WO2013046715A1 - 除湿システム - Google Patents

除湿システム Download PDFInfo

- Publication number

- WO2013046715A1 WO2013046715A1 PCT/JP2012/006243 JP2012006243W WO2013046715A1 WO 2013046715 A1 WO2013046715 A1 WO 2013046715A1 JP 2012006243 W JP2012006243 W JP 2012006243W WO 2013046715 A1 WO2013046715 A1 WO 2013046715A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- air

- adsorption

- heat exchanger

- dehumidifying unit

- unit

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/12—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling

- F24F3/14—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification

- F24F3/1411—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification by absorbing or adsorbing water, e.g. using an hygroscopic desiccant

- F24F3/1423—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification by absorbing or adsorbing water, e.g. using an hygroscopic desiccant with a moving bed of solid desiccants, e.g. a rotary wheel supporting solid desiccants

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/12—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling

- F24F3/14—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification

- F24F3/1405—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification in which the humidity of the air is exclusively affected by contact with the evaporator of a closed-circuit cooling system or heat pump circuit

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/12—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling

- F24F3/14—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification

- F24F3/1411—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification by absorbing or adsorbing water, e.g. using an hygroscopic desiccant

- F24F3/1429—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification by absorbing or adsorbing water, e.g. using an hygroscopic desiccant alternatively operating a heat exchanger in an absorbing/adsorbing mode and a heat exchanger in a regeneration mode

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F5/00—Air-conditioning systems or apparatus not covered by F24F1/00 or F24F3/00, e.g. using solar heat or combined with household units such as an oven or water heater

- F24F5/0007—Air-conditioning systems or apparatus not covered by F24F1/00 or F24F3/00, e.g. using solar heat or combined with household units such as an oven or water heater cooling apparatus specially adapted for use in air-conditioning

- F24F5/001—Compression cycle type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F5/00—Air-conditioning systems or apparatus not covered by F24F1/00 or F24F3/00, e.g. using solar heat or combined with household units such as an oven or water heater

- F24F5/0007—Air-conditioning systems or apparatus not covered by F24F1/00 or F24F3/00, e.g. using solar heat or combined with household units such as an oven or water heater cooling apparatus specially adapted for use in air-conditioning

- F24F5/0014—Air-conditioning systems or apparatus not covered by F24F1/00 or F24F3/00, e.g. using solar heat or combined with household units such as an oven or water heater cooling apparatus specially adapted for use in air-conditioning using absorption or desorption

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2203/00—Devices or apparatus used for air treatment

- F24F2203/02—System or Device comprising a heat pump as a subsystem, e.g. combined with humidification/dehumidification, heating, natural energy or with hybrid system

- F24F2203/021—Compression cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2203/00—Devices or apparatus used for air treatment

- F24F2203/02—System or Device comprising a heat pump as a subsystem, e.g. combined with humidification/dehumidification, heating, natural energy or with hybrid system

- F24F2203/026—Absorption - desorption cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2203/00—Devices or apparatus used for air treatment

- F24F2203/10—Rotary wheel

- F24F2203/1016—Rotary wheel combined with another type of cooling principle, e.g. compression cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2203/00—Devices or apparatus used for air treatment

- F24F2203/10—Rotary wheel

- F24F2203/1032—Desiccant wheel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2203/00—Devices or apparatus used for air treatment

- F24F2203/10—Rotary wheel

- F24F2203/108—Rotary wheel comprising rotor parts shaped in sector form

Definitions

- the present invention relates to a dehumidification system that supplies dehumidified air into a room.

- Patent Documents 1 and 2 disclose this type of dehumidification system.

- Patent Documents 1 and 2 describe a configuration in which adsorption rotors are arranged in three stages in series on an air passage.

- the air passage is composed of an air supply passage that supplies outdoor air after processing it with an adsorption rotor, and an exhaust passage that discharges indoor air to the outside.

- the adsorption rotor is disposed across the air supply passage and the exhaust passage, and is configured to be rotatable about a rotation axis between both passages.

- the adsorption rotor adsorbs moisture in the air flowing through the air supply passage to dehumidify it, and regenerates it by releasing moisture into the air flowing through the exhaust passage.

- the exhaust passage is provided with a heater for heating air in order to heat the air and use it for regeneration of the adsorption rotor.

- the adsorption rotor rotates and moves to the exhaust passage when the moisture adsorption amount of the portion that adsorbs moisture increases, and is regenerated by releasing moisture therein, and then used again on the adsorption side.

- the air adsorbed into the room becomes air with a low dew point.

- the air supplied to a dry clean room for manufacturing a lithium ion battery (air with a dew point of about ⁇ 50 ° C.) Can be used.

- This type of system often employs a configuration in which the adsorption rotor has two stages.

- each adsorption rotor becomes a dehumidification regeneration unit.

- the adsorption rotor itself is a high-cost component. Since the regeneration temperature of the adsorption rotor by the heater is high, the running cost required for the heat quantity of the heater is also increased.

- the energy consumption of the air conditioning system accounts for about 50%, and energy saving of this system greatly contributes to the cost reduction of the lithium battery.

- the amount of heat provided for the regeneration of the adsorption rotor is large, it has been extremely difficult to realize a reduction in cost of the dehumidification system.

- the present invention has been made in view of such a point, and an object thereof is to enable energy saving and cost reduction of the dehumidification system.

- the first invention is an air passage (40, 50) having an air supply passage (40) through which air supplied to the indoor space (S) passes and an exhaust passage (50) through which air discharged to the outside passes.

- a dehumidifying unit (60, 20, 30) disposed on the air passage (40, 50), and the dehumidifying unit (60, 20, 30) is on the inlet side of the air supplied to the room

- a dehumidification system including a first dehumidifying unit (60), a second dehumidifying unit (20), and a third dehumidifying unit (30) arranged in order from the indoor space (S).

- the first dehumidifying unit (60) includes an outdoor air cooling heat exchanger (61) for cooling and dehumidifying the air supplied to the room, and the second dehumidifying unit (20) is alternately arranged on the adsorption side and the regeneration side.

- the 3 dehumidification unit (30) includes an adsorption rotor (31) partly configured as an adsorption part (32) and the other part configured as a regeneration part (34), and the second dehumidification unit (20)

- the air dehumidified in step (32) is further dehumidified by the adsorption part (32).

- air such as outdoor air supplied to the room is first cooled and dehumidified by the outdoor air cooling heat exchanger (61) of the first dehumidifying unit (60).

- the air that has been cooled and dehumidified by the outside air cooling heat exchanger (61) passes through the second dehumidifying unit (20), and moisture is adsorbed by the adsorbent of the adsorption heat exchanger on the adsorption side. Since the adsorption heat generated when moisture in the air is adsorbed by the adsorption heat exchanger (22, 24) is absorbed by the adsorption heat exchanger (22, 24), the temperature rise of the air can be suppressed.

- the two adsorption heat exchangers (22, 24) are alternately switched between the adsorption side and the regeneration side, and the air supplied to the indoor space (S) always passes through the adsorption side adsorption heat exchanger.

- the rise in temperature is suppressed and the air whose humidity is reduced passes through the adsorption rotor (31) of the third dehumidification unit (30).

- the adsorption rotor (31) moisture in the air is further adsorbed by the adsorbent. Then, the low dew point air that has passed through the adsorption rotor (31) is supplied to the indoor space (S).

- the third dehumidifying unit (30) is disposed on the inlet side of the regenerated air to the adsorption rotor (31) in addition to the adsorption rotor (31). It is characterized by having a vessel (65).

- the suction rotor (31) is regenerated by supplying the air heated by the air heater (65) to the suction rotor (31). Since this air is air cooled by the adsorption heat exchanger (22, 24), the temperature rise of the adsorption rotor (31) is suppressed, and low temperature regeneration becomes possible.

- the air heater (65) is a regenerative heat exchanger (65) configured by a condenser provided in a refrigerant circuit (70a, 120) for performing a refrigeration cycle. It is characterized by being.

- the adsorption rotor (31) is regenerated by supplying air heated by the regeneration heat exchanger (65) to the adsorption rotor (31). Since this air is air cooled by the adsorption heat exchanger (22, 24), the temperature rise of the adsorption rotor (31) is suppressed, and low temperature regeneration becomes possible.

- a fourth invention is the refrigerant circuit according to the third invention, wherein the refrigerant circuit (70a, 120) has the regeneration heat exchanger (65) as a condenser and the outside air cooling heat exchanger (61) as an evaporator. (70a, 120).

- the adsorption rotor (31) is regenerated by releasing the heat that the refrigerant has taken from the outdoor air by the outdoor air cooling heat exchanger (61) by the regenerative heat exchanger (65).

- the fifth invention is characterized in that, in the second invention, the air heater (65) is an electric heater or a steam heater.

- the adsorption rotor (31) is regenerated by supplying air heated by the air heater (65) such as the electric heater or steam heater to the adsorption rotor (31). Since this air is air cooled by the adsorption heat exchanger (22, 24), the temperature rise of the adsorption rotor (31) is suppressed, and low temperature regeneration becomes possible.

- the air heater (65) such as the electric heater or steam heater

- the second dehumidifying unit (20) and the third dehumidifying unit (30) are adsorption heat exchangers (22, 24) on the adsorption side.

- the suction portion (32) of the suction rotor (31) is positioned downstream of the supply passage (40), and the exhaust passage (50) passing through the regeneration portion (34) of the suction rotor (31).

- the adsorption heat exchanger (24, 22) on the regeneration side is located downstream.

- the air flowing out from the adsorption heat exchanger (22, 24) on the adsorption side is further dehumidified by the adsorption section (32) of the adsorption rotor (31).

- the regeneration-side adsorption heat exchanger (24, 22) is regenerated by the air flowing out from the regeneration unit (34) of the adsorption rotor (31).

- the two adsorption heat exchangers (22, 24) of the second dehumidifying unit (20) are constituted by two heat exchangers provided in the refrigerant circuit (22a). And the second dehumidifying unit (20) reverses the flow direction of the refrigerant in the refrigerant circuit (20a) so that the two adsorption heat exchangers (22, 24) are on the adsorption side and the regeneration side.

- the refrigerant flow switching mechanism (25), which switches alternately to the condenser, and the adsorption heat exchanger (22, 24), which serves as the evaporator, are connected to the air supply passage (40) to perform the adsorption heat exchange, which serves as the condenser.

- an air passage switching mechanism (26, 27) for switching the air flow so as to connect the chamber (24, 22) to the exhaust passage (50), and the adsorption rotor (31 of the third dehumidifying unit (30)) ) Is disposed across the air supply passage (40) and the exhaust passage (50), and the rotation shaft between the passages (40, 50).

- It is configured to be rotatable as a center so that the portion through which the air supply passage (40) passes becomes the adsorption portion (32), and the portion through which the exhaust passage (50) passes becomes the regeneration portion (24). It is characterized by being composed.

- the two adsorption heat exchangers (22, 24) are alternately switched between the evaporator and the condenser, and the air passage is also switched.

- the adsorption-side adsorption heat exchanger (22, 24) as an evaporator is connected to the supply air passage (40)

- the regeneration-side adsorption heat exchanger (24, 22) as a condenser is connected to the exhaust passage (50). ).

- the second dehumidifying unit (20) and the third dehumidifying unit (30) are the second dehumidifying unit (20) and the third dehumidifying unit. It is characterized in that it is directly connected to the air supply passage (40) without an intermediate cooler between (30) and (30).

- the dehumidified air cooled by the second dehumidifying unit (20) is supplied to the third dehumidifying unit (30) without passing through the intermediate cooler, and further dehumidified by the third dehumidifying unit (30). Will be.

- the return air port (58a) communicating with the indoor space (S) is connected to the second dehumidifying unit (20) and the third dehumidifying unit ( It is characterized by having a return air passage (58) connected to the air supply passage (40) between the air supply passage (30) and the air supply passage (30).

- the air returning from the indoor space (S) through the return air passage (58) to the air supply passage (40) is mixed with the air having passed through the second dehumidification unit (20) to form the third dehumidification unit. Supplied to the unit (30).

- the return air passage (58) is provided with a return air fan (59) for pushing indoor air toward the air supply passage (40). Yes.

- the pressure in the system communicating from the return air passage (58) to the air supply passage (40) is positive.

- this system becomes negative pressure the moisture in the outdoor air may be sucked into the air supply passage (40).

- the above-mentioned system is kept at a positive pressure to prevent an increase in the humidity of the system.

- the return air passage (58) is provided with a return air cooler (67) for cooling the air flowing through the return air passage (58). It is said.

- the return air is cooled and returned to the supply passage (40), so that the temperature of the supply air after mixing can be kept low. And since the temperature of the air supplied to the adsorption rotor (31) is kept low, the regeneration temperature of the adsorption rotor (31) can also be kept low.

- the adsorbent provided in the adsorption heat exchanger (22, 24) is a unit of relative humidity as the relative humidity of air increases.

- the maximum adsorption amount at a high relative humidity water vapor partial pressure

- the adsorption rotor (31) of the third dehumidifying unit (30) that treats air with relatively low humidity is adsorbed by the adsorbent that can obtain the maximum adsorption amount when the relative humidity is low. Moisture is efficiently adsorbed by the adsorbent that can be used.

- the second dehumidification unit ( 20) is configured to be connected between the first dehumidifying unit (60) and the third dehumidifying unit (30).

- the second dehumidifying unit (20) is an optional unit for the first dehumidifying unit (60) with respect to the existing system including the first dehumidifying unit (60) and the third dehumidifying unit (30).

- a third dehumidifying unit (30) a dehumidifying system including three stages of dehumidifying units (60, 20, 30) is constructed.

- the refrigerant circuit (70a, 120) is disposed on the downstream side of the adsorption rotor (31) in the supply passage (40) to constitute a condenser.

- the heat heat exchanger (64) and the return air port (58a) communicating with the indoor space (S) are connected to the air supply path (40 between the second dehumidifying unit (20) and the third dehumidifying unit (30)).

- an air cooling heat exchanger (67) serving as an air cooling section which is disposed in the return air passage (58) connected to the gas generator and constitutes the evaporator.

- the air dehumidified by the adsorption rotor (31) when the air dehumidified by the adsorption rotor (31) is heated by the reheat heat exchanger (64), it is then supplied into the room. As a result, the relative humidity of the air supplied into the room decreases. Further, the indoor air is cooled by the annular cooling heat exchanger (67) and then returned to the upstream side of the adsorption rotor (31).

- the reheat heat exchanger (64) and the recirculation cooling heat exchanger (67) are connected to the refrigerant circuit (70a, 120).

- the compressed refrigerant flows through the reheat heat exchanger (64) serving as a condenser. That is, in the reheat heat exchanger (64), the refrigerant dissipates heat to the air and condenses.

- the condensed refrigerant flows through the recirculation cooling heat exchanger (67) serving as an evaporator after being decompressed. That is, in the recirculation cooling heat exchanger (67), the refrigerant absorbs heat from the air and evaporates.

- the heat deprived from the air by the annular cooling heat exchanger (67) is used for heating the air by the reheat heat exchanger (64).

- the refrigerant circuit (70a, 120) is a unitary refrigeration cycle in which the condenser (64, 65) and the evaporator (61, 67) are connected to one closed circuit. It is characterized by being a refrigerant circuit (70a) of the type.

- the condenser (64, 65) and the evaporator (61, 67) described above are connected to the refrigerant circuit (70a) of the single refrigeration cycle type. Thereby, simplification of a refrigerant circuit (70a) is achieved.

- the refrigerant circuit (70a) has a higher required capacity on the condenser (64, 65) side than a required capacity on the evaporator (61, 67) side.

- the rotation speed is controlled so that the condensation pressure approaches the target pressure

- the required capacity on the evaporator (61, 67) side is higher than the required capacity on the condenser (64, 65) side

- the evaporation pressure A variable displacement compressor (80) whose rotational speed is controlled so as to approach the target pressure is connected.

- the refrigerant circuit (70a) of the sixteenth invention is connected to a variable capacity compressor (80) whose rotation speed can be adjusted.

- the rotation speed of the compressor (80) is adjusted according to the operating conditions. Specifically, when the required capacity on the condenser (64, 65) side is higher than the required capacity on the evaporator (61, 67) side, the compressor (80) rotates so that the condensation pressure approaches the target pressure. The number is controlled. As a result, the necessary capacity on the condenser (64, 65) side can be ensured by quickly setting the condensation pressure as the target pressure.

- the rotation speed of the compressor (80) is set so that the evaporation pressure approaches the target pressure. Be controlled. As a result, the necessary capacity on the evaporator (61, 67) side can be ensured by quickly setting the evaporation pressure as the target pressure.

- the refrigerant circuit (70a, 120) is configured such that the first compressor (130) and the regenerative heat exchanger (65) are connected to perform a refrigeration cycle.

- a low pressure side circuit (120b) in which a circuit (120a), a second compressor (150) and the outside air cooling heat exchanger (61) are connected to perform a refrigeration cycle, and a low pressure of the high pressure side circuit (120a)

- the refrigerant circuit (120) is a two-stage refrigeration cycle type having a refrigerant and an intermediate heat exchanger (140) for exchanging heat with the high-pressure refrigerant of the low-pressure circuit (120b).

- the high-pressure side circuit (120a) to which the regenerative heat exchanger (65) is connected and the low-pressure side circuit (120b) to which the outside air cooling heat exchanger (61) is connected are an intermediate heat exchanger.

- the refrigerant circuit (120) of the two-stage refrigeration cycle type is configured by being connected to each other via (140). Thereby, a sufficient difference between the condensation pressure of the regenerative heat exchanger (65) and the evaporation pressure of the outside air cooling heat exchanger (61) can be secured. As a result, the air heating capacity in the regenerative heat exchanger (65) is increased, and the cooling capacity of the outside air cooling heat exchanger (61) is also increased.

- the cooling and dehumidification performed by the first dehumidifying unit (60) there is a possibility that a large amount of water vapor is contained in the outside air.

- Dehumidification is advantageous in that the cost is low and the energy consumption is relatively small.

- the adsorption rotor (31) is used for the adsorption dehumidification as before. If the heat treatment is performed, heat of adsorption is generated simultaneously with dehumidification, so that a high regeneration temperature is required. Therefore, in the present invention, by performing adsorption while cooling with the adsorption heat exchanger (22, 24), adsorption is performed while removing the heat of adsorption, so that the dew point is ⁇ 10 to ⁇ 20 with high efficiency while suppressing temperature rise. C. air can be obtained.

- the heat of adsorption generated when the third dehumidifying unit (30) performs adsorption is reduced, so that the temperature rise due to the heat of adsorption is absorbed. It does not become a hindrance factor. For this reason, it is possible to reduce the residence time per unit volume by carrying out adsorption using the adsorption rotor (31), which makes it easier to increase the contact area with air than the adsorption heat exchanger (22, 24). Can be efficiently dehumidified.

- the adsorption heat exchanger (22, 24) is used in the second dehumidifying unit (20), so that the humidity of the air is lowered and the temperature is lowered. Therefore, the adsorption rotor (31) Regeneration temperature can be lowered. That is, by combining the adsorption heat exchanger (22, 24) of the second dehumidification unit (20) and the adsorption rotor (31) of the third dehumidification unit (30), the adsorption rotor (31 of the third dehumidification unit (30)).

- the regeneration temperature can be lowered, for example, exhaust heat generated in a lithium ion battery manufacturing facility can be used as regeneration energy for the adsorption rotor (31), and further energy saving can be promoted. Become.

- the regeneration temperature can be lowered as compared with the prior art, so the amount of heat required for the heating is reduced. Energy saving.

- the regenerative heat exchanger (65) constituted by the condenser provided in the refrigerant circuit (70a, 120) for performing the refrigeration cycle is the air heater (65).

- the regenerative air supplied to the adsorption rotor (31) can be heated more efficiently, and further energy saving can be achieved.

- the regenerative heat exchanger (65) can regenerate the adsorption rotor (31) using the heat that the refrigerant has taken from the outdoor air by the outdoor air cooling heat exchanger (61), Energy efficiency can be increased.

- the regeneration temperature can be lowered as compared with the prior art. Energy saving can be realized by reducing the amount of heat required for the heating.

- the adsorption heat exchanger (22, 24) on the adsorption side is located upstream of the adsorption portion (32) of the adsorption rotor (31), and air with low humidity and temperature is supplied to the adsorption rotor (31 ) Can be supplied to the adsorbing part (32), so that the temperature rise of the adsorbing rotor (31) can be suppressed. Further, by supplying the air heated through the regeneration section (34) of the adsorption rotor (31) to the adsorption heat exchanger (24, 22) on the regeneration side, this air is supplied to the adsorption heat exchanger (24 , 22) can also be used for playback.

- the second dehumidifying unit (20) is provided with the two adsorption heat exchangers (22, 24) and switches between the adsorption side and the regeneration side alternately.

- the third dehumidifying unit (30) using 31) an apparatus for performing a continuous dehumidifying operation can be easily realized.

- the dehumidified air cooled by the second dehumidifying unit (20) is supplied to the third dehumidifying unit (30) without going through the intermediate cooler, it is conventionally used. However, the energy required for air cooling of the intermediate cooler, which is generally used, is no longer necessary. Further, in the present invention, since the air can be cooled and dehumidified by the second dehumidifying unit (20), it becomes possible to realize a configuration that does not use an intermediate cooler, so that further energy saving and cost reduction can be realized. .

- the air returning from the indoor space (S) through the return air passage (58) to the air supply passage (40) is used together with the air passing through the second dehumidifying unit (20). Air with low humidity and temperature can be supplied to the adsorption part (32) of the adsorption rotor (31).

- the return air passage (58) is provided with the return air fan (59) for pushing the room air toward the air supply passage (40), thereby supplying the air from the return air passage (58).

- the system communicating with the air passage (40) has a positive pressure. And since the entrance of moisture into the air supply passage (40) can be prevented by keeping the inside of the system at a positive pressure, the performance of the system can be improved.

- the return air cooler (67) for cooling the air flowing through the return air passage (58) is provided in the return air passage (58), whereby the cooled return air is supplied to the air supply passage (40 ) So that the temperature of the air supply after mixing can be kept low. Therefore, the temperature of the air supplied to the adsorption rotor (31) is kept low, and the regeneration temperature of the adsorption rotor (31) is also kept low. Therefore, it is possible to further reduce energy by suppressing the amount of heat required for regeneration. Become.

- the adsorption isotherm provided in the adsorption heat exchanger (22, 24) is an adsorption isotherm in which the amount of adsorption per unit increase in relative humidity increases as the relative humidity of air increases.

- the adsorbent provided in the adsorption rotor (31) is an adsorbent having an adsorption isotherm in which the amount of adsorption per unit increase in relative humidity increases as the relative humidity of air decreases.

- the second dehumidifying unit (20) is replaced with the first dehumidifying unit (60) and the third dehumidifying unit with respect to the existing system including the first dehumidifying unit (60) and the third dehumidifying unit (30). Since the connection is made between the dehumidifying units (30), it is possible to realize a three-stage dehumidifying system capable of low temperature regeneration even in the existing system, and to realize energy saving of the existing system. It becomes possible.

- the recirculation heat exchanger (67) is connected to the refrigerating circuit (70a, 120) by connecting the reheat heat exchanger (64) and the recirculation cooling heat exchanger (67).

- the heat recovered from the air can be used to heat the air in the reheat heat exchanger (64).

- the energy saving performance of the dehumidification system can be further improved.

- the condenser (64, 65) and the evaporator (61, 67) are connected to one refrigerant circuit (70a), the refrigerant circuit (70a) can be simplified and reduced in cost. Can be planned.

- the condensing pressure can be quickly reached the target pressure, and the necessary capacity of the condenser (64, 65) can be secured.

- the evaporation pressure can be quickly reached the target pressure to ensure the required capacity of the evaporator (61, 67).

- a sufficient differential pressure difference between the regenerative heat exchanger (65) and the outside air cooling heat exchanger (61) is ensured by employing the refrigerant circuit (120) of the dual refrigeration cycle type. it can. As a result, the capacity of both the regenerative heat exchanger (65) and the outside air cooling heat exchanger (61) can be sufficiently obtained.

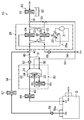

- FIG. 1 is a schematic configuration diagram illustrating an overall configuration of a dehumidifying system according to an embodiment, and illustrates a state in which the dehumidifying unit is in a first operation.

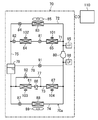

- FIG. 2 is a schematic configuration diagram illustrating the overall configuration of the dehumidification system of the embodiment, and illustrates a state in which the dehumidification unit is in the second operation.

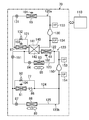

- FIG. 3 is a piping system diagram of the refrigerant circuit of the dehumidification system according to the embodiment.

- FIG. 4A is a graph showing the adsorption isotherm of the adsorbent used in the adsorption heat exchanger, and FIG.

- FIG. 4B is a graph showing the adsorption isotherm of the adsorbent used in the adsorption rotor.

- FIG. 5 is a graph showing a preferable range of dehumidification by the first dehumidifying unit, the second dehumidifying unit, and the third dehumidifying unit.

- Drawing 6 is a mimetic diagram showing operation of a dehumidification system concerning an embodiment.

- FIG. 7 is a schematic diagram illustrating the operation of the dehumidification system according to the comparative example.

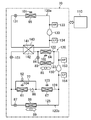

- FIG. 8 is a piping diagram of the refrigerant circuit of the dehumidification system according to the first modification of the embodiment.

- FIG. 9 is a piping system diagram of the refrigerant circuit of the dehumidification system according to the second modification of the embodiment.

- FIG. 10 is a diagram illustrating a second dehumidifying unit of the dehumidifying system according to the third modification of the embodiment, in which FIG. 10 (A) is a first operation state, and FIG. 10 (B) is a second operation state. .

- Embodiment of this invention is related with the dehumidification system (10) which dehumidifies indoor space (S).

- This dehumidification system (10) dehumidifies outdoor air (OA) and supplies this air to the room as supply air (SA).

- the indoor space (S) to be dehumidified is a dry clean area of a lithium battery production line where low dew point air is required, and the dehumidification system (10) of FIG. 1 constitutes a part of the lithium ion battery production line. Is.

- the dehumidification system (10) includes a first dehumidification unit (60), a second dehumidification unit (20), and a third dehumidification unit (30).

- This dehumidification system (10) includes an air supply passage (40) for dehumidifying outdoor air (OA) and supplying it to the room as supply air (SA).

- the supply passage (40) has first to third supply passages (41, 42, 43).

- the first air supply path (41) is formed on the upstream side of the second dehumidifying unit (20).

- the 2nd air supply path (42) is formed between the 2nd dehumidification unit (20) and the 3rd dehumidification unit (30), and the 2nd dehumidification unit (20) and the 3rd dehumidification unit are not passed through an intercooler. (30) is connected directly.

- the third air supply path (43) is formed on the downstream side of the third dehumidifying unit (30).

- the dehumidification system (10) includes an exhaust passage (50) for discharging a part of the air in the air supply passage (40) to the outside as exhaust (EA).

- the exhaust passage (50) includes first to fourth exhaust passages (51, 52, 53, 54).

- the exhaust passage (50) has an inflow end connected to the second air supply path (42) and an outflow end communicating with the outside of the room.

- the air supply passage (40) is a passage through which air supplied to the indoor space (S) passes

- the exhaust passage (50) is a passage through which air discharged to the outside passes.

- 40) and the exhaust passage (50) constitute an air passage (40, 50).

- the first dehumidifying unit (60), the second dehumidifying unit (20), and the third dehumidifying unit (30) receive outdoor air that is supplied to the room. They are arranged in order from the entrance side.

- the first dehumidifying unit (60) includes an outside air cooling heat exchanger (61) that cools and dehumidifies the outdoor air, and a drain pan (62) that collects water condensed in the outside air cooling heat exchanger (61).

- the outdoor air cooling heat exchanger (61) is provided in the first air supply path (41).

- the second air supply path (42) is provided with an air supply fan (63) for conveying air into the room.

- the third air supply passage (43) is provided with a reheat heat exchanger (64) for heating air.

- the second dehumidifying unit (20) is connected to the compressor (21), the first adsorption heat exchanger (22), the expansion valve (23), the second adsorption heat exchanger (24), and the four-way switching valve (25).

- the dehumidification side refrigerant circuit (20a) is provided, and the device is housed in a casing (not shown).

- the dehumidification side refrigerant circuit (20a) constitutes a heat medium circuit in which a refrigerant as a heat medium circulates.

- Each adsorption heat exchanger (22, 24) has an adsorbent supported on the surface of a fin-and-tube heat exchanger, and the casing accommodates the first adsorption heat exchanger (22).

- a storage chamber (not shown) for storing the second adsorption heat exchanger (24).

- the four-way switching valve (25) has first to fourth ports, the first port being the discharge side of the compressor (21), the second port being the suction side of the compressor (21), and the third port.

- the port is connected to the end of the first adsorption heat exchanger (22), and the fourth port is connected to the end of the second adsorption heat exchanger (24).

- the four-way switching valve (25) has a first state (state indicated by a solid line in FIG. 1) in which the first port and the third port communicate with each other and a second port and a fourth port communicate with each other,

- the four ports communicate with each other and can be switched to a second state (state indicated by a broken line in FIG. 1) in which the second port and the third port communicate.

- the second dehumidifying unit (20) includes a first flow path switching unit (26) that changes the flow of air flowing into the two adsorption heat exchangers (22, 24), and two adsorption heat exchangers (22, 24). And a second flow path switching unit (27) for changing the flow of the air that has flowed out of the air.

- Each flow path switching unit (26, 27) is composed of a plurality of open / close dampers.

- Each flow path switching unit (26, 27) is configured to be able to switch the air flow path between a state indicated by a solid line in FIG. 1 and a state indicated by a second solid line.

- the second dehumidifying unit includes the four-way switching valve that alternately switches the two adsorption heat exchangers (22, 24) provided in the refrigerant circuit (20a) between the dehumidifying side and the regeneration side. (25) having a first flow path for switching so that the adsorption heat exchanger as an evaporator is connected to the air supply passage (40) and the adsorption heat exchanger as a condenser is connected to the exhaust passage (50) It is a dehumidifying unit having a switching part (26) and a second flow path switching part (27) as an air passage switching mechanism (26, 27).

- the third dehumidifying unit (30) has an adsorption rotor (31) and a regenerative heat exchanger (air heater) (65).

- the adsorption rotor (31) is configured by carrying an adsorbent on the surface of a disk-shaped porous substrate.

- the adsorption rotor (31) is disposed across the air supply passage (40) and the exhaust passage (50), and is driven by a drive mechanism (not shown), so that the axis between the passages (40, 50) is located. It is comprised so that it may rotate around.

- the adsorption rotor (31) includes a first adsorption part (32) through which air flowing through the third supply passage (43) of the supply passage (40) passes, and a first exhaust passage (51) of the exhaust passage (50). ) Through which the air flowing through the second adsorbing portion (33) passes and the regenerating portion (34) through which the air flowing through the second exhaust passage (52) of the exhaust passage (50) passes.

- the first adsorbing part (32) and the second adsorbing part (33) adsorb moisture in the air, and the regenerating part (34) releases moisture in the adsorbent into the air.

- the first exhaust passage (51) is formed on the upstream side of the second adsorption portion (33) of the adsorption rotor (31).

- the second exhaust path (52) is formed between the second adsorption part (33) of the adsorption rotor (31) and the regeneration part (34) of the adsorption rotor (31).

- the third exhaust path (53) is formed between the regeneration unit (34) of the adsorption rotor (31) and the second dehumidifying unit (20).

- the fourth exhaust path (54) is formed on the downstream side of the second dehumidification unit (20).

- the regeneration heat exchanger (65) for heating air to regenerate the adsorption rotor (31) is provided on the inlet side of the regeneration air to the adsorption rotor (31). Yes.

- the fourth exhaust path (54) is provided with an exhaust fan (66) for releasing air to the outside of the room.

- the third exhaust path (53) is connected to the first air supply path (41) via the branch path (55).

- the dehumidification system (10) includes a return air passage (58) for returning room air (RA) to the air supply passage (40).

- the return air passage (58) has an inflow end connected to a return air port (58a) communicating with the indoor space (S), and an outflow end connected to the second air supply path (42). That is, the outflow end of the return air passage (58) is connected between the second dehumidifying unit (20) and the adsorption rotor (31) in the air supply passage (40).

- the outflow end of the return air passage (58) is located upstream of the inflow end of the exhaust passage (50).

- the return air passage (58) is provided with a ventilation fan (59) that sends room air to the air supply passage (40) and an air cooling heat exchanger (return air cooler) (67) that constitutes an air cooling section. It has been.

- Adsorbents with different properties are used for the adsorption heat exchangers (22, 24) and the adsorption rotor (31). Specifically, in the adsorption heat exchanger (22, 24) located on the front stage side, the adsorbent is operated at a high water vapor partial pressure (relative humidity), and therefore, as shown in FIG. Adsorbents that have an adsorption isotherm that protrudes downward with respect to a straight line that rises to the right, such as sorbents and B-type silica gel, are used for the adsorption rotor (31) located on the higher stage side, with a low water vapor partial pressure. In order to operate the adsorbent at (relative humidity), as shown in FIG.

- an adsorbent having an adsorption isotherm that is convex upward with respect to a straight line rising to the right is used, such as A-type silica gel or zeolite. It has been.

- an adsorption isotherm where the moisture content is large when the relative humidity is relatively high and the amount of adsorption per unit increase in relative humidity increases as the relative humidity of air increases.

- the adsorption rotor (31) has a high moisture content when the relative humidity is relatively low, and the adsorption amount per unit increase of the relative humidity increases as the relative humidity of the air decreases.

- Adsorbents with isotherms have been selected.

- FIG. 5 shows a suitable temperature range for dehumidification by each dehumidifying unit (60, 20, 30) in a graph with the horizontal axis representing the dry bulb temperature and the vertical axis representing the relative humidity.

- Cooling dehumidification by the outside air cooling heat exchanger (61) of the first dehumidification unit (60) is in the region where the dew point is about 8 ° C or higher, and adsorption dehumidification by the adsorption heat exchanger (22, 24) of the second dehumidification unit (20).

- adsorption dehumidification by the adsorption heat exchanger (22, 24) of the second dehumidification unit (20) Is suitable for use in the region where the dew point is about -20 ° C to -20 ° C.

- Dry dehumidification by the adsorption rotor (31) of the third dehumidification unit (30) is suitable for the region where the dew point is about -20 ° C to -80

- the dehumidification system (10) of this embodiment includes a refrigeration unit (70) having a refrigerant circuit (70a) to which the heat exchangers (61, 64, 65, 67) are connected. ing.

- the refrigerant circuit (70a) of the present embodiment is a single refrigeration cycle type refrigerant circuit in which the refrigerant circulates through one closed circuit.

- the compressor (80) is connected to the refrigerant circuit (70a).

- the compressor (80) is a rotary fluid machine such as a rotary type, a swing type, or a scroll type.

- the compressor (80) is configured as a variable capacity type in which the rotation speed is adjusted by an inverter circuit.

- the discharge side of the compressor (80) branches into a first discharge line (71) and a second discharge line (72).

- first discharge line (71) the regeneration heat exchanger (65), the first expansion valve (81), the reheat heat exchanger (64), and the second are sequentially arranged from the upstream side to the downstream side.

- An expansion valve (82) is connected.

- a condensation pressure adjusting heat exchanger (83) and a third expansion valve (84) are connected to the second discharge line (72) in order from the upstream side toward the downstream side.

- a first outdoor fan (85) for blowing outdoor air is provided in the vicinity of the condensing pressure adjusting heat exchanger (83).

- the suction side of the compressor (80) branches into a first suction line (73) and a second suction line (74).

- the outside air cooling heat exchanger (61), the check valve (86), and the ambient air cooling heat exchanger (67) are connected to the first suction line (73) in order from the upstream side to the downstream side.

- a bypass pipe (77) that bypasses the outside air cooling heat exchanger (61) and the check valve (86) is connected to the first suction line (73).

- the bypass pipe (77) is provided with an electromagnetic on-off valve (92).

- a fourth expansion valve (87) and an evaporation pressure adjusting heat exchanger (88) are connected to the second suction line (74) in order from the upstream side to the downstream side.

- a second outdoor fan (89) for blowing outdoor air is provided in the vicinity of the evaporation pressure adjusting heat exchanger (88).

- a single junction pipe (75) is connected between the outlet end of each discharge line (71, 72) and the inlet end of each suction line (73, 74).

- the merge pipe (75) is provided with a gas-liquid separator (79).

- the inflow end of the injection pipe (76) is connected to the gas phase portion of the gas-liquid separator (79).

- the outflow end of the injection pipe (76) is connected to the suction pipe of the compressor (80).

- the injection pipe (76) is provided with a fifth expansion valve (91).

- the regenerative heat exchanger (65), the reheat heat exchanger (64), and the condensing pressure adjustment heat exchanger (83) constitute a condenser in which the refrigerant dissipates heat to the air and condenses.

- the outside air cooling heat exchanger (61), the ambient air cooling heat exchanger (67), and the evaporation pressure adjusting heat exchanger (88) constitute an evaporator in which the refrigerant absorbs heat from the air and evaporates.

- Each expansion valve (81, 82, 84, 87, 91) described above is an electronic expansion valve, for example, and constitutes a pressure reducing mechanism that adjusts the pressure of the refrigerant.

- the dehumidification system (10) is equipped with various sensors. Specifically, the dehumidification system (10) includes a high pressure sensor (95) that detects the high pressure (condensation pressure) of the refrigerant circuit (70a) and a low pressure that detects the low pressure (evaporation pressure) of the refrigerant circuit (70a). And a pressure sensor (96). The dehumidification system (10) detects the required capacity of the regenerative heat exchanger (65), reheat heat exchanger (64), outside air cooling heat exchanger (61), and ambient air cooling heat exchanger (67). Load detecting means is provided.

- This load detection means detects, for example, the first air temperature sensor (101) that detects the air temperature downstream of the regenerative heat exchanger (65), and the air temperature downstream of the reheat heat exchanger (64).

- the second air temperature sensor (102), the third air temperature sensor (103) for detecting the air temperature downstream of the outside air cooling heat exchanger (61), and the air downstream of the ambient air cooling heat exchanger (67) It comprises a fourth air temperature sensor (104) that detects the temperature.

- the dehumidification system (10) includes a controller (110).

- the controller (110) determines the rotation speed of the compressor (80), the expansion valves (81, 82, 84, 87, 91) opening degree, and the amount of air blown by each outdoor fan (85, 89).

- the second dehumidifying unit (20) alternately performs the first operation shown in FIG. 1 and the second operation shown in FIG. 2 at predetermined time intervals (for example, at intervals of 5 minutes).

- air is dehumidified by the second adsorption heat exchanger (24), and at the same time, the adsorbent of the first adsorption heat exchanger (22) is regenerated.

- the four-way switching valve (25) is in the state shown in FIG. 1, and the expansion valve (23) is controlled to a predetermined opening.

- the first flow path switching unit (26) communicates the first air supply path (41) with the accommodation chamber (not shown) of the second adsorption heat exchanger (24), and the third exhaust path (53).

- the accommodation chamber (not shown) of the first adsorption heat exchanger (22) is communicated.

- the second flow path switching unit (27) communicates the storage chamber of the second adsorption heat exchanger (24) with the second air supply path (42), and the first adsorption heat exchanger (22).

- the accommodation chamber and the fourth exhaust path (54) are communicated with each other.

- the refrigerant compressed by the compressor (21) passes through the four-way switching valve (25) and flows through the first adsorption heat exchanger (22).

- the first adsorption heat exchanger (22) the adsorbent is heated by the refrigerant, and moisture in the adsorbent is released to the air.

- the refrigerant radiated and condensed by the first adsorption heat exchanger (22) is depressurized by the expansion valve (23) and then flows through the second adsorption heat exchanger (24).

- the second adsorption heat exchanger (24) moisture in the air is adsorbed by the adsorbent, and adsorption heat generated at this time is imparted to the refrigerant.

- the refrigerant that has absorbed heat and evaporated in the second adsorption heat exchanger (24) is sucked into the compressor (21) and compressed.

- air is dehumidified by the first adsorption heat exchanger (22), and at the same time, the adsorbent of the second adsorption heat exchanger (24) is regenerated.

- the four-way switching valve (25) is in the state shown in FIG. 2, and the expansion valve (23) is controlled to a predetermined opening.

- the first flow path switching unit (26) communicates the first air supply path (41) with the accommodation chamber (not shown) of the first adsorption heat exchanger (22), and the third exhaust path (53).

- the accommodation chamber (not shown) of the second adsorption heat exchanger (24) is communicated.

- the second flow path switching unit (27) communicates the storage chamber of the first adsorption heat exchanger (22) with the second air supply path (42), and the second adsorption heat exchanger (24).

- the accommodation chamber and the fourth exhaust path (54) are communicated with each other.

- the refrigerant compressed by the compressor (21) passes through the four-way switching valve (25) and flows through the second adsorption heat exchanger (24).

- the adsorbent is heated by the refrigerant, and moisture in the adsorbent is released to the air.

- the refrigerant radiated and condensed by the second adsorption heat exchanger (24) is depressurized by the expansion valve (23) and then flows through the first adsorption heat exchanger (22).

- the first adsorption heat exchanger (22) moisture in the air is adsorbed by the adsorbent, and adsorption heat generated at this time is imparted to the refrigerant.

- the refrigerant that has absorbed heat and evaporated in the first adsorption heat exchanger (22) is sucked into the compressor (21) and compressed.

- ⁇ Basic operation of refrigeration unit> During operation of the dehumidification system, a refrigeration cycle is performed in the refrigeration unit (70). During basic operation of the refrigeration unit (70), the opening degrees of the first expansion valve (81), the second expansion valve (82), and the fifth expansion valve (91) are adjusted as appropriate, and the third expansion valve (84) The fourth expansion valve (87) is fully closed. Further, the first outdoor fan (85) and the second outdoor fan (89) are stopped.

- the refrigerant compressed by the compressor (80) is sent to the first discharge line (71) and flows through the regenerative heat exchanger (65).

- the refrigerant dissipates heat to the air and condenses.

- the refrigerant condensed in the regenerative heat exchanger (65) is depressurized to a slightly lower pressure by the first expansion valve (81) and then flows through the reheat heat exchanger (64).

- the reheat heat exchanger (64) the refrigerant dissipates heat to the air and condenses.

- the refrigerant condensed in the reheat heat exchanger (64) is depressurized to a low pressure by the second expansion valve (82), passes through the gas-liquid separator (90), and is sent to the first suction line (73).

- the opening degree of the second expansion valve (82) is controlled by the degree of superheat of the refrigerant on the suction side of the compressor (80).

- the refrigerant sent to the first suction line (73) flows through the outside air cooling heat exchanger (61).

- the refrigerant absorbs heat from the air and evaporates.

- the refrigerant evaporated in the outside air cooling heat exchanger (61) passes through the check valve (86) and flows through the circulating air cooling heat exchanger (67).

- the refrigerant absorbs heat from the air and evaporates.

- the refrigerant evaporated in the recirculation cooling heat exchanger (67) is sucked into the compressor (80) and compressed.

- Outdoor air (OA) flows into the first air supply passage (41) of the air supply passage (40). This air is relatively hot and humid air.

- the air flowing through the first air supply path (41) is cooled by the outside air cooling heat exchanger (61) of the first dehumidifying unit (60).

- the condensed water generated from the air during cooling is collected in the drain pan (62).

- the air cooled and dehumidified by the outside air cooling heat exchanger (61) passes through the second adsorption heat exchanger (24) of the second dehumidifying unit (20).

- the second adsorption heat exchanger (24) moisture in the air is adsorbed by the adsorbent.

- the air cooled and dehumidified by the outside air cooling heat exchanger (61) is dehumidified by the first adsorption heat exchanger (22) of the second dehumidifying unit (20).

- each adsorption heat exchanger (22, 24) The adsorption heat generated when moisture is adsorbed by the adsorbent in each adsorption heat exchanger (22, 24) is given to the refrigerant flowing through the adsorption heat exchanger (22, 24). Further, since the air flowing through the air supply passage (40) is cooled by the refrigerant, the air is dehumidified to reduce the humidity and is cooled to decrease the temperature.

- the air dehumidified by the second dehumidifying unit (20) flows through the second air supply path (42) and passes through the first adsorption part (32) of the adsorption rotor (31). As a result, the moisture in the air is adsorbed by the adsorbent of the adsorption rotor (31).

- the air dehumidified by the adsorption rotor (31) is supplied to the room as supply air (SA) after the temperature is adjusted by the reheat heat exchanger (64).

- the second adsorption unit (33) is a stage in the middle of the movement of the regeneration unit (34) through which the high-temperature regeneration air has passed to the first adsorption unit (32), and the second adsorption unit (33) has a second air supply path.

- the second adsorbing part (33) is cooled.

- the air dehumidified by the second adsorption part (33) of the adsorption rotor (31) flows through the second exhaust path (52) and is heated by the regenerative heat exchanger (65).

- the heated air passes through the regeneration unit (34) of the adsorption rotor (31).

- moisture is desorbed from the adsorbent of the adsorption rotor (31) into the air, and the adsorbent is regenerated.

- the air used for regeneration of the adsorption rotor (31) flows through the third exhaust passage (53) and is mixed with the air sent from the branch passage (55).

- this air passes through the first adsorption heat exchanger (22) of the second dehumidification unit (20).

- the first adsorption heat exchanger (22) moisture is desorbed from the adsorbent into the air, and the adsorbent is regenerated.

- the air used for regeneration of the adsorbent in the first adsorption heat exchanger (22) flows through the fourth exhaust path (54) and is discharged to the outside as exhaust (EA).

- exhaust (EA) exhaust gas

- the air after regenerating the adsorption rotor (31) is also used for regenerating the adsorption heat exchanger (22, 24).

- a part of the air in the indoor space (S) is exhausted to the outside as exhaust (EA).

- a part of the air in the indoor space (S) flows into the return air passage (58).

- the air flowing through the return air passage (58) is cooled by the circulating air cooling heat exchanger (67) and then returned to the second air supply path (42).

- This return air is mixed with the air dehumidified by the second dehumidifying unit (20).

- the air dehumidified by the second dehumidifying unit (20) and the air returned from the indoor space (S) the returned air has a lower temperature and lower humidity.

- the air dehumidified by the second dehumidifying unit (20) is further mixed with the return air to further reduce the temperature and humidity.

- suction rotor (31) improves.

- the air flowing through the return air passage (58) is pushed into the second intake passage (42) by the return air fan (59).

- air is supplied by sucking high-humidity outdoor air from outside the duct.

- the return air fan (59) pushes air into the second intake passage (42), so that the system has a positive pressure, and high humidity is likely. Inhalation of outside air is prevented. Therefore, it is possible to prevent the humidity of the supply air (SA) from increasing.

- FIG. 6 is a schematic diagram of a dehumidifying system according to the present embodiment

- FIG. 7 is a schematic diagram of a dehumidifying system according to a comparative example in which an adsorption rotor type dehumidifying unit is used in two stages after the first dehumidifying unit for cooling dehumidification. is there. 6 and 7, for each point indicated by capital letters of the alphabet, the upper part shows the dry bulb temperature (° C.) and the lower part shows the water vapor amount (g / Kg).

- reference numerals (101) to (109) are assigned to circuit components, and reference numerals (111) to (120) are assigned to air passages.

- outdoor air (point K) with a dry bulb temperature of 35 ° C. and a water vapor amount of 23.3 g / Kg is cooled and dehumidified by the outdoor air cooling heat exchanger (101) to change the temperature to the L point temperature and the water vapor amount.

- the amount of water vapor is reduced by merging with the air at point M in the passage (118) (point N).

- This air is introduced into the first stage dehumidification rotor (102), dehumidified to change to point O, and combined with return air (Q point) from the indoor space flowing through the passage (114) to cool the cooling coil (105) (R point).

- low dew point air of S point is created by the second stage dehumidifying rotor (106) and supplied to the room (dry clean room).

- the air at point S contains almost no water vapor and has a dew point of about ⁇ 50 ° C.

- the dehumidified air in which moisture is adsorbed by the adsorbing portion of the dehumidifying rotor (106) flows to the passages (115, 116) and is further divided into the passage (117) and the passage (118).

- the air in the passage (117) is heated by the heater (107) and changes its state to the T point, and then merges with the air flowing through the passage (115) and changes to the U point.

- This air is further heated by the heater (108) to become high-temperature air at point V (140 ° C.), and moisture is desorbed from the dehumidification rotor (102) and exhausted outdoors.

- the energy used for raising the temperature to the regeneration temperature (140 ° C.) at this time is the thermal energy of an electric heater or a steam heater.

- the air at point W flowing through the passage (118) is mixed with the air at point L via the outdoor air cooling heat exchanger (101).

- the regeneration temperature of the dehumidifying rotor (102) needs to be high (140 ° C.), and the energy for that is enormous, whether it is steam or electricity.

- the second stage dehumidification rotor (106) since the humidity of the air passing through the first stage dehumidification rotor (102) decreases while the temperature increases, the second stage dehumidification rotor (106) obtains low dew point air. Therefore, it is necessary to cool the air at the inlet, and the energy consumption of the cooling coil (105) provided for this is large.

- the energy consumption of the air conditioning system in the lithium ion battery manufacturing process accounts for about 50% of the entire process. It is a factor.

- the pressure in the return air passage (114) is a negative pressure

- the air at point A passes through the outside air cooling heat exchanger (61), and the temperature and humidity are lowered, and the state changes to point B.

- the air at point B passes through the adsorption heat exchanger (22, 24), and the temperature and humidity are further lowered to change to point C.

- This air is mixed with the air at point E flowing through the return air passage (58) to lower the humidity (point D), and further passes through the adsorption rotor (31), so that it substantially does not contain water vapor.

- the air has a low dew point (about ⁇ 50 ° C.) and is supplied indoors.

- the adsorption heat exchanger (22, 24) is difficult to increase the adsorption area due to manufacturing problems, whereas the adsorption rotor (31) reduces the adsorption area to the adsorption heat exchanger (22, 24). Therefore, the amount of dehumidification is large in order to earn more, and low temperature and low temperature air can be obtained.

- the regeneration temperature for obtaining the low dew point air required a high temperature of about 140 ° C.

- the regeneration heat exchanger (65) was used for heating.

- 60 ° C. air (point G) as the regeneration air, it is possible to obtain the same low dew point air, and the energy required for regeneration of the adsorption rotor (31) can be reduced.

- the H point air that has passed through the adsorption rotor (31) is mixed with the air in the passage (55) to change to the I point and used for regeneration of the adsorption heat exchanger (22, 24).

- Lowering the regeneration temperature of the adsorption rotor (31) is achieved by using low dew point air (-15 ° C to -20 ° C) dehumidified by the adsorption heat exchanger (22, 24) installed in the second stage. It has become possible. In other words, since air with a low dew point is supplied to the adsorption rotor (31), as described above, a large amount of moisture is adsorbed and even if the humidity is low, almost no heat of adsorption is generated and the regeneration temperature is lowered. Can do.

- the regeneration temperature is 60 ° C., which is lower than that of the comparative example, it has been difficult to realize the regeneration heat source by heating with a heat pump.

- the entire system is positively pressurized by providing the blower (59) in the return air passage (58) from the dry clean room, the possibility of moisture being mixed into the air is reduced. Stability is also improved.

- the controller (110) requires the required capacity Qc on the condenser side (ie, the regeneration heat exchanger (65) and the reheat heat exchanger (64) side) and the evaporator side (ie, outside air cooling).

- the required capacity Qe of the heat exchanger (61) and the ambient air cooling heat exchanger (67) side is calculated based on the detected temperature of each temperature sensor (101 to 104).

- the condensation pressure detected by the high-pressure sensor (95) reaches the target condensation pressure determined based on the required capacity Qc.

- the rotation speed of the compressor (80) is adjusted.

- the condensing pressure can be quickly reached the target condensing pressure, and the necessary capacity Qc can be ensured.

- the third expansion valve (84) is opened at a predetermined opening.

- the refrigerant on the discharge side of the compressor (80) flows through both the first discharge line (71) and the second discharge line (72), and condensing pressure adjustment heat exchange is performed.

- the refrigerant also condenses in the vessel (83).

- the rotation speed of the compressor (80) increases so as to maintain the condensation pressure at the target condensation pressure.

- the evaporation pressure can be reduced to approach the target evaporation pressure.

- the evaporation pressure detected by the low pressure sensor (96) becomes the target evaporation pressure determined based on the required capacity Qe.

- the rotational speed of the compressor (80) is adjusted to reach. Thereby, the required pressure Qe can be ensured by causing the evaporation pressure to quickly reach the target evaporation pressure.

- the fourth expansion valve (87) is opened at a predetermined opening.

- the refrigerant on the suction side of the compressor (80) flows through both the first suction line (73) and the second suction line (74), and evaporative pressure adjustment heat exchange is performed.

- the refrigerant also evaporates in the vessel (88).

- the rotation speed of the compressor (80) increases so as to maintain the evaporation pressure at the target evaporation pressure.

- the condensation pressure can be raised to approach the target condensation pressure.

- the open / close valve (92) is opened when the temperature of the outdoor air (OA) detected by the outside air temperature sensor (not shown) is lower than the target evaporation pressure.

- the refrigerant can be sent to the ambient air cooling heat exchanger (67) by bypassing the outside air cooling heat exchanger (61).

- the regeneration temperature can be greatly lowered from 140 ° C. to 60 ° C. as described above to reduce the amount of heat for regeneration, so that significant energy saving can be achieved.

- the power consumption is reduced by about 35%, and the running cost of the system is greatly reduced.

- the regenerative heat exchanger (65) is a heat exchanger of the refrigerant circuit (70a), the energy saving effect can be further enhanced.

- the regeneration temperature of the adsorption rotor (31) can be set to 60 ° C., so that the exhaust heat generated from the lithium ion battery manufacturing facility can be used for regeneration, or the refrigerant circuit (70a). It is possible to use the exhaust heat of the heat, and further energy saving can be achieved. The ability to use the exhaust heat in this way is effective not only in the production equipment for lithium ion batteries but also in production lines of other factories.

- the regenerative heat exchanger (65), the outside air cooling heat exchanger (61), the reheat heat exchanger (64), and the ambient air cooling heat exchanger (67) are connected to the same refrigerant circuit ( 70a).

- the heat of the air recovered by the outdoor air cooling heat exchanger (61) and the ambient air cooling heat exchanger (67) is heated by the regenerative heat exchanger (65) and the reheat heat exchanger (64).

- the dehumidification system (10) of Modification 1 is different from the above-described embodiment in the configuration of the refrigeration unit (70).

- the refrigeration unit (70) of the first modification is provided with a refrigerant circuit (120) of a two-way refrigeration cycle type. That is, in the refrigerant circuit (120), the high-pressure side circuit (120a) and the low-pressure side circuit (120b) are connected to each other via the cascade heat exchanger (140) constituting the intermediate heat exchanger.

- the high pressure side circuit (120a) includes a high pressure side compressor (130) as a first compressor, a regenerative heat exchanger (65), a high pressure side expansion valve (131), and an ambient air cooling heat exchanger (67). Connected in order.

- a first flow path (141) of the cascade heat exchanger (140) is connected to the downstream side of the ambient air cooling heat exchanger (67).

- the high pressure side circuit (120a) is connected to a high pressure side bypass pipe (121) that bypasses the ambient air cooling heat exchanger (67).

- the high pressure side bypass pipe (121) is provided with an electromagnetic high pressure side on-off valve (132).

- the high pressure side circuit (120a) is provided with a high pressure sensor (133) on the discharge side of the high pressure compressor (130) and a low pressure sensor (134) on the suction side of the high pressure compressor (130). ing.

- the low-pressure circuit (120b) is provided with a low-pressure compressor (150) as a second compressor.

- the discharge side of the low-pressure compressor (150) branches into a first discharge line (122) and a second discharge line (123).

- the regenerative heat exchanger (64) and the second flow path (142) of the cascade heat exchanger (140) are sequentially connected to the first discharge line (122).

- a condensation pressure adjusting heat exchanger (83) and a third expansion valve (84) are sequentially connected to the second discharge line (123).

- the suction side of the low pressure side compressor (150) branches into a first suction line (124) and a second suction line (125).

- An external air cooling heat exchanger (61) and a check valve (86) are sequentially connected to the first suction line (124).

- a bypass pipe (77) is connected to the first suction line (124) as in the embodiment.

- a fourth expansion valve (87) and an evaporation pressure adjusting heat exchanger (88) are sequentially connected to the second suction line (125).

- the low pressure side circuit (120b) has a low pressure side expansion valve (151) connected between the outflow end of each discharge line (122, 123) and the inflow end of each suction line (124, 125).

- the low pressure side circuit (120b) is provided with a high pressure sensor (153) on the discharge side of the low pressure compressor (150) and a low pressure sensor (154) on the suction side of the low pressure compressor (150). ing.

- a dual refrigeration cycle is performed.

- the refrigerant compressed by the high-pressure side compressor (130) dissipates heat to the air by the regenerative heat exchanger (65) and condenses, and then is decompressed by the high-pressure side expansion valve (131).

- the depressurized refrigerant absorbs heat from the air and evaporates in the annular cooling heat exchanger (67), and then flows through the first flow path (141) of the cascade heat exchanger (140).

- the refrigerant flowing through the first flow path (141) absorbs heat from the refrigerant flowing through the second flow path (142) and evaporates.

- the evaporated refrigerant is sucked into the high-pressure compressor (130) and compressed.

- the refrigerant compressed by the low-pressure side compressor (150) dissipates heat to the air by the reheat heat exchanger (64) and condenses, and then flows through the second flow path (142) of the cascade heat exchanger (140).

- the refrigerant flowing through the second flow path (142) dissipates heat to the refrigerant flowing through the first flow path (141) and condenses.

- the condensed refrigerant is depressurized by the low pressure side expansion valve (151), and then flows through the outside air cooling heat exchanger (61).

- the outdoor air cooling heat exchanger (61) the refrigerant absorbs heat from the air and evaporates. The evaporated refrigerant is sucked into the low-pressure compressor (150) and compressed.

- the refrigerant circulates in the high-pressure side circuit (120a) and the low-pressure side circuit (120b) to perform the refrigeration cycle.

- a sufficient differential pressure between the condensation pressure on the regenerative heat exchanger (65) side and the evaporation pressure on the outside air cooling heat exchanger (61) side can be secured, and consequently the heating capacity of the regenerative heat exchanger (65)

- the cooling capacity of the outside air cooling heat exchanger (61) can be sufficiently obtained.

- FIG. 9 shows a second modification. As shown in FIG. 5, even if an ambient air cooling heat exchanger (67) is connected to the downstream side of the outside air cooling heat exchanger (61) in the first suction line (124) of the low pressure side circuit (120b). Good.

- FIG. 10 shows a third modification.