EP0031334B1 - Kokille mit kernzug - Google Patents

Kokille mit kernzug Download PDFInfo

- Publication number

- EP0031334B1 EP0031334B1 EP80901145A EP80901145A EP0031334B1 EP 0031334 B1 EP0031334 B1 EP 0031334B1 EP 80901145 A EP80901145 A EP 80901145A EP 80901145 A EP80901145 A EP 80901145A EP 0031334 B1 EP0031334 B1 EP 0031334B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- core

- stud

- mold

- mold according

- holding device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 229910052751 metal Inorganic materials 0.000 claims description 6

- 239000002184 metal Substances 0.000 claims description 6

- 239000000853 adhesive Substances 0.000 claims description 2

- 230000001070 adhesive effect Effects 0.000 claims description 2

- 239000012778 molding material Substances 0.000 claims description 2

- 239000000956 alloy Substances 0.000 claims 1

- 229910045601 alloy Inorganic materials 0.000 claims 1

- 239000004576 sand Substances 0.000 abstract description 11

- 235000019994 cava Nutrition 0.000 abstract 1

- 239000007789 gas Substances 0.000 description 4

- 238000007711 solidification Methods 0.000 description 4

- 230000008023 solidification Effects 0.000 description 4

- 238000005266 casting Methods 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 239000000463 material Substances 0.000 description 2

- 229910000599 Cr alloy Inorganic materials 0.000 description 1

- 229920001353 Dextrin Polymers 0.000 description 1

- 239000004375 Dextrin Substances 0.000 description 1

- 229910000640 Fe alloy Inorganic materials 0.000 description 1

- GXDVEXJTVGRLNW-UHFFFAOYSA-N [Cr].[Cu] Chemical compound [Cr].[Cu] GXDVEXJTVGRLNW-UHFFFAOYSA-N 0.000 description 1

- 238000004873 anchoring Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000000788 chromium alloy Substances 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 235000019425 dextrin Nutrition 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 235000019353 potassium silicate Nutrition 0.000 description 1

- NTHWMYGWWRZVTN-UHFFFAOYSA-N sodium silicate Chemical compound [Na+].[Na+].[O-][Si]([O-])=O NTHWMYGWWRZVTN-UHFFFAOYSA-N 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22C—FOUNDRY MOULDING

- B22C9/00—Moulds or cores; Moulding processes

- B22C9/10—Cores; Manufacture or installation of cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22C—FOUNDRY MOULDING

- B22C9/00—Moulds or cores; Moulding processes

- B22C9/06—Permanent moulds for shaped castings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D17/00—Pressure die casting or injection die casting, i.e. casting in which the metal is forced into a mould under high pressure

- B22D17/20—Accessories: Details

- B22D17/22—Dies; Die plates; Die supports; Cooling equipment for dies; Accessories for loosening and ejecting castings from dies

- B22D17/24—Accessories for locating and holding cores or inserts

Definitions

- the invention relates to a mold with at least one core pull in its wall.

- Core trains in molds are known and have u. a. the advantage that they are placed and fixed exactly in the mold cavity and do not slip.

- Cantilever cavities d. H. however, those that enlarge into the mold cavity cannot be produced. However, they are particularly important as anchoring slots or the like for wear parts which consist of hard cast materials, since these cannot be machined with the usual tools.

- cantilevered cavities had to be formed with the aid of sand cores, but this is not without problems. Solidification and saturation are disturbed by the different thermal conductivities of molding material and metal. Accurate fixation (securing against floating) and positioning using core brands and gas formation also pose difficulties.

- a slidable core holder which can be made of metal, among other things. Since this holder described is designed for sand molds, it is immovable and non-retractable during solidification. This core holder is therefore not suitable for permanent forms. In contrast to sand molds, a permanent retraction of the core holder during solidification is necessary in order to allow the casting to shrink freely.

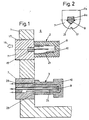

- a mold has, in its side wall 1, two slidable core pulls 2 and 3, each with a core holder 7, a pin 9 projecting into the cavity 8 of the mold, both made of metal and advantageously made of a copper-chromium alloy (CuCrl), and one Have sleeve 10 made of core sand.

- the pin 9 can be screwed into the core holder 7 by means of a screw pin 15 (core pull 2) or pin 9 and holder 7 can be formed together from one piece (core pull 3). The sleeve 10 is pushed onto the retracted pin from the mold cavity.

- the core pull 2 or 3 is extended in accordance with the arrow 16, the sand sleeve 10 remaining in the casting.

- the sleeve 10 cannot twist.

- the sleeve 10 must be secured against rotation on the pin 9 and the holder 7 must be retractable and retractable.

- the holder 7 therefore has two longitudinal grooves 17 (core pull 2).

- the pin 9, which tapers for easier attachment and for better detachment or stripping from the sleeve 10 when extended to its free end opposite the holder 7, has a round shape, as shown in FIG. 2, lower half Cross-section and longitudinal ribs 21 thereon.

- a non-circular cross-section, for example a square pin 9a shown in FIG. 2, upper half, can effectively counter rotation of the sleeve 10; Longitudinal ribs 21 are then not required.

- an adhesive for example water glass or dextrin, can connect the sleeve 10 to the pin 9.

- the core pull 3 has a separate water cooling. Water is supplied through a central tube 24 which extends into the free end region of the pin 9. An annular groove 25 is also milled out in the end face of the holder 7, where the sand sleeve 10 abuts, via the core gases a line 26 can be discharged outdoors. The core gases can also be drawn off through line 26.

- the core pulls can also be retracted and extended at an angle with respect to the wall 1. It is also possible to produce a continuous, cantilevered cavity in the central region by moving two core pulls 3 according to the invention, from opposite walls, onto one another so that they just touch.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Molds, Cores, And Manufacturing Methods Thereof (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

- Coloring (AREA)

- Casting Devices For Molds (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH628979A CH640160A5 (de) | 1979-07-05 | 1979-07-05 | Kokille mit kernzug. |

| CH6289/79 | 1979-07-05 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0031334A1 EP0031334A1 (de) | 1981-07-08 |

| EP0031334B1 true EP0031334B1 (de) | 1983-06-15 |

Family

ID=4307207

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP80901145A Expired EP0031334B1 (de) | 1979-07-05 | 1981-01-26 | Kokille mit kernzug |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4462455A (enExample) |

| EP (1) | EP0031334B1 (enExample) |

| JP (1) | JPS56500765A (enExample) |

| AT (1) | ATE3758T1 (enExample) |

| CH (1) | CH640160A5 (enExample) |

| DE (1) | DE3063764D1 (enExample) |

| WO (1) | WO1981000067A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105945535A (zh) * | 2016-05-30 | 2016-09-21 | 方雪锋 | 一种传动轴突缘叉加工方法 |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH074646B2 (ja) * | 1989-02-20 | 1995-01-25 | リョービ株式会社 | 高圧鋳造用砂中子及びその製造方法 |

| AU677903B2 (en) * | 1994-06-01 | 1997-05-08 | Toyota Jidosha Kabushiki Kaisha | Casting method with improved resin core removing step and apparatus for performing the method |

| JPH0871699A (ja) * | 1994-09-07 | 1996-03-19 | Shinmori Shoji Kk | 鋳造金型の中子支持体 |

| JP3274069B2 (ja) * | 1996-02-09 | 2002-04-15 | リョービ株式会社 | クローズドデッキタイプシリンダブロック鋳造装置と該装置に用いられる砂中子との組合せ |

| DE102011079356A1 (de) * | 2011-07-18 | 2013-01-24 | Mahle International Gmbh | Gießkern einer Gussform zur Herstellung eines Zylinders |

| CN105921958B (zh) * | 2016-05-30 | 2018-10-26 | 河南省豫煤矿机有限公司 | 一种传动轴花键轴头锻造工艺 |

| DE102018215955A1 (de) * | 2018-09-19 | 2020-03-19 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Gießform zur Herstellung von wendelförmigen Gusskörpern |

| CN113000790A (zh) * | 2021-01-19 | 2021-06-22 | 安徽省恒泰动力科技有限公司 | 一种活塞整体抽芯模具 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB775496A (enExample) * | ||||

| DE386763C (de) * | 1923-12-22 | Guido Allendorf | Einrichtung zum Halten von Kernen | |

| DE392909C (de) * | 1924-04-02 | Guido Allendorf | Einrichtung zum Halten von Kernen | |

| US818413A (en) * | 1904-03-03 | 1906-04-24 | Arthur B Underhill | Combined metal core vent and support. |

| FR693752A (fr) * | 1930-04-11 | 1930-11-25 | Fermiere Des Fonderies Et Acie | Noyau de fonderie pour cylindres de moteurs |

| FR928617A (fr) * | 1946-06-07 | 1947-12-03 | Perfectionnement aux noyaux magnétiques | |

| FR1056470A (fr) * | 1952-04-30 | 1954-02-26 | Aubry Ets | Perfectionnement dans la confection des moules et noyaux de fonderie |

| US2752652A (en) * | 1954-09-28 | 1956-07-03 | Central States Ind Supply Comp | Method of reinforcing cores, utilizing glass tubes |

| US3098270A (en) * | 1961-04-18 | 1963-07-23 | Nat Lead Co | Die casting method and article |

| US3528637A (en) * | 1965-08-24 | 1970-09-15 | Microdot Inc | Core set for molding a partial thread |

| US3374827A (en) * | 1965-11-17 | 1968-03-26 | Gen Motors Corp | Method of using vaporizable core assembly spacers |

| GB1199673A (en) * | 1968-04-20 | 1970-07-22 | Ford Motor Co | Method of Casting a Light Metal |

| FR1597446A (enExample) * | 1968-08-19 | 1970-06-29 |

-

1979

- 1979-07-05 CH CH628979A patent/CH640160A5/de not_active IP Right Cessation

-

1980

- 1980-07-02 AT AT80901145T patent/ATE3758T1/de active

- 1980-07-02 US US06/243,957 patent/US4462455A/en not_active Expired - Lifetime

- 1980-07-02 DE DE8080901145T patent/DE3063764D1/de not_active Expired

- 1980-07-02 JP JP50144180A patent/JPS56500765A/ja active Pending

- 1980-07-02 WO PCT/CH1980/000076 patent/WO1981000067A1/de not_active Ceased

-

1981

- 1981-01-26 EP EP80901145A patent/EP0031334B1/de not_active Expired

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105945535A (zh) * | 2016-05-30 | 2016-09-21 | 方雪锋 | 一种传动轴突缘叉加工方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0031334A1 (de) | 1981-07-08 |

| WO1981000067A1 (fr) | 1981-01-22 |

| US4462455A (en) | 1984-07-31 |

| JPS56500765A (enExample) | 1981-06-11 |

| CH640160A5 (de) | 1983-12-30 |

| DE3063764D1 (en) | 1983-07-21 |

| ATE3758T1 (de) | 1983-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0268910B1 (de) | Kokille zum Stranggiessen von Stahlband | |

| DE8900819U1 (de) | Gießform zum Metallgießen und Hülse hierfür | |

| DE2727742A1 (de) | Verschleissteile fuer schiebeverschluesse, verfahren zur herstellung solcher verschleissteile und schiebeverschluss mit solchen verschleissteilen | |

| EP0031334B1 (de) | Kokille mit kernzug | |

| DE69110786T2 (de) | Verfahren zur Gestaltung eines Gusstückes aus Aluminium oder seinen Legierungen mit eingegliederten Giessläufen. | |

| DE844806C (de) | Verfahren und Vorrichtung zur Herstellung von Verbundmetallstraengen | |

| EP0230886A2 (de) | Kokille zum Stranggiessen von stahlband | |

| DE69327714T2 (de) | Feingiessverfahren zur Herstellung von Gussstücken | |

| DE2635082B2 (de) | Metallische Endplatte zum Verschließen der Enden von Schleudergießkokillen | |

| DE2622891B2 (de) | Hilfseinrichtung IBr das Abgießen von Metallschmelzen in Dauerformen | |

| DE736672C (de) | Verfahren zur Herstellung von plattierten Brammen | |

| DE10059481B4 (de) | Speiser mit einem rohrähnlichen Körper | |

| AT295765B (de) | Kokille zum Herstellen von Hohlblöcken aus Metall oder Metallegierungen | |

| DE680515C (de) | Vorrichtung zum Herstellen von Verbundgussstuecken, insbesondere Hartgusswalzen | |

| DE607281C (de) | Verfahren zur Herstellung von Verbundgusswalzen | |

| DE3511119A1 (de) | Verfahren und vorrichtung zum aufklappbaren anschliessen eines deckels an einem henkel eines gefaesses | |

| DE2429905A1 (de) | Verfahren zum herstellen von metallgussformen oder -hohlraeumen | |

| DE731146C (de) | Zweiteilige Kokille zum Giessen von Zapfhaehnen | |

| DE496820C (de) | Vorrichtung zum gleichzeitigen Giessen mehrerer Hohlbloecke aus echter Bronze | |

| DE1806297C (de) | Metallgießform für den waagerechten Guß von Stangen u. dgl | |

| DE3516033A1 (de) | Verfahren und speiserform zum herstellen eines einen gekruemmten speiserkanal aufweisenden speisereinsatzes, insbesondere seitenspeisereinsatzes | |

| DE319861C (de) | Verfahren und Vorrichtung zur Herstellung von Verschleissfutter aus Hartguss fuer Spuelversatzrohre | |

| DE3206987A1 (de) | Giessform zum herstellen von hohlgussstuecken | |

| DE674611C (de) | Mehrteiliger Metallkern | |

| DE801162C (de) | Verfahren zum Giessen von Hohlformstuecken, insbesondere Motorkolben und -zylinder |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19810223 |

|

| AK | Designated contracting states |

Designated state(s): AT DE FR GB LU NL SE |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT DE FR GB LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 3758 Country of ref document: AT Date of ref document: 19830615 Kind code of ref document: T |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19830629 Year of fee payment: 4 |

|

| REF | Corresponds to: |

Ref document number: 3063764 Country of ref document: DE Date of ref document: 19830721 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19830731 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19840630 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19840813 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19840914 Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19850711 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19850731 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19860702 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19860703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19870201 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19870331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19870401 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19881118 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 80901145.5 Effective date: 19870518 |