JP2010010673A - 圧粉磁性体用軟磁性粉末およびそれを用いた圧粉磁性体 - Google Patents

圧粉磁性体用軟磁性粉末およびそれを用いた圧粉磁性体 Download PDFInfo

- Publication number

- JP2010010673A JP2010010673A JP2009129795A JP2009129795A JP2010010673A JP 2010010673 A JP2010010673 A JP 2010010673A JP 2009129795 A JP2009129795 A JP 2009129795A JP 2009129795 A JP2009129795 A JP 2009129795A JP 2010010673 A JP2010010673 A JP 2010010673A

- Authority

- JP

- Japan

- Prior art keywords

- powder

- magnetic

- soft magnetic

- magnetic material

- heat treatment

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

- C22C33/0257—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/14—Treatment of metallic powder

- B22F1/142—Thermal or thermo-mechanical treatment

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/12—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials

- H01F1/14—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys

- H01F1/20—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/12—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials

- H01F1/14—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys

- H01F1/20—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder

- H01F1/22—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder pressed, sintered, or bound together

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/12—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials

- H01F1/14—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys

- H01F1/20—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder

- H01F1/22—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder pressed, sintered, or bound together

- H01F1/24—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder pressed, sintered, or bound together the particles being insulated

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F41/00—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties

- H01F41/02—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets

- H01F41/0206—Manufacturing of magnetic cores by mechanical means

- H01F41/0246—Manufacturing of magnetic circuits by moulding or by pressing powder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/05—Metallic powder characterised by the size or surface area of the particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/16—Metallic particles coated with a non-metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/24—After-treatment of workpieces or articles

- B22F2003/248—Thermal after-treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/06—Making metallic powder or suspensions thereof using physical processes starting from liquid material

- B22F9/08—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying

- B22F9/082—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid

- B22F2009/0824—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid with a specific atomising fluid

- B22F2009/0828—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid with a specific atomising fluid with water

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2998/00—Supplementary information concerning processes or compositions relating to powder metallurgy

- B22F2998/10—Processes characterised by the sequence of their steps

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C2202/00—Physical properties

- C22C2202/02—Magnetic

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12181—Composite powder [e.g., coated, etc.]

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Mechanical Engineering (AREA)

- Organic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Metallurgy (AREA)

- Materials Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Powder Metallurgy (AREA)

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

- Soft Magnetic Materials (AREA)

Abstract

【解決手段】Nb,Ta,Ti,Zr,Vから成る群から選択された少なくとも1種を0.001〜0.03原子%含む水アトマイズFe粉末が、母相に、Nb,Ta,Ti,ZrあるいはVの少なくとも1種と、酸素とを主成分とする平均粒子径が0.02μm以上0.5μm以下の粒子を析出させた圧粉磁性体用軟磁性粉末である。開示された軟磁性粉末の製造方法は、Nb,Ta,Ti,Zr,Vから成る群から選択された少なくとも1種を添加し、水素を含む還元雰囲気で熱処理することにより製造する圧粉磁性体用軟磁性粉末の製造方法である。この方法により、ガス不純物、特に酸素を低減,無害化して、Fe粉末及び成形体の磁気特性を向上させることができる。

【選択図】 図3

Description

以下、実施例で更に詳細を説明する。

25種類のFe粉末は、水アトマイズFe粉であるため、酸素を不純物として多量(質量%で0.17〜0.2%の範囲)に含んでいる。酸化皮膜形成の寄与が大である。不純物Cの濃度は0.001〜0.003%程度である。またN濃度は、いずれの材料でも0.002%以下となり、非常に少ない。C,Nはアトマイズ中に水(すなわち酸素)との反応でかなりの量が除去されていると思われる。

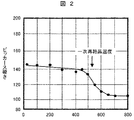

温度範囲で等時焼鈍実験を実施した。焼鈍条件は、100℃からスタートして、温度上昇間隔ΔT=50℃,保持時間30分である。100,200,300,400,450,500,550,600,650,700,800までそれぞれ焼鈍した。焼鈍された成形体を上記のプロセスに従い、室温で硬さ試験した。

径15mm,厚さ5mmのリング形状とした。鉄リン酸ガラスの耐熱温度が最大550℃であ

るため、成形体を窒素ガス雰囲気で530℃で60分間の熱処理を行った。

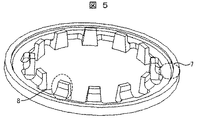

のフランジ部7と爪部8を数箇所切り出して、アルキメデス法でそれらの密度を測定した。No.5,No.12,No.15,No.21の爪部の密度はそれぞれ平均7.55,7.54,7.56,7.56であった。外周,平坦部を含むフランジ部は爪部より0.01〜0.03低かった。

2 薄い酸化皮膜層

3 結晶粒界

4 析出物

5 微結晶

6 転位

7 フランジ部

8 爪部

Claims (10)

- 鉄を主成分とする圧粉磁性体用軟磁性粉末であって、

前記粉末は、V,Nb,Ta,Ti,Zrから成る群から選ばれた少なくとも一種の元素を合計量で0.001〜0.03原子%と、炭素,窒素,酸素を合計量で0.05質量%以下と、不可避の金属不純物を0.25質量%以下とを含む鉄より成り、

前記粉末は、表面に形成された酸化層と、内部母相に析出した析出粒子を含み、

前記析出粒子はV,Nb,Ta,Ti,Zrから成る群から選ばれた少なくとも一種の元素と、酸素とを主成分とする粒子であって、

前記析出粒子の平均粒子径が0.02μm以上0.5μm以下である、圧粉磁性体用軟磁性粉末。 - 請求項1に記載された圧粉磁性体用軟磁性粉末であって、

前記粉末は少なくともVを含む圧粉磁性体用軟磁性粉末。 - 請求項1に記載された圧粉磁性体用軟磁性粉末であって、

前記粉末は前記不可避の金属不純物としてCr,Mn,Siから成る群から選ばれた少なくとも一種を含み、それぞれの含有率がCr:0.05質量%以下,Mn:0.1質量%以下,Si:0.02質量%以下である圧粉磁性体用軟磁性粉末。 - 請求項1に記載された圧粉磁性体用軟磁性粉末であって、

前記粉末の粒子の平均マイクロビッカース硬さが120以下である圧粉磁性体用軟磁性粉末。 - 請求項1に記載された圧粉磁性体用軟磁性粉末であって、粉末粒子の表面に絶縁被覆層を有する圧粉磁性体用軟磁性粉末。

- 鉄を主成分とし、V,Nb,Ta,Ti,Zrから成る群から選ばれた少なくとも一種を0.001〜0.03原子%有する溶融合金に水を吹付けて冷却し、微粉化された合金を、水素を含む還元雰囲気中800℃〜1000℃の温度範囲で熱処理し、前記合金粉末を圧粉成形する圧粉磁性体の製造方法であって、

前記圧粉成形後に、前記圧粉成形体を再結晶させる工程を有し、前記再結晶温度が600℃以下である、圧粉磁性体の製造方法。 - 請求項6に記載された圧粉磁性体の製造方法であって、

前記熱処理された合金粉末に絶縁被覆層を設ける工程を含み、前記絶縁被覆層を有する粉末粒子から成る合金粉末を圧粉成形することを含む圧粉磁性体の製造方法。 - 請求項1で規定される圧粉磁性体用軟磁性粉末を用いて形成した圧粉磁性体。

- 鉄を主成分とし、V,Nb,Ta,Ti,Zrから成る群から選ばれた少なくとも一種を0.001〜0.03原子%含む溶融合金に水を吹付けて冷却し、微粉化された合金を、水素を含む還元雰囲気中、800℃〜1000℃の温度範囲で熱処理することを含む圧粉磁性体用軟磁性粉末の製造方法。

- 請求項9に記載された圧粉磁性体用軟磁性粉末の製造方法であって、前記熱処理後に絶縁被覆層を設ける工程を更に含む圧粉磁性体用軟磁性粉末の製造方法。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009129795A JP5308916B2 (ja) | 2008-05-30 | 2009-05-29 | 圧粉磁性体用軟磁性粉末およびそれを用いた圧粉磁性体 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008141838 | 2008-05-30 | ||

| JP2008141838 | 2008-05-30 | ||

| JP2009129795A JP5308916B2 (ja) | 2008-05-30 | 2009-05-29 | 圧粉磁性体用軟磁性粉末およびそれを用いた圧粉磁性体 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010010673A true JP2010010673A (ja) | 2010-01-14 |

| JP5308916B2 JP5308916B2 (ja) | 2013-10-09 |

Family

ID=41379078

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009129795A Expired - Fee Related JP5308916B2 (ja) | 2008-05-30 | 2009-05-29 | 圧粉磁性体用軟磁性粉末およびそれを用いた圧粉磁性体 |

Country Status (3)

| Country | Link |

|---|---|

| US (2) | US20090295518A1 (ja) |

| JP (1) | JP5308916B2 (ja) |

| CN (1) | CN101615465B (ja) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2472530A1 (en) | 2010-12-28 | 2012-07-04 | Kabushiki Kaisha Kobe Seiko Sho (Kobe Steel, Ltd.) | Iron-based soft magnetic powder for dust core, preparation process thereof, and dust core |

| JP2012132095A (ja) * | 2010-10-29 | 2012-07-12 | General Electric Co <Ge> | ナノ構造化フェライト合金を用いて形成された物品 |

| WO2013108642A1 (ja) * | 2012-01-17 | 2013-07-25 | 株式会社日立産機システム | 圧粉磁性体用の鉄粉、圧粉磁性体、圧粉磁性体用の鉄粉の製造方法、及び圧粉磁性体の製造方法 |

| JP2013165251A (ja) * | 2012-01-12 | 2013-08-22 | Kobe Steel Ltd | 軟磁性鉄基粉末およびその製造方法 |

| JP2014103267A (ja) * | 2012-11-20 | 2014-06-05 | Jfe Steel Corp | 圧粉磁芯用粉末の製造方法および圧粉磁芯用粉末 |

| JP2016125102A (ja) * | 2015-01-06 | 2016-07-11 | セイコーエプソン株式会社 | 粉末冶金用金属粉末、コンパウンド、造粒粉末および焼結体 |

| JP2016145402A (ja) * | 2015-02-09 | 2016-08-12 | セイコーエプソン株式会社 | 粉末冶金用金属粉末、コンパウンド、造粒粉末および焼結体 |

| JP2016216818A (ja) * | 2015-05-14 | 2016-12-22 | Tdk株式会社 | 軟磁性金属粉末、および、軟磁性金属圧粉コア。 |

| TWI569292B (zh) * | 2013-09-20 | 2017-02-01 | 太陽誘電股份有限公司 | 磁性體及使用其之電子部件 |

| KR101773093B1 (ko) * | 2015-11-27 | 2017-08-30 | 엘지이노텍 주식회사 | 무선 전력 충전기를 위한 자성 차폐 블록 제조 방법 |

| WO2020084997A1 (ja) * | 2018-10-25 | 2020-04-30 | 株式会社神戸製鋼所 | 汚染水処理用鉄粉及び汚染水処理用鉄粉製造方法 |

| JP2023134350A (ja) * | 2022-03-14 | 2023-09-27 | 株式会社東芝 | 磁性材料及び回転電機 |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101881952B1 (ko) * | 2010-06-09 | 2018-07-26 | 신토고교 가부시키가이샤 | 철족계 연자성 분말재 |

| CN101982856B (zh) * | 2010-09-21 | 2012-02-15 | 李延军 | 笔杆式汽车点火线圈内用软磁铁芯及其制作方法 |

| JP4906972B1 (ja) * | 2011-04-27 | 2012-03-28 | 太陽誘電株式会社 | 磁性材料およびそれを用いたコイル部品 |

| JP5919144B2 (ja) | 2012-08-31 | 2016-05-18 | 株式会社神戸製鋼所 | 圧粉磁心用鉄粉および圧粉磁心の製造方法 |

| JP6131577B2 (ja) * | 2012-11-20 | 2017-05-24 | セイコーエプソン株式会社 | 複合粒子、圧粉磁心、磁性素子および携帯型電子機器 |

| CN108962529A (zh) * | 2018-06-27 | 2018-12-07 | 绵阳西磁科技有限公司 | 一种高性能金属磁芯及其器件用合金粉末的制备方法 |

| CN109202092B (zh) * | 2018-09-17 | 2020-06-05 | 横店集团东磁股份有限公司 | 一种使用非真空气雾化制备铁硅铝粉末并制作磁芯的工艺 |

| WO2021202942A2 (en) * | 2020-04-02 | 2021-10-07 | Persimmon Technologies Corporation | Core-shell particles and composite material synthesized therefrom |

| KR102237022B1 (ko) * | 2020-08-07 | 2021-04-08 | 주식회사 포스코 | 연자성 철계 분말 및 그 제조방법, 연자성 부품 |

| CN113096948B (zh) * | 2021-03-16 | 2022-06-07 | 深圳顺络电子股份有限公司 | 一种高磁导率高饱和软磁合金材料及其制备方法 |

| JP7644336B2 (ja) * | 2021-03-19 | 2025-03-12 | 愛知製鋼株式会社 | 磁心用粉末とその製造方法および圧粉磁心 |

Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07157803A (ja) * | 1993-05-18 | 1995-06-20 | Kawasaki Steel Corp | 粉末冶金用水アトマイズ鉄粉およびその製造方法 |

| JP2003268509A (ja) * | 2001-12-28 | 2003-09-25 | Jfe Steel Kk | 回転機鉄芯用高加工性高強度熱延鋼板およびその製造方法 |

| JP2004131822A (ja) * | 2002-10-11 | 2004-04-30 | Kanagawa Prefecture | 超細粒鋼およびその製造方法 |

| JP2005213583A (ja) * | 2004-01-29 | 2005-08-11 | Cbmm Asia Co Ltd | 溶接継ぎ手性能の優れた鋼及びその製造方法 |

| JP2005307291A (ja) * | 2004-04-22 | 2005-11-04 | Alps Electric Co Ltd | 非晶質軟磁性合金粉末及びそれを用いた圧粉コアと電波吸収体 |

| JP2007013069A (ja) * | 2005-05-31 | 2007-01-18 | Mitsubishi Materials Pmg Corp | MgおよびSi含有酸化物被覆軟磁性粉末の製造方法 |

| JP2007092162A (ja) * | 2005-02-03 | 2007-04-12 | Jfe Steel Kk | 高圧縮性鉄粉、およびそれを用いた圧粉磁芯用鉄粉と圧粉磁芯 |

| JP2007231415A (ja) * | 2006-02-02 | 2007-09-13 | Nec Tokin Corp | 非晶質軟磁性合金、非晶質軟磁性合金部材、非晶質軟磁性合金薄帯、非晶質軟磁性合金粉末、及びそれを用いた磁芯ならびにインダクタンス部品 |

| JP2007291520A (ja) * | 2006-03-31 | 2007-11-08 | Jfe Steel Kk | 電磁棒鋼及びその製造方法 |

| JP2008028162A (ja) * | 2006-07-21 | 2008-02-07 | Sumitomo Electric Ind Ltd | 軟磁性材料の製造方法、軟磁性材料、および圧粉磁心 |

| WO2008038474A1 (fr) * | 2006-09-27 | 2008-04-03 | Nippon Steel Corporation | Tôle en acier pour émaillage présentant une très faible propension à l'écaillage et procédé pour la produire |

| JP2008091873A (ja) * | 2006-09-08 | 2008-04-17 | Nichia Chem Ind Ltd | 希土類−鉄−窒素系磁性粉末及びその製造方法 |

| WO2008093430A1 (ja) * | 2007-01-30 | 2008-08-07 | Jfe Steel Corporation | 高圧縮性鉄粉、およびそれを用いた圧粉磁芯用鉄粉と圧粉磁芯 |

| JP2008189950A (ja) * | 2007-02-01 | 2008-08-21 | Sumitomo Electric Ind Ltd | 軟磁性粉末の製造方法、軟磁性材料の製造方法、圧粉磁心の製造方法、軟磁性粉末、軟磁性材料、および圧粉磁心 |

| JP2009088502A (ja) * | 2007-09-12 | 2009-04-23 | Seiko Epson Corp | 酸化物被覆軟磁性粉末の製造方法、酸化物被覆軟磁性粉末、圧粉磁心および磁性素子 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5225004A (en) * | 1985-08-15 | 1993-07-06 | Massachusetts Institute Of Technology | Bulk rapidly solifidied magnetic materials |

| JP2002121601A (ja) * | 2000-10-16 | 2002-04-26 | Aisin Seiki Co Ltd | 軟磁性金属粉末粒子、軟磁性金属粉末粒子の処理方法、軟磁性成形体、軟磁性成形体の製造方法 |

| JP2005213621A (ja) * | 2004-01-30 | 2005-08-11 | Sumitomo Electric Ind Ltd | 軟磁性材料および圧粉磁心 |

| US7285329B2 (en) * | 2004-02-18 | 2007-10-23 | Hitachi Metals, Ltd. | Fine composite metal particles and their production method, micro-bodies, and magnetic beads |

| JP4650073B2 (ja) * | 2005-04-15 | 2011-03-16 | 住友電気工業株式会社 | 軟磁性材料の製造方法、軟磁性材料および圧粉磁心 |

| CN100490029C (zh) * | 2005-12-28 | 2009-05-20 | 安泰科技股份有限公司 | 磁粉芯用非晶纳米晶复合粉末及其磁粉芯制备方法 |

-

2009

- 2009-05-26 CN CN2009102028566A patent/CN101615465B/zh not_active Expired - Fee Related

- 2009-05-28 US US12/473,982 patent/US20090295518A1/en not_active Abandoned

- 2009-05-29 JP JP2009129795A patent/JP5308916B2/ja not_active Expired - Fee Related

-

2014

- 2014-03-20 US US14/220,672 patent/US20140205485A1/en not_active Abandoned

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07157803A (ja) * | 1993-05-18 | 1995-06-20 | Kawasaki Steel Corp | 粉末冶金用水アトマイズ鉄粉およびその製造方法 |

| JP2003268509A (ja) * | 2001-12-28 | 2003-09-25 | Jfe Steel Kk | 回転機鉄芯用高加工性高強度熱延鋼板およびその製造方法 |

| JP2004131822A (ja) * | 2002-10-11 | 2004-04-30 | Kanagawa Prefecture | 超細粒鋼およびその製造方法 |

| JP2005213583A (ja) * | 2004-01-29 | 2005-08-11 | Cbmm Asia Co Ltd | 溶接継ぎ手性能の優れた鋼及びその製造方法 |

| JP2005307291A (ja) * | 2004-04-22 | 2005-11-04 | Alps Electric Co Ltd | 非晶質軟磁性合金粉末及びそれを用いた圧粉コアと電波吸収体 |

| JP2007092162A (ja) * | 2005-02-03 | 2007-04-12 | Jfe Steel Kk | 高圧縮性鉄粉、およびそれを用いた圧粉磁芯用鉄粉と圧粉磁芯 |

| JP2007013069A (ja) * | 2005-05-31 | 2007-01-18 | Mitsubishi Materials Pmg Corp | MgおよびSi含有酸化物被覆軟磁性粉末の製造方法 |

| JP2007231415A (ja) * | 2006-02-02 | 2007-09-13 | Nec Tokin Corp | 非晶質軟磁性合金、非晶質軟磁性合金部材、非晶質軟磁性合金薄帯、非晶質軟磁性合金粉末、及びそれを用いた磁芯ならびにインダクタンス部品 |

| JP2007291520A (ja) * | 2006-03-31 | 2007-11-08 | Jfe Steel Kk | 電磁棒鋼及びその製造方法 |

| JP2008028162A (ja) * | 2006-07-21 | 2008-02-07 | Sumitomo Electric Ind Ltd | 軟磁性材料の製造方法、軟磁性材料、および圧粉磁心 |

| JP2008091873A (ja) * | 2006-09-08 | 2008-04-17 | Nichia Chem Ind Ltd | 希土類−鉄−窒素系磁性粉末及びその製造方法 |

| WO2008038474A1 (fr) * | 2006-09-27 | 2008-04-03 | Nippon Steel Corporation | Tôle en acier pour émaillage présentant une très faible propension à l'écaillage et procédé pour la produire |

| WO2008093430A1 (ja) * | 2007-01-30 | 2008-08-07 | Jfe Steel Corporation | 高圧縮性鉄粉、およびそれを用いた圧粉磁芯用鉄粉と圧粉磁芯 |

| JP2008189950A (ja) * | 2007-02-01 | 2008-08-21 | Sumitomo Electric Ind Ltd | 軟磁性粉末の製造方法、軟磁性材料の製造方法、圧粉磁心の製造方法、軟磁性粉末、軟磁性材料、および圧粉磁心 |

| JP2009088502A (ja) * | 2007-09-12 | 2009-04-23 | Seiko Epson Corp | 酸化物被覆軟磁性粉末の製造方法、酸化物被覆軟磁性粉末、圧粉磁心および磁性素子 |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012132095A (ja) * | 2010-10-29 | 2012-07-12 | General Electric Co <Ge> | ナノ構造化フェライト合金を用いて形成された物品 |

| EP2472530A1 (en) | 2010-12-28 | 2012-07-04 | Kabushiki Kaisha Kobe Seiko Sho (Kobe Steel, Ltd.) | Iron-based soft magnetic powder for dust core, preparation process thereof, and dust core |

| US9275779B2 (en) | 2010-12-28 | 2016-03-01 | Kobe Steel, Ltd. | Iron-based soft magnetic powder for dust core, preparation process thereof, and dust core |

| JP2013165251A (ja) * | 2012-01-12 | 2013-08-22 | Kobe Steel Ltd | 軟磁性鉄基粉末およびその製造方法 |

| US9589712B2 (en) | 2012-01-12 | 2017-03-07 | Kobe Steel, Ltd. | Iron-based soft magnetic powder and production method thereof |

| WO2013108642A1 (ja) * | 2012-01-17 | 2013-07-25 | 株式会社日立産機システム | 圧粉磁性体用の鉄粉、圧粉磁性体、圧粉磁性体用の鉄粉の製造方法、及び圧粉磁性体の製造方法 |

| JP2013149661A (ja) * | 2012-01-17 | 2013-08-01 | Hitachi Industrial Equipment Systems Co Ltd | 圧粉磁性体用の鉄粉、圧粉磁性体、圧粉磁性体用の鉄粉の製造方法、及び圧粉磁性体の製造方法 |

| JP2014103267A (ja) * | 2012-11-20 | 2014-06-05 | Jfe Steel Corp | 圧粉磁芯用粉末の製造方法および圧粉磁芯用粉末 |

| TWI569292B (zh) * | 2013-09-20 | 2017-02-01 | 太陽誘電股份有限公司 | 磁性體及使用其之電子部件 |

| JP2016125102A (ja) * | 2015-01-06 | 2016-07-11 | セイコーエプソン株式会社 | 粉末冶金用金属粉末、コンパウンド、造粒粉末および焼結体 |

| JP2016145402A (ja) * | 2015-02-09 | 2016-08-12 | セイコーエプソン株式会社 | 粉末冶金用金属粉末、コンパウンド、造粒粉末および焼結体 |

| JP2016216818A (ja) * | 2015-05-14 | 2016-12-22 | Tdk株式会社 | 軟磁性金属粉末、および、軟磁性金属圧粉コア。 |

| KR101773093B1 (ko) * | 2015-11-27 | 2017-08-30 | 엘지이노텍 주식회사 | 무선 전력 충전기를 위한 자성 차폐 블록 제조 방법 |

| US10439447B2 (en) | 2015-11-27 | 2019-10-08 | Lg Innotek Co., Ltd. | Method of manufacturing magnetic shielding block for wireless power chargers |

| WO2020084997A1 (ja) * | 2018-10-25 | 2020-04-30 | 株式会社神戸製鋼所 | 汚染水処理用鉄粉及び汚染水処理用鉄粉製造方法 |

| JP2020066778A (ja) * | 2018-10-25 | 2020-04-30 | 株式会社神戸製鋼所 | 汚染水処理用鉄粉及び汚染水処理用鉄粉製造方法 |

| CN112469518A (zh) * | 2018-10-25 | 2021-03-09 | 株式会社神户制钢所 | 污染水处理用铁粉和污染水处理用铁粉制造方法 |

| KR20210046719A (ko) * | 2018-10-25 | 2021-04-28 | 가부시키가이샤 고베 세이코쇼 | 오염수 처리용 철분말 및 오염수 처리용 철분말 제조 방법 |

| KR102414870B1 (ko) * | 2018-10-25 | 2022-06-29 | 가부시키가이샤 고베 세이코쇼 | 오염수 처리용 철분말 및 오염수 처리용 철분말 제조 방법 |

| CN112469518B (zh) * | 2018-10-25 | 2023-02-17 | 株式会社神户制钢所 | 污染水处理用铁粉和污染水处理用铁粉制造方法 |

| JP2023134350A (ja) * | 2022-03-14 | 2023-09-27 | 株式会社東芝 | 磁性材料及び回転電機 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20140205485A1 (en) | 2014-07-24 |

| CN101615465A (zh) | 2009-12-30 |

| US20090295518A1 (en) | 2009-12-03 |

| CN101615465B (zh) | 2012-10-17 |

| JP5308916B2 (ja) | 2013-10-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5308916B2 (ja) | 圧粉磁性体用軟磁性粉末およびそれを用いた圧粉磁性体 | |

| KR100360533B1 (ko) | 고실리콘 함유강의 제조 방법과 규소강 | |

| JP4636207B2 (ja) | 表面改質された希土類系焼結磁石の製造方法および表面改質された希土類系焼結磁石 | |

| EP3666419A1 (en) | CRYSTALLINE Fe-BASED ALLOY POWDER AND METHOD FOR PRODUCING SAME | |

| JP2713363B2 (ja) | Fe基軟磁性合金圧粉体及びその製造方法 | |

| JP2017193731A (ja) | 電磁鋼板、及びその製造方法 | |

| JP2017145462A (ja) | 電磁鋼板、及びその製造方法 | |

| JP2009194262A (ja) | 希土類磁石の製造方法 | |

| JP2008028162A (ja) | 軟磁性材料の製造方法、軟磁性材料、および圧粉磁心 | |

| JP5427664B2 (ja) | 圧粉磁性体用軟磁性粉末、それを用いた圧粉磁性体および製造方法 | |

| JP2019178402A (ja) | 軟磁性粉末 | |

| CN109983550A (zh) | 高频下使用的磁性粉末和含有其的磁性树脂组合物 | |

| JP2014198874A (ja) | 耐食性と磁気特性に優れた鋼材およびその製造方法 | |

| Saito | Magnetic properties of Mn–Al system alloys produced by mechanical alloying | |

| JPWO2020196608A1 (ja) | アモルファス合金薄帯、アモルファス合金粉末、及びナノ結晶合金圧粉磁心、並びにナノ結晶合金圧粉磁心の製造方法 | |

| JP5613856B1 (ja) | R−t−b系希土類焼結磁石用合金、r−t−b系希土類焼結磁石用合金の製造方法、r−t−b系希土類焼結磁石用合金材料、r−t−b系希土類焼結磁石、r−t−b系希土類焼結磁石の製造方法およびモーター | |

| JPH05335129A (ja) | Fe基軟磁性合金粉末およびその製造方法 | |

| JP7545281B2 (ja) | 軟磁性材料、軟磁性材料の製造方法および電動機 | |

| Dillon | Effects of heat treatment and processing modifications on microstructure in alnico 8H permanent magnet alloys for high temperature applications | |

| WO2013108642A1 (ja) | 圧粉磁性体用の鉄粉、圧粉磁性体、圧粉磁性体用の鉄粉の製造方法、及び圧粉磁性体の製造方法 | |

| JPH0768604B2 (ja) | Fe基磁性合金 | |

| US20200063250A1 (en) | Iron-copper alloy having high thermal conductivity and method for manufacturing the same | |

| WO2021117672A1 (ja) | 希土類焼結磁石 | |

| JP2021150555A (ja) | 圧粉磁心及びその製造方法 | |

| CN113948265B (zh) | 一种铁基非晶软磁合金粉末及其制备方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110803 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120516 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120522 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120712 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121204 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130201 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130604 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130701 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 5308916 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| LAPS | Cancellation because of no payment of annual fees |