JP4419703B2 - 紡機における繊維束集束装置 - Google Patents

紡機における繊維束集束装置 Download PDFInfo

- Publication number

- JP4419703B2 JP4419703B2 JP2004183990A JP2004183990A JP4419703B2 JP 4419703 B2 JP4419703 B2 JP 4419703B2 JP 2004183990 A JP2004183990 A JP 2004183990A JP 2004183990 A JP2004183990 A JP 2004183990A JP 4419703 B2 JP4419703 B2 JP 4419703B2

- Authority

- JP

- Japan

- Prior art keywords

- fiber bundle

- yarn

- perforated belt

- spinning machine

- suction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01H—SPINNING OR TWISTING

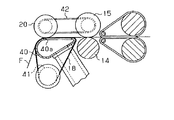

- D01H5/00—Drafting machines or arrangements ; Threading of roving into drafting machine

- D01H5/18—Drafting machines or arrangements without fallers or like pinned bars

- D01H5/70—Constructional features of drafting elements

- D01H5/72—Fibre-condensing guides

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D3/00—Woven fabrics characterised by their shape

- D03D3/02—Tubular fabrics

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01H—SPINNING OR TWISTING

- D01H5/00—Drafting machines or arrangements ; Threading of roving into drafting machine

- D01H5/18—Drafting machines or arrangements without fallers or like pinned bars

- D01H5/70—Constructional features of drafting elements

- D01H5/86—Aprons; Apron supports; Apron tensioning arrangements

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/20—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads

- D03D15/283—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads synthetic polymer-based, e.g. polyamide or polyester fibres

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/20—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads

- D03D15/292—Conjugate, i.e. bi- or multicomponent, fibres or filaments

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/50—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the properties of the yarns or threads

- D03D15/587—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the properties of the yarns or threads adhesive; fusible

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2201/00—Cellulose-based fibres, e.g. vegetable fibres

- D10B2201/01—Natural vegetable fibres

- D10B2201/02—Cotton

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2331/00—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products

- D10B2331/02—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products polyamides

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2401/00—Physical properties

- D10B2401/04—Heat-responsive characteristics

- D10B2401/041—Heat-responsive characteristics thermoplastic; thermosetting

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2401/00—Physical properties

- D10B2401/06—Load-responsive characteristics

- D10B2401/061—Load-responsive characteristics elastic

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2401/00—Physical properties

- D10B2401/16—Physical properties antistatic; conductive

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Mechanical Engineering (AREA)

- Spinning Or Twisting Of Yarns (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

- Woven Fabrics (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004183990A JP4419703B2 (ja) | 2004-06-22 | 2004-06-22 | 紡機における繊維束集束装置 |

| CNB2005100687363A CN100451196C (zh) | 2004-06-22 | 2005-04-30 | 纺纱机的纤维束集束装置 |

| DE602005016338T DE602005016338D1 (de) | 2004-06-22 | 2005-05-19 | Vorrichtung zum Bündeln eines in einer Spinnereimaschine verzogenen Faserverbandes |

| EP05010863A EP1612309B1 (en) | 2004-06-22 | 2005-05-19 | Fibre condensing device for a spinning machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004183990A JP4419703B2 (ja) | 2004-06-22 | 2004-06-22 | 紡機における繊維束集束装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006009166A JP2006009166A (ja) | 2006-01-12 |

| JP2006009166A5 JP2006009166A5 (zh) | 2007-06-07 |

| JP4419703B2 true JP4419703B2 (ja) | 2010-02-24 |

Family

ID=35169394

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004183990A Expired - Fee Related JP4419703B2 (ja) | 2004-06-22 | 2004-06-22 | 紡機における繊維束集束装置 |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1612309B1 (zh) |

| JP (1) | JP4419703B2 (zh) |

| CN (1) | CN100451196C (zh) |

| DE (1) | DE602005016338D1 (zh) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006051875A1 (de) * | 2006-10-31 | 2008-05-08 | Maschinenfabrik Rieter Ag | Kepa-Streckwerk für eine Spinnmaschine |

| CH704133A2 (de) | 2010-11-26 | 2012-05-31 | Rieter Ag Maschf | Vorrichtung zum Verdichten eines Faserbandes an einer Spinnmaschine. |

| CH704137A1 (de) * | 2010-11-26 | 2012-05-31 | Rieter Ag Maschf | Vorrichtung zum Verdichten eines Faserverbandes an einer Spinnmaschine sowie Spinnmaschine. |

| JP2012127007A (ja) * | 2010-12-13 | 2012-07-05 | Toyota Industries Corp | 前紡工程のドラフト装置 |

| CN102605487A (zh) * | 2011-09-07 | 2012-07-25 | 常熟市迅达粉末冶金有限公司 | 一种抗静电紧密纺用网格圈 |

| CN102418175A (zh) * | 2011-09-22 | 2012-04-18 | 吴江秦邦纺织有限公司 | 一种抗静电紧密纺用网格圈的制备工艺 |

| CN102418177A (zh) * | 2011-09-26 | 2012-04-18 | 吴江伊兰吉纺织品有限公司 | 一种耐磨型紧密纺用网格圈的制备工艺 |

| JP2013124432A (ja) * | 2011-12-15 | 2013-06-24 | Toyota Industries Corp | 繊維束集束装置の通気搬送ベルト |

| CH706258A2 (de) | 2012-03-21 | 2013-09-30 | Rieter Ag Maschf | Tragelement für eine Verdichtungsvorrichtung. |

| CN103469385B (zh) * | 2013-09-13 | 2015-10-14 | 顾祥茂 | 一种耐磨型紧密纺用网格圈的制备方法 |

| JP6608649B2 (ja) * | 2015-08-26 | 2019-11-20 | 日産自動車株式会社 | 多孔性シートの製造方法、および多孔性シートの製造装置 |

| DE102016106207A1 (de) * | 2016-04-05 | 2017-10-05 | Maschinenfabrik Rieter Ag | Saugkörper für eine pneumatisch arbeitende Faserverdichtungseinrichtung sowie damit ausgestattete Spinnereimaschine |

| CH713916A1 (de) | 2017-06-23 | 2018-12-28 | Rieter Ag Maschf | Verdichtungsvorrichtung für eine Spinnmaschine. |

| CH714068A1 (de) | 2017-08-17 | 2019-02-28 | Rieter Ag Maschf | Mehrfachdüsenanschluss einer Textilmaschine und Textilmaschine. |

| ES2880678T3 (es) * | 2017-10-10 | 2021-11-25 | Groz Beckert Kg | Dispositivo y procedimiento para fabricar una pieza de soporte que presenta varios haces de fibras |

| JP7180333B2 (ja) * | 2018-12-04 | 2022-11-30 | 株式会社豊田自動織機 | 紡機の繊維束集束装置 |

| DE102019113676A1 (de) * | 2019-05-22 | 2020-11-26 | Maschinenfabrik Rieter Ag | Verdichtereinheit für ein Streckwerk einer Textilmaschine |

| DE102019115219A1 (de) * | 2019-06-05 | 2020-12-10 | Maschinenfabrik Rieter Ag | Saugrohr für eine Verdichtungsvorrichtung und Vorrichtung zum pneumatischen Verdichten eines verstreckten Faserverbandes |

| CN112626660B (zh) * | 2020-12-25 | 2022-11-04 | 淄博银仕来纺织有限公司 | 一种多组分介入纺幻彩纱线的制备方法及其应用 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1704429A1 (de) * | 1967-07-05 | 1972-02-17 | Lissmann Alkor Werk | Verfahren zur Herstellung eines textilbewehrten Werkstoffs auf Kunststoffbasis |

| DE3839549A1 (de) * | 1988-11-24 | 1990-05-31 | Schlatterer Gmbh & Co Kg Max | Foerderband zum foerdern eines tabakstranges |

| CH693214A5 (de) * | 1998-07-14 | 2003-04-15 | Schurr Stahlecker & Grill | Vorrichtung zum Verdichten eines verstreckten Faserverbandes. |

| DE19837181A1 (de) * | 1998-08-17 | 2000-02-24 | Stahlecker Fritz | Vorrichtung zum Verdichten eines verstreckten Faserverbandes |

| DE19837183C5 (de) * | 1998-08-17 | 2010-12-30 | Spindelfabrik Suessen Gmbh | Endloses Transportband zum Transportieren eines verstreckten Faserverbandes |

| DE19837182B4 (de) * | 1998-08-17 | 2007-01-25 | Stahlecker, Fritz | Transportband zum Transportieren eines zu verdichtenden Faserverbandes |

| JP2004100093A (ja) * | 2002-09-10 | 2004-04-02 | Toyota Industries Corp | 紡機における繊維束集束装置 |

| DE10324287A1 (de) * | 2003-05-21 | 2004-12-16 | Wilhelm Stahlecker Gmbh | Transportband zum Transportieren eines Faserverbandes |

| DE10325383A1 (de) * | 2003-05-30 | 2005-01-05 | J.H. Vom Baur Sohn Gmbh & Co Kg | Verfahren zur Herstellung von Transportbändern |

-

2004

- 2004-06-22 JP JP2004183990A patent/JP4419703B2/ja not_active Expired - Fee Related

-

2005

- 2005-04-30 CN CNB2005100687363A patent/CN100451196C/zh active Active

- 2005-05-19 DE DE602005016338T patent/DE602005016338D1/de active Active

- 2005-05-19 EP EP05010863A patent/EP1612309B1/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| CN1712587A (zh) | 2005-12-28 |

| DE602005016338D1 (de) | 2009-10-15 |

| EP1612309A3 (en) | 2006-04-26 |

| EP1612309A2 (en) | 2006-01-04 |

| JP2006009166A (ja) | 2006-01-12 |

| CN100451196C (zh) | 2009-01-14 |

| EP1612309B1 (en) | 2009-09-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4419703B2 (ja) | 紡機における繊維束集束装置 | |

| JP4774930B2 (ja) | 紡機における繊維束集束装置 | |

| JP3820951B2 (ja) | 紡機における繊維束集束装置 | |

| JP5177571B2 (ja) | 嵩高紡績糸の製造装置および製造方法 | |

| CN106048789B (zh) | 牵伸装置以及纺纱机 | |

| JP2020125554A (ja) | 和紙糸製造装置及び和紙糸製造方法 | |

| JP3786069B2 (ja) | 紡機の繊維束集束装置 | |

| WO2019216149A1 (ja) | 工業用織物 | |

| JP2004100093A (ja) | 紡機における繊維束集束装置 | |

| JP2004346472A (ja) | スライバを搬送するための搬送ベルト | |

| US11761147B2 (en) | Creasing method, creasing apparatus, and long fiber non-woven fabric | |

| JP2006188786A (ja) | 紡績機におけるドラフトローラのクリーニング装置 | |

| JP2004100094A (ja) | 紡機における繊維束集束装置 | |

| KR101885725B1 (ko) | 핫멜트 접착제를 이용한 날개사 제조장치 및 그 장치에 의해 제조된 날개사 | |

| JPH05106145A (ja) | 織機における揚糸処理方法 | |

| JP2004100092A (ja) | 紡績機械及び紡績方法 | |

| JP2004360159A (ja) | 集束される繊維ストランドを輸送するための輸送ベルト | |

| JP2005089936A (ja) | 無杼織機における仮撚装置 | |

| CN208517732U (zh) | 一种纺织面料 | |

| US20060150374A1 (en) | Clearer roller holding device for drafting arrangements in spinning groups | |

| JP2000017532A (ja) | 複合糸の製造方法、その複合糸、及びその織編物 | |

| CN115305678A (zh) | 一种纺织机械新型辊筒拉毛机 | |

| JP2013124432A (ja) | 繊維束集束装置の通気搬送ベルト | |

| JPS6320927B2 (zh) | ||

| CN118345540A (zh) | 基于微积分原理的卷芯纺纱装置及其方法与应用 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070413 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070413 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090811 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091013 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20091110 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20091123 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121211 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121211 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |