JP5314964B2 - 半導体装置の製造方法 - Google Patents

半導体装置の製造方法 Download PDFInfo

- Publication number

- JP5314964B2 JP5314964B2 JP2008208472A JP2008208472A JP5314964B2 JP 5314964 B2 JP5314964 B2 JP 5314964B2 JP 2008208472 A JP2008208472 A JP 2008208472A JP 2008208472 A JP2008208472 A JP 2008208472A JP 5314964 B2 JP5314964 B2 JP 5314964B2

- Authority

- JP

- Japan

- Prior art keywords

- film

- forming

- mixed

- silicon oxide

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004065 semiconductor Substances 0.000 title claims description 98

- 238000004519 manufacturing process Methods 0.000 title claims description 59

- 229910052751 metal Inorganic materials 0.000 claims abstract description 256

- 239000002184 metal Substances 0.000 claims abstract description 236

- 239000000758 substrate Substances 0.000 claims abstract description 96

- 230000001681 protective effect Effects 0.000 claims abstract description 89

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims abstract description 79

- 229910052814 silicon oxide Inorganic materials 0.000 claims abstract description 79

- 229910052735 hafnium Inorganic materials 0.000 claims abstract description 42

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 claims abstract description 42

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims abstract description 39

- 229910052760 oxygen Inorganic materials 0.000 claims abstract description 39

- 239000001301 oxygen Substances 0.000 claims abstract description 39

- 239000000463 material Substances 0.000 claims description 138

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 claims description 102

- 238000000034 method Methods 0.000 claims description 58

- 238000000137 annealing Methods 0.000 claims description 45

- 229910044991 metal oxide Inorganic materials 0.000 claims description 38

- 150000004706 metal oxides Chemical class 0.000 claims description 38

- 230000008569 process Effects 0.000 claims description 27

- 229910000449 hafnium oxide Inorganic materials 0.000 claims description 11

- WIHZLLGSGQNAGK-UHFFFAOYSA-N hafnium(4+);oxygen(2-) Chemical compound [O-2].[O-2].[Hf+4] WIHZLLGSGQNAGK-UHFFFAOYSA-N 0.000 claims description 11

- 238000005121 nitriding Methods 0.000 claims description 3

- 238000003892 spreading Methods 0.000 claims description 2

- 230000007480 spreading Effects 0.000 claims description 2

- 230000001590 oxidative effect Effects 0.000 claims 1

- 239000010408 film Substances 0.000 abstract description 886

- 239000010409 thin film Substances 0.000 abstract description 133

- 230000003647 oxidation Effects 0.000 abstract description 12

- 238000007254 oxidation reaction Methods 0.000 abstract description 12

- 239000011777 magnesium Substances 0.000 description 76

- 229910052581 Si3N4 Inorganic materials 0.000 description 37

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 37

- 229910004298 SiO 2 Inorganic materials 0.000 description 33

- 239000000470 constituent Substances 0.000 description 27

- 230000006870 function Effects 0.000 description 22

- 238000004544 sputter deposition Methods 0.000 description 21

- 229910021420 polycrystalline silicon Inorganic materials 0.000 description 19

- 229920005591 polysilicon Polymers 0.000 description 19

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 18

- 229910052749 magnesium Inorganic materials 0.000 description 18

- 239000007772 electrode material Substances 0.000 description 17

- 229910052782 aluminium Inorganic materials 0.000 description 13

- 230000015572 biosynthetic process Effects 0.000 description 13

- 238000012546 transfer Methods 0.000 description 13

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 12

- 239000010936 titanium Substances 0.000 description 12

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 11

- 239000012535 impurity Substances 0.000 description 11

- 229910052710 silicon Inorganic materials 0.000 description 11

- 239000010703 silicon Substances 0.000 description 11

- CPLXHLVBOLITMK-UHFFFAOYSA-N Magnesium oxide Chemical compound [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 10

- 238000000206 photolithography Methods 0.000 description 10

- 229910021332 silicide Inorganic materials 0.000 description 10

- FVBUAEGBCNSCDD-UHFFFAOYSA-N silicide(4-) Chemical compound [Si-4] FVBUAEGBCNSCDD-UHFFFAOYSA-N 0.000 description 10

- 238000003860 storage Methods 0.000 description 10

- 230000004075 alteration Effects 0.000 description 9

- CJNBYAVZURUTKZ-UHFFFAOYSA-N hafnium(iv) oxide Chemical compound O=[Hf]=O CJNBYAVZURUTKZ-UHFFFAOYSA-N 0.000 description 9

- 238000010438 heat treatment Methods 0.000 description 9

- 229910052719 titanium Inorganic materials 0.000 description 9

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 8

- 238000010586 diagram Methods 0.000 description 8

- 239000011229 interlayer Substances 0.000 description 8

- 238000005229 chemical vapour deposition Methods 0.000 description 7

- 238000005530 etching Methods 0.000 description 7

- 238000005406 washing Methods 0.000 description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- 238000001039 wet etching Methods 0.000 description 7

- 239000012298 atmosphere Substances 0.000 description 6

- 238000001312 dry etching Methods 0.000 description 6

- 238000002955 isolation Methods 0.000 description 6

- 229910004129 HfSiO Inorganic materials 0.000 description 5

- 230000000694 effects Effects 0.000 description 5

- 239000000395 magnesium oxide Substances 0.000 description 5

- 239000012528 membrane Substances 0.000 description 5

- 229910052715 tantalum Inorganic materials 0.000 description 5

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 4

- 101150110971 CIN7 gene Proteins 0.000 description 4

- 101100286980 Daucus carota INV2 gene Proteins 0.000 description 4

- 101150110298 INV1 gene Proteins 0.000 description 4

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 4

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 4

- 101100397044 Xenopus laevis invs-a gene Proteins 0.000 description 4

- 101100397045 Xenopus laevis invs-b gene Proteins 0.000 description 4

- 229910052785 arsenic Inorganic materials 0.000 description 4

- RQNWIZPPADIBDY-UHFFFAOYSA-N arsenic atom Chemical compound [As] RQNWIZPPADIBDY-UHFFFAOYSA-N 0.000 description 4

- 229910052796 boron Inorganic materials 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 4

- 238000009792 diffusion process Methods 0.000 description 4

- 229910052746 lanthanum Inorganic materials 0.000 description 4

- FZLIPJUXYLNCLC-UHFFFAOYSA-N lanthanum atom Chemical compound [La] FZLIPJUXYLNCLC-UHFFFAOYSA-N 0.000 description 4

- 229910021421 monocrystalline silicon Inorganic materials 0.000 description 4

- 229910052698 phosphorus Inorganic materials 0.000 description 4

- 239000011574 phosphorus Substances 0.000 description 4

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 4

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 4

- 229910052721 tungsten Inorganic materials 0.000 description 4

- 239000010937 tungsten Substances 0.000 description 4

- 229910052688 Gadolinium Inorganic materials 0.000 description 3

- 229910021193 La 2 O 3 Inorganic materials 0.000 description 3

- 230000000295 complement effect Effects 0.000 description 3

- 239000004020 conductor Substances 0.000 description 3

- 230000006866 deterioration Effects 0.000 description 3

- 239000011810 insulating material Substances 0.000 description 3

- 238000005468 ion implantation Methods 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 150000004767 nitrides Chemical class 0.000 description 3

- 238000000059 patterning Methods 0.000 description 3

- MZLGASXMSKOWSE-UHFFFAOYSA-N tantalum nitride Chemical compound [Ta]#N MZLGASXMSKOWSE-UHFFFAOYSA-N 0.000 description 3

- 229910052727 yttrium Inorganic materials 0.000 description 3

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 2

- KRHYYFGTRYWZRS-UHFFFAOYSA-N Fluorane Chemical compound F KRHYYFGTRYWZRS-UHFFFAOYSA-N 0.000 description 2

- 238000004380 ashing Methods 0.000 description 2

- 238000000231 atomic layer deposition Methods 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- UIWYJDYFSGRHKR-UHFFFAOYSA-N gadolinium atom Chemical compound [Gd] UIWYJDYFSGRHKR-UHFFFAOYSA-N 0.000 description 2

- 238000009413 insulation Methods 0.000 description 2

- 239000012212 insulator Substances 0.000 description 2

- 239000010410 layer Substances 0.000 description 2

- 229910052759 nickel Inorganic materials 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 238000002161 passivation Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 description 2

- 229910015900 BF3 Inorganic materials 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910001218 Gallium arsenide Inorganic materials 0.000 description 1

- QXZUUHYBWMWJHK-UHFFFAOYSA-N [Co].[Ni] Chemical compound [Co].[Ni] QXZUUHYBWMWJHK-UHFFFAOYSA-N 0.000 description 1

- MIQVEZFSDIJTMW-UHFFFAOYSA-N aluminum hafnium(4+) oxygen(2-) Chemical compound [O-2].[Al+3].[Hf+4] MIQVEZFSDIJTMW-UHFFFAOYSA-N 0.000 description 1

- 229910052788 barium Inorganic materials 0.000 description 1

- DSAJWYNOEDNPEQ-UHFFFAOYSA-N barium atom Chemical compound [Ba] DSAJWYNOEDNPEQ-UHFFFAOYSA-N 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- WTEOIRVLGSZEPR-UHFFFAOYSA-N boron trifluoride Chemical compound FB(F)F WTEOIRVLGSZEPR-UHFFFAOYSA-N 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 230000005684 electric field Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000005669 field effect Effects 0.000 description 1

- 230000012447 hatching Effects 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 229910052747 lanthanoid Inorganic materials 0.000 description 1

- 150000002602 lanthanoids Chemical class 0.000 description 1

- 238000005224 laser annealing Methods 0.000 description 1

- 238000001459 lithography Methods 0.000 description 1

- OYVDXKZFBGEMKU-UHFFFAOYSA-N magnesium hafnium(4+) oxygen(2-) Chemical compound [Hf+4].[O-2].[Mg+2].[O-2].[O-2] OYVDXKZFBGEMKU-UHFFFAOYSA-N 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 229910003455 mixed metal oxide Inorganic materials 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- RUFLMLWJRZAWLJ-UHFFFAOYSA-N nickel silicide Chemical compound [Ni]=[Si]=[Ni] RUFLMLWJRZAWLJ-UHFFFAOYSA-N 0.000 description 1

- 229910021334 nickel silicide Inorganic materials 0.000 description 1

- 239000012299 nitrogen atmosphere Substances 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 229910052761 rare earth metal Inorganic materials 0.000 description 1

- 150000002910 rare earth metals Chemical class 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 238000009751 slip forming Methods 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 230000005641 tunneling Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/77—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate

- H01L21/78—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate with subsequent division of the substrate into plural individual devices

- H01L21/82—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate with subsequent division of the substrate into plural individual devices to produce devices, e.g. integrated circuits, each consisting of a plurality of components

- H01L21/822—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate with subsequent division of the substrate into plural individual devices to produce devices, e.g. integrated circuits, each consisting of a plurality of components the substrate being a semiconductor, using silicon technology

- H01L21/8232—Field-effect technology

- H01L21/8234—MIS technology, i.e. integration processes of field effect transistors of the conductor-insulator-semiconductor type

- H01L21/8238—Complementary field-effect transistors, e.g. CMOS

- H01L21/823857—Complementary field-effect transistors, e.g. CMOS with a particular manufacturing method of the gate insulating layers, e.g. different gate insulating layer thicknesses, particular gate insulator materials or particular gate insulator implants

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02123—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon

- H01L21/02164—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material being a silicon oxide, e.g. SiO2

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02172—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides

- H01L21/02175—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides characterised by the metal

- H01L21/02178—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides characterised by the metal the material containing aluminium, e.g. Al2O3

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02172—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides

- H01L21/02175—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides characterised by the metal

- H01L21/02181—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides characterised by the metal the material containing hafnium, e.g. HfO2

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02172—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides

- H01L21/02175—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides characterised by the metal

- H01L21/02194—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides characterised by the metal the material containing more than one metal element

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/022—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates the layer being a laminate, i.e. composed of sublayers, e.g. stacks of alternating high-k metal oxides

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02296—Forming insulating materials on a substrate characterised by the treatment performed before or after the formation of the layer

- H01L21/02318—Forming insulating materials on a substrate characterised by the treatment performed before or after the formation of the layer post-treatment

- H01L21/02321—Forming insulating materials on a substrate characterised by the treatment performed before or after the formation of the layer post-treatment introduction of substances into an already existing insulating layer

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/314—Inorganic layers

- H01L21/316—Inorganic layers composed of oxides or glassy oxides or oxide based glass

- H01L21/31604—Deposition from a gas or vapour

- H01L21/31608—Deposition of SiO2

- H01L21/31612—Deposition of SiO2 on a silicon body

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/314—Inorganic layers

- H01L21/316—Inorganic layers composed of oxides or glassy oxides or oxide based glass

- H01L21/31604—Deposition from a gas or vapour

- H01L21/31645—Deposition of Hafnium oxides, e.g. HfO2

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/77—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate

- H01L21/78—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate with subsequent division of the substrate into plural individual devices

- H01L21/82—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate with subsequent division of the substrate into plural individual devices to produce devices, e.g. integrated circuits, each consisting of a plurality of components

- H01L21/822—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate with subsequent division of the substrate into plural individual devices to produce devices, e.g. integrated circuits, each consisting of a plurality of components the substrate being a semiconductor, using silicon technology

- H01L21/8232—Field-effect technology

- H01L21/8234—MIS technology, i.e. integration processes of field effect transistors of the conductor-insulator-semiconductor type

- H01L21/8238—Complementary field-effect transistors, e.g. CMOS

- H01L21/823828—Complementary field-effect transistors, e.g. CMOS with a particular manufacturing method of the gate conductors, e.g. particular materials, shapes

- H01L21/823842—Complementary field-effect transistors, e.g. CMOS with a particular manufacturing method of the gate conductors, e.g. particular materials, shapes gate conductors with different gate conductor materials or different gate conductor implants, e.g. dual gate structures

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10B—ELECTRONIC MEMORY DEVICES

- H10B10/00—Static random access memory [SRAM] devices

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10B—ELECTRONIC MEMORY DEVICES

- H10B10/00—Static random access memory [SRAM] devices

- H10B10/12—Static random access memory [SRAM] devices comprising a MOSFET load element

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Physics & Mathematics (AREA)

- Power Engineering (AREA)

- Metal-Oxide And Bipolar Metal-Oxide Semiconductor Integrated Circuits (AREA)

- Insulated Gate Type Field-Effect Transistor (AREA)

- Electrodes Of Semiconductors (AREA)

- Formation Of Insulating Films (AREA)

- Semiconductor Memories (AREA)

- Thin Film Transistor (AREA)

Description

H.N. Alshareef et al., Symp. VLSI Tech., Dig., p.10, 2006 H-S. Jung, et al., Symp. VLSI Tech. Dig., p.204, 2006 T. Schram, et al., Symp. VLSI Tech. Dig., p.44, 2008

本実施の形態では、SRAM(static random access memory)を備えた半導体装置に本発明を適用した場合について説明する。

前記実施の形態1では、pMISトランジスタQpのHfAlO膜6pと、nMISトランジスタQnのHfMgO膜6nの2種類の混合膜(高誘電率膜)を形成するために、それぞれに対応するAl膜7およびMg膜11の金属薄膜の切り分けに際し、レジスト膜10、14を用いたマスク合わせを2回行う場合について説明した。本実施の形態では、そのレジスト膜を用いたマスク合わせを1回省略する場合について説明する。それに伴う製造工程は前記実施の形態1と異なるが、最終構造は前記実施の形態1と同様となる。以下に、前記実施の形態1と相違する点を中心に説明する。図22〜図24は本実施の形態における製造工程中の半導体装置の要部を模式的に示す断面図である。

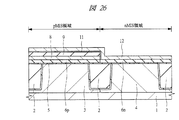

前記実施の形態2では、ハードマスクとして用いたSiN膜9を除去し、pMIS領域で保護膜のTiN膜8を露出した後、nMIS領域に金属薄膜のMg膜11、保護膜のTiN膜12を形成する場合について説明した。本実施の形態では、ハードマスクとして用いたSiN膜9を除去せずに以降の工程を行う場合について説明する。それに伴う製造工程は前記実施の形態2と異なるが、最終構造は前記実施の形態2と同様となる。以下に、前記実施の形態2と相違する点を中心に説明する。図25〜図26は本実施の形態における製造工程中の半導体装置の要部を模式的に示す断面図である。

前記実施の形態1では、例えば図19を参照して、大気暴露により金属薄膜の変質を抑制するために、金属薄膜(例えばMg膜)上に保護膜(例えばTiN膜)を設ける場合について、例えば図19を参照して説明した。本実施の形態では、この保護膜を設けずに、ベース絶縁膜に金属薄膜の金属元素を拡散させる場合について説明する。図27は、本実施の形態における高誘電率膜の形成を説明するための図であり、nMISトランジスタの場合が示されている。なお、前記実施の形態1とは相違する点を中心に説明し、pMISトランジスタの場合も同様の工程で形成することができるのでその説明は省略する。

前記実施の形態1では、例えば図19を参照して、大気暴露などにより金属薄膜の変質を抑制するために、金属薄膜(例えばMg膜)上のみに保護膜(例えばTiN膜)を設けた場合について説明した。本実施の形態では金属薄膜を保護膜で挟んで金属薄膜を保護する場合について説明する。図28は、本実施の形態における高誘電率膜の形成を説明するための図であり、nMISトランジスタの場合が示されている。なお、前記実施の形態1とは相違する点を中心に説明し、pMISトランジスタの場合も同様の工程で形成することができるのでその説明は省略する。

前記実施の形態1では、例えば図19を参照して、大気暴露により金属薄膜の変質を抑制するために、金属薄膜(例えばMg膜)上に保護膜(例えばTiN膜)を設ける場合について、例えば図19を参照して説明した。本実施の形態では、ベース絶縁膜(例えばHfO2膜)上に保護膜(例えばTiN膜)を設け、基板界面絶縁膜(SiO2膜)とベース絶縁膜(HfO2膜)との間に金属薄膜(例えばMg膜)を設ける場合について説明する。図29は、本実施の形態における高誘電率膜の形成を説明するための図であり、nMISトランジスタの場合が示されている。なお、前記実施の形態1とは相違する点を中心に説明し、pMISトランジスタの場合も同様の工程で形成することができるのでその説明は省略する。

2 素子分離領域

3 nウェル

4 pウェル

5 SiO2膜

6 HfO2膜

6n HfMgO膜

6p HfAlO膜

7 Al膜

8 TiN膜

9 SiN膜

10 レジスト膜

11 Mg膜

12 TiN膜

13 SiN膜

14 レジスト膜

15 TiN膜

16 ポリシリコン膜

17 p型半導体領域(ソース/ドレイン)

18 n型半導体領域(ソース/ドレイン)

19 サイドウォール

20 シリサイド膜

21 層間絶縁膜

22 コンタクトホール

23 配線

101 基板

102 高誘電率膜

103 金属酸化膜

104 ゲート絶縁膜

105 ゲート電極

CNT コンタクト

G ゲート電極

Qn nMISトランジスタ

Qp pMISトランジスタ

Claims (13)

- 以下の工程を含むMISトランジスタを備えた半導体装置の製造方法:

(a)半導体基板の主面上に、酸化シリコン膜を形成する工程;

(b)前記酸化シリコン膜上に、ハフニウムおよび酸素を含む膜状の基材を形成する工程;

(c)前記基材上に、前記基材より薄く、かつ、金属元素のみからなる膜状の混合材を形成する工程;

(d)前記混合材の表面を窒化した後にアニール処理を施し、前記基材に前記混合材を拡散することによって、前記酸化シリコン膜上に、酸化シリコンより誘電率が高く、前記基材のハフニウムおよび酸素と、前記混合材の金属元素とを含む混合膜を形成する工程;

(e)前記混合膜上に、導電性膜を形成する工程;

(f)前記導電性膜から構成されるゲート電極、前記混合膜および前記酸化シリコン膜から構成されるゲート絶縁膜を形成する工程。 - 以下の工程を含むMISトランジスタを備えた半導体装置の製造方法:

(a)半導体基板の主面上に、酸化シリコン膜を形成する工程;

(b)前記酸化シリコン膜上に、ハフニウムおよび酸素を含む膜状の基材を形成する工程;

(c)前記基材上に、前記基材より薄く、かつ、金属元素のみからなる膜状の混合材を形成する工程;

(d)前記混合材の表面を酸化した後にアニール処理を施し、前記基材に前記混合材を拡散することによって、前記酸化シリコン膜上に、酸化シリコンより誘電率が高く、前記基材のハフニウムおよび酸素と、前記混合材の金属元素とを含む混合膜を形成する工程;

(e)前記混合膜上に、導電性膜を形成する工程;

(f)前記導電性膜から構成されるゲート電極、前記混合膜および前記酸化シリコン膜から構成されるゲート絶縁膜を形成する工程。 - 以下の工程を含むMISトランジスタを備えた半導体装置の製造方法:

(a)半導体基板の主面上に、酸化シリコン膜を形成する工程;

(b)前記酸化シリコン膜上に、ハフニウムおよび酸素を含む膜状の基材を形成する工程;

(c)前記基材上に、前記基材より薄く、かつ、金属元素のみからなる膜状の混合材を形成する工程;

(d)前記混合材の表面を酸化し、さらに窒化した後にアニール処理を施し、前記基材に前記混合材を拡散することによって、前記酸化シリコン膜上に、酸化シリコンより誘電率が高く、前記基材のハフニウムおよび酸素と、前記混合材の金属元素とを含む混合膜を形成する工程;

(e)前記混合膜上に、導電性膜を形成する工程;

(f)前記導電性膜から構成されるゲート電極、前記混合膜および前記酸化シリコン膜から構成されるゲート絶縁膜を形成する工程。 - 以下の工程を含むMISトランジスタを備えた半導体装置の製造方法:

(a)半導体基板の主面上に、酸化シリコン膜を形成する工程;

(b)前記酸化シリコン膜上に、ハフニウムおよび酸素を含む膜状の基材を形成する工程;

(c)前記基材上に、前記基材より薄く、かつ、金属元素のみからなる膜状の混合材を形成する工程;

(d)前記混合材上に、保護膜を形成する工程;

(e)前記保護膜を有する状態で、前記基材に前記混合材を拡散することによって、前記酸化シリコン膜上に、酸化シリコンより誘電率が高く、前記基材のハフニウムおよび酸素と、前記混合材の金属元素とを含む混合膜を形成する工程;

(f)前記工程(e)の後、前記保護膜を除去する工程;

(g)前記混合膜上に、導電性膜を形成する工程;

(h)前記導電性膜から構成されるゲート電極、前記混合膜および前記酸化シリコン膜から構成されるゲート絶縁膜を形成する工程。 - 前記MISトランジスタはnチャネル型であり、

前記工程(c)において、酸化ハフニウムより電気陰性度が小さい酸化金属物を構成する金属元素からなる前記混合材を形成することを特徴とする請求項4記載の半導体装置の製造方法。 - 前記MISトランジスタはpチャネル型であり、

前記工程(c)において、酸化ハフニウムより電気陰性度が大きい酸化金属物を構成する金属元素からなる前記混合材を形成することを特徴とする請求項4記載の半導体装置の製造方法。 - 前記工程(e)において、アニール処理によって前記基材に前記混合材を拡散することを特徴とする請求項4記載の半導体装置の製造方法。

- 前記工程(c)で真空状態において前記混合材を形成し、その真空状態を保ったまま前記工程(d)で前記保護膜を形成することを特徴とする請求項4記載の半導体装置の製造方法。

- 前記工程(d)では、保護膜として窒化チタン膜を形成することを特徴とする請求項4記載の半導体装置の製造方法。

- 以下の工程を含むMISトランジスタを備えた半導体装置の製造方法:

(a)半導体基板の主面上に、酸化シリコン膜を形成する工程;

(b)前記酸化シリコン膜上に、ハフニウムおよび酸素を含む膜状の基材を形成する工程;

(c)前記基材上に、保護膜を形成する工程;

(d)前記保護膜上に、前記基材より薄く、かつ、金属元素のみからなる膜状の混合材を形成する工程;

(e)前記保護膜を有する状態で、前記基材に前記混合材を拡散することによって、前記酸化シリコン膜上に、酸化シリコンより誘電率が高く、前記基材のハフニウムおよび酸素と、前記混合材の金属元素とを含む混合膜を形成する工程;

(f)前記工程(e)の後、前記保護膜を除去する工程;

(g)前記混合膜上に、導電性膜を形成する工程;

(h)前記導電性膜から構成されるゲート電極、前記混合膜および前記酸化シリコン膜から構成されるゲート絶縁膜を形成する工程。 - 以下の工程を含むMISトランジスタを備えた半導体装置の製造方法:

(a)半導体基板の主面上に、酸化シリコン膜を形成する工程;

(b)前記酸化シリコン膜上に、ハフニウムおよび酸素を含む膜状の基材を形成する工程;

(c)前記基材上に、第1保護膜を形成する工程;

(d)前記第1保護膜上に、前記基材より薄く、かつ、金属元素のみからなる膜状の混合材を形成する工程;

(e)前記混合材上に、第2保護膜を形成する工程;

(f)前記第1保護膜および前記第2保護膜を有する状態で、前記基材に前記混合材を拡散することによって、前記酸化シリコン膜上に、酸化シリコンより誘電率が高く、前記基材のハフニウムおよび酸素と、前記混合材の金属元素とを含む混合膜を形成する工程;

(g)前記工程(f)の後、前記第2保護膜および前記第1保護膜を除去する工程;

(h)前記混合膜上に、導電性膜を形成する工程;

(i)前記導電性膜から構成されるゲート電極、前記混合膜および前記酸化シリコン膜から構成されるゲート絶縁膜を形成する工程。 - 以下の工程を含むCMISを備えた半導体装置の製造方法:

(a)前記CMISの一方を構成する第1MISトランジスタが形成される第1領域と、前記CMISの他方を構成する第2MISトランジスタが形成される第2領域とを有する半導体基板を準備する工程;

(b)前記半導体基板の主面上に、酸化シリコン膜を形成する工程;

(c)前記酸化シリコン膜上に、ハフニウムおよび酸素を含む膜状の基材を形成する工程;

(d)前記基材上に、金属元素のみからなる膜状の第1混合材を形成する工程;

(e)前記第1混合材上に、第1保護膜を形成する工程;

(f)前記第2領域の前記第1保護膜および前記第1混合材を除去する工程;

(g)前記第2領域の前記基材上に、前記基材より薄く、かつ、前記第1混合材の金属元素とは異なる金属元素のみからなる膜状の第2混合材を形成する工程;

(h)前記第2混合材上に、第2保護膜を形成する工程;

(i)前記第1保護膜および前記第2保護膜を有する状態で、前記第1領域の前記基材に前記第1混合材を拡散すると共に、前記第2領域の前記基材に前記第2混合材を拡散することによって、

前記第1領域では、前記酸化シリコン膜上に、酸化シリコンより誘電率が高く、前記基材のハフニウムおよび酸素と、前記第1混合材の金属元素とを含む第1混合膜を形成し、

前記第2領域では、前記酸化シリコン膜上に、酸化シリコンより誘電率が高く、前記基材のハフニウムおよび酸素と、前記第2混合材の金属元素とを含む第2混合膜を形成する工程;

(j)前記工程(i)の後、前記第1保護膜および前記第2保護膜を除去する工程;

(k)前記第1混合膜および前記第2混合膜上に、導電性膜を形成する工程;

(l)前記導電性膜から構成される前記第1MISトランジスタのゲート電極、前記第1混合膜および前記酸化シリコン膜から構成される前記第1MISトランジスタのゲート絶縁膜を形成し、

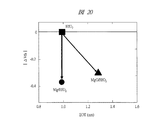

前記導電性膜から構成される前記第2MISトランジスタのゲート電極、前記第2混合膜および前記酸化シリコン膜から構成される前記第2MISトランジスタのゲート絶縁膜を形成する工程。 - 前記工程(d)において、酸化ハフニウムより電気陰性度が大きい酸化金属物を構成する金属元素からなる前記第1混合材を形成し、

前記工程(g)において、酸化ハフニウムより電気陰性度が小さい酸化金属物を構成する金属元素からなる前記第2混合材を形成することを特徴とする請求項12記載の半導体装置の製造方法。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008208472A JP5314964B2 (ja) | 2008-08-13 | 2008-08-13 | 半導体装置の製造方法 |

| TW098117118A TWI456697B (zh) | 2008-08-13 | 2009-05-22 | 半導體裝置之製造方法及半導體裝置 |

| CN2009101584767A CN101651120B (zh) | 2008-08-13 | 2009-07-08 | 半导体器件的制造方法和半导体器件 |

| US12/537,875 US8288221B2 (en) | 2008-08-13 | 2009-08-07 | Method of manufacturing semiconductor device and semiconductor device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008208472A JP5314964B2 (ja) | 2008-08-13 | 2008-08-13 | 半導体装置の製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010045210A JP2010045210A (ja) | 2010-02-25 |

| JP2010045210A5 JP2010045210A5 (ja) | 2011-09-15 |

| JP5314964B2 true JP5314964B2 (ja) | 2013-10-16 |

Family

ID=41673309

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008208472A Expired - Fee Related JP5314964B2 (ja) | 2008-08-13 | 2008-08-13 | 半導体装置の製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US8288221B2 (ja) |

| JP (1) | JP5314964B2 (ja) |

| CN (1) | CN101651120B (ja) |

| TW (1) | TWI456697B (ja) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5329294B2 (ja) * | 2009-04-30 | 2013-10-30 | ルネサスエレクトロニクス株式会社 | 半導体装置の製造方法 |

| US8399344B2 (en) * | 2009-10-07 | 2013-03-19 | Asm International N.V. | Method for adjusting the threshold voltage of a gate stack of a PMOS device |

| US8659155B2 (en) * | 2009-11-05 | 2014-02-25 | Taiwan Semiconductor Manufacturing Company, Ltd. | Mechanisms for forming copper pillar bumps |

| US8343865B2 (en) * | 2010-01-21 | 2013-01-01 | Renesas Electronics Corporation | Semiconductor device having dual work function metal |

| JP2011176173A (ja) * | 2010-02-25 | 2011-09-08 | Renesas Electronics Corp | 半導体装置及びその製造方法 |

| JP5548550B2 (ja) * | 2010-07-30 | 2014-07-16 | ルネサスエレクトロニクス株式会社 | 半導体装置の製造方法 |

| JP2012044013A (ja) * | 2010-08-20 | 2012-03-01 | Renesas Electronics Corp | 半導体装置の製造方法 |

| JP2013098214A (ja) * | 2011-10-28 | 2013-05-20 | Elpida Memory Inc | 半導体装置及びその製造方法 |

| JP5638559B2 (ja) | 2012-03-26 | 2014-12-10 | 株式会社東芝 | 半導体装置 |

| JP5823353B2 (ja) * | 2012-06-20 | 2015-11-25 | 株式会社東芝 | 不揮発性半導体記憶装置の製造方法 |

| EP2717308A1 (en) * | 2012-10-08 | 2014-04-09 | Imec | A method for manufacturing a dual work function semiconductor device |

| KR20140122585A (ko) * | 2013-04-10 | 2014-10-20 | 삼성전자주식회사 | 반도체 소자 및 이의 제조 방법 |

| US9263270B2 (en) * | 2013-06-06 | 2016-02-16 | Globalfoundries Inc. | Method of forming a semiconductor device structure employing fluorine doping and according semiconductor device structure |

| JP6581446B2 (ja) * | 2015-09-09 | 2019-09-25 | 東芝メモリ株式会社 | 絶縁膜及び記憶装置 |

| JP2017092191A (ja) * | 2015-11-06 | 2017-05-25 | 株式会社デンソー | 炭化珪素半導体装置 |

| CN106952917A (zh) * | 2016-01-07 | 2017-07-14 | 中国科学院上海微系统与信息技术研究所 | 一种soi六晶体管sram单元及其制作方法 |

| CN113809012B (zh) * | 2020-06-12 | 2024-02-09 | 长鑫存储技术有限公司 | 半导体器件及其制造方法 |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR19990014155A (ko) * | 1997-07-24 | 1999-02-25 | 윌리엄 비. 켐플러 | 고 유전율 실리케이트 게이트 유전체 |

| JP3944367B2 (ja) * | 2001-02-06 | 2007-07-11 | 松下電器産業株式会社 | 絶縁膜の形成方法及び半導体装置の製造方法 |

| JP4895430B2 (ja) | 2001-03-22 | 2012-03-14 | ルネサスエレクトロニクス株式会社 | 半導体装置及び半導体装置の製造方法 |

| US7326988B2 (en) * | 2002-07-02 | 2008-02-05 | Matsushita Electric Industrial Co., Ltd. | Semiconductor device and method for fabricating the same |

| AU2003281112A1 (en) * | 2002-07-16 | 2004-02-02 | Nec Corporation | Semiconductor device, production method and production device thereof |

| WO2005038929A1 (ja) * | 2003-10-15 | 2005-04-28 | Nec Corporation | 半導体装置の製造方法 |

| US6897095B1 (en) * | 2004-05-12 | 2005-05-24 | Freescale Semiconductor, Inc. | Semiconductor process and integrated circuit having dual metal oxide gate dielectric with single metal gate electrode |

| JP4005055B2 (ja) * | 2004-05-25 | 2007-11-07 | Necエレクトロニクス株式会社 | 半導体装置およびその製造方法 |

| US7060568B2 (en) | 2004-06-30 | 2006-06-13 | Intel Corporation | Using different gate dielectrics with NMOS and PMOS transistors of a complementary metal oxide semiconductor integrated circuit |

| JP4792716B2 (ja) | 2004-07-06 | 2011-10-12 | 日本電気株式会社 | 半導体装置およびその製造方法 |

| US7087476B2 (en) | 2004-07-28 | 2006-08-08 | Intel Corporation | Using different gate dielectrics with NMOS and PMOS transistors of a complementary metal oxide semiconductor integrated circuit |

| JP4372024B2 (ja) | 2005-02-14 | 2009-11-25 | 株式会社東芝 | Cmos半導体装置 |

| JP2006295131A (ja) * | 2005-03-17 | 2006-10-26 | Renesas Technology Corp | 半導体装置およびその製造方法 |

| JP4850458B2 (ja) | 2005-09-12 | 2012-01-11 | 富士通セミコンダクター株式会社 | 半導体装置およびその製造方法 |

| JP2007080995A (ja) * | 2005-09-13 | 2007-03-29 | Toshiba Corp | 半導体装置 |

| JP2007243009A (ja) * | 2006-03-10 | 2007-09-20 | Renesas Technology Corp | 半導体装置およびその製造方法 |

| WO2007116470A1 (ja) * | 2006-03-31 | 2007-10-18 | Fujitsu Limited | 半導体装置及びその製造方法 |

| JPWO2007138693A1 (ja) * | 2006-05-31 | 2009-10-01 | 富士通株式会社 | 半導体デバイスおよびその作製方法 |

| JP4282691B2 (ja) * | 2006-06-07 | 2009-06-24 | 株式会社東芝 | 半導体装置 |

| JP2008311464A (ja) * | 2007-06-15 | 2008-12-25 | National Institute Of Advanced Industrial & Technology | 半導体装置とその製造方法 |

| TWI492367B (zh) | 2007-12-03 | 2015-07-11 | Renesas Electronics Corp | Cmos半導體裝置之製造方法 |

-

2008

- 2008-08-13 JP JP2008208472A patent/JP5314964B2/ja not_active Expired - Fee Related

-

2009

- 2009-05-22 TW TW098117118A patent/TWI456697B/zh not_active IP Right Cessation

- 2009-07-08 CN CN2009101584767A patent/CN101651120B/zh active Active

- 2009-08-07 US US12/537,875 patent/US8288221B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| TWI456697B (zh) | 2014-10-11 |

| US20100038729A1 (en) | 2010-02-18 |

| CN101651120B (zh) | 2013-10-02 |

| US8288221B2 (en) | 2012-10-16 |

| CN101651120A (zh) | 2010-02-17 |

| TW201013847A (en) | 2010-04-01 |

| JP2010045210A (ja) | 2010-02-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5314964B2 (ja) | 半導体装置の製造方法 | |

| JP5128121B2 (ja) | 高性能cmos回路及びその製造方法 | |

| US7732872B2 (en) | Integration scheme for multiple metal gate work function structures | |

| JP5550286B2 (ja) | 半導体装置の製造方法 | |

| US7863127B2 (en) | Manufacturing method of semiconductor device | |

| CN101123252B (zh) | 半导体装置及其制造方法 | |

| US20150102418A1 (en) | Semiconductor device and method for manufacturing the device | |

| US9431498B2 (en) | Semiconductor device including first and second MISFETs | |

| TWI469262B (zh) | 半導體裝置之製造方法及半導體裝置 | |

| JP2007005721A (ja) | 半導体装置およびその製造方法 | |

| KR102434987B1 (ko) | 박막 형성 방법 및 반도체 소자의 제조 방법 | |

| JP2008124393A (ja) | 半導体装置の製造方法 | |

| US20080283928A1 (en) | Semiconductor device and manufacturing method thereof | |

| TW202234595A (zh) | 半導體結構 | |

| WO2011057492A1 (zh) | 一种半导体器件及其制造方法 | |

| US20100252888A1 (en) | Semiconductor device | |

| JP2009267180A (ja) | 半導体装置 | |

| JP2011003717A (ja) | 半導体装置及びその製造方法 | |

| JP5291992B2 (ja) | 半導体装置の製造方法 | |

| JP4163164B2 (ja) | 半導体装置およびその製造方法 | |

| JP2010062499A (ja) | 半導体装置および半導体装置の製造方法 | |

| JP2008066715A (ja) | 半導体装置及びその製造方法 | |

| JP2013118311A (ja) | 半導体装置の製造方法 | |

| US20120068275A1 (en) | Semiconductor device and method for fabricating the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20100528 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110801 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110801 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130222 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130305 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130422 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130611 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130708 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5314964 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |