JP7516786B2 - 半導体装置及びその製造方法 - Google Patents

半導体装置及びその製造方法 Download PDFInfo

- Publication number

- JP7516786B2 JP7516786B2 JP2020040801A JP2020040801A JP7516786B2 JP 7516786 B2 JP7516786 B2 JP 7516786B2 JP 2020040801 A JP2020040801 A JP 2020040801A JP 2020040801 A JP2020040801 A JP 2020040801A JP 7516786 B2 JP7516786 B2 JP 7516786B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- layer

- semiconductor device

- base material

- circuit element

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004065 semiconductor Substances 0.000 title claims description 183

- 238000004519 manufacturing process Methods 0.000 title claims description 22

- 239000000758 substrate Substances 0.000 claims description 436

- 239000004020 conductor Substances 0.000 claims description 59

- 239000000463 material Substances 0.000 claims description 55

- 229910000679 solder Inorganic materials 0.000 claims description 41

- 239000012212 insulator Substances 0.000 claims description 36

- 239000002184 metal Substances 0.000 claims description 34

- 229910052751 metal Inorganic materials 0.000 claims description 34

- 238000000034 method Methods 0.000 claims description 27

- 150000001875 compounds Chemical class 0.000 claims description 24

- 239000010409 thin film Substances 0.000 claims description 21

- 239000011347 resin Substances 0.000 claims description 14

- 229920005989 resin Polymers 0.000 claims description 14

- 239000002131 composite material Substances 0.000 claims description 6

- 238000005530 etching Methods 0.000 claims description 5

- 239000010408 film Substances 0.000 description 41

- 230000017525 heat dissipation Effects 0.000 description 29

- 229910001218 Gallium arsenide Inorganic materials 0.000 description 18

- 239000004642 Polyimide Substances 0.000 description 14

- 229920001721 polyimide Polymers 0.000 description 14

- UMIVXZPTRXBADB-UHFFFAOYSA-N benzocyclobutene Chemical compound C1=CC=C2CCC2=C1 UMIVXZPTRXBADB-UHFFFAOYSA-N 0.000 description 10

- 230000000694 effects Effects 0.000 description 10

- 229920002577 polybenzoxazole Polymers 0.000 description 10

- 230000035882 stress Effects 0.000 description 8

- 230000000052 comparative effect Effects 0.000 description 7

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 6

- 239000010949 copper Substances 0.000 description 5

- 229910045601 alloy Inorganic materials 0.000 description 4

- 239000000956 alloy Substances 0.000 description 4

- 230000008646 thermal stress Effects 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 3

- 229910052681 coesite Inorganic materials 0.000 description 3

- 230000008602 contraction Effects 0.000 description 3

- 229910052906 cristobalite Inorganic materials 0.000 description 3

- 229910003460 diamond Inorganic materials 0.000 description 3

- 239000010432 diamond Substances 0.000 description 3

- 238000010292 electrical insulation Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 239000000377 silicon dioxide Substances 0.000 description 3

- 235000012239 silicon dioxide Nutrition 0.000 description 3

- 229910052682 stishovite Inorganic materials 0.000 description 3

- 229910052905 tridymite Inorganic materials 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- -1 InN Chemical compound 0.000 description 2

- 229910000673 Indium arsenide Inorganic materials 0.000 description 2

- 229910007637 SnAg Inorganic materials 0.000 description 2

- BOTDANWDWHJENH-UHFFFAOYSA-N Tetraethyl orthosilicate Chemical compound CCO[Si](OCC)(OCC)OCC BOTDANWDWHJENH-UHFFFAOYSA-N 0.000 description 2

- 239000003990 capacitor Substances 0.000 description 2

- 239000013078 crystal Substances 0.000 description 2

- QZQVBEXLDFYHSR-UHFFFAOYSA-N gallium(III) oxide Inorganic materials O=[Ga]O[Ga]=O QZQVBEXLDFYHSR-UHFFFAOYSA-N 0.000 description 2

- WPYVAWXEWQSOGY-UHFFFAOYSA-N indium antimonide Chemical compound [Sb]#[In] WPYVAWXEWQSOGY-UHFFFAOYSA-N 0.000 description 2

- RPQDHPTXJYYUPQ-UHFFFAOYSA-N indium arsenide Chemical compound [In]#[As] RPQDHPTXJYYUPQ-UHFFFAOYSA-N 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 239000011368 organic material Substances 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 229910017083 AlN Inorganic materials 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910003327 LiNbO3 Inorganic materials 0.000 description 1

- 229910012463 LiTaO3 Inorganic materials 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 229910000577 Silicon-germanium Inorganic materials 0.000 description 1

- 241001125929 Trisopterus luscus Species 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 230000003321 amplification Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 229910052593 corundum Inorganic materials 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000003989 dielectric material Substances 0.000 description 1

- 239000006023 eutectic alloy Substances 0.000 description 1

- 230000005496 eutectics Effects 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910003465 moissanite Inorganic materials 0.000 description 1

- 238000003199 nucleic acid amplification method Methods 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 229910001845 yogo sapphire Inorganic materials 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/28—Encapsulations, e.g. encapsulating layers, coatings, e.g. for protection

- H01L23/31—Encapsulations, e.g. encapsulating layers, coatings, e.g. for protection characterised by the arrangement or shape

- H01L23/3157—Partial encapsulation or coating

- H01L23/3171—Partial encapsulation or coating the coating being directly applied to the semiconductor body, e.g. passivation layer

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L29/00—Semiconductor devices specially adapted for rectifying, amplifying, oscillating or switching and having potential barriers; Capacitors or resistors having potential barriers, e.g. a PN-junction depletion layer or carrier concentration layer; Details of semiconductor bodies or of electrodes thereof ; Multistep manufacturing processes therefor

- H01L29/66—Types of semiconductor device ; Multistep manufacturing processes therefor

- H01L29/68—Types of semiconductor device ; Multistep manufacturing processes therefor controllable by only the electric current supplied, or only the electric potential applied, to an electrode which does not carry the current to be rectified, amplified or switched

- H01L29/70—Bipolar devices

- H01L29/72—Transistor-type devices, i.e. able to continuously respond to applied control signals

- H01L29/73—Bipolar junction transistors

- H01L29/737—Hetero-junction transistors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/50—Assembly of semiconductor devices using processes or apparatus not provided for in a single one of the subgroups H01L21/06 - H01L21/326, e.g. sealing of a cap to a base of a container

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/34—Arrangements for cooling, heating, ventilating or temperature compensation ; Temperature sensing arrangements

- H01L23/36—Selection of materials, or shaping, to facilitate cooling or heating, e.g. heatsinks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/34—Arrangements for cooling, heating, ventilating or temperature compensation ; Temperature sensing arrangements

- H01L23/36—Selection of materials, or shaping, to facilitate cooling or heating, e.g. heatsinks

- H01L23/373—Cooling facilitated by selection of materials for the device or materials for thermal expansion adaptation, e.g. carbon

- H01L23/3738—Semiconductor materials

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/48—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor

- H01L23/488—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor consisting of soldered or bonded constructions

- H01L23/498—Leads, i.e. metallisations or lead-frames on insulating substrates, e.g. chip carriers

- H01L23/49811—Additional leads joined to the metallisation on the insulating substrate, e.g. pins, bumps, wires, flat leads

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/48—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor

- H01L23/488—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor consisting of soldered or bonded constructions

- H01L23/498—Leads, i.e. metallisations or lead-frames on insulating substrates, e.g. chip carriers

- H01L23/49838—Geometry or layout

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/562—Protection against mechanical damage

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/10—Bump connectors ; Manufacturing methods related thereto

- H01L24/11—Manufacturing methods

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/10—Bump connectors ; Manufacturing methods related thereto

- H01L24/12—Structure, shape, material or disposition of the bump connectors prior to the connecting process

- H01L24/13—Structure, shape, material or disposition of the bump connectors prior to the connecting process of an individual bump connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/10—Bump connectors ; Manufacturing methods related thereto

- H01L24/12—Structure, shape, material or disposition of the bump connectors prior to the connecting process

- H01L24/14—Structure, shape, material or disposition of the bump connectors prior to the connecting process of a plurality of bump connectors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/10—Bump connectors ; Manufacturing methods related thereto

- H01L24/15—Structure, shape, material or disposition of the bump connectors after the connecting process

- H01L24/17—Structure, shape, material or disposition of the bump connectors after the connecting process of a plurality of bump connectors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/02—Bonding areas; Manufacturing methods related thereto

- H01L2224/03—Manufacturing methods

- H01L2224/034—Manufacturing methods by blanket deposition of the material of the bonding area

- H01L2224/0346—Plating

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/02—Bonding areas; Manufacturing methods related thereto

- H01L2224/04—Structure, shape, material or disposition of the bonding areas prior to the connecting process

- H01L2224/0401—Bonding areas specifically adapted for bump connectors, e.g. under bump metallisation [UBM]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/02—Bonding areas; Manufacturing methods related thereto

- H01L2224/04—Structure, shape, material or disposition of the bonding areas prior to the connecting process

- H01L2224/05—Structure, shape, material or disposition of the bonding areas prior to the connecting process of an individual bonding area

- H01L2224/05001—Internal layers

- H01L2224/05099—Material

- H01L2224/051—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/05138—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/05144—Gold [Au] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/02—Bonding areas; Manufacturing methods related thereto

- H01L2224/04—Structure, shape, material or disposition of the bonding areas prior to the connecting process

- H01L2224/05—Structure, shape, material or disposition of the bonding areas prior to the connecting process of an individual bonding area

- H01L2224/05001—Internal layers

- H01L2224/05099—Material

- H01L2224/051—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/05163—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than 1550°C

- H01L2224/05164—Palladium [Pd] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/02—Bonding areas; Manufacturing methods related thereto

- H01L2224/04—Structure, shape, material or disposition of the bonding areas prior to the connecting process

- H01L2224/05—Structure, shape, material or disposition of the bonding areas prior to the connecting process of an individual bonding area

- H01L2224/05001—Internal layers

- H01L2224/05099—Material

- H01L2224/051—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/05163—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than 1550°C

- H01L2224/05169—Platinum [Pt] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/02—Bonding areas; Manufacturing methods related thereto

- H01L2224/04—Structure, shape, material or disposition of the bonding areas prior to the connecting process

- H01L2224/05—Structure, shape, material or disposition of the bonding areas prior to the connecting process of an individual bonding area

- H01L2224/0554—External layer

- H01L2224/05599—Material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/02—Bonding areas; Manufacturing methods related thereto

- H01L2224/04—Structure, shape, material or disposition of the bonding areas prior to the connecting process

- H01L2224/06—Structure, shape, material or disposition of the bonding areas prior to the connecting process of a plurality of bonding areas

- H01L2224/0601—Structure

- H01L2224/0603—Bonding areas having different sizes, e.g. different heights or widths

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/11—Manufacturing methods

- H01L2224/114—Manufacturing methods by blanket deposition of the material of the bump connector

- H01L2224/1146—Plating

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/11—Manufacturing methods

- H01L2224/1147—Manufacturing methods using a lift-off mask

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/11—Manufacturing methods

- H01L2224/118—Post-treatment of the bump connector

- H01L2224/11848—Thermal treatments, e.g. annealing, controlled cooling

- H01L2224/11849—Reflowing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/12—Structure, shape, material or disposition of the bump connectors prior to the connecting process

- H01L2224/13—Structure, shape, material or disposition of the bump connectors prior to the connecting process of an individual bump connector

- H01L2224/13001—Core members of the bump connector

- H01L2224/13075—Plural core members

- H01L2224/1308—Plural core members being stacked

- H01L2224/13082—Two-layer arrangements

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/12—Structure, shape, material or disposition of the bump connectors prior to the connecting process

- H01L2224/13—Structure, shape, material or disposition of the bump connectors prior to the connecting process of an individual bump connector

- H01L2224/13001—Core members of the bump connector

- H01L2224/13099—Material

- H01L2224/131—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/13101—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of less than 400°C

- H01L2224/13111—Tin [Sn] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/12—Structure, shape, material or disposition of the bump connectors prior to the connecting process

- H01L2224/13—Structure, shape, material or disposition of the bump connectors prior to the connecting process of an individual bump connector

- H01L2224/13001—Core members of the bump connector

- H01L2224/13099—Material

- H01L2224/131—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/13138—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/13139—Silver [Ag] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/12—Structure, shape, material or disposition of the bump connectors prior to the connecting process

- H01L2224/13—Structure, shape, material or disposition of the bump connectors prior to the connecting process of an individual bump connector

- H01L2224/13001—Core members of the bump connector

- H01L2224/13099—Material

- H01L2224/131—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/13138—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/13147—Copper [Cu] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/12—Structure, shape, material or disposition of the bump connectors prior to the connecting process

- H01L2224/14—Structure, shape, material or disposition of the bump connectors prior to the connecting process of a plurality of bump connectors

- H01L2224/1401—Structure

- H01L2224/1403—Bump connectors having different sizes, e.g. different diameters, heights or widths

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/15—Structure, shape, material or disposition of the bump connectors after the connecting process

- H01L2224/16—Structure, shape, material or disposition of the bump connectors after the connecting process of an individual bump connector

- H01L2224/161—Disposition

- H01L2224/16151—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive

- H01L2224/16221—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked

- H01L2224/16225—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being non-metallic, e.g. insulating substrate with or without metallisation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/15—Structure, shape, material or disposition of the bump connectors after the connecting process

- H01L2224/17—Structure, shape, material or disposition of the bump connectors after the connecting process of a plurality of bump connectors

- H01L2224/1751—Function

- H01L2224/17515—Bump connectors having different functions

- H01L2224/17519—Bump connectors having different functions including bump connectors providing primarily thermal dissipation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/81—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a bump connector

- H01L2224/8119—Arrangement of the bump connectors prior to mounting

- H01L2224/81191—Arrangement of the bump connectors prior to mounting wherein the bump connectors are disposed only on the semiconductor or solid-state body

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/81—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a bump connector

- H01L2224/8138—Bonding interfaces outside the semiconductor or solid-state body

- H01L2224/81399—Material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/81—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a bump connector

- H01L2224/818—Bonding techniques

- H01L2224/81801—Soldering or alloying

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/02—Bonding areas ; Manufacturing methods related thereto

- H01L24/03—Manufacturing methods

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/02—Bonding areas ; Manufacturing methods related thereto

- H01L24/04—Structure, shape, material or disposition of the bonding areas prior to the connecting process

- H01L24/05—Structure, shape, material or disposition of the bonding areas prior to the connecting process of an individual bonding area

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/02—Bonding areas ; Manufacturing methods related thereto

- H01L24/04—Structure, shape, material or disposition of the bonding areas prior to the connecting process

- H01L24/06—Structure, shape, material or disposition of the bonding areas prior to the connecting process of a plurality of bonding areas

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L24/81—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a bump connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L29/00—Semiconductor devices specially adapted for rectifying, amplifying, oscillating or switching and having potential barriers; Capacitors or resistors having potential barriers, e.g. a PN-junction depletion layer or carrier concentration layer; Details of semiconductor bodies or of electrodes thereof ; Multistep manufacturing processes therefor

- H01L29/66—Types of semiconductor device ; Multistep manufacturing processes therefor

- H01L29/68—Types of semiconductor device ; Multistep manufacturing processes therefor controllable by only the electric current supplied, or only the electric potential applied, to an electrode which does not carry the current to be rectified, amplified or switched

- H01L29/70—Bipolar devices

- H01L29/72—Transistor-type devices, i.e. able to continuously respond to applied control signals

- H01L29/73—Bipolar junction transistors

- H01L29/737—Hetero-junction transistors

- H01L29/7371—Vertical transistors

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Computer Hardware Design (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Ceramic Engineering (AREA)

- Geometry (AREA)

- Wire Bonding (AREA)

- Cooling Or The Like Of Semiconductors Or Solid State Devices (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

- Computer Networks & Wireless Communication (AREA)

- Signal Processing (AREA)

- Bipolar Transistors (AREA)

Description

表面に回路素子及び当該回路素子に接続される電極を有する基板と、当該基板上に設けられ、前記回路素子又は前記電極に接して電気的に接続された外部接続用の導体突起部と、を備え、前記基板は、第1基材と、当該第1基材上に配置された第2基材とを含み、前記回路素子及び前記電極が前記第2基材に形成された、半導体装置の製造方法であって、

表面に前記回路素子及び前記電極を有する半導体薄膜を、剥離層を介して化合物半導体基材に形成する工程と、

前記剥離層をエッチングにより除去して前記半導体薄膜を前記化合物半導体基材から剥離する工程と、

前記第1基材を構成する単体半導体基材上の所定位置に、前記第2基材を構成する前記半導体薄膜を接合する工程と、

前記第2基材上に設けられ、前記回路素子又は前記電極に接続される外部接続用の導体突起部を形成する工程と、

を有する。

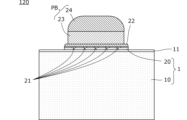

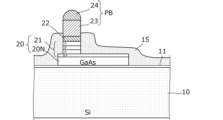

図1は第1の実施形態に係る半導体装置110の断面図である。この半導体装置110は、基板1と、この基板1上に設けられた第2基材側電極22に接して電気的に接続された導体ピラー23と、この導体ピラー23上に形成されたはんだ層24と、を備える。この導体ピラー23及びはんだ層24によって導体ピラーバンプPBが構成されている。

第2の実施形態では、第1の実施形態とは導体突起部の構成が異なる半導体装置について示す。

第3の実施形態では、平坦化樹脂層を備える幾つかの半導体装置について例示する。

第4の実施形態では、複数箇所に外部接続用の導体突起を備える一つの半導体装置の例について示す。

第5の実施形態では、第2基材の製造方法、及び第1基材に対する第2基材の接合方法について示す。

第6の実施形態では、第1基材10と第2基材20とを接合する接合層の構造に特徴を有する半導体装置について示す。

第7の実施形態では、第1基材10と第2基材20とを接合する接合層の構造に特徴を有する半導体装置について示す。

(1)第1基材10の表面に、第1層としての絶縁体層17を形成する。

(2)その絶縁体層17の表面に第2層としての金属層18Aを形成する。

(3)この金属層18の表面に第3層としての絶縁体層17を形成する。

(4)この絶縁体層17の所定位置(下層の金属層18Aの形成位置)に開口を形成する。

(5)絶縁体層17上に金属層18Cを形成するとともに、上記開口内に金属層18Bを形成する。

(6)最上層としての絶縁体層17を形成する。

1…基板

10…第1基材

11…接合層

12…第1基材側電極

15…平坦化樹脂層

16…絶縁体層

20…第2基材

20D…エピタキシャル層

20N…半導体基材

21…回路素子

22…第2基材側電極

13,23…導体ピラー

14,24…はんだ層

29…剥離層

30…GaAs基板

32,42…電極

33,43…導体ピラー

34,44…はんだ層

51A,51B…ヘテロ接合バイポーラトランジスタ

52…スパイラルインダクタ

53…MIMC

85…レジスト膜

90…実装基板

91,92…実装基板側電極

110,111,120,130A,130B,131,140,160,170…半導体装置

200…母基板

Claims (13)

- 表面に回路素子及び当該回路素子に接続される電極を有する基板と、

前記基板上に設けられ、前記回路素子又は前記電極に接続された外部接続用の導体突起部と、

を備え、

前記基板は、第1基材と、当該第1基材上に配置され、前記第1基材とは材料が異なる第2基材とを含み、

前記回路素子及び前記電極は前記第2基材に形成され、

前記第1基材と前記第2基材との間に、前記第1基材と前記第2基材とを接合する接合層を備え、

前記第1基材は前記第2基材に比べて熱伝導率が高く、

前記接合層は前記第2基材に比べて熱伝導率が高く、

前記接合層は前記第1基材に比較して電気抵抗率が高い絶縁体である、

半導体装置。 - 表面に回路素子及び当該回路素子に接続される電極を有する基板と、

前記基板上に設けられ、前記回路素子又は前記電極に接続された外部接続用の導体突起部と、

を備え、

前記基板は、第1基材と、当該第1基材上に配置され、前記第1基材とは材料が異なる第2基材とを含み、

前記回路素子及び前記電極は前記第2基材に形成され、

前記第1基材と前記第2基材との間に、前記第1基材と前記第2基材とを接合する接合層を備え、

前記第1基材は前記第2基材に比べて熱伝導率が高く、

前記接合層は前記第2基材に比べて熱伝導率が高く、

前記接合層は、絶縁体層と金属層とを含む複合材料の層である、

半導体装置。 - 前記第1基材は単体半導体の基材であり、

前記第2基材は化合物半導体の基材である、

請求項1または請求項2に記載の半導体装置。 - 前記第2基材は前記第1基材より薄い、

請求項1乃至請求項3のいずれかに記載の半導体装置。 - 前記回路素子は動作時に発熱する発熱体であり、前記導体突起部は前記発熱体である前記回路素子の直近に設けられている、

請求項1乃至請求項4のいずれかに記載の半導体装置。 - 前記第2基材は前記第1基材の外縁からはみ出さない、

請求項1乃至請求項5のいずれかに記載の半導体装置。 - 前記接合層は、前記第1基材に比べて熱伝導率が高い、

請求項1に記載の半導体装置。 - 前記第1基材はSi基材であり、

前記絶縁体層はSi化合物の層である、

請求項2に記載の半導体装置。 - 前記絶縁体層の少なくとも一部は樹脂である、

請求項2に記載の半導体装置。 - 前記第1基材の、前記第2基材に重ならない位置の表面に第1基材側電極が形成され、

前記導体突起部は前記第1基材側電極に接続された、

請求項1乃至請求項9のいずれかに記載の半導体装置。 - 前記導体突起部は、導体ピラー上にはんだ層が形成された導体ピラーである、

請求項1乃至請求項10のいずれかに記載の半導体装置。 - 表面に回路素子及び当該回路素子に接続される電極を有する基板と、当該基板上に設けられ、前記回路素子又は前記電極に接して電気的に接続された外部接続用の導体突起部と、を備え、前記基板は、第1基材と、当該第1基材上に配置された第2基材とを含み、前記回路素子及び前記電極が前記第2基材に形成された、半導体装置の製造方法であって、

表面に前記回路素子及び前記電極を有する半導体薄膜を、剥離層を介して化合物半導体基材に形成する工程と、

前記剥離層をエッチングにより除去して前記半導体薄膜を前記化合物半導体基材から剥離する工程と、

前記第2基材に比べて熱伝導率が高い前記第1基材を構成する単体半導体基材上の所定位置に、前記第2基材に比べて熱伝導率が高く、前記第1基材に比較して電気抵抗率が高い絶縁体である接合層を用いて、前記第2基材を構成する前記半導体薄膜を接合する工程と、

前記第2基材上に設けられ、前記回路素子又は前記電極に接続される外部接続用の導体突起部を形成する工程と、

を有する半導体装置の製造方法。 - 表面に回路素子及び当該回路素子に接続される電極を有する基板と、当該基板上に設けられ、前記回路素子又は前記電極に接して電気的に接続された外部接続用の導体突起部と、を備え、前記基板は、第1基材と、当該第1基材上に配置された第2基材とを含み、前記回路素子及び前記電極が前記第2基材に形成された、半導体装置の製造方法であって、

表面に前記回路素子及び前記電極を有する半導体薄膜を、剥離層を介して化合物半導体基材に形成する工程と、

前記剥離層をエッチングにより除去して前記半導体薄膜を前記化合物半導体基材から剥離する工程と、

前記第2基材に比べて熱伝導率が高い前記第1基材を構成する単体半導体基材上の所定位置に、前記第2基材に比べて熱伝導率が高く、絶縁体層と金属層とを含む複合材料の層である接合層を用いて、前記第2基材を構成する前記半導体薄膜を接合する工程と、

前記第2基材上に設けられ、前記回路素子又は前記電極に接続される外部接続用の導体突起部を形成する工程と、

を有する半導体装置の製造方法。

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| TW112130657A TWI854787B (zh) | 2019-06-21 | 2020-05-14 | 半導體裝置 |

| TW109116022A TWI825318B (zh) | 2019-06-21 | 2020-05-14 | 半導體裝置及其製造方法 |

| US16/901,980 US11677018B2 (en) | 2019-06-21 | 2020-06-15 | Semiconductor device and method for producing the same |

| CN202010564522.XA CN112117246A (zh) | 2019-06-21 | 2020-06-19 | 半导体装置及其制造方法 |

| US18/296,778 US20230246094A1 (en) | 2019-06-21 | 2023-04-06 | Semiconductor device and method for producing the same |

| JP2024077830A JP2024102316A (ja) | 2019-06-21 | 2024-05-13 | 半導体装置及びその製造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019115560 | 2019-06-21 | ||

| JP2019115560 | 2019-06-21 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2024077830A Division JP2024102316A (ja) | 2019-06-21 | 2024-05-13 | 半導体装置及びその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2021002644A JP2021002644A (ja) | 2021-01-07 |

| JP2021002644A5 JP2021002644A5 (ja) | 2022-11-17 |

| JP7516786B2 true JP7516786B2 (ja) | 2024-07-17 |

Family

ID=73995452

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020040801A Active JP7516786B2 (ja) | 2019-06-21 | 2020-03-10 | 半導体装置及びその製造方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US11677018B2 (ja) |

| JP (1) | JP7516786B2 (ja) |

| TW (1) | TWI825318B (ja) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113517209A (zh) * | 2020-04-10 | 2021-10-19 | 长鑫存储技术有限公司 | 半导体结构及其形成方法 |

| CN117546291A (zh) * | 2021-06-11 | 2024-02-09 | 株式会社村田制作所 | 半导体装置 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009190918A (ja) | 2008-02-13 | 2009-08-27 | New Japan Radio Co Ltd | 窒化物半導体基板の製造方法及び窒化物半導体装置の製造方法 |

| JP2012169586A (ja) | 2011-01-24 | 2012-09-06 | Fujitsu Ltd | ヒートスプレッダ及びその製造方法、半導体装置、電子装置 |

| JP2013191655A (ja) | 2012-03-13 | 2013-09-26 | Nippon Telegr & Teleph Corp <Ntt> | ヘテロ接合バイポーラトランジスタおよびその製造方法 |

| JP2019009409A (ja) | 2017-06-28 | 2019-01-17 | 株式会社村田製作所 | 半導体チップ |

| JP2019075536A (ja) | 2017-10-11 | 2019-05-16 | 株式会社村田製作所 | パワーアンプモジュール |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7247892B2 (en) * | 2000-04-24 | 2007-07-24 | Taylor Geoff W | Imaging array utilizing thyristor-based pixel elements |

| KR100687758B1 (ko) * | 2005-12-08 | 2007-02-27 | 한국전자통신연구원 | 이종 접합 바이폴라 트랜지스터 및 그 제조방법 |

| JP2010206020A (ja) * | 2009-03-04 | 2010-09-16 | Panasonic Corp | 半導体装置 |

| US20100270591A1 (en) * | 2009-04-27 | 2010-10-28 | University Of Seoul Industry Cooperation Foundation | High-electron mobility transistor |

| US8772817B2 (en) * | 2010-12-22 | 2014-07-08 | Cree, Inc. | Electronic device submounts including substrates with thermally conductive vias |

| CN104160502A (zh) * | 2012-03-09 | 2014-11-19 | 三菱电机株式会社 | 半导体模块 |

| JP6307832B2 (ja) * | 2013-01-22 | 2018-04-11 | 三菱マテリアル株式会社 | パワーモジュール用基板、ヒートシンク付パワーモジュール用基板、ヒートシンク付パワーモジュール |

| JP6120704B2 (ja) * | 2013-07-03 | 2017-04-26 | 三菱電機株式会社 | 半導体装置 |

| JP2015065241A (ja) * | 2013-09-24 | 2015-04-09 | ルネサスエレクトロニクス株式会社 | 半導体装置の製造方法および半導体装置 |

| KR102019914B1 (ko) * | 2014-06-11 | 2019-11-04 | 엘지이노텍 주식회사 | 발광 소자 |

| US20160141220A1 (en) * | 2014-11-18 | 2016-05-19 | Sumitomo Electric Industries, Ltd. | Hetero-bipolar transistor and method for producing the same |

| JP6071009B2 (ja) | 2014-11-27 | 2017-02-01 | 株式会社村田製作所 | 化合物半導体装置 |

| JP6415381B2 (ja) * | 2015-04-30 | 2018-10-31 | 三菱電機株式会社 | 半導体装置の製造方法 |

| JP6348451B2 (ja) | 2015-05-25 | 2018-06-27 | 日本電信電話株式会社 | ヘテロ接合バイポーラトランジスタ |

| WO2016209282A1 (en) * | 2015-06-26 | 2016-12-29 | Intel Corporation | Gan devices on engineered silicon substrates |

| JP2018026406A (ja) * | 2016-08-08 | 2018-02-15 | 株式会社村田製作所 | ヘテロ接合バイポーラトランジスタ |

| US9997590B2 (en) * | 2016-10-24 | 2018-06-12 | International Büsiness Machines Corporation | FinFET resistor and method to fabricate same |

| US10847436B2 (en) * | 2017-10-11 | 2020-11-24 | Murata Manufacturing Co., Ltd. | Power amplifier module |

| JP2019102724A (ja) * | 2017-12-06 | 2019-06-24 | 株式会社村田製作所 | 半導体素子 |

-

2020

- 2020-03-10 JP JP2020040801A patent/JP7516786B2/ja active Active

- 2020-05-14 TW TW109116022A patent/TWI825318B/zh active

- 2020-06-15 US US16/901,980 patent/US11677018B2/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009190918A (ja) | 2008-02-13 | 2009-08-27 | New Japan Radio Co Ltd | 窒化物半導体基板の製造方法及び窒化物半導体装置の製造方法 |

| JP2012169586A (ja) | 2011-01-24 | 2012-09-06 | Fujitsu Ltd | ヒートスプレッダ及びその製造方法、半導体装置、電子装置 |

| JP2013191655A (ja) | 2012-03-13 | 2013-09-26 | Nippon Telegr & Teleph Corp <Ntt> | ヘテロ接合バイポーラトランジスタおよびその製造方法 |

| JP2019009409A (ja) | 2017-06-28 | 2019-01-17 | 株式会社村田製作所 | 半導体チップ |

| JP2019075536A (ja) | 2017-10-11 | 2019-05-16 | 株式会社村田製作所 | パワーアンプモジュール |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2021002644A (ja) | 2021-01-07 |

| TWI825318B (zh) | 2023-12-11 |

| US11677018B2 (en) | 2023-06-13 |

| US20200403088A1 (en) | 2020-12-24 |

| TW202101762A (zh) | 2021-01-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI333278B (en) | Group iii nitride bases flip-chip integrated circuit and method for fabricating | |

| US8314472B2 (en) | Semiconductor structure comprising pillar | |

| JP7516786B2 (ja) | 半導体装置及びその製造方法 | |

| US11863130B2 (en) | Group III nitride-based radio frequency transistor amplifiers having source, gate and/or drain conductive vias | |

| JP2021197447A (ja) | 半導体装置 | |

| JP5381480B2 (ja) | 電子装置および電子装置の製造方法 | |

| JP2021145329A (ja) | Rf回路モジュール及びその製造方法 | |

| JP2006229218A (ja) | 半導体デバイスの製造方法、および得られるデバイス | |

| JP2004319552A (ja) | フリップチップ型対面電極hemt | |

| JP3913402B2 (ja) | 高周波回路装置 | |

| WO2019208295A1 (ja) | バイポーラトランジスタおよびその製造方法 | |

| JP2024102316A (ja) | 半導体装置及びその製造方法 | |

| TWI854787B (zh) | 半導體裝置 | |

| JP2012209334A (ja) | ミリ波帯用薄型パッケージおよびその製造方法 | |

| JP5562898B2 (ja) | 半導体装置およびその製造方法 | |

| JP3744828B2 (ja) | 半導体装置 | |

| TW202435452A (zh) | 半導體裝置 | |

| TWI785503B (zh) | Rf電路模組及其製造方法 | |

| JP2010186962A (ja) | 半導体パッケージおよびその作製方法 | |

| JP2000101067A (ja) | 半導体装置および集積回路装置 | |

| WO2024202593A1 (ja) | 化合物半導体増幅器及び回路モジュール | |

| JPH09246812A (ja) | 高周波半導体装置 | |

| TW202239000A (zh) | 功率放大器 | |

| JP5671861B2 (ja) | 半導体装置及びその製造方法 | |

| JP2012028693A (ja) | 半導体装置及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20221109 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20221109 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20230823 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20230926 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20231124 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20240213 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20240513 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20240520 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20240604 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20240617 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7516786 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |