KR20120082901A - 오목 구조들에서 연속적 루테늄 필름 상 다중-단계 구리 도금 방법들 - Google Patents

오목 구조들에서 연속적 루테늄 필름 상 다중-단계 구리 도금 방법들 Download PDFInfo

- Publication number

- KR20120082901A KR20120082901A KR1020127010660A KR20127010660A KR20120082901A KR 20120082901 A KR20120082901 A KR 20120082901A KR 1020127010660 A KR1020127010660 A KR 1020127010660A KR 20127010660 A KR20127010660 A KR 20127010660A KR 20120082901 A KR20120082901 A KR 20120082901A

- Authority

- KR

- South Korea

- Prior art keywords

- continuous

- metal

- concave structure

- metal layer

- gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 165

- 238000007747 plating Methods 0.000 title claims abstract description 139

- 239000010949 copper Substances 0.000 title claims description 405

- 229910052707 ruthenium Inorganic materials 0.000 title claims description 11

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 title claims description 10

- 229910052802 copper Inorganic materials 0.000 title claims description 10

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 title claims description 8

- 229910052751 metal Inorganic materials 0.000 claims abstract description 382

- 239000002184 metal Substances 0.000 claims abstract description 382

- 238000011049 filling Methods 0.000 claims abstract description 38

- 239000007789 gas Substances 0.000 claims description 174

- 239000002243 precursor Substances 0.000 claims description 135

- 239000000758 substrate Substances 0.000 claims description 130

- 230000008569 process Effects 0.000 claims description 101

- 238000000151 deposition Methods 0.000 claims description 73

- 238000000137 annealing Methods 0.000 claims description 70

- 230000008021 deposition Effects 0.000 claims description 45

- 230000001590 oxidative effect Effects 0.000 claims description 42

- 239000011261 inert gas Substances 0.000 claims description 35

- 230000004888 barrier function Effects 0.000 claims description 34

- 239000010936 titanium Substances 0.000 claims description 34

- 238000002230 thermal chemical vapour deposition Methods 0.000 claims description 31

- 238000009792 diffusion process Methods 0.000 claims description 29

- 239000012159 carrier gas Substances 0.000 claims description 23

- 229910052739 hydrogen Inorganic materials 0.000 claims description 22

- 229910052715 tantalum Inorganic materials 0.000 claims description 22

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical group [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 claims description 22

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 17

- 229910052719 titanium Inorganic materials 0.000 claims description 17

- 239000001257 hydrogen Substances 0.000 claims description 16

- 150000002431 hydrogen Chemical class 0.000 claims description 16

- NFFIWVVINABMKP-UHFFFAOYSA-N methylidynetantalum Chemical compound [Ta]#C NFFIWVVINABMKP-UHFFFAOYSA-N 0.000 claims description 16

- 229910003468 tantalcarbide Inorganic materials 0.000 claims description 16

- MTPVUVINMAGMJL-UHFFFAOYSA-N trimethyl(1,1,2,2,2-pentafluoroethyl)silane Chemical compound C[Si](C)(C)C(F)(F)C(F)(F)F MTPVUVINMAGMJL-UHFFFAOYSA-N 0.000 claims description 16

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 claims description 16

- 229910052721 tungsten Inorganic materials 0.000 claims description 16

- 239000010937 tungsten Substances 0.000 claims description 16

- 239000000203 mixture Substances 0.000 claims description 15

- MZLGASXMSKOWSE-UHFFFAOYSA-N tantalum nitride Chemical compound [Ta]#N MZLGASXMSKOWSE-UHFFFAOYSA-N 0.000 claims description 15

- 239000000126 substance Substances 0.000 claims description 14

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 claims description 13

- 229910052760 oxygen Inorganic materials 0.000 claims description 8

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 claims description 7

- 229910052786 argon Inorganic materials 0.000 claims description 7

- IVHJCRXBQPGLOV-UHFFFAOYSA-N azanylidynetungsten Chemical compound [W]#N IVHJCRXBQPGLOV-UHFFFAOYSA-N 0.000 claims description 7

- 229910002091 carbon monoxide Inorganic materials 0.000 claims description 7

- 239000001301 oxygen Substances 0.000 claims description 7

- UONOETXJSWQNOL-UHFFFAOYSA-N tungsten carbide Chemical compound [W+]#[C-] UONOETXJSWQNOL-UHFFFAOYSA-N 0.000 claims description 7

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 6

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 6

- JPVYNHNXODAKFH-UHFFFAOYSA-N Cu2+ Chemical compound [Cu+2] JPVYNHNXODAKFH-UHFFFAOYSA-N 0.000 claims description 5

- 229910001431 copper ion Inorganic materials 0.000 claims description 5

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 claims description 4

- 238000007654 immersion Methods 0.000 claims description 4

- 238000007772 electroless plating Methods 0.000 claims description 2

- OOUGXYOQJHBKRC-UHFFFAOYSA-N C([O-])[O-].[Ti+4].C([O-])[O-] Chemical compound C([O-])[O-].[Ti+4].C([O-])[O-] OOUGXYOQJHBKRC-UHFFFAOYSA-N 0.000 claims 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical group [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 claims 1

- 150000004767 nitrides Chemical class 0.000 claims 1

- 229910052698 phosphorus Inorganic materials 0.000 claims 1

- 239000011574 phosphorus Substances 0.000 claims 1

- 230000015572 biosynthetic process Effects 0.000 abstract description 12

- 239000010408 film Substances 0.000 description 160

- 239000010410 layer Substances 0.000 description 154

- 239000000463 material Substances 0.000 description 30

- 230000008016 vaporization Effects 0.000 description 30

- 238000009834 vaporization Methods 0.000 description 28

- 239000012212 insulator Substances 0.000 description 27

- 238000009826 distribution Methods 0.000 description 22

- 238000012545 processing Methods 0.000 description 19

- 238000004519 manufacturing process Methods 0.000 description 8

- 238000010586 diagram Methods 0.000 description 7

- 230000009977 dual effect Effects 0.000 description 7

- 239000012535 impurity Substances 0.000 description 7

- 238000005240 physical vapour deposition Methods 0.000 description 7

- 239000004065 semiconductor Substances 0.000 description 7

- 239000007787 solid Substances 0.000 description 7

- 238000004627 transmission electron microscopy Methods 0.000 description 7

- 239000007983 Tris buffer Substances 0.000 description 6

- 239000012530 fluid Substances 0.000 description 6

- 238000005086 pumping Methods 0.000 description 6

- 235000012431 wafers Nutrition 0.000 description 6

- 229910004298 SiO 2 Inorganic materials 0.000 description 5

- 238000005229 chemical vapour deposition Methods 0.000 description 5

- 238000010438 heat treatment Methods 0.000 description 5

- 229910052734 helium Inorganic materials 0.000 description 5

- 229910052743 krypton Inorganic materials 0.000 description 5

- 238000001465 metallisation Methods 0.000 description 5

- 229910052754 neon Inorganic materials 0.000 description 5

- 229910052756 noble gas Inorganic materials 0.000 description 5

- 238000012546 transfer Methods 0.000 description 5

- 238000000231 atomic layer deposition Methods 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 4

- 238000009833 condensation Methods 0.000 description 4

- 230000005494 condensation Effects 0.000 description 4

- 238000000354 decomposition reaction Methods 0.000 description 4

- 229910052757 nitrogen Inorganic materials 0.000 description 4

- 229910052710 silicon Inorganic materials 0.000 description 4

- 230000003746 surface roughness Effects 0.000 description 4

- 229910052724 xenon Inorganic materials 0.000 description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 3

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 3

- -1 TDEAT) Substances 0.000 description 3

- 239000003638 chemical reducing agent Substances 0.000 description 3

- 238000011161 development Methods 0.000 description 3

- 230000018109 developmental process Effects 0.000 description 3

- 239000011229 interlayer Substances 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 238000001020 plasma etching Methods 0.000 description 3

- 238000002203 pretreatment Methods 0.000 description 3

- 239000010703 silicon Substances 0.000 description 3

- 239000004094 surface-active agent Substances 0.000 description 3

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- 229910004129 HfSiO Inorganic materials 0.000 description 2

- OAKJQQAXSVQMHS-UHFFFAOYSA-N Hydrazine Chemical compound NN OAKJQQAXSVQMHS-UHFFFAOYSA-N 0.000 description 2

- 229910005881 NiSi 2 Inorganic materials 0.000 description 2

- 229910006501 ZrSiO Inorganic materials 0.000 description 2

- 230000001276 controlling effect Effects 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 230000008020 evaporation Effects 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 229910052736 halogen Inorganic materials 0.000 description 2

- 239000011810 insulating material Substances 0.000 description 2

- 150000002500 ions Chemical class 0.000 description 2

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 2

- 238000011068 loading method Methods 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- NFHFRUOZVGFOOS-UHFFFAOYSA-N palladium;triphenylphosphane Chemical compound [Pd].C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1 NFHFRUOZVGFOOS-UHFFFAOYSA-N 0.000 description 2

- 230000035515 penetration Effects 0.000 description 2

- 238000000623 plasma-assisted chemical vapour deposition Methods 0.000 description 2

- 238000003672 processing method Methods 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 238000001004 secondary ion mass spectrometry Methods 0.000 description 2

- MNWRORMXBIWXCI-UHFFFAOYSA-N tetrakis(dimethylamido)titanium Chemical compound CN(C)[Ti](N(C)C)(N(C)C)N(C)C MNWRORMXBIWXCI-UHFFFAOYSA-N 0.000 description 2

- GWSOSPTYOIRWNO-UHFFFAOYSA-N 2-(dimethylamino)ethanolate;ethanolate;tantalum(5+) Chemical compound [Ta+5].CC[O-].CC[O-].CC[O-].CC[O-].CN(C)CC[O-] GWSOSPTYOIRWNO-UHFFFAOYSA-N 0.000 description 1

- VLJQDHDVZJXNQL-UHFFFAOYSA-N 4-methyl-n-(oxomethylidene)benzenesulfonamide Chemical compound CC1=CC=C(S(=O)(=O)N=C=O)C=C1 VLJQDHDVZJXNQL-UHFFFAOYSA-N 0.000 description 1

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 1

- 235000014653 Carica parviflora Nutrition 0.000 description 1

- 241000243321 Cnidaria Species 0.000 description 1

- 229910019001 CoSi Inorganic materials 0.000 description 1

- 101100521334 Mus musculus Prom1 gene Proteins 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

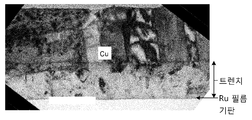

- 238000003917 TEM image Methods 0.000 description 1

- 229910010413 TiO 2 Inorganic materials 0.000 description 1

- 229910008484 TiSi Inorganic materials 0.000 description 1

- 238000002441 X-ray diffraction Methods 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- PPJPTAQKIFHZQU-UHFFFAOYSA-N bis(tert-butylimino)tungsten;dimethylazanide Chemical compound C[N-]C.C[N-]C.CC(C)(C)N=[W]=NC(C)(C)C PPJPTAQKIFHZQU-UHFFFAOYSA-N 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- FQNHWXHRAUXLFU-UHFFFAOYSA-N carbon monoxide;tungsten Chemical group [W].[O+]#[C-].[O+]#[C-].[O+]#[C-].[O+]#[C-].[O+]#[C-].[O+]#[C-] FQNHWXHRAUXLFU-UHFFFAOYSA-N 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000004590 computer program Methods 0.000 description 1

- 238000002425 crystallisation Methods 0.000 description 1

- 230000008025 crystallization Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- QUPDWYMUPZLYJZ-UHFFFAOYSA-N ethyl Chemical compound C[CH2] QUPDWYMUPZLYJZ-UHFFFAOYSA-N 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 230000031700 light absorption Effects 0.000 description 1

- 239000012705 liquid precursor Substances 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- WCYWZMWISLQXQU-UHFFFAOYSA-N methyl Chemical compound [CH3] WCYWZMWISLQXQU-UHFFFAOYSA-N 0.000 description 1

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- 229910021340 platinum monosilicide Inorganic materials 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 230000002028 premature Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000013515 script Methods 0.000 description 1

- 150000004760 silicates Chemical class 0.000 description 1

- 229910021332 silicide Inorganic materials 0.000 description 1

- FVBUAEGBCNSCDD-UHFFFAOYSA-N silicide(4-) Chemical compound [Si-4] FVBUAEGBCNSCDD-UHFFFAOYSA-N 0.000 description 1

- 150000003376 silicon Chemical class 0.000 description 1

- LIVNPJMFVYWSIS-UHFFFAOYSA-N silicon monoxide Chemical compound [Si-]#[O+] LIVNPJMFVYWSIS-UHFFFAOYSA-N 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 241000894007 species Species 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 238000000859 sublimation Methods 0.000 description 1

- 230000008022 sublimation Effects 0.000 description 1

- OEIMLTQPLAGXMX-UHFFFAOYSA-I tantalum(v) chloride Chemical compound Cl[Ta](Cl)(Cl)(Cl)Cl OEIMLTQPLAGXMX-UHFFFAOYSA-I 0.000 description 1

- HSXKFDGTKKAEHL-UHFFFAOYSA-N tantalum(v) ethoxide Chemical compound [Ta+5].CC[O-].CC[O-].CC[O-].CC[O-].CC[O-] HSXKFDGTKKAEHL-UHFFFAOYSA-N 0.000 description 1

- DHHKPEUQJIEKOA-UHFFFAOYSA-N tert-butyl 2-[6-(nitromethyl)-6-bicyclo[3.2.0]hept-3-enyl]acetate Chemical compound C1C=CC2C(CC(=O)OC(C)(C)C)(C[N+]([O-])=O)CC21 DHHKPEUQJIEKOA-UHFFFAOYSA-N 0.000 description 1

- 125000000999 tert-butyl group Chemical group [H]C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000000427 thin-film deposition Methods 0.000 description 1

- XJDNKRIXUMDJCW-UHFFFAOYSA-J titanium tetrachloride Chemical compound Cl[Ti](Cl)(Cl)Cl XJDNKRIXUMDJCW-UHFFFAOYSA-J 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

- NXHILIPIEUBEPD-UHFFFAOYSA-H tungsten hexafluoride Chemical compound F[W](F)(F)(F)(F)F NXHILIPIEUBEPD-UHFFFAOYSA-H 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/1601—Process or apparatus

- C23C18/1633—Process of electroless plating

- C23C18/1646—Characteristics of the product obtained

- C23C18/165—Multilayered product

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/06—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of metallic material

- C23C16/16—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of metallic material from metal carbonyl compounds

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/1601—Process or apparatus

- C23C18/1603—Process or apparatus coating on selected surface areas

- C23C18/1607—Process or apparatus coating on selected surface areas by direct patterning

- C23C18/161—Process or apparatus coating on selected surface areas by direct patterning from plating step, e.g. inkjet

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/1601—Process or apparatus

- C23C18/1633—Process of electroless plating

- C23C18/1646—Characteristics of the product obtained

- C23C18/165—Multilayered product

- C23C18/1651—Two or more layers only obtained by electroless plating

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/1601—Process or apparatus

- C23C18/1633—Process of electroless plating

- C23C18/1689—After-treatment

- C23C18/1692—Heat-treatment

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/31—Coating with metals

- C23C18/38—Coating with copper

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/02—Electroplating of selected surface areas

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/10—Electroplating with more than one layer of the same or of different metals

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/48—After-treatment of electroplated surfaces

- C25D5/50—After-treatment of electroplated surfaces by heat-treatment

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/283—Deposition of conductive or insulating materials for electrodes conducting electric current

- H01L21/285—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation

- H01L21/28506—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers

- H01L21/28512—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers on semiconductor bodies comprising elements of Group IV of the Periodic Table

- H01L21/28556—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers on semiconductor bodies comprising elements of Group IV of the Periodic Table by chemical means, e.g. CVD, LPCVD, PECVD, laser CVD

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/283—Deposition of conductive or insulating materials for electrodes conducting electric current

- H01L21/288—Deposition of conductive or insulating materials for electrodes conducting electric current from a liquid, e.g. electrolytic deposition

- H01L21/2885—Deposition of conductive or insulating materials for electrodes conducting electric current from a liquid, e.g. electrolytic deposition using an external electrical current, i.e. electro-deposition

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76841—Barrier, adhesion or liner layers

- H01L21/76843—Barrier, adhesion or liner layers formed in openings in a dielectric

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76877—Filling of holes, grooves or trenches, e.g. vias, with conductive material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76877—Filling of holes, grooves or trenches, e.g. vias, with conductive material

- H01L21/76883—Post-treatment or after-treatment of the conductive material

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/34—Pretreatment of metallic surfaces to be electroplated

- C25D5/38—Pretreatment of metallic surfaces to be electroplated of refractory metals or nickel

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Electrochemistry (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

- Electrodes Of Semiconductors (AREA)

- Chemically Coating (AREA)

- Electroplating Methods And Accessories (AREA)

- Chemical Vapour Deposition (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/571,162 US8076241B2 (en) | 2009-09-30 | 2009-09-30 | Methods for multi-step copper plating on a continuous ruthenium film in recessed features |

| US12/571,162 | 2009-09-30 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20120082901A true KR20120082901A (ko) | 2012-07-24 |

Family

ID=43743696

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020127010660A Ceased KR20120082901A (ko) | 2009-09-30 | 2010-09-30 | 오목 구조들에서 연속적 루테늄 필름 상 다중-단계 구리 도금 방법들 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US8076241B2 (enExample) |

| JP (1) | JP2013507008A (enExample) |

| KR (1) | KR20120082901A (enExample) |

| CN (1) | CN102859035A (enExample) |

| TW (1) | TW201113934A (enExample) |

| WO (1) | WO2011041522A2 (enExample) |

Families Citing this family (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101271869B1 (ko) * | 2008-12-09 | 2013-06-07 | 가부시키가이샤 알박 | 질화 탄탈막의 형성 방법 및 그 성막 장치 |

| US20110204518A1 (en) * | 2010-02-23 | 2011-08-25 | Globalfoundries Inc. | Scalability with reduced contact resistance |

| US9257274B2 (en) | 2010-04-15 | 2016-02-09 | Lam Research Corporation | Gapfill of variable aspect ratio features with a composite PEALD and PECVD method |

| US9287113B2 (en) | 2012-11-08 | 2016-03-15 | Novellus Systems, Inc. | Methods for depositing films on sensitive substrates |

| US9997357B2 (en) | 2010-04-15 | 2018-06-12 | Lam Research Corporation | Capped ALD films for doping fin-shaped channel regions of 3-D IC transistors |

| US8637411B2 (en) | 2010-04-15 | 2014-01-28 | Novellus Systems, Inc. | Plasma activated conformal dielectric film deposition |

| US8661664B2 (en) | 2010-07-19 | 2014-03-04 | International Business Machines Corporation | Techniques for forming narrow copper filled vias having improved conductivity |

| KR101780050B1 (ko) * | 2011-02-28 | 2017-09-20 | 삼성전자주식회사 | 반도체 기억 소자 및 반도체 기억 소자의 형성 방법 |

| JP5862353B2 (ja) * | 2011-08-05 | 2016-02-16 | 東京エレクトロン株式会社 | 半導体装置の製造方法 |

| US8518818B2 (en) | 2011-09-16 | 2013-08-27 | Taiwan Semiconductor Manufacturing Co., Ltd. | Reverse damascene process |

| US9214383B2 (en) * | 2013-01-18 | 2015-12-15 | Taiwan Semiconductor Manufacturing Company, Ltd. | Method of semiconductor integrated circuit fabrication |

| US9536830B2 (en) | 2013-05-09 | 2017-01-03 | Globalfoundries Inc. | High performance refractory metal / copper interconnects to eliminate electromigration |

| US9171801B2 (en) * | 2013-05-09 | 2015-10-27 | Globalfoundries U.S. 2 Llc | E-fuse with hybrid metallization |

| EP3049555B1 (en) * | 2013-09-26 | 2025-05-14 | Atotech Deutschland GmbH & Co. KG | Novel adhesion promoting process for metallisation of substrate surfaces |

| JP2015160963A (ja) * | 2014-02-26 | 2015-09-07 | 東京エレクトロン株式会社 | ルテニウム膜の成膜方法および成膜装置、ならびに半導体装置の製造方法 |

| FR3017993B1 (fr) * | 2014-02-27 | 2017-08-11 | Commissariat Energie Atomique | Procede de realisation d'une structure par assemblage d'au moins deux elements par collage direct |

| US9564312B2 (en) | 2014-11-24 | 2017-02-07 | Lam Research Corporation | Selective inhibition in atomic layer deposition of silicon-containing films |

| US10566187B2 (en) | 2015-03-20 | 2020-02-18 | Lam Research Corporation | Ultrathin atomic layer deposition film accuracy thickness control |

| US9875890B2 (en) * | 2015-03-24 | 2018-01-23 | Lam Research Corporation | Deposition of metal dielectric film for hardmasks |

| JP6329199B2 (ja) * | 2016-03-30 | 2018-05-23 | 株式会社日立国際電気 | 半導体装置の製造方法、基板処理装置およびプログラム |

| WO2017218044A1 (en) * | 2016-06-15 | 2017-12-21 | Applied Materials, Inc. | Gas distribution plate assembly for high power plasma etch processes |

| US9773643B1 (en) | 2016-06-30 | 2017-09-26 | Lam Research Corporation | Apparatus and method for deposition and etch in gap fill |

| US10062563B2 (en) | 2016-07-01 | 2018-08-28 | Lam Research Corporation | Selective atomic layer deposition with post-dose treatment |

| US10037884B2 (en) | 2016-08-31 | 2018-07-31 | Lam Research Corporation | Selective atomic layer deposition for gapfill using sacrificial underlayer |

| CN107731703A (zh) * | 2017-08-31 | 2018-02-23 | 长江存储科技有限责任公司 | 一种互连结构及其制作方法和半导体器件的制作方法 |

| WO2019050714A1 (en) * | 2017-09-05 | 2019-03-14 | Applied Materials, Inc. | ASCENDING APPROACH FOR HIGH-FORM SHAPE FORMATION IN 3D MEMORY STRUCTURES |

| US10269559B2 (en) | 2017-09-13 | 2019-04-23 | Lam Research Corporation | Dielectric gapfill of high aspect ratio features utilizing a sacrificial etch cap layer |

| KR102789261B1 (ko) * | 2017-10-19 | 2025-04-01 | 램 리써치 코포레이션 | 단일 금속의 멀티배스 (multibath) 도금 |

| US11284510B2 (en) | 2018-04-17 | 2022-03-22 | Board Of Trustees Of Michigan State University | Controlled wetting and spreading of metals on substrates using porous interlayers and related articles |

| US11631680B2 (en) * | 2018-10-18 | 2023-04-18 | Applied Materials, Inc. | Methods and apparatus for smoothing dynamic random access memory bit line metal |

| US12040181B2 (en) | 2019-05-01 | 2024-07-16 | Lam Research Corporation | Modulated atomic layer deposition |

| US12431349B2 (en) | 2019-06-07 | 2025-09-30 | Lam Research Corporation | In-situ control of film properties during atomic layer deposition |

| JP7713456B2 (ja) | 2020-01-10 | 2025-07-25 | ラム リサーチ コーポレーション | Tsv処理窓ならびに長いパルス出力および傾斜部形成による充填性能強化 |

| JP7206355B2 (ja) * | 2020-11-12 | 2023-01-17 | アプライド マテリアルズ インコーポレイテッド | ダイナミックランダムアクセスメモリビット線金属を滑らかにするための方法及び装置 |

| US20220415651A1 (en) * | 2021-06-29 | 2022-12-29 | Applied Materials, Inc. | Methods Of Forming Memory Device With Reduced Resistivity |

| US20230197620A1 (en) * | 2021-12-21 | 2023-06-22 | Intel Corporation | Methods, systems, apparatus, and articles of manufacture for integrated circuit package substrates with high aspect ratio through glass vias |

Family Cites Families (57)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0524931A (ja) | 1991-07-16 | 1993-02-02 | Hitachi Metals Ltd | 窒化アルミニウム焼結体 |

| US5888870A (en) * | 1997-10-22 | 1999-03-30 | Advanced Micro Devices, Inc. | Memory cell fabrication employing an interpoly gate dielectric arranged upon a polished floating gate |

| JPH11168096A (ja) | 1997-12-04 | 1999-06-22 | Sony Corp | 高誘電酸化膜の形成方法 |

| US6200898B1 (en) * | 1999-10-25 | 2001-03-13 | Vanguard International Semiconductor Corporation | Global planarization process for high step DRAM devices via use of HF vapor etching |

| WO2002071463A1 (en) * | 2001-03-02 | 2002-09-12 | Tokyo Electron Limited | Shower head gas injection apparatus with secondary high pressure pulsed gas injection |

| JP4895430B2 (ja) * | 2001-03-22 | 2012-03-14 | ルネサスエレクトロニクス株式会社 | 半導体装置及び半導体装置の製造方法 |

| US6506668B1 (en) * | 2001-06-22 | 2003-01-14 | Advanced Micro Devices, Inc. | Utilization of annealing enhanced or repaired seed layer to improve copper interconnect reliability |

| JP4921652B2 (ja) * | 2001-08-03 | 2012-04-25 | エイエスエム インターナショナル エヌ.ヴェー. | イットリウム酸化物およびランタン酸化物薄膜を堆積する方法 |

| US6797599B2 (en) * | 2001-08-31 | 2004-09-28 | Texas Instruments Incorporated | Gate structure and method |

| EP1294021A1 (de) * | 2001-08-31 | 2003-03-19 | Infineon Technologies AG | Kondensatoreinrichtung für eine Halbleiterschaltungsanordnung und Verfahren zu deren Herstellung |

| JP3611545B2 (ja) * | 2001-12-20 | 2005-01-19 | 株式会社荏原製作所 | めっき装置 |

| JP3756456B2 (ja) * | 2002-03-07 | 2006-03-15 | 富士通株式会社 | 半導体装置の製造方法 |

| JP3588607B2 (ja) * | 2002-03-29 | 2004-11-17 | 株式会社東芝 | 電界効果トランジスタ |

| US6680130B2 (en) * | 2002-05-28 | 2004-01-20 | Agere Systems, Inc. | High K dielectric material and method of making a high K dielectric material |

| US6730164B2 (en) * | 2002-08-28 | 2004-05-04 | Micron Technology, Inc. | Systems and methods for forming strontium- and/or barium-containing layers |

| US6794284B2 (en) * | 2002-08-28 | 2004-09-21 | Micron Technology, Inc. | Systems and methods for forming refractory metal nitride layers using disilazanes |

| US20040051126A1 (en) * | 2002-09-16 | 2004-03-18 | Structured Materials Inc. | Compositionally engineered CexMnyO3 and semiconductor devices based thereon |

| US6858524B2 (en) * | 2002-12-03 | 2005-02-22 | Asm International, Nv | Method of depositing barrier layer for metal gates |

| JP4647311B2 (ja) | 2002-12-09 | 2011-03-09 | アイメック | 誘電体スタックの形成方法 |

| US6828200B2 (en) * | 2003-01-03 | 2004-12-07 | Texas Instruments Incorporated | Multistage deposition that incorporates nitrogen via an intermediate step |

| US7071519B2 (en) * | 2003-01-08 | 2006-07-04 | Texas Instruments Incorporated | Control of high-k gate dielectric film composition profile for property optimization |

| US6974768B1 (en) * | 2003-01-15 | 2005-12-13 | Novellus Systems, Inc. | Methods of providing an adhesion layer for adhesion of barrier and/or seed layers to dielectric films |

| JP3920235B2 (ja) * | 2003-03-24 | 2007-05-30 | 株式会社ルネサステクノロジ | 半導体装置の製造方法 |

| TW200506093A (en) * | 2003-04-21 | 2005-02-16 | Aviza Tech Inc | System and method for forming multi-component films |

| US20050274621A1 (en) * | 2004-06-10 | 2005-12-15 | Zhi-Wen Sun | Method of barrier layer surface treatment to enable direct copper plating on barrier metal |

| US7378129B2 (en) * | 2003-08-18 | 2008-05-27 | Micron Technology, Inc. | Atomic layer deposition methods of forming conductive metal nitride comprising layers |

| US7135361B2 (en) * | 2003-12-11 | 2006-11-14 | Texas Instruments Incorporated | Method for fabricating transistor gate structures and gate dielectrics thereof |

| US6979623B2 (en) * | 2003-12-17 | 2005-12-27 | Texas Instruments Incorporated | Method for fabricating split gate transistor device having high-k dielectrics |

| JP2005191482A (ja) | 2003-12-26 | 2005-07-14 | Semiconductor Leading Edge Technologies Inc | 半導体装置及びその製造方法 |

| WO2005065402A2 (en) | 2003-12-29 | 2005-07-21 | Translucent Photonics, Inc. | Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon |

| JP2005340721A (ja) * | 2004-05-31 | 2005-12-08 | Anelva Corp | 高誘電率誘電体膜を堆積する方法 |

| CN1965110A (zh) * | 2004-06-10 | 2007-05-16 | 应用材料公司 | 能够在阻挡金属上直接镀铜的阻挡层表面处理的方法 |

| KR100589040B1 (ko) | 2004-08-05 | 2006-06-14 | 삼성전자주식회사 | 막 형성방법 및 이를 이용한 반도체 장치의 커패시터제조방법 |

| US7138680B2 (en) * | 2004-09-14 | 2006-11-21 | Infineon Technologies Ag | Memory device with floating gate stack |

| US7270848B2 (en) * | 2004-11-23 | 2007-09-18 | Tokyo Electron Limited | Method for increasing deposition rates of metal layers from metal-carbonyl precursors |

| US7279421B2 (en) * | 2004-11-23 | 2007-10-09 | Tokyo Electron Limited | Method and deposition system for increasing deposition rates of metal layers from metal-carbonyl precursors |

| US7442267B1 (en) * | 2004-11-29 | 2008-10-28 | Novellus Systems, Inc. | Anneal of ruthenium seed layer to improve copper plating |

| US7064043B1 (en) * | 2004-12-09 | 2006-06-20 | Texas Instruments Incorporated | Wafer bonded MOS decoupling capacitor |

| US7312139B2 (en) * | 2005-01-03 | 2007-12-25 | United Microelectronics Corp. | Method of fabricating nitrogen-containing gate dielectric layer and semiconductor device |

| US7316962B2 (en) * | 2005-01-07 | 2008-01-08 | Infineon Technologies Ag | High dielectric constant materials |

| EP1853745A2 (en) * | 2005-01-27 | 2007-11-14 | Applied Materials, Inc. | Ruthenium layer deposition apparatus and method |

| JP2006245558A (ja) * | 2005-02-04 | 2006-09-14 | Advanced Lcd Technologies Development Center Co Ltd | 銅配線層、銅配線層の形成方法、半導体装置、及び半導体装置の製造方法 |

| US7498247B2 (en) * | 2005-02-23 | 2009-03-03 | Micron Technology, Inc. | Atomic layer deposition of Hf3N4/HfO2 films as gate dielectrics |

| US7432139B2 (en) * | 2005-06-29 | 2008-10-07 | Amberwave Systems Corp. | Methods for forming dielectrics and metal electrodes |

| US20070077750A1 (en) * | 2005-09-06 | 2007-04-05 | Paul Ma | Atomic layer deposition processes for ruthenium materials |

| US7456102B1 (en) * | 2005-10-11 | 2008-11-25 | Novellus Systems, Inc. | Electroless copper fill process |

| JP2010507263A (ja) * | 2006-10-17 | 2010-03-04 | エントン インコーポレイテッド | 超小型電子デバイスの製造におけるフィチャーを埋め込むための銅堆積 |

| US20080296768A1 (en) * | 2006-12-14 | 2008-12-04 | Chebiam Ramanan V | Copper nucleation in interconnects having ruthenium layers |

| JP4397399B2 (ja) * | 2007-02-15 | 2010-01-13 | 富士通株式会社 | 半導体装置の製造方法 |

| US7470617B2 (en) * | 2007-03-01 | 2008-12-30 | Intel Corporation | Treating a liner layer to reduce surface oxides |

| US7799684B1 (en) * | 2007-03-05 | 2010-09-21 | Novellus Systems, Inc. | Two step process for uniform across wafer deposition and void free filling on ruthenium coated wafers |

| US20080242088A1 (en) * | 2007-03-29 | 2008-10-02 | Tokyo Electron Limited | Method of forming low resistivity copper film structures |

| US8058164B2 (en) * | 2007-06-04 | 2011-11-15 | Lam Research Corporation | Methods of fabricating electronic devices using direct copper plating |

| US20090020434A1 (en) * | 2007-07-02 | 2009-01-22 | Akira Susaki | Substrate processing method and substrate processing apparatus |

| JP2009099585A (ja) * | 2007-10-12 | 2009-05-07 | Panasonic Corp | 埋め込み配線の形成方法 |

| US7964506B1 (en) * | 2008-03-06 | 2011-06-21 | Novellus Systems, Inc. | Two step copper electroplating process with anneal for uniform across wafer deposition and void free filling on ruthenium coated wafers |

| US8247030B2 (en) * | 2008-03-07 | 2012-08-21 | Tokyo Electron Limited | Void-free copper filling of recessed features using a smooth non-agglomerated copper seed layer |

-

2009

- 2009-09-30 US US12/571,162 patent/US8076241B2/en active Active

-

2010

- 2010-09-29 TW TW099133025A patent/TW201113934A/zh unknown

- 2010-09-30 KR KR1020127010660A patent/KR20120082901A/ko not_active Ceased

- 2010-09-30 JP JP2012532310A patent/JP2013507008A/ja active Pending

- 2010-09-30 WO PCT/US2010/050878 patent/WO2011041522A2/en not_active Ceased

- 2010-09-30 CN CN2010800536818A patent/CN102859035A/zh active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| US8076241B2 (en) | 2011-12-13 |

| TW201113934A (en) | 2011-04-16 |

| JP2013507008A (ja) | 2013-02-28 |

| CN102859035A (zh) | 2013-01-02 |

| WO2011041522A3 (en) | 2012-01-05 |

| WO2011041522A2 (en) | 2011-04-07 |

| US20110076390A1 (en) | 2011-03-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8076241B2 (en) | Methods for multi-step copper plating on a continuous ruthenium film in recessed features | |

| CN101981686B (zh) | 用于将选择性的低温钌沉积集成到半导体器件的铜金属化中的方法 | |

| JP2013507008A5 (enExample) | ||

| JP5674669B2 (ja) | ルテニウム金属キャップ層を形成する方法 | |

| US7838441B2 (en) | Deposition and densification process for titanium nitride barrier layers | |

| US20120252210A1 (en) | Method for modifying metal cap layers in semiconductor devices | |

| US6645847B2 (en) | Microelectronic interconnect material with adhesion promotion layer and fabrication method | |

| US10784157B2 (en) | Doped tantalum nitride for copper barrier applications | |

| US7829454B2 (en) | Method for integrating selective ruthenium deposition into manufacturing of a semiconductior device | |

| US7704879B2 (en) | Method of forming low-resistivity recessed features in copper metallization | |

| US20100151676A1 (en) | Densification process for titanium nitride layer for submicron applications | |

| US7713876B2 (en) | Method for integrating a ruthenium layer with bulk copper in copper metallization | |

| US20090209101A1 (en) | Ruthenium alloy film for copper interconnects | |

| US7473634B2 (en) | Method for integrated substrate processing in copper metallization | |

| WO2009109934A1 (en) | Void-free copper filling of recessed features using a smooth non-agglomerated copper seed layer | |

| WO2007117802A2 (en) | Method for integrating a conformal ruthenium layer into copper metallization of high aspect ratio features | |

| US20070069383A1 (en) | Semiconductor device containing a ruthenium diffusion barrier and method of forming | |

| JP2002280387A (ja) | 半導体素子の金属配線形成方法 | |

| JP4065351B2 (ja) | 欠陥密度の低いTi−Si−N及びTi−B−Nベースの絶縁保護性障壁膜の製法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20120425 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20150810 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20160618 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20160903 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20160618 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |