WO2019054246A1 - 配線回路基板およびその製造方法 - Google Patents

配線回路基板およびその製造方法 Download PDFInfo

- Publication number

- WO2019054246A1 WO2019054246A1 PCT/JP2018/032849 JP2018032849W WO2019054246A1 WO 2019054246 A1 WO2019054246 A1 WO 2019054246A1 JP 2018032849 W JP2018032849 W JP 2018032849W WO 2019054246 A1 WO2019054246 A1 WO 2019054246A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- insulating layer

- shield

- circuit board

- adhesion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/0213—Electrical arrangements not otherwise provided for

- H05K1/0216—Reduction of cross-talk, noise or electromagnetic interference

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/0213—Electrical arrangements not otherwise provided for

- H05K1/0216—Reduction of cross-talk, noise or electromagnetic interference

- H05K1/0218—Reduction of cross-talk, noise or electromagnetic interference by printed shielding conductors, ground planes or power plane

- H05K1/0219—Printed shielding conductors for shielding around or between signal conductors, e.g. coplanar or coaxial printed shielding conductors

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/03—Use of materials for the substrate

- H05K1/0313—Organic insulating material

- H05K1/032—Organic insulating material consisting of one material

- H05K1/0346—Organic insulating material consisting of one material containing N

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/11—Printed elements for providing electric connections to or between printed circuits

- H05K1/115—Via connections; Lands around holes or via connections

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/38—Improvement of the adhesion between the insulating substrate and the metal

- H05K3/388—Improvement of the adhesion between the insulating substrate and the metal by the use of a metallic or inorganic thin film adhesion layer

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/46—Manufacturing multilayer circuits

- H05K3/4644—Manufacturing multilayer circuits by building the multilayer layer by layer, i.e. build-up multilayer circuits

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/03—Use of materials for the substrate

- H05K1/05—Insulated conductive substrates, e.g. insulated metal substrate

- H05K1/056—Insulated conductive substrates, e.g. insulated metal substrate the metal substrate being covered by an organic insulating layer

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/01—Dielectrics

- H05K2201/0137—Materials

- H05K2201/0154—Polyimide

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/03—Conductive materials

- H05K2201/0332—Structure of the conductor

- H05K2201/0335—Layered conductors or foils

- H05K2201/0338—Layered conductor, e.g. layered metal substrate, layered finish layer or layered thin film adhesion layer

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/03—Conductive materials

- H05K2201/0332—Structure of the conductor

- H05K2201/0335—Layered conductors or foils

- H05K2201/0344—Electroless sublayer, e.g. Ni, Co, Cd or Ag; Transferred electroless sublayer

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/07—Electric details

- H05K2201/0707—Shielding

- H05K2201/0715—Shielding provided by an outer layer of PCB

Definitions

- the present invention relates to a printed circuit board and a method of manufacturing the same.

- the ground layer is filled in the lower ground layer and the opening of the insulating layer, disposed on the upper surface of the side ground wiring in contact with the lower ground layer, and on the upper surface of the insulating layer, and integrally with the side ground wiring. And an upper ground wiring formed on the The upper ground layer is electrically connected to the lower ground wiring through the side ground wiring and acts as a shield layer.

- the side ground wiring and the upper ground wiring have a substantially T-shaped cross section, and the upper surface of the upper ground wiring has a flat shape. Therefore, the ground layer has excellent strength and is excellent in shape retention even if stress is applied to the ground layer. Therefore, the adhesion of the ground layer to the insulating layer is unlikely to be reduced.

- the upper surface of the upper ground wiring may have a recess that is recessed downward corresponding to the opening of the insulating layer.

- the strength of the ground layer is low due to the recess, and therefore, when stress is applied to the ground layer, the upper ground wiring is easily expanded and contracted in the surface direction, and hence the adhesion of the upper ground wiring to the insulating layer

- the adhesion of the side ground wiring to the lower ground wiring is also reduced.

- the inventor of the present application has intensively studied the printed circuit board in which the adhesion of the shield layer is improved even if the shield layer has a recess, and the shield layer includes the adhesion layer and the main body layer, Furthermore, it has been found that if the ratio (Tb / Ta) of the thickness Tb of the main body layer to the thickness Ta of the adhesion layer is 4 or more, the adhesion of the shield layer can be improved.

- the present invention (1) comprises a conductor layer, an insulating layer, and a shield layer in this order toward one side in the thickness direction, the insulating layer covering the conductor layer, and a part of the conductor layer

- the insulating layer has an insulating opening that exposes one surface in the thickness direction

- the shield layer has a recess that is disposed in the insulating opening and that is recessed toward the other side in the thickness direction so as to contact the conductor layer.

- the shield layer includes an adhesion layer and a main body layer sequentially toward the one side in the thickness direction, and the ratio (Tb / Ta) of the thickness Tb of the main body layer to the thickness Ta of the adhesion layer is 4 or more.

- the shield layer has a recess, and stress is applied to the shield layer, and even if the shield layer expands and contracts, the shield layer includes the adhesion layer and the main layer in order toward one side in the thickness direction. Since the ratio (Tb / Ta) of the thickness Tb of the main body layer to the thickness Ta of the layer is 4 or more, the decrease in adhesion to the insulating layer can be suppressed, and further, the decrease in adhesion to a part of the conductor layer It can be suppressed.

- the present invention (2) includes the wired circuit board according to (1), wherein the shield layer has a shield opening that exposes the one surface in the thickness direction of a part of the insulating layer.

- the shield layer since the shield layer has a shield opening, the shield opening can be provided in a portion where the shielding of the electromagnetic wave is unnecessary, and the electromagnetic wave can be shielded by the shield layer in other portions.

- the material of the insulating layer is polyimide

- the material of the adhesion layer is chromium

- the material of the main body layer is copper, according to (1) or (2). Including a printed circuit board.

- the adhesion layer can more effectively suppress the decrease in the adhesion of the main body layer to the insulating layer.

- the present invention (4) includes the wired circuit board according to any one of (1) to (3), which is a wired circuit board for an imaging device.

- the printed circuit board is a printed circuit board for an imaging device, an imaging device having excellent reliability can be manufactured.

- the present invention (5) comprises a conductor layer, an insulating layer, and a shield layer in this order toward one side in the thickness direction, and the shield layer is a shield that exposes the one surface in the thickness direction of a part of the insulating layer. It includes a printed circuit board having an opening.

- the shield layer since the shield layer has a shield opening, the shield opening can be provided in a portion where the shielding of the electromagnetic wave is unnecessary, and the electromagnetic wave can be shielded by the shield layer in other portions.

- the present invention (6) comprises a first step of providing a conductor layer, and an insulating layer covering the conductor layer and having an insulating opening that exposes the one surface in the thickness direction of a part of the conductor layer.

- the adhesion layer is formed by the thickness direction one surface of the insulating layer, the inner side surface of the insulating layer facing the insulating opening, and the thickness of the conductive layer exposed from the insulating opening

- Ta) is 4 or more, made of wired circuit board It includes

- the shield layer has a recess, stress is applied to the shield layer, and even if the shield layer expands and contracts, the shield layer includes the adhesion layer and the main layer in this order toward one side in the thickness direction. Since the ratio (Tb / Ta) of the thickness Tb of the main body layer to the thickness Ta of the adhesion layer is 4 or more, the decrease in adhesion to the insulating layer can be suppressed, and further, the adhesion to a part of the conductor layer Can be suppressed.

- the adhesion layer and the insulating layer have different coefficients of thermal expansion, the adhesion layer is likely to be damaged, such as cracks, due to the difference in coefficient of thermal expansion due to heating in the subsequent steps. .

- the present invention (7) is characterized in that, in the third step, the shield layer is provided with a shield opening that exposes the one surface in the thickness direction of a part of the insulating layer. Including the method.

- the insulating layer is formed of polyimide

- the adhesion layer is formed of chromium

- the main layer is formed of The manufacturing method of the printed circuit board as described in (6) or (7) formed from copper is included.

- the adhesion layer can more effectively suppress the reduction in the adhesion of the main body layer to the insulating layer.

- the thermal expansion coefficient of polyimide is similar to that of copper, it is significantly different from that of chromium. Therefore, the adhesion layer can not follow the elongation of the insulating layer and the main body layer by heating in the subsequent step, and the adhesion layer is likely to be damaged such as a crack.

- the ratio (Tb / Ta) of the thickness Tb of the main body layer to the thickness Ta of the adhesion layer is 4 or more, it is possible to secure good adhesion of the shield layer to the insulating layer. it can.

- the present invention (9) includes the method for producing a wired circuit board according to any one of (6) to (8), which is a method for producing a wired circuit board for an imaging device.

- this manufacturing method is a method of manufacturing a printed circuit board for an imaging device, an imaging device having excellent reliability can be manufactured from the obtained printed circuit board.

- the present invention (10) comprises a first step of providing a conductor layer, a second step of providing an insulating layer so as to cover the conductor layer, and a third step of providing a shield layer on one surface of the insulating layer in the thickness direction.

- the third step includes the method of manufacturing a printed circuit board, wherein the shield layer is provided with a shield opening that exposes the one surface in the thickness direction of the part of the insulating layer.

- the shield layer has a shield opening

- the shield opening can be provided in a portion where shielding of electromagnetic waves is unnecessary.

- the shield opening can be provided in a portion where the shielding of the electromagnetic wave is unnecessary.

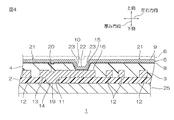

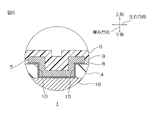

- FIGS. 3D to 3E are process drawings for explaining the method of manufacturing the printed circuit board shown in FIG. 1B following FIG. 2C, and FIG.

- FIG. 3D is a third step of providing a shield layer

- FIG. 3E is a cover insulating layer. It shows the process of providing.

- FIG. 4 shows a modification of the printed circuit board shown in FIG. 1B.

- FIG. 5 shows a modification of the printed circuit board shown in FIG. 1B.

- FIG. 6 shows a modification of the printed circuit board shown in the enlarged view of FIG. 1B.

- the left-right direction in the drawing shows the left-right direction (first direction).

- the vertical direction of the drawing shows the vertical direction (an example of the thickness direction) (second direction orthogonal to the first direction)

- the upper side of the drawing is the upper side (an example of one side in the thickness direction) (second direction one side)

- the lower side of the drawing shows the lower side (the other side in the thickness direction) (the other side in the second direction).

- the up and down direction on the drawing indicates the front-rear direction (a third direction orthogonal to the first direction and the second direction).

- the direction conforms to the direction arrow in each figure.

- the cover insulating layer 6 (described later) is omitted to clearly show the arrangement and shape of the shield layer 5 (described later).

- the printed circuit board 1 has a sheet shape having a predetermined thickness T and extending in the surface direction (both in the left-right direction and in the front-rear direction).

- the wired circuit board 1 is a wired circuit board for an imaging device to be electrically connected to an imaging element (not shown) disposed on the lower side and provided (embedded) in an imaging device (not shown). is there.

- the printed circuit board 1 includes a base insulating layer 2, a conductor layer 3, an intermediate insulating layer 4 as an example of an insulating layer, a shield layer 5, and a cover insulating layer 6 in order from the upper side.

- the base insulating layer 2 has a sheet shape extending in the surface direction.

- the base insulating layer 2 forms the lower surface of the printed circuit board 1.

- the base insulating layer 2 has a base opening 11 penetrating in the thickness direction.

- the material of the base insulating layer 2 is an insulating material.

- the insulating material include synthetic resins such as polyimide, polyamide imide, acrylic, polyether nitrile, polyether sulfone, polyethylene terephthalate, polyethylene naphthalate, polyvinyl chloride and the like.

- a polyimide etc. are mentioned.

- the thermal expansion coefficient of the base insulating layer 2 is, for example, 10 (ppm / K) or more, preferably 15 (ppm / K) or more, and for example, 50 (ppm / K) or less.

- the thermal expansion coefficient of the base insulating layer 2 is a linear thermal expansion coefficient in the surface direction, and can be measured, for example, by thermal mechanical analysis under the conditions of JIS K7197.

- the thickness of the base insulating layer 2 is, for example, 1 ⁇ m or more, preferably 5 ⁇ m or more, and for example, 30 ⁇ m or less, preferably 10 ⁇ m or less.

- the conductor layer 3 is disposed on the base insulating layer 2.

- the conductor layer 3 has a plurality of patterns spaced apart from one another in the surface direction.

- the conductor layer 3 independently includes a signal layer 12 electrically connected to an imaging element (not shown) and a ground layer 13.

- a plurality of signal layers 12 are arranged on the upper surface of the base insulating layer 2 at intervals in the surface direction.

- the signal layer 12 is electrically connected to an imaging device (described later, not shown).

- the ground layer 13 integrally includes a ground contact portion 14 and an extension portion 16 extending in the surface direction from the ground contact portion 14.

- the ground contact portion 14 is positioned in the base opening 11 when projected in the thickness direction, and extends in the vertical direction.

- the ground contact portion 14 includes a ground lower portion 19 filled in the base opening 11 and a ground upper portion 20 continuously provided on the upper side of the ground lower portion 19.

- the extension portion 16 is integrally formed with the upper ground portion 20.

- the extension portion 16 is disposed adjacent to the ground contact portion 14 when projected in the thickness direction.

- the material of the conductor layer 3 examples include metal materials such as copper, silver, gold, nickel or alloys containing them, and solder. Preferably, copper is mentioned.

- the thickness of the conductor layer 3 is 1 ⁇ m or more, preferably 3 ⁇ m or more, and for example, 15 ⁇ m or less, preferably 10 ⁇ m or less.

- the intermediate insulating layer 4 has a sheet shape extending in the surface direction.

- the intermediate insulating layer 4 is disposed on the upper surface of the base insulating layer 2 so as to cover the conductor layer 3. Specifically, the intermediate insulating layer 4 covers the signal layer 12, the ground upper portion 20 and the extension portion 16.

- the intermediate insulating layer 4 has an intermediate opening 15 as an example of an insulating opening that exposes the upper surface of a part of the extension 16.

- the intermediate opening 15 penetrates the intermediate insulating layer 4 (in the upper portion with respect to the extending portion 16) in the thickness direction.

- the intermediate opening 15 has a tapered shape in which the opening cross-sectional area (opening cross-sectional area when cut along the surface direction) becomes smaller toward the lower side.

- the inner side surface 10 of the intermediate insulating layer 4 partitioning the intermediate opening 15 has a cylindrical shape extending along the thickness direction, and more specifically, when cut along the thickness direction and the left and right direction ), Which are tapered surfaces (inclined surfaces) opposed to each other in the left-right direction, and the opposing distances thereof become smaller toward the lower side. That is, the intermediate opening 15 has a substantially frusto-conical shape whose diameter decreases downward.

- the material of the intermediate insulating layer 4 is the same as the material of the base insulating layer 2.

- the thickness of the intermediate insulating layer 4 is a distance between the upper surface of the base insulating layer 2 and the upper surface of the intermediate insulating layer 4 and is, for example, 1 ⁇ m or more, preferably 5 ⁇ m or more, and for example, 30 ⁇ m or less, preferably Is 10 ⁇ m or less.

- the maximum length (maximum diameter) of the upper end edge of the intermediate opening 15 is, for example, 10 ⁇ m or more, preferably 50 ⁇ m or more, and for example, 2000 ⁇ m or less, preferably 1500 ⁇ m or less.

- the maximum length (maximum diameter) of the lower end edge of the intermediate opening 15 is, for example, 10 ⁇ m or more, preferably 50 ⁇ m or more, and for example, 2000 ⁇ m or less, preferably 1500 ⁇ m or less.

- An angle ⁇ between the inner side surface 10 and the upper surface of the extension 16 exposed from the intermediate opening 15 is, for example, 90 degrees or more, preferably 120 degrees or more, and for example, 170 degrees or less, preferably , Less than 160 degrees.

- the shield layer 5 is a layer that shields electromagnetic waves from the outside.

- the shield layer 5 is disposed on the upper side with respect to the conductor layer 3.

- the shield layer 5 has a sheet shape extending in the front-rear direction. Specifically, a plurality of shield layers 5 are arranged at intervals in the left-right direction. Thus, shield openings 27 are provided between the adjacent shield layers 5.

- a plurality of shield openings 27 are provided at intervals in the left-right direction, and each shield opening 27 exposes the upper surface of a part of the intermediate insulating layer 4. Further, the shield layer 5 is provided with the above-described shield opening 27 and has a pattern including the intermediate opening 15.

- the area ratio of the shield opening 27 in the shield layer 5 is, for example, 1% or more, preferably 10% or more, and for example, 90% or less, preferably 70% or less.

- the shield layer 5 includes a flat portion 21 and a recess 22.

- the flat portion 21 is disposed on the upper surface of the intermediate insulating layer 4.

- the flat portion 21 also has a pattern surrounding the intermediate opening 15.

- the flat portion 21 has a predetermined thickness and has a sheet shape extending in the surface direction.

- the recess 22 is disposed in the middle opening 15 and has a shape that is recessed downward from the inner edge of the flat portion 21 around the middle opening 15.

- the recess 22 has a substantially U-shaped cross section which is disposed continuously with the inner surface 10 and the upper surface of the extension 16 exposed from the intermediate opening 15.

- the recess 22 integrally includes the side wall 23 and the second flat portion 24.

- the side wall 23 is an inclined wall which is inclined downward (specifically, obliquely downward and inward) from the inner edge of the recess 22 around the middle opening 15.

- the side wall 23 has a substantially truncated cone shape (a truncated cone whose inside is hollow) whose diameter decreases downward.

- the side wall 23 covers the inner surface 10.

- the second flat portion 24 is a bottom wall connecting the lower end edge of the side wall 23.

- the second flat portion 24 is in contact with the upper surface of the extension 16 exposed from the intermediate opening 15.

- the second flat portion 24 has a shape corresponding to the lower end edge of the inner side surface 10, specifically, a substantially circular shape in plan view.

- the thickness of the flat portion 21, the thickness of the side wall 23, and the thickness of the second flat portion 24 are substantially the same, which is the thickness Ts of the shield layer 5.

- the shield layer 5 includes the adhesion layer 8 and the main body layer 9 in order from the upper side.

- the shield layer 5 is a laminate of the adhesion layer 8 and the main body layer 9.

- the shield layer 5 comprises only the adhesion layer 8 and the main body layer 9.

- each of the flat portion 21 and the recess 22 includes the adhesion layer 8 and the main body layer 9.

- the main body layer 9 adheres to the upper surface of the intermediate insulating layer 4 via the adhesive layer 8.

- the main body layer 9 is in close contact with the inner side surface 10 of the intermediate insulating layer 4 via the adhesion layer 8 and in close contact with the upper surface of the extension 16 exposed from the intermediate opening 15.

- the adhesion of the adhesion layer 8 to the intermediate insulation layer 4 and the adhesion of the adhesion layer 8 to the main layer 9 are larger than the adhesion of the main layer 9 to the intermediate insulation layer 4.

- chromium, nickel, etc. are mentioned, for example, Preferably, chromium is mentioned. If the material of the adhesion layer 8 is chromium, the adhesion of the main body layer 9 to the intermediate insulating layer 4 and the adhesion of the main body layer 9 to the extension 16 exposed from the intermediate opening 15 are further enhanced. Can.

- the thermal expansion coefficient of the adhesion layer 8 is different from, for example, the thermal expansion coefficient of the intermediate insulating layer 4. Specifically, the thermal expansion coefficient of the adhesion layer 8 is smaller than the thermal expansion coefficient of the intermediate insulating layer 4, and more specifically, for example, 90% of the thermal expansion coefficient of the intermediate insulating layer 4

- the content is preferably 75% or less, more preferably 50% or less, and even more preferably 45% or less, and for example, 10% or more, preferably 20% or more.

- the adhesive layer 8 stretches in the surface direction of the intermediate insulating layer 4 by heating in the manufacturing process described later. It is difficult to follow, and the crack in the adhesion layer 8 is likely to be damaged.

- the ratio (Tb / Ta) of the thickness Tb of the main body layer 9 to the thickness Ta of the adhesion layer 8 is 4 or more. 8 damage can be suppressed.

- the thermal expansion coefficient of the adhesion layer 8 is, for example, less than 10 (ppm / K), preferably 9 (ppm / K) or less, more preferably 8 (ppm / K) or less, For example, it is 1 (ppm / K) or more.

- the thickness Ta of the adhesion layer 8 is set to satisfy a ratio (Tb / Ta) described later to the thickness Ta of the adhesion layer 8 of the thickness Tb of the main body layer 9, and specifically, for example, less than 100 nm, preferably 50 nm or less, more preferably 40 nm or less, still more preferably 30 nm or less, and for example, 2 nm or more.

- the material of the main body layer 9 is selected so that the adhesion of the adhesion layer 8 to the main body layer 9 is larger than the adhesion of the main body layer 9 to the intermediate insulating layer 4.

- the material of the main body layer 9 may be, for example, the same as or different from the material of the adhesion layer 8, and preferably different.

- examples of the material of the main body layer 9 include metals such as copper, chromium, nickel, gold, silver, platinum, palladium, titanium, tantalum, solder, or alloys thereof, preferably copper, Nickel, more preferably copper.

- the thermal expansion coefficient of the main body layer 9 approximates, for example, the thermal expansion coefficient of the intermediate insulating layer 4.

- the thermal expansion coefficient of the main body layer 9 is, for example, 70% or more, preferably 80% or more, more preferably 90% or more, preferably 95% or more, relative to the thermal expansion coefficient of the intermediate insulating layer 4 Also, for example, it is 110% or less, preferably 100% or less.

- the thermal expansion coefficient of the main layer 9 is the thermal expansion coefficient of the intermediate insulating layer 4 Similar to the above, even if the thermal expansion coefficient of the adhesive layer 8 is significantly different from the thermal expansion coefficient of the intermediate insulating layer 4, the elongation of the intermediate insulating layer 4 and the elongation of the adhesive layer 8 in heating in the manufacturing process described later It can be made to match and damage to adhesion layer 8 can be controlled.

- the thermal expansion coefficient of the main layer 9 is, for example, 10 (ppm / K) or more, preferably 13 (ppm / K) or more, more preferably 15 (ppm / K) or more, For example, it is 20 (ppm / K) or less.

- the thickness Tb of the main body layer 9 is set to satisfy a ratio (Tb / Ta) described later, and specifically, for example, 50 nm or more, preferably 100 nm or more, more preferably 110 nm or more, For example, it is 250 nm or less, preferably 200 nm or less.

- the ratio (Tb / Ta) of the thickness Tb of the main body layer 9 to the thickness Ta of the adhesion layer 8 is 4 or more, preferably 5 or more, and for example, 20 or less, preferably 10 or less.

- the ratio (Tb / Ta) is less than the above-described lower limit, the adhesion of the shield layer 5 can not be improved.

- the ratio (Tb / Ta) is equal to or more than the above-described lower limit, so that the adhesion of the shield layer 5 can be improved.

- ratio (Tb / Ta) is more than the above-mentioned lower limit, adhesion layer 8 will be thin enough compared with body layer 9. Therefore, the adhesion layer 8 can follow the intermediate insulating layer 4 and the main body layer 9, and the damage in the adhesion layer 8 can be suppressed. Further, when the ratio (Tb / Ta) is equal to or more than the above-described lower limit, the main body layer 9 is sufficiently thicker than the adhesion layer 8. Therefore, the main body layer 9 can sufficiently press the adhesion layer 8, so that damage in the adhesion layer 8 can be suppressed.

- the thickness Ts of the shield layer 5 is, for example, 60 nm or more, preferably 100 nm or more, and for example, 3000 nm or less, preferably 1000 nm or less.

- the thickness Ts of the shield layer 5 is the sum (Ta + Tb) of the thickness Ta of the adhesion layer 8 and the thickness Tb of the main body layer 9.

- the cover insulating layer 6 has a sheet shape extending in the surface direction.

- the cover insulating layer 6 forms the upper surface of the printed circuit board 1.

- the cover insulating layer 6 is disposed on the upper surface of the intermediate insulating layer 4 so as to cover the shield layer 5.

- the cover insulating layer 6 is also filled in the recess 22.

- the cover insulating layer 6 is the same as the material of the base insulating layer 2.

- the thermal expansion coefficient of the cover insulating layer 6 is the same as the thermal expansion coefficient of the base insulating layer 2.

- the thickness of the cover insulating layer 6 is not particularly limited, and is, for example, 1 ⁇ m or more, preferably 5 ⁇ m or more, and for example, 30 ⁇ m or less, preferably 10 ⁇ m or less.

- the thickness T of the printed circuit board 1 is the sum of the thicknesses of the base insulating layer 2, the intermediate insulating layer 4 and the cover insulating layer 6. Specifically, the lower surface of the base insulating layer 2 and the upper surface of the cover insulating layer 6 Distance. Specifically, the thickness T of the printed circuit board 1 is, for example, 5 ⁇ m or more, preferably 10 ⁇ m or more, and for example, 100 ⁇ m or less, preferably 50 ⁇ m or less.

- the steps of providing the base insulating layer 2 on the support substrate 25, the first step of providing the conductor layer 3, and the intermediate insulating layer 4 A second step of providing, a third step of providing the shield layer 5, a step of providing the cover insulating layer 6, and a step of removing the support substrate 25 are sequentially provided.

- the support substrate 25 is prepared.

- the support substrate 25 has a sheet shape extending in the surface direction and having a flat upper surface.

- Examples of the material of the support substrate 25 include metals such as stainless steel, 42 alloy, and aluminum, for example, resins, for example, ceramics, and the like, with preference given to metals.

- the thickness of the support substrate 25 is, for example, 5 ⁇ m or more, preferably 10 ⁇ m or more, and for example, 50 ⁇ m or less, preferably 30 ⁇ m or less.

- the base insulating layer 2 having the base opening 11 is formed on the upper surface of the support substrate 25 from an insulating material by photo processing, for example.

- the base insulating layer 2 in which the base opening 11 is formed is disposed (placed) on the upper surface of the support substrate 25 in advance.

- the insulating base layer 2 is provided on the upper surface of the support substrate 25.

- the conductor layer 3 is provided on the base insulating layer 2.

- the conductor layer 3 is formed from the signal layer 12 and the ground layer 13 by a patterning method such as, for example, an additive method or a subtractive method.

- the intermediate insulating layer 4 covers the conductor layer 3 and has an intermediate opening 15 that exposes the upper surface of a part of the extension 16. Set up.

- an intermediate insulating layer 4 having an intermediate opening 15 is formed from the insulating material on the entire top surface of the base insulating layer 2 and the top and side surfaces of the conductor layer 3 by photo processing.

- the intermediate insulating layer 4 in which the intermediate opening 15 is formed is arranged (mounted) in advance on the base insulating layer 2 and the conductor layer 3.

- the intermediate insulating layer 4 is provided so as to cover the conductor layer 3 (excluding a part of the extension 16) and to have the intermediate opening 15.

- the shield layer 5 is provided on the upper surface of the intermediate insulating layer 4 so as to have a recess 22 which is disposed in the intermediate opening 15 and is recessed downward.

- the adhesion layer 8 is formed by a thin film forming method such as sputtering or plating (electroless plating) (fourth step), and then the main body layer 9 is formed (fifth step)

- the shield layer 5 is formed from the adhesion layer 8 and the main body layer 9.

- the shield layer 5 is formed by sputtering. In the case of sputtering, it is possible to form a shield layer 5 of uniform thickness (specifically, an adhesion layer 8 of uniform thickness and a body layer 9 of uniform thickness).

- the method of forming the adhesion layer 8 and the method of forming the main body layer 9 may be the same as or different from each other, and are preferably the same.

- each of the adhesion layer 8 and the main body layer 9 is formed by sputtering. That is, the adhesion layer 8 is formed by sputtering (fourth step), and subsequently, the main body layer 9 is formed by sputtering on the upper surface of the adhesion layer 8 (fifth step).

- the shield opening 27 is formed in the shield layer 5 by, for example, a thin film removal method such as etching (dry etching, wet etching).

- the cover insulating layer 6 is provided on the upper surface of the intermediate insulating layer 4 and the upper surface and the side surface of the shield layer 5.

- the cover insulating layer 6 is provided by photo processing. Specifically, in photo processing, first, a photosensitive insulating composition containing a photosensitive component and an insulating material is prepared, and then, the photosensitive insulating composition is formed on the upper surface of the intermediate insulating layer 4 and the upper surface of the shield layer 5 Apply to the side and then dry if necessary to form a film. Then, the film is exposed through a photomask and developed to form a cover insulating layer 6. Thereafter, the cover insulating layer 6 is heated (heating after exposure).

- the heating conditions are, for example, conditions under which the insulating material can be sufficiently cured (specifically, imidization and the like). Specifically, the temperature is, for example, 250 ° C. or more, preferably 300 ° C. or more, Also, for example, the temperature is 400 ° C. or less, and the time is, for example, 10 minutes or more, preferably 30 minutes or more, and for example, 100 minutes or less.

- the cover insulating layer 6 formed in a predetermined pattern in advance is disposed (placed) on the intermediate insulating layer 4 and the shield layer 5.

- photo processing is used from the viewpoint of reliable patterning and arrangement.

- the support substrate 25 is then removed from the lower surface of the insulating base layer 2 and the lower surface of the lower ground portion 19 by, for example, peeling.

- the lower surface of the base insulating layer 2 and the lower surface of the lower ground portion 19 are exposed to the lower side.

- an imaging element (not shown) is prepared under the printed circuit board 1, and the imaging element (not shown) is electrically connected to the signal layer 12. Further, the ground contact portion 14 is electrically connected to a ground contact (not shown) to ground the ground layer 13.

- the imaging device 30 provided with the printed circuit board 1 and an imaging element (not shown) is obtained.

- shield layer 5 has crevice 22, and even if stress F shown in arrow F of Drawing 1B is applied to shield layer 5 and it is going to expand and contract, shield layer 5 is an adhesion layer. 8, and the ratio (Tb / Ta) of the thickness Tb of the main body layer 9 to the thickness Ta of the adhesion layer 8 is 4 or more, so that the intermediate insulating layer 4 is provided. It is possible to suppress the decrease in the adhesion to the surface, and to suppress the decrease in the adhesion to a part of the extension portion 16.

- the shield opening 27 is provided in a portion where the shielding of the electromagnetic wave is unnecessary, and the electromagnetic wave is shielded by the shield layer 5 in other portions. can do.

- the main body layer 9 is formed of the adhesion layer 8. The reduction in adhesion to the intermediate insulating layer 4 can be more effectively suppressed.

- the printed circuit board 1 is a printed circuit board for an imaging device, the imaging device 30 excellent in reliability can be manufactured.

- the adhesion layer 8 and the intermediate insulating layer 4 have different coefficients of thermal expansion, heating of the cover insulating layer 6 shown in FIG. 3E (heating after exposure) As a result, due to the difference in thermal expansion coefficient between the adhesion layer 8 and the intermediate insulating layer 4, the adhesion layer 8 is likely to be damaged such as a crack.

- the ratio (Tb / Ta) of the thickness Tb of the main body layer 9 to the thickness Ta of the adhesive layer 8 is 4 or more. Damage can be suppressed.

- the thermal expansion coefficient (17 (ppm / K)) of polyimide is similar to the thermal expansion coefficient (16.8 (ppm / K)) of copper, the thermal expansion coefficient of chromium (6.8 (ppm / K) It differs significantly from)). Therefore, the adhesion layer 8 can not follow the elongation of the intermediate insulation layer 4 and the main body layer 9 by heating (heating after exposure) of the cover insulating layer 6 shown in FIG. 3E, and damage such as cracks occurs in the adhesion layer 8 easy.

- the imaging device 30 which is excellent in reliability can be manufactured.

- the printed circuit board 1 has been described as a printed circuit board for an imaging device, but the application is not limited to this, and for example, a test board (anisotropic conductive sheet), a flexible printed circuit board, etc. It can be used.

- middle opening part 15 exposes the upper surface of a part of the extension part 16, although it does not show in figure, for example, it replaces with this or

- the upper surface of (the part or all of) the upper ground portion 20 can be exposed.

- the second flat portion 24 of the recess 22 contacts the upper surface of the upper ground portion 20.

- the shield opening 27 is formed in the shield layer 5.

- the shield layer 5 not having the shield opening 27 may be formed from the entire upper surface of the intermediate insulating layer 4, the inner side surface 10 and the intermediate opening 15. It can also be continuously formed on the exposed upper surface of the extending portion 16.

- a shield opening 27 is formed in the shield layer 5.

- the shield opening 27 is not formed in the shield layer 5

- the gas from the intermediate insulating layer 4 water vapor derived from the moisture absorbed by the intermediate insulating layer 4 is obtained by heating in the step shown in FIG. Even if G) is generated, the shield layer 5 shields the gas G, which causes damage such as deformation of the intermediate insulating layer 4, and as a result, the adhesion of the adhesive layer 8 to the intermediate insulating layer 4 descend.

- the gas G described above can be efficiently released from the shield opening 27. Therefore, the adhesion of the shield layer 5 to the intermediate insulating layer 4 can be further improved.

- the shield layer 5 can be configured without providing the recess 22.

- the shield layer 5 continuously has the flat portion 21 and the filling portion 28 with which the intermediate opening 15 is filled, and their upper surface has a flat shape.

- the upper surface of the shield layer 5 is parallel to the upper surface of the intermediate insulating layer 4.

- the filling portion 28 is solid and has a flat upper surface.

- the inner surface 10 has a tapered shape, but may have a straight shape along the thickness direction, for example, as shown in FIG.

- blending ratios content ratios

- physical property values parameters, etc. used in the following description are the blending ratios (content ratios) corresponding to those described in the above-mentioned “embodiments for carrying out the invention” ), Physical property values, parameters, etc. may be substituted for the upper limit (numerical values defined as “below”, “less than”) or lower limit (numerical values defined as “above”, “exceed”), etc. it can.

- Example 1 As shown in FIG. 2A, the base insulating layer 2 made of polyimide was formed by photo processing on the upper surface of the support substrate 25 made of stainless steel.

- a conductor layer 3 comprising a signal layer 12 and a ground layer 13 independently and made of copper was formed on the upper surface of the base insulating layer 2 by an additive method (first step).

- an intermediate insulating layer 4 having an intermediate opening 15 and made of polyimide (coefficient of thermal expansion 17 (ppm / K)) is coated with the conductor layer 3 on the upper surface of the base insulating layer 2. As a result, it was formed by photo processing (second step).

- the thickness of the intermediate insulating layer 4 was 10 ⁇ m.

- the adhesion layer 8 is formed of chromium (thermal expansion coefficient 6.8 (ppm / K)) and has a thickness Ta of 30 ⁇ m by sputtering (fourth step)

- a main body layer 9 made of copper (thermal expansion coefficient 16.8 (ppm / K)) and having a thickness Tb of 120 ⁇ m was formed by a sputtering method (fifth step).

- the shield layer 5 having the flat portion 21 and the concave portion 22 was formed.

- Shield layer 5 does not have shield opening 27 yet, that is, adhesion layer 8 is formed from the entire upper surface of intermediate insulating layer 4, inner side surface 10 of shield layer 5, and intermediate opening 15. It formed continuously with the upper surface of the extension part 16 to expose, and formed the main layer 9 in the whole upper surface of the contact

- the shield layer 5 was formed into a pattern having the shield opening 27 by wet etching (third step).

- a cover insulating layer 6 was formed on the upper surface of the intermediate insulating layer 4 so as to cover the shield layer 5 by photo processing. Specifically, a photosensitive polyimide composition is applied to the upper surface of the intermediate insulating layer 4 and the upper and side surfaces of the shield layer 5 and then dried to form a film, and then through a photomask. The film was exposed and developed to form a cover insulating layer 6. Thereafter, the cover insulating layer 6 was post-exposure heated at 325 ° C. for 20 minutes.

- the support substrate 25 was removed by peeling.

- the printed circuit board 1 was manufactured.

- Example 2 to Comparative Example 2 A printed circuit board 1 was manufactured in the same manner as in Example 1 except that the thickness Ta of the adhesion layer 8 and the thickness Tb of the main body layer 9 were changed according to Table 1.

- the wired circuit board is used for an imaging device.

- Wiring circuit board (wiring circuit board for imaging device) Reference Signs List 3 conductor layer 4 intermediate insulating layer 5 shield layer 8 adhesion layer 9 main body layer 15 intermediate opening 22 concave portion 30 thickness of imaging device Ta adhesion layer thickness of Tb main body layer

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Shielding Devices Or Components To Electric Or Magnetic Fields (AREA)

- Structure Of Printed Boards (AREA)

- Production Of Multi-Layered Print Wiring Board (AREA)

- Laminated Bodies (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/644,781 US11297711B2 (en) | 2017-09-15 | 2018-09-05 | Wiring circuit board and producing method thereof |

| CN201880059596.9A CN111096087B (zh) | 2017-09-15 | 2018-09-05 | 布线电路基板及其制造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017177786A JP7407498B2 (ja) | 2017-09-15 | 2017-09-15 | 配線回路基板およびその製造方法 |

| JP2017-177786 | 2017-09-15 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019054246A1 true WO2019054246A1 (ja) | 2019-03-21 |

Family

ID=65723582

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/032849 Ceased WO2019054246A1 (ja) | 2017-09-15 | 2018-09-05 | 配線回路基板およびその製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11297711B2 (enExample) |

| JP (1) | JP7407498B2 (enExample) |

| CN (1) | CN111096087B (enExample) |

| TW (1) | TWI786184B (enExample) |

| WO (1) | WO2019054246A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7424802B2 (ja) * | 2019-11-12 | 2024-01-30 | 日東電工株式会社 | 配線回路基板およびその製造方法 |

| US20230014046A1 (en) * | 2021-07-13 | 2023-01-19 | Mediatek Inc. | Semiconductor devices with in-package PGS for coupling noise suppression |

| US20230076844A1 (en) * | 2021-09-09 | 2023-03-09 | Qualcomm Incorporated | Semiconductor die module packages with void-defined sections in a metal structure(s) in a package substrate to reduce die-substrate mechanical stress, and related methods |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04165696A (ja) * | 1990-10-30 | 1992-06-11 | Fujitsu Ltd | 薄膜多層基板の製造方法 |

| JP2009278048A (ja) * | 2008-05-19 | 2009-11-26 | Kyocera Chemical Corp | シールド被覆フレキシブルプリント配線板の製造方法 |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TW448524B (en) * | 1997-01-17 | 2001-08-01 | Seiko Epson Corp | Electronic component, semiconductor device, manufacturing method therefor, circuit board and electronic equipment |

| JP3702646B2 (ja) * | 1998-05-20 | 2005-10-05 | 富士通株式会社 | 回路基板の製造方法 |

| JP3756041B2 (ja) * | 1999-05-27 | 2006-03-15 | Hoya株式会社 | 多層プリント配線板の製造方法 |

| JP4369684B2 (ja) * | 2003-05-26 | 2009-11-25 | 大日本印刷株式会社 | 多層配線基板およびその製造方法 |

| JP4366292B2 (ja) * | 2004-11-04 | 2009-11-18 | 北川工業株式会社 | 電磁波シールドフィルム |

| JP2006339661A (ja) * | 2006-06-13 | 2006-12-14 | Kaneka Corp | 多層ボンディングシート及びフレキシブル両面金属張積層板の製造方法 |

| JP4790558B2 (ja) | 2006-10-02 | 2011-10-12 | 日東電工株式会社 | 配線回路基板の製造方法 |

| JP2008192978A (ja) * | 2007-02-07 | 2008-08-21 | Shinko Electric Ind Co Ltd | 半導体装置の製造方法 |

| JP2009295850A (ja) * | 2008-06-06 | 2009-12-17 | Hitachi Chem Co Ltd | 多層回路基板の製造方法及びこれから得られる多層回路基板、半導体チップ搭載基板並びにこの基板を用いた半導体パッケージ |

| JP2011103414A (ja) * | 2009-11-12 | 2011-05-26 | Toray Advanced Film Co Ltd | 金属パターン積層基材の製造方法。 |

| CN102959948A (zh) * | 2011-04-05 | 2013-03-06 | 松下电器产业株式会社 | 固态成像装置和固态成像装置的制造方法 |

| JP5829100B2 (ja) | 2011-10-27 | 2015-12-09 | 日東電工株式会社 | 配線回路基板 |

| JP6030394B2 (ja) * | 2012-09-26 | 2016-11-24 | 住友電工プリントサーキット株式会社 | プリント配線板 |

| JP6418605B2 (ja) * | 2015-07-31 | 2018-11-07 | 東芝メモリ株式会社 | 半導体装置および半導体装置の製造方法 |

| JP5975364B2 (ja) | 2015-08-10 | 2016-08-23 | 大日本印刷株式会社 | サスペンション用基板の製造方法 |

| JP6713784B2 (ja) * | 2016-02-18 | 2020-06-24 | 日鉄ケミカル&マテリアル株式会社 | ポリイミド、ポリイミド溶液、樹脂フィルム、ポリイミド組成物、架橋ポリイミド、カバーレイフィルム及び回路基板 |

-

2017

- 2017-09-15 JP JP2017177786A patent/JP7407498B2/ja active Active

-

2018

- 2018-09-05 US US16/644,781 patent/US11297711B2/en active Active

- 2018-09-05 CN CN201880059596.9A patent/CN111096087B/zh active Active

- 2018-09-05 WO PCT/JP2018/032849 patent/WO2019054246A1/ja not_active Ceased

- 2018-09-13 TW TW107132161A patent/TWI786184B/zh active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04165696A (ja) * | 1990-10-30 | 1992-06-11 | Fujitsu Ltd | 薄膜多層基板の製造方法 |

| JP2009278048A (ja) * | 2008-05-19 | 2009-11-26 | Kyocera Chemical Corp | シールド被覆フレキシブルプリント配線板の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20210084750A1 (en) | 2021-03-18 |

| US11297711B2 (en) | 2022-04-05 |

| CN111096087B (zh) | 2023-11-24 |

| JP7407498B2 (ja) | 2024-01-04 |

| JP2019054130A (ja) | 2019-04-04 |

| TWI786184B (zh) | 2022-12-11 |

| CN111096087A (zh) | 2020-05-01 |

| TW201933954A (zh) | 2019-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10943740B2 (en) | Electrical connection contact for a ceramic component, a ceramic component, and a component arrangement | |

| WO2019054246A1 (ja) | 配線回路基板およびその製造方法 | |

| JP5829100B2 (ja) | 配線回路基板 | |

| JP7390779B2 (ja) | フレキシブル配線回路基板および撮像装置 | |

| TW202014070A (zh) | 復合電路板及其製造方法 | |

| JP2023073270A5 (enExample) | ||

| TWI526131B (zh) | 印刷電路板及其製造方法 | |

| US11627661B2 (en) | Wired circuit board and imaging device | |

| TWI661751B (zh) | 電路板及其製作方法 | |

| JP6294861B2 (ja) | 回路付サスペンション基板、および、回路付サスペンション基板の製造方法 | |

| TWI762626B (zh) | 配線電路基板及攝像裝置 | |

| TW201817291A (zh) | 可伸縮電路板及其製作方法 | |

| JP4687205B2 (ja) | 電子部品 | |

| CN106879163B (zh) | 布线基板 | |

| US11291110B2 (en) | Resin substrate and electronic device | |

| JPWO2022085715A5 (enExample) | ||

| KR101799095B1 (ko) | 메탈코어를 구비한 인쇄회로기판 및 그 제조방법 | |

| TWI739008B (zh) | 配線基板及配線基板的製造方法 | |

| WO2018199128A1 (ja) | フレキシブル配線回路基板および撮像装置 | |

| JP4841865B2 (ja) | プリント回路板 | |

| JP6981038B2 (ja) | 貫通電極基板及びその製造方法 | |

| JP2021022651A (ja) | 配線基板の製造方法、配線基板形成用基板、配線基板中間品、配線基板および素子付配線基板 | |

| TW202543329A (zh) | 配線電路基板 | |

| JPH0697662A (ja) | 薄膜多層基板 | |

| JP2005293883A (ja) | コネクタ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18855787 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18855787 Country of ref document: EP Kind code of ref document: A1 |