WO2019031172A1 - 電力変換装置 - Google Patents

電力変換装置 Download PDFInfo

- Publication number

- WO2019031172A1 WO2019031172A1 PCT/JP2018/026932 JP2018026932W WO2019031172A1 WO 2019031172 A1 WO2019031172 A1 WO 2019031172A1 JP 2018026932 W JP2018026932 W JP 2018026932W WO 2019031172 A1 WO2019031172 A1 WO 2019031172A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- flow path

- housing

- electrical component

- path forming

- power conversion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K7/00—Constructional details common to different types of electric apparatus

- H05K7/20—Modifications to facilitate cooling, ventilating, or heating

- H05K7/2089—Modifications to facilitate cooling, ventilating, or heating for power electronics, e.g. for inverters for controlling motor

- H05K7/209—Heat transfer by conduction from internal heat source to heat radiating structure

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G2/00—Details of capacitors not covered by a single one of groups H01G4/00-H01G11/00

- H01G2/02—Mountings

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G2/00—Details of capacitors not covered by a single one of groups H01G4/00-H01G11/00

- H01G2/02—Mountings

- H01G2/04—Mountings specially adapted for mounting on a chassis

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G2/00—Details of capacitors not covered by a single one of groups H01G4/00-H01G11/00

- H01G2/08—Cooling arrangements; Heating arrangements; Ventilating arrangements

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/32—Wound capacitors

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K5/00—Casings; Enclosures; Supports

- H02K5/04—Casings or enclosures characterised by the shape, form or construction thereof

- H02K5/20—Casings or enclosures characterised by the shape, form or construction thereof with channels or ducts for flow of cooling medium

- H02K5/203—Casings or enclosures characterised by the shape, form or construction thereof with channels or ducts for flow of cooling medium specially adapted for liquids, e.g. cooling jackets

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M7/00—Conversion of AC power input into DC power output; Conversion of DC power input into AC power output

- H02M7/42—Conversion of DC power input into AC power output without possibility of reversal

- H02M7/44—Conversion of DC power input into AC power output without possibility of reversal by static converters

- H02M7/48—Conversion of DC power input into AC power output without possibility of reversal by static converters using discharge tubes with control electrode or semiconductor devices with control electrode

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K7/00—Constructional details common to different types of electric apparatus

- H05K7/20—Modifications to facilitate cooling, ventilating, or heating

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K7/00—Constructional details common to different types of electric apparatus

- H05K7/20—Modifications to facilitate cooling, ventilating, or heating

- H05K7/2089—Modifications to facilitate cooling, ventilating, or heating for power electronics, e.g. for inverters for controlling motor

- H05K7/20927—Liquid coolant without phase change

Definitions

- the present disclosure relates to a power converter.

- an electric component such as a capacitor constituting a power conversion circuit and a case for housing the same are provided, and the case has a refrigerant flow path through which a refrigerant for cooling the electric component flows.

- Some are integrally formed with the housing.

- the capacitor constituting the power conversion circuit is pressed against the outer wall surface of the refrigerant flow path integrally formed in the housing so that both are closely attached to the housing. It is fixed. Thereby, the cooling of the capacitor is promoted to enhance the heat dissipation.

- the present disclosure is intended to provide a power converter that can obtain a high cooling effect while absorbing dimensional variations of electrical components.

- One aspect of the present disclosure is an electrical component that constitutes at least a part of a power conversion circuit, A housing that accommodates the electrical component and the electrical component is fixed; A flow path forming portion that forms a refrigerant flow path through which the refrigerant flows, and is thermally connected to the electrical component, Equipped with The flow passage forming unit is a separate member from the casing, and an elastically deformable spacer is provided between the flow passage forming unit and the casing.

- the flow passage forming portion to which the electric component is thermally connected is formed separately from the housing. And, an elastically deformable spacer is provided between the housing and the flow path forming portion. Therefore, the relative position between the housing and the flow path forming portion can be easily changed by elastically deforming the spacer. Then, by adjusting the relative position of the casing and the flow path forming portion in accordance with the dimensional variation of the electrical component, the dimensional variation of the electrical component can be absorbed. Therefore, the cooling effect of the electrical component can be improved while suppressing the generation of stress in the electrical component.

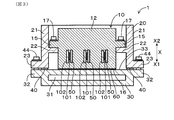

- FIG. 1 is a cross-sectional conceptual view of a power conversion device according to a first embodiment

- FIG. 2 is a cross-sectional conceptual view of the power conversion device in the second embodiment

- FIG. 3 is a cross-sectional conceptual view of the power conversion device in the third embodiment.

- the power converter device 1 of this embodiment is equipped with the electrical component 10, the housing

- the electrical component 10 constitutes at least a part of a power conversion circuit.

- the housing 20 accommodates the electrical component 10 and the electrical component 10 is fixed.

- the flow path forming unit 30 forms a refrigerant flow path 31 through which the refrigerant flows, and is thermally connected to the electric component 10.

- the flow path forming unit 30 is a separate member from the housing 20, and an elastically deformable spacer 40 is provided between the flow path forming unit 30 and the housing 20.

- the power conversion device 1 of the present embodiment has a power conversion function such as an inverter or a converter.

- the power converter 1 can be mounted on an electric vehicle or the like.

- the side on which the flow path forming unit 30 is provided in the housing 20 is referred to as the lower side X1

- the opposite side is referred to as the upper side X2

- the vertical direction X is referred to as the vertical direction X.

- the electric component 10 shown in FIG. 1 constitutes a part of a power conversion circuit (not shown).

- the electrical component 10 can be, for example, a capacitor, a current sensor, a reactor, a power module, or the like, and is a capacitor in the present embodiment.

- the electrical component 10 includes a capacitor element 11 and a case 12.

- the capacitor element 11 comprises an electrode 13.

- the electrode 13 is a metallikon electrode formed by spraying metal melted by metallikon.

- the bus bar 50 is connected to the electrode 13 by the bonding member 14 made of solder.

- the bus bar 50 is connected to an electric component such as a power module having a semiconductor element (not shown).

- the case 12 of the electrical component 10 can be made of resin, but not limited to, and in this embodiment, made of PPS (polyphenyl sulfide) resin.

- the case 12 includes the capacitor element 11 and has a case fixing rib 15 for fixing to the case 20. Further, in the present embodiment, a part of the bus bar 50 is also located in the case 12.

- the lower surface 16 of the case 12 is flat.

- the housing 20 has four side walls 21 and has a substantially cylindrical shape with a lower side X1 and an upper side X2 opened.

- an electrical component 10 is housed inside the housing 20.

- a projecting portion 22 is provided on the inner side surface of the side wall 21 of the casing 20, and a casing fixing rib 15 of the electric component 10 is fixed to the projecting portion 22 by a fastening member 17.

- the electrical component 10 is attached to the housing 20.

- An upper lid member (not shown) is provided at the upper end portion of the housing 20, and the upper lid member covers the opening of the upper side X2 of the housing 20.

- the flow path forming unit 30 is formed separately from the housing 20.

- a refrigerant flow path 31 is provided inside the flow path formation unit 30.

- the refrigerant channel 31 has a refrigerant inlet for supplying the refrigerant to the refrigerant channel 31 and a refrigerant outlet for discharging the refrigerant from the refrigerant channel 31.

- a flow path forming portion fixing rib 32 projecting outward is provided. The flow path formation portion fixing rib 32 is fixed to the flange 23 of the housing 20 via the fastening member 44.

- the flow path forming unit 30 is attached to the lower end portion of the housing 20 and covers the opening of the lower side X1 of the housing 20.

- the flow path forming unit 30 also functions as a lid of the lower side X1 in the housing 20.

- a spacer 40 is interposed between the flow path forming portion 30 and the housing 20.

- the spacer 40 is made of an elastically deformable material.

- the spacer 40 is made of a material that can seal between the flow passage forming portion 30 and the housing 20.

- the spacer 40 is provided along the entire circumference of the lower end portion of the housing 20 to seal the space between the housing 20 and the flow path forming portion 30 so that water or the like infiltrates into the housing 20 from the outside. It is being prevented.

- the heat dissipation material 60 is provided between the lower surface 16 of the electric component 10 and the upper surface 33 of the flow path forming portion 30.

- the electrical component 10 and the flow path forming unit 30 are thermally connected to each other through the heat dissipation material 60.

- the lower surface 16 of the electric component 10 and the upper surface 33 of the flow path forming portion 30 are each planar and parallel to each other.

- the heat dissipation material 60 is in the form of a sheet.

- the shape of the heat dissipation material 60 is not particularly limited, but in the present embodiment, the shape is substantially the same as the lower surface 16 of the electric component 10 in a plan view.

- the thickness of the heat dissipation material 60 is not particularly limited, but is preferably 1.0 mm or less, and is about 0.1 mm in the present embodiment.

- the material of the heat dissipating material 60 can have a thermal conductivity higher than that of the material forming the flow path forming portion 30.

- the heat dissipating material 60 is preferably made of an elastically deformable material.

- the flow path forming unit 30 to which the electrical component 10 is thermally connected is formed separately from the housing 20.

- An elastically deformable spacer 40 intervenes between the housing 20 and the flow path forming unit 30. Therefore, by elastically deforming the spacer 40, the relative position between the housing 20 and the flow path forming portion 30 can be easily changed. Then, by adjusting the relative position between the housing 20 and the flow path forming unit 30 in accordance with the dimensional variation of the electrical component 10, the dimensional variation of the electrical component 10 can be absorbed. Therefore, the cooling effect of the electrical component 10 can be improved while suppressing the generation of stress in the electrical component 10.

- the heat dissipation material 60 is interposed between the electrical component 10 and the flow path forming portion 30. Thereby, the cooling effect of the electrical component 10 can be further improved. Furthermore, in the present embodiment, the heat dissipation material 60 is elastically deformable. As a result, it is possible to absorb the dimensional variation of the electrical component 10 by both the spacer 40 and the heat dissipation material 60, so that the dimensional variation of the electrical component 10 is reliably absorbed, and the generation of stress in the electrical component 10 is further enhanced. It can be suppressed. Further, since the spacer 40 can be elastically deformed, the thickness of the heat dissipating material 60 can be sufficiently reduced, so that the cooling effect of the electric component 10 can be improved.

- the spacer 40 seals between the housing 20 and the flow path forming portion 30.

- the spacer 40 has both the function of absorbing the dimensional variation of the electric component 10 and the function of the seal between the housing 20 and the flow path forming portion 30, so it is necessary to separately use a sealing material. Contribute to reducing the number of parts.

- the electric component 10 is a capacitor, and includes the capacitor element 11 and the electrode 13 provided on the capacitor element 11, and the bus bar 50 is connected to the electrode 13 by the bonding member 14. .

- elastic deformation of the spacer 40 between the housing 20 and the flow path forming portion 30 allows stress between the bus bar 50, the bonding member 14, the electrode 13 and the capacitor element 11 to be The occurrence can be suppressed. As a result, it is possible to prevent the occurrence of a crack and to prevent the capacity decrease of the capacitor.

- the refrigerant flowing through the refrigerant channel 31 can also cool other electric components and devices provided on the lower side X1 of the channel forming unit 30.

- the power conversion device 1 capable of obtaining a high cooling effect while absorbing the dimensional variation of the electric component 10.

- the power conversion device 1 of the present embodiment includes a current sensor as the electric component 100 shown in FIG. 2 in place of the capacitor as the electric component 10 in the first embodiment shown in FIG.

- the other components are the same as in the case of the first embodiment, and the same reference numerals as in the case of the first embodiment are used in this embodiment as well, and the description thereof is omitted.

- the electrical component 100 is a current sensor, and includes a sensor element 101, a substrate 102 on which the sensor element 101 is mounted, and a case 12 for holding these.

- the sensor element 101 is connected to the bus bar 50.

- the substrate 102 and the bus bar 50 are provided in parallel with the lower surface 16 in contact with the flow path forming portion 30 in the electric component 100.

- an electrical component (not shown) is mounted on the substrate 102.

- the spacer 40 between the housing 20 and the flow path forming portion 30 is elastically deformed to be mounted on the substrate 102 or the substrate 102. It is possible to suppress the generation of stress in the electric component such as the sensor element 101 and the like. This can prevent the electrical component such as the sensor element 101 from falling off the substrate 102. Also in the present embodiment, the same effects as those of the first embodiment can be obtained.

- the power conversion device 1 of the present embodiment includes, as the electric component 100, a current sensor in a form different from the current sensor in the second embodiment shown in FIG. 2.

- the other components are the same as in the first and second embodiments, and the same reference numerals as in the first and second embodiments are used in this embodiment as well, and the description thereof is omitted.

- the electrical component 100 is a current sensor, and the substrate 102 and the bus bar 50 are provided perpendicularly to the lower surface 16 in contact with the flow path forming portion 30 in the electrical component 100. Also in the present embodiment, the same operation and effect as those of the second embodiment can be obtained. Furthermore, in the present embodiment, the substrate 102 and the bus bar 50 are provided perpendicularly to the lower surface 16, and the positional deviation is likely to occur between the sensor element 101 and the bus bar 50 due to the vibration in the vertical direction X. However, due to the elastic deformation of the spacer 40 between the housing 20 and the flow path forming portion 30, the occurrence of positional deviation between the sensor element 101 and the bus bar 50 described above can be prevented. It is possible to prevent the decrease in detection accuracy in

- the present disclosure is not limited to the above embodiments, and can be applied to various embodiments without departing from the scope of the invention.

- a lid member that does not have the coolant channel 31 is used instead of the channel forming unit 30 in order to share the configuration other than the channel forming unit 30.

- the configuration without the refrigerant channel 31 can be easily realized.

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Inverter Devices (AREA)

- Cooling Or The Like Of Electrical Apparatus (AREA)

- Casings For Electric Apparatus (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/782,468 US11432440B2 (en) | 2017-08-09 | 2020-02-05 | Power conversion apparatus |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017154361A JP2019033624A (ja) | 2017-08-09 | 2017-08-09 | 電力変換装置 |

| JP2017-154361 | 2017-08-09 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US16/782,468 Continuation US11432440B2 (en) | 2017-08-09 | 2020-02-05 | Power conversion apparatus |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019031172A1 true WO2019031172A1 (ja) | 2019-02-14 |

Family

ID=65272176

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/026932 Ceased WO2019031172A1 (ja) | 2017-08-09 | 2018-07-18 | 電力変換装置 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US11432440B2 (enExample) |

| JP (3) | JP2019033624A (enExample) |

| WO (1) | WO2019031172A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020120447A (ja) * | 2019-01-21 | 2020-08-06 | 株式会社デンソー | 電力変換ユニット |

| WO2024106227A1 (ja) * | 2022-11-18 | 2024-05-23 | 株式会社デンソー | コンデンサ装置 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2629375B (en) * | 2023-04-25 | 2025-09-17 | Mclaren Applied Ltd | Electronic unit cooling |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005245164A (ja) * | 2004-02-27 | 2005-09-08 | Mitsubishi Heavy Ind Ltd | カーエアコン用インバータの筐体構造、及び、その筐体の組立方法 |

| JP2007295639A (ja) * | 2006-04-20 | 2007-11-08 | Denso Corp | 車両用モータ駆動装置 |

| JP2007306671A (ja) * | 2006-05-09 | 2007-11-22 | Denso Corp | 車両用のモータ駆動装置 |

| WO2014024361A1 (ja) * | 2012-08-08 | 2014-02-13 | 富士電機株式会社 | 冷却構造体及び電力変換装置 |

Family Cites Families (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5455458A (en) * | 1993-08-09 | 1995-10-03 | Hughes Aircraft Company | Phase change cooling of semiconductor power modules |

| JPH11297906A (ja) * | 1998-03-23 | 1999-10-29 | Motorola Inc | 電子アセンブリおよび製造方法 |

| US6414867B2 (en) * | 2000-02-16 | 2002-07-02 | Hitachi, Ltd. | Power inverter |

| US7564129B2 (en) * | 2007-03-30 | 2009-07-21 | Nichicon Corporation | Power semiconductor module, and power semiconductor device having the module mounted therein |

| JP4797077B2 (ja) * | 2009-02-18 | 2011-10-19 | 株式会社日立製作所 | 半導体パワーモジュール、電力変換装置、および、半導体パワーモジュールの製造方法 |

| JP5702988B2 (ja) * | 2010-01-29 | 2015-04-15 | 株式会社 日立パワーデバイス | 半導体パワーモジュール及びそれが搭載される電力変換装置並びに半導体パワーモジュール搭載用水路形成体の製造方法 |

| CN103765751B (zh) * | 2011-09-02 | 2016-08-17 | 富士电机株式会社 | 电力变换装置 |

| US8963321B2 (en) * | 2011-09-12 | 2015-02-24 | Infineon Technologies Ag | Semiconductor device including cladded base plate |

| EP2830073B1 (en) * | 2012-03-19 | 2017-09-13 | Mitsubishi Electric Corporation | Power conversion apparatus |

| JP5962752B2 (ja) * | 2012-03-21 | 2016-08-03 | 富士電機株式会社 | 電力変換装置 |

| JP6060553B2 (ja) * | 2012-04-06 | 2017-01-18 | 株式会社豊田自動織機 | 半導体装置 |

| JPWO2014045766A1 (ja) * | 2012-09-19 | 2016-08-18 | 富士電機株式会社 | 半導体装置及び半導体装置の製造方法 |

| WO2014061178A1 (ja) * | 2012-10-16 | 2014-04-24 | 富士電機株式会社 | 冷却構造体及び発熱体 |

| TWI482244B (zh) * | 2012-11-19 | 2015-04-21 | 財團法人工業技術研究院 | 熱交換器以及半導體模組 |

| JP5953246B2 (ja) * | 2013-02-20 | 2016-07-20 | 株式会社日立製作所 | 電力変換装置 |

| CN104704934B (zh) * | 2013-03-19 | 2017-02-22 | 富士电机株式会社 | 冷却装置以及具备该冷却装置的电力转换装置 |

| JP6350785B2 (ja) * | 2013-09-03 | 2018-07-04 | Tdk株式会社 | インバータ装置 |

| CN105051892B (zh) * | 2013-09-05 | 2018-06-15 | 富士电机株式会社 | 电力用半导体模块 |

| FR3011713B1 (fr) * | 2013-10-09 | 2017-06-23 | Valeo Systemes De Controle Moteur | Module electrique, systeme electrique comportant un tel module electrique, procedes de fabrication correspondants |

| WO2015075976A1 (ja) * | 2013-11-20 | 2015-05-28 | 日産自動車株式会社 | 電力変換装置 |

| JP6112003B2 (ja) * | 2013-12-18 | 2017-04-12 | トヨタ自動車株式会社 | 冷却機能付き電子装置 |

| WO2016031462A1 (ja) * | 2014-08-28 | 2016-03-03 | 富士電機株式会社 | パワー半導体モジュール |

| CN106716815B (zh) * | 2014-09-25 | 2019-03-15 | 日立汽车系统株式会社 | 电力变换装置 |

| JP2016073144A (ja) * | 2014-10-01 | 2016-05-09 | 日産自動車株式会社 | 電力変換装置 |

| JP5925863B2 (ja) | 2014-11-07 | 2016-05-25 | 日立オートモティブシステムズ株式会社 | 電力変換装置 |

| JP6398704B2 (ja) * | 2014-12-25 | 2018-10-03 | アイシン・エィ・ダブリュ株式会社 | インバータ装置 |

| JP6119787B2 (ja) * | 2015-03-31 | 2017-04-26 | トヨタ自動車株式会社 | ケース体に対する回路基板の姿勢維持構造 |

| JP6384609B2 (ja) * | 2015-06-17 | 2018-09-05 | 富士電機株式会社 | パワー半導体モジュール及び冷却器 |

| JP6606938B2 (ja) * | 2015-09-16 | 2019-11-20 | 富士電機株式会社 | 電力変換装置 |

| CA2953678A1 (en) * | 2016-01-05 | 2017-07-05 | Atse, Llc | Power converter |

| US20190096787A1 (en) * | 2017-09-25 | 2019-03-28 | General Electric Company | Methods and Devices for Attaching and Sealing a Semiconductor Cooling Structure |

| JP6457678B1 (ja) * | 2018-03-19 | 2019-01-23 | 株式会社ケーヒン | 電力変換装置 |

| JP7275706B2 (ja) * | 2019-03-20 | 2023-05-18 | セイコーエプソン株式会社 | 液体吐出ユニットおよび液体吐出装置 |

-

2017

- 2017-08-09 JP JP2017154361A patent/JP2019033624A/ja active Pending

-

2018

- 2018-07-18 WO PCT/JP2018/026932 patent/WO2019031172A1/ja not_active Ceased

-

2020

- 2020-02-05 US US16/782,468 patent/US11432440B2/en active Active

- 2020-12-21 JP JP2020210934A patent/JP2021065089A/ja active Pending

-

2022

- 2022-12-21 JP JP2022204381A patent/JP2023027342A/ja active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005245164A (ja) * | 2004-02-27 | 2005-09-08 | Mitsubishi Heavy Ind Ltd | カーエアコン用インバータの筐体構造、及び、その筐体の組立方法 |

| JP2007295639A (ja) * | 2006-04-20 | 2007-11-08 | Denso Corp | 車両用モータ駆動装置 |

| JP2007306671A (ja) * | 2006-05-09 | 2007-11-22 | Denso Corp | 車両用のモータ駆動装置 |

| WO2014024361A1 (ja) * | 2012-08-08 | 2014-02-13 | 富士電機株式会社 | 冷却構造体及び電力変換装置 |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020120447A (ja) * | 2019-01-21 | 2020-08-06 | 株式会社デンソー | 電力変換ユニット |

| JP7099340B2 (ja) | 2019-01-21 | 2022-07-12 | 株式会社デンソー | 電力変換ユニット |

| WO2024106227A1 (ja) * | 2022-11-18 | 2024-05-23 | 株式会社デンソー | コンデンサ装置 |

| JP2024073864A (ja) * | 2022-11-18 | 2024-05-30 | 株式会社デンソー | コンデンサ装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019033624A (ja) | 2019-02-28 |

| US20200178424A1 (en) | 2020-06-04 |

| US11432440B2 (en) | 2022-08-30 |

| JP2023027342A (ja) | 2023-03-01 |

| JP2021065089A (ja) | 2021-04-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4124137B2 (ja) | 電子ユニット筐体 | |

| JP5991440B2 (ja) | 半導体装置、半導体モジュール | |

| JP5423655B2 (ja) | 電力変換装置 | |

| JP2023027342A (ja) | 電力変換装置 | |

| CN111371289B (zh) | 电力转换装置 | |

| JPWO2018055668A1 (ja) | 電力変換装置 | |

| JP6236904B2 (ja) | 電力変換装置 | |

| US9992915B2 (en) | Power conversion device | |

| WO2016189658A1 (ja) | 機電一体型の回転電機装置 | |

| US10524383B2 (en) | Inverter device | |

| JP2008306048A (ja) | 電子ユニット筐体 | |

| JP2010087002A (ja) | 発熱部品冷却構造 | |

| US10461656B2 (en) | Power conversion device having a cover that covers DC positive and negative terminals | |

| JP6253815B2 (ja) | 電力変換装置 | |

| JP2015088629A (ja) | 電子制御装置 | |

| JP5826373B2 (ja) | 電子モジュールおよびその製造方法 | |

| WO2014024361A1 (ja) | 冷却構造体及び電力変換装置 | |

| JP4450632B2 (ja) | 電力変換装置 | |

| WO2014020808A1 (ja) | 冷却構造体及び電力変換装置 | |

| JP2019033624A5 (enExample) | ||

| JP6432909B2 (ja) | 電力機器 | |

| JP2018110469A (ja) | 半導体装置 | |

| NL2021196B1 (en) | Module and power conversion device | |

| JP7081525B2 (ja) | 電力変換装置 | |

| CN110520981A (zh) | 功率转换装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18843898 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18843898 Country of ref document: EP Kind code of ref document: A1 |