JP5238687B2 - 被覆物 - Google Patents

被覆物Info

- Publication number

- JP5238687B2 JP5238687B2 JP2009505793A JP2009505793A JP5238687B2 JP 5238687 B2 JP5238687 B2 JP 5238687B2 JP 2009505793 A JP2009505793 A JP 2009505793A JP 2009505793 A JP2009505793 A JP 2009505793A JP 5238687 B2 JP5238687 B2 JP 5238687B2

- Authority

- JP

- Japan

- Prior art keywords

- layer

- hard material

- material layer

- atomic

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000576 coating method Methods 0.000 title claims description 46

- 239000011248 coating agent Substances 0.000 title claims description 41

- 239000000463 material Substances 0.000 claims abstract description 110

- 239000000758 substrate Substances 0.000 claims abstract description 60

- 229910052751 metal Inorganic materials 0.000 claims abstract description 47

- 229910052782 aluminium Inorganic materials 0.000 claims abstract description 44

- 229910052710 silicon Inorganic materials 0.000 claims abstract description 39

- 238000000034 method Methods 0.000 claims abstract description 38

- 229910052804 chromium Inorganic materials 0.000 claims abstract description 37

- 229910052760 oxygen Inorganic materials 0.000 claims abstract description 34

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims abstract description 31

- 239000001301 oxygen Substances 0.000 claims abstract description 31

- 229910052757 nitrogen Inorganic materials 0.000 claims abstract description 30

- 229910052799 carbon Inorganic materials 0.000 claims abstract description 10

- 239000010410 layer Substances 0.000 claims description 210

- 239000012790 adhesive layer Substances 0.000 claims description 43

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 37

- 239000000203 mixture Substances 0.000 claims description 28

- 230000007704 transition Effects 0.000 claims description 24

- 238000001755 magnetron sputter deposition Methods 0.000 claims description 18

- 239000002184 metal Substances 0.000 claims description 17

- 238000005520 cutting process Methods 0.000 claims description 8

- 230000000737 periodic effect Effects 0.000 claims description 6

- 229910052755 nonmetal Inorganic materials 0.000 claims description 3

- 239000000314 lubricant Substances 0.000 claims description 2

- 238000005477 sputtering target Methods 0.000 claims description 2

- 239000012791 sliding layer Substances 0.000 claims 1

- 229910052796 boron Inorganic materials 0.000 abstract description 4

- 238000000889 atomisation Methods 0.000 abstract 1

- 239000011651 chromium Substances 0.000 description 47

- 239000012071 phase Substances 0.000 description 34

- 239000007789 gas Substances 0.000 description 15

- 238000005240 physical vapour deposition Methods 0.000 description 15

- 229910045601 alloy Inorganic materials 0.000 description 11

- 239000000956 alloy Substances 0.000 description 11

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 10

- 239000013078 crystal Substances 0.000 description 10

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 9

- 239000012535 impurity Substances 0.000 description 8

- 239000012495 reaction gas Substances 0.000 description 8

- 238000001228 spectrum Methods 0.000 description 8

- 238000004544 sputter deposition Methods 0.000 description 8

- 239000013077 target material Substances 0.000 description 8

- 230000015572 biosynthetic process Effects 0.000 description 7

- 150000002500 ions Chemical class 0.000 description 7

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 6

- 150000001875 compounds Chemical class 0.000 description 6

- 238000000168 high power impulse magnetron sputter deposition Methods 0.000 description 6

- 229910052786 argon Inorganic materials 0.000 description 5

- 230000008020 evaporation Effects 0.000 description 5

- 238000001704 evaporation Methods 0.000 description 5

- 150000004767 nitrides Chemical class 0.000 description 5

- 230000001590 oxidative effect Effects 0.000 description 5

- 229910018557 Si O Inorganic materials 0.000 description 4

- 238000006243 chemical reaction Methods 0.000 description 4

- 230000000052 comparative effect Effects 0.000 description 4

- 150000002739 metals Chemical class 0.000 description 4

- LIVNPJMFVYWSIS-UHFFFAOYSA-N silicon monoxide Inorganic materials [Si-]#[O+] LIVNPJMFVYWSIS-UHFFFAOYSA-N 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 238000000151 deposition Methods 0.000 description 3

- 238000011049 filling Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000008018 melting Effects 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 231100000572 poisoning Toxicity 0.000 description 3

- 230000000607 poisoning effect Effects 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 239000010936 titanium Substances 0.000 description 3

- 229910052719 titanium Inorganic materials 0.000 description 3

- 229910006360 Si—O—N Inorganic materials 0.000 description 2

- 229910010038 TiAl Inorganic materials 0.000 description 2

- 229910021417 amorphous silicon Inorganic materials 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 230000008021 deposition Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000010891 electric arc Methods 0.000 description 2

- 230000003628 erosive effect Effects 0.000 description 2

- 238000002474 experimental method Methods 0.000 description 2

- -1 for example Inorganic materials 0.000 description 2

- 238000010849 ion bombardment Methods 0.000 description 2

- 239000007791 liquid phase Substances 0.000 description 2

- 229910052756 noble gas Inorganic materials 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 230000002829 reductive effect Effects 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 229910021364 Al-Si alloy Inorganic materials 0.000 description 1

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- 229910019819 Cr—Si Inorganic materials 0.000 description 1

- MYMOFIZGZYHOMD-UHFFFAOYSA-N Dioxygen Chemical compound O=O MYMOFIZGZYHOMD-UHFFFAOYSA-N 0.000 description 1

- 229910007991 Si-N Inorganic materials 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 229910006294 Si—N Inorganic materials 0.000 description 1

- 229910010037 TiAlN Inorganic materials 0.000 description 1

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 229910001315 Tool steel Inorganic materials 0.000 description 1

- 229910009043 WC-Co Inorganic materials 0.000 description 1

- 238000002441 X-ray diffraction Methods 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000008186 active pharmaceutical agent Substances 0.000 description 1

- 238000007792 addition Methods 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 125000004429 atom Chemical group 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000002939 deleterious effect Effects 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 229910001882 dioxygen Inorganic materials 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 150000004820 halides Chemical class 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 238000007733 ion plating Methods 0.000 description 1

- 229910052743 krypton Inorganic materials 0.000 description 1

- DNNSSWSSYDEUBZ-UHFFFAOYSA-N krypton atom Chemical compound [Kr] DNNSSWSSYDEUBZ-UHFFFAOYSA-N 0.000 description 1

- 239000002346 layers by function Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 229910052752 metalloid Inorganic materials 0.000 description 1

- 150000002738 metalloids Chemical class 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 239000012768 molten material Substances 0.000 description 1

- 229940110728 nitrogen / oxygen Drugs 0.000 description 1

- 150000002843 nonmetals Chemical class 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 238000001020 plasma etching Methods 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 239000007790 solid phase Substances 0.000 description 1

- 238000002230 thermal chemical vapour deposition Methods 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

- 229910052723 transition metal Inorganic materials 0.000 description 1

- 150000003624 transition metals Chemical class 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- 239000011882 ultra-fine particle Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/08—Oxides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0641—Nitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0676—Oxynitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/35—Sputtering by application of a magnetic field, e.g. magnetron sputtering

- C23C14/352—Sputtering by application of a magnetic field, e.g. magnetron sputtering using more than one target

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/04—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings of inorganic non-metallic material

- C23C28/042—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings of inorganic non-metallic material including a refractory ceramic layer, e.g. refractory metal oxides, ZrO2, rare earth oxides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/04—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings of inorganic non-metallic material

- C23C28/044—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings of inorganic non-metallic material coatings specially adapted for cutting tools or wear applications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/04—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings of inorganic non-metallic material

- C23C28/048—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings of inorganic non-metallic material with layers graded in composition or physical properties

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/40—Coatings including alternating layers following a pattern, a periodic or defined repetition

- C23C28/42—Coatings including alternating layers following a pattern, a periodic or defined repetition characterized by the composition of the alternating layers

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C30/00—Coating with metallic material characterised only by the composition of the metallic material, i.e. not characterised by the coating process

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C30/00—Coating with metallic material characterised only by the composition of the metallic material, i.e. not characterised by the coating process

- C23C30/005—Coating with metallic material characterised only by the composition of the metallic material, i.e. not characterised by the coating process on hard metal substrates

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/34—Gas-filled discharge tubes operating with cathodic sputtering

- H01J37/3464—Operating strategies

- H01J37/3467—Pulsed operation, e.g. HIPIMS

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Metallurgy (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Analytical Chemistry (AREA)

- Physical Vapour Deposition (AREA)

- Cutting Tools, Boring Holders, And Turrets (AREA)

Description

硬質合金工具の上に、Al−Cr−Si−窒化物接着層およびAl−Cr−Si−酸窒化物移行層を備えたAl−Cr−Si−酸化物層をPVD法により堆積させる。

nmである。作成された層の硬度は、約2400HVである。XRDスペクトルでは、(Al、Cr)2O3または(Al、Cr、Si)2O3置換混晶のガンマ相が特に示された。

実施例1においてと本質的に同様のパラメーターに調節したが、ターゲットは、ケイ素を包含せず、Cr−充填物を備えた純粋なアルミニウムからなる。パラメーターを、変化したターゲットに関連して、僅かに調整した。被覆時間を、実施例1においてと同様の層厚が生じるように選択した。

実施例1においてと本質的に同様のパラメーターに調節するが、ターゲットは、アルミニウムのみからなる。パラメーターを、変化したターゲットに関連して、僅かに調整した。被覆時間を、実施例1においてと同様の層厚が生じるように選択した。硬度は、僅か1200HVであった。Al2O3の結晶相は、見つけられないか、暗にしか見つけられなかった。

12 被覆室

16 陰極

18 基板ホルダー

20 回転基板テーブル

24 ガス入口

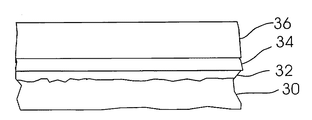

30 基材

32 接着層

34 勾配移行層

36 硬質材料層

36a Crの乏しい硬質材料層

36b Crの豊富な硬質材料層

Claims (19)

- 基材と、

該基材に施与されている硬質材料層とを備え、

マグネトロンスパッタリングにより堆積された該硬材料層で少なくとも部分的に被覆された物であって、

前記硬質材料層が、金属元素Al、CrおよびSiと、B、C、N、Oの群から選択される非金属元素とを含有し、

前記非金属元素中の酸素の原子割合が、30%よりも高いことを特徴とする物。 - 前記非金属元素中の酸素の前記原子割合が、70%よりも高いことを特徴とする請求項1に記載の物。

- 前記非金属元素中の酸素の前記原子割合が、ほぼ100%であることを特徴とする請求項2に記載の物。

- 前記硬質材料層中の前記金属元素Al、CrおよびSiが、式AlxCrySizの組成を有し、ここで、x、yおよびzは、前記3種の元素の割合を相互に原子パーセントで示しており、x、y、zは、条件

x=100%−y−z、

1%≦y≦70%および

0.1%≦z≦20%

を満たしていることを特徴とする請求項1から3のいずれか一項に記載の物。 - 前記硬質材料層において、Al、Cr、Siの群からなる前記金属元素の原子割合が、全部で50原子%よりも高く、さらに好ましくは80原子%よりも高く、特に好ましくはほぼ100原子%であることを特徴とする請求項1から4のいずれか一項に記載の物。

- 前記基材および前記硬質材料層の間に、Al、SiおよびIUPAC(1988年)による周期律表の第4から6族の元素から選択された元素と、B、C、N、Oの群からなる非金属元素から選択された元素とから組成されている接着層が存在することを特徴とする請求項1から5のいずれか一項に記載の物。

- 前記接着層の前記金属元素が、前記硬質材料層の前記金属元素の群から選択されていて、前記接着層中の前記非金属元素中のNの原子割合が、前記硬質材料層においてよりも高いことを特徴とする請求項6に記載の物。

- 前記硬質材料層および前記接着層の間に、前記硬質材料層および接着層を形成する元素から選択された元素で組成されている移行層が存在することを特徴とする請求項6又は7のいずれか一項に記載の物。

- 前記移行層は、層を横断する方向に沿って少なくとも1種の元素の濃度が連続的に変化しており、その元素の前記濃度が、前記硬質材料層との境界のところでは、前記硬質材料層での濃度と本質的に等しくなっていて、前記接着層との境界のところでは、前記接着層での濃度と本質的に等しくなっていることを特徴とする請求項8に記載の物。

- 前記硬質材料層が、本質的にAl、Cr、SiおよびOからなり、前記接着層がAl、Cr、SiおよびNからなることを特徴とする請求項6から9のいずれか一項に記載の物。

- 前記接着層が、(Al、Cr、Si)Nからなることを特徴とする請求項6から10のいずれか一項に記載の物。

- 前記硬質材料層が、いちばん外側の層であるか、又は着色層、滑り層またはドライ潤滑剤層が施与されている場合、これらの層の下の最終層であることを特徴とする請求項1か ら11のいずれか一項に記載の物。

- 前記接着層、移行層および硬質材料層の連続からなる多層被覆を有することを特徴とする請求項1から12のいずれか一項に記載の物。

- 切削のための切断工具であることを特徴とする請求項1から13のいずれか一項に記載の物。

- 前記硬質材料層は、前記非金属中の窒素割合が、10原子%〜70原子%の範囲であることを特徴とする請求項1から14のいずれか一項に記載の物。

- 硬質材料層を基材上に作成する方法であって、

マグネトロンスパッタリングにより、硬質材料層を前記基材上に堆積させ、

前記硬質材料層が、金属元素Al、CrおよびSiと、B、C、N、Oの群から選択される非金属元素とを含有し、

前記非金属元素中の酸素の原子割合が、30%よりも高い方法。 - 前記硬質材料層を、高出力パルスマグネトロンスパッタリングで施与する請求項16に 記載の方法。

- 前記高出力パルスマグネトロンスパッタリングは、スパッタリングターゲットにより5 00〜5000W/cm 2 の出力密度に達する高い出力を有する請求項17に記載の方法 。

- 前記高出力パルスマグネトロンスパッタリングは、サイクル時間の最大20%のパルス を印加する請求項17または18に記載の方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006019055.6 | 2006-04-21 | ||

| DE102006019055 | 2006-04-21 | ||

| PCT/EP2007/003509 WO2007121954A1 (de) | 2006-04-21 | 2007-04-20 | Beschichteter körper |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009534524A JP2009534524A (ja) | 2009-09-24 |

| JP2009534524A5 JP2009534524A5 (ja) | 2010-05-20 |

| JP5238687B2 true JP5238687B2 (ja) | 2013-07-17 |

Family

ID=38255331

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009505793A Active JP5238687B2 (ja) | 2006-04-21 | 2007-04-20 | 被覆物 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8173278B2 (ja) |

| EP (1) | EP2010691B1 (ja) |

| JP (1) | JP5238687B2 (ja) |

| CN (1) | CN101426947A (ja) |

| WO (1) | WO2007121954A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190081387A (ko) * | 2017-12-29 | 2019-07-09 | 한국야금 주식회사 | 절삭공구용 경질피막 |

| KR20190081103A (ko) * | 2017-12-29 | 2019-07-09 | (주)서영 | 산소 주입에 의한 CrAlSiON 층이 삽입된 고내식성 CrAlSiN 코팅막의 제조방법 및 그에 따른 다이캐스팅 금형 |

Families Citing this family (44)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5261981B2 (ja) * | 2007-05-17 | 2013-08-14 | 日立ツール株式会社 | 被覆切削工具 |

| JP2009120912A (ja) | 2007-11-15 | 2009-06-04 | Kobe Steel Ltd | 硬質皮膜を備えた耐摩耗性部材 |

| US20090220777A1 (en) * | 2008-03-03 | 2009-09-03 | Martin Sporn | Sputter Deposition Method, Sputter Deposition System and Chip |

| US8691058B2 (en) * | 2008-04-03 | 2014-04-08 | Oerlikon Advanced Technologies Ag | Apparatus for sputtering and a method of fabricating a metallization structure |

| JP4975682B2 (ja) * | 2008-05-21 | 2012-07-11 | 日立ツール株式会社 | 被覆切削工具の製造方法 |

| DE102008028140B3 (de) * | 2008-06-13 | 2009-12-03 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zur Herstellung einer transparenten und leitfähigen Metalloxidschicht durch gepulstes, hochionisierendes Magnetronsputtern |

| ATE535629T1 (de) | 2008-07-29 | 2011-12-15 | Sulzer Metaplas Gmbh | Gepulstes hochleistungs-magnetronsputterverfahren sowie hochleistungs-elektroenergiequelle |

| DE102009001675A1 (de) | 2009-03-19 | 2010-09-23 | Eberhard-Karls-Universität Tübingen | Schneidwerkzeug |

| JP5614405B2 (ja) * | 2009-07-15 | 2014-10-29 | 日立ツール株式会社 | 硬質皮膜被覆工具及びその製造方法 |

| CN102791409B (zh) * | 2009-11-12 | 2015-12-16 | Osg株式会社 | 硬质被膜及硬质被膜被覆工具 |

| EP2514552A4 (en) | 2009-12-17 | 2017-04-05 | Sumitomo Electric Industries, Ltd. | Coated rotary tool |

| DE102010011694B4 (de) * | 2010-03-17 | 2013-09-19 | Karlsruher Institut für Technologie | Hexagonaler Mischkristall aus einem Al-Cr-O-N Stoffsystem |

| JP5333418B2 (ja) * | 2010-03-31 | 2013-11-06 | 日立ツール株式会社 | 硬質皮膜被覆工具の製造方法 |

| CN102595833A (zh) * | 2011-01-05 | 2012-07-18 | 鸿富锦精密工业(深圳)有限公司 | 铝或铝合金的壳体及其制造方法 |

| WO2012095994A1 (ja) * | 2011-01-14 | 2012-07-19 | 日立ツール株式会社 | 硬質皮膜被覆工具及びその製造方法 |

| JP5660457B2 (ja) * | 2011-01-19 | 2015-01-28 | 日立金属株式会社 | 硬質皮膜被覆金型 |

| CN102650051A (zh) * | 2011-02-25 | 2012-08-29 | 鸿富锦精密工业(深圳)有限公司 | 铝或铝合金的壳体及其制造方法 |

| CN102676989A (zh) * | 2011-03-11 | 2012-09-19 | 鸿富锦精密工业(深圳)有限公司 | 镀膜件及其制备方法 |

| BR112013026914A2 (pt) * | 2011-04-20 | 2018-02-14 | Oerlikon Trading Ag | método de bombardeio de magnetrão de impulso de energia alta provendo ionização intensificada das partículas bombardeadas e aparelho para sua implementação |

| WO2012146311A1 (en) * | 2011-04-29 | 2012-11-01 | Istanbul Teknik Universitesi | Method for modifying and alloying surfaces of wc based hard metal structures |

| BRPI1102335A2 (pt) * | 2011-05-27 | 2013-06-25 | Mahle Metal Leve Sa | elemento dotado de pelo menos uma superfÍcie de deslizamento com um revestimento para uso em um motor de combustço interna ou em um compressor |

| DE102011053372A1 (de) * | 2011-09-07 | 2013-03-07 | Walter Ag | Werkzeug mit chromhaltiger Funktionsschicht |

| CN102345606A (zh) * | 2011-10-19 | 2012-02-08 | 上海西工压缩机配件有限公司 | 经表面改性的GCr15压缩机叶片及其制备工艺 |

| DE102011116576A1 (de) * | 2011-10-21 | 2013-04-25 | Oerlikon Trading Ag, Trübbach | Bohrer mit Beschichtung |

| WO2013159870A1 (en) * | 2012-04-22 | 2013-10-31 | Oerlikon Trading Ag, Trübbach | Arc-deposited al-cr-o coatings having enhanced coating properties |

| DE102012013577A1 (de) * | 2012-07-10 | 2014-01-16 | Oerlikon Trading Ag, Trübbach | Hochleistungsimpulsbeschichtungsmethode |

| DE102012107163A1 (de) * | 2012-08-03 | 2014-05-15 | INI Coatings Ltd. | Verfahren zur Beschichtung eines Substrats mittels Hochenergieimpulsmagnetronsputtern |

| DE102012017809A1 (de) * | 2012-09-10 | 2014-03-13 | Oerlikon Trading Ag, Trübbach | Verfahren zur Herstellung einer Metallborocarbidschicht auf einem Substrat |

| WO2014123053A1 (ja) * | 2013-02-07 | 2014-08-14 | 三菱重工業株式会社 | 表面被覆材料及びこれを利用する切削工具及び工作機械 |

| EP2977131B1 (en) * | 2013-03-22 | 2019-01-02 | Mitsubishi Materials Corporation | Surface-coated cutting tool |

| JP5742042B2 (ja) * | 2013-10-31 | 2015-07-01 | 住友電工ハードメタル株式会社 | 表面被覆窒化硼素焼結体工具 |

| CN107667185A (zh) | 2015-05-27 | 2018-02-06 | 美国圣戈班性能塑料公司 | 导电薄膜复合材料 |

| DE102015212588A1 (de) * | 2015-07-06 | 2017-01-12 | Oerlikon Surface Solutions Ag, Trübbach | Konturtreue Schutzschicht für Verdichterbauteile von Gasturbinen |

| CN109072409B (zh) * | 2016-02-19 | 2020-09-04 | 瓦尔特公开股份有限公司 | 切削刀具 |

| CN106381471B (zh) * | 2016-09-19 | 2018-11-23 | 中国科学院宁波材料技术与工程研究所 | 一种硬度宽变的耐磨涂层及其制备方法及应用 |

| KR101844687B1 (ko) * | 2016-11-28 | 2018-05-15 | (주)서영 | 내부식 특성이 향상된 고경도 코팅막의 제조방법 |

| CN106987816B (zh) * | 2017-04-06 | 2019-07-02 | 天津职业技术师范大学 | 一种高铝含量超致密Al-Cr-Si-N涂层制备工艺 |

| EP3406761A1 (en) * | 2017-05-24 | 2018-11-28 | Walter Ag | A method for producing a coated cutting tool and a coated cutting tool |

| EP3406751A1 (en) | 2017-05-24 | 2018-11-28 | Walter Ag | A coated cutting tool and a method for its production |

| CN107747093B (zh) * | 2017-10-10 | 2019-10-29 | 岭南师范学院 | 一种柔性硬质复合涂层及其制备方法和涂层刀具 |

| WO2019122229A1 (de) * | 2017-12-22 | 2019-06-27 | Oerlikon Surface Solutions Ag, Pfäffikon | Korrosions- und erosionsbeständige beschichtung für turbinenschaufeln von gasturbinen |

| DE102018211649A1 (de) * | 2018-07-12 | 2020-01-16 | Robert Bosch Gmbh | Verfahren zum Beschichten wenigstens eines metallischen Bauteils |

| WO2020025102A1 (en) * | 2018-07-30 | 2020-02-06 | Applied Materials, Inc. | Method of coating a flexible substrate with a stack of layers, layer stack, and deposition apparatus for coating a flexible substrate with a stack of layers |

| DE102019124616A1 (de) * | 2019-09-12 | 2021-03-18 | Cemecon Ag | Mehrlagige Beschichtung |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE406090B (sv) * | 1977-06-09 | 1979-01-22 | Sandvik Ab | Belagd hardmetallkropp samt sett att framstalla en dylik kropp |

| SE518151C2 (sv) * | 1997-12-10 | 2002-09-03 | Sandvik Ab | Multiskiktbelagt skärverktyg |

| JP2002239810A (ja) | 2001-02-22 | 2002-08-28 | Mmc Kobelco Tool Kk | 切粉に対する表面潤滑性にすぐれた表面被覆超硬合金製切削工具 |

| AU2003227598A1 (en) * | 2002-04-11 | 2003-10-20 | Cemecon Ag | Coated bodies and a method for coating a body |

| JP3697221B2 (ja) * | 2002-05-01 | 2005-09-21 | 三菱重工業株式会社 | 耐高温酸化に優れた高耐摩耗性・高硬度皮膜 |

| JP3640310B2 (ja) * | 2002-11-25 | 2005-04-20 | 日立ツール株式会社 | 硬質皮膜 |

| DK1422311T3 (da) | 2002-11-19 | 2007-06-11 | Hitachi Tool Eng | Hård film og værktöj coatet med hård film |

| JP3669700B2 (ja) * | 2002-11-19 | 2005-07-13 | 日立ツール株式会社 | 硬質皮膜 |

| JP2005126736A (ja) * | 2003-10-21 | 2005-05-19 | Hitachi Tool Engineering Ltd | 硬質皮膜 |

| US6767627B2 (en) * | 2002-12-18 | 2004-07-27 | Kobe Steel, Ltd. | Hard film, wear-resistant object and method of manufacturing wear-resistant object |

| DE10362382B3 (de) | 2002-12-27 | 2017-08-17 | Kabushiki Kaisha Kobe Seiko Sho (Kobe Steel Co., Ltd.) | Harter Überzug mit hervorragender Haftung |

| JP3781374B2 (ja) * | 2003-12-09 | 2006-05-31 | 日立ツール株式会社 | 硬質皮膜被覆工具及びその製造方法 |

| EP1614655B2 (en) * | 2004-06-18 | 2018-08-08 | Hitachi Tool Engineering Ltd. | Hard coating and its production method |

| DE102004044240A1 (de) | 2004-09-14 | 2006-03-30 | Walter Ag | Schneidwerkzeug mit oxidischer Beschichtung |

| JP3934136B2 (ja) * | 2004-11-11 | 2007-06-20 | 日立ツール株式会社 | 硬質皮膜被覆部材及びその被覆方法 |

| US7348074B2 (en) * | 2005-04-01 | 2008-03-25 | Oc Oerlikon Balzers Ag | Multilayer hard coating for tools |

-

2007

- 2007-04-20 WO PCT/EP2007/003509 patent/WO2007121954A1/de active Application Filing

- 2007-04-20 US US12/297,009 patent/US8173278B2/en active Active

- 2007-04-20 EP EP07724445.7A patent/EP2010691B1/de active Active

- 2007-04-20 JP JP2009505793A patent/JP5238687B2/ja active Active

- 2007-04-20 CN CNA2007800143520A patent/CN101426947A/zh active Pending

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190081387A (ko) * | 2017-12-29 | 2019-07-09 | 한국야금 주식회사 | 절삭공구용 경질피막 |

| KR20190081103A (ko) * | 2017-12-29 | 2019-07-09 | (주)서영 | 산소 주입에 의한 CrAlSiON 층이 삽입된 고내식성 CrAlSiN 코팅막의 제조방법 및 그에 따른 다이캐스팅 금형 |

| KR102009688B1 (ko) | 2017-12-29 | 2019-08-12 | 한국야금 주식회사 | 절삭공구용 경질피막 |

| KR102036974B1 (ko) | 2017-12-29 | 2019-11-26 | (주)서영 | 산소 주입에 의한 CrAlSiON 층이 삽입된 고내식성 CrAlSiN 코팅막의 제조방법 및 그에 따른 다이캐스팅 금형 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2010691A1 (de) | 2009-01-07 |

| US20090252973A1 (en) | 2009-10-08 |

| US8173278B2 (en) | 2012-05-08 |

| EP2010691B1 (de) | 2017-12-06 |

| WO2007121954A1 (de) | 2007-11-01 |

| CN101426947A (zh) | 2009-05-06 |

| JP2009534524A (ja) | 2009-09-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5238687B2 (ja) | 被覆物 | |

| JP6854241B2 (ja) | 多層pvdコーティングを有する切削工具 | |

| US8540786B2 (en) | Method for producing PVD coatings | |

| RU2456371C2 (ru) | Слоистая система с по меньшей мере одним слоем смешанных кристаллов многокомпонентного оксида | |

| JP4824173B2 (ja) | Pvd被膜切削工具およびその製造方法 | |

| JP5856148B2 (ja) | 混合結晶層を蒸着するためのpvdハイブリッド法 | |

| JP6428899B2 (ja) | Wc基超硬合金基体の改質方法 | |

| JP5190971B2 (ja) | 被膜、切削工具および被膜の製造方法 | |

| JP2008512261A (ja) | 耐摩耗性被膜を備えた切削工具及びその製造方法 | |

| JP2008512261A6 (ja) | 耐摩耗性被膜を備えた切削工具及びその製造方法 | |

| CN108998758B (zh) | 具有涂层的钻头 | |

| US9822438B2 (en) | Coated cutting tool and method for the production thereof | |

| JP2012505308A (ja) | 非ガンマ相立方晶AlCrO | |

| KR20100049572A (ko) | 코팅된 공구 | |

| US6451180B1 (en) | Method of making a PVD Al2O3 coated cutting tool | |

| JP2008290163A (ja) | 被膜、切削工具および被膜の製造方法 | |

| JP6789503B2 (ja) | 硬質皮膜の成膜方法 | |

| EP3394320B1 (en) | Method of producing a pvd layer and a coated cutting tool | |

| JP6895631B2 (ja) | 硬質皮膜の成膜方法 | |

| JP5580906B2 (ja) | 被膜、切削工具および被膜の製造方法 | |

| US9126273B2 (en) | Tool for the cutting machining of workpieces and process for coating substrate bodies | |

| JP2004230515A (ja) | 高機能加工用工具 | |

| JP5186631B2 (ja) | 被膜、切削工具および被膜の製造方法 | |

| JP2019131861A (ja) | 硬質皮膜、硬質皮膜被覆工具及びその製造方法 | |

| JP5229826B2 (ja) | 被膜、切削工具および被膜の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100402 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100402 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121002 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121228 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121228 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130312 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130401 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5238687 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160405 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |