JP4688890B2 - マンガン含有量の多い軽量鋼を製造するための方法及び設備 - Google Patents

マンガン含有量の多い軽量鋼を製造するための方法及び設備 Download PDFInfo

- Publication number

- JP4688890B2 JP4688890B2 JP2007557433A JP2007557433A JP4688890B2 JP 4688890 B2 JP4688890 B2 JP 4688890B2 JP 2007557433 A JP2007557433 A JP 2007557433A JP 2007557433 A JP2007557433 A JP 2007557433A JP 4688890 B2 JP4688890 B2 JP 4688890B2

- Authority

- JP

- Japan

- Prior art keywords

- bloom

- casting powder

- casting

- sio

- steel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 229910000831 Steel Inorganic materials 0.000 title claims description 32

- 239000010959 steel Substances 0.000 title claims description 32

- 238000000034 method Methods 0.000 title claims description 30

- 239000011572 manganese Substances 0.000 title claims description 22

- 229910052748 manganese Inorganic materials 0.000 title claims description 17

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 title claims description 12

- 238000005266 casting Methods 0.000 claims description 32

- 239000000843 powder Substances 0.000 claims description 24

- 229910052782 aluminium Inorganic materials 0.000 claims description 16

- 229910004298 SiO 2 Inorganic materials 0.000 claims description 15

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 12

- 238000007711 solidification Methods 0.000 claims description 10

- 230000008023 solidification Effects 0.000 claims description 10

- 229910052710 silicon Inorganic materials 0.000 claims description 7

- 229910018072 Al 2 O 3 Inorganic materials 0.000 claims description 6

- 238000009749 continuous casting Methods 0.000 claims description 6

- 238000001816 cooling Methods 0.000 claims description 6

- 238000004519 manufacturing process Methods 0.000 claims description 6

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 5

- 239000000203 mixture Substances 0.000 claims description 5

- 229910052799 carbon Inorganic materials 0.000 claims description 4

- 238000005096 rolling process Methods 0.000 claims description 4

- 239000000126 substance Substances 0.000 claims description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 3

- 239000010703 silicon Substances 0.000 claims description 3

- BTBUEUYNUDRHOZ-UHFFFAOYSA-N Borate Chemical compound [O-]B([O-])[O-] BTBUEUYNUDRHOZ-UHFFFAOYSA-N 0.000 claims description 2

- 229910010413 TiO 2 Inorganic materials 0.000 claims description 2

- 229910052742 iron Inorganic materials 0.000 claims description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 claims 2

- 229910018068 Li 2 O Inorganic materials 0.000 claims 1

- 239000012535 impurity Substances 0.000 claims 1

- 239000004615 ingredient Substances 0.000 claims 1

- 238000006722 reduction reaction Methods 0.000 claims 1

- 238000005098 hot rolling Methods 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 4

- 230000007423 decrease Effects 0.000 description 3

- 239000002893 slag Substances 0.000 description 3

- 239000000956 alloy Substances 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 238000005275 alloying Methods 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005336 cracking Methods 0.000 description 2

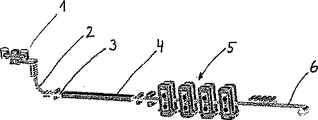

- 238000010586 diagram Methods 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 229910052698 phosphorus Inorganic materials 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 229910000914 Mn alloy Inorganic materials 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000005097 cold rolling Methods 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000011573 trace mineral Substances 0.000 description 1

- 235000013619 trace mineral Nutrition 0.000 description 1

- 229910052720 vanadium Inorganic materials 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B1/00—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations

- B21B1/46—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling metal immediately subsequent to continuous casting

- B21B1/466—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling metal immediately subsequent to continuous casting in a non-continuous process, i.e. the cast being cut before rolling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B3/00—Rolling materials of special alloys so far as the composition of the alloy requires or permits special rolling methods or sequences ; Rolling of aluminium, copper, zinc or other non-ferrous metals

- B21B3/02—Rolling special iron alloys, e.g. stainless steel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/10—Supplying or treating molten metal

- B22D11/11—Treating the molten metal

- B22D11/111—Treating the molten metal by using protecting powders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/12—Accessories for subsequent treating or working cast stock in situ

- B22D11/1213—Accessories for subsequent treating or working cast stock in situ for heating or insulating strands

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/14—Plants for continuous casting

- B22D11/142—Plants for continuous casting for curved casting

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/005—Heat treatment of ferrous alloys containing Mn

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/021—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips involving a particular fabrication or treatment of ingot or slab

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/021—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips involving a particular fabrication or treatment of ingot or slab

- C21D8/0215—Rapid solidification; Thin strip casting

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Metal Rolling (AREA)

- Continuous Casting (AREA)

- Heat Treatment Of Steel (AREA)

- Treatment Of Steel In Its Molten State (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102005010243.3 | 2005-03-05 | ||

| DE102005010243A DE102005010243A1 (de) | 2005-03-05 | 2005-03-05 | Verfahren und Anlage zur Herstellung eines Leichtbaustahls mit einem hohen Mangan-Gehalt |

| PCT/EP2006/001954 WO2006094718A1 (de) | 2005-03-05 | 2006-03-03 | Verfahren und anlage zur herstellung eines leichtbaustahls mit einem hohe mangan-gehalt |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008531292A JP2008531292A (ja) | 2008-08-14 |

| JP2008531292A5 JP2008531292A5 (de) | 2009-03-19 |

| JP4688890B2 true JP4688890B2 (ja) | 2011-05-25 |

Family

ID=36218445

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007557433A Expired - Fee Related JP4688890B2 (ja) | 2005-03-05 | 2006-03-03 | マンガン含有量の多い軽量鋼を製造するための方法及び設備 |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US20080164003A1 (de) |

| EP (1) | EP1725347B1 (de) |

| JP (1) | JP4688890B2 (de) |

| KR (1) | KR101153735B1 (de) |

| CN (1) | CN101160183B (de) |

| CA (1) | CA2560681A1 (de) |

| DE (1) | DE102005010243A1 (de) |

| RU (1) | RU2335358C2 (de) |

| TW (1) | TW200700566A (de) |

| UA (1) | UA80237C2 (de) |

| WO (1) | WO2006094718A1 (de) |

| ZA (1) | ZA200607920B (de) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008005806A1 (de) * | 2008-01-17 | 2009-09-10 | Technische Universität Bergakademie Freiberg | Bauteile aus hochmanganhaltigem, festem und zähem Stahlformguss, Verfahren zu deren Herstellung sowie deren Verwendung |

| KR20100108610A (ko) * | 2008-01-30 | 2010-10-07 | 코루스 스타알 베.뷔. | 열간-압연 twip-강의 제조 방법 및 이에 의해 제조된 twip-강 제품 |

| CN101543837B (zh) * | 2008-03-24 | 2012-02-29 | 宝山钢铁股份有限公司 | 一种Fe-Mn-C系高锰钢薄带连铸连轧制造方法 |

| DE102009030324A1 (de) * | 2009-06-24 | 2011-01-05 | Voestalpine Stahl Gmbh | Manganstahl und Verfahren zur Herstellung desselben |

| DE102010034161B4 (de) * | 2010-03-16 | 2014-01-02 | Salzgitter Flachstahl Gmbh | Verfahren zur Herstellung von Werkstücken aus Leichtbaustahl mit über die Wanddicke einstellbaren Werkstoffeigenschaften |

| CN104328360B (zh) * | 2014-11-20 | 2017-02-22 | 北京科技大学 | 双相孪生诱导塑性超高强度汽车钢板及其制备工艺 |

| CN104711494B (zh) * | 2015-04-14 | 2017-11-28 | 钢铁研究总院 | 低密度高塑性NiAl增强超高强度钢及制备方法 |

| CN106480366A (zh) * | 2015-08-31 | 2017-03-08 | 鞍钢股份有限公司 | 一种高等轴晶率高锰钢钢锭及其冶炼方法 |

| CN106653127B (zh) * | 2015-10-28 | 2018-03-23 | 丹阳市龙鑫合金有限公司 | 一种acp1000核电站用抗振条组件及其生产方法 |

| CN106624603A (zh) * | 2015-10-28 | 2017-05-10 | 丹阳市龙鑫合金有限公司 | Acp1000抗振条组件及其生产方法 |

| CN106653128B (zh) * | 2015-10-28 | 2018-03-23 | 丹阳市龙鑫合金有限公司 | Acp1000核电站用抗振条组件及其生产方法 |

| CN106624601A (zh) * | 2015-10-28 | 2017-05-10 | 丹阳市龙鑫合金有限公司 | 一种核电站用抗振条组件及其生产方法 |

| CN106624602A (zh) * | 2015-10-28 | 2017-05-10 | 丹阳市龙鑫合金有限公司 | 水堆核电站acp1000用抗振条组件及其生产方法 |

| CN106271449A (zh) * | 2016-08-31 | 2017-01-04 | 云南德胜钢铁有限公司 | 一种采用钢坯生产细晶粒盘螺钢筋的工艺 |

| CN110238203A (zh) * | 2019-06-13 | 2019-09-17 | 首钢集团有限公司 | 一种消除热轧工具钢边部翘皮的方法 |

| CN110819908B (zh) * | 2019-11-18 | 2021-03-23 | 燕山大学 | 一种高强低密度奥氏体钢及其制备方法 |

| CN112391571A (zh) * | 2020-11-25 | 2021-02-23 | 攀钢集团西昌钢钒有限公司 | 一种高强高铝高锰钢洁净度的控制方法 |

| CN112760568B (zh) * | 2020-12-25 | 2022-02-25 | 钢铁研究总院 | 一种高强度高塑性低密度钢及其制备方法 |

| CN115106490B (zh) * | 2021-03-19 | 2024-06-04 | 宝山钢铁股份有限公司 | 连铸生产用中空颗粒型开浇渣及其制备方法 |

| CN115058661A (zh) * | 2022-06-17 | 2022-09-16 | 湖南华菱涟源钢铁有限公司 | 一种高碳高锰钢板及其生产方法 |

| CN116287975A (zh) * | 2023-01-09 | 2023-06-23 | 鞍钢股份有限公司 | 一种高熵钢及制造方法 |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6310052A (ja) * | 1986-06-30 | 1988-01-16 | Nisshin Steel Co Ltd | 含Al溶鋼の連続鋳造法 |

| JPH0377753A (ja) * | 1989-08-14 | 1991-04-03 | Nippon Steel Corp | 高アルミニウム含有鋼の鋳造用パウダー及び鋳造法 |

| JPH06238410A (ja) * | 1993-02-16 | 1994-08-30 | Voest Alpine Ind Anlagen Gmbh | ストリップ、ストリップ用素材またはスラブの製造法および製造装置 |

| JPH0976049A (ja) * | 1995-09-14 | 1997-03-25 | Nippon Yakin Kogyo Co Ltd | 含a1溶鋼連続鋳造用フラックス及び連続鋳造方法 |

| JPH10296318A (ja) * | 1997-03-24 | 1998-11-10 | Sms Schloeman Siemag Ag | 連続鋳造されたスラブから熱間広幅ストリップを圧延するための方法および設備 |

| JPH1177102A (ja) * | 1997-06-16 | 1999-03-23 | Sms Schloeman Siemag Ag | Cps−設備により幅広ホットストリップを圧延するための方法および圧延設備 |

| JPH11226712A (ja) * | 1998-02-10 | 1999-08-24 | Kawasaki Steel Corp | 高Al含有鋼鋳造用モールドパウダー |

| WO2000033992A1 (fr) * | 1998-12-08 | 2000-06-15 | Shinagawa Refractories Co., Ltd. | Poudre pour moulage d'acier par coulee continue et procede de moulage par coulee continue |

| JP2002507251A (ja) * | 1997-07-01 | 2002-03-05 | フロムマイヤー,ゲオルク | 軽量構造用鋼およびその使用 |

| JP2002172401A (ja) * | 2000-09-29 | 2002-06-18 | Kawasaki Heavy Ind Ltd | 連続鋳造熱延設備および連続鋳造熱延方法 |

| JP2002346708A (ja) * | 2001-05-28 | 2002-12-04 | Sumitomo Metal Ind Ltd | 連続鋳造用モールドパウダ |

| JP2003053496A (ja) * | 2001-08-07 | 2003-02-26 | Sanyo Special Steel Co Ltd | アルミニウム含有鋼の連続鋳造用モールドパウダー |

| JP2004515362A (ja) * | 2000-12-06 | 2004-05-27 | ティッセンクルップ シュタール アクチェンゲゼルシャフト | 高いマンガン含有量を有する鋼からの熱間ストリップの製造方法 |

| JP2004521192A (ja) * | 2001-06-13 | 2004-07-15 | ティッセンクルップ シュタール アクチェンゲゼルシャフト | 冷間成形用高強度鋼および鋼帯もしくは鋼板、鋼帯の製造方法および鋼の製造方法 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4235632A (en) * | 1979-04-04 | 1980-11-25 | Mobay Chemical Corporation | Particulate slagging composition for the extended optimum continuous casting of steel |

| DE3837642A1 (de) * | 1988-11-05 | 1990-05-17 | Schloemann Siemag Ag | Verfahren und vorrichtung zur herstellung von warmgewalzten stahlbaendern |

| DE3839954A1 (de) * | 1988-11-26 | 1990-05-31 | Schloemann Siemag Ag | Anlage zur herstellung von warmgewalztem stahlband |

| DE4234733A1 (de) * | 1992-10-15 | 1994-04-21 | Schloemann Siemag Ag | Ausgleichs- und/oder Speicherofen einer CSP-Anlage |

| DE19814223A1 (de) * | 1998-03-31 | 1999-10-07 | Schloemann Siemag Ag | Verfahren zur Herstellung von mikrolegierten Baustählen |

| DE10047044A1 (de) * | 2000-09-22 | 2002-04-25 | Sms Demag Ag | Verfahren und Anlagen zum Herstellen von Bändern und Blechen aus Stahl |

-

2005

- 2005-03-05 DE DE102005010243A patent/DE102005010243A1/de not_active Withdrawn

-

2006

- 2006-03-03 RU RU2006136036/02A patent/RU2335358C2/ru not_active IP Right Cessation

- 2006-03-03 EP EP06723198A patent/EP1725347B1/de active Active

- 2006-03-03 WO PCT/EP2006/001954 patent/WO2006094718A1/de active Application Filing

- 2006-03-03 KR KR1020067018434A patent/KR101153735B1/ko not_active IP Right Cessation

- 2006-03-03 CN CN2006800071903A patent/CN101160183B/zh not_active Expired - Fee Related

- 2006-03-03 US US11/666,535 patent/US20080164003A1/en not_active Abandoned

- 2006-03-03 TW TW095107128A patent/TW200700566A/zh unknown

- 2006-03-03 JP JP2007557433A patent/JP4688890B2/ja not_active Expired - Fee Related

- 2006-03-03 CA CA002560681A patent/CA2560681A1/en not_active Abandoned

- 2006-03-03 UA UAA200611050A patent/UA80237C2/uk unknown

- 2006-09-19 ZA ZA200607920A patent/ZA200607920B/en unknown

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6310052A (ja) * | 1986-06-30 | 1988-01-16 | Nisshin Steel Co Ltd | 含Al溶鋼の連続鋳造法 |

| JPH0377753A (ja) * | 1989-08-14 | 1991-04-03 | Nippon Steel Corp | 高アルミニウム含有鋼の鋳造用パウダー及び鋳造法 |

| JPH06238410A (ja) * | 1993-02-16 | 1994-08-30 | Voest Alpine Ind Anlagen Gmbh | ストリップ、ストリップ用素材またはスラブの製造法および製造装置 |

| JPH0976049A (ja) * | 1995-09-14 | 1997-03-25 | Nippon Yakin Kogyo Co Ltd | 含a1溶鋼連続鋳造用フラックス及び連続鋳造方法 |

| JPH10296318A (ja) * | 1997-03-24 | 1998-11-10 | Sms Schloeman Siemag Ag | 連続鋳造されたスラブから熱間広幅ストリップを圧延するための方法および設備 |

| JPH1177102A (ja) * | 1997-06-16 | 1999-03-23 | Sms Schloeman Siemag Ag | Cps−設備により幅広ホットストリップを圧延するための方法および圧延設備 |

| JP2002507251A (ja) * | 1997-07-01 | 2002-03-05 | フロムマイヤー,ゲオルク | 軽量構造用鋼およびその使用 |

| JPH11226712A (ja) * | 1998-02-10 | 1999-08-24 | Kawasaki Steel Corp | 高Al含有鋼鋳造用モールドパウダー |

| WO2000033992A1 (fr) * | 1998-12-08 | 2000-06-15 | Shinagawa Refractories Co., Ltd. | Poudre pour moulage d'acier par coulee continue et procede de moulage par coulee continue |

| JP2002172401A (ja) * | 2000-09-29 | 2002-06-18 | Kawasaki Heavy Ind Ltd | 連続鋳造熱延設備および連続鋳造熱延方法 |

| JP2004515362A (ja) * | 2000-12-06 | 2004-05-27 | ティッセンクルップ シュタール アクチェンゲゼルシャフト | 高いマンガン含有量を有する鋼からの熱間ストリップの製造方法 |

| JP2002346708A (ja) * | 2001-05-28 | 2002-12-04 | Sumitomo Metal Ind Ltd | 連続鋳造用モールドパウダ |

| JP2004521192A (ja) * | 2001-06-13 | 2004-07-15 | ティッセンクルップ シュタール アクチェンゲゼルシャフト | 冷間成形用高強度鋼および鋼帯もしくは鋼板、鋼帯の製造方法および鋼の製造方法 |

| JP2003053496A (ja) * | 2001-08-07 | 2003-02-26 | Sanyo Special Steel Co Ltd | アルミニウム含有鋼の連続鋳造用モールドパウダー |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1725347B1 (de) | 2012-12-26 |

| UA80237C2 (en) | 2007-08-27 |

| EP1725347A1 (de) | 2006-11-29 |

| US20080164003A1 (en) | 2008-07-10 |

| KR101153735B1 (ko) | 2012-06-08 |

| RU2335358C2 (ru) | 2008-10-10 |

| WO2006094718A1 (de) | 2006-09-14 |

| DE102005010243A1 (de) | 2006-09-07 |

| TW200700566A (en) | 2007-01-01 |

| CA2560681A1 (en) | 2006-09-14 |

| ZA200607920B (en) | 2008-04-30 |

| RU2006136036A (ru) | 2008-05-10 |

| KR20070108440A (ko) | 2007-11-12 |

| CN101160183A (zh) | 2008-04-09 |

| JP2008531292A (ja) | 2008-08-14 |

| CN101160183B (zh) | 2011-07-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4688890B2 (ja) | マンガン含有量の多い軽量鋼を製造するための方法及び設備 | |

| KR101080164B1 (ko) | 발화저항성과 기계적 특성이 우수한 마그네슘 합금 및 그 제조방법 | |

| CN109852893B (zh) | 一种低温高韧性耐火钢及其制备方法 | |

| CN109338236B (zh) | 一种基于薄带铸轧的易焊接碳素结构钢及其制造方法 | |

| CN102952997A (zh) | 一种帘线钢盘条及其Al2O3夹杂控制方法 | |

| CN107438487A (zh) | 热轧轻型马氏体钢板及其制作方法 | |

| CN111014603B (zh) | 加硼钢的双辊铸轧生产方法 | |

| CN106756528B (zh) | 一种高氮中锰钢薄带及其近终成形制备方法 | |

| EP2738281B1 (de) | Austenitischen edelstahls mit hohem si-gehalt | |

| CN106978566A (zh) | 一种铁道车辆用耐大气腐蚀钢及其制备方法 | |

| CN109536822B (zh) | 一种索具用低碳优质碳素结构钢及其制备方法 | |

| JP4417792B2 (ja) | 疲労強度又は冷間加工性に優れた高清浄度鋼 | |

| CN105543646A (zh) | 一种薄板坯中高碳钢生产工艺 | |

| CN110592475A (zh) | 一种大规格高碳硅锰钢及其制造方法 | |

| CN113584398B (zh) | 耐蚀钢板以及耐蚀钢板的生产方法 | |

| CN114107840A (zh) | 一种HRB400cE耐氯离子腐蚀钢筋及其生产工艺 | |

| JP4182429B2 (ja) | Cr−Zr−Al系銅合金線素材の製造方法 | |

| CN114622135A (zh) | 微铌合金化q355b低合金高强度结构钢板及其制造方法 | |

| JP2001303197A (ja) | 凝固組織が微細な鋼 | |

| CN102312162B (zh) | 内燃机气阀用精炼马氏体合金及其生产工艺 | |

| JP2003147492A (ja) | 表面性状に優れたTi含有Fe−Cr−Ni鋼およびその鋳造方法 | |

| JP5720867B1 (ja) | Cu−Sn共存鋼およびその製造方法 | |

| JP4357080B2 (ja) | 凝固結晶粒微細化鋼及び凝固結晶粒微細化オーステナイト系ステンレス鋼並びにそれらの溶接継ぎ手 | |

| CN115807185B (zh) | 一种低成本高强度耐大气腐蚀铁路用集装箱热轧钢带q450nqr1生产方法 | |

| CN110218916B (zh) | 一种高抗拉强度胎铃用铝合金锭及其生产工艺 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090127 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090127 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090512 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100323 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100517 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100622 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100914 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101206 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110125 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110215 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4688890 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140225 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |