WO2018190288A1 - 雌端子 - Google Patents

雌端子 Download PDFInfo

- Publication number

- WO2018190288A1 WO2018190288A1 PCT/JP2018/014879 JP2018014879W WO2018190288A1 WO 2018190288 A1 WO2018190288 A1 WO 2018190288A1 JP 2018014879 W JP2018014879 W JP 2018014879W WO 2018190288 A1 WO2018190288 A1 WO 2018190288A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- contact pressure

- contact

- male terminal

- pressure applying

- terminal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/02—Contact members

- H01R13/10—Sockets for co-operation with pins or blades

- H01R13/11—Resilient sockets

- H01R13/115—U-shaped sockets having inwardly bent legs, e.g. spade type

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/02—Contact members

- H01R13/10—Sockets for co-operation with pins or blades

- H01R13/11—Resilient sockets

- H01R13/113—Resilient sockets co-operating with pins or blades having a rectangular transverse section

Definitions

- the technology disclosed in this specification relates to a female terminal.

- a female terminal described in Japanese Patent Application Laid-Open No. 2014-53205 (Patent Document 1 below) is known.

- This female terminal is made by pressing and bending a sheet metal. Further, the processed female terminal is plated.

- the female terminal has a rectangular tubular box part into which the male tab terminal is inserted, and a conductor crimping part to which the conductor of the electric wire is crimped on the rear side of the box part.

- a leaf spring and a tab receiving portion are provided inside the box portion.

- the leaf spring is provided on the upper wall inside the box portion and elastically contacts the male tab terminal.

- the tab receiving portion is provided on the lower wall inside the box portion and comes into contact with the male tab terminal.

- the male tab terminal is made by pressing and bending a sheet metal. Further, the processed male tab terminal is plated.

- the male tab terminal has a male-side main body that forms a rod shape.

- the male side main body part When the male side main body part is inserted into the box part of the female terminal, the male side main body part is sandwiched between the leaf spring and the tab receiving part. Thereby, a male tab terminal and a female terminal contact elastically, and are electrically connected.

- the male side main body part of the male tab terminal is inserted while being elastically pressed against the leaf spring inside the box part, so the contact part between the male tab terminal and the female terminal Then, the plating applied to the female terminal is worn.

- plating wear increases. In order to prevent such plating wear, it is generally necessary to reduce the contact pressure of the leaf spring of the female terminal.

- the contact pressure of the leaf spring of the female terminal is lowered, the connection reliability between the terminals is lowered, and there is a problem that a connection failure between the terminals easily occurs due to vibration or the like.

- a female terminal disclosed in the present specification is a female terminal fitted to a male terminal, and has a ceiling wall and a bottom wall facing in the vertical direction, and the male terminal is inserted and opened in the front-rear direction.

- a pressure application unit, and a second contact pressure application unit that is provided at a position facing the first contact pressure application unit in the vertical direction and that contacts the male terminal from the bottom wall side to apply contact pressure,

- the first contact portion where the first contact pressure applying portion and the male terminal are in contact with each other, and the second contact portion where the second contact pressure applying portion and the male terminal are in contact with each other are shifted in the front-rear direction.

- the contact pressure applied to the male terminal by the first contact pressure applying unit is the contact pressure applied to the male terminal by the second contact pressure applying unit. It is lower.

- the contact pressure applied to the male terminal by the second contact pressure applying portion from the bottom wall side inside the female side main body portion is set as a high contact pressure, and the ceiling wall side inside the female side main body portion is set.

- the contact pressure applied to the male terminal by the first contact pressure applying unit can be set to a low contact pressure.

- the high contact pressure is a contact pressure at which electrical connection is not interrupted at the contact portion between the female terminal and the male terminal when vibration or the like is applied to the fitted male terminal and female terminal. .

- the low contact pressure is a contact pressure lower than the high contact pressure. Even when the male terminal is inserted into and removed from the female terminal, the plating applied to the female terminal does not wear at the contact portion between the male terminal and the female terminal. The contact pressure is about. By doing in this way, the plating applied to the female terminal will be worn at the second contact part where the second contact pressure applying part of high contact pressure and the male terminal are in contact with each other. It becomes difficult to receive, and it becomes difficult to produce the connection failure between both male and female terminals. On the other hand, in the first contact portion where the low contact pressure first contact pressure applying portion and the male terminal are in contact with each other, the wear of the plating applied to the female terminal can be prevented.

- the second contact pressure applying portion having a high contact pressure allows the plating to be worn while ensuring the connection reliability between the terminals, and the first contact pressure applying portion having a low contact pressure prevents the plating from being worn. Continuity is also ensured by multiple insertion / extraction of male terminals to / from female terminals.

- two said 1st contact pressure provision parts and said 2nd contact pressure provision parts are distribute

- a third contact pressure applying portion that contacts the male terminal from the ceiling wall side to apply a contact pressure, and is provided at a position facing the third contact pressure applying portion in the vertical direction.

- a fourth contact pressure applying portion that contacts from the bottom wall side and applies a contact pressure; a third contact portion that contacts the third contact pressure applying portion and the male terminal; and the fourth contact pressure applying portion.

- the fourth contact portion in contact with the male terminal are arranged to be displaced in the front-rear direction, and the contact pressure applied to the male terminal by the third contact pressure applying portion is the fourth contact pressure applying It may be higher than the contact pressure applied to the male terminal by the portion.

- a high contact pressure is applied to the male terminal from the bottom wall side by the two second contact pressure applying portions, and from the ceiling wall side, the high contact pressure is applied by the one third contact pressure applying portion. Contact pressure will be applied.

- the male terminal in the male housing may be rattled to facilitate the fitting of the male terminal and the female terminal.

- the male terminal When the male terminal is rattling in this way and there is only one pair of the low contact pressure first contact pressure applying portion and the high contact pressure second contact pressure applying portion, When the terminal passes through the second contact portion of the high contact pressure second contact pressure applying portion, the male terminal is displaced to the ceiling wall side by rattling in the male housing, and the first contact pressure with the male terminal is low contact pressure. The application part slides in contact with the contact pressure with a high contact pressure. Thereby, the plating of the first contact pressure applying portion is worn.

- the male terminal can be inserted into and removed from the inside of the female-side main body without the plating of the contact pressure applying portion being worn.

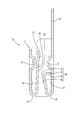

- the second contact pressure applying portion includes a second vertical piece extending vertically from the second contact portion toward the bottom wall, and the end surface of the second vertical piece is inserted into the second vertical piece by the insertion of the male terminal. It is good also as contacting the bottom wall.

- the second contact portion of the second contact pressure applying portion that contacts the male terminal is displaced toward the bottom wall.

- the second vertical piece of the second contact pressure applying portion is also displaced toward the bottom wall, and the end surface of the second vertical piece comes into contact with the bottom wall.

- the second vertical piece extends vertically from the second contact portion toward the bottom wall, it hardly bends. Therefore, when the second vertical piece comes into contact with the bottom wall, the second contact portion is Little displacement towards the bottom wall. Therefore, the second contact pressure applying unit can apply a high contact pressure to the male terminal.

- the third contact pressure applying portion includes a third vertical piece extending vertically from the third contact portion toward the ceiling wall, and insertion of the male terminal causes an end surface of the third vertical piece to be It is good also as contacting a ceiling wall.

- the third contact pressure applying unit can apply a high contact pressure to the male terminal, similarly to the above-described second contact pressure applying unit.

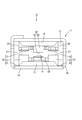

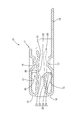

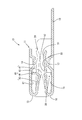

- FIG. BB Front view of female terminal Top view of female terminal Rear view of female terminal AA sectional view in FIG. BB sectional view in FIG. CC sectional view in FIG. DD sectional view in FIG. EE sectional view in FIG.

- the present embodiment will be described with reference to FIGS.

- the female terminal 10 of this embodiment is formed by punching and bending a copper sheet metal. Further, the processed female terminal 10 is plated with silver or the like. As shown in FIG. 1, the female terminal 10 includes a female-side main body 11 and a wire connecting portion 18 provided behind the female-side main body 11. The female terminal 10 is fitted with a male terminal (not shown).

- the male terminal has a plate shape and is formed by punching a sheet metal or the like. Furthermore, the processed male terminal is plated with silver or the like.

- the female main body 11 has a box shape and is open in the front-rear direction.

- the female side main body 11 has a ceiling wall 12 and a bottom wall 15 that face each other in the vertical direction.

- the fitting direction of the female terminal 10 with the male terminal is the front, and the direction from the bottom wall 15 of the female-side main body 11 to the ceiling wall 12 is the upper side.

- the ceiling wall 12 includes two first contact pressure applying portions 20 that apply a low contact pressure to the male terminal, and one first contact that applies a high contact pressure to the male terminal. And a three-contact pressure applying unit 40.

- the high contact pressure is a contact pressure at which electrical connection is not interrupted at the contact portion between the female terminal 10 and the male terminal when vibration or the like is applied to the fitted male terminal and female terminal 10. It is. When such a high contact pressure is applied to the male terminal, when the male terminal is inserted into and extracted from the female terminal 10, the plating applied to the contact portion between the male terminal and the female terminal 10 is worn.

- the low contact pressure is a contact pressure lower than the high contact pressure, and the plating applied to the female terminal 10 at the contact portion between the male terminal and the female terminal 10 even if the male terminal is inserted into and removed from the female terminal 10.

- the contact pressure is such that does not wear.

- the two first contact pressure applying portions 20 are connected via a first base end portion 13 having a shape folded from the front end edge of the ceiling wall 12 to the inside of the female side main body portion 11. It is formed to extend rearward.

- the first contact portion 21 is provided on the rear end side of the female-side main body 11 and is formed to protrude downward in an embossed shape inside the female-side main body 11.

- the first contact portion 21 contacts a male terminal (not shown).

- the third contact pressure applying unit 40 is disposed between the two first contact pressure applying units 20 as shown in FIGS. 2 and 6.

- the third contact pressure applying part 40 includes a third contact part 41 that contacts a male terminal (not shown), and a third inclined part 42 that is inclined from the third contact part 41 toward the first base end part 13 on the ceiling wall 12 side. And a third vertical piece 43 extending vertically from the third contact portion 41 toward the ceiling wall 12.

- the third contact portion 41 is provided in front of the first contact portion 21 of the first contact pressure applying portion 20 that applies a low contact pressure.

- the end surface 44 of the third vertical piece 43 and the ceiling wall 12 are not in contact with each other.

- the end surface 44 and the bottom wall 15 are in contact with each other.

- the male terminal is further inserted into the female main body 11 with the end face 44 in contact with the ceiling wall 12, the third vertical piece 43 is held down against the ceiling wall 12 by the male terminal.

- the second contact pressure applying portion 30 is hardly bent. Therefore, the contact pressure applied to the male terminal by the second contact pressure applying unit 30 is a high contact pressure.

- the bottom wall 15 includes two second contact pressure applying portions 30 that apply a high contact pressure to the male terminal and one first contact that applies a low contact pressure to the male terminal. And a four-contact pressure applying unit 50.

- the two second contact pressure applying portions 30 are provided at positions facing the first contact pressure applying portion 20 in the vertical direction as shown in FIGS. 2, 5, and 7. Further, as shown in FIG. 5, the two second contact pressure applying portions 30 include a second contact portion 31 that contacts a male terminal (not shown), and a second base end portion that extends from the second contact portion 31 to the bottom wall 15. 16 and a second vertical piece 33 extending vertically from the second contact portion 31 toward the ceiling wall 12. The end surface 34 of the second vertical piece 33 and the bottom wall 15 are not in contact with each other, but when a male terminal (not shown) is inserted into the female main body 11, the end surface 34 and the bottom wall 15 are in contact with each other. .

- the second base end portion 16 has a shape that is folded back from the front end edge of the bottom wall 15 to the inside of the female-side main body portion 11.

- the second contact portion 31 is provided in front of a fourth contact portion 51 described later.

- the 2nd contact pressure provision part 30 has comprised the same shape as the 3rd contact pressure provision part 40, and can provide a high contact pressure with respect to a male terminal.

- the fourth contact pressure applying unit 50 is provided at a position facing the third contact pressure applying unit 40 in the vertical direction.

- the fourth contact pressure applying part 50 is formed to extend rearward via the second base end part 16.

- the fourth contact portion 51 is provided on the rear end side of the female-side main body 11 and is formed to protrude upward in an embossed shape inside the female-side main body 11.

- the fourth contact portion 51 contacts a male terminal (not shown).

- a first excessive deflection preventing portion 14 is provided behind the ceiling wall 12 of the female side main body portion 11.

- the first excessive deflection preventing portion 14 is formed by hitting a part of the ceiling wall 12 and extruding inward from the opposite surface of the ceiling wall 12.

- a second excessive deflection preventing portion 17 is provided behind the bottom wall 15 of the female side main body portion 11.

- the second excessive deflection preventing portion 17 is also formed in the same manner as the first excessive deflection preventing portion 14, and prevents the second contact pressure applying portion 30 and the fourth contact pressure applying portion 50 from being excessively bent and plastically deformed. Yes.

- the wire connecting portion 18 is formed to protrude rearward from the rear end of the bottom wall 15.

- An electric wire (not shown) is connected to the electric wire connecting portion 18 so that the female terminal 10 and the electric wire are electrically connected.

- the male terminal When the male terminal is inserted into the female-side main body 11 of the female terminal 10, although not shown, the male terminal has two second contact pressure applying portions 30 that apply high contact pressure on the bottom wall 15 side, and high contact pressure.

- the third contact pressure application part 40 on the ceiling wall 12 side that applies Thereby, the male terminal and the second contact part 31 of the second contact pressure applying part 30 slide. Further, the male terminal and the third contact part 41 of the third contact pressure applying part 40 slide.

- the plating applied to the second contact pressure applying portion 30 and the third contact pressure applying portion 40 of the female terminal 10 is worn, but the electrical connection is not interrupted by vibration as will be described later.

- the first inclined portion 22 of the first contact pressure applying portion 20 is provided at a position facing the vertical direction of the second contact portion 31, and the first inclined portion 22 of the third contact portion 41 is positioned at the position facing the vertical direction.

- a fourth inclined portion 52 of the four contact pressure applying portion 50 is provided.

- the first inclined portion 22 and the fourth inclined portion 52 are positioned at positions facing the vertical direction. Even if there is the second contact portion 31 and the third contact portion 41 that apply a high contact pressure, the high contact pressure is not applied, and the plating applied to the first inclined portion 22 and the fourth inclined portion 52 does not wear.

- the male terminal When the male terminal is further inserted into the female-side main body 11, although not shown, the male terminal is connected to the first contact portion 21 of the first contact pressure applying portion 20 that applies a low contact pressure and the low contact pressure. It contacts with the fourth contact part 51 of the fourth contact pressure applying part 50 for applying the pressure. As a result, the male terminal and the first contact portion 21 slide, and the male terminal and the fourth contact portion 51 slide. However, since the contact pressure applied to the male terminal by the first contact pressure applying portion 20 and the fourth contact pressure applying portion 50 is low contact pressure, the plating applied to the first contact portion 21 and the fourth contact portion 51 is Does not wear.

- the contact point between the male terminal and the female terminal 10 also swings.

- the male terminal includes two second contact pressure applying portions 30 and one Since the high contact pressure is applied by the third contact pressure applying unit 40, the electrical connection between the male terminal and the female terminal 10 is maintained without interruption.

- the first contact portion 21 and the fourth contact pressure of the first contact pressure applying portion 20 that apply a low contact pressure are the same as when the male terminal is inserted.

- the plating does not wear at the fourth contact portion 51 of the applying portion 50.

- the plating is worn at the second contact portion 31 of the second contact pressure applying portion 30 that applies a high contact pressure and the third contact portion 41 of the third contact pressure applying portion 40. Accordingly, even if the second contact pressure applying portion 20 and the third contact pressure applying portion 30 that apply high contact pressure and the wear of the plating due to sliding between the male terminals is allowed, the first contact pressure that applies low contact pressure. Plating wear due to sliding between the applying portion 20 and the fourth contact pressure applying portion 50 and the male terminal can be prevented.

- the contact pressure applied to the male terminal by the second contact pressure applying unit 30 from the bottom wall 15 side inside the female side body unit 11 is set to a high contact pressure

- the female side body unit 11 the contact pressure applied to the male terminal by the first contact pressure applying unit 20 from the inside of the ceiling wall 12 can be set to a low contact pressure

- the high contact pressure is a contact pressure at which electrical connection is not interrupted at the contact portion between the female terminal and the male terminal 10 when vibration or the like is applied to the fitted male terminal and female terminal 10. It is.

- the low contact pressure is a contact pressure lower than the high contact pressure, and the plating applied to the female terminal 10 at the contact portion between the male terminal and the female terminal 10 even if the male terminal is inserted into and removed from the female terminal 10.

- the contact pressure is such that does not wear.

- the high contact pressure second contact pressure applying portion 30 ensures the connection reliability between the terminals while allowing plating wear, and the low contact pressure first contact pressure applying portion 20 prevents plating wear.

- electrical continuity is ensured by multiple insertion / extraction of the male terminal with respect to the female terminal 10.

- a high contact pressure is applied to the male terminal from the bottom wall 15 side by the two second contact pressure applying portions 30, and a high contact pressure is applied from the ceiling wall 12 side by the one third contact pressure applying portion 40. Pressure will be applied.

- the male terminal in the male housing may be rattled to facilitate the fitting of the male terminal and the female terminal 10. In this way, when the male terminal is rattling, there is only one pair of the low contact pressure first contact pressure applying portion 20 and the high contact pressure second contact pressure applying portion 30.

- the male terminal passes through the second contact portion 31 of the second contact pressure applying portion 30 having a high contact pressure, the male terminal is displaced to the ceiling wall 12 side by rattling in the male housing, and the male terminal has a low contact pressure.

- the first contact pressure applying portion 20 contacts and slides at a high contact pressure. Thereby, the plating of the first contact pressure applying portion 20 is worn.

- the male terminal can be inserted into and removed from the female main body 11 without the plating of the first contact pressure applying portion 20 being worn.

- the second contact portion 31 of the second contact pressure applying portion 30 that contacts the male terminal is displaced toward the bottom wall 15. Accordingly, the second vertical piece 33 of the second contact pressure applying unit 30 is also displaced toward the bottom wall, and the end surface of the second vertical piece 33 comes into contact with the bottom wall.

- the second vertical piece 33 extends vertically from the second contact portion toward the bottom wall, it hardly bends. Therefore, when the second vertical piece 33 abuts against the bottom wall 15, the second contact point The portion 31 is hardly displaced toward the bottom wall 15. Therefore, the second contact pressure applying unit 30 can apply a high contact pressure to the male terminal.

- the third contact pressure applying unit 40 can apply a high contact pressure to the male terminal.

- the technology disclosed in the present specification is not limited to the embodiments described with reference to the above description and drawings, and includes, for example, the following various aspects.

- the second contact pressure applying unit 30 and the third contact pressure applying unit 40 that apply a high contact pressure are integrated with the female main body 11, but may be separate.

- the first contact pressure applying portion 20 and the third contact pressure applying portion 40 are formed to extend backward via the first base end portion 13 provided at the front end of the ceiling wall 12. But, A base end portion may be provided at the rear end of the ceiling wall 12 and may be formed to extend forward from the base end portion.

- the second contact pressure applying portion 30 and the fourth contact pressure applying portion 50 are formed to extend rearward through the second base end portion 16 provided at the front end of the bottom wall 15.

- a base end portion may be provided at the rear end, and the base end portion may be formed to extend forward.

Landscapes

- Connector Housings Or Holding Contact Members (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/604,991 US10819056B2 (en) | 2017-04-14 | 2018-04-09 | Female terminal |

| CN201880024086.8A CN110546820B (zh) | 2017-04-14 | 2018-04-09 | 阴端子 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-080527 | 2017-04-14 | ||

| JP2017080527A JP6807024B2 (ja) | 2017-04-14 | 2017-04-14 | 雌端子 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018190288A1 true WO2018190288A1 (ja) | 2018-10-18 |

Family

ID=63792609

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/014879 Ceased WO2018190288A1 (ja) | 2017-04-14 | 2018-04-09 | 雌端子 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US10819056B2 (enExample) |

| JP (1) | JP6807024B2 (enExample) |

| CN (1) | CN110546820B (enExample) |

| WO (1) | WO2018190288A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022190950A1 (ja) * | 2021-03-08 | 2022-09-15 | 株式会社オートネットワーク技術研究所 | 端子ユニット,雌端子,雄端子 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN211975239U (zh) | 2020-03-25 | 2020-11-20 | 浙江双良汽车零部件有限公司 | 一种燃油泵组件 |

| JP7435329B2 (ja) * | 2020-07-14 | 2024-02-21 | 住友電装株式会社 | 端子金具 |

| JP7487674B2 (ja) * | 2021-01-18 | 2024-05-21 | 住友電装株式会社 | 端子金具 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5675483U (enExample) * | 1979-11-15 | 1981-06-19 | ||

| JPH01106083U (enExample) * | 1988-01-07 | 1989-07-17 | ||

| JP2002063961A (ja) * | 2000-06-07 | 2002-02-28 | Yazaki Corp | 雌端子、及び、雌端子と雄端子との接続構造 |

| JP2014232576A (ja) * | 2013-05-28 | 2014-12-11 | 株式会社オートネットワーク技術研究所 | 多接点型雌端子 |

| JP2015084310A (ja) * | 2013-10-25 | 2015-04-30 | 古河電気工業株式会社 | メス端子及び接続構造 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0028465A1 (en) | 1979-11-02 | 1981-05-13 | Imperial Chemical Industries Plc | Acylanilide compounds, methods for their preparation, compositions containing them, and processes for combatting fungi |

| JPH01106083A (ja) | 1987-10-20 | 1989-04-24 | Ricoh Co Ltd | 現像剤補給装置 |

| JP3473899B2 (ja) * | 1999-05-11 | 2003-12-08 | 矢崎総業株式会社 | 雌端子 |

| JP2006134681A (ja) * | 2004-11-05 | 2006-05-25 | Tyco Electronics Amp Kk | 雌端子およびこれを使用した電気コネクタ |

| JP4858293B2 (ja) * | 2007-05-08 | 2012-01-18 | 住友電装株式会社 | 雌端子金具 |

| DE102007049055B3 (de) * | 2007-10-11 | 2009-03-26 | Tyco Electronics Amp Gmbh | Vibrationsdämpfendes Kontaktelement |

| JP5285985B2 (ja) * | 2008-07-17 | 2013-09-11 | 矢崎総業株式会社 | 雌型端子金具 |

| JP5375564B2 (ja) * | 2009-12-02 | 2013-12-25 | 住友電装株式会社 | 端子金具 |

| US8419486B2 (en) * | 2010-12-17 | 2013-04-16 | Tyco Electronics Corporation | Receptacle terminal with a contact spring |

| JP2014053205A (ja) | 2012-09-07 | 2014-03-20 | Yazaki Corp | メス端子、及び、それを用いたコネクタ |

| JP5938067B2 (ja) * | 2013-05-24 | 2016-06-22 | イリソ電子工業株式会社 | コネクタ |

| US10230178B2 (en) * | 2013-06-07 | 2019-03-12 | Amphenol Fci Asia Pte Ltd | Cable connector |

| WO2015125682A1 (ja) * | 2014-02-18 | 2015-08-27 | 矢崎総業株式会社 | 接続端子 |

-

2017

- 2017-04-14 JP JP2017080527A patent/JP6807024B2/ja active Active

-

2018

- 2018-04-09 US US16/604,991 patent/US10819056B2/en active Active

- 2018-04-09 WO PCT/JP2018/014879 patent/WO2018190288A1/ja not_active Ceased

- 2018-04-09 CN CN201880024086.8A patent/CN110546820B/zh active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5675483U (enExample) * | 1979-11-15 | 1981-06-19 | ||

| JPH01106083U (enExample) * | 1988-01-07 | 1989-07-17 | ||

| JP2002063961A (ja) * | 2000-06-07 | 2002-02-28 | Yazaki Corp | 雌端子、及び、雌端子と雄端子との接続構造 |

| JP2014232576A (ja) * | 2013-05-28 | 2014-12-11 | 株式会社オートネットワーク技術研究所 | 多接点型雌端子 |

| JP2015084310A (ja) * | 2013-10-25 | 2015-04-30 | 古河電気工業株式会社 | メス端子及び接続構造 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022190950A1 (ja) * | 2021-03-08 | 2022-09-15 | 株式会社オートネットワーク技術研究所 | 端子ユニット,雌端子,雄端子 |

| JP7498431B2 (ja) | 2021-03-08 | 2024-06-12 | 株式会社オートネットワーク技術研究所 | 端子ユニットおよび端子ユニットにおいて用いられる雌端子 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6807024B2 (ja) | 2021-01-06 |

| CN110546820A (zh) | 2019-12-06 |

| JP2018181631A (ja) | 2018-11-15 |

| US10819056B2 (en) | 2020-10-27 |

| US20200161787A1 (en) | 2020-05-21 |

| CN110546820B (zh) | 2020-12-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8795007B2 (en) | Terminal fitting | |

| JP6044513B2 (ja) | 端子金具 | |

| US8616925B2 (en) | Multi-contact terminal fitting | |

| US7789722B2 (en) | Terminals and a terminal connecting structure | |

| JP5958394B2 (ja) | 端子金具 | |

| JP2007165195A (ja) | コネクタ | |

| JP2008123720A (ja) | 雌型コンタクト | |

| JP7039435B2 (ja) | コネクタ組立体 | |

| JP2015207359A (ja) | 電気コネクタ組立体 | |

| JP2014110214A (ja) | 雌端子 | |

| JP2010049896A (ja) | コネクタ | |

| WO2018190288A1 (ja) | 雌端子 | |

| JP6988921B2 (ja) | 端子 | |

| JP6085527B2 (ja) | 雌端子 | |

| TWI606645B (zh) | 電連接器 | |

| JP2011129271A (ja) | 端子金具 | |

| JP2013093133A (ja) | コネクタ端子 | |

| JP2022136778A (ja) | 端子ユニット,雌端子,雄端子 | |

| JP2021034307A (ja) | 端子、および端子付き電線 | |

| KR20210081676A (ko) | 암단자 | |

| JP2016207253A (ja) | コネクタと端子金具の接続構造 | |

| JP2024036858A (ja) | 端子ユニット,雌端子,雄端子 | |

| JP2013258067A (ja) | コネクタ | |

| JP6801563B2 (ja) | 雌端子 | |

| EP2575215B1 (en) | Terminal fitting |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18784137 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18784137 Country of ref document: EP Kind code of ref document: A1 |