EP2301859B1 - Standbeutel aus einer heißsiegelfähigen Kunststofffolie und Verfahren zu ihrer Herstellung - Google Patents

Standbeutel aus einer heißsiegelfähigen Kunststofffolie und Verfahren zu ihrer Herstellung Download PDFInfo

- Publication number

- EP2301859B1 EP2301859B1 EP09012196A EP09012196A EP2301859B1 EP 2301859 B1 EP2301859 B1 EP 2301859B1 EP 09012196 A EP09012196 A EP 09012196A EP 09012196 A EP09012196 A EP 09012196A EP 2301859 B1 EP2301859 B1 EP 2301859B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- film

- pouch

- stand

- handle

- front wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002985 plastic film Substances 0.000 title claims description 9

- 229920006255 plastic film Polymers 0.000 title claims description 9

- 238000000034 method Methods 0.000 title claims description 7

- 238000004519 manufacturing process Methods 0.000 title claims description 6

- 238000007789 sealing Methods 0.000 claims description 37

- 239000000463 material Substances 0.000 claims description 12

- 239000007788 liquid Substances 0.000 claims description 7

- 230000002787 reinforcement Effects 0.000 claims 2

- 239000011888 foil Substances 0.000 description 56

- 238000004806 packaging method and process Methods 0.000 description 12

- 239000004698 Polyethylene Substances 0.000 description 8

- 239000002131 composite material Substances 0.000 description 4

- 229920000642 polymer Polymers 0.000 description 4

- 238000010276 construction Methods 0.000 description 3

- 230000003014 reinforcing effect Effects 0.000 description 3

- 230000004888 barrier function Effects 0.000 description 2

- 239000004744 fabric Substances 0.000 description 2

- 230000009969 flowable effect Effects 0.000 description 2

- 239000012263 liquid product Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 102100025908 5-oxoprolinase Human genes 0.000 description 1

- 229920000219 Ethylene vinyl alcohol Polymers 0.000 description 1

- 101000720962 Homo sapiens 5-oxoprolinase Proteins 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 229920002472 Starch Polymers 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- UFRKOOWSQGXVKV-UHFFFAOYSA-N ethene;ethenol Chemical compound C=C.OC=C UFRKOOWSQGXVKV-UHFFFAOYSA-N 0.000 description 1

- 239000004715 ethylene vinyl alcohol Substances 0.000 description 1

- 238000009963 fulling Methods 0.000 description 1

- -1 polyethylene Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 239000008107 starch Substances 0.000 description 1

- 235000019698 starch Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/06—Handles

- B65D33/10—Handles formed of similar material to that used for the bag

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/008—Standing pouches, i.e. "Standbeutel"

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/52—Details

- B65D75/54—Cards, coupons, or other inserts or accessories

- B65D75/56—Handles or other suspension means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/52—Details

- B65D75/58—Opening or contents-removing devices added or incorporated during package manufacture

- B65D75/5861—Spouts

- B65D75/5872—Non-integral spouts

- B65D75/5883—Non-integral spouts connected to the package at the sealed junction of two package walls

Definitions

- the invention relates to a stand-up pouch made of a heat-sealable plastic film, in particular for liquid filling material, with a front wall and a rear wall, which are connected at their longitudinal edges by sealing seams, and with an inwardly folded film bottom and a likewise folded inward Foliendeckel.

- the front wall and the Foliendeckel are connected by a transverse sealing seam.

- a closure device is arranged, which is connected in a fluid-tight manner to the adjacent surfaces of the foil lid and the front wall.

- Stand-up pouches with the features described above are for example made EP 1 233 915 A1 known. They are characterized in comparison to blow-molded packaging containers by a much lower weight and also have the advantage that the empty containers can be transported to save space and the packaging can be folded again after their emptying and disposed of to save space. Due to their low dimensional stability, however, the flexible bag packaging can be handled worse when pouring the contents. It is difficult to keep the bag packaging when pouring the contents, since the bag walls are resilient and the shape and the bag volume changes constantly during the Browntddling. A metered Artholdtddling requires some skill. The problems increase with increasing container size.

- the invention has for its object to improve the handling of a bag used for packaging purposes.

- the object is to provide a stand-up pouch that can be taken safely when pouring or pouring the contents and allows a metered delivery of flowable, especially liquid products.

- a foil-carrying handle is arranged approximately centrally on the rear wall.

- the pouring element may be formed as a pouring spout, which allows accurate metering of the poured contents and is closed with a cap.

- the pouring element can also have a screw cap, with which a dense and reliable reclosure can be achieved.

- the packaging is always held during the pouring out of the filling material in such a manner that the closing device is necessarily at the lowest point.

- This allows a metered delivery of product and unproblematic emptying.

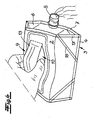

- the stand-up pouch according to the invention can always be held securely with one hand and aligned in such a way that the filling material contained in the stand-up pouch, in particular a liquid, flows to the closure device.

- the foil handle can have a handle loop, which is aligned either parallel or transverse to the longitudinal edges.

- the film carrier handle is preferably within the outer contour of the bag and therefore does not interfere with the transport of the flattened and initially unfilled bag.

- the foil handle according to the invention also allows the packaging can be refolded after their complete emptying and disposed of in a space-saving manner.

- a first embodiment provides that the foil-engaging handle is fastened to the inner side surface of the rear wall or the foil bottom and accessible through a handle opening in the rear wall or in the foil bottom.

- the attachment is preferably effected by heat sealing.

- the handle opening is liquid-tightly closed by a foil sheet, which is connected to the rear side of the foil-holding handle by a sealing seam surrounding the handle opening with the inner surface of the bag.

- the handle opening is closed by a detachable film section of the front wall or the foil bottom, so that the foil-engaging handle is arranged completely within the contour of the stand-up pouch.

- the stand-up pouches which initially leave a pouch-making plant as flattened, unfilled pouches, have smooth surfaces and as a result can be easily stacked and transported. Also, the transport of filled pouches, for example, in cartons or other packaging is not affected if the foil handle is hidden behind a smooth outer surface of the bag.

- the foil carrier handle has in this case an existing loop of a film strip which engages around a carrier sheet.

- the carrier sheet projecting on both sides of the loop is preferably secured to the rear foil sheet and / or to the inner surface of the bag by heat sealing.

- the carrying handle construction described has the advantage that the force acting when wearing the bag stand first is distributed on the carrier sheet and thus on a large area. The even force distribution allows the transmission of large loads.

- the foil-engaging handle can also be designed as a simple foil strip.

- a reinforcing sheet is arranged on the inner surface of the bag and connected to the inner surface by heat sealing, wherein a handle loop is formed from a section of the bag foil and the reinforcing sheet bounded on the edge by two slits.

- a closure sheet is provided, with which an opening formed by the grip loop is covered on the inside of the bag.

- the slots defining the grip loop can each be arranged between two sealing seams with which the reinforcing sheet is sealed onto the inner surface of the bag.

- the front wall, the rear wall, the foil bottom and the foil lid can be formed by folding a flat material web.

- the front wall and the film lid are connected by a sealed seam, which closes the folded material web tubular and forms an edge of the bag.

- the folding edges between the foil bottom and the foil surfaces of the front wall and rear wall and the folded edges between the foil lid and the foil surfaces of the front wall and back wall are expediently reinforced by sealing seams, so-called blind seal seams.

- sealing seams so-called blind seal seams.

- diagonal sealing seams are provided, which extend from the edges of the foil bottom or the foil lid each up to the Longitudinal edges of the bag and connect the front wall or rear wall with an adjacent edge of the foil bottom or Foliendeckels.

- the foil bottom and the foil lid have the same dimensions.

- the film bottom has a greater width than the film lid. This means that the film base in the flat state forms a deeper fold than the region of the film lid.

- the stand-up pouch can be made of transparent polymers or equipped with windows in order to be able to recognize the fill level.

- Advantageous material combinations are, for example, PET / PE, OPP / PE, PET / OPA / PP, OPP / PP and PE / PE.

- transparent barrier layers can be formed by SiOx-coated films or by coextruded barrier polymer layers, e.g. B. EVOH be provided.

- plastic films and composite materials may be used which have one or more layers of biodegradable and renewable resources. Examples are cellulose / starch polyester and OPLA / PLA polyester compounds.

- composite materials which comprise a metallic intermediate layer or an intermediate layer of a metallized polymer are also particularly suitable for the stand-up pouch according to the invention.

- Advantageous material combinations are PET / Alu / PE, PET / Alu / PP and OPP (metallized) / PP.

- the thickness of the plastic film depends largely on the bag size and the filling weight for which the stand-up pouch is designed.

- a stand-up pouch for liquids with a filling volume of about 2.5 L can for example be made of a plastic film, which has a three-layer structure with a 12 ⁇ m thick outer layer of PET, a 12 ⁇ m thick intermediate layer of PET and a 100 ⁇ m thick polyethylene layer on the inside of the bag.

- fabrics in the film composite it is also possible to use fabrics in the film composite.

- Such a plastic film has, for example, a layer composite of PE / fabric / PE.

- the invention also provides a method for producing the described bag with the method steps described below.

- foil-carrying handles are fixed so that the foil tucking handles are positioned after folding the foil web on a foil surface, which forms a rear wall of the stand-up pouch.

- the film web is formed by folding in a flattened gusseted tube, which is still open on one longitudinal side between a V-shaped inserted fold and the front wall of the stand-up bag forming surface.

- the gusseted tube is closed at its open longitudinal side with a longitudinal sealing seam, which is interrupted at predetermined intervals and thereby releases openings for inserting closure devices.

- the closure devices are then inserted into the openings in the longitudinal sealing seam and subsequently connected in a liquid-tight manner to the film web.

- the connection is preferably made with a heat-sealing tool, wherein the shape of the heat-sealing tool is adapted to the contour of the pouring element.

- the bottom and top film surfaces of the flattened gusseted bag are then still connected with transverse sealing sutures before separating from the gusseted tube stand-up pouches whose longitudinal edges have been formed by the transverse sealing sutures.

- the in the Fig. 1 to 4 and 6 illustrated stand-up pouch consists of a heat-sealable, preferably multilayer plastic film and is used to package flowable, especially liquid products.

- the stand-up pouch is manufactured as a flattened pouch and filled with the contents in bottling plants.

- the stand-up pouch shown in the figures consists in its basic structure of a front wall 1 and a rear wall 2, which are connected at their longitudinal edges 3 by sealing seams 4, and an inwardly folded Foil bottom 5 and a likewise folded inward Foliendeckel 6.

- the front wall 1 and the Foliendeckel 6 are connected by a transverse seam 7.

- a pouring element provided with a closure is arranged as a closure device 8, which is connected in a liquid-tight manner to the adjacent surfaces of the foil lid 6 and the front wall 1.

- a film bag handle 9 which the in Fig. 5 having shown construction.

- the film carrier handle 9 lies within the outer contour of the bag. It is attached to the bag inside surface of the rear wall 2 and accessible through a handle opening 10 in the rear wall 2.

- the handle opening 10 is liquid-tightly closed by a foil sheet 11, which is connected to the rear side of the foil-holding handle 9 by a sealing seam 12 surrounding the handle opening with the inner surface of the bag.

- the representation in Fig. 2 It can be seen that the handle opening 10 may be covered by a detachable film section 13 of the rear wall.

- the foil-holding handle 9 has a loop consisting of a film strip 14, which surrounds a carrier sheet 15.

- the carrier sheet 15 protrudes on both sides of the loop 14 and is secured to the overhanging ends by a seal 16 on the rear side foil sheet 11. It may additionally or alternatively also be sealed directly on the inner surface of the bag.

- the front wall 1, the rear wall 2, the film bottom 5 and the Foliendeckel 6 are formed by folding a flat material web.

- the front wall 1 and the film lid 6 are connected by a sealed seam 7, which closes the folded material web tubular and an edge of the bag forms.

- the folded edges between the foil bottom 5 and the foil surfaces of the front wall and rear wall and the folded edges between the foil lid 6 and the foil surfaces of the front wall and back wall are reinforced by sealing seams, so-called blind seal seams 17.

- the blind seal seams 17 have no sealing function and serve exclusively to reinforce or stiffen the bag.

- Diagonal sealing seams 18, which extend from the edges of the foil bottom 5 or the foil lid 6 to the longitudinal edges 3 of the pouch are also provided in the pouch corners. They each connect the front wall 1 or rear wall 2 with an adjacent flank of the foil bottom 5 or foil lid 6.

- the Fig. 6 shows the handling of a bag used as packaging for liquids when pouring the contents.

- the arrangement of the film carrier handle 9 on the rear wall 2 of the bag is achieved that the packaging is always kept during pouring of the contents so that the closure device 8 is located at the lowest point and a complete emptying of the packaging is easily possible.

- the closure device 8 in the form of a pouring element is arranged approximately at the center of the edge bounding the foil lid 6. Even off-center arrangements are readily possible.

- the film carrier handle 9 can be aligned parallel or transverse to the longitudinal edges 3.

- the Fig. 7 shows a method for producing the stand-up pouch.

- foil carrier handles 9 are fastened at predetermined intervals such that the foil tundishes 9 are positioned on a foil surface after folding over the foil web 19, which forms a back wall 2 or an inwardly folded foil bottom 5 of the stand-up pouches.

- the foil carrier handles 9 are prefabricated elements and have, for example, the in Fig. 5 shown construction.

- the gusseted tube 20 On its open longitudinal side 22, the gusseted tube 20 is closed with a longitudinal sealing seam 23, which corresponds to the transverse seal seam 7 in the finished stand-up pouch.

- the longitudinal sealing seam 23 is interrupted at predetermined intervals and thereby releases openings 24 for inserting pouring elements 8.

- pouring elements 8 are inserted into the openings 24 in the longitudinal sealing seam 23 and connected to the film web 19 in a liquid-tight manner.

- the lower and upper foil surfaces of the flattened gusseted tube 20 are connected to transverse sealing sutures 25.

- stand bags are separated from the gusseted tube, whose longitudinal edges have been formed by the transverse sealing seams 25.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bag Frames (AREA)

- Making Paper Articles (AREA)

Priority Applications (9)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09012196A EP2301859B1 (de) | 2009-09-25 | 2009-09-25 | Standbeutel aus einer heißsiegelfähigen Kunststofffolie und Verfahren zu ihrer Herstellung |

| PL09012196T PL2301859T3 (pl) | 2009-09-25 | 2009-09-25 | Torba stojąca z termozgrzewalnej folii z tworzywa sztucznego i sposób jej wytwarzania |

| ES09012196T ES2413191T3 (es) | 2009-09-25 | 2009-09-25 | Bolsa de fondo plano formada de una lámina de plástico apta para sellado con calor y procedimiento para su fabricación |

| US12/887,130 US8414188B2 (en) | 2009-09-25 | 2010-09-21 | Stand-up film bag and method of making same |

| CA2715240A CA2715240C (en) | 2009-09-25 | 2010-09-23 | Stand-up film bag and method of making same |

| JP2010213894A JP2011068412A (ja) | 2009-09-25 | 2010-09-24 | 直立バッグおよび直立バッグを製造するための方法 |

| RU2010139530/12A RU2533351C2 (ru) | 2009-09-25 | 2010-09-24 | Стоячий пакет из термосвариваемой синтетической пленки и способ его изготовления |

| MX2010010459A MX336084B (es) | 2009-09-25 | 2010-09-24 | Bolsa de fondo plano a partir de una lamina de plastico termosellable y procedimiento para su fabricacion. |

| CN201010546219.3A CN102030134B (zh) | 2009-09-25 | 2010-09-25 | 直立薄膜袋及其制造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09012196A EP2301859B1 (de) | 2009-09-25 | 2009-09-25 | Standbeutel aus einer heißsiegelfähigen Kunststofffolie und Verfahren zu ihrer Herstellung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2301859A1 EP2301859A1 (de) | 2011-03-30 |

| EP2301859B1 true EP2301859B1 (de) | 2013-03-13 |

Family

ID=41667483

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09012196A Active EP2301859B1 (de) | 2009-09-25 | 2009-09-25 | Standbeutel aus einer heißsiegelfähigen Kunststofffolie und Verfahren zu ihrer Herstellung |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US8414188B2 (es) |

| EP (1) | EP2301859B1 (es) |

| JP (1) | JP2011068412A (es) |

| CN (1) | CN102030134B (es) |

| CA (1) | CA2715240C (es) |

| ES (1) | ES2413191T3 (es) |

| MX (1) | MX336084B (es) |

| PL (1) | PL2301859T3 (es) |

| RU (1) | RU2533351C2 (es) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009057245A1 (de) * | 2009-12-08 | 2011-06-09 | Haver & Boecker Ohg | Vorrichtung und Verfahren zum Verarbeiten von Schlauchfolie zu Säcken und Füllen derselben mit Schüttgütern |

| HUE034644T2 (en) * | 2010-05-12 | 2018-02-28 | Mondi Halle Gmbh | Bottom pouch made of hot-welded plastic |

| US8322923B2 (en) * | 2010-06-15 | 2012-12-04 | Mondi Jackson, Inc | Film bag with handle |

| EP2433879B1 (de) * | 2010-09-27 | 2013-07-31 | Mondi Halle GmbH | Standbeutel für schüttfähige Güter sowie Verfahren zur Herstellung eines Standbeutels |

| DE202011102943U1 (de) * | 2011-07-05 | 2012-07-04 | Bischof + Klein Gmbh & Co. Kg | Verpackungsbehälter |

| US20140044379A1 (en) | 2012-08-10 | 2014-02-13 | Mark W. Gum | Stand-up bag of a weldable foil for holding pourable contents |

| US9682802B2 (en) * | 2012-09-09 | 2017-06-20 | Coveris Flexibles Us Llc | Gusseted pouches |

| US8961012B2 (en) | 2012-10-19 | 2015-02-24 | Peel Plastic Products Limited | Bag with handle |

| CA2893581A1 (en) * | 2012-12-20 | 2014-06-26 | Nestec S.A. | Flexible pouch wih a larger opening |

| JP6073711B2 (ja) * | 2013-03-04 | 2017-02-01 | 株式会社細川洋行 | 袋体及び当該袋体を用いた流体吐出方法 |

| US20140346252A1 (en) * | 2013-05-23 | 2014-11-27 | Chris Davis | Spray container |

| US9533463B2 (en) * | 2013-08-18 | 2017-01-03 | Mondi Jackson, Inc | Film bag |

| CA2927233A1 (en) * | 2013-11-06 | 2015-05-14 | The Procter & Gamble Company | Containers having a product volume and a stand-off structure coupled thereto |

| US9493272B2 (en) * | 2013-12-06 | 2016-11-15 | Mondi Jackson, Inc | Film bag |

| JP2016064848A (ja) * | 2014-09-24 | 2016-04-28 | 株式会社フジシールインターナショナル | パウチ容器およびパウチ容器の製造方法 |

| JP6345416B2 (ja) * | 2013-12-09 | 2018-06-20 | 株式会社フジシールインターナショナル | パウチ容器 |

| US20160304261A1 (en) * | 2013-12-09 | 2016-10-20 | Fuji Seal International, Inc. | Pouch container and method for manufacturing pouch container |

| US9650178B2 (en) * | 2014-01-16 | 2017-05-16 | The Fresh Group, Ltd. | Watermelon pouch |

| JP2016188093A (ja) * | 2015-03-30 | 2016-11-04 | 株式会社フジシールインターナショナル | パウチ容器 |

| KR101969665B1 (ko) | 2015-04-10 | 2019-04-16 | 더 프록터 앤드 갬블 캄파니 | 보강 시일을 가진 가요성 용기 |

| EP3184455A1 (en) * | 2015-12-21 | 2017-06-28 | Dow Global Technologies LLC | Flexible packaging with a straining feature |

| DE102016119113A1 (de) * | 2016-06-16 | 2017-12-21 | Windmöller & Hölscher Kg | Sack, sowie Verfahren zur Herstellung eines Sackes |

| IT201600079828A1 (it) * | 2016-07-29 | 2018-01-29 | Goglio Spa | Confezione per prodotti fluidi o semi-solidi e relativo metodo di produzione |

| TWI643792B (zh) * | 2018-05-16 | 2018-12-11 | 張祿文 | 具強化壓痕之軟性包裝袋及其製造方法 |

| US20220097942A1 (en) * | 2019-01-10 | 2022-03-31 | Positive Packaging United (ME)FZCO | A panel for a flexible package |

| CN111196425A (zh) * | 2019-01-25 | 2020-05-26 | 汕头市虹桥包装实业有限公司 | 包装袋结构及其加工方法 |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2059621A (en) * | 1935-04-29 | 1936-11-03 | Bemis Bro Bag Co | Carrying handle for containers |

| FR2215359B1 (es) * | 1973-01-26 | 1980-03-21 | Doyen Leon | |

| DE3119179A1 (de) | 1981-05-14 | 1982-12-02 | Kessel, Christoph, Ing.(grad.), 3030 Walsrode | Bodenfaltenbeutel |

| DE3205340A1 (de) * | 1982-02-15 | 1983-08-25 | Nordenia Kunststoffwerke Peter Mager KG, 2841 Steinfeld | Sack, insbesondere ventilsack, vorzugsweise aus kunststoffolie |

| DE3812444A1 (de) * | 1988-04-14 | 1989-10-26 | Minnesota Mining & Mfg | Verfahren zum versehen von verpackungen, insbesondere parallelepipedischen wie kartons oder von zuschnitten fuer verpackungen mit einem handgriff |

| DE8905480U1 (de) * | 1989-04-29 | 1989-06-22 | Bischof Und Klein Gmbh & Co, 4540 Lengerich | Formbodensack mit einem Traggriff |

| DE3925379A1 (de) * | 1989-06-30 | 1991-01-03 | Hoechst Ag | Standfaehiger beutel |

| DE3925981A1 (de) * | 1989-08-05 | 1991-02-07 | Hoechst Ag | Prismatischer standbeutel fuer fliessfaehige fuellgueter |

| US5160308A (en) * | 1990-01-11 | 1992-11-03 | Canon Kabushiki Kaisha | Flexible bag with pouring spout |

| DE69110284T2 (de) * | 1990-06-01 | 1995-10-19 | Johnson & Son Inc S C | Standfester beutel mit querverschluss sowie verfahren zu seiner herstellung. |

| US6213641B1 (en) * | 1997-08-25 | 2001-04-10 | S. C. Johnson Home Storage, Inc. | Thermoplastic bag with offset fastener |

| GB2331065B (en) * | 1997-11-10 | 2002-01-16 | Gr Advanced Materials Ltd | Dispensing container for highly viscous liquids |

| JP4108848B2 (ja) * | 1998-11-20 | 2008-06-25 | 大日本印刷株式会社 | 注出口付き自立袋 |

| JP4139494B2 (ja) * | 1998-11-20 | 2008-08-27 | 大日本印刷株式会社 | 上下ガセット付き液体用パウチ |

| RU2239588C2 (ru) * | 1999-03-29 | 2004-11-10 | АМКОР ФЛЕКСИБЛЕС ЮРОП А/С к/о ГОРРИССЕН ФЕДЕРСПИЕЛ КИЕРКЕГОР | Вертикально стоящий пакет |

| JP4601763B2 (ja) * | 1999-11-17 | 2010-12-22 | 大日本印刷株式会社 | ボトル形パウチ |

| DE19957563A1 (de) | 1999-11-30 | 2001-06-07 | Sps Verpackungs System Gmbh | Standbeutel mit umknickbarem Verschlusselement |

| EP1133915A1 (de) | 2000-03-15 | 2001-09-19 | Thomas Schmidmeier | Verfahren und Vorrichtung zur vollkontinuierlichen Häckselung von Strohballen und staubfreien Ablegung des gehäckselten Guts. |

| JP3516031B2 (ja) * | 2000-04-25 | 2004-04-05 | 花王株式会社 | 袋 |

| US6361209B1 (en) * | 2000-07-14 | 2002-03-26 | Pactiv Corporation | Handle bag with closure |

| FR2838077B1 (fr) * | 2002-04-09 | 2004-11-26 | Flexico France Sarl | Sac double soufflet |

| US7396163B2 (en) * | 2002-12-14 | 2008-07-08 | Mcgregor James Ray | Paper and plastic bags flexible packages and other containers with re-closable device and method of making the same |

| DE20311386U1 (de) * | 2003-07-25 | 2003-10-16 | Bischof + Klein GmbH & Co. KG, 49525 Lengerich | Verpackungsbehälter aus Kunststoffolie |

| JP2005088927A (ja) * | 2003-09-17 | 2005-04-07 | Toppan Printing Co Ltd | 帯付き包装袋 |

| JP2005231677A (ja) * | 2004-02-19 | 2005-09-02 | Dainippon Printing Co Ltd | チャックテープ付き袋 |

| DK1792722T3 (da) | 2006-10-02 | 2009-02-23 | Nordenia D Halle Gmbh | Folieemballagepose |

| JP5302554B2 (ja) * | 2008-03-06 | 2013-10-02 | 押尾産業株式会社 | 自立包装袋及びその製造方法 |

| US7971720B2 (en) * | 2009-06-24 | 2011-07-05 | The Clorox Company | Vertically stacking litter bag with handle |

| HUE034644T2 (en) * | 2010-05-12 | 2018-02-28 | Mondi Halle Gmbh | Bottom pouch made of hot-welded plastic |

| US20110286688A1 (en) * | 2010-05-18 | 2011-11-24 | Gum Mark W | Recolsable gusset bag |

-

2009

- 2009-09-25 PL PL09012196T patent/PL2301859T3/pl unknown

- 2009-09-25 ES ES09012196T patent/ES2413191T3/es active Active

- 2009-09-25 EP EP09012196A patent/EP2301859B1/de active Active

-

2010

- 2010-09-21 US US12/887,130 patent/US8414188B2/en active Active

- 2010-09-23 CA CA2715240A patent/CA2715240C/en not_active Expired - Fee Related

- 2010-09-24 MX MX2010010459A patent/MX336084B/es unknown

- 2010-09-24 RU RU2010139530/12A patent/RU2533351C2/ru active

- 2010-09-24 JP JP2010213894A patent/JP2011068412A/ja active Pending

- 2010-09-25 CN CN201010546219.3A patent/CN102030134B/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN102030134B (zh) | 2015-04-22 |

| CN102030134A (zh) | 2011-04-27 |

| EP2301859A1 (de) | 2011-03-30 |

| MX2010010459A (es) | 2011-03-24 |

| RU2010139530A (ru) | 2012-03-27 |

| JP2011068412A (ja) | 2011-04-07 |

| CA2715240C (en) | 2017-11-28 |

| RU2533351C2 (ru) | 2014-11-20 |

| US20110229060A1 (en) | 2011-09-22 |

| US8414188B2 (en) | 2013-04-09 |

| PL2301859T3 (pl) | 2013-08-30 |

| MX336084B (es) | 2016-01-05 |

| ES2413191T3 (es) | 2013-07-15 |

| CA2715240A1 (en) | 2011-03-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2301859B1 (de) | Standbeutel aus einer heißsiegelfähigen Kunststofffolie und Verfahren zu ihrer Herstellung | |

| EP2386493B1 (de) | Standbodenbeutel aus einer heißsiegelfähigen Kunststofffolie | |

| EP2148820B1 (de) | Folienverpackungsbeutel | |

| EP3023356B1 (de) | Verfahren zur herstellung eines seitenfaltenbeutels | |

| EP2032454B2 (de) | Folienbeutel | |

| EP2039620B1 (de) | Seitenfaltenbeutel | |

| EP2354026B1 (de) | Seitenfaltenbeutel und Verfahren zur Herstellung eines Seitenfaltenbeutels | |

| DE69506841T2 (de) | Flüssigkeitsbehälter und verfahren zu seiner herstellung | |

| EP0491694A1 (de) | Verpackungsbehälter aus karton mit innenbeutel zur aufnhame von flüssigkeiten. | |

| EP2583912B1 (de) | Verpackungsbehältnis | |

| EP2433879A1 (de) | Standbeutel für schüttfähige Güter sowie Verfahren zur Herstellung eines Standbeutels | |

| EP2555995B1 (de) | PACKUNG FÜR FLIEßFÄHIGE PRODUKTE | |

| EP3246266A1 (de) | Verfahren zur herstellung eines seitenfaltenbeutels sowie flachliegender, unbefüllter seitenfaltenbeutel | |

| EP2228315A1 (de) | Verpackungsbeutel | |

| EP2511187A2 (de) | Behälter zum Verpacken von Füllgütern und Verfahren zur Bearbeitung einer Materialbahn | |

| EP0915031B1 (de) | Satbilisierter, kubischer, flexibler Behälter | |

| EP3643635B1 (de) | Unbefüllter, unverschlossener seitenfaltenverpackungsbeutel | |

| DE9200869U1 (de) | Verpackungsbeutel aus flexiblem Material | |

| DE202016102623U1 (de) | Flachliegender, unbefüllter Seitenfaltenbeutel | |

| EP1538095B1 (de) | Deckblatt für Sack-, Beutel- o. dgl. Verpackungen | |

| DE202012006946U1 (de) | Verpackungsbehälter mit Entlüftungsfunktion | |

| EP3170765A2 (de) | Verpackungsbeutel aus kunststofffolie mit einem tragegriff | |

| DE202023104536U1 (de) | Nahrungsmittelzubereitung in verbesserter Darreichungsform | |

| DE102017121981A1 (de) | Folienbeutel sowie Verfahren zur Bildung von Folienbeuteln | |

| DE102016121949A1 (de) | Folienbeutel zur dosierten Entnahme einer Flüssigkeit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20110126 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: MONDI HALLE GMBH |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 600668 Country of ref document: AT Kind code of ref document: T Effective date: 20130315 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009006449 Country of ref document: DE Effective date: 20130508 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2413191 Country of ref document: ES Kind code of ref document: T3 Effective date: 20130715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130613 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130613 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20130313 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130614 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130713 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130715 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 |

|

| 26N | No opposition filed |

Effective date: 20131216 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009006449 Country of ref document: DE Effective date: 20131216 |

|

| BERE | Be: lapsed |

Owner name: MONDI HALLE G.M.B.H. Effective date: 20130930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130925 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20140822 Year of fee payment: 6 Ref country code: ES Payment date: 20140926 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090925 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130313 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130925 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 600668 Country of ref document: AT Kind code of ref document: T Effective date: 20140925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140925 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20170227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150926 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20210920 Year of fee payment: 13 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220925 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220925 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20230922 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230830 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240925 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240924 Year of fee payment: 16 |