EP0135818A2 - Procédé et dispositif pour envelopper des paquets de cigarettes dans des feuilles - Google Patents

Procédé et dispositif pour envelopper des paquets de cigarettes dans des feuilles Download PDFInfo

- Publication number

- EP0135818A2 EP0135818A2 EP84110102A EP84110102A EP0135818A2 EP 0135818 A2 EP0135818 A2 EP 0135818A2 EP 84110102 A EP84110102 A EP 84110102A EP 84110102 A EP84110102 A EP 84110102A EP 0135818 A2 EP0135818 A2 EP 0135818A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- packs

- blank

- overall

- folded

- revolver

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B11/00—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material

- B65B11/004—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material in blanks, e.g. sheets precut and creased for folding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B11/00—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material

- B65B11/06—Wrapping articles, or quantities of material, by conveying wrapper and contents in common defined paths

- B65B11/28—Wrapping articles, or quantities of material, by conveying wrapper and contents in common defined paths in a curved path, e.g. on rotary tables or turrets

- B65B11/30—Wrapping articles, or quantities of material, by conveying wrapper and contents in common defined paths in a curved path, e.g. on rotary tables or turrets to fold the wrappers in tubular form about contents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B19/00—Packaging rod-shaped or tubular articles susceptible to damage by abrasion or pressure, e.g. cigarettes, cigars, macaroni, spaghetti, drinking straws or welding electrodes

- B65B19/02—Packaging cigarettes

- B65B19/22—Wrapping the cigarettes; Packaging the cigarettes in containers formed by folding wrapping material around formers

- B65B19/223—Wrapping the cigarettes; Packaging the cigarettes in containers formed by folding wrapping material around formers in a curved path; in a combination of straight and curved paths, e.g. on rotary tables or other endless conveyors

Definitions

- the invention relates to a method for wrapping objects in blanks, in particular packs (cigarette packs) in foil blanks, which are folded in a U-shape around the packs conveyed relative to them and then finished. Furthermore, the invention relates to a device for performing the above method.

- Cigarette packs are predominantly provided with an outer wrapper, which consists of a cellophane film or - more recently - a plastic film.

- the film blank When wrapping the pack, the film blank is predominantly placed in a U-shape around the long side of the (cuboid) pack, so that cut parts stand over the pack in the region of the end faces and an opposite long side. These are folded by means of movable or stationary folding members as a result of relative movement with the pack against the associated sides thereof. In the region of the tubular flaps of the film blank which overlap one another on the long side, they can be connected to one another by welding or gluing.

- the object of the invention is accordingly to increase the performance in the area of film wrapping, without there being disadvantages as a result of mechanical stressing of the sensitive (cigarette) packs as a result of excessive conveying speeds.

- the method according to the invention is therefore used in multi-lane operation, in particular with two (cigarette) packs conveyed simultaneously and in the same transverse planes.

- Another special feature is that a common, appropriately sized overall blank is fed to the adjacent packs and folded around the packs in a U-shape.

- the use of an overall blank for all packs fed in at the same time has the advantage that the folding processes can be carried out more precisely and more quickly.

- the packs held together by the common overall cut form a unit that is easy to handle.

- a blank the size of a total blank is easier to handle with the usual extremely thin-walled material.

- a blank tube of the appropriate length is formed by overlapping edge-side tube tabs and connecting them to one another.

- a three-dimensionally shaped overall blank which can be severed in the area between the packs which are kept at a distance, without any relative displacements of the packs or the sheet blanks now obtained from one another.

- front end flaps of the entire blank that are protruding in the direction of transport and protrude on the long sides are folded over, namely against the assigned end face of the pack, by means of stationary folding members.

- This also applies to the side end lobes formed in the area between the packs conveyed next to one another.

- the overall cut or a material Provide the web with a pre-cut to form the blanks at a suitable point, which extends approximately in the longitudinal direction of the material web or in the transport direction of the overall blank and separates the side end flaps to be folded there.

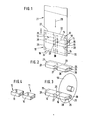

- the device according to the invention for wrapping cigarette packs in film blanks is accordingly equipped with a revolving conveyor, in particular a revolver, which has pockets which are open in the radial direction and which are dimensioned correspondingly to the number of packs transversely to the conveying direction.

- Fixed folding thumbs are arranged on the pockets of the revolver on the outside of the pockets and in the center or at a distance corresponding to the distance between the packs.

- a revolving knife is assigned to the revolver, in particular a rotatingly driven knife disk which projects into a circumferential, narrow knife slot of the revolver and cuts through the (tubular) overall blank in the area of a separating station.

- the present exemplary embodiment relates to the wrapping of cuboid packs 10, 11, in particular cigarette packs, into a blank made of a plastic film or cellophane.

- the packs 10, 11 are delimited by the front 12 and back 13, by end faces 14 and 15 and by long sides 16 and 17.

- a special feature is that several, namely two spaced packs 10 and 11 are aligned in the transverse direction and fed at a distance from one another and together in one appropriately sized overall cut 18 are wrapped. This is divided into twice the width of an individual film blank 19 or 20 for a pack 10, 11 from a continuous material web 21 by a cross-cut 22.

- the overall blank 18 is then placed in a U-shape around the two packs 10, 11 (FIG. 2), in such a way that upper and lower tubular tabs 23, 24 protrude on the rear side in the transport direction (long sides 17). Laterally, that is to say transversely to the conveying direction, upper and lower longitudinal front flaps 25 and 26 project beyond the front sides 14, 15. In an extension of the forward longitudinal sides 16, side end flaps 27 and 28 are formed by the overall blank 18.

- the side end flaps 27 and 28 for each pack 10, 11 are first folded on the end face 14, 15 thereof.

- the overall blank 18 has a previously made pre-cut 29 in the area of the side end flaps 27 to be formed. This is located in the middle between the packs 10, 11 in the area of a material strip 30 in the double width of a side face flap 27.

- the pre-cut 29 is already made in the material web 21 at a predetermined position. Due to the length of the pre-cut 29, the folding of the side end flaps 27 against the mutually facing end faces 14, 15 of the packs 10, 11 is possible while maintaining the unity of the overall blank 18.

- a blanking tube is formed by folding and partially covering the tube tabs 23, 24 and by connecting them (FIG. 3).

- the entire blank 18 is then cut in the area between the packs 10, 11, namely in addition to the pre-cut 29.

- the tabs then still protruding on the end faces 14, 15, namely longitudinal end flaps 25 and 26 and rear side end flaps 30, become more common Folded against the end faces 14, 15 so that the folding image of the packs 10, 11 shown in FIG. 4 is generated.

- the packs 10, 11 (in pairs) lying next to one another are delivered in succession on a common feed path 31.

- a circulating conveyor (chain conveyor 32) is used to transport the packs 10, 11 on the horizontal feed conveyor 31. From this, the packs 10, 11 are taken over by a slide 33 which dips from above into the path of movement of the packs 10, 11 and the packs 10, 11 by grasping on the back (long sides 17) until they are received in a pocket 34 Revolvers 35 transported on. After the packs 10, 11 have been transferred to the turret 35, the slide 33 is moved upward and returns to the starting position shown in dashed lines above the feed path 31. Entry into this takes place via an opening 36 in an upper guide 37 of the feed conveyor track 31.

- the overall blank 18 is fed transversely to the conveying direction of the packs 10, 11, in the present case in a vertical plane, from top to bottom.

- the entire blank 18 is transported in the region on both sides of the feed conveyor 31 by suction air acted on conveyor belts, namely two perforated belts 38 and 39 running at a distance from one another.

- the configuration of the same and the device for applying suction air to the perforated belts 38, 39 can be carried out in a suitable manner, in particular in the embodiment of DE-OS 25 30 992.

- the perforated belts 38, 39 are guided over an upper deflecting roller 40 and a lower, not shown corresponding deflecting roller below the feed conveyor 31.

- the material web 21 is fed to the above-described film conveyor, namely the perforated belts 38, 39 via pull rollers 41, 42.

- These also have the task of making the pre-cut 29 at a suitable location within the material web 21.

- the larger diameter roller 42 is equipped with knife segments 43 and 44 which protrude beyond the outer surface of the roller 42 and make the pre-cut of the appropriate length in the material web 21.

- two pre-cuts 29 are accordingly made, that is to say two overall cuts 18 are prepared accordingly.

- the knife segments 43, 44 are arranged centrally on the pull roller 42 when two packs 10, 11 are simultaneously wrapped.

- the opposite, smaller pull roller 41 is provided in the same plane, that is to say also centrally in the present case, with a circumferential groove 45, into which the knife segments 43, 44 enter when performing the cut 29.

- a further separating device is arranged upstream of the deflecting roller 40, namely a knife roller 46 with a fixed counter knife 47.

- a (transverse) partial cut is made in the material web 21 by this separating device, essentially Lichen in the area of the perforated strips 38, 39, which subsequently capture the material web 21.

- a main cut adjoining the partial cuts to complete the continuous cross-cutting cut 42 is produced in the region of the perforated strips 38, 39 lying between them by a further knife roller 48 with counter knife 49.

- the method of severing a material web 21 in several successive partial cuts is carried out according to the features of DE-OS 25 30 992.

- a U-shaped cut for producing two grip tongues 50 is made in the region of a tear strip 51 applied to the material web 21.

- the tear strips 51 are attached in such a way that they run eccentrically in the usual manner within the wrapping of the finished packs 10, 11, namely facing one of the end faces.

- the thus cut and prepared overall blanks 18 are gripped in the area of a mouthpiece 52 by two packs 10, 11, which are simultaneously conveyed at a distance from one another, conveyed through the mouthpiece 52 into a pocket 34 of the revolver 35 held ready immediately after the mouthpiece 52

- Overall blank 18 is placed around the packs 10, 11 in a U-shape in the manner described.

- the pocket 34 is dimensioned in the radial direction such that the packs 10, 11 are essentially flush with the outer boundary of the pocket 34 with the rear or outer longitudinal side 17.

- Hose tabs 23, 24 projecting rearward accordingly protrude from the pocket 34.

- a folding element 53 designed as an arcuate plate is moved in the circumferential direction of the revolver 35 and concentrically to it - in the illustration in FIG. 5 in the upward direction.

- the lower tube tab 24 is thereby folded over against the long side 17 and fixed in this position until the revolver is transported in the counterclockwise direction.

- the circular-arc-shaped folding member 53 is accordingly moved back and forth in the circumferential direction to carry out the folds.

- the pocket 34 with the inserted packs 10, 11 arrives in the area of a fixed guide wall 54 closely clinging to the circumference of the turret 35.

- the guide wall 54 merges into the upper part of the mouthpiece 52.

- the partially overlapping tubular tabs 23, 24 are connected to one another in the area of a sealing station by a sealing tool in the form of a sealing strip 55 by means of pressure and thermal action.

- the sealing strip is brought from the outside to the longitudinal side 17 or to the tubular tabs 23, 24, the sealing strip 55 passing through a slot-shaped opening 56 in the guide wall 54.

- the sealing strip 55 is in the present the embodiment can be moved into the sealing position by a swivel arm 57.

- a separation station 58 follows. In this, the blanking tube is severed in the middle or in the middle between two adjacent packs 10, 11.

- a disc-shaped, rotationally driven thin cutting knife 59 enters the revolver 35, through a knife slot 60 in the guide wall 54.

- a drive shaft 61 for the cutting knife 59 is arranged outside the turret or outside the guide wall 54, parallel to the axis of a turret shaft 62.

- the revolver 35 itself in the area of the pockets 34 is provided with a thin knife gap 63 running all around. This enables the cutting knife 59 to penetrate into the turret 35 with the required depth in such a way that the cutting tube can be completely severed in the cutting station 58.

- a subsequent ejection station 64 there are packs 10, 11 with separate, individual film blanks 19 and 20 in the pocket 34.

- the packs 10, 11 with the film blanks are moved by a pusher 65 which can be moved in a suitable manner in the radial direction 19, 20 ejected together.

- a discharge track 66 connects to the turret 34.

- Side guides of the same are equipped in a known manner as folding members.

- the inlet end of the discharge conveyor 66 adjoining the turret 35 is laterally provided with a folding tongue 67. This folds the one when it is extended of the packs 10, 11 from the turret 35, the side end flaps 30 now lying forward against the assigned end faces 14 and 15.

- the lower longitudinal end flap 26 is folded against the end face 14, 15, by a fixed folding switch 68.

- the upstream packing tower 69 adjoins the horizontal discharge conveyor 66 in the present case, into which the mostly finished packs 10, 11 are inserted one after the other from below by a plunger 70.

- the upper longitudinal front flap 25 is folded through the side walls of the same to complete the packing 10, 11 against the end face 14, 15. The completed packs 10, 11 are thus transported further within the packing tower 69.

- a special feature is that when the packs 10, 11 are inserted, the side end flaps 27 and 28, which are initially in the transport direction, are folded against the associated end faces 14, 15 by stationary organs, although the unit of the overall blank 18 still exists of the revolver 35 are equipped with index fingers 71 and 72 for this purpose.

- These folding members form the side boundary of the pockets 34, the folding fingers 72, which extend in the center in the radial direction, being separated from one another by the knife gap 63.

- the pockets 34 which extend over the full width of the revolver 35 designed in the present case on two packs 10, 11, are accordingly divided into two partial pockets by the middle folding fingers 72, each for receiving a pack 10, 11.

- the pockets 34 of the turret 35 are, moreover, each formed by tongues 73 and 74 arranged in pairs at a distance from one another for reasons of material saving.

- the device described is not only suitable for processing two packs at the same time. As can be seen, with the appropriate design of the pockets of a revolver and the conveying and separating elements, several packs can be processed in a line next to one another, whereby a common overall cut for all packs or several overall cuts each covering two packs can be used .

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3332950 | 1983-09-13 | ||

| DE19833332950 DE3332950A1 (de) | 1983-09-13 | 1983-09-13 | Verfahren und vorrichtung zum einhuellen von zigaretten-packungen in folien-zuschnitte |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0135818A2 true EP0135818A2 (fr) | 1985-04-03 |

| EP0135818A3 EP0135818A3 (en) | 1986-06-04 |

| EP0135818B1 EP0135818B1 (fr) | 1988-07-20 |

Family

ID=6208912

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84110102A Expired EP0135818B1 (fr) | 1983-09-13 | 1984-08-24 | Procédé et dispositif pour envelopper des paquets de cigarettes dans des feuilles |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4617780A (fr) |

| EP (1) | EP0135818B1 (fr) |

| JP (1) | JPH06528B2 (fr) |

| BR (1) | BR8404551A (fr) |

| CA (1) | CA1227414A (fr) |

| DE (2) | DE3332950A1 (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0197368A2 (fr) * | 1985-04-06 | 1986-10-15 | Focke & Co. (GmbH & Co.) | Procédé et dispositif pour l'empaquetage, en particulier de cigarettes |

| EP0304736A2 (fr) * | 1987-08-28 | 1989-03-01 | Focke & Co. (GmbH & Co.) | Procédé et dispositif pour envelopper spécialement des paquets de cigarettes |

| DE4335666A1 (de) * | 1993-10-20 | 1995-04-27 | Focke & Co | Vorrichtung zum Herstellen von Packungsgebinden |

| EP1260442A2 (fr) * | 2001-05-11 | 2002-11-27 | G.D Societ Per Azioni | Procédé de suremballage de paquets |

| WO2007014917A1 (fr) * | 2005-07-29 | 2007-02-08 | Azionaria Costruzioni Macchine Automatiche A.C.M.A. S.P.A. | Procede et machine servant a former des groupes de produits et a emballer chaque groupe |

| WO2008089879A1 (fr) * | 2007-01-22 | 2008-07-31 | Focke & Co. (Gmbh & Co. Kg) | Dispositif de travail pour machines d'emballage |

| EP1555228B2 (fr) † | 2004-01-13 | 2011-11-16 | G.D Società Per Azioni | Procédé et dispositif pour transfert des paquets |

| US8631715B2 (en) | 2010-06-09 | 2014-01-21 | Copan Italia S.P.A. | Method for quantitative transfer of analytes |

Families Citing this family (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3618736A1 (de) * | 1986-06-04 | 1987-12-10 | Schmermund Maschf Alfred | Verfahren und vorrichtung zum einhuellen von zigarettenpaeckchen in klarsichtfolie |

| DE3639994A1 (de) * | 1986-11-22 | 1988-05-26 | Focke & Co | Verpackungsmaschine, insbesondere fuer zigarettenpackungen |

| DE3701273A1 (de) * | 1987-01-17 | 1988-07-28 | Focke & Co | Verfahren und vorrichtung zum verpacken von papier-taschentuechern |

| DE3800432A1 (de) * | 1988-01-09 | 1989-07-20 | Hauni Werke Koerber & Co Kg | Vorrichtung zum einhuellen von packungen mit huellmaterial |

| DE3800664A1 (de) * | 1988-01-13 | 1989-07-27 | Focke & Co | Verfahren und vorrichtung zum herstellen von einen kragen aufweisenden klappschachteln, insbesondere fuer zigaretten |

| IT1236030B (it) * | 1989-10-11 | 1992-12-22 | Gd Spa | Macchina incartatrice di prodotti sostanzialmente parallelepipedi |

| IT1252424B (it) * | 1991-07-16 | 1995-06-14 | Gd Spa | Metodo e dispositivo per la realizzazione di stecche divisibili per pacchetti di sigarette |

| IT1259800B (it) * | 1992-11-20 | 1996-03-26 | Gd Spa | Metodo e dispositivo per la realizzazione di sovraincarti tubolari di materiale termosaldabile. |

| GB9321148D0 (en) * | 1993-10-13 | 1993-12-01 | Molins Plc | Package blank feeding |

| ITBO940213A1 (it) * | 1994-05-16 | 1995-11-16 | Gd Spa | Metodo per la realizzazione di stecche di sigarette con involucro rigido del tipo a coperchio incernierato. |

| IT1285617B1 (it) * | 1996-03-15 | 1998-06-18 | Gd Spa | Metodo di incarto di prodotti |

| IT1285922B1 (it) * | 1996-05-06 | 1998-06-26 | Gd Spa | Metodo e dispositivo per la piegatura di lembi di estremita' di involucri tubolari |

| IT1291264B1 (it) * | 1997-03-17 | 1998-12-30 | Gd Spa | Metodo di piegatura per la formazione di un involucro a tubo sigillato |

| IT1304778B1 (it) * | 1998-07-06 | 2001-03-29 | Gd Spa | Macchina impacchettatrice. |

| DE19907579A1 (de) * | 1999-02-23 | 2000-09-14 | Topack Verpacktech Gmbh | Vorrichtung zur Beförderung von Gegenständen |

| US6305146B1 (en) * | 1999-03-09 | 2001-10-23 | Jensen Ag Burgdorf | Process for the final folding and subsequent storage of a piece of linen and final folding means |

| DE10123804A1 (de) * | 2001-05-16 | 2002-11-28 | Christian Senning Verpackungsm | Verfahren und Vorrichtung zum gleichzeitigen Verpacken auf mehr als einer Verpackungslinie |

| ITBO20030317A1 (it) * | 2003-05-22 | 2004-11-23 | Gd Spa | Metodo ed unita' per l'incarto di gruppi di prodotti. |

| ITBO20030706A1 (it) * | 2003-11-21 | 2005-05-22 | Gd Spa | Unita' di incarto di prodotti. |

| ITBO20040434A1 (it) * | 2004-07-12 | 2004-10-12 | Gd Spa | Metodo per la formazione di un pacchetto a portafoglio a coperchio incernierato |

| ITBO20060237A1 (it) * | 2006-04-04 | 2006-07-04 | Gd Spa | Metodo e macchina per l'incarto di articoli. |

| US8046978B2 (en) * | 2009-10-02 | 2011-11-01 | R.J. Reynolds Tobacco Company | Equipment and method for packaging multiple packets of cigarettes |

| DE102009060134A1 (de) | 2009-12-09 | 2011-06-16 | Focke & Co.(Gmbh & Co. Kg) | Packungen insbesondere für Zigaretten sowie Verfahren und Vorrichtung zum Herstellen derselben |

| EP2981471B1 (fr) * | 2013-04-03 | 2017-05-31 | JT International S.A. | Procédé et appareil d'emballage |

| EP2894103B1 (fr) | 2014-01-10 | 2016-09-07 | Robert Bosch Gmbh | Procédé et dispositif d'emballage de produits alimentaires en portions individuelles |

| DE102015001027A1 (de) * | 2014-11-27 | 2016-06-02 | Focke & Co. (Gmbh & Co. Kg) | Verfahren und Vorrichtung zum Herstellen von Zigarettenpackungen |

| ITUB20160589A1 (it) * | 2016-02-09 | 2017-08-09 | Ima Spa | Unita' e metodo per disporre oggetti entro scatole. |

| ITUB20160604A1 (it) * | 2016-02-09 | 2017-08-09 | Ima Spa | Unita' e metodo per disporre oggetti entro scatole. |

| DE102017002934A1 (de) * | 2017-03-24 | 2018-09-27 | Focke & Co. (Gmbh & Co. Kg) | Verfahren und Vorrichtung zum Herstellen von (Zigaretten-)Packungen |

| IT201800010315A1 (it) * | 2018-11-14 | 2020-05-14 | Gd Spa | Metodo di incarto per realizzare contemporaneamente due confezioni |

| IT201800010313A1 (it) * | 2018-11-14 | 2020-05-14 | Gd Spa | Metodo ed unità di alimentazione di due fogli di incarto in una macchina impacchettatrice |

| EP3915890A1 (fr) * | 2020-05-29 | 2021-12-01 | OCME S.r.l. | Appareil pour la fabrication d'une pluralité de paquets |

| DE102022105779A1 (de) * | 2022-03-11 | 2023-09-14 | Focke & Co. (Gmbh & Co. Kg) | Vorrichtung und Verfahren zum Handhaben von Zuschnitten für eine Umhüllung von Packungen für Produkte der Zigarettenindustrie |

| CN115140357A (zh) * | 2022-04-29 | 2022-10-04 | 河南中烟工业有限责任公司 | 一种盒烟包装后包装盒自动塑封机 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR599407A (fr) * | 1926-01-12 | |||

| AT293281B (de) * | 1967-01-10 | 1971-09-27 | Heinz Focke | Vorrichtung zum Verpacken von Zigaretten in Weichpackungen |

| GB2003817A (en) * | 1977-09-07 | 1979-03-21 | Focke & Co | Apparatus for applying wrappers to articles |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE802564C (de) * | 1949-07-13 | 1951-02-15 | Kurt Koerber & Co K G | Verfahren und Maschine zum Verpacken von Zigaretten und aehnlichem Gut |

| DE1169835B (de) * | 1960-07-07 | 1964-05-06 | Hauni Werke Koerber & Co Kg | Verpackungsmaschine zum Einwickeln von Zigarettenpackungen |

| DE1217848B (de) * | 1963-05-09 | 1966-05-26 | Hauni Werke Koerber & Co Kg | Verfahren und Vorrichtung zum Einschlagen von Zigarettenpackungen und aehnlichem Verpackungsgut in eine Kunststoff-Folie |

| CH527090A (de) * | 1970-06-03 | 1972-08-31 | Sig Schweiz Industrieges | Verfahren zum Verpacken von gleichartigen Gegenständen und Maschine zur Durchführung des Verfahrens |

| DE2407580A1 (de) * | 1974-02-16 | 1975-08-21 | Focke Pfuhl Verpack Automat | Anlage zum herstellen und verpacken von zigaretten o.dgl. sowie verfahren zur speicherung derselben |

| IT1060149B (it) * | 1976-03-31 | 1982-07-10 | Gd Spa | Dispositivo perfezionato per la realizzazione dell involuoro interno di carta stagnola con sovrapposizione delle estremita longitudinali dello spezzone su una delle facce maggiori del gruppo di sigarette nelle macchine condizionatrici di sigarette in pacchetti molli ad al tissima velocita produttiva |

| IT1120350B (it) * | 1979-05-04 | 1986-03-19 | Gd Spa | Macchina perfezionata per l'incarto ed il raggruppamento di prodotti |

| DE2949685A1 (de) * | 1979-12-11 | 1981-06-19 | Focke & Co, 2810 Verden | Vorrichtung zum herstellen von packungszuschnitten durch abtrennen von einer fortlaufenden bahn |

| US4495745A (en) * | 1979-12-26 | 1985-01-29 | Package Machinery Company | Sealing wheel for forming fin seal package |

| JPS6016487Y2 (ja) * | 1981-05-09 | 1985-05-22 | 日本包装機械株式会社 | 2列物品同時包装装置 |

-

1983

- 1983-09-13 DE DE19833332950 patent/DE3332950A1/de not_active Withdrawn

-

1984

- 1984-08-24 EP EP84110102A patent/EP0135818B1/fr not_active Expired

- 1984-08-24 DE DE8484110102T patent/DE3472780D1/de not_active Expired

- 1984-08-29 US US06/645,187 patent/US4617780A/en not_active Expired - Lifetime

- 1984-09-12 CA CA000462990A patent/CA1227414A/fr not_active Expired

- 1984-09-12 BR BR8404551A patent/BR8404551A/pt not_active IP Right Cessation

- 1984-09-13 JP JP59190719A patent/JPH06528B2/ja not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR599407A (fr) * | 1926-01-12 | |||

| AT293281B (de) * | 1967-01-10 | 1971-09-27 | Heinz Focke | Vorrichtung zum Verpacken von Zigaretten in Weichpackungen |

| GB2003817A (en) * | 1977-09-07 | 1979-03-21 | Focke & Co | Apparatus for applying wrappers to articles |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0197368A2 (fr) * | 1985-04-06 | 1986-10-15 | Focke & Co. (GmbH & Co.) | Procédé et dispositif pour l'empaquetage, en particulier de cigarettes |

| DE3512611A1 (de) * | 1985-04-06 | 1986-10-16 | Focke & Co (GmbH & Co), 2810 Verden | Verfahren und vorrichtung zum verpacken von insbesondere zigaretten |

| EP0197368A3 (en) * | 1985-04-06 | 1987-01-07 | Focke & Co. (Gmbh & Co.) | Method and apparatus for packaging cigarettes in particular |

| DE3728716C2 (de) * | 1987-08-28 | 1999-10-07 | Focke & Co | Verfahren zum Einhüllen von quaderförmigen Gegenständen, insbesondere Zigaretten-Packungen sowie Vorrichtung zur Durchführung des Verfahrens |

| DE3728716A1 (de) * | 1987-08-28 | 1989-03-09 | Focke & Co | Verfahren und vorrichtung zum einhuellen von insbesondere zigaretten-packungen |

| JPS6470322A (en) * | 1987-08-28 | 1989-03-15 | Focke & Co | Method and device for packaging package, particularly, cigarette pack |

| EP0304736A3 (en) * | 1987-08-28 | 1990-03-14 | Focke & Co. (Gmbh & Co.) | Method and device for enveloping, especially cigarette packages |

| EP0304736A2 (fr) * | 1987-08-28 | 1989-03-01 | Focke & Co. (GmbH & Co.) | Procédé et dispositif pour envelopper spécialement des paquets de cigarettes |

| DE4335666A1 (de) * | 1993-10-20 | 1995-04-27 | Focke & Co | Vorrichtung zum Herstellen von Packungsgebinden |

| EP1260442A2 (fr) * | 2001-05-11 | 2002-11-27 | G.D Societ Per Azioni | Procédé de suremballage de paquets |

| EP1260442A3 (fr) * | 2001-05-11 | 2003-01-02 | G.D Societ Per Azioni | Procédé de suremballage de paquets |

| US6643996B2 (en) | 2001-05-11 | 2003-11-11 | G.D. Societa' Per Azioni | Method of overwrapping packets |

| EP1555228B2 (fr) † | 2004-01-13 | 2011-11-16 | G.D Società Per Azioni | Procédé et dispositif pour transfert des paquets |

| WO2007014917A1 (fr) * | 2005-07-29 | 2007-02-08 | Azionaria Costruzioni Macchine Automatiche A.C.M.A. S.P.A. | Procede et machine servant a former des groupes de produits et a emballer chaque groupe |

| WO2008089879A1 (fr) * | 2007-01-22 | 2008-07-31 | Focke & Co. (Gmbh & Co. Kg) | Dispositif de travail pour machines d'emballage |

| US8631715B2 (en) | 2010-06-09 | 2014-01-21 | Copan Italia S.P.A. | Method for quantitative transfer of analytes |

Also Published As

| Publication number | Publication date |

|---|---|

| US4617780A (en) | 1986-10-21 |

| EP0135818B1 (fr) | 1988-07-20 |

| JPH06528B2 (ja) | 1994-01-05 |

| BR8404551A (pt) | 1985-08-06 |

| EP0135818A3 (en) | 1986-06-04 |

| JPS6090108A (ja) | 1985-05-21 |

| DE3472780D1 (en) | 1988-08-25 |

| DE3332950A1 (de) | 1985-03-28 |

| CA1227414A (fr) | 1987-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0135818B1 (fr) | Procédé et dispositif pour envelopper des paquets de cigarettes dans des feuilles | |

| EP2477907B1 (fr) | Emballages, en particulier de cigarettes, et procédé et dispositif pour leur fabrication | |

| DE2407767C3 (de) | Verfahren und Vorrichtung zum Einschlagen von Zigarettengruppen o.dgl | |

| EP2509889B1 (fr) | Procede et dispositif pour fabriquer des emballages en particulier pour des cigarettes | |

| DE3348487C2 (de) | Vorrichtung zum Herstellen von Großpackungen | |

| DE2840850C2 (fr) | ||

| DE2952939T1 (de) | Packing machines | |

| EP1067049B1 (fr) | Procédé et dispositif pour la fabrication de paquets | |

| DE4436667A1 (de) | Packverfahren und -vorrichtung | |

| DE3536791C2 (fr) | ||

| DE2350111A1 (de) | Schnellaufender bodenfaltungspacker | |

| EP0304736B1 (fr) | Procédé et dispositif pour envelopper spécialement des paquets de cigarettes | |

| DE3824316A1 (de) | Verfahren und vorrichtung zum herstellen einer quaderfoermigen packung | |

| DE3414364A1 (de) | Zigarettenverpackungsmaschinen | |

| EP1601575B1 (fr) | Procede et dispositif pour produire des emballages d'au moins deux paquets | |

| DE19642373A1 (de) | Verfahren und Maschine zur Umhüllung von Zigarettenpackungen | |

| DE1235217B (de) | Packmaschine, insbesondere Zigarettenpackmaschine | |

| EP0174591A2 (fr) | Dispositif pour fabriquer des emballages, en particulier cartouches de cigarettes | |

| DE1436853B2 (de) | Verfahren zum maschinellen herstellen von flachbeuteln mit einer einzigen mittel- und seitenklebung ihrer seitenklappen aus von einem von einer rolle ablaufendem bande aus papier o.dgl. abgetrennten abschnitten | |

| DE19650182A1 (de) | Fördervorrichtung für Hüllmaterial | |

| DE3824315A1 (de) | Verfahren zum herstellen einer quaderfoermigen packung | |

| DE2507022C3 (de) | Sammelpackanlage für flache, rechteckige Gegenstände, insbesondere einzeln eingewickelte Schokoladentafeln oder -riegel | |

| EP0872421B1 (fr) | Station de coupe et de transfert pour une machine de traitement de sacs plats opérant de façon intermittente | |

| DE2462535C2 (de) | Vorrichtung zum aufeinanderfolgenden Abtrennen von Zuschnitten unterschiedlicher Länge | |

| DE102004012642A1 (de) | Vorrichtung und Verfahren zur Verpackung von Produkten der Tabak verarbeitenden Industrie |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: FOCKE & CO. (GMBH & CO.) |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19860705 |

|

| 17Q | First examination report despatched |

Effective date: 19870422 |

|

| ITF | It: translation for a ep patent filed |

Owner name: STUDIO MASSARI S.R.L. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT NL SE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3472780 Country of ref document: DE Date of ref document: 19880825 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19940809 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19940817 Year of fee payment: 11 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 84110102.5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950825 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960430 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84110102.5 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19970826 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990301 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19990301 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20000822 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20000823 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010824 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20010824 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020501 |