torques. However, this burden is largely evenly distributed on both sides. Since the rollers 145 and 146 are mounted identically at both ends the parallel positioning of the rollers 145, 146 in the horizontal direction with the screw 167 by screwing it (at both roller ends) more or less into the clamp 166. The spring preload is always retained since the nut 171 is secured to the screw 167 with a stud screw.

- the axes of rotation of the rollers 145 and 146 are leveled by pivoting the bearing housing about the lower screw of the screw connection 4 ', 5' or 6 ', with subsequent fixing of the bearing base 147 by tightening both screws.

- the parallelism of the rollers 145, 146 is achieved by screwing the screw 167 more or less into the clamp 166.

- an adjustable stop screw 182 is screwed into the bearing base 33 on both roller ends, which interacts with a stop plate 183 which is fixedly arranged on the movable bearing shell 157 in such a way that it moves together the rollers are mechanically prevented.

- a stationary safety switch 184 is connected to the column 2 and can be actuated by a sensor 185 attached to the movable bearing shell 157. The switching point is adjustable by means of a micrometer screw 186.

- the shaft 164 is provided with a rotational position indicator 187, which interacts with a stationary (ie firmly connected to the column 2) reference switch 188.

- the reference switch 188 and the rotational position indicator 187 are matched to one another in such a way that the latter closes a switching contact in the first with a switching accuracy of ⁇ 2/100 millimeters when the movable roller 145 reaches its disengaged position.

- the reference switch 188 signals that the defined disengagement path has been reached within the tolerance mentioned. If this signal is missing at the end of the disengagement process, there may be an adjustment and the rollers will switch off automatically.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Mechanical Engineering (AREA)

- Combined Means For Separation Of Solids (AREA)

- Apparatuses For Bulk Treatment Of Fruits And Vegetables And Apparatuses For Preparing Feeds (AREA)

- Crushing And Grinding (AREA)

- Disintegrating Or Milling (AREA)

- Cereal-Derived Products (AREA)

- Formation And Processing Of Food Products (AREA)

- Adjustment And Processing Of Grains (AREA)

- Fodder In General (AREA)

- Feed For Specific Animals (AREA)

- Vending Machines For Individual Products (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8916140U DE8916140U1 (de) | 1988-03-10 | 1989-03-03 | Vorrichtung für die Vermahlung und/oder Verpressung von Nahrungs- oder Futtermittelkomponenten |

Applications Claiming Priority (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19883807843 DE3807843A1 (de) | 1988-03-10 | 1988-03-10 | Vorrichtung zum vermahlen und separieren von korngut |

| DE3807843 | 1988-03-10 | ||

| DE3812056 | 1988-04-12 | ||

| DE3812056A DE3812056A1 (de) | 1988-04-12 | 1988-04-12 | Vorrichtung zum vermahlen und separieren von korngut |

| CH17689 | 1989-01-20 | ||

| CH176/89 | 1989-01-20 | ||

| EP90122696A EP0428183B1 (fr) | 1988-03-10 | 1989-03-03 | Appareillage pour broyer et séparer des grains |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90122696.9 Division | 1990-11-28 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0598705A2 true EP0598705A2 (fr) | 1994-05-25 |

| EP0598705A3 EP0598705A3 (en) | 1994-07-20 |

| EP0598705B1 EP0598705B1 (fr) | 1997-05-28 |

Family

ID=27171871

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94101739A Expired - Lifetime EP0598705B1 (fr) | 1988-03-10 | 1989-03-03 | Dispositif de broyage et/ou compactage de composants d'aliments ou de fourrage |

| EP89903742A Expired - Lifetime EP0357762B1 (fr) | 1988-03-10 | 1989-03-03 | Procede et dispositif pour moudre et separer le grain |

| EP90122696A Expired - Lifetime EP0428183B1 (fr) | 1988-03-10 | 1989-03-03 | Appareillage pour broyer et séparer des grains |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89903742A Expired - Lifetime EP0357762B1 (fr) | 1988-03-10 | 1989-03-03 | Procede et dispositif pour moudre et separer le grain |

| EP90122696A Expired - Lifetime EP0428183B1 (fr) | 1988-03-10 | 1989-03-03 | Appareillage pour broyer et séparer des grains |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5031845A (fr) |

| EP (3) | EP0598705B1 (fr) |

| JP (1) | JPH02503401A (fr) |

| AT (2) | ATE120986T1 (fr) |

| BR (1) | BR8906382A (fr) |

| DE (3) | DE58909179D1 (fr) |

| WO (1) | WO1989008501A1 (fr) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0734770A1 (fr) * | 1995-03-27 | 1996-10-02 | BERGA S.p.A. | Broyeur à cylindres pour céréales comportant un dispositif à axe unique de rotation pour le réglage de l'écartement des cylindres broyeurs |

| EP2098110A3 (fr) * | 2008-03-04 | 2009-12-16 | Deere & Company | Assemblage de compresseur de pointeau |

| CN104826689A (zh) * | 2015-04-27 | 2015-08-12 | 王洪 | 一种流化床锅炉燃料用杂质分拣综合破碎机 |

| CN112138773A (zh) * | 2020-10-23 | 2020-12-29 | 安徽康迪纳电力科技有限责任公司 | 一种输煤系统用的粉碎筛选装置 |

| CN114798051A (zh) * | 2022-05-16 | 2022-07-29 | 淮北师范大学 | 一种煤矸石破碎筛分一体化处理设备 |

| CN116328892A (zh) * | 2023-03-31 | 2023-06-27 | 江西金博实业有限公司 | 一种有机谷物制备营养米粉的多级细化装置 |

| CN117101763A (zh) * | 2023-08-18 | 2023-11-24 | 深圳市建筑装饰(集团)有限公司 | 一种基于绿色施工的建筑垃圾生态环保处理设备 |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2012555A6 (es) * | 1987-10-06 | 1990-04-01 | Buehler Ag Geb | Procedimiento, molino de cilindros e instalacion para la fabricacion de productos de molienda de cereales. |

| US5100539A (en) * | 1989-11-02 | 1992-03-31 | Sizetec, Inc. | Dual-screen particle sizing apparatus and method |

| DE4029202A1 (de) * | 1990-09-14 | 1992-03-19 | Buehler Ag | Verfahren zum sortieren von partikeln eines schuettgutes und vorrichtungen hierfuer |

| GB2252517A (en) * | 1991-02-07 | 1992-08-12 | Smidth & Co As F L | Roller press with torque counter balancing |

| DE4220468C2 (de) * | 1992-06-23 | 1996-04-11 | Heidenauer Maschf Gmbh | Einrichtung zum Einstellen des Walzenspaltes eines Walzenpaares |

| GB2273154B (en) * | 1992-12-02 | 1996-12-11 | Buehler Ag | Method for cleaning and sorting bulk material |

| US5336408A (en) * | 1993-03-29 | 1994-08-09 | Sizetec, Inc. | Apparatus for separating particles from a fluid stream |

| DE4335156B4 (de) * | 1993-10-15 | 2005-08-25 | BüHLER GMBH | Regelvorrichtung für ein Mahlwerk |

| US5544820A (en) * | 1995-02-21 | 1996-08-13 | Walters; Jerry W. | Clear-trajectory rotary-driven impact comminuter |

| US5829692A (en) * | 1995-02-21 | 1998-11-03 | Wildcat Services Inc. | Modularly tiered clear-trajectory impact comminuter and modular comminution chamber |

| DE19700989B4 (de) * | 1996-01-16 | 2004-06-09 | Künzel Maschinenbau GmbH | Verfahren und Einrichtung zur Gewinnung von Malzschrot für die Bierherstellung |

| JP2002346479A (ja) * | 2001-05-22 | 2002-12-03 | Koei Sangyo Kk | 円形振動ふるい機の静電気除去構造 |

| CA2492884A1 (fr) * | 2005-01-13 | 2006-07-13 | Stephane Chevigny | Methode a haute efficacite de reduction granulometrique de polysaccharides ayant l'aspect du verre |

| US7159809B1 (en) * | 2006-03-20 | 2007-01-09 | Yu-Lung Cheng | Waste food processor |

| CN103301904B (zh) * | 2013-05-30 | 2015-04-15 | 中华人民共和国北海出入境检验检疫局 | 一种安全防爆的烟火药剂碾磨装置 |

| CN103831145B (zh) * | 2014-03-11 | 2016-03-30 | 西南大学 | 一种土壤样品制备机 |

| CN111530537A (zh) * | 2018-01-28 | 2020-08-14 | 周文剑 | 一种基于节能环保的建筑建设用破碎装置 |

| CN108126783B (zh) * | 2018-02-08 | 2023-09-29 | 吉林大学 | 一种中药用研磨装置 |

| CN108855360A (zh) * | 2018-07-04 | 2018-11-23 | 芜湖明凯医疗器械科技有限公司 | 一种手动中药粉碎机 |

| CN110038665A (zh) * | 2019-05-09 | 2019-07-23 | 成都雄健粉业有限公司 | 一种小麦制粉用皮磨装置 |

| CN110215993B (zh) * | 2019-06-12 | 2022-01-25 | 杨锦程 | 一种循环式药物制备装置及使用方法 |

| CN110813742A (zh) * | 2019-11-03 | 2020-02-21 | 杭州和源园艺有限公司 | 带研磨功能的谷物筛选机 |

| CN111644245A (zh) * | 2020-05-25 | 2020-09-11 | 中国一冶集团有限公司 | 淤泥预脱水装置 |

| CN111672553A (zh) * | 2020-06-19 | 2020-09-18 | 颍上县三星米业有限公司 | 一种多功能大米加工筛糠设备及筛糠方法 |

| CN112295633A (zh) * | 2020-08-27 | 2021-02-02 | 江苏优先粮食科技有限公司 | 一种新型的粮食清筛设备 |

| CN111974486A (zh) * | 2020-09-11 | 2020-11-24 | 安徽省东博米业有限公司 | 一种大米加工用砻谷设备 |

| CN112354601A (zh) * | 2020-09-22 | 2021-02-12 | 盐城市新澳精密锻造有限公司 | 用于氧化膜生产的原料粉碎设备 |

| CN112473837A (zh) * | 2020-11-16 | 2021-03-12 | 四川铁鹰机械制造有限公司 | 一种便捷式的破碎筛分系统 |

| CN112774784A (zh) * | 2021-01-07 | 2021-05-11 | 曾林香 | 一种粉科配合饲料生产用研磨装置 |

| CN112774974B (zh) * | 2021-02-02 | 2022-09-06 | 安阳市宝机石油机械制造有限公司 | 一种独立调频式振动筛 |

| CN115155760B (zh) * | 2022-06-23 | 2023-04-28 | 厚德食品股份有限公司 | 一种用于蛋鸡饲料加工的筛分装置 |

| CN115350749B (zh) * | 2022-06-30 | 2023-08-25 | 华能伊敏煤电有限责任公司 | 一种露天煤矿冬季煤层保温装置 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20526C (de) * | A. MECHWART in Budapest | Neuerungen an Walzenstuhlungen | ||

| FR2358195A1 (fr) * | 1976-07-16 | 1978-02-10 | Buehler Ag Geb | Procede et dispositif de mouture de cereales |

| US4377110A (en) * | 1980-12-11 | 1983-03-22 | Iseki & Co., Ltd. | Auto-control equipment of hull-removing roll in rice-hulling machines |

| EP0124872A2 (fr) * | 1983-05-06 | 1984-11-14 | GOLFETTO S.p.A. | Moulin à cylindres du type horizontal pour céréales |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US453364A (en) * | 1891-06-02 | Cereal food and process of manufacturing it | ||

| DE236485C (fr) * | ||||

| DE42475C (de) * | W. BÄSCH in Berlin, Blücherplatz 3, und E. PALM in Berlin, Papenstr. 5/6 | Sicherheitsvorrichtung an Kassenschränken | ||

| US1349221A (en) * | 1918-06-17 | 1920-08-10 | Nolen Robert Rufus | Mill |

| GB407316A (en) * | 1932-08-13 | 1934-03-13 | Windham Francis Carey | Improvements in or relating to the pulverising of coal |

| GB529518A (en) * | 1939-05-20 | 1940-11-22 | Simon Ltd Henry | Improvements relating to the milling of wheat flour |

| DE709957C (de) * | 1940-08-21 | 1941-08-30 | Miag Muehlenbau Und Ind Akt Ge | Vorrichtung zum Umstellen der Schrotfuehrung fuer Malzschrotmuehlen |

| US3027101A (en) * | 1958-05-22 | 1962-03-27 | Gen Mills Inc | Milling apparatus |

| GB1156051A (en) * | 1966-06-03 | 1969-06-25 | Simon Ltd Henry | Improvements in or relating to Rollermills. |

| US3419223A (en) * | 1966-12-23 | 1968-12-31 | Nelson H. Morin | Granulators |

| DE2610742C3 (de) * | 1976-03-13 | 1979-06-28 | Buehler-Miag Gmbh, 3300 Braunschweig | Gehäuse für Walzenstühle zum Vermählen von Cerealien und anderem Gut |

| US4043514A (en) * | 1976-03-16 | 1977-08-23 | Conair, Inc. | Comminution device |

| DE2632330C2 (de) * | 1976-07-17 | 1983-04-07 | Neue Bruderhaus Maschinenfabrik GmbH, 7410 Reutlingen | Schneidmühle |

| US4220287A (en) * | 1978-03-23 | 1980-09-02 | Maple Leaf Mills Limited | Process for the treatment of oats |

| GB2029264B (en) * | 1978-09-01 | 1982-10-13 | Simon Ltd H | Rollermills |

| ES2012555A6 (es) * | 1987-10-06 | 1990-04-01 | Buehler Ag Geb | Procedimiento, molino de cilindros e instalacion para la fabricacion de productos de molienda de cereales. |

-

1989

- 1989-03-03 EP EP94101739A patent/EP0598705B1/fr not_active Expired - Lifetime

- 1989-03-03 BR BR898906382A patent/BR8906382A/pt not_active IP Right Cessation

- 1989-03-03 JP JP1503416A patent/JPH02503401A/ja active Pending

- 1989-03-03 US US07/438,422 patent/US5031845A/en not_active Expired - Lifetime

- 1989-03-03 WO PCT/EP1989/000221 patent/WO1989008501A1/fr active IP Right Grant

- 1989-03-03 EP EP89903742A patent/EP0357762B1/fr not_active Expired - Lifetime

- 1989-03-03 DE DE58909179T patent/DE58909179D1/de not_active Expired - Lifetime

- 1989-03-03 AT AT90122696T patent/ATE120986T1/de not_active IP Right Cessation

- 1989-03-03 EP EP90122696A patent/EP0428183B1/fr not_active Expired - Lifetime

- 1989-03-03 AT AT94101739T patent/ATE153565T1/de not_active IP Right Cessation

- 1989-03-03 DE DE58909800T patent/DE58909800D1/de not_active Expired - Lifetime

- 1989-03-03 DE DE8989903742T patent/DE58900497D1/de not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20526C (de) * | A. MECHWART in Budapest | Neuerungen an Walzenstuhlungen | ||

| FR2358195A1 (fr) * | 1976-07-16 | 1978-02-10 | Buehler Ag Geb | Procede et dispositif de mouture de cereales |

| US4377110A (en) * | 1980-12-11 | 1983-03-22 | Iseki & Co., Ltd. | Auto-control equipment of hull-removing roll in rice-hulling machines |

| EP0124872A2 (fr) * | 1983-05-06 | 1984-11-14 | GOLFETTO S.p.A. | Moulin à cylindres du type horizontal pour céréales |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0734770A1 (fr) * | 1995-03-27 | 1996-10-02 | BERGA S.p.A. | Broyeur à cylindres pour céréales comportant un dispositif à axe unique de rotation pour le réglage de l'écartement des cylindres broyeurs |

| US5816511A (en) * | 1995-03-27 | 1998-10-06 | Berga S.P.A. | Cylinder-type machine for milling seed and grain having a device with a single axis of rotation for adjusting the interaxial distance of the cylinders |

| EP2098110A3 (fr) * | 2008-03-04 | 2009-12-16 | Deere & Company | Assemblage de compresseur de pointeau |

| CN104826689A (zh) * | 2015-04-27 | 2015-08-12 | 王洪 | 一种流化床锅炉燃料用杂质分拣综合破碎机 |

| CN104826689B (zh) * | 2015-04-27 | 2017-03-15 | 王洪 | 一种流化床锅炉燃料用杂质分拣综合破碎机 |

| CN112138773A (zh) * | 2020-10-23 | 2020-12-29 | 安徽康迪纳电力科技有限责任公司 | 一种输煤系统用的粉碎筛选装置 |

| CN114798051A (zh) * | 2022-05-16 | 2022-07-29 | 淮北师范大学 | 一种煤矸石破碎筛分一体化处理设备 |

| CN116328892A (zh) * | 2023-03-31 | 2023-06-27 | 江西金博实业有限公司 | 一种有机谷物制备营养米粉的多级细化装置 |

| CN116328892B (zh) * | 2023-03-31 | 2024-06-11 | 江西金博实业有限公司 | 一种有机谷物制备营养米粉的多级细化装置 |

| CN117101763A (zh) * | 2023-08-18 | 2023-11-24 | 深圳市建筑装饰(集团)有限公司 | 一种基于绿色施工的建筑垃圾生态环保处理设备 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0428183A2 (fr) | 1991-05-22 |

| BR8906382A (pt) | 1990-11-20 |

| DE58909179D1 (de) | 1995-05-18 |

| ATE153565T1 (de) | 1997-06-15 |

| DE58900497D1 (de) | 1992-01-09 |

| DE58909800D1 (de) | 1997-07-03 |

| EP0598705B1 (fr) | 1997-05-28 |

| EP0428183A3 (en) | 1992-05-06 |

| WO1989008501A1 (fr) | 1989-09-21 |

| EP0428183B1 (fr) | 1995-04-12 |

| ATE120986T1 (de) | 1995-04-15 |

| EP0598705A3 (en) | 1994-07-20 |

| US5031845A (en) | 1991-07-16 |

| JPH02503401A (ja) | 1990-10-18 |

| EP0357762B1 (fr) | 1991-11-27 |

| EP0357762A1 (fr) | 1990-03-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0598705B1 (fr) | Dispositif de broyage et/ou compactage de composants d'aliments ou de fourrage | |

| DE2760350C2 (fr) | ||

| DE69522280T2 (de) | Getreide-Mühle | |

| DE2606476A1 (de) | Vorrichtung zum maehen und darauffolgenden quetschen von erntegut | |

| DE2704243A1 (de) | Walzenmuehle | |

| DE2730166C3 (de) | Walzenstuhl für die Vermahlung und Schrotung von Getreide | |

| DE2821650A1 (de) | Einrichtung zum ausbreiten von im strang behandelten geweben | |

| DE69214933T3 (de) | Rollenpresse | |

| WO2010023183A1 (fr) | Broyeur à cylindre | |

| DE3238630A1 (de) | Maschine zum zerkleinern von gut, insbesondere von keramischem oder aehnlichem mahlgut | |

| DE2059283A1 (de) | Bandfuehrungs- und -dehnvorrichtung | |

| DE2623825C3 (de) | Rippenwalzwerk zum Bearbeiten von Tabakrippen | |

| DE8916140U1 (de) | Vorrichtung für die Vermahlung und/oder Verpressung von Nahrungs- oder Futtermittelkomponenten | |

| DE19826324C1 (de) | Walzenschüsselmühle | |

| DE2939693C2 (de) | Vliesabnahmevorrichtung | |

| DE3211137A1 (de) | Zerkleinerungseinrichtung | |

| DE3240931A1 (de) | Vertikale rollenmuehle | |

| DE2609272A1 (de) | Feldhaecksler | |

| DE69713814T2 (de) | Verbesserungen an ringwalzenmühlen | |

| DE907884C (de) | Walzenanstellvorrichtung zum Hoehenverstellen und/oder Seitenverstellen der Walzen | |

| DE1088785B (de) | UEberlastungsschutz fuer Backenbrecher | |

| DE903779C (de) | Tellerbrecher | |

| DE2338980C3 (de) | Straßenwalze mit zwei Walztrommeln | |

| DE846199C (de) | Walzenmuehle, insbesondere Zweiwalzenmuehle | |

| DE133086C (fr) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19940204 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 428183 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19960712 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 428183 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 153565 Country of ref document: AT Date of ref document: 19970615 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 58909800 Country of ref document: DE Date of ref document: 19970703 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19970624 |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19980303 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19980320 Year of fee payment: 10 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990303 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990331 |

|

| BERE | Be: lapsed |

Owner name: BUHLER G.M.B.H. Effective date: 19990331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20000224 Year of fee payment: 12 Ref country code: SE Payment date: 20000224 Year of fee payment: 12 Ref country code: FR Payment date: 20000224 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010303 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010304 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 94101739.4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050303 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20070305 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20080219 Year of fee payment: 20 Ref country code: GB Payment date: 20080211 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080331 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20090302 |

|

| NLV7 | Nl: ceased due to reaching the maximum lifetime of a patent |

Effective date: 20090303 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090303 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090302 |