EP2326780B1 - Schlosseinheit mit mehrklinken-gesperre - Google Patents

Schlosseinheit mit mehrklinken-gesperre Download PDFInfo

- Publication number

- EP2326780B1 EP2326780B1 EP20090748949 EP09748949A EP2326780B1 EP 2326780 B1 EP2326780 B1 EP 2326780B1 EP 20090748949 EP20090748949 EP 20090748949 EP 09748949 A EP09748949 A EP 09748949A EP 2326780 B1 EP2326780 B1 EP 2326780B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pawl

- lever

- catch

- lock unit

- blocking lever

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 230000000903 blocking effect Effects 0.000 claims description 46

- 230000002093 peripheral effect Effects 0.000 description 3

- 230000003111 delayed effect Effects 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B85/00—Details of vehicle locks not provided for in groups E05B77/00 - E05B83/00

- E05B85/20—Bolts or detents

- E05B85/24—Bolts rotating about an axis

- E05B85/26—Cooperation between bolts and detents

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B15/00—Other details of locks; Parts for engagement by bolts of fastening devices

- E05B15/16—Use of special materials for parts of locks

- E05B2015/1685—Sheet materials

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S292/00—Closure fasteners

- Y10S292/23—Vehicle door latches

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/08—Bolts

- Y10T292/1043—Swinging

- Y10T292/1044—Multiple head

- Y10T292/1045—Operating means

- Y10T292/1047—Closure

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/08—Bolts

- Y10T292/1043—Swinging

- Y10T292/1075—Operating means

- Y10T292/108—Lever

Definitions

- the present invention relates to a lock unit for a motor vehicle, comprising at least one catch with a pre-catch and a main catch and two pawls that block the catch in certain positions.

- a blocking lever is additionally provided which fixes the first pawl.

- Such lock units with multi-part pawls are for example from the WO 2008/061491 A1 known.

- lock units with multi-part pawl has already proven itself outstanding and is characterized in particular by the high operating comfort and low noise during operation of the lock unit.

- Such lock units are used in particular in doors and / or flaps of motor vehicles.

- a lock unit should be specified, which is designed to save space and can be operated quickly and quietly.

- the lock unit is used in particular for locking doors in a motor vehicle.

- the lock unit in addition to the components mentioned above, additional elements, levers, Bowden cables, buffer elements and the like, here will be limited to the configuration of the multi-ratchet locking mechanism.

- the rotary latch is used in particular for secure fixing of a lock holder in a motor vehicle door. It is known to secure the catch already in a position between the open position and closed position, so that a Release of the lock holder is not possible, the so-called pre-locking position. If the catch has reached its desired position in the closed position, it is secured by the so-called main catch. Pre-rest and main rest are regularly provided on the surface or the peripheral surface of the catch locking surfaces.

- the rotary latch, the first pawl, the second pawl, the blocking lever and the release lever have a metallic base body and are stamped components.

- the first pawl and the second pawl are also rotatably mounted on a common first pawl rotation axis, which may optionally be biased by a spring.

- the first pawl serves to lock the catch in the main catch (main catch pawl) and the second pawl is used to lock the catch on the Vorrast (pre-locking pawl).

- the engagement between the first pawl and the rotary latch is such that the first pawl does not block the catch itself or movement alone. Rather, the engagement between the first pawl and the rotary latch is such that the rotary latch exerts a force on the first pawl, so that it is moved into a position releasing the rotary latch. In order nevertheless to ensure that the first pawl rests securely against the main catch of the rotary latch in the closed position, such pivoting of the first pawl with the blocking lever is suppressed, which presses or holds the first pawl against the rotary latch or main catch.

- a release lever is provided, with which the blocking lever can be pivoted in the initiation of the opening process.

- the first pawl, the second pawl and at least the locking lever are designed as a pivot lever, that is, these can be pivoted (in a limited pivoting range) about its axis.

- these components to be arranged so that the first pawl and the blocking lever are pivoted in the same direction. If the first pawl, when lifted from the main catch of the rotary latch, pivots in a certain direction of rotation (e.g., clockwise), the blocking lever or trip lever is arranged such that the blocking lever is also pivoted in this clockwise direction. This can be achieved, in particular, that the blocking lever can be removed after a short Verschwenkweg from the pivoting range of the first pawl, so that here with very small movements, the desired release of the catch can be achieved.

- the release lever pivots the second pawl during the opening process.

- the pivoting of the second pawl with the release lever can take place at the same time as the pivoting of the blocking lever or optionally delayed.

- the release lever may have a plurality of legs, which lie directly and / or are positioned with a clearance to the blocking lever or the second pawl in the closed position in the lock unit.

- the release lever pivots the blocking lever and the second pawl with the same direction of rotation simultaneously.

- a particularly space-saving arrangement of the two pawls, the blocking lever and the release lever can be achieved, for example, by the release lever between the pawls and the blocking lever is arranged.

- the release lever is rotatable about a trigger lever axis.

- the release lever is also designed as a pivotable lever. In order to achieve again a particularly space-saving arrangement of the various levers, this pivots with a direction of rotation, which is opposite to the direction of rotation of the first pawl and the blocking lever (and the second pawl).

- the second pawl is contacted with a counter to its direction of rotation during the opening operation acting return spring.

- the return spring thus acts on the second pawl so that it is pressed permanently towards the catch and thus a secure contact with an external stop and / or the catch is realized.

- the return spring is preferably mounted on the basis of the second pawl opposite to the rotary latch.

- a motor vehicle which has at least one lock unit described here according to the invention.

- a lock unit is provided, in particular for locking doors and / or flaps of such motor vehicles.

- the Fig. 1 schematically indicates a motor vehicle 2 with a door 19 on which a lock unit 1 according to the invention is provided.

- the lock unit 1 is preferably arranged in a housing 16 on which an inlet mouth 17 is provided for the lock holder 15 arranged on the body of the motor vehicle 2.

- the Fig. 1 shows the locked state of the lock unit 1, in which the rotary latch 3 has the indicated lock holder 15 securely received in the receptacle 18 provided therefor.

- the rotary latch 3 is designed with a main catch 5 and a pre-latching 4.

- the rotary latch 3 exerts a force on the first pawl 6. This force results on the one hand from the spring preload, which moves the rotary latch 3 in the opening device (white arrow), as well as a force on the lock holder 15 and the door seals acting between the door 19 and the body of the motor vehicle 2, which are compressed here.

- a blocking lever 9 is provided with a blocking lever axis 10. The first pawl axis and the blocking lever axis are arranged away from each other.

- the blocking lever 9 can now be actuated via the release lever 11 when an opening operation is to be initiated.

- the trigger lever 11 here has a trigger lever axis 13, which is arranged away from the first pawl axis 7 and the blocking lever axis 10. It is preferred that the axis of rotation of the rotary latch and the trigger lever axis 13 is arranged on different sides of an imaginary connecting line between the first pawl axis 7 and the blocking lever axis 10.

- the opening process is initiated by means of the trigger lever 11, which is pivoted counterclockwise about the trigger lever axis 13 here.

- the release lever 11 directly contacts the blocking lever 9, which thereby performs a pivoting movement in the direction of rotation 12 (clockwise).

- This will be the blocking lever 9 very quickly removed from the pivoting area or from the contact surface with the first pawl 6, so that the first pawl 6 is pushed away by the opening movement of the rotary latch and the catch can move.

- the release lever 11 also pivots the second pawl 8 during its pivoting movement. The first pawl 6 and the second pawl 8 pivot both in a clockwise direction.

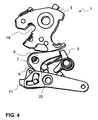

- a multi-ratchet locking a lock unit 1 shown in the three different positions.

- the rotary latch 3 can be seen.

- the first pawl 6 and the second pawl 8 can be seen, both of which are rotatably mounted on the first pawl axis 7.

- the rotatable locking lever 9 is shown.

- a return spring 14 is also provided, which acts on the blocking lever 9 and the second pawl 8. Below the pawls and the blocking lever of the release lever 11 can be seen, which is partially hidden in these representations of another lever.

- Fig. 2 When closed, as in Fig. 2 is shown, the first pawl 6 bears against the main catch 5 of the rotary latch 3. The first pawl 6 is thereby blocked by a corresponding leg of the blocking lever 9 movement. Another leg of the locking lever 9 is located on the trigger lever 11 directly.

- the second pawl 8 is pressed by means of the return spring 14 in the counterclockwise direction and is located on the stop 20 securely. With a small clearance of the trigger lever 11 is disposed in front of a corresponding leg of the second pawl 8. The actuation of the blocking lever 9 and the second pawl 8 by the release lever 11 is offset in time.

- Fig. 3 shows the position at which the second pawl 8 is engaged with the rotary latch 3.

- the rotary catch 3 has a preliminary catch 4 which rises laterally from the rotary catch 3 and which now rests against the second locking pawl 8.

- the second pawl 8 does not change its position in the main latch and pre-latch position, but that it is clearly defined via the return spring 14 and the stop 20.

- the first pawl 6 is deflected and abuts against a peripheral surface of the rotary latch 3.

- the blocking lever 9 rests in the region of the blocking surface of the first pawl 6, wherein no contact with the release lever 11, but a bias towards counterclockwise direction is provided.

- the rotary latch 3 for example. By an electric drive, further rotated counterclockwise, so that the spring-biased components are moved to the position as shown in Fig. 2 are shown as soon as the catch 3 reaches the corresponding position.

- both the first pawl 6 and the second pawl 8 are located on a peripheral portion of the rotary latch 3 outside the pre-locking and main catch. They are both pressed by a spring against the catch. In the illustrated position of the rotary latch 3, the lock holder can leave the receptacle 18 without further ado or dive into the receptacle 18 for the new closing operation.

- the invention makes it possible, in particular, to provide low-noise lock units which can be operated with high operating comfort and low force (also due to the smaller pivoting range of the pawls).

Landscapes

- Lock And Its Accessories (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200810048712 DE102008048712A1 (de) | 2008-09-24 | 2008-09-24 | Schlosseinheit mit Mehrklinken-Gesperre |

| PCT/DE2009/001320 WO2010034295A1 (de) | 2008-09-24 | 2009-09-18 | Schlosseinheit mit mehrklinken-gesperre |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2326780A1 EP2326780A1 (de) | 2011-06-01 |

| EP2326780B1 true EP2326780B1 (de) | 2013-04-10 |

Family

ID=41665199

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20090748949 Not-in-force EP2326780B1 (de) | 2008-09-24 | 2009-09-18 | Schlosseinheit mit mehrklinken-gesperre |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8827329B2 (zh) |

| EP (1) | EP2326780B1 (zh) |

| JP (1) | JP5351273B2 (zh) |

| CN (1) | CN102089488B (zh) |

| BR (1) | BRPI0913492B1 (zh) |

| DE (1) | DE102008048712A1 (zh) |

| WO (1) | WO2010034295A1 (zh) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102020105836A1 (de) | 2020-03-04 | 2021-09-09 | Brose Schließsysteme GmbH & Co. Kommanditgesellschaft | Kraftfahrzeugschloss |

Families Citing this family (46)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202008012706U1 (de) * | 2008-09-24 | 2008-12-18 | Kiekert Ag | Schlosseinheit mit mehrteiliger Sperrklinke und federvorgespannter Blockierklinke |

| DE102010003483B4 (de) * | 2009-06-12 | 2019-08-01 | Kiekert Ag | Schloss mit Zwangsführung für Sperrklinke |

| US20120175896A1 (en) * | 2010-05-05 | 2012-07-12 | Alfredo Martinez | Vehicle door latch |

| GB2480860B (en) * | 2010-06-04 | 2014-05-21 | Body Systems Usa Llc | Latch assembly |

| DE102010030595A1 (de) * | 2010-06-28 | 2011-12-29 | Kiekert Ag | Schloss für Kraftfahrzeug oder Gebäude |

| DE102011010816A1 (de) * | 2011-02-09 | 2012-08-09 | Kiekert Ag | Kraftfahrzeugtürverschluss |

| DE102011004170B4 (de) * | 2011-02-15 | 2012-09-13 | Kiekert Ag | Schloss für eine Klappe oder Tür |

| DE202011004952U1 (de) * | 2011-04-06 | 2012-07-09 | BROSE SCHLIEßSYSTEME GMBH & CO. KG | Kraftfahrzeugschloss |

| JP5437309B2 (ja) * | 2011-04-22 | 2014-03-12 | アイシン精機株式会社 | 回転レバーの位置保持装置および該回転レバーの位置保持装置を備える車両用ドアロック装置 |

| RU2624900C2 (ru) * | 2011-10-21 | 2017-07-07 | Киекерт Акциенгезельшафт | Устройство замыкания с многокомпонентной собачкой |

| DE102012203734A1 (de) * | 2012-03-09 | 2013-09-12 | Kiekert Ag | Schloss für eine Klappe oder Tür |

| DE102012103383A1 (de) * | 2012-04-18 | 2013-10-24 | Deutsches Zentrum für Luft- und Raumfahrt e.V. | Verfahren zur Herstellung eines Trägersubstrats, Trägersubstrat und elektrochemische Einrichtung |

| DE102012207441A1 (de) * | 2012-05-04 | 2013-11-07 | Kiekert Ag | Schloss für eine Klappe oder Tür |

| DE102012207440A1 (de) * | 2012-05-04 | 2013-11-07 | Kiekert Ag | Schloss für eine Klappe oder Tür |

| DE102012207442A1 (de) * | 2012-05-04 | 2013-11-07 | Kiekert Ag | Schloss für eine Klappe oder Tür |

| DE102012207443A1 (de) * | 2012-05-04 | 2013-11-07 | Kiekert Ag | Schloss für eine Klappe oder Tür |

| DE102012023236A1 (de) * | 2012-11-28 | 2014-05-28 | Kiekert Aktiengesellschaft | Kraftfahrzeugtürschloss |

| DE102012024285A1 (de) * | 2012-12-12 | 2014-06-12 | Kiekert Ag | Kraftfahrzeugtürschloss |

| DE102012024379A1 (de) * | 2012-12-12 | 2014-03-27 | Kiekert Aktiengesellschaft | Verfahren zum Herstellen von Kraftfahrzeugschlössern mit tordierter Gesperreteilkante |

| DE102012024303A1 (de) * | 2012-12-12 | 2014-06-12 | Kiekert Aktiengesellschaft | Kraftfahrzeugtürschloss |

| DE102012025053A1 (de) * | 2012-12-21 | 2014-06-26 | BROSE SCHLIEßSYSTEME GMBH & CO. KG | Kraftfahrzeugschloss |

| US9212509B2 (en) * | 2013-03-27 | 2015-12-15 | Kiekert Ag | Locking mechanism |

| DE102013103245A1 (de) | 2013-03-28 | 2014-10-02 | Kiekert Aktiengesellschaft | Kraftfahrzeugtürverschluss |

| EP3444418B1 (en) * | 2013-11-22 | 2020-03-04 | Gecom Corporation | Vehicle hood latches |

| CN103603561B (zh) * | 2013-11-30 | 2016-06-29 | 烟台三环锁业集团有限公司 | 汽车发动机罩盖锁的双拉开启结构 |

| DE102014001789A1 (de) * | 2014-02-12 | 2015-08-13 | Kiekert Aktiengesellschaft | Krahftfahrzeugtürschloss |

| KR101560979B1 (ko) * | 2014-05-30 | 2015-10-15 | 평화정공 주식회사 | 2단 해제용 후드래치 |

| KR101673705B1 (ko) | 2014-12-02 | 2016-11-07 | 현대자동차주식회사 | 차량용 도어 래치 장치 |

| US20160168883A1 (en) * | 2014-12-15 | 2016-06-16 | GM Global Technology Operations LLC | Double pull action vehicle hood latch |

| CN107406015B (zh) | 2015-03-12 | 2021-01-12 | 开开特股份公司 | 机动车门锁,特别是机动车座椅上的靠背锁 |

| US10941592B2 (en) * | 2015-05-21 | 2021-03-09 | Magna Closures Inc. | Latch with double actuation and method of construction thereof |

| DE112015006641A5 (de) * | 2015-06-22 | 2018-05-03 | Kiekert Ag | Kraftfahrzeugtürschloss |

| CN109339599B (zh) * | 2016-01-29 | 2021-03-12 | 开开特股份公司 | 机动车锁 |

| DE102017209376A1 (de) * | 2016-06-07 | 2017-12-07 | Magna Closures Inc. | Fahrzeugverschluss-Verriegelungsanordnung mit Doppelklinken-Verriegelungsmechanismus |

| US10808437B2 (en) * | 2017-07-21 | 2020-10-20 | Kiekert Ag | Motor vehicle door latch with primary and secondary pawl |

| DE102017122803A1 (de) * | 2017-09-29 | 2019-04-04 | Brose Schließsysteme GmbH & Co. Kommanditgesellschaft | Kraftfahrzeugschloss |

| JP6891801B2 (ja) * | 2017-12-25 | 2021-06-18 | トヨタ自動車株式会社 | 車両用ドアロック装置 |

| CN110130753B (zh) | 2018-02-08 | 2022-03-15 | 麦格纳覆盖件有限公司 | 具备具有滚子掣爪组件的闩锁机构的闭合闩锁组件 |

| DE102018113595A1 (de) * | 2018-06-07 | 2019-12-12 | Kiekert Ag | Kraftfahrzeugtürschloss |

| US11421455B2 (en) * | 2018-10-03 | 2022-08-23 | Inteva Products, Llc | Hood latch for motor vehicle having under hood storage |

| DE102019123837A1 (de) * | 2018-10-22 | 2020-04-23 | Kiekert Aktiengesellschaft | Kraftfahrzeugschloss |

| US10864831B2 (en) * | 2019-01-11 | 2020-12-15 | Kiekert Ag | Motor vehicle latch, in particular, backrest latch on a motor vehicle seat |

| US11339591B2 (en) * | 2019-02-12 | 2022-05-24 | GM Global Technology Operations LLC | Latch assembly having self re-latching feature |

| DE102019131179A1 (de) * | 2019-11-19 | 2021-05-20 | Kiekert Aktiengesellschaft | Kraftfahrzeug-Schloss |

| DE102020133537A1 (de) * | 2020-12-15 | 2022-06-15 | Brose Schließsysteme GmbH & Co. Kommanditgesellschaft | Kraftfahrzeugschloss |

| WO2022245866A1 (en) * | 2021-05-17 | 2022-11-24 | Motown Engineering, Inc. | Vehicle door latch |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3801581C1 (zh) * | 1988-01-21 | 1988-10-13 | Bomoro Bocklenberg & Motte Gmbh & Co Kg, 5600 Wuppertal, De | |

| JP2504946Y2 (ja) * | 1990-05-29 | 1996-07-24 | 三菱自動車工業株式会社 | ドアロック装置 |

| CN1058068C (zh) | 1994-11-10 | 2000-11-01 | 三井金属矿业株式会社 | 车辆用门锁装置 |

| DE19937405B4 (de) * | 1999-08-07 | 2011-06-01 | Bayerische Motoren Werke Aktiengesellschaft | Verschluß für eine klappbare Haube eines Kraftfahrzeugs |

| DE20104625U1 (de) | 2001-03-17 | 2002-08-01 | Bayerische Motoren Werke AG, 80809 München | Kraftfahrzeugtürverschluss |

| EP1380715A1 (en) | 2002-07-12 | 2004-01-14 | SO.GE.MI.- S.p.A. | Safety lock for car bonnets or doors |

| DE10336049A1 (de) * | 2003-08-01 | 2005-02-17 | Kiekert Ag | Kraftfahrzeugtürverschluss |

| KR20050032210A (ko) | 2003-10-01 | 2005-04-07 | 기아자동차주식회사 | 차량용 도어 래치 구조 |

| CN2809129Y (zh) | 2005-01-18 | 2006-08-23 | 鑫田集团有限公司 | 一种汽车门锁 |

| DE102007003948A1 (de) | 2006-11-22 | 2008-05-29 | Kiekert Ag | Schlosseinheit mit mehrteiliger Sperrklinke |

| DE102008035607A1 (de) * | 2008-07-31 | 2010-02-04 | Kiekert Ag | Schlosseinheit mit zwei Sperrklinken und Positionserkennungsmitteln |

| US8235428B2 (en) * | 2009-07-14 | 2012-08-07 | Kiekert Ag | Lock unit having a slotted pawl |

| DE102011012370A1 (de) * | 2010-02-24 | 2011-08-25 | Magna Closures S.P.A. | Fahrzeugschloss mit Sperrklinke mit einzelner Kerbe |

-

2008

- 2008-09-24 DE DE200810048712 patent/DE102008048712A1/de not_active Withdrawn

-

2009

- 2009-09-18 EP EP20090748949 patent/EP2326780B1/de not_active Not-in-force

- 2009-09-18 BR BRPI0913492-1A patent/BRPI0913492B1/pt not_active IP Right Cessation

- 2009-09-18 CN CN2009801371523A patent/CN102089488B/zh not_active Expired - Fee Related

- 2009-09-18 US US13/120,156 patent/US8827329B2/en active Active

- 2009-09-18 JP JP2011528185A patent/JP5351273B2/ja not_active Expired - Fee Related

- 2009-09-18 WO PCT/DE2009/001320 patent/WO2010034295A1/de active Application Filing

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102020105836A1 (de) | 2020-03-04 | 2021-09-09 | Brose Schließsysteme GmbH & Co. Kommanditgesellschaft | Kraftfahrzeugschloss |

Also Published As

| Publication number | Publication date |

|---|---|

| US20110169280A1 (en) | 2011-07-14 |

| JP2012503723A (ja) | 2012-02-09 |

| DE102008048712A1 (de) | 2010-03-25 |

| JP5351273B2 (ja) | 2013-11-27 |

| CN102089488B (zh) | 2013-08-21 |

| BRPI0913492A2 (pt) | 2018-01-09 |

| WO2010034295A1 (de) | 2010-04-01 |

| CN102089488A (zh) | 2011-06-08 |

| EP2326780A1 (de) | 2011-06-01 |

| US8827329B2 (en) | 2014-09-09 |

| BRPI0913492B1 (pt) | 2019-02-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2326780B1 (de) | Schlosseinheit mit mehrklinken-gesperre | |

| EP2326781B1 (de) | Schlosseinheit mit mehrteiliger sperrklinke und federvorgespannter blockierklinke | |

| EP2347071B1 (de) | Schlosseinheit mit mehrklinken-gesperre | |

| EP2089599B1 (de) | Schlosseinheit mit mehrteiliger sperrklinke | |

| EP2291568B1 (de) | Schliessvorrichtung mit zwei sperrklinken und motorisch angetriebenen stellantrieb | |

| EP2823120B1 (de) | Schloss für eine klappe oder tür | |

| EP2964859B1 (de) | Schloss für ein kraftfahrzeug | |

| EP2929114B1 (de) | Schloss für eine klappe oder tür | |

| EP2291571B1 (de) | Schliessvorrichtung mit sperrklinkenfeder | |

| EP2929112B1 (de) | Schloss für eine klappe oder tür | |

| EP1460211A2 (de) | Kraftfahrzeugschloss | |

| DE102014001490A1 (de) | Schloss für ein Kraftfahrzeug | |

| WO2015090286A1 (de) | Schloss für ein kraftfahrzeug | |

| DE102013110756A1 (de) | Kraftfahrzeugtürschloss | |

| EP3784855B1 (de) | Kraftfahrzeugschloss | |

| DE102010061427A1 (de) | Drehfallenverschluss mit Sperrnocken | |

| EP2545234B1 (de) | Kraftfahrzeugschloss mit kraftübertragung auf den schlosskasten | |

| EP3179021B1 (de) | Türgriffanordnung für ein kraftfahrzeug | |

| DE102012207443A1 (de) | Schloss für eine Klappe oder Tür | |

| DE102012207440A1 (de) | Schloss für eine Klappe oder Tür | |

| DE102008034638A1 (de) | Schlosseinheit mit blockierter Sperrklinke | |

| DE102008039240A1 (de) | Schließvorrichtung mit Sperrklinkenfeder | |

| WO2019048006A1 (de) | Kraftfahrzeugtürschloss | |

| EP3385482A1 (de) | Schlossanordnung für ein fahrzeug | |

| DE102017108916A1 (de) | Kraftfahrzeugtürverschluss |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20110224 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHOLZ, MICHAEL Inventor name: GOETZ, OLIVER |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: GOETZ, OLIVER Inventor name: SCHOLZ, MICHAEL |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 606131 Country of ref document: AT Kind code of ref document: T Effective date: 20130415 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009006820 Country of ref document: DE Effective date: 20130606 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D Ref country code: NL Ref legal event code: VDEP Effective date: 20130410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130710 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130711 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130812 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130810 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 |

|

| 26N | No opposition filed |

Effective date: 20140113 |

|

| BERE | Be: lapsed |

Owner name: KIEKERT A.G. Effective date: 20130930 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009006820 Country of ref document: DE Effective date: 20140113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130918 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130918 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130918 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130918 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090918 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 606131 Country of ref document: AT Kind code of ref document: T Effective date: 20140918 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140918 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20220920 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20220921 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502009006820 Country of ref document: DE |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20240404 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230930 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240403 |