EP4064951B1 - Reinigungsroboter und reinigungssystem - Google Patents

Reinigungsroboter und reinigungssystem Download PDFInfo

- Publication number

- EP4064951B1 EP4064951B1 EP20747362.0A EP20747362A EP4064951B1 EP 4064951 B1 EP4064951 B1 EP 4064951B1 EP 20747362 A EP20747362 A EP 20747362A EP 4064951 B1 EP4064951 B1 EP 4064951B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cleaning

- mop

- cleaning robot

- covers

- receiving unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4036—Parts or details of the surface treating tools

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/02—Floor surfacing or polishing machines

- A47L11/10—Floor surfacing or polishing machines motor-driven

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/28—Floor-scrubbing machines, motor-driven

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4002—Installations of electric equipment

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4091—Storing or parking devices, arrangements therefor; Means allowing transport of the machine when it is not being used

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L2201/00—Robotic cleaning machines, i.e. with automatic control of the travelling movement or the cleaning operation

- A47L2201/02—Docking stations; Docking operations

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L2201/00—Robotic cleaning machines, i.e. with automatic control of the travelling movement or the cleaning operation

- A47L2201/02—Docking stations; Docking operations

- A47L2201/028—Refurbishing floor engaging tools, e.g. cleaning of beating brushes

Definitions

- the invention relates to a cleaning robot comprising a base body, a drive device, and a cleaning device.

- the cleaning device is equipped for wet cleaning floors to be cleaned.

- a receiving unit for a mop cover is assigned to the base body on the side facing the floor to be cleaned.

- a mop cover is attached to the receiving unit for wet cleaning.

- the invention further relates to a cleaning system comprising a cleaning robot and a base station.

- Robots that are trained for wet cleaning are, for example, from the EP 3 482 669 A1 known.

- a cleaning element can be placed on the floor to be cleaned and then removed from the floor to be cleaned.

- the cleaning element is firmly connected to the cleaning robot.

- the disadvantage here is that the area coverage of such a cleaning robot is limited, as dirt accumulates on the cleaning element, which must be removed from time to time. However, this requires interrupting the cleaning robot's cleaning work and manually removing the dirt from the cleaning element.

- the invention is based on the object of providing a cleaning robot for wet cleaning which has a higher area performance.

- the cleaning robot is equipped to automatically replace the mop cover attached to the receiving unit with another mop cover.

- the mop cover is detachably attached to the receiving unit, and the cleaning robot is equipped to automatically replace the mop cover without the assistance of an operator. If a larger area needs to be cleaned, it is conceivable that the surface coverage of a single mop cover may not be sufficient.

- the inventive design allows the cleaning robot to replace a worn mop cover with a new one during cleaning. This enables the cleaning robot to achieve a higher surface coverage and, in particular, to completely clean larger areas.

- the mop covers are attached to the receiving unit by a fixing device.

- the fixing device can consist, for example, of magnets attached to the mop cover and the receiving unit. It is also conceivable for the mop cover to be attached to the receiving unit by means of a hook-and-loop fastener.

- the receiving unit is designed to be movably mounted beneath the base body and retracts into the base body to remove the mop cover. The mop cover is then removed from the receiving unit and can be replaced.

- a first storage unit for storing mop covers can be assigned to the base body.

- the first storage unit is equipped to hold multiple mop covers and feed them to the receiving unit as required.

- the first storage unit can be equipped to hold five unused mop covers.

- the mop covers stored in the first storage unit can be provided with a cleaning agent.

- the mop covers are stored in the first storage unit pre-moistened and prepared for cleaning.

- the mop covers stored in this way are immediately ready for wet cleaning after being fed to the receiving unit.

- a second storage unit for storing used mop covers can be assigned to the base body. If a used mop cover is replaced with a new one during cleaning, a new mop cover is removed from the first storage unit and the used mop cover is transferred to the second storage unit.

- the mop covers can be reusable. Such mop covers are preferably made of a textile fabric.

- the mop covers are preferably machine washable, allowing hygienic cleaning of the mop covers in a washing machine.

- the mop covers can be designed as disposable items.

- the disposable items can be designed as disposable wipes.

- the disposable items are pre-moistened with a cleaning agent and stored in a box.

- the box contains a represents a sales unit and that the box with the mop covers arranged therein can be purchased by the user as a unit.

- the box could serve as the storage unit, allowing the box and the mop covers stored therein to be placed directly into the base of the cleaning robot. This makes handling particularly easy.

- the mop covers can be made of a textile material, making them reusable. It is particularly advantageous if the mop covers are machine washable. This design also reduces the amount of waste.

- a transport device can be assigned to the base body, which transports mop covers from the storage unit to the receiving unit and/or from the receiving unit to the second storage unit.

- the transport device can, for example, comprise a gear arrangement or a belt drive or the like.

- the mop covers are preferably held in a form-fitting manner on the receiving unit.

- the mop covers can be provided with an arrangement of perforations on opposing edges, for example in the form of a perforated strip pattern.

- the perforations engage with elevations assigned to the receiving unit, for example, gear-like projections. This allows the mop cover to be securely held on the receiving unit.

- the transport unit it is conceivable for the transport unit to engage with the form-fitting elements and transport the mop cover from the first storage unit to the receiving unit and/or from the receiving unit to the second storage unit.

- the mop cover can be equipped with a stiffener. This can be made from the textile strips assigned to the edges of the mop cover or

- Plastic strips are used. The stiffening results in a dimensionally stable mop cover.

- the cleaning system for solving the problem comprises a cleaning robot as described above and a base station, wherein the base station is equipped to receive a first supply of mop covers.

- Base stations for cleaning robots are well known.

- the base station is used to charge the batteries of the cleaning robot's electric drive.

- the cleaning robot can drive to the base station automatically.

- the base station is further provided with a first supply unit in which mop covers are stored.

- the cleaning robot can automatically pick up one or more mop covers from the base station. If the cleaning robot is equipped to pick up only one mop cover, it is fed directly to the pick-up unit. If the cleaning robot is equipped to pick up multiple mop covers, they are fed to the cleaning robot's storage unit.

- the base station can be equipped with a second supply for used mop covers.

- the cleaning robot it is conceivable for the cleaning robot to be equipped with only a single mop cover, which is located on the receiving unit, with the cleaning robot driving to the base station to replace the mop cover.

- the mop cover can be transferred directly from the receiving unit to the second supply.

- the cleaning robot is equipped to feed used mop covers temporarily stored in a second storage unit to the second supply of the base station.

- the base station can have a pretreatment device for pretreating the mop covers.

- the base station can be equipped with a fresh water connection and/or a waste water connection.

- the base station is equipped with a pretreatment device, the mop covers can be stored untreated, i.e. dry, in the first storage area.

- the pretreatment device pretreats the mop covers.

- the mop covers arranged in the first storage area can also be pretreated.

- the mop covers are preferably provided with a suitable cleaning agent. It is conceivable that a cleaning agent tailored to the upcoming cleaning task is applied to the mop cover. For example, a cleaning agent suitable for natural stone or a cleaning agent suitable for wooden floors can be applied to the mop cover as needed. Furthermore, it is conceivable to apply fragrances or care products to the mop covers.

- the dosage and selection of cleaning agents or care products can depend on automatic recognition of the cleaning task at hand, the floor to be cleaned, or a predefined assignment of a floor area or room to be cleaned.

- the cleaning robot can be equipped with a room recognition device.

- the cleaning robot can be provided with a memory unit in which a predetermined cleaning program is stored for a specific room.

- the cleaning program can specify the wiping duration, the amount of cleaning fluid to be applied, the contact pressure of the mop cover on the floor to be cleaned, and/or the type of cleaning or care product.

- the mop cover may be equipped with communication means for communicating with the cleaning robot.

- Various, preferably electronically readable, identifiers are conceivable as communication means.

- Such identifiers include, for example, QR codes, punched tape patterns, and radio transponders such as RFID chips.

- the cleaning robot it is conceivable for the cleaning robot to have variously designed mop covers available in the storage unit or in the base station, and for the cleaning robot to select a mop cover specified by the cleaning program for the upcoming cleaning task, with the mop cover being located using the communication means.

- the pretreatment device can be designed as a spray device that sprays the mop covers with a cleaning and care agent when they are removed from the supply.

- the pretreatment device is equipped to pretreat all mop covers stored in the first supply.

- the base station can have a post-treatment device for post-treating mop covers.

- the post-treatment device is particularly equipped to post-treat the used mop covers transferred by the cleaning robot to the second supply.

- the post-treatment can include disinfection and/or drying. For disinfection, it is conceivable to expose the used mop covers to UV light.

- the mop covers can be dried using an air stream, for example, via a fan.

- Figure 1 shows a cleaning robot 1, comprising a base body 2, a drive device 3, and a cleaning device 4.

- the cleaning robot 1 is equipped to move autonomously across a floor to be cleaned and to perform cleaning work in the process.

- the drive device 3 comprises wheels driven by an electric motor, wherein the electric motor is powered by a rechargeable battery.

- the drive device 3 further comprises a sensor device by means of which the cleaning robot 1 can navigate across the floor to be cleaned.

- the battery is charged in a base station 13.

- the cleaning robot 1 is configured to approach the base station 13 automatically.

- the cleaning device 4 is equipped for wet cleaning floors to be cleaned.

- a receiving unit 5 for a mop cover 6 is assigned to the base body 2 on the side facing the floor to be cleaned.

- a mop cover 6 is attached to the receiving unit 5.

- the cleaning robot 1 is equipped to automatically exchange the mop cover 6 attached to the receiving unit 5 for another mop cover 6.

- the base body 2 can be provided with a first storage unit 7 for storing mop covers

- the first storage unit 7 is preferably integrated into the base body 2, so that a supply of mop covers 6 is arranged in the first storage unit 7 within the base body 2.

- the mop covers 6 stored in the storage unit 7 can be pretreated with a cleaning agent so that they are immediately ready for use when they are fed to the receiving unit 5.

- a second storage unit 8 for storing used mop covers 6 can be assigned to the base body 2.

- the mop covers 6 are preferably designed to be reusable.

- the wiping covers 6 can be designed as disposable items or disposable wipes.

- FIG. 2 shows in detail the recording unit 5 of the Figure 1 described cleaning robot 1.

- the base body 2 is assigned a transport device 10, which transports mop covers 6 from the first storage unit 7 to the receiving unit 5 and then from the receiving unit 5 to the second storage unit 8.

- the mop cover 6 is held in a form-fitting manner on the receiving unit 5 and is securely held on the receiving unit 5 by a fixing means 11 in the form of magnets.

- FIG 3 shows a further development of the Figure 1 described cleaning robot 1, wherein the mop cover 6 is equipped with communication means 9 for communicating with the cleaning robot 1.

- the cleaning robot 1 also comprises communication means 9 in order to be able to exchange data with the mop cover 6.

- the communication means 9 are equipped to communicate via near field communication (NFC).

- NFC near field communication

- an RFID chip can be integrated into the mop cover 6.

- the RFID chip can contain data that enable the mop cover 6 to be clearly assigned. In this context, it is particularly conceivable to record the number of cleaning cycles completed by the mop cover 6 and to localize the mop cover 6.

- Figure 4 shows various designs of mop covers.

- the mop cover 6 shown above is made of a textile material and is reusable. For cleaning, the mop cover 6 can be machine washed.

- the mop cover 6 shown below is designed as a disposable item or as a single-use cloth.

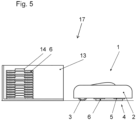

- Figure 5 shows a cleaning system 17 comprising a cleaning robot 1 as described above, and a base station 13.

- the base station 13 is equipped to receive a first supply 14 of mop covers 6.

- the cleaning robot 1 is equipped to remove a mop cover 6 from the first supply 14 and feed it to the receiving unit 5. If the cleaning robot 1 has a storage unit 8, the cleaning robot 1 can also remove multiple mop covers 6 from the first supply 14.

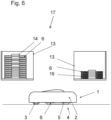

- Figure 6 shows a further development of the Figure 5 described cleaning system 17.

- the base station 13 comprises a second supply 15 for receiving used mop covers 6.

- Figure 7 shows the process of exchanging mop covers 6 while the cleaning robot 1 is in the base station 13. While the mop covers 6 are being exchanged, a charging process can take place at the same time, during which the rechargeable battery integrated in the base body 2 of the cleaning robot 1 is charged. If the cleaning robot 1 is in the base station 13, a used mop cover 6 can be transported from the receiving unit 5 towards the second supply 15 via the transport device 10. A fresh mop cover 6 is then removed from the first supply 14 and fed to the receiving unit 5 via the transport device 10, where it is fastened to the receiving unit 5 in a force-fitting and form-fitting manner by means of the fixing means 11.

- the cleaning robot 1 has a first storage unit 7 and a second storage unit 8

- the used mop covers 6 held in the second storage unit 8 are fed to the second supply 15, while several mop covers 6 are removed from the first supply 14 and fed to the first storage unit 7.

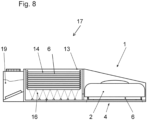

- Figure 8 shows a further development of the previously described cleaning system 17.

- the base station 13 is equipped with a pretreatment device 16 for pretreating mop covers 6.

- the pretreatment device 16 is configured to apply a cleaning agent adapted to the upcoming cleaning task to a mop cover 6.

- the pretreatment device 16 comprises a spray device which is designed to provide the mop covers 6 arranged in the first supply 14 with a cleaning agent.

- the mop cover which is fed to the receiving unit 5 of the cleaning robot 1 is pretreated.

- the cleaning agent is therefore applied immediately before being fed to the receiving unit 5.

- the pretreatment device 16 comprises a reservoir 19 in which cleaning agent is arranged.

- Figure 9 shows a further embodiment of the cleaning system 17.

- the base station 13 is equipped with a first supply 14 for receiving unused mop covers 6 and a second supply 15 for receiving used mop covers 6.

- the base station 13 has a pretreatment device 16 for pretreating mop covers 6, which are arranged in the first supply 14.

- the base station 13 has a post-treatment device 18 for post-treating mop covers 6, which are located in the second supply 15.

- the post-treatment device 18 is designed as a drying device and has a fan for this purpose.

Landscapes

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

- Spray Control Apparatus (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102019132312.6A DE102019132312B4 (de) | 2019-11-28 | 2019-11-28 | Reinigungsroboter und Reinigungssystem |

| PCT/EP2020/070771 WO2021104689A1 (de) | 2019-11-28 | 2020-07-23 | Reinigungsroboter und reinigungssystem |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP4064951A1 EP4064951A1 (de) | 2022-10-05 |

| EP4064951C0 EP4064951C0 (de) | 2025-05-21 |

| EP4064951B1 true EP4064951B1 (de) | 2025-05-21 |

Family

ID=71846371

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20747362.0A Active EP4064951B1 (de) | 2019-11-28 | 2020-07-23 | Reinigungsroboter und reinigungssystem |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US11690493B2 (pl) |

| EP (1) | EP4064951B1 (pl) |

| KR (1) | KR102773632B1 (pl) |

| CN (1) | CN114340463B (pl) |

| CA (1) | CA3144815C (pl) |

| DE (1) | DE102019132312B4 (pl) |

| PL (1) | PL4064951T3 (pl) |

| WO (1) | WO2021104689A1 (pl) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115736713A (zh) * | 2019-05-05 | 2023-03-07 | 苏州宝时得电动工具有限公司 | 基站和机器人清洁系统 |

| DE102021203332B3 (de) | 2021-04-01 | 2022-03-24 | BSH Hausgeräte GmbH | Vorrichtung zur Reinigung eines Bodentuchs |

| JP7717193B2 (ja) * | 2021-06-04 | 2025-08-01 | ポジテック パワー ツールズ(スーチョウ)カンパニー,リミティド | 掃除ロボットのメンテナンスシステム及びその制御方法 |

| CN119584908A (zh) * | 2022-07-22 | 2025-03-07 | 三星电子株式会社 | 机器人清洁器、对接站及包括机器人清洁器和对接站的清洁系统 |

| KR20240013508A (ko) * | 2022-07-22 | 2024-01-30 | 삼성전자주식회사 | 로봇 청소기, 도킹 스테이션 및 이들을 포함한 청소 시스템 |

| KR20240019600A (ko) * | 2022-08-04 | 2024-02-14 | 삼성전자주식회사 | 로봇 청소기, 도킹 스테이션 및 이를 포함한 청소 시스템 |

| US20240041290A1 (en) * | 2022-08-04 | 2024-02-08 | Samsung Electronics Co., Ltd. | Robot cleaner, docking station and cleaning system having the same |

| KR20240019577A (ko) * | 2022-08-04 | 2024-02-14 | 삼성전자주식회사 | 로봇 청소기, 도킹 스테이션 및 이를 포함한 청소 시스템 |

| KR20240174380A (ko) * | 2023-06-08 | 2024-12-17 | 삼성전자주식회사 | 스테이션 및 이를 포함하는 청소 시스템 |

| KR102816419B1 (ko) * | 2023-07-06 | 2025-06-04 | 삼성전자주식회사 | 스테이션, 이를 포함하는 청소 시스템 및 스테이션의 청소 패드 교체 방법 |

| KR20250056016A (ko) * | 2023-10-18 | 2025-04-25 | 삼성전자주식회사 | 로봇 청소기 스테이션 및 이를 구비한 로봇 청소기 시스템 |

| CN222722923U (zh) * | 2024-05-30 | 2025-04-08 | 北京石头世纪科技股份有限公司 | 基站和清洁系统 |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10256089A1 (de) | 2002-12-02 | 2004-06-17 | BSH Bosch und Siemens Hausgeräte GmbH | Reinigungsanlage mit Basisstation |

| US8961695B2 (en) * | 2008-04-24 | 2015-02-24 | Irobot Corporation | Mobile robot for cleaning |

| EP2918212B1 (en) * | 2008-04-24 | 2016-06-08 | iRobot Corporation | Application of localization, positioning & navigation systems for robotic enabled mobile products |

| KR101138657B1 (ko) * | 2010-06-21 | 2012-04-19 | (주)마미로봇 | 로봇 청소기 |

| CN203354471U (zh) | 2013-06-19 | 2013-12-25 | 业展电器(深圳)有限公司 | 自动地面抹布机 |

| KR102103420B1 (ko) * | 2013-12-30 | 2020-05-29 | 삼성전자주식회사 | 패드 교체 장치, 이를 포함하는 청소기 및 청소기 시스템 |

| US9265396B1 (en) * | 2015-03-16 | 2016-02-23 | Irobot Corporation | Autonomous floor cleaning with removable pad |

| US9907449B2 (en) * | 2015-03-16 | 2018-03-06 | Irobot Corporation | Autonomous floor cleaning with a removable pad |

| CN204813712U (zh) * | 2015-06-10 | 2015-12-02 | 玛纽尔科贸(北京)有限公司 | 湿抹布清洁机器人 |

| EP3338151B1 (en) * | 2015-08-18 | 2024-11-20 | Nilfisk A/S | Mobile robotic cleaner |

| CN106889955A (zh) * | 2015-12-19 | 2017-06-27 | 天津蓝莓信息技术有限责任公司 | 一种自动更换清洁机器人抹布的装置及方法 |

| CN106859512A (zh) * | 2017-02-22 | 2017-06-20 | 深圳市软晶科技有限公司 | 一种自动更换拖布的清洁机器人系统 |

| CN206880637U (zh) * | 2017-02-22 | 2018-01-16 | 深圳市软晶科技有限公司 | 一种自动更换拖布的清洁机器人系统 |

| CN207755219U (zh) * | 2017-06-23 | 2018-08-24 | 杭州九阳小家电有限公司 | 一种清洁机器人系统 |

| DE102017126414A1 (de) | 2017-11-10 | 2019-05-16 | Vorwerk & Co. Interholding Gmbh | Feuchtreinigungseinrichtung zur Reinigung einer Fläche |

| DE102017222044B4 (de) | 2017-12-06 | 2019-07-04 | BSH Hausgeräte GmbH | Verfahren und Vorrichtung zum Austausch von Funktionsmodulen eines Haushaltsroboters |

| DE102018000083B4 (de) | 2018-01-09 | 2022-03-31 | Carl Freudenberg Kg | Reinigungsroboter, Reinigungssystem mit Reinigungsroboter und Verfahren zur Reinigung einer Fläche |

| CN108814458A (zh) * | 2018-05-31 | 2018-11-16 | 芜湖聚网信息技术有限公司 | 自动更换清洁垫的擦地机器人 |

| CN209236042U (zh) | 2018-06-26 | 2019-08-13 | 北京三辰环卫机械有限公司 | 自动擦地机 |

| KR102575206B1 (ko) * | 2018-11-06 | 2023-09-07 | 삼성전자주식회사 | 로봇 청소기, 스테이션 및 청소 시스템 |

| CN110151065A (zh) | 2019-05-21 | 2019-08-23 | 深圳市银星智能科技股份有限公司 | 柔性清洁薄片安装机构及清洁机器人 |

-

2019

- 2019-11-28 DE DE102019132312.6A patent/DE102019132312B4/de active Active

-

2020

- 2020-07-23 US US17/778,867 patent/US11690493B2/en active Active

- 2020-07-23 KR KR1020227000980A patent/KR102773632B1/ko active Active

- 2020-07-23 EP EP20747362.0A patent/EP4064951B1/de active Active

- 2020-07-23 WO PCT/EP2020/070771 patent/WO2021104689A1/de not_active Ceased

- 2020-07-23 CA CA3144815A patent/CA3144815C/en active Active

- 2020-07-23 PL PL20747362.0T patent/PL4064951T3/pl unknown

- 2020-07-23 CN CN202080060977.6A patent/CN114340463B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CA3144815A1 (en) | 2021-06-03 |

| EP4064951C0 (de) | 2025-05-21 |

| KR20220020360A (ko) | 2022-02-18 |

| US11690493B2 (en) | 2023-07-04 |

| US20220409001A1 (en) | 2022-12-29 |

| CN114340463B (zh) | 2023-11-21 |

| PL4064951T3 (pl) | 2025-10-06 |

| DE102019132312B4 (de) | 2022-11-03 |

| KR102773632B1 (ko) | 2025-02-25 |

| WO2021104689A1 (de) | 2021-06-03 |

| CN114340463A (zh) | 2022-04-12 |

| EP4064951A1 (de) | 2022-10-05 |

| CA3144815C (en) | 2024-04-16 |

| DE102019132312A1 (de) | 2021-06-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP4064951B1 (de) | Reinigungsroboter und reinigungssystem | |

| DE60318498T2 (de) | Roboter zur Behandlung von Behälter für biologische Proben | |

| DE69616564T2 (de) | Wischmop | |

| DE60103253T2 (de) | Reinigen von oberflächen | |

| DE102022102918A1 (de) | Bodenreinigungsgerät mit Kassette | |

| WO2017153450A1 (de) | Flächen-reinigungsmaschine | |

| DE212007000004U1 (de) | Handgeführtes Gerät und damit verbindbare Werkzeuge | |

| EP0659053B1 (de) | Aufbewahrungs- und wartungseinrichtung | |

| DE202022101312U1 (de) | Bodenreinigungsgerät mit Kassette | |

| EP4070711B1 (de) | Vorrichtung zur reinigung eines bodentuchs | |

| DE212021000577U1 (de) | Bodenbehandlungsmaschine | |

| EP3669739B1 (de) | Haushaltsroboter und verfahren für seine steuerung | |

| EP1190663A2 (de) | Wischmop | |

| WO2019145246A1 (de) | Reinigungswalze und boden-reinigungsmaschine damit | |

| DE102020108607B4 (de) | Reinigungseinrichtung zur Feuchtreinigung | |

| WO2019042570A1 (de) | Staubfilter für eine reinigungsmaschine mit einer filter-abreinigungseinrichtung, reinigungsmaschine, und verfahren zur herstellung eines staubfilters | |

| DE60318392T2 (de) | Maschine mit mehreren Stationen für die automatische Bearbeitung von Schuhrändern und Schuhboden | |

| DE60019330T2 (de) | Vorrichtung und verfahren zum reinigen von bodenpflegescheiben | |

| DE102018113493A1 (de) | Werkzeug und Verfahren zum Bearbeiten von plattenförmigen Werkstücken, insbesondere von Blechen | |

| DD259350A1 (de) | Vorrichtung zum nassreinigen glatter flaechen, wie scheiben, waende, decken und boeden | |

| DE102006051094A1 (de) | Handgerät zum Reinigen von Tieren | |

| DE202016008945U1 (de) | Flächen-Reinigungsmaschine | |

| DE9313324U1 (de) | Vorrichtung zum Entfernen einer Schutzfolie von einem Dichtungskörper | |

| WO2019215307A1 (de) | Schuhputzvorrichtung | |

| DE102019005840A1 (de) | Fußmattenvorrichtung mit einer Reinigungseinrichtung, Kraftfahrzeug sowie Verfahren |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20220419 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20241220 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| U01 | Request for unitary effect filed |

Effective date: 20250521 |

|

| U07 | Unitary effect registered |

Designated state(s): AT BE BG DE DK EE FI FR IT LT LU LV MT NL PT RO SE SI Effective date: 20250526 |

|

| U20 | Renewal fee for the european patent with unitary effect paid |

Year of fee payment: 6 Effective date: 20250725 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250821 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250822 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20250808 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250722 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250821 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250921 |