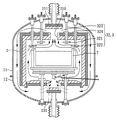

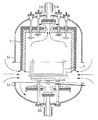

JP4986964B2 - 対流冷却構造を有する結晶成長炉 - Google Patents

対流冷却構造を有する結晶成長炉 Download PDFInfo

- Publication number

- JP4986964B2 JP4986964B2 JP2008250165A JP2008250165A JP4986964B2 JP 4986964 B2 JP4986964 B2 JP 4986964B2 JP 2008250165 A JP2008250165 A JP 2008250165A JP 2008250165 A JP2008250165 A JP 2008250165A JP 4986964 B2 JP4986964 B2 JP 4986964B2

- Authority

- JP

- Japan

- Prior art keywords

- heater

- crystal growth

- heating chamber

- furnace

- growth furnace

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000013078 crystal Substances 0.000 title claims description 74

- 238000001816 cooling Methods 0.000 title claims description 19

- 238000010438 heat treatment Methods 0.000 claims description 64

- 238000005192 partition Methods 0.000 claims description 44

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 19

- 229910002804 graphite Inorganic materials 0.000 claims description 17

- 239000010439 graphite Substances 0.000 claims description 17

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 59

- 229910052710 silicon Inorganic materials 0.000 description 59

- 239000010703 silicon Substances 0.000 description 59

- 239000002002 slurry Substances 0.000 description 27

- 239000007789 gas Substances 0.000 description 13

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 10

- 238000000034 method Methods 0.000 description 10

- 239000002994 raw material Substances 0.000 description 10

- 229910052786 argon Inorganic materials 0.000 description 5

- 238000009413 insulation Methods 0.000 description 4

- 238000002844 melting Methods 0.000 description 4

- 230000008018 melting Effects 0.000 description 4

- 238000007711 solidification Methods 0.000 description 4

- 230000008023 solidification Effects 0.000 description 4

- 238000010521 absorption reaction Methods 0.000 description 3

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 3

- 239000000112 cooling gas Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000002425 crystallisation Methods 0.000 description 2

- 230000008025 crystallization Effects 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 239000002210 silicon-based material Substances 0.000 description 2

- 238000000137 annealing Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 230000003749 cleanliness Effects 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 230000003203 everyday effect Effects 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000010309 melting process Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000009828 non-uniform distribution Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000013612 plasmid Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 239000007790 solid phase Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000003039 volatile agent Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B11/00—Single-crystal growth by normal freezing or freezing under temperature gradient, e.g. Bridgman-Stockbarger method

- C30B11/003—Heating or cooling of the melt or the crystallised material

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B11/00—Single-crystal growth by normal freezing or freezing under temperature gradient, e.g. Bridgman-Stockbarger method

- C30B11/002—Crucibles or containers for supporting the melt

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B29/00—Single crystals or homogeneous polycrystalline material with defined structure characterised by the material or by their shape

- C30B29/02—Elements

- C30B29/06—Silicon

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1004—Apparatus with means for measuring, testing, or sensing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1004—Apparatus with means for measuring, testing, or sensing

- Y10T117/1008—Apparatus with means for measuring, testing, or sensing with responsive control means

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1016—Apparatus with means for treating single-crystal [e.g., heat treating]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1024—Apparatus for crystallization from liquid or supercritical state

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1024—Apparatus for crystallization from liquid or supercritical state

- Y10T117/1092—Shape defined by a solid member other than seed or product [e.g., Bridgman-Stockbarger]

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Silicon Compounds (AREA)

- Furnace Charging Or Discharging (AREA)

- Furnace Details (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| TW096149221A TW200928018A (en) | 2007-12-21 | 2007-12-21 | Crystal-growing furnace with convectional cooling structure |

| TW096149221 | 2007-12-21 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009150637A JP2009150637A (ja) | 2009-07-09 |

| JP4986964B2 true JP4986964B2 (ja) | 2012-07-25 |

Family

ID=40690082

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008250165A Expired - Fee Related JP4986964B2 (ja) | 2007-12-21 | 2008-09-29 | 対流冷却構造を有する結晶成長炉 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US8062423B2 (enExample) |

| JP (1) | JP4986964B2 (enExample) |

| DE (1) | DE102008026144B4 (enExample) |

| TW (1) | TW200928018A (enExample) |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TW200928018A (en) * | 2007-12-21 | 2009-07-01 | Green Energy Technology Inc | Crystal-growing furnace with convectional cooling structure |

| TW200932963A (en) * | 2008-01-29 | 2009-08-01 | Green Energy Technology Inc | Crystal growing furnace with heating improvement structure |

| KR100902859B1 (ko) * | 2009-02-17 | 2009-06-16 | (주) 썸백엔지니어링 | 태양전지용 실리콘 제조용 캐스팅 장치 |

| IT1396761B1 (it) * | 2009-10-21 | 2012-12-14 | Saet Spa | Metodo e dispositivo per l'ottenimento di un materiale semiconduttore multicristallino, in particolare silicio |

| CN101949056B (zh) * | 2010-09-25 | 2013-01-30 | 王敬 | 在坩埚侧壁底端设置有保温部件的定向凝固炉 |

| US8562740B2 (en) * | 2010-11-17 | 2013-10-22 | Silicor Materials Inc. | Apparatus for directional solidification of silicon including a refractory material |

| US9352389B2 (en) * | 2011-09-16 | 2016-05-31 | Silicor Materials, Inc. | Directional solidification system and method |

| TWI539039B (zh) * | 2012-01-26 | 2016-06-21 | 希利柯爾材料股份有限公司 | 矽的純化方法 |

| EP2864529A1 (en) * | 2012-06-25 | 2015-04-29 | Silicor Materials Inc. | Lining for surfaces of a refractory crucible for purification of silicon melt and method of purification of the silicon melt using that crucible (s) for melting and further directional solidification |

| CN103014851B (zh) * | 2012-12-25 | 2016-01-27 | 南昌大学 | 一种生产定向凝固多晶硅锭的方法 |

| TWI643983B (zh) | 2013-03-14 | 2018-12-11 | 美商希利柯爾材料股份有限公司 | 定向凝固系統及方法 |

| GB201319671D0 (en) | 2013-11-07 | 2013-12-25 | Ebner Ind Ofenbau | Controlling a temperature of a crucible inside an oven |

| CN103615891B (zh) * | 2013-11-20 | 2016-10-05 | 合肥日新高温技术有限公司 | 一种真空气氛高压碳板炉 |

| TWM485251U (zh) * | 2014-04-03 | 2014-09-01 | Globalwafers Co Ltd | 晶體生長裝置及其保溫罩 |

| CN105648525B (zh) * | 2014-11-17 | 2018-07-10 | 镇江荣德新能源科技有限公司 | 用于多晶硅定向凝固工艺的多晶炉 |

| TWI614473B (zh) * | 2015-07-20 | 2018-02-11 | 茂迪股份有限公司 | 長晶爐設備 |

| US20180347071A1 (en) * | 2015-07-27 | 2018-12-06 | Corner Star Limited | Systems and methods for low-oxygen crystal growth using a double-layer continuous czochralski process |

| CN105088338A (zh) * | 2015-08-14 | 2015-11-25 | 晶科能源有限公司 | 一种多晶铸锭炉及排气装置 |

| CN108048903A (zh) * | 2016-02-03 | 2018-05-18 | 陈鸽 | 一种改变载气流向的引流装置 |

| EP3558780B1 (en) * | 2016-12-22 | 2023-06-07 | ETran, Inc. | Elevated transportation system |

| CN107523865A (zh) * | 2017-09-28 | 2017-12-29 | 浙江晶盛机电股份有限公司 | 一种定向水冷散热的节能型高效多晶硅铸锭炉 |

| JP7186534B2 (ja) | 2018-07-25 | 2022-12-09 | 昭和電工株式会社 | 結晶成長装置 |

| CN108842180A (zh) * | 2018-08-24 | 2018-11-20 | 常州四杰机械科技有限公司 | 一种准单晶铸锭炉下炉体机构 |

| CN109295495B (zh) * | 2018-11-19 | 2020-08-04 | 江苏斯力康科技有限公司 | 利于控制定向凝固平直液固界面的温场调控机构 |

| CN110184651A (zh) * | 2019-07-17 | 2019-08-30 | 晶科能源有限公司 | 一种多晶铸锭炉 |

| CN112857039B (zh) * | 2021-03-06 | 2023-08-15 | 陕西万豪钛金特材科技有限公司 | 一种基于合金熔炼的烧结炉及冷却方法 |

| CN114455591B (zh) * | 2022-01-18 | 2023-08-18 | 山西宏晟利隆科技有限公司 | 一种工业制造二氧化硅设备 |

Family Cites Families (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS56129696A (en) * | 1980-03-12 | 1981-10-09 | Toshiba Corp | Crystal growing apparatus |

| JPH0672744B2 (ja) * | 1986-08-15 | 1994-09-14 | 石川島播磨重工業株式会社 | 焼結炉 |

| US5312600A (en) * | 1990-03-20 | 1994-05-17 | Toshiba Ceramics Co. | Silicon single crystal manufacturing apparatus |

| JP3263104B2 (ja) * | 1991-11-27 | 2002-03-04 | 川崎製鉄株式会社 | 金属シリコンの精製方法 |

| JP3388664B2 (ja) * | 1995-12-28 | 2003-03-24 | シャープ株式会社 | 多結晶半導体の製造方法および製造装置 |

| JPH09263491A (ja) * | 1996-03-27 | 1997-10-07 | Shin Etsu Handotai Co Ltd | シリコン単結晶の製造装置 |

| JP3000923B2 (ja) * | 1996-03-28 | 2000-01-17 | 住友金属工業株式会社 | 単結晶引き上げ方法 |

| JP3892496B2 (ja) * | 1996-04-22 | 2007-03-14 | Sumco Techxiv株式会社 | 半導体単結晶製造方法 |

| DE19628851A1 (de) * | 1996-07-17 | 1998-01-22 | Wacker Siltronic Halbleitermat | Verfahren und Vorrichtung zur Herstellung eines Einkristalls |

| JP3988217B2 (ja) * | 1997-09-09 | 2007-10-10 | 株式会社ニコン | 大口径蛍石の製造装置および製造方法 |

| JP3992800B2 (ja) * | 1997-09-22 | 2007-10-17 | Sumco Techxiv株式会社 | 単結晶製造装置および単結晶の製造方法 |

| JPH11310496A (ja) * | 1998-02-25 | 1999-11-09 | Mitsubishi Materials Corp | 一方向凝固組織を有するシリコンインゴットの製造方法およびその製造装置 |

| JP4014758B2 (ja) * | 1999-04-30 | 2007-11-28 | 三菱マテリアルテクノ株式会社 | 結晶シリコン製造装置 |

| JP4357068B2 (ja) * | 1999-05-11 | 2009-11-04 | Sumco Techxiv株式会社 | 単結晶インゴット製造装置及び方法 |

| JP2001048696A (ja) * | 1999-08-06 | 2001-02-20 | Mitsubishi Materials Corp | 結晶シリコン製造装置 |

| JP3846285B2 (ja) * | 2001-11-26 | 2006-11-15 | 三菱マテリアル株式会社 | 結晶製造装置及び結晶製造方法 |

| KR20040044146A (ko) * | 2002-11-19 | 2004-05-27 | 가부시끼가이샤 도꾸야마 | 플루오르화 금속용 단결정 인출 장치 |

| JP4573290B2 (ja) * | 2003-10-17 | 2010-11-04 | 株式会社Ihi | 高圧熱処理炉 |

| TWI263713B (en) * | 2004-11-04 | 2006-10-11 | Univ Nat Central | Heat shield and crystal growth equipment |

| US7344596B2 (en) * | 2005-08-25 | 2008-03-18 | Crystal Systems, Inc. | System and method for crystal growing |

| JP2007261846A (ja) * | 2006-03-28 | 2007-10-11 | Sumco Techxiv株式会社 | 無欠陥のシリコン単結晶を製造する方法 |

| US8057598B2 (en) * | 2006-06-13 | 2011-11-15 | Young Sang Cho | Manufacturing equipment for polysilicon ingot |

| TW200928018A (en) * | 2007-12-21 | 2009-07-01 | Green Energy Technology Inc | Crystal-growing furnace with convectional cooling structure |

| TW200932963A (en) * | 2008-01-29 | 2009-08-01 | Green Energy Technology Inc | Crystal growing furnace with heating improvement structure |

| TW200936823A (en) * | 2008-02-21 | 2009-09-01 | Green Energy Technology Inc | Heating electrode and fastening structure for crystal-growing furnace |

-

2007

- 2007-12-21 TW TW096149221A patent/TW200928018A/zh not_active IP Right Cessation

-

2008

- 2008-05-21 US US12/153,545 patent/US8062423B2/en not_active Expired - Fee Related

- 2008-05-30 DE DE102008026144A patent/DE102008026144B4/de not_active Expired - Fee Related

- 2008-09-29 JP JP2008250165A patent/JP4986964B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DE102008026144B4 (de) | 2013-02-14 |

| TWI363109B (enExample) | 2012-05-01 |

| US20090158995A1 (en) | 2009-06-25 |

| JP2009150637A (ja) | 2009-07-09 |

| US8062423B2 (en) | 2011-11-22 |

| DE102008026144A1 (de) | 2009-06-25 |

| TW200928018A (en) | 2009-07-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4986964B2 (ja) | 対流冷却構造を有する結晶成長炉 | |

| CN101440518B (zh) | 安装有采用铰链的门开关装置的太阳能电池用多结晶硅锭块制造装置 | |

| JPH11310496A (ja) | 一方向凝固組織を有するシリコンインゴットの製造方法およびその製造装置 | |

| CN100464149C (zh) | 多晶硅铸锭炉的热场结构 | |

| JP2009180495A (ja) | 加熱改良構造を有する結晶成長炉 | |

| US20110104036A1 (en) | Method and apparatus for purifying metallurgical grade silicon by directional solidification and for obtaining silicon ingots for photovoltaic use | |

| JP3964070B2 (ja) | 結晶シリコン製造装置 | |

| CN101481825B (zh) | 具有对流式散热构造的长晶炉 | |

| KR20110003322A (ko) | 단결정 제조장치 및 단결정의 제조방법 | |

| KR20110056635A (ko) | 태양전지용 다결정 실리콘 잉곳 제조장치 | |

| KR20080068423A (ko) | 태양전지용 다결정 실리콘 주괴 제조 장치 | |

| KR100902859B1 (ko) | 태양전지용 실리콘 제조용 캐스팅 장치 | |

| EP2376244B1 (en) | Process for producing multicrystalline silicon ingots by the induction method and apparatus for carrying out the same | |

| KR200446667Y1 (ko) | 솔라셀용 실리콘 잉곳 제조장치 | |

| JP2002193610A (ja) | 結晶シリコン製造装置 | |

| KR20120128040A (ko) | 단결정 시드를 이용한 실리콘 잉곳 제조장치 | |

| JP5371701B2 (ja) | 多結晶シリコンインゴットの製造装置及び多結晶シリコンインゴットの製造方法 | |

| CN202785671U (zh) | 一种反向诱导凝固提纯多晶硅的设备 | |

| JP4444482B2 (ja) | 結晶シリコン製造装置 | |

| CN110820043A (zh) | 晶体生长装置及生长方法 | |

| KR101139846B1 (ko) | 효과적인 단열보호판을 구비한 태양전지용 다결정 실리콘잉곳 제조장치 | |

| JP4273659B2 (ja) | 結晶シリコン製造装置 | |

| JP2014227586A (ja) | アルミニウム精製方法、及び精製装置 | |

| JP4273664B2 (ja) | 結晶シリコン製造装置 | |

| CN201081541Y (zh) | 多晶硅铸锭炉的热场节能增效装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20111208 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111220 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120315 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120403 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120424 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150511 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |