WO2018123787A1 - 低温酸化触媒の製造方法 - Google Patents

低温酸化触媒の製造方法 Download PDFInfo

- Publication number

- WO2018123787A1 WO2018123787A1 PCT/JP2017/045857 JP2017045857W WO2018123787A1 WO 2018123787 A1 WO2018123787 A1 WO 2018123787A1 JP 2017045857 W JP2017045857 W JP 2017045857W WO 2018123787 A1 WO2018123787 A1 WO 2018123787A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- noble metal

- halogen

- carrier

- production method

- support

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/38—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals

- B01J23/54—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals combined with metals, oxides or hydroxides provided for in groups B01J23/02 - B01J23/36

- B01J23/56—Platinum group metals

- B01J23/58—Platinum group metals with alkali- or alkaline earth metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/0201—Impregnation

- B01J37/0203—Impregnation the impregnation liquid containing organic compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/74—General processes for purification of waste gases; Apparatus or devices specially adapted therefor

- B01D53/86—Catalytic processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/74—General processes for purification of waste gases; Apparatus or devices specially adapted therefor

- B01D53/86—Catalytic processes

- B01D53/8668—Removing organic compounds not provided for in B01D53/8603 - B01D53/8665

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

- B01J23/89—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper combined with noble metals

- B01J23/8906—Iron and noble metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J27/00—Catalysts comprising the elements or compounds of halogens, sulfur, selenium, tellurium, phosphorus or nitrogen; Catalysts comprising carbon compounds

- B01J27/06—Halogens; Compounds thereof

- B01J27/128—Halogens; Compounds thereof with iron group metals or platinum group metals

- B01J27/13—Platinum group metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J27/00—Catalysts comprising the elements or compounds of halogens, sulfur, selenium, tellurium, phosphorus or nitrogen; Catalysts comprising carbon compounds

- B01J27/06—Halogens; Compounds thereof

- B01J27/138—Halogens; Compounds thereof with alkaline earth metals, magnesium, beryllium, zinc, cadmium or mercury

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/0215—Coating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/0215—Coating

- B01J37/0219—Coating the coating containing organic compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/0236—Drying, e.g. preparing a suspension, adding a soluble salt and drying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/08—Heat treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/16—Reducing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/16—Reducing

- B01J37/18—Reducing with gases containing free hydrogen

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2257/00—Components to be removed

- B01D2257/70—Organic compounds not provided for in groups B01D2257/00 - B01D2257/602

- B01D2257/702—Hydrocarbons

- B01D2257/7022—Aliphatic hydrocarbons

Definitions

- a second object of the present invention is to provide a method for producing a catalyst capable of efficiently oxidizing carbon monoxide emitted from automobile exhaust gas and many other sources at a low temperature of, for example, 100 ° C. or lower.

- step (3) the support obtained in step (2) is treated with a halide solution to further support the halide on the support. 4).

- step (3) a halide solution is further supported on the carrier by spray-coating the halide solution on the carrier obtained in step (2). 5).

- the noble metal is at least one element selected from the group consisting of platinum, gold, palladium, ruthenium, rhodium and iridium. 6).

- the halogen-free noble metal compound in step (1) is dinitrodiammine platinum. 7). 7.

- the carrier may preferably have a specific surface area of 100 to 3000 m 2 / g, more preferably 300 to 2000 m 2 / g, such as 500 to 1500 m 2 / g.

- a carrier having a specific surface area in the above range has high mechanical strength and exhibits good oxidation activity.

- the support preferably the oxide support, may contain a promoter component in order to improve the oxidation activity of the oxidation reaction.

- a promoter component transition metals, such as iron, ruthenium, cerium, cobalt, copper, nickel, manganese, can be included, for example.

- the platinum precursor (that is, platinum as a raw material before being supported on the carrier, typically a platinum compound) is preferably a halogen-free raw material.

- the reason is to suppress halogen gas emission generated from the precursor and the solution when heat treatment such as heating and baking is performed after being supported on the carrier.

- halogen-free platinum precursors include dinitrodiammine platinum [Pt (NH 3 ) 2 (NO 2 ) 2 ], tetraammine platinum hydroxide [Pt (NH 3 ) 4 ] (OH) 2 , and tetraammine platinum.

- rhodium when rhodium is used instead of platinum, rhodium nitrate, acetylacetone rhodium or the like can be used as a precursor thereof.

- palladium when palladium is used, palladium (II) nitrate [Pd (NO) is used as a precursor thereof. 3 ) 2 ], inorganic Pd compounds such as tetraamminepalladium (II) nitrate [Pd (NH 3 ) 4 ] (NO 3 ) 2 or Pd (NH 3 ) 2 (OH) 2 , Pd carboxylates

- iridium it is similarly selected from inorganic and organic compounds of iridium.

- oxidizing atmosphere examples include air, oxygen gas, oxygen gas-containing argon gas, oxygen gas-containing nitrogen gas, and the like. Firing in an oxidizing atmosphere can be performed, for example, under normal pressure at a temperature of 100 to 800 ° C., preferably 150 to 600 ° C., more preferably 200 ° C. to 500 ° C., and still more preferably 250 to 450 ° C.

- the firing time can be, for example, 1 to 20 hours, preferably 2 to 10 hours, more preferably 3 to 7 hours.

- the platinum compound on the support is usually oxidized to platinum oxide.

- this firing treatment can be a step of obtaining a noble metal oxide from a noble metal compound, or in some cases, a thermal decomposition step of the noble metal compound (in the latter case, a noble metal in a metal form is obtained). ).

- Examples of the alkali metal used in the present invention include Li, K, Na, and Rb, examples of the alkaline earth metal include Mg, Ca, and Ba, and examples of the transition metal include Fe, Ti, Co, and V. , Mn, Ni, Cu and the like. Moreover, Al etc. are mentioned as a group 13 metal.

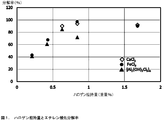

- the halogen-carrying treatment of the present invention can also be performed with an aqueous hydrogen chloride solution without using the above-described metal halide.

- the treatment with hydrogen chloride solution hydrogen chloride solution

- the treatment with hydrogen chloride solution can exhibit extremely high oxidation reaction activity, but has an unstable performance. The reason for this is not clear, but the amount of chlorine supported on the catalyst tends to fluctuate because the hydrogen chloride tends to volatilize in the process of drying the water after treatment with the aqueous hydrogen chloride solution, and the performance as a catalyst fluctuates. It is presumed to be caused by the ease.

- hydrogen chloride is a strong acid, there is anxiety in terms of work safety, and it may be preferable to use a metal halide salt rather than an aqueous hydrogen chloride solution.

- Spray coating can be performed by spraying an aqueous halide solution from a sprayer while rotating a noble metal-supported carrier in a rotating container such as a cement mixer.

- the spraying conditions vary depending on the amount of treatment, but the spraying can be performed, for example, under the conditions of a mixer rotational speed of 1 to 5 rpm, for example 2 rpm, and a spray pressure of 0.1 to 0.5 Mpa, for example 0.3 Mpa.

- a halide for example 0.01 to 15%, calculated as a halogen element

- % By weight preferably 0.1-8% by weight, more preferably 0.2-5% by weight, still more preferably 0.3-3% by weight, for example 0.4-2% by weight or 0.5-1. 8% by weight of halide can be applied to the carrier.

- the catalyst is, for example, -30 to 100 ° C, preferably -20 to 50 ° C, more preferably for the oxidation of cold materials (preferably gaseous cryogenic materials).

- cold materials preferably gaseous cryogenic materials.

- a temperature of ⁇ 10 to 30 ° C. for example ⁇ 5 to 25 ° C., ⁇ 2 to 10 ° C., or 0 to 5 ° C. It can be used to oxidize formaldehyde gas.

- a halogen-free noble metal can be supported on the support. Thereafter, 0.02% by weight or more of the halogen calculated on the basis of the total weight of the noble metal and the carrier as a halogen element on the carrier carrying the noble metal is similarly converted to, for example, 0.1 to 5% by weight.

- a solution preferably an aqueous hydrogen chloride solution or an aqueous metal halide solution

- a solution preferably 0.5 to 2% by weight can be applied by spraying at room temperature, for example.

- the spray application device is not particularly limited, and for example, a spray for spraying agricultural chemicals or a spray for painting can be used.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Environmental & Geological Engineering (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Biomedical Technology (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Catalysts (AREA)

- Exhaust Gas Treatment By Means Of Catalyst (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/469,895 US20190314793A1 (en) | 2016-12-26 | 2017-12-21 | Method for manufacturing low-temperature oxidation catalyst |

| KR1020197017708A KR20190091470A (ko) | 2016-12-26 | 2017-12-21 | 저온 산화 촉매의 제조 방법 |

| EP17889498.6A EP3560590A4 (en) | 2016-12-26 | 2017-12-21 | METHOD OF MANUFACTURING A LOW TEMPERATURE OXIDIZATION CATALYST |

| CN201780080184.9A CN110114141A (zh) | 2016-12-26 | 2017-12-21 | 低温氧化催化剂的制造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016-251891 | 2016-12-26 | ||

| JP2016251891A JP6886290B2 (ja) | 2016-12-26 | 2016-12-26 | 低温酸化触媒の製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018123787A1 true WO2018123787A1 (ja) | 2018-07-05 |

Family

ID=62710551

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/045857 Ceased WO2018123787A1 (ja) | 2016-12-26 | 2017-12-21 | 低温酸化触媒の製造方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20190314793A1 (enExample) |

| EP (1) | EP3560590A4 (enExample) |

| JP (1) | JP6886290B2 (enExample) |

| KR (1) | KR20190091470A (enExample) |

| CN (1) | CN110114141A (enExample) |

| WO (1) | WO2018123787A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019027057A1 (ja) * | 2017-08-04 | 2019-02-07 | 国立大学法人北海道大学 | 酸化分解用触媒及びその利用 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020121079A1 (en) * | 2018-12-13 | 2020-06-18 | 3M Innovative Properties Company | Catalyst |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3041272A (en) * | 1959-12-15 | 1962-06-26 | Sinclair Refining Co | Process for activating a noble-metalalumina-aluminum halide catalyst |

| JPS5480292A (en) * | 1977-12-09 | 1979-06-26 | Matsushita Electric Ind Co Ltd | Carbon monoxide oxidation catalyst |

| JPS58207947A (ja) * | 1982-05-27 | 1983-12-03 | Gosei Kagaku Kenkyusho:Kk | 一酸化炭素の酸化触媒 |

| JP2002320855A (ja) * | 2001-04-25 | 2002-11-05 | Scientific Design Co Inc | 酸化エチレン用触媒 |

| JP2003164764A (ja) | 2001-09-21 | 2003-06-10 | Katsuhiko Wakabayashi | 一酸化炭素酸化用触媒、その製造方法及び一酸化炭素の酸化方法 |

| JP4062053B2 (ja) | 2002-10-29 | 2008-03-19 | 株式会社豊田中央研究所 | ホルムアルデヒド分解触媒及びその製造方法 |

| JP2009061372A (ja) | 2007-09-05 | 2009-03-26 | Taiyo Kagaku Co Ltd | 一酸化炭素選択酸化触媒、及び該触媒を用いた水素中の一酸化炭素の除去方法 |

| WO2011142481A1 (ja) * | 2010-05-13 | 2011-11-17 | 国立大学法人山梨大学 | 燃料改質装置、一酸化炭素の選択的メタン化方法、一酸化炭素の選択的メタン化触媒及びその製造方法 |

| JP2012055826A (ja) * | 2010-09-08 | 2012-03-22 | National Institute Of Advanced Industrial Science & Technology | 低温酸化触媒とその製造方法およびその触媒を用いた酸化方法 |

| JP2012081458A (ja) * | 2010-09-14 | 2012-04-26 | Tokyo Metropolitan Univ | エチレン触媒燃焼反応用の触媒組成物およびそれを用いたエチレンの分解方法 |

| JP2013198875A (ja) * | 2012-03-26 | 2013-10-03 | Nippon Shokubai Co Ltd | エチレンオキシド製造用触媒およびそれを用いたエチレンオキシド製造方法。 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4165276A (en) * | 1977-09-14 | 1979-08-21 | Uop Inc. | Hydrocarbon conversion with a superactive multimetallic catalytic composite |

| FR2631858A1 (fr) * | 1988-05-24 | 1989-12-01 | Solvay | Compositions catalytiques, procede pour leur obtention et procede d'hydrogenation de chlorofluoralcenes au moyen de ces compositions |

| CN1089638C (zh) * | 1998-10-12 | 2002-08-28 | 大连化学工业股份有限公司 | 催化剂的制法及其在制备乙酸烯酯中的用途 |

| JP2003144925A (ja) * | 2001-11-07 | 2003-05-20 | Sud-Chemie Catalysts Inc | 一酸化炭素シフト反応用触媒の製造方法 |

| WO2007145151A1 (en) * | 2006-06-13 | 2007-12-21 | Showa Denko K.K. | Process for production of supported catalyst for acetic acid production |

| DE102007020143A1 (de) * | 2007-04-26 | 2008-10-30 | Bayer Materialscience Ag | Verfahren zur Erhöhung der Langzeitstabilität und Aktivität von Ruthenium-Katalysatoren |

| CN102247872A (zh) * | 2010-05-21 | 2011-11-23 | 中国石油化工股份有限公司 | 负载型铂催化剂及其制备方法 |

-

2016

- 2016-12-26 JP JP2016251891A patent/JP6886290B2/ja not_active Expired - Fee Related

-

2017

- 2017-12-21 WO PCT/JP2017/045857 patent/WO2018123787A1/ja not_active Ceased

- 2017-12-21 EP EP17889498.6A patent/EP3560590A4/en not_active Withdrawn

- 2017-12-21 CN CN201780080184.9A patent/CN110114141A/zh active Pending

- 2017-12-21 KR KR1020197017708A patent/KR20190091470A/ko not_active Ceased

- 2017-12-21 US US16/469,895 patent/US20190314793A1/en not_active Abandoned

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3041272A (en) * | 1959-12-15 | 1962-06-26 | Sinclair Refining Co | Process for activating a noble-metalalumina-aluminum halide catalyst |

| JPS5480292A (en) * | 1977-12-09 | 1979-06-26 | Matsushita Electric Ind Co Ltd | Carbon monoxide oxidation catalyst |

| JPS58207947A (ja) * | 1982-05-27 | 1983-12-03 | Gosei Kagaku Kenkyusho:Kk | 一酸化炭素の酸化触媒 |

| JP2002320855A (ja) * | 2001-04-25 | 2002-11-05 | Scientific Design Co Inc | 酸化エチレン用触媒 |

| JP2003164764A (ja) | 2001-09-21 | 2003-06-10 | Katsuhiko Wakabayashi | 一酸化炭素酸化用触媒、その製造方法及び一酸化炭素の酸化方法 |

| JP4062053B2 (ja) | 2002-10-29 | 2008-03-19 | 株式会社豊田中央研究所 | ホルムアルデヒド分解触媒及びその製造方法 |

| JP2009061372A (ja) | 2007-09-05 | 2009-03-26 | Taiyo Kagaku Co Ltd | 一酸化炭素選択酸化触媒、及び該触媒を用いた水素中の一酸化炭素の除去方法 |

| WO2011142481A1 (ja) * | 2010-05-13 | 2011-11-17 | 国立大学法人山梨大学 | 燃料改質装置、一酸化炭素の選択的メタン化方法、一酸化炭素の選択的メタン化触媒及びその製造方法 |

| JP2012055826A (ja) * | 2010-09-08 | 2012-03-22 | National Institute Of Advanced Industrial Science & Technology | 低温酸化触媒とその製造方法およびその触媒を用いた酸化方法 |

| JP2012081458A (ja) * | 2010-09-14 | 2012-04-26 | Tokyo Metropolitan Univ | エチレン触媒燃焼反応用の触媒組成物およびそれを用いたエチレンの分解方法 |

| JP2013198875A (ja) * | 2012-03-26 | 2013-10-03 | Nippon Shokubai Co Ltd | エチレンオキシド製造用触媒およびそれを用いたエチレンオキシド製造方法。 |

Non-Patent Citations (3)

| Title |

|---|

| ANGEW. CHEM. INT. ED., vol. 52, 2013, pages 6253 - 6268 |

| FUKUOKA, ATSUSHI ET AL.: "Preferential oxidation of carbon monoxide catalyzed by platinum nanoparticles in mesoporous silica", JOURNAL OF THE AMERICAN CHEMICAL SOCIETY, vol. 129, no. 33, 31 July 2007 (2007-07-31), pages 10120 - 10125, XP055393283 * |

| See also references of EP3560590A4 * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019027057A1 (ja) * | 2017-08-04 | 2019-02-07 | 国立大学法人北海道大学 | 酸化分解用触媒及びその利用 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6886290B2 (ja) | 2021-06-16 |

| JP2018103103A (ja) | 2018-07-05 |

| EP3560590A4 (en) | 2020-08-19 |

| CN110114141A (zh) | 2019-08-09 |

| EP3560590A1 (en) | 2019-10-30 |

| KR20190091470A (ko) | 2019-08-06 |

| US20190314793A1 (en) | 2019-10-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4565191B2 (ja) | 微粒子触媒の製造方法、微粒子触媒、及び改質装置 | |

| JP5030818B2 (ja) | 排ガス浄化用触媒および排ガス浄化方法 | |

| CN103221128A (zh) | 催化剂及其制备方法 | |

| JP2004512162A (ja) | Co、vocおよびハロゲン化有機物の放出物を消失させる触媒 | |

| WO2018123786A1 (ja) | 低温酸化触媒 | |

| JP5607131B2 (ja) | 排ガス浄化用触媒 | |

| CN104676610A (zh) | 一种催化氧化去除甲苯的方法 | |

| JP2001187343A (ja) | 常温浄化触媒およびその使用方法 | |

| JP6886290B2 (ja) | 低温酸化触媒の製造方法 | |

| JP5706476B2 (ja) | 一酸化炭素酸化触媒、及びその製造方法 | |

| JP4986149B2 (ja) | 可視光応答性光触媒と環境汚染物質の光分解法 | |

| JP5503155B2 (ja) | 一酸化炭素除去フィルター | |

| JP4865250B2 (ja) | 排ガス処理用触媒の製造方法 | |

| JP4901366B2 (ja) | 排ガス中のメタンの酸化除去用触媒および排ガス中のメタンの酸化除去方法 | |

| JP3604740B2 (ja) | オゾン分解用触媒及びオゾン分解方法 | |

| JP6614897B2 (ja) | メタン酸化除去用触媒の製造方法およびメタン酸化除去方法 | |

| JP2002210369A (ja) | 排気ガス浄化用触媒及びその製造方法 | |

| JP5216001B2 (ja) | 有機酸含有排ガス処理用触媒および有機酸含有排ガス処理方法 | |

| JP6225807B2 (ja) | Voc分解除去用触媒、その製造方法、及びそれを用いたvoc分解除去方法 | |

| JP5112966B2 (ja) | リーンバーン排ガス浄化用触媒 | |

| JP2006305406A (ja) | 排NOx浄化用触媒 | |

| JP2017100120A (ja) | メタン酸化除去用触媒の製造方法およびメタン酸化除去用触媒 | |

| JP4233572B2 (ja) | 排ガス浄化用ハニカム触媒 | |

| TWI293036B (en) | Catalyst, method for producing the same and method for treating volatile organic compounds | |

| JPH06343827A (ja) | フロン含有ガスの処理方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17889498 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 20197017708 Country of ref document: KR Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2017889498 Country of ref document: EP |